Unlocking Value: A Strategic Analysis of the Conveyor At The Store Market

Introduction: Navigating the Global Market for conveyor at the store

In today’s competitive retail landscape, sourcing efficient conveyor systems for checkout counters can significantly enhance operational productivity and customer satisfaction. International B2B buyers face the challenge of navigating a complex market filled with diverse options tailored to various store formats and consumer needs. This comprehensive guide delves into the multifaceted world of conveyor systems, providing insights into different types, applications, and the essential criteria for supplier vetting.

The guide covers critical aspects such as cost considerations, maintenance requirements, and compliance with international standards, ensuring that businesses can make informed decisions that align with their operational goals. By addressing the specific needs of B2B buyers from regions like Africa, South America, the Middle East, and Europe—including markets in Brazil and Vietnam—this resource empowers stakeholders to identify the most suitable conveyor solutions for their unique retail environments.

As you explore this guide, you will gain valuable knowledge on optimizing checkout processes, enhancing customer experience, and ultimately driving sales growth. The insights provided will equip you to confidently engage with suppliers, negotiate effectively, and select the right conveyor systems that meet your business’s demands in an ever-evolving market.

Understanding conveyor at the store Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Checkout Counter Conveyor | Integrated conveyor belt for efficient customer checkout | Supermarkets, convenience stores | Pros: Increases checkout speed; enhances customer experience. Cons: Initial investment may be high. |

| Non-Belted Express Counter | Simple, streamlined design for quick transactions | Small retailers, express lanes | Pros: Cost-effective; easy to maintain. Cons: Limited capacity for large transactions. |

| Tri-Belt Lanes | Multiple conveyor belts for high-volume processing | Large supermarkets, busy retail areas | Pros: Reduces wait times; efficient for high customer flow. Cons: Requires more space and higher costs. |

| Modular Checkout Solutions | Customizable configurations to fit various store layouts | Retail chains, franchises | Pros: Flexible design; can adapt to changing needs. Cons: May involve longer lead times for customization. |

| Food-Grade Conveyor Belts | Specialized belts for handling food products, compliant with health regulations | Grocery stores, food processing units | Pros: Ensures food safety; meets regulatory standards. Cons: Higher maintenance required to ensure hygiene. |

What Are the Key Characteristics of Checkout Counter Conveyors?

Checkout counter conveyors are designed to enhance the efficiency of customer transactions in retail environments. These systems typically feature a belt that moves items from the customer to the cashier, significantly speeding up the checkout process. They are particularly suitable for supermarkets and convenience stores where high customer volumes are common. When considering a purchase, B2B buyers should assess the belt’s durability, ease of cleaning, and compatibility with existing store layouts.

Illustrative image related to conveyor at the store

How Do Non-Belted Express Counters Function in Retail?

Non-belted express counters are designed for quick transactions, making them ideal for small retailers and express lanes. Their simple design allows cashiers to handle items directly without the need for a conveyor belt. This type of counter is cost-effective and easy to maintain, appealing to businesses with lower transaction volumes. Buyers should consider the trade-off between speed and capacity, as these counters may not accommodate larger purchases as efficiently.

What Are the Benefits of Using Tri-Belt Lanes?

Tri-belt lanes feature multiple conveyor belts that cater to high-volume processing needs, making them suitable for large supermarkets and busy retail areas. This design reduces wait times by allowing multiple customers to check out simultaneously. While they improve customer flow, B2B buyers must evaluate the space requirements and costs associated with installation and maintenance, as these systems can be more complex than traditional checkout solutions.

How Do Modular Checkout Solutions Enhance Retail Flexibility?

Modular checkout solutions provide customizable configurations that can adapt to various store layouts and needs. This flexibility makes them a popular choice for retail chains and franchises looking to optimize space while accommodating different customer volumes. Buyers should consider the potential for future expansion or layout changes when investing in modular systems, as they can offer long-term value despite potentially longer lead times for customization.

Why Choose Food-Grade Conveyor Belts for Grocery Stores?

Food-grade conveyor belts are specifically designed for handling food products and comply with health regulations, making them essential for grocery stores and food processing units. These belts ensure food safety and hygiene, which is critical in maintaining compliance with health standards. However, B2B buyers should be prepared for higher maintenance requirements to ensure cleanliness and functionality, weighing these considerations against the benefits of regulatory compliance.

Key Industrial Applications of conveyor at the store

| Industry/Sector | Specific Application of conveyor at the store | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail Grocery Stores | Checkout Counter Conveyor Belts | Enhances checkout speed, improving customer experience and reducing wait times. | Durability, ease of cleaning, and compatibility with existing setups. |

| Food and Beverage | Food Packaging and Display | Streamlines packaging processes for various food items, ensuring compliance with health regulations. | Food-grade materials, customization options, and temperature resistance. |

| E-commerce Fulfillment | Order Processing Conveyors | Increases efficiency in order picking and packing, allowing for faster delivery times. | Modular design for flexibility, integration with existing systems, and scalability. |

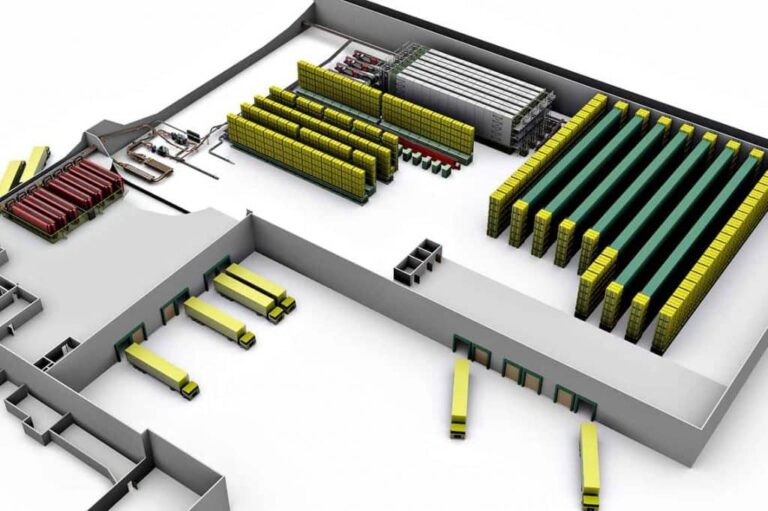

| Warehousing and Logistics | Inventory Management Conveyors | Optimizes inventory flow and minimizes labor costs by automating product movement. | Load capacity, maintenance requirements, and adaptability to different warehouse layouts. |

| Convenience Stores | Express Checkout Solutions | Facilitates quick transactions, catering to customers looking for speed and convenience. | Compact design, ease of installation, and aesthetic compatibility with store layout. |

How is ‘Conveyor at the Store’ Beneficial in Retail Grocery Stores?

In retail grocery stores, checkout counter conveyor belts are pivotal in enhancing customer experience. These systems facilitate a swift checkout process, significantly reducing customer wait times. By ensuring that items move smoothly from the cashier to the bagging area, they help maintain an efficient workflow. For international buyers, sourcing durable belts that are easy to clean and compatible with existing counter designs is essential to ensure longevity and hygiene.

What Role Does Conveyor Play in Food and Beverage Industries?

In the food and beverage sector, conveyors are integral to packaging and display processes. They streamline the movement of products, from processing to packaging, ensuring compliance with stringent health regulations. Food-grade materials are crucial for these applications, as they must withstand various temperatures and conditions. Buyers should prioritize suppliers that offer customizable solutions tailored to specific food items, enhancing operational efficiency and product safety.

How Do Conveyors Enhance E-commerce Fulfillment Operations?

E-commerce fulfillment centers leverage conveyors for order processing, allowing for rapid picking and packing of products. This automation enhances efficiency, leading to quicker delivery times and improved customer satisfaction. For B2B buyers in this sector, sourcing modular conveyor systems that can easily integrate with existing setups is vital. Flexibility in design enables businesses to scale operations as demand fluctuates, making it a key consideration.

What Advantages Do Conveyors Offer in Warehousing and Logistics?

In warehousing and logistics, conveyors optimize inventory management by automating the movement of products throughout the facility. This reduces labor costs and minimizes human error, enhancing overall operational efficiency. Buyers should consider conveyors with high load capacities and low maintenance requirements to ensure reliability. Additionally, adaptability to various warehouse layouts is crucial for maximizing space utilization and improving workflow.

How Do Conveyors Improve Convenience Store Operations?

For convenience stores, express checkout solutions utilizing conveyors facilitate quick transactions, catering to customers who prioritize speed. These systems enable cashiers to efficiently process multiple customers in a limited space. When sourcing these solutions, buyers should look for compact designs that can be easily installed without disrupting the store layout, as well as aesthetically pleasing options that align with the store’s branding.

3 Common User Pain Points for ‘conveyor at the store’ & Their Solutions

Scenario 1: Inefficiencies at Checkout Leading to Customer Frustration

The Problem: Many supermarket chains experience significant delays at checkout due to inefficient conveyor systems. Long lines can result from outdated or poorly maintained conveyor belts, causing customer dissatisfaction and potential loss of sales. B2B buyers often struggle to find reliable suppliers who can provide high-quality, durable conveyor systems that can handle high volumes of transactions without breakdowns. Additionally, the lack of a comprehensive maintenance plan can lead to increased downtime, impacting both customer experience and revenue.

The Solution: To tackle this issue, B2B buyers should prioritize sourcing conveyor systems that are specifically designed for high-traffic environments. Suppliers should be vetted based on their ability to offer not only robust conveyor belts but also maintenance support. Investing in conveyor systems with features such as easy-to-clean surfaces and high-capacity designs can enhance operational efficiency. Furthermore, establishing a proactive maintenance schedule with the supplier can mitigate the risks of unexpected breakdowns. Buyers should also consider customizable options that fit their unique store layouts and customer flow patterns, ensuring that the conveyor systems align with their operational needs.

Illustrative image related to conveyor at the store

Scenario 2: Regulatory Compliance Challenges with Food Safety

The Problem: In regions where food safety regulations are stringent, such as the European Union and parts of the Middle East, supermarket chains face the challenge of ensuring that their conveyor systems meet these compliance standards. Non-compliance can lead to hefty fines and damage to brand reputation. B2B buyers are often uncertain about which materials and designs are suitable for food handling, especially for perishable goods, creating a barrier to procurement.

The Solution: B2B buyers must engage with suppliers who specialize in USDA-certified food-grade conveyor belts. These products are designed to withstand high temperatures and resist contamination, ensuring compliance with food safety regulations. Buyers should inquire about the specific materials used in the conveyor systems, as well as their cleaning protocols. Additionally, partnering with suppliers who offer customization options—such as adjustable speed settings and modular designs—can facilitate a more efficient food handling process, ensuring compliance without sacrificing performance. Regular training for staff on food safety practices related to conveyor use can further enhance compliance efforts.

Scenario 3: Limited Space and Layout Constraints in Retail Environments

The Problem: Retailers often face the challenge of limited space, particularly in urban areas where store footprints are smaller. This limitation makes it difficult to implement traditional conveyor systems that require significant floor space, leading to a less efficient checkout process and potential overcrowding. B2B buyers may struggle to find innovative solutions that maximize their available space while still providing a seamless customer experience.

The Solution: To address space constraints, B2B buyers should explore compact conveyor systems that are specifically engineered for smaller retail environments. Suppliers should be able to offer modular designs that can be adapted to various store layouts, such as conveyor belts that can be integrated into existing checkout counters or those that feature vertical stacking for bags. Additionally, incorporating features like dual conveyor lanes can facilitate faster service without requiring additional space. Buyers should also consider consulting with layout design experts to optimize the checkout area, ensuring that the conveyor system enhances rather than hinders customer flow. By investing in space-efficient solutions, retailers can improve operational efficiency while maintaining a positive shopping experience.

Strategic Material Selection Guide for conveyor at the store

What Are the Key Materials for Conveyor Belts in Retail Environments?

When selecting materials for conveyor systems in retail settings, particularly at checkout counters, it is essential to consider various factors such as durability, cost, and regulatory compliance. Below are analyses of four common materials used in conveyor belts, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

1. PVC (Polyvinyl Chloride)

Key Properties:

PVC is known for its excellent chemical resistance and good mechanical strength. It can withstand temperatures ranging from -10°C to 60°C, making it suitable for various retail environments.

Pros & Cons:

PVC conveyor belts are lightweight and cost-effective, making them a popular choice for many retailers. However, they may not be as durable as other materials, leading to higher replacement costs over time.

Impact on Application:

PVC is compatible with a wide range of products, including packaged goods and groceries. However, it may not be suitable for heavy loads or extreme temperatures.

Considerations for International Buyers:

Buyers should ensure compliance with local regulations regarding material safety and food-grade certifications. Standards such as ASTM and DIN are commonly referenced in Europe and the Middle East.

2. PU (Polyurethane)

Key Properties:

Polyurethane belts offer excellent abrasion resistance and can handle temperatures up to 80°C. They are also resistant to oils and fats, making them ideal for food applications.

Pros & Cons:

While PU belts are more durable than PVC, they tend to be more expensive. Their manufacturing complexity can also lead to longer lead times.

Impact on Application:

PU belts are particularly suited for handling food items, as they meet stringent hygiene standards. They are less suitable for environments where heavy loads are frequently moved.

Considerations for International Buyers:

Given the varying regulations across regions, buyers should verify that the PU materials meet local food safety standards, especially in Africa and South America, where compliance can vary significantly.

3. Stainless Steel

Key Properties:

Stainless steel conveyor belts are highly resistant to corrosion and can operate in extreme temperatures, making them ideal for various retail environments.

Illustrative image related to conveyor at the store

Pros & Cons:

These belts are incredibly durable and have a long lifespan, but they come at a higher cost. Their weight can also complicate installation and maintenance.

Impact on Application:

Stainless steel is perfect for high-load applications and environments requiring frequent sanitation, such as food processing areas. However, they may not be necessary for lighter retail applications.

Considerations for International Buyers:

Buyers must consider the specific grades of stainless steel and their compliance with international standards, such as JIS in Japan and ASTM in the U.S. This is particularly important in regions like Europe, where material quality is heavily regulated.

Illustrative image related to conveyor at the store

4. Fabric-Backed Belts

Key Properties:

Fabric-backed conveyor belts, often made of polyester or nylon, offer flexibility and good tensile strength. They can typically handle temperatures up to 70°C.

Pros & Cons:

These belts are versatile and can be manufactured in various widths and lengths. However, they may require more maintenance and are less durable than metal options.

Impact on Application:

Fabric-backed belts are suitable for light to medium loads and are often used in retail checkout counters for their ease of installation and adaptability.

Considerations for International Buyers:

Buyers should ensure that fabric-backed belts meet local fire safety and environmental regulations, particularly in regions like Africa and South America, where standards may differ significantly.

Summary Table of Conveyor Belt Materials

| Material | Typical Use Case for conveyor at the store | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | General retail checkout counters | Cost-effective and lightweight | Less durable, higher replacement costs | Low |

| PU | Food handling applications | Excellent abrasion resistance | More expensive and complex to manufacture | High |

| Stainless Steel | High-load and sanitation-required areas | Extremely durable and long-lasting | Higher cost and complicated installation | High |

| Fabric-Backed Belts | Light to medium load applications | Versatile and adaptable | Requires more maintenance, less durable | Medium |

By understanding these materials and their implications, international B2B buyers can make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for conveyor at the store

What Are the Key Stages in the Manufacturing Process of Conveyors for Retail?

The manufacturing process for conveyors used in retail environments involves several critical stages, each designed to ensure that the end product is reliable, efficient, and meets specific customer needs. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

1. Material Preparation

The manufacturing process begins with the selection of appropriate materials, which is crucial for the durability and functionality of the conveyor systems. Common materials include stainless steel, plastic, and rubber, selected based on their specific properties like resistance to wear, corrosion, and ease of cleaning. Suppliers often use advanced techniques like laser cutting and CNC machining to prepare these materials, ensuring precision and consistency in dimensions.

2. Forming Techniques

Once the materials are prepared, they undergo various forming processes to create the components of the conveyor system. Techniques such as bending, welding, and molding are employed to shape the materials into the desired forms. For instance, steel components may be welded together to form a robust framework, while plastic parts could be molded into complex shapes. The choice of technique depends on the design specifications and the intended application of the conveyor.

3. Assembly Process

The assembly stage is where all the individual components come together to create the final product. This process can be manual or automated, depending on the complexity of the conveyor system and the manufacturer’s capabilities. Automated assembly lines often improve efficiency and consistency, while manual assembly allows for greater flexibility and attention to detail. During this phase, components such as motors, belts, and control systems are integrated, ensuring that the conveyor operates seamlessly.

4. Finishing Touches

After assembly, the conveyor systems undergo finishing processes to enhance their aesthetics and functionality. This may include painting, coating, or polishing surfaces to improve resistance to wear and corrosion. Quality suppliers also ensure that all components are thoroughly cleaned and inspected before shipment, ready for immediate installation in retail environments.

Illustrative image related to conveyor at the store

How Is Quality Assurance Implemented in Conveyor Manufacturing?

Quality assurance (QA) is a vital aspect of the manufacturing process, ensuring that conveyor systems meet established standards for performance and safety. B2B buyers should be aware of the various QA practices that suppliers implement.

International Standards and Certifications

Most reputable manufacturers adhere to international quality standards such as ISO 9001, which outlines requirements for a quality management system. Additionally, industry-specific certifications like CE (Conformité Européenne) indicate compliance with EU safety, health, and environmental protection standards. Buyers should look for suppliers that can provide documentation of these certifications, as they reflect a commitment to quality.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is typically integrated into the manufacturing process at several critical checkpoints:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival to ensure they meet specifications. This step is crucial for preventing defects that could arise from substandard materials.

-

In-Process Quality Control (IPQC): During the manufacturing stages, regular inspections are conducted to monitor the quality of components as they are being produced. This may involve checking dimensions, mechanical properties, and surface finishes.

-

Final Quality Control (FQC): Once assembly is complete, the entire conveyor system undergoes rigorous testing to verify its performance and safety. This may include load testing, operational testing, and inspections for compliance with design specifications.

What Testing Methods Are Commonly Used in Conveyor Quality Assurance?

B2B buyers should be aware of the testing methods that suppliers use to ensure the quality of their conveyor systems. Common testing methods include:

-

Load Testing: This method assesses the conveyor’s ability to handle specified weights, ensuring it operates efficiently under expected load conditions.

-

Operational Testing: Suppliers conduct tests to evaluate the conveyor’s performance, checking for speed, alignment, and overall functionality.

-

Durability Testing: This involves simulating extended use to identify potential failure points, ensuring the conveyor can withstand the rigors of daily operations.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is essential. Here are actionable steps to ensure supplier integrity:

Supplier Audits

Conducting supplier audits is a critical step in verifying quality control practices. This involves visiting the manufacturing facility to assess processes, equipment, and adherence to quality standards. Audits allow buyers to gain firsthand insight into the supplier’s operations and commitment to quality.

Requesting Quality Reports

Buyers should request detailed quality reports that outline the QC processes, testing results, and compliance with international standards. These reports provide transparency and can help identify any potential risks associated with the supplier’s practices.

Engaging Third-Party Inspectors

Utilizing third-party inspection services can further validate a supplier’s quality assurance processes. These independent inspectors can conduct thorough evaluations and provide unbiased reports on the manufacturing and quality control processes.

Are There Specific Quality Control Nuances for International Buyers?

International buyers must be aware of specific nuances related to quality control that can impact their purchasing decisions. For instance, different regions may have varying regulations and standards, which can affect compliance and product suitability. Understanding these differences is crucial for ensuring that the conveyors meet local market requirements.

Additionally, language barriers and cultural differences may impact communication regarding quality standards and expectations. Buyers should establish clear lines of communication with suppliers to ensure mutual understanding of quality requirements.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance practices for conveyor systems is essential for B2B buyers. By focusing on these aspects, buyers can make informed decisions, ensuring they select reliable suppliers that provide high-quality products tailored to their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘conveyor at the store’

Introduction

This practical sourcing guide serves as a comprehensive checklist for B2B buyers looking to procure conveyor systems for retail environments, particularly supermarket checkout counters. A well-chosen conveyor system can enhance operational efficiency, improve customer experience, and ultimately drive sales. By following these steps, you can ensure that your sourcing process is thorough and effective.

Step 1: Define Your Technical Specifications

Before starting your procurement process, clearly outline your technical requirements. This includes understanding the size, capacity, and speed of the conveyor system needed for your store layout.

- Considerations: Assess the flow of customer traffic and the types of products you will be handling. This will help you determine if you need a standard conveyor or a specialized model for items like perishable goods.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in conveyor systems for retail environments.

- Key Factors: Look for companies with a strong reputation and positive reviews from existing clients. Supplier experience, particularly in your target region, can also indicate their ability to meet local regulations and standards.

Step 3: Evaluate Supplier Certifications

Before finalizing any agreements, verify that potential suppliers hold relevant certifications.

- Importance: Certifications such as ISO 9001 for quality management or compliance with local safety regulations ensure that the supplier adheres to high standards. This is crucial for maintaining both product quality and safety in your store.

Step 4: Request and Compare Quotes

Once you have shortlisted suppliers, request detailed quotes from each.

- What to Include: Ensure the quotes cover all aspects of the conveyor system, including installation, maintenance, and warranty options. Comparing these quotes side by side will help you identify the best overall value.

Step 5: Assess After-Sales Support and Warranty

Inquire about after-sales support and warranty terms provided by the suppliers.

- Critical Aspects: A reliable after-sales support system can save you time and money in case of operational issues. Look for suppliers that offer comprehensive service packages, including training for your staff on equipment usage.

Step 6: Consider Customization Options

Evaluate whether the suppliers can customize the conveyor systems to fit your specific needs.

- Benefits: Customization can enhance efficiency and user experience, especially in stores with unique layouts or product types. Ensure that the supplier has the capability and flexibility to provide tailored solutions.

Step 7: Finalize the Purchase Agreement

Once you have selected a supplier, carefully review and finalize the purchase agreement.

- Important Elements: Pay close attention to payment terms, delivery timelines, and installation services. Make sure that all verbal agreements are documented to avoid misunderstandings later on.

By following this checklist, B2B buyers can confidently navigate the procurement process for conveyor systems, ensuring they select the right equipment to enhance their retail operations.

Comprehensive Cost and Pricing Analysis for conveyor at the store Sourcing

What Are the Key Cost Components in Sourcing Conveyors for Stores?

When sourcing conveyor systems for retail environments, understanding the cost structure is vital for effective budgeting and financial planning. The primary cost components include:

Illustrative image related to conveyor at the store

-

Materials: The type of materials used in manufacturing conveyors significantly impacts cost. High-quality materials such as stainless steel or specialized food-grade belts may incur higher initial costs but often lead to lower maintenance expenses and longer lifespans.

-

Labor: Labor costs can vary depending on the region and the complexity of the conveyor system. Custom solutions that require specialized craftsmanship will typically have higher labor costs compared to standardized models.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities, facility maintenance, and administrative expenses. These costs are usually factored into the final price of the conveyor.

-

Tooling: The investment in specialized tools for manufacturing can affect pricing. Custom conveyors may require unique tooling, which increases the upfront cost but can be amortized over larger production runs.

-

Quality Control (QC): Ensuring product quality through rigorous testing and inspection processes adds to the cost. However, investing in QC can prevent costly issues and product failures in the long run.

-

Logistics: Shipping costs, including freight and customs duties, can vary widely based on the location of the supplier and the destination. International buyers should consider these logistics costs as part of the total expenditure.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the market rates and negotiating can help buyers achieve a more favorable margin.

How Do Price Influencers Affect Conveyor Pricing for International Buyers?

Several factors can influence the pricing of conveyors, especially for international B2B buyers:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes often lead to discounts. Buyers should assess their needs and negotiate terms that allow for flexibility in order sizes to maximize savings.

-

Specifications and Customization: Custom features tailored to specific operational needs can increase costs. Buyers should weigh the benefits of customization against their budget constraints.

-

Materials and Quality Certifications: The choice of materials and adherence to industry certifications (such as USDA for food applications) can affect pricing. Buyers should prioritize quality that meets regulatory standards to avoid future liabilities.

-

Supplier Factors: The reputation, reliability, and geographic location of suppliers can impact pricing. Established suppliers with a track record may offer better service and warranties, justifying higher prices.

-

Incoterms: Understanding the Incoterms (International Commercial Terms) applicable to the transaction is crucial. These terms dictate responsibilities for shipping, insurance, and tariffs, directly affecting the overall cost.

What Are the Best Buyer Tips for Cost-Efficiency in Conveyor Sourcing?

For B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, here are some actionable tips:

-

Negotiate Effectively: Always enter negotiations with a clear understanding of the market value and be prepared to discuss pricing openly. Leverage quotes from multiple suppliers to strengthen your position.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the initial purchase price, but also the long-term costs associated with maintenance, energy consumption, and potential downtime. A slightly higher upfront investment in a durable conveyor may yield significant savings over time.

-

Understand Pricing Nuances for International Transactions: Be aware of currency fluctuations, potential import duties, and local regulations that may affect pricing. Establishing a strong relationship with suppliers can also help mitigate risks associated with international procurement.

-

Request Detailed Quotations: Ask suppliers for a breakdown of costs to understand where savings can be made. Detailed quotes can help identify areas for negotiation or alternative solutions.

In summary, effective sourcing of conveyor systems requires a comprehensive understanding of the cost components and pricing influencers while leveraging strategic negotiation and evaluation techniques to ensure cost-efficiency and long-term value.

Alternatives Analysis: Comparing conveyor at the store With Other Solutions

Exploring Alternatives to Conveyor Systems in Retail Settings

In the competitive landscape of retail operations, efficiency and customer experience are paramount. As businesses seek to streamline processes, conveyor systems at checkout counters have emerged as a popular solution. However, several alternatives offer unique benefits that may align better with specific operational needs. This analysis compares the traditional conveyor system against two viable alternatives: Mobile Checkout Stations and Self-Checkout Kiosks.

| Comparison Aspect | Conveyor At The Store | Mobile Checkout Stations | Self-Checkout Kiosks |

|---|---|---|---|

| Performance | High throughput; reduces wait times. | Flexible; can adapt to customer flow. | Moderate; depends on customer familiarity. |

| Cost | Moderate to high initial investment. | Lower startup cost; may require additional staff. | Varies; often cost-effective in the long run. |

| Ease of Implementation | Requires installation; can be complex. | Simple setup; portable and quick to deploy. | Requires software integration; user training needed. |

| Maintenance | Regular upkeep needed; potential for breakdowns. | Minimal maintenance; easy to relocate. | Requires software updates; hardware upkeep. |

| Best Use Case | High-volume retail environments. | Seasonal promotions or events. | Stores seeking to reduce staffing needs. |

What Are the Pros and Cons of Mobile Checkout Stations?

Mobile checkout stations offer flexibility that traditional conveyor systems cannot. These stations allow staff to process transactions anywhere in the store, accommodating changing customer flows and reducing congestion during peak hours. The lower initial investment can be appealing for businesses looking to enhance customer service without significant capital expenditure. However, they may require additional staff to operate effectively, which can offset some cost savings. Furthermore, their performance heavily relies on staff training and customer adaptability.

Illustrative image related to conveyor at the store

How Do Self-Checkout Kiosks Compare?

Self-checkout kiosks are increasingly popular for retailers looking to enhance customer autonomy. These kiosks can significantly reduce labor costs by allowing customers to scan and pay for items themselves. While they can lead to long-term savings, the initial investment can vary widely based on the technology used. Self-checkout systems also demand a certain level of customer tech-savviness, which may lead to delays if users are unfamiliar with the process. Additionally, maintenance can be focused on software, requiring ongoing updates and technical support to ensure smooth operations.

Making the Right Choice: What Should B2B Buyers Consider?

When evaluating solutions for checkout processes, B2B buyers should consider their specific operational needs, customer demographics, and budget constraints. If high efficiency and throughput are essential, traditional conveyor systems may still be the best option, particularly for larger retail environments. For businesses that experience fluctuating traffic or seasonal peaks, mobile checkout stations might provide the necessary flexibility. Conversely, self-checkout kiosks can be ideal for retailers looking to empower customers and reduce labor costs.

Ultimately, the decision should align with the store’s overall strategy, customer expectations, and operational capabilities. By carefully analyzing these factors, buyers can choose the most effective solution to enhance their retail environment.

Illustrative image related to conveyor at the store

Essential Technical Properties and Trade Terminology for conveyor at the store

What Are the Key Technical Properties of Conveyors at the Store?

When selecting conveyors for retail environments, understanding their technical specifications is crucial. Here are several critical properties that directly impact operational efficiency and cost-effectiveness:

-

Material Grade

The material grade of the conveyor belt significantly influences its durability and maintenance needs. Common materials include PVC, polyurethane, and stainless steel. Each material offers different levels of resistance to wear, chemicals, and temperature variations. For instance, stainless steel is ideal for food-related applications due to its hygiene properties and resistance to corrosion. -

Belt Width and Length

The width and length of the conveyor belt must align with the store’s specific requirements. A wider belt can accommodate larger items and increase throughput, while a longer belt can facilitate more extensive product ranges or longer checkout lines. Tailoring these dimensions helps optimize space and improve customer flow. -

Load Capacity

Understanding the load capacity is vital for ensuring that the conveyor can handle the expected product weight and volume. This specification determines the maximum weight per linear foot that the conveyor can support without compromising performance. Selecting a conveyor with an appropriate load capacity prevents breakdowns and increases operational reliability. -

Speed and Control Mechanisms

Conveyor speed is a critical factor in customer experience and operational efficiency. Adjustable speed settings can help manage high-traffic periods while ensuring smooth transitions between checkout processes. Advanced control mechanisms, such as variable frequency drives (VFD), enable precise speed adjustments, contributing to a more efficient workflow. -

Durability and Maintenance Requirements

The durability of conveyor systems is essential to minimize downtime and repair costs. Features such as sealed bearings and high-quality belt materials can reduce wear and tear. Understanding maintenance requirements, including lubrication and cleaning schedules, helps ensure long-term operational efficiency. -

Energy Efficiency

With increasing operational costs, energy-efficient conveyors are becoming a priority for many retailers. Systems designed to reduce energy consumption, such as those with energy-efficient motors and smart control systems, can lead to significant savings over time.

What Are Common Trade Terms Used in Conveyor Procurement?

Familiarity with industry jargon is crucial for effective communication and negotiation. Here are several common terms used in the procurement of conveyor systems:

-

OEM (Original Equipment Manufacturer)

An OEM refers to the company that manufactures the conveyor equipment. Understanding who the OEM is can provide insights into product quality, support, and warranty options. Buyers often prefer established OEMs with a proven track record in the industry. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. This term is particularly important for B2B buyers as it affects budget considerations and inventory management. Understanding the MOQ can help in planning purchases effectively. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to request pricing and terms for specific products, including conveyor systems. It is an essential step in the procurement process, ensuring that buyers receive competitive quotes and can make informed decisions. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping, insurance, and customs clearance. Familiarity with these terms can help buyers mitigate risks and understand their obligations when purchasing conveyors from overseas suppliers. -

Lead Time

Lead time refers to the time it takes from placing an order until the product is delivered. For B2B buyers, understanding lead times is crucial for inventory planning and ensuring that operational timelines are met. -

Warranty and Service Agreements

These terms outline the manufacturer’s commitment to repair or replace defective parts within a specified period. Understanding warranty details and service agreements can provide peace of mind and protect investments in conveyor systems.

By comprehensively understanding these technical properties and trade terms, B2B buyers can make informed decisions, streamline procurement processes, and enhance overall operational efficiency in retail environments.

Navigating Market Dynamics and Sourcing Trends in the conveyor at the store Sector

What Are the Key Market Drivers and Trends for Conveyor Systems in Retail?

The global conveyor systems market is experiencing significant growth, driven by the increasing demand for automation in retail environments. Factors such as the rise in e-commerce and the need for efficient customer service in supermarkets and convenience stores are propelling the adoption of conveyor systems. International buyers from regions like Africa, South America, the Middle East, and Europe must stay abreast of emerging technologies, such as IoT-enabled conveyor belts that enhance operational efficiency and provide real-time data analytics. These innovations not only streamline operations but also improve inventory management and customer flow, critical for boosting sales in high-traffic areas.

Additionally, the shift towards modular and customizable conveyor solutions is gaining traction. Retailers are looking for systems that can be easily adapted to changing store layouts or seasonal demands. For instance, modular designs allow for quick reconfiguration, enabling businesses to respond to market fluctuations more effectively. The focus on user-friendly interfaces and the integration of automated checkout systems are also shaping sourcing decisions. International buyers should prioritize suppliers who offer comprehensive maintenance services and rapid response times to ensure minimal downtime.

How Is Sustainability Influencing B2B Sourcing in the Conveyor Sector?

Sustainability is becoming a cornerstone of B2B sourcing strategies, particularly in the retail sector. The environmental impact of conveyor systems, from production to disposal, is under scrutiny, pushing businesses to seek eco-friendly materials and practices. Buyers are increasingly interested in suppliers who provide ‘green’ certifications, indicating compliance with environmental standards. This shift not only helps in mitigating the carbon footprint but also aligns with consumer demand for sustainable practices, enhancing brand reputation.

Moreover, ethical sourcing is essential for building trust with consumers and stakeholders. Suppliers who demonstrate a commitment to fair labor practices and responsible sourcing of materials are more likely to gain favor with discerning buyers. The adoption of recycled materials in the production of conveyor belts and other components is also on the rise, reflecting a broader commitment to sustainability. For international buyers, especially in emerging markets, establishing partnerships with suppliers who prioritize sustainability can serve as a competitive advantage.

What Is the Historical Context of Conveyor Systems in Retail?

The evolution of conveyor systems in retail can be traced back to the early 20th century when they were first introduced in manufacturing. The concept was quickly adopted in supermarkets to enhance efficiency during checkout processes. Over the decades, advancements in technology and design have transformed conveyor systems into essential components of modern retail operations. The introduction of automated systems and digital interfaces has not only improved speed but also enhanced the overall shopping experience for customers.

As the retail landscape continues to evolve with the rise of e-commerce and changing consumer behaviors, conveyor systems are adapting to meet new demands. Today, they are integral to operational efficiency and customer satisfaction, reflecting the ongoing innovations in retail technology. For B2B buyers, understanding this historical context is crucial in making informed sourcing decisions that align with current market trends and future developments.

Illustrative image related to conveyor at the store

Frequently Asked Questions (FAQs) for B2B Buyers of conveyor at the store

-

How do I choose the right conveyor system for my store?

Selecting the right conveyor system depends on several factors, including the type of products, store layout, and volume of transactions. For high-traffic areas, opt for durable, high-speed conveyors that can handle various product sizes. Consider features such as adjustable speed, incline options, and modular designs for easy integration into existing systems. Consulting with suppliers who offer customization can also ensure you meet specific operational needs while maximizing efficiency. -

What is the best conveyor type for supermarket checkout counters?

For supermarket checkout counters, belt conveyors are typically the most effective choice. They provide smooth, efficient product movement and can be easily integrated with scanning and bagging stations. Look for heavy-duty belts that can withstand high volumes and are easy to clean, especially if handling food items. Customization options, such as length and width, can also be tailored to fit your specific checkout layout. -

What should I consider when vetting suppliers for conveyor systems?

When vetting suppliers, prioritize their experience in the retail sector and their ability to provide tailored solutions. Check for certifications that ensure compliance with safety and quality standards. Ask for references from previous clients and evaluate their response times and customer service. Additionally, consider their capacity for after-sales support and maintenance, which is crucial for long-term operational efficiency. -

What are typical minimum order quantities (MOQs) for conveyor systems?

Minimum order quantities can vary widely based on the supplier and the type of conveyor system. Many suppliers may require MOQs ranging from a few units to several dozen, particularly for custom designs. It’s essential to discuss your needs directly with suppliers to negotiate terms that work for both parties, especially if you are a smaller business looking to scale operations. -

What payment terms should I expect when sourcing conveyor systems internationally?

Payment terms for international transactions typically involve a mix of upfront deposits and payment upon delivery. Many suppliers may require a 30% deposit to initiate production, with the remaining balance due before shipment. It’s advisable to clarify these terms upfront and consider options like letters of credit for larger orders to protect your investment and ensure compliance with international trade regulations. -

How do I ensure quality assurance (QA) for my conveyor systems?

To ensure quality assurance, request detailed specifications and certifications from your supplier regarding materials and manufacturing processes. Conduct pre-shipment inspections to verify that the products meet your standards. Some companies may offer warranties or guarantees, which can provide additional peace of mind regarding the durability and reliability of the conveyor systems. -

What logistics considerations should I keep in mind when importing conveyor systems?

When importing conveyor systems, consider shipping options, customs regulations, and potential tariffs. Work with logistics partners experienced in handling industrial equipment to streamline the process. Ensure you have all necessary documentation, such as bills of lading and customs declarations, to avoid delays. Additionally, factor in lead times for production and shipping when planning your inventory needs. -

How can I customize a conveyor system to fit my store’s specific needs?

Customization options for conveyor systems can include size adjustments, speed control, and integration with existing checkout technology. Discuss your specific requirements with suppliers, who may offer bespoke solutions to enhance efficiency. Consider factors like product types, space constraints, and operational workflows to develop a conveyor system that optimally supports your store’s layout and customer flow.

Top 7 Conveyor At The Store Manufacturers & Suppliers List

1. JFFixtures – Supermarket Checkout Conveyor Belt

Domain: jffixtures.com

Registered: 2000 (25 years)

Introduction: Supermarket checkout counter with conveyor belt designed for efficiency in retail. Benefits include speed, organization, and improved customer experience. Key considerations for choosing a conveyor belt include length and width, speed settings, and material durability. Design tips focus on optimal placement, clear layout, and accessibility. Maintenance tips include regular cleaning, routine inspec…

2. iStock – Grocery Store Conveyor Belt Images

Domain: istockphoto.com

Registered: 2000 (25 years)

Introduction: This company, iStock – Grocery Store Conveyor Belt Images, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. MIPR Corp – Checkout Counter Conveyor Belts

Domain: miprcorp.com

Registered: 2003 (22 years)

Introduction: Checkout Counter Conveyor Belts: MIPR Corp stocks and manufactures checkout counter belting with tough, long-lasting black mat top covers that clean easily and do not reflect fluorescent lighting. Features hot process endless or stainless steel checkout counter belt lacing with nylon-coated pins for steady movement. Offers same-day shipping for replacement supermarket belting. Teflon Food Belts: F…

4. R.W. Rogers Company – Checkout Counters

Domain: rwrogerscompany.com

Registered: 2001 (24 years)

Introduction: R.W. Rogers Company offers a variety of checkout counters, including both new and reconditioned options. Key features of specific models include:

1. **Carousel Lanes**:

– Carousel bag holders for quick cashier filling and easy customer pickup.

– Ideal for high volume locations.

2. **Non-Belted Express**:

– Simple design for limited quantity express checkouts.

3. **PTA-009 Checkou…

5. FMH Conveyors – Conveyor Systems for Retail

Domain: fmhconveyors.com

Registered: 2014 (11 years)

Introduction: FMH Conveyors offers a variety of conveyor systems for grocery and retail stores, including: Automated Conveyor and Sortation Systems, Flexible Gravity Conveyors, Flexible Powered Conveyors, Telescopic Belt Conveyors, Live Roller Conveyors, Curved Belt Conveyors, Rigid Drive-Out Conveyors, and Rigid Truck Loaders. These systems are designed to optimize product flow, reduce labor costs, and limit p…

6. Highbright – Checkout Counter with Conveyor Belt

Domain: supermarketequipments.com

Registered: 2011 (14 years)

Introduction: {“Product Name”: “Checkout Counter with Conveyor Belt No Extra Platform”, “Product Model”: “HBE-CC-22A”, “Brand”: “highbright”, “Size”: “2500*630*900”, “Weight”: {“N.W.”: “130kg”, “G.W.”: “180kg”}, “Carton Size”: “2600*710*1060”, “Material”: “steel”, “Availability”: “Inquire”, “MOQ”: “1pcs”}

7. Facebook – 1960s Steinberg’s Grocery Pickup

Strategic Sourcing Conclusion and Outlook for conveyor at the store

How Can Strategic Sourcing Enhance Your Conveyor Solutions?

In conclusion, strategic sourcing for conveyor systems at retail stores offers a multifaceted approach to optimizing operations and enhancing customer experience. By selecting high-quality, durable conveyor belts and checkout counters, businesses can significantly improve efficiency, reduce maintenance costs, and elevate customer satisfaction. Suppliers like MIPR Corp and R.W. Rogers Company provide tailored solutions that meet diverse needs, ensuring that companies are equipped to handle high-volume transactions effectively.

International buyers from Africa, South America, the Middle East, and Europe should prioritize partnerships with suppliers who demonstrate a commitment to quality and innovation. This ensures not only compliance with local regulations but also the capability to adapt to evolving market demands. Emphasizing strategic sourcing will empower your business to leverage competitive pricing and superior products, ultimately driving profitability.

As you look to the future, consider the potential of modular designs and advanced conveyor technologies to transform your retail space. Engage with trusted suppliers today to explore how strategic sourcing can enhance your operations and position your business for sustained growth in an increasingly competitive marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.