Unlocking Value: A Strategic Analysis of the Clay Insulators Market

Introduction: Navigating the Global Market for clay insulators

In today’s competitive landscape, sourcing high-quality clay insulators is a critical challenge for international B2B buyers seeking reliable electrical and thermal solutions. With the increasing demand for durable and efficient insulators across various industries—from power generation to telecommunications—understanding the nuances of the global market is essential. This comprehensive guide delves into the diverse types of clay insulators, their applications, and the benefits they offer, ensuring that buyers can make informed decisions that align with their operational needs.

As we explore the intricacies of clay insulators, this guide will provide actionable insights on supplier vetting processes, cost considerations, and best practices for procurement. We recognize that international buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and Germany—face unique challenges in navigating a fragmented supply chain. This guide empowers you with the knowledge to assess potential suppliers, evaluate product specifications, and understand market dynamics, enabling you to optimize your purchasing strategies.

By the end of this guide, you will be equipped with the tools to confidently select the right clay insulators for your projects, ensuring long-term performance and reliability in your operations. Join us as we navigate the complexities of this vital market and unlock the potential of clay insulators in your business.

Understanding clay insulators Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Porcelain Insulators | High dielectric strength, corrosion resistance | Power transmission, telecommunications | Pros: Durable, withstands harsh environments. Cons: Can be brittle, requires careful handling. |

| Alumina Insulators | High hardness, excellent thermal stability | Industrial electrical applications | Pros: Long lifespan, high performance. Cons: Higher cost, complex manufacturing process. |

| Zirconia Insulators | Exceptional toughness and corrosion resistance | High voltage applications | Pros: Greater strength than traditional ceramics. Cons: Limited availability, premium pricing. |

| Composite Insulators | Lightweight, non-ceramic, weather-resistant | Renewable energy, outdoor installations | Pros: Easy to install, resistant to UV and pollution. Cons: May have lower thermal stability than ceramics. |

| Hybrid Insulators | Combination of materials for enhanced performance | High voltage lines, railway systems | Pros: Optimized for performance, versatile applications. Cons: Potentially higher maintenance needs. |

What Are the Key Characteristics of Porcelain Insulators?

Porcelain insulators are widely recognized for their high dielectric strength and durability, making them ideal for various power transmission applications. Their resistance to corrosion and weathering ensures longevity, even in harsh environments. B2B buyers should consider the specific environmental conditions their insulators will face, as porcelain can be brittle and requires careful handling during installation and maintenance. This type of insulator is particularly suitable for utility companies and telecommunications, where reliability is paramount.

Why Choose Alumina Insulators for Industrial Applications?

Alumina insulators are characterized by their high hardness and exceptional thermal stability, making them suitable for industrial electrical applications. They are typically manufactured through complex processes, which can lead to a higher price point. However, their long lifespan and ability to perform under extreme conditions often justify the investment for businesses in manufacturing and energy sectors. When purchasing, buyers should evaluate the required specifications and the potential return on investment over time.

How Do Zirconia Insulators Stand Out in High Voltage Applications?

Zirconia insulators are known for their exceptional toughness and corrosion resistance, making them a preferred choice for high voltage applications. Their strength surpasses that of traditional ceramics, providing enhanced performance in demanding conditions. B2B buyers should consider the availability and pricing, as zirconia insulators may not be as widely accessible as other types. Their application is ideal for utility companies looking to enhance the reliability of their infrastructure.

What Advantages Do Composite Insulators Offer for Renewable Energy?

Composite insulators are lightweight and offer excellent weather resistance, making them ideal for renewable energy applications and outdoor installations. Their ease of installation can significantly reduce labor costs, which is attractive for businesses looking to optimize project budgets. However, buyers should be aware of potential thermal stability limitations compared to ceramic options. Evaluating the specific environmental conditions and performance requirements is crucial when selecting composite insulators.

Why Are Hybrid Insulators Gaining Popularity in Modern Infrastructure?

Hybrid insulators combine materials to optimize performance, making them increasingly popular in high voltage lines and railway systems. Their versatile applications allow for tailored solutions that can enhance overall system efficiency. While they provide numerous advantages, buyers should consider the potential for higher maintenance needs and ensure that their procurement aligns with long-term operational goals. The investment in hybrid insulators may lead to improved performance and reduced downtime in critical infrastructure projects.

Key Industrial Applications of clay insulators

| Industry/Sector | Specific Application of clay insulators | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Power Generation | Used in high-voltage transmission lines | Ensures reliable power delivery and reduces maintenance costs | Compliance with international safety standards |

| Telecommunications | Insulators for communication towers and antennas | Enhances signal integrity and minimizes interference | Availability of various sizes and types for specific needs |

| Rail Transport | Insulators for railway overhead lines | Improves safety and efficiency of electric trains | Durability against environmental stressors and weather conditions |

| Construction | Insulators in electrical installations in buildings | Increases safety and efficiency of electrical systems | Certifications for fire resistance and insulation properties |

| Renewable Energy | Used in solar panel installations | Supports sustainable energy generation and reduces downtime | Compatibility with various mounting systems and environmental resilience |

How Are Clay Insulators Used in Power Generation?

In the power generation sector, clay insulators are critical components in high-voltage transmission lines. They prevent electrical leakage and ensure that power is transmitted efficiently over long distances. By minimizing maintenance needs and enhancing reliability, businesses can significantly reduce operational costs. International buyers must ensure that these insulators comply with regional safety standards and are suitable for the voltage levels specific to their infrastructure.

What Role Do Clay Insulators Play in Telecommunications?

In telecommunications, clay insulators are utilized in communication towers and antennas to maintain signal integrity. These insulators help prevent signal interference and ensure that communication systems operate smoothly. For businesses, this translates to better service quality and customer satisfaction. Buyers should consider the specific dimensions and types of insulators that fit their equipment, as well as the environmental durability to withstand local conditions.

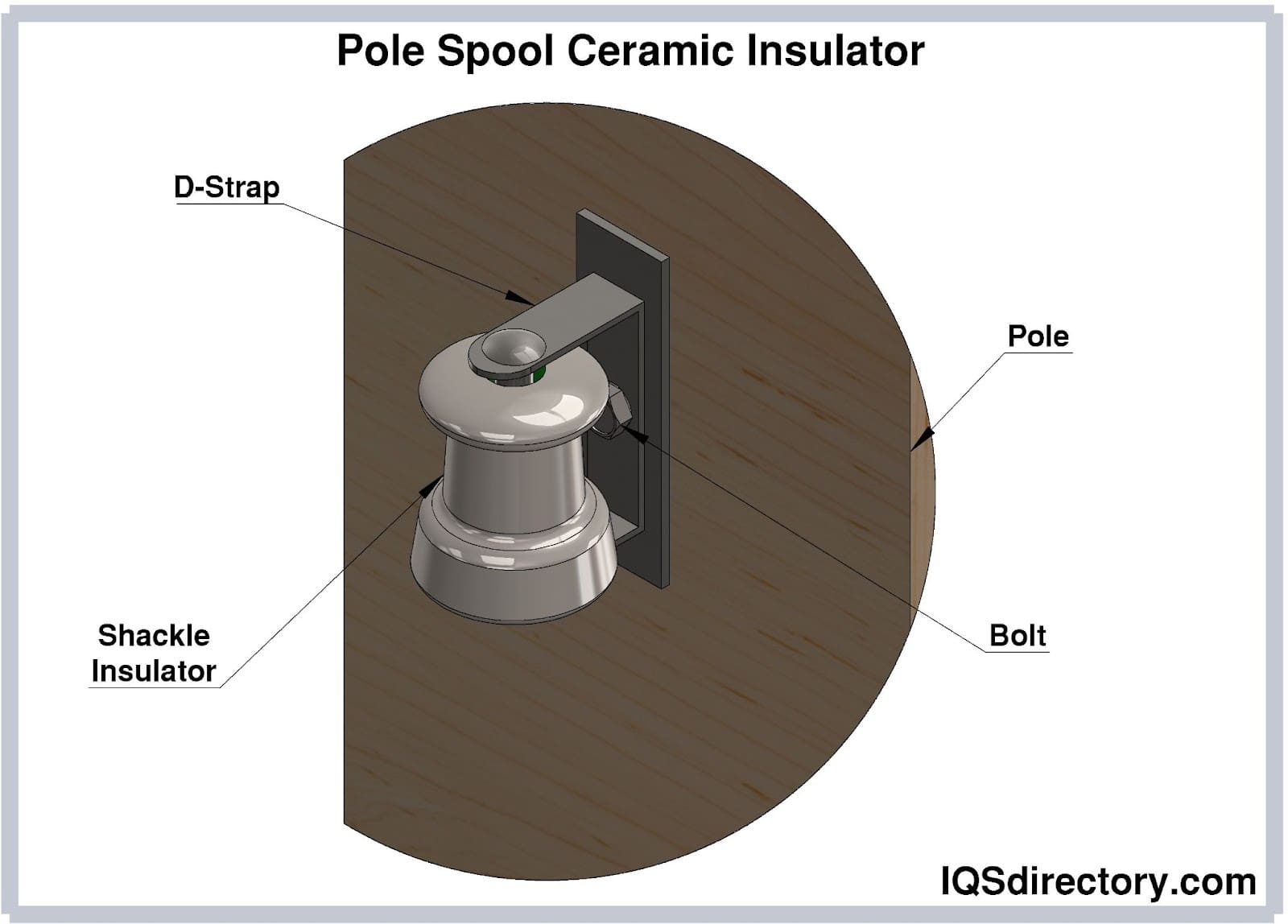

Illustrative image related to clay insulators

How Are Clay Insulators Essential for Rail Transport?

Rail transport relies heavily on clay insulators for the overhead lines that power electric trains. These insulators enhance safety by preventing electrical faults and improving the efficiency of the rail system. The use of durable materials helps reduce the frequency of replacements, providing cost savings over time. Buyers in this sector must prioritize insulators that can withstand extreme weather conditions and meet stringent safety regulations.

In What Ways Are Clay Insulators Used in Construction?

In the construction industry, clay insulators are essential for electrical installations within buildings. They ensure safety by preventing short circuits and electrical fires, thus protecting both infrastructure and occupants. Sourcing considerations include ensuring that these insulators meet fire resistance standards and are compatible with various electrical systems. Buyers should also look for suppliers that offer comprehensive technical support and certification documentation.

How Do Clay Insulators Support Renewable Energy Initiatives?

Clay insulators are increasingly being used in renewable energy applications, particularly in solar panel installations. They play a vital role in ensuring the reliability and efficiency of solar energy systems. By providing reliable insulation, they help reduce downtime and maintenance costs associated with energy generation. Buyers should seek insulators that are compatible with diverse mounting systems and can withstand environmental factors like temperature fluctuations and moisture.

3 Common User Pain Points for ‘clay insulators’ & Their Solutions

Scenario 1: Managing High Voltage Transmission Challenges

The Problem:

B2B buyers in the electrical utility sector often face significant challenges when it comes to ensuring the reliability of high voltage (HV) transmission systems. Clay insulators, while effective in their insulating properties, can fail due to environmental stressors such as pollution, moisture, or temperature fluctuations. Such failures can lead to outages, affecting service delivery and increasing maintenance costs. Buyers must therefore prioritize insulator specifications that can withstand harsh conditions while maintaining performance.

The Solution:

To address these challenges, buyers should prioritize sourcing clay insulators specifically designed for high voltage applications and extreme environmental conditions. This involves conducting a thorough analysis of the local environmental factors, such as humidity levels and pollution rates, and selecting insulators with enhanced durability features, like RTV coatings or hybrid materials. Additionally, collaborating with reputable suppliers who offer customization options can ensure that the insulators meet the specific voltage and environmental requirements of the installation site. Regular testing and maintenance schedules should also be established to monitor the insulator condition over time, thereby reducing the risk of unexpected failures.

Scenario 2: Cost Efficiency in Large-Scale Projects

The Problem:

In large-scale construction or utility projects, budget constraints are a primary concern for B2B buyers. The initial costs associated with high-quality clay insulators can be daunting, particularly when considering the need for bulk purchases. Buyers may find themselves torn between opting for cheaper alternatives or investing in reliable insulators that ensure long-term performance and safety, which can lead to project delays and increased expenditures due to failures.

The Solution:

To optimize cost efficiency, B2B buyers should take a strategic approach to sourcing clay insulators. This can be achieved by analyzing the total cost of ownership rather than just the initial purchase price. Investing in high-quality insulators can lead to reduced maintenance costs and longer lifespan, ultimately proving to be more economical over time. Additionally, negotiating bulk purchasing agreements with suppliers can yield significant discounts and favorable payment terms. Buyers should also consider the potential for lower insurance premiums and reduced risk of liability when investing in reliable products. Engaging in partnerships with suppliers who offer long-term warranties can provide peace of mind and financial security for large projects.

Scenario 3: Ensuring Compliance with International Standards

The Problem:

B2B buyers operating in international markets face the challenge of navigating various regulatory compliance requirements regarding electrical insulation products. Different regions may have distinct standards for clay insulators concerning material properties, performance metrics, and environmental impact. Failure to comply with these standards can result in project delays, fines, and reputational damage.

The Solution:

To ensure compliance, buyers should conduct comprehensive research into the specific regulations governing clay insulators in their target markets. This includes understanding the standards set by organizations such as IEC (International Electrotechnical Commission) or local regulatory bodies. Collaborating with manufacturers who have a proven track record in producing compliant products is crucial. Buyers should request certifications and test reports from suppliers to verify that the insulators meet or exceed the required standards. Additionally, establishing a quality assurance process to periodically review supplier compliance can mitigate risks associated with regulatory changes and ensure that all installations remain within legal frameworks. Engaging legal and regulatory experts can also provide guidance on navigating complex compliance landscapes across different regions.

Strategic Material Selection Guide for clay insulators

What Are the Key Materials Used in Clay Insulators?

When selecting materials for clay insulators, it is crucial to consider their properties, advantages, disadvantages, and suitability for specific applications. Below, we analyze four common materials used in the manufacturing of clay insulators: alumina ceramics, zirconia ceramics, porcelain, and kaolin clay.

How Does Alumina Ceramic Perform in Clay Insulators?

Alumina ceramics are known for their high hardness and durability, making them suitable for applications that require resistance to wear and mechanical stress. They can withstand high temperatures, typically up to 1,600°C, and exhibit excellent corrosion resistance. However, the manufacturing process is complex, often requiring diamond grinding for shaping, which can increase production costs.

Illustrative image related to clay insulators

Pros: High durability, excellent thermal stability, and good corrosion resistance make alumina ceramics ideal for high-performance applications.

Cons: The complexity of manufacturing and higher costs may deter some buyers, especially in markets sensitive to price.

For international buyers, particularly in regions like Europe and the Middle East, compliance with standards such as ASTM and DIN is essential. Buyers should also consider the availability of alumina ceramics in local markets, as sourcing can impact lead times.

What Are the Benefits of Zirconia Ceramics for Insulators?

Zirconia ceramics, or zirconium dioxide ceramics, are recognized for their exceptional toughness and resistance to thermal shock. They can handle high pressures and temperatures, making them suitable for environments with fluctuating conditions. Moreover, they do not exhibit the brittleness often associated with other ceramics.

Pros: High toughness and thermal shock resistance make zirconia ceramics a reliable choice for demanding applications.

Cons: The cost of zirconia ceramics is generally higher than that of other materials, which may be a limiting factor for budget-conscious buyers.

International buyers should be aware of the specific applications where zirconia ceramics excel, such as in high-voltage environments. Compliance with international standards is critical, especially in regions like South America, where local regulations may differ.

Illustrative image related to clay insulators

Why Choose Porcelain for Clay Insulators?

Porcelain is a widely used material for insulators due to its excellent electrical insulating properties and mechanical strength. It is highly resistant to moisture and environmental factors, making it suitable for outdoor applications. Porcelain insulators are also relatively easy to manufacture and can be produced at a lower cost compared to advanced ceramics.

Pros: Cost-effective, good mechanical strength, and resistance to environmental degradation make porcelain a popular choice.

Cons: While durable, porcelain can be more susceptible to cracking under extreme stress compared to advanced ceramics.

For buyers in regions like Africa and Europe, the availability of porcelain insulators is generally high, and they often meet established international standards. Buyers should ensure that the porcelain products they source are certified to comply with local electrical safety regulations.

What Role Does Kaolin Clay Play in Insulator Manufacturing?

Kaolin clay is a fundamental component in the production of ceramic materials, including insulators. It provides excellent plasticity and workability during manufacturing, allowing for intricate designs and shapes. Kaolin clay is also cost-effective, making it an attractive option for large-scale production.

Pros: Low cost and excellent workability make kaolin clay an ideal choice for mass production of insulators.

Cons: While it provides good insulating properties, kaolin clay may not offer the same level of durability and thermal resistance as advanced ceramics.

International buyers should consider the sourcing of kaolin clay, as its availability can vary by region. Compliance with local standards is also essential, particularly in markets that prioritize sustainability and environmental impact.

Summary Table of Material Selection for Clay Insulators

| Material | Typical Use Case for clay insulators | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Alumina Ceramics | High-performance electrical insulators | High durability and thermal stability | Complex manufacturing process | High |

| Zirconia Ceramics | High-voltage applications | Exceptional toughness and thermal shock resistance | Higher cost compared to other materials | High |

| Porcelain | Outdoor electrical insulators | Cost-effective and good mechanical strength | Susceptible to cracking under stress | Medium |

| Kaolin Clay | Mass production of insulators | Low cost and excellent workability | Lower durability and thermal resistance | Low |

This guide provides a comprehensive overview of the strategic material selection for clay insulators, offering valuable insights for international B2B buyers. Understanding the properties, advantages, and limitations of each material will aid in making informed purchasing decisions that align with specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for clay insulators

What Are the Key Stages in the Manufacturing Process of Clay Insulators?

The manufacturing of clay insulators involves several critical stages, each contributing to the final product’s quality and performance. Understanding these stages is essential for B2B buyers looking for reliable suppliers.

Material Preparation: How Are Raw Materials Processed?

The first step in manufacturing clay insulators is the preparation of raw materials. Clay, often combined with other materials like feldspar and quartz, is carefully sourced and processed. This may involve drying and grinding the materials to achieve the desired particle size. Quality control begins here, as the purity of the materials directly affects the insulator’s performance. Suppliers often conduct checks for impurities and consistency in material properties to ensure the final product meets industry standards.

Illustrative image related to clay insulators

Forming: What Techniques Are Used to Shape Clay Insulators?

Once the materials are prepared, the next stage is forming. Several techniques can be employed, including:

- Pressing: This method involves placing the clay mixture into molds and applying pressure to shape it. It is commonly used for high-volume production and ensures uniformity.

- Extrusion: In this technique, the clay is forced through a die to create a continuous shape, which can then be cut to length. This method is effective for producing long rod insulators.

- Slip Casting: This involves pouring a liquid clay mixture into plaster molds. The plaster absorbs water, allowing a solid form to develop. This technique is often used for intricate designs and shapes.

Each of these methods requires precise control over parameters like moisture content and temperature to ensure the integrity of the insulators.

Assembly: How Are Components Joined Together?

For insulators with multiple components, assembly is a crucial step. This may involve attaching metal fittings or other components necessary for the insulator’s functionality. Assembly processes must be carefully controlled to ensure that all parts fit securely and meet design specifications. Quality checks during this stage may include visual inspections and measurements to confirm proper alignment and fit.

Finishing: What Processes Enhance Durability and Performance?

The finishing stage includes several processes designed to enhance the insulator’s performance and durability. These may include:

Illustrative image related to clay insulators

- Drying: After forming, insulators are dried to remove excess moisture, which is vital for preventing cracking during firing.

- Firing: The dried insulators are then subjected to high temperatures in a kiln, which vitrifies the clay, giving it strength and electrical insulation properties. The firing temperature and duration are critical factors that influence the final product’s characteristics.

- Surface Treatment: Insulators may undergo additional treatments, such as glazing or applying coatings, to improve their resistance to environmental factors like moisture and pollution.

What Quality Assurance Measures Are Essential for Clay Insulators?

Quality assurance (QA) is paramount in the manufacturing of clay insulators, ensuring that they meet both international standards and specific industry requirements.

Which International Standards Should Be Considered?

B2B buyers should be aware of several key international standards that influence the manufacturing and quality control of clay insulators:

- ISO 9001: This standard outlines the requirements for a quality management system (QMS). Suppliers certified under ISO 9001 demonstrate a commitment to quality processes and customer satisfaction.

- CE Marking: In Europe, CE marking indicates compliance with health, safety, and environmental protection standards. This is especially relevant for electrical insulators.

- API Standards: For insulators used in the oil and gas industry, adherence to American Petroleum Institute (API) standards is crucial, ensuring that products can withstand harsh operational environments.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This initial stage involves testing raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, inspections and tests are conducted to catch defects early. This includes monitoring the forming and firing processes.

- Final Quality Control (FQC): After manufacturing, finished products undergo rigorous testing, including electrical and mechanical tests, to ensure they meet performance criteria.

How Can B2B Buyers Verify Supplier Quality Control?

When selecting suppliers, B2B buyers should conduct thorough due diligence to verify the quality control measures in place.

What Methods Can Be Used for Supplier Audits?

- On-Site Audits: Visiting the manufacturing facility allows buyers to assess the production environment, equipment, and processes. This firsthand observation can reveal a supplier’s commitment to quality.

- Documentation Review: Requesting quality control reports, inspection records, and certifications can provide insight into the supplier’s adherence to standards.

- Third-Party Inspections: Engaging independent auditors can offer an unbiased evaluation of the supplier’s quality control processes and product reliability.

What Are the Specific QC Nuances for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control.

- Regulatory Compliance: Different regions have varying regulations regarding product safety and performance. Understanding local compliance requirements is essential for ensuring market acceptance.

- Cultural Differences in Quality Expectations: Buyers should be aware that quality expectations may vary by region. Engaging with local partners can help bridge these gaps and ensure that products meet both local and international standards.

- Logistics and Supply Chain Considerations: Quality assurance does not end with manufacturing; it extends to the supply chain. Ensuring that products are handled and transported correctly is critical to maintaining quality.

Conclusion: Ensuring Quality in Clay Insulator Procurement

For B2B buyers, understanding the manufacturing processes and quality assurance measures for clay insulators is vital for making informed purchasing decisions. By focusing on reliable suppliers who adhere to international standards and demonstrating robust quality control processes, buyers can ensure they receive high-quality insulators that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘clay insulators’

When sourcing clay insulators, it is essential to follow a systematic approach to ensure you select the right products for your needs. This guide provides a step-by-step checklist that B2B buyers can use to navigate the procurement process effectively.

Step 1: Define Your Technical Specifications

Clearly articulate the technical requirements for the clay insulators you need. Consider factors such as voltage rating, environmental conditions, and mechanical strength. This step is crucial because it directly impacts the performance and longevity of the insulators in your application.

Step 2: Research Market Trends and Materials

Investigate the latest advancements in clay insulator technology and materials. Understanding the differences between various types, such as alumina and zirconia ceramics, will help you make informed decisions. Pay attention to the benefits of each material, such as hardness, corrosion resistance, and thermal stability.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers before making a commitment. Request detailed company profiles, case studies, and references from other buyers in your industry or region. An established supplier with a strong track record can provide the reliability and support necessary for your projects.

- Check for certifications: Ensure suppliers have relevant industry certifications and compliance with international standards.

- Review customer feedback: Look for reviews or testimonials that highlight the supplier’s performance and reliability.

Step 4: Request Product Samples

Before finalizing your order, request samples of the clay insulators. This allows you to assess their quality, durability, and compatibility with your systems. Testing samples in your specific applications can prevent costly mistakes and ensure that the products meet your expectations.

Step 5: Negotiate Pricing and Terms

Engage in negotiations to secure favorable pricing and terms. Discuss bulk order discounts, payment terms, and shipping costs. Effective negotiation can lead to significant savings and better overall value for your purchase.

Step 6: Verify After-Sales Support and Warranty

Inquire about after-sales support and warranty terms provided by the supplier. Reliable support can be crucial for addressing any issues that may arise after installation. A good warranty demonstrates the supplier’s confidence in their products and can protect your investment.

Step 7: Finalize Your Purchase Order

Once you have evaluated all factors, finalize your purchase order. Ensure that all details, including quantities, specifications, and delivery timelines, are clearly documented. Clear communication at this stage can help prevent misunderstandings and ensure a smooth procurement process.

By following this checklist, B2B buyers can make informed decisions when sourcing clay insulators, ensuring they select high-quality products that meet their specific requirements.

Comprehensive Cost and Pricing Analysis for clay insulators Sourcing

What Are the Key Cost Components in Sourcing Clay Insulators?

When sourcing clay insulators, understanding the cost structure is critical for effective budgeting and negotiation. The primary cost components include:

-

Materials: The base materials for clay insulators, such as alumina or zirconia ceramics, significantly influence the cost. The quality and source of these materials can vary, impacting both price and performance.

-

Labor: Skilled labor is essential for the manufacturing and finishing processes. Labor costs can fluctuate based on location, skill level, and local labor laws.

-

Manufacturing Overhead: This includes costs associated with facility maintenance, utilities, and equipment depreciation. Efficient production techniques can help minimize these expenses.

-

Tooling: The initial setup costs for molds and other production tools can be substantial, especially for custom or specialized insulators. This cost is often amortized over larger production runs.

-

Quality Control (QC): Ensuring that insulators meet industry standards requires investment in quality control measures. This includes testing and certification processes, which are essential for maintaining product integrity.

-

Logistics: Transportation costs can vary widely depending on the distance from the manufacturing site to the buyer and the method of shipping. International logistics can introduce complexities such as customs duties and tariffs.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on market conditions and competition.

How Do Price Influencers Impact the Cost of Clay Insulators?

Several factors can influence the final pricing of clay insulators:

-

Volume/MOQ (Minimum Order Quantity): Purchasing larger quantities often leads to volume discounts. Buyers should assess their needs carefully to balance inventory costs against potential savings.

-

Specifications and Customization: Custom designs or specific performance specifications can increase costs. Buyers should clearly communicate their requirements to avoid unexpected charges.

-

Material Quality and Certifications: Higher-quality materials and certifications (e.g., ISO, CE) often come at a premium. These certifications can be crucial for buyers in regulated industries.

-

Supplier Factors: The supplier’s experience, reputation, and location can all impact pricing. Established suppliers with a history of reliability may command higher prices but offer greater assurance in quality and service.

-

Incoterms: The choice of Incoterms (International Commercial Terms) affects shipping responsibilities and costs. Understanding these terms is essential for calculating the total cost of ownership.

What Are Some Effective Buyer Tips for Sourcing Clay Insulators?

To maximize value when sourcing clay insulators, consider the following strategies:

-

Negotiation: Engage suppliers in discussions about pricing, especially if you can demonstrate a commitment to large orders or long-term partnerships. Leveraging multiple quotes can also enhance your negotiating position.

-

Cost-Efficiency: Assess the total cost of ownership, which includes not just the purchase price but also logistics, installation, and maintenance costs. A lower initial price may not always result in overall savings.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import duties, and local regulations that can affect pricing. Establishing relationships with local distributors can also help mitigate risks.

-

Regular Market Research: Stay informed about market trends and pricing fluctuations in the ceramics industry. This knowledge can empower buyers to make informed purchasing decisions.

Disclaimer on Indicative Prices

Prices for clay insulators can vary widely based on the aforementioned factors. The examples provided are indicative and should not be taken as final quotes. Always consult multiple suppliers and request detailed quotations to ensure accurate budgeting and planning for your projects.

Alternatives Analysis: Comparing clay insulators With Other Solutions

Exploring Alternatives to Clay Insulators: A Comparative Analysis

In the realm of electrical insulation, clay insulators are a popular choice due to their durability and thermal resistance. However, various alternative solutions are available that may better meet specific operational requirements, particularly for B2B buyers in diverse markets such as Africa, South America, the Middle East, and Europe. This analysis compares clay insulators with two viable alternatives: porcelain insulators and composite insulators.

| Comparison Aspect | Clay Insulators | Porcelain Insulators | Composite Insulators |

|---|---|---|---|

| Performance | High thermal and electrical resistance; suitable for harsh environments | Excellent electrical properties; high mechanical strength | Good electrical performance; lightweight and resistant to environmental degradation |

| Cost | Moderate initial investment; long lifespan offers cost-effectiveness | Generally lower cost per unit; may require more frequent replacements | Higher initial cost but often lower long-term maintenance costs |

| Ease of Implementation | Requires specialized installation techniques | Easier to install and replace; widely available | Flexible installation options; may need specialized skills for some types |

| Maintenance | Low maintenance requirements; durable | Moderate maintenance; can chip or crack under extreme conditions | Low maintenance; resistant to corrosion and UV degradation |

| Best Use Case | High-voltage applications in extreme environments | General electrical applications; utility poles and transmission lines | Urban environments with limited space and harsh conditions |

What Are the Pros and Cons of Porcelain Insulators?

Porcelain insulators are a long-standing alternative to clay insulators, known for their excellent electrical properties and mechanical strength. They are widely used in various electrical applications, including power transmission and distribution. The primary advantages of porcelain insulators include lower costs per unit and ease of installation. However, they are susceptible to chipping and cracking under severe mechanical stress or thermal shock, which could lead to performance issues over time. Thus, while they may be suitable for many applications, they may not perform as reliably in extreme conditions compared to clay insulators.

How Do Composite Insulators Compare?

Composite insulators represent a modern alternative that combines lightweight materials with strong electrical performance. They excel in environments where weight and space are critical factors, making them ideal for urban installations. Composite insulators are resistant to environmental degradation, including UV exposure and moisture, which enhances their longevity and reduces maintenance needs. However, they typically have a higher initial cost compared to both clay and porcelain insulators. This investment may be justified in applications where long-term durability and reduced maintenance significantly lower overall operational costs.

Conclusion: How to Choose the Right Insulator for Your Needs

When selecting the right insulation solution, B2B buyers should evaluate their specific requirements, including environmental conditions, installation capabilities, and budget constraints. Clay insulators may be the best choice for high-voltage applications in extreme environments due to their robustness and low maintenance. In contrast, porcelain insulators may offer cost advantages for standard applications, while composite insulators could be ideal for projects requiring lightweight and durable solutions. By carefully considering these factors, businesses can make informed decisions that align with their operational goals and budgetary constraints.

Essential Technical Properties and Trade Terminology for clay insulators

What Are the Essential Technical Properties of Clay Insulators?

When sourcing clay insulators, understanding their technical properties is crucial for making informed purchasing decisions. Here are some key specifications to consider:

-

Material Grade

The material grade of clay insulators typically refers to the type of clay used in their manufacture, such as porcelain or stoneware. Higher-grade materials often exhibit superior dielectric strength and thermal stability, which are essential for high-voltage applications. For B2B buyers, selecting the right material grade can significantly impact the longevity and reliability of the insulators in various environmental conditions. -

Dielectric Strength

Dielectric strength measures the insulator’s ability to withstand electrical stress without breaking down. It is a critical parameter for insulators used in electrical applications. A higher dielectric strength indicates better performance in high-voltage environments, minimizing the risk of electrical failures. Buyers should ensure the insulators meet the required dielectric specifications based on their application needs. -

Thermal Conductivity

This property indicates how well an insulator can conduct heat. Low thermal conductivity is desirable as it helps maintain temperature stability and reduces the risk of overheating. For businesses operating in extreme climates, selecting insulators with optimal thermal properties can enhance performance and reduce maintenance costs. -

Mechanical Strength

Mechanical strength is the ability of the insulator to withstand physical stresses without breaking or deforming. This is particularly important for outdoor applications where insulators may be exposed to wind, ice, or other mechanical forces. B2B buyers should look for insulators with high mechanical strength ratings to ensure they can endure the demands of their specific installations. -

Moisture Absorption

The ability of clay insulators to absorb moisture can affect their performance, particularly in humid environments. Low moisture absorption rates are essential to prevent degradation and ensure longevity. Buyers should inquire about moisture absorption specifications when sourcing insulators for regions with high humidity. -

Tolerance Levels

Tolerance refers to the allowable deviation from specified dimensions in the manufacturing process. Precise tolerances are vital for ensuring that insulators fit correctly within electrical systems, minimizing the risk of malfunctions. Buyers should request tolerance specifications to ensure compatibility with their existing infrastructure.

What Are Common Trade Terms in the Clay Insulator Industry?

Familiarizing yourself with industry terminology can facilitate smoother transactions and clearer communication with suppliers. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of clay insulators, understanding whether a supplier is an OEM can help assess the quality and reliability of the products. -

MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units a buyer must purchase in a single order. This term is crucial for budgeting and inventory management, especially for smaller companies or those entering new markets. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to request pricing and terms for specific products or services. Including detailed specifications for clay insulators in an RFQ can help ensure accurate and competitive pricing. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is essential for managing shipping costs, risks, and delivery timelines effectively. -

Lead Time

Lead time is the amount of time it takes for a supplier to process an order and deliver the goods. This term is vital for project planning, as delays in lead time can impact overall timelines and costs. -

Certification

Certification refers to the validation of products against specific industry standards or regulations. For clay insulators, certifications can indicate compliance with safety and performance standards, providing assurance to buyers regarding the quality of their purchases.

In summary, grasping the essential technical properties and trade terminology related to clay insulators can empower B2B buyers to make informed decisions, optimize procurement strategies, and ensure the successful implementation of electrical systems across diverse applications.

Navigating Market Dynamics and Sourcing Trends in the clay insulators Sector

What Are the Current Market Dynamics and Key Trends in the Clay Insulators Sector?

The global market for clay insulators is influenced by a variety of factors, including the increasing demand for reliable electrical infrastructure, particularly in developing regions such as Africa and South America. As urbanization accelerates, countries like Saudi Arabia and Germany are expanding their electrical grids to accommodate growing populations and industrial needs. This surge is driving investment in high-voltage and ultra-high-voltage transmission systems, where clay insulators play a critical role due to their durability and high dielectric strength.

Emerging technologies in manufacturing, such as advanced ceramic processing techniques and the integration of IoT for predictive maintenance, are reshaping the sourcing landscape. B2B buyers are increasingly looking for suppliers who can provide not only high-quality products but also innovative solutions that enhance performance and reliability. Additionally, the shift towards automation and digital supply chains is streamlining sourcing processes, making it easier for international buyers to access a wide range of products and services.

As climate change becomes a pressing concern, the clay insulator market is also experiencing a shift towards sustainability. Suppliers are adapting to these market dynamics by focusing on reducing their environmental footprint and improving energy efficiency in their manufacturing processes. This trend presents an opportunity for buyers to collaborate with manufacturers who prioritize sustainable practices, thus enhancing their own brand reputation in the marketplace.

How Important Is Sustainability and Ethical Sourcing in the Clay Insulators Sector?

Sustainability has become a critical consideration in the sourcing of clay insulators, driven by increasing regulatory pressures and consumer demand for environmentally friendly products. The production of clay insulators typically involves significant energy consumption and resource extraction, which can have detrimental environmental impacts. Therefore, B2B buyers are increasingly prioritizing suppliers who adhere to sustainable practices, such as using locally sourced materials, minimizing waste, and implementing energy-efficient manufacturing processes.

Ethical sourcing is equally important, as buyers seek to ensure that their supply chains are free from human rights violations and environmental degradation. Certifications such as ISO 14001 for environmental management and adherence to the UN Global Compact principles are becoming benchmarks for assessing suppliers. Moreover, companies that invest in sustainable materials and processes are not only mitigating risks but are also appealing to a growing market of environmentally conscious consumers.

By partnering with suppliers who demonstrate a commitment to sustainability and ethical sourcing, B2B buyers can enhance their corporate social responsibility profiles. This alignment not only fosters customer loyalty but also positions companies favorably in a competitive marketplace increasingly focused on sustainability.

What Is the Historical Context of Clay Insulators in the B2B Space?

The use of clay insulators dates back to the early days of electrical transmission, when porcelain was recognized for its insulating properties. Initially employed in low-voltage applications, advancements in material science and manufacturing techniques have allowed for the development of high-voltage and ultra-high-voltage insulators, which are essential for modern electrical grids. Over the decades, the industry has evolved from simple, handcrafted insulators to sophisticated, engineered solutions that meet the rigorous demands of contemporary electrical infrastructure.

As the global energy landscape continues to shift towards renewable sources, the role of clay insulators remains pivotal. They are integral to ensuring the reliability and safety of transmission lines, particularly in regions prone to harsh environmental conditions. This historical context underscores the importance of clay insulators in the B2B supply chain, highlighting their enduring relevance as the industry adapts to new technological and environmental challenges.

Frequently Asked Questions (FAQs) for B2B Buyers of clay insulators

-

How do I determine the right type of clay insulator for my application?

To select the appropriate clay insulator, consider the specific electrical and environmental requirements of your application. Assess factors such as voltage levels, environmental conditions (humidity, temperature, and pollution), and mechanical load. Additionally, consult with manufacturers to understand the performance characteristics of different insulator types, such as porcelain or alumina ceramics, as these can significantly impact durability and reliability. -

What are the key benefits of using ceramic insulators in electrical applications?

Ceramic insulators offer numerous advantages, including high dielectric strength, thermal stability, and resistance to corrosion and weathering. Their durability ensures a longer lifespan, reducing maintenance costs and downtime. Furthermore, ceramic materials can withstand extreme temperatures and are less prone to breakage compared to glass insulators, making them ideal for harsh environments in industries such as power transmission and railway systems. -

What is the minimum order quantity (MOQ) for clay insulators?

Minimum order quantities for clay insulators can vary significantly by supplier and product type. Typically, MOQs may range from a few dozen to several hundred units. It is advisable to discuss your specific needs with potential suppliers to determine their MOQ and explore possibilities for smaller orders, especially if you are testing a new product or entering a new market. -

How can I vet suppliers of clay insulators for quality and reliability?

To vet suppliers, start by reviewing their certifications and industry standards compliance, such as ISO or IEC certifications. Request samples to assess product quality firsthand, and seek testimonials or references from other B2B buyers. Additionally, evaluate the supplier’s production capacity, delivery times, and responsiveness to inquiries, as these factors are crucial for maintaining a reliable supply chain. -

What payment terms should I expect when purchasing clay insulators internationally?

Payment terms can vary widely among suppliers. Common terms include advance payment, letter of credit, or payment upon delivery. Ensure you discuss payment options upfront and understand any associated fees. It may also be beneficial to negotiate terms that provide some level of security for both parties, such as a partial payment upfront and the balance upon delivery or inspection. -

What logistics considerations should I be aware of when importing clay insulators?

When importing clay insulators, consider shipping methods, customs regulations, and potential tariffs or duties. Evaluate the most efficient transportation modes, such as sea freight for bulk orders or air freight for smaller, urgent shipments. Ensure compliance with local regulations and prepare all necessary documentation, including invoices, packing lists, and certificates of origin, to facilitate smooth customs clearance. -

How do I ensure quality assurance for clay insulators during the manufacturing process?

To ensure quality assurance, request information about the supplier’s quality control processes and testing protocols. Look for suppliers that conduct routine inspections and tests throughout production, including electrical and mechanical tests. Additionally, consider third-party inspections or audits to verify compliance with industry standards and specifications before shipment. -

Can I customize clay insulators to meet specific project requirements?

Many manufacturers offer customization options for clay insulators, including size, shape, and electrical specifications. Discuss your project requirements with potential suppliers to determine their ability to accommodate your needs. Customization may involve additional costs and lead times, so it is essential to plan accordingly and communicate your specifications clearly to avoid delays in production.

Top 7 Clay Insulators Manufacturers & Suppliers List

1. eBay – Ceramic Insulators for Sale

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Ceramic Insulator for sale on eBay. Categories include various types such as Antique Square D Porcelain Ceramic Safety Switch Insulator, Vintage Large Ceramic Insulator, High Voltage Brown Ceramic Insulator, and more. Prices range from under $15 to over $35. Shipping options include free shipping and local pickup. Condition of items varies from new to pre-owned. Featured refinements include types …

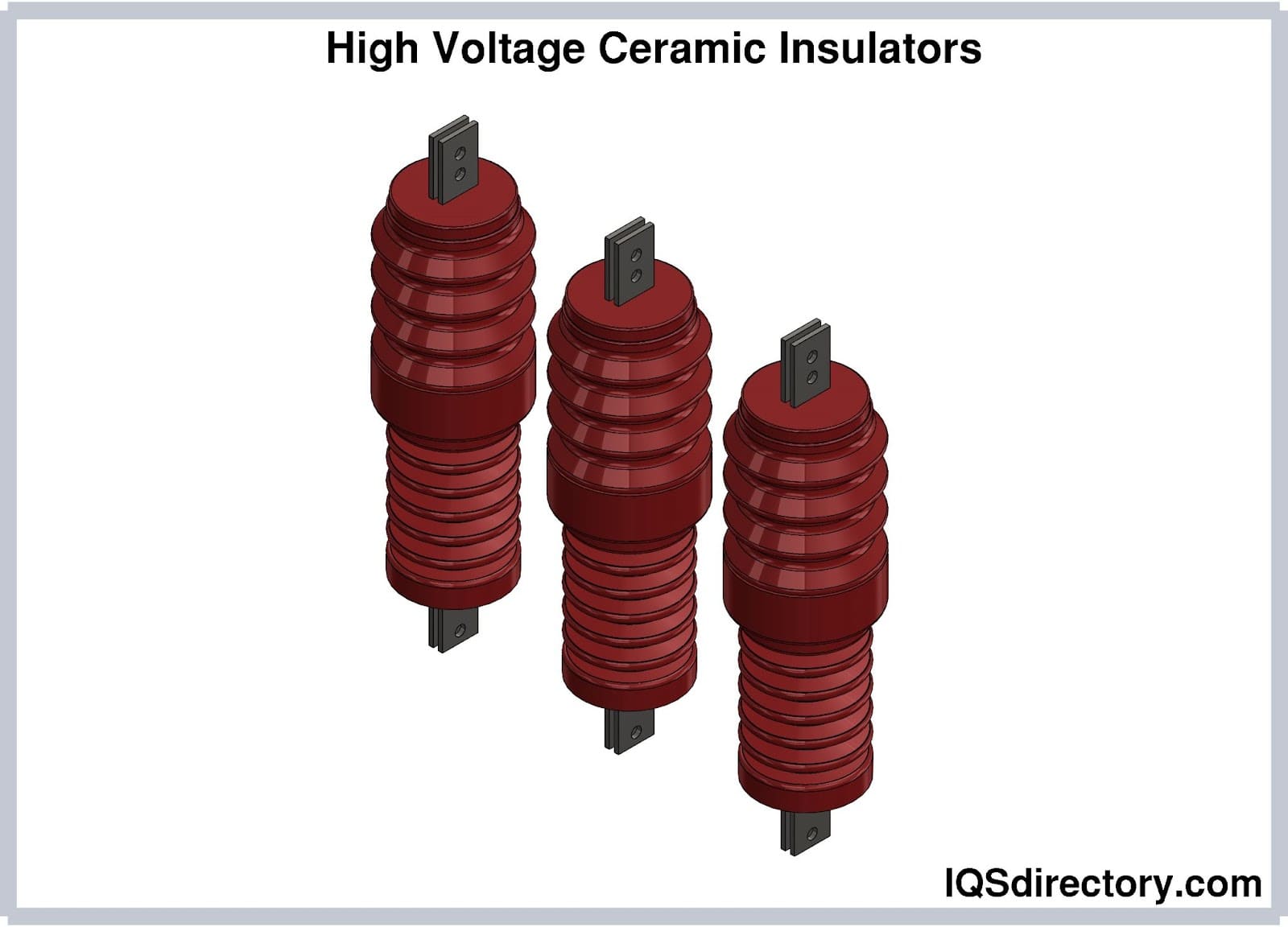

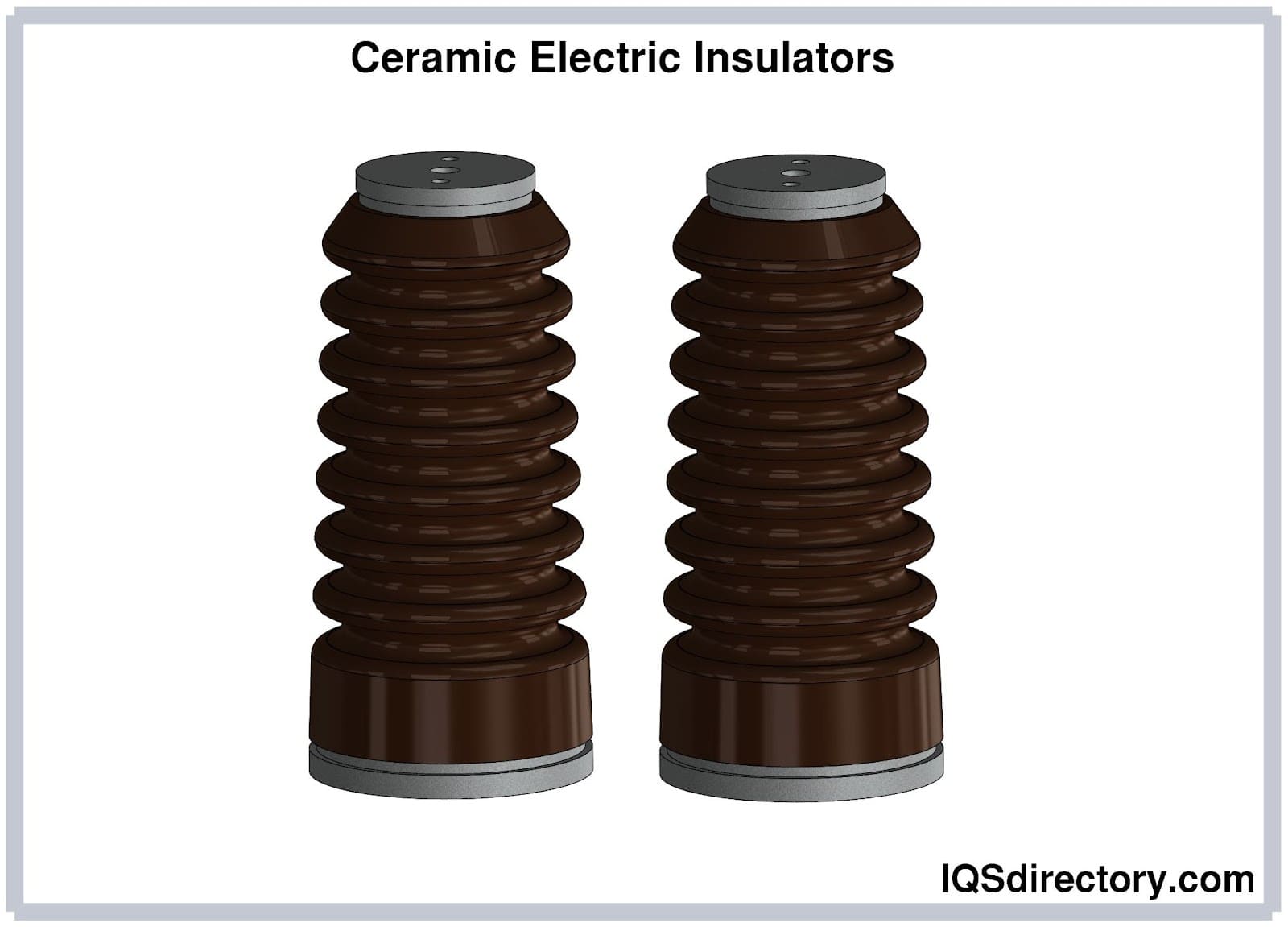

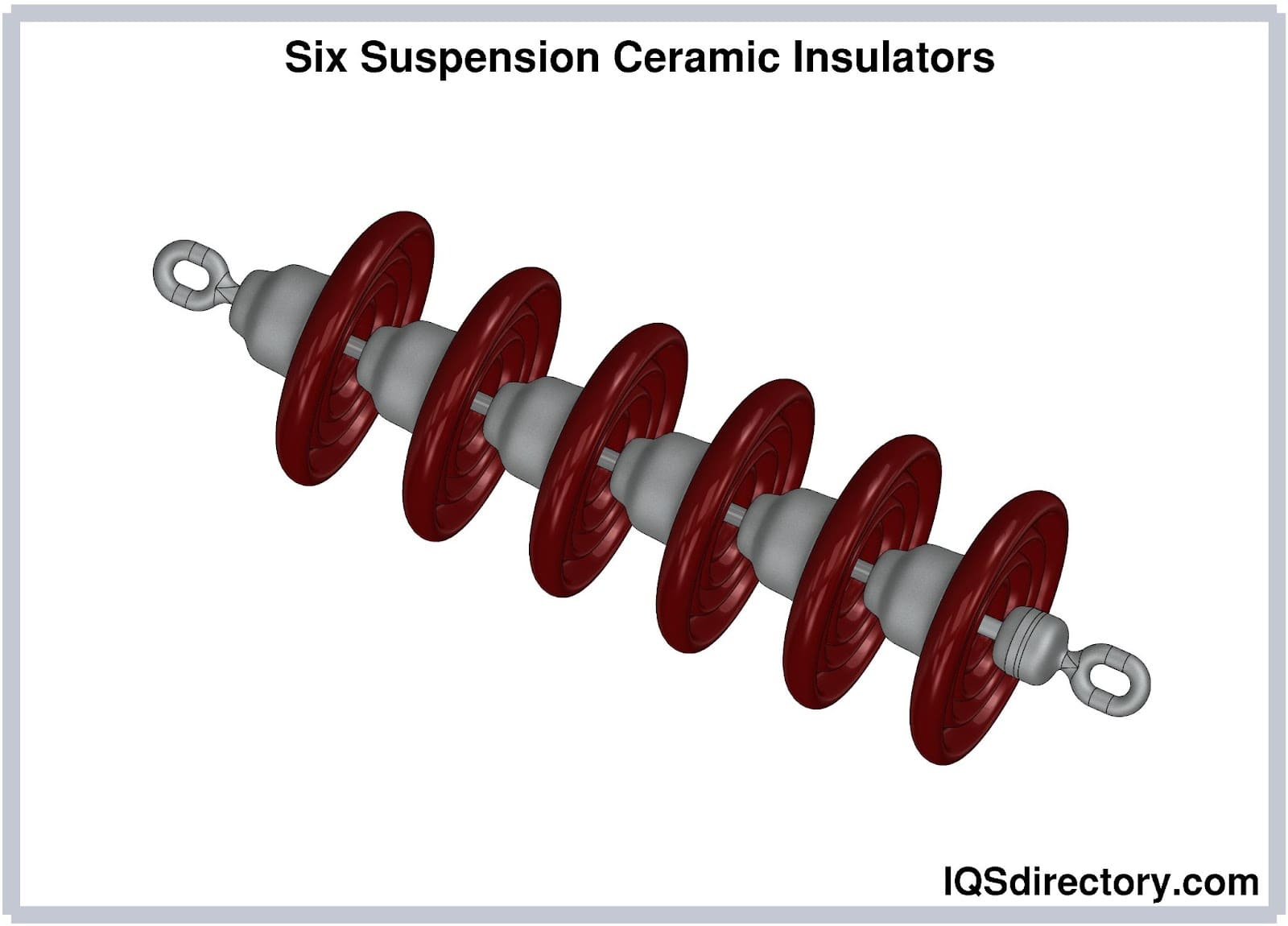

2. IQS Directory – Ceramic Insulators

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Ceramic insulators are insulating materials made from clay, available in red, brown, or white, characterized by a porous texture. They offer outstanding dielectric properties, exceptional resistance to electrical currents, low energy dissipation, and are easy to maintain with high resistance to staining and residue buildup. They are used in high-voltage power transmission systems, coaxial cables, …

3. The Ceramic Shop – Porcelain Insulator

Domain: theceramicshop.com

Registered: 2003 (22 years)

Introduction: {“product_name”: “Porcelain Insulator”, “price”: “$1.20”, “availability”: “New”, “category”: “Insulators”}

4. PPC Insulators – Electrical Porcelain Insulators

Domain: ppcinsulators.com

Registered: 2002 (23 years)

Introduction: PPC Insulators offers a range of electrical porcelain insulators including: 1. PPC Porcelain Post Insulators 2. PPC Fiber Optic Hole Post Insulators 3. PPC Hybrid Post Insulators 4. PPC Porcelain Hollow Insulators 5. PPC Porcelain Long Rod Insulators 6. PPC T&D Insulators 7. PPC Hybrid Line Post Insulators 8. PPC Railway Insulators 9. PPC Electrostatic Precipitator Insulators (ESP Insulators) 10. …

5. Associated Ceramics – Custom Electrical and Thermal Insulators

Domain: associatedceramics.com

Introduction: Associated Ceramics manufactures custom electrical ceramic insulators and thermal ceramic insulators for various industries including appliance, power generation, medical, and electronics. Key materials used include:

– Alumina: High strength and hardness, excellent electrical resistance, high thermal conductivity, high resistance to chemical and corrosion, 0-0.05% porosity, high dielectric streng…

6. Daburn – Wire Insulators

Domain: daburn.com

Registered: 1995 (30 years)

Introduction: Daburn Electronics & Cable offers a variety of wire insulators including:

1. **Airplane Insulators** – Suitable for mobile or aircraft wire applications, made of dry process porcelain.

2. **Antenna Insulators** – Glazed with white porcelain, featuring a smooth glazed exterior.

3. **Feeder Spreader Insulators** – Made of high vitrified-low absorption hi-tensile strength material, suitable for buss…

7. NGK Insulators – High-Quality Porcelain & Long Rod Insulators

Domain: ngk-insulators.com

Registered: 2001 (24 years)

Introduction: NGK Insulators specializes in high-quality insulators that ensure the safety and stability of energy transmission. Key products include:

1. **Porcelain Insulators** – Support transmission lines on steel towers while isolating them from the towers.

2. **Long Rod Insulators** – Used individually or in configurations to support and isolate transmission lines.

3. **Station Post Insulators** – Found…

Strategic Sourcing Conclusion and Outlook for clay insulators

As the global demand for reliable and durable insulators continues to rise, strategic sourcing of clay insulators presents significant opportunities for B2B buyers across various regions, including Africa, South America, the Middle East, and Europe. Understanding the diverse applications and benefits of clay insulators, such as their excellent mechanical strength and resistance to thermal shock, can enhance procurement strategies and operational efficiency.

Investing in high-quality clay insulators not only ensures compliance with international standards but also contributes to long-term sustainability goals. Buyers should prioritize suppliers with advanced manufacturing capabilities and a proven track record in delivering innovative solutions that meet specific environmental challenges.

Looking ahead, the integration of new technologies in the production of clay insulators will likely reshape the market landscape. Now is the time for international buyers to engage with suppliers who demonstrate agility and responsiveness in adapting to changing demands. By forming strategic partnerships, organizations can secure a competitive edge and foster growth in their respective markets. Embrace the opportunity to enhance your sourcing strategy for clay insulators today—your future projects depend on it.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.