Unlocking Value: A Strategic Analysis of the China Warehouse Market

Introduction: Navigating the Global Market for china warehouse

Navigating the complexities of the global market for China warehouse solutions can be daunting for international B2B buyers, especially those sourcing products from regions like Africa, South America, the Middle East, and Europe. The challenge often lies in identifying reliable warehousing partners that not only store goods but also streamline logistics and ensure compliance with international shipping standards. This guide addresses these critical needs by exploring various warehouse types, applications, and essential factors for supplier vetting, enabling buyers to make informed decisions.

In the following sections, we will delve into the different types of warehouses available in China, including e-commerce fulfillment centers, third-party logistics (3PL) providers, and specialized facilities for Amazon FBA sellers. We will also cover key considerations such as cost structures, service offerings, and the technological advancements that can enhance supply chain efficiency. By equipping buyers with actionable insights and expert recommendations, this guide aims to simplify the procurement process and foster successful partnerships with Chinese warehouses.

Whether you are a retailer in Nigeria looking to streamline your inventory management or a brand owner in Vietnam seeking efficient logistics solutions, understanding the landscape of China warehouses is crucial for optimizing your global supply chain. With the right knowledge, you can confidently navigate this vital market and unlock opportunities for growth.

Understanding china warehouse Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| E-commerce Fulfillment Center | Specializes in rapid order processing and shipping for online sales. | E-commerce, Amazon FBA, Dropshipping | Pros: Fast shipping, integrated tech solutions. Cons: May have higher fees for small businesses. |

| 3PL (Third-Party Logistics) | Offers comprehensive services including warehousing, shipping, and customs. | General B2B logistics, inventory management | Pros: Scalability, expertise in logistics. Cons: Less control over inventory management. |

| Cold Storage Warehouse | Maintains specific temperature conditions for perishable goods. | Food & beverage, pharmaceuticals | Pros: Essential for compliance, quality preservation. Cons: Higher operational costs. |

| Bonded Warehouse | Stores goods without immediate customs duties; ideal for international trade. | Import/export businesses | Pros: Defers duties, facilitates international trade. Cons: Complex regulations and compliance requirements. |

| Consolidation Warehouse | Combines shipments from multiple suppliers into one for cost savings. | Retailers, wholesalers | Pros: Cost-effective shipping, efficient logistics. Cons: Potential delays in consolidation. |

What Are the Characteristics of E-commerce Fulfillment Centers?

E-commerce fulfillment centers are designed to streamline the order processing and shipping of goods sold online. These warehouses typically feature advanced technology for inventory management and order tracking, allowing for rapid fulfillment of customer orders. They are particularly suitable for businesses that sell through platforms like Amazon, as they often have direct integration capabilities with these systems. When considering e-commerce fulfillment services, buyers should assess the warehouse’s shipping speed, technology integration, and scalability to match their growth.

How Do 3PL Services Enhance B2B Logistics?

Third-party logistics (3PL) providers offer a comprehensive suite of services that go beyond simple storage. They manage everything from warehousing to shipping, customs clearance, and even inventory management. This type of warehouse is ideal for businesses looking to outsource their logistics needs entirely. Buyers should consider the 3PL’s expertise, technology capabilities, and flexibility in adapting to their specific logistics requirements. While 3PLs can provide significant operational efficiencies, they may also lead to reduced control over inventory processes.

Why Are Cold Storage Warehouses Important for Certain Industries?

Cold storage warehouses are essential for businesses that handle perishable goods, such as food and pharmaceuticals. These facilities maintain specific temperature and humidity levels to ensure product quality and compliance with health regulations. For B2B buyers in the food and beverage or pharmaceutical sectors, choosing a cold storage warehouse is critical for maintaining product integrity. However, buyers should be aware of the higher operational costs associated with these facilities and ensure that they meet all necessary compliance standards.

What Advantages Do Bonded Warehouses Offer for International Trade?

Bonded warehouses are specialized facilities that allow businesses to store goods without paying customs duties until they are released for sale. This is particularly beneficial for companies involved in international trade, as it provides cash flow advantages and simplifies the import/export process. When selecting a bonded warehouse, buyers should understand the regulatory requirements and ensure that the facility has a strong compliance record. While bonded warehouses can facilitate smoother international transactions, they also come with complex regulations that must be navigated carefully.

How Can Consolidation Warehouses Save Costs for Retailers?

Consolidation warehouses focus on combining shipments from multiple suppliers into a single shipment, reducing overall shipping costs. This model is particularly advantageous for retailers and wholesalers who want to optimize their logistics and reduce expenses. Buyers should evaluate the consolidation process, including the time it takes to combine shipments and any potential delays. While this approach can lead to significant cost savings, it may also introduce complexities in inventory management and timing.

Key Industrial Applications of china warehouse

| Industry/Sector | Specific Application of China Warehouse | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| E-commerce | Fulfillment services for online retailers | Streamlined order processing and faster delivery times | Need for integration with e-commerce platforms and logistics capabilities |

| Manufacturing | Inventory storage and distribution for components | Efficient management of supply chain and reduced lead times | Proximity to suppliers and capabilities for kitting and assembly |

| Automotive | Parts storage and global distribution | Enhanced supply chain efficiency and reduced transportation costs | Compliance with international shipping regulations and customs |

| Consumer Electronics | Centralized logistics for product launches | Improved market responsiveness and inventory control | Ability to handle high-volume shipments and rapid turnover |

| Fashion and Apparel | Seasonal inventory management and order fulfillment | Flexibility to respond to fashion trends and consumer demands | Fast turnaround times and ability to manage returns efficiently |

How Are China Warehouses Used in E-commerce Fulfillment?

In the fast-paced world of e-commerce, China warehouses serve as critical fulfillment centers for international retailers. They enable sellers to store inventory closer to their customer base, significantly reducing shipping times and costs. By utilizing these warehouses, businesses can efficiently manage their stock levels, process orders quickly, and enhance customer satisfaction. For international buyers, particularly from Africa, South America, the Middle East, and Europe, it’s essential to choose warehouses that integrate seamlessly with their existing e-commerce platforms and offer robust logistics capabilities to handle cross-border shipping.

Illustrative image related to china warehouse

What Role Do China Warehouses Play in Manufacturing?

For manufacturers, China warehouses provide vital inventory storage and distribution services for components and finished goods. This centralized approach allows businesses to optimize their supply chain, ensuring that parts are readily available for production and that finished products can be dispatched quickly to global markets. Buyers in this sector should prioritize warehouses that offer kitting and assembly services, as well as those located near key manufacturing hubs to minimize transportation delays and costs.

How Do Automotive Companies Benefit from China Warehouses?

In the automotive industry, China warehouses are essential for storing parts and facilitating global distribution. They help streamline the supply chain by ensuring that components are available when needed, thereby reducing downtime in production lines. International buyers must consider compliance with shipping regulations and customs requirements when selecting a warehouse, as automotive parts are often subject to strict scrutiny during transit.

Why Are China Warehouses Important for Consumer Electronics?

For consumer electronics companies, China warehouses act as centralized logistics hubs that support product launches and inventory management. They enable businesses to respond swiftly to market demands and trends, ensuring that new products reach consumers without delay. Buyers should look for warehouses with the capability to handle high-volume shipments and rapid turnover to maintain a competitive edge in this dynamic sector.

How Do Fashion and Apparel Brands Utilize China Warehouses?

Fashion and apparel brands leverage China warehouses for seasonal inventory management and efficient order fulfillment. These warehouses allow companies to quickly adapt to changing consumer preferences and trends, ensuring that the latest styles are available when demanded. Fast turnaround times and efficient returns management are critical considerations for international buyers in this sector, making it essential to partner with a warehouse that can support these needs effectively.

Illustrative image related to china warehouse

3 Common User Pain Points for ‘china warehouse’ & Their Solutions

Scenario 1: Navigating Complex Customs Regulations

The Problem: International B2B buyers often face significant challenges when it comes to customs regulations while using warehouses in China. The complexities of import/export documentation, tariffs, and compliance can be overwhelming, leading to delays and unexpected costs. Buyers may find that their goods are held up in customs, which not only affects their supply chain but also impacts customer satisfaction and sales.

The Solution: To mitigate these customs-related issues, B2B buyers should partner with a warehouse that offers comprehensive customs brokerage services. Look for providers that have a robust understanding of both Chinese export regulations and the import requirements of the destination country. For instance, a warehouse with established connections to customs authorities can facilitate smoother clearance processes. Additionally, ensure that the warehouse can handle the necessary documentation and compliance checks on your behalf. Investing in a warehouse that provides end-to-end support, including customs clearance, will streamline your operations, minimize delays, and ultimately reduce costs.

Scenario 2: Managing Inventory Fluctuations

The Problem: Another common pain point for B2B buyers using warehouses in China is managing inventory fluctuations. Many buyers struggle with overstocking or stockouts due to unpredictable demand, seasonal variations, or production delays. This imbalance can lead to increased holding costs for excess inventory or lost sales opportunities when items are unavailable.

The Solution: To effectively manage inventory fluctuations, B2B buyers should leverage advanced inventory management systems offered by their warehouse partner. Choose a warehouse that utilizes technology such as AI and machine learning to predict demand based on historical sales data and market trends. These systems can provide real-time insights, allowing buyers to adjust their inventory levels proactively. Furthermore, consider implementing a just-in-time (JIT) inventory strategy, where the warehouse can ship products on an as-needed basis, minimizing holding costs while ensuring product availability. Collaborating closely with your warehouse provider to establish clear communication channels will also help in forecasting and managing inventory effectively.

Illustrative image related to china warehouse

Scenario 3: Ensuring Timely Deliveries Across Borders

The Problem: Timeliness is crucial for B2B buyers, especially when dealing with international shipments. Delays in delivery can lead to dissatisfied customers and lost business opportunities. Buyers often encounter issues with unreliable shipping schedules, miscommunication between suppliers and warehouses, and unforeseen delays at various transit points.

The Solution: To ensure timely deliveries, B2B buyers should select a warehouse that specializes in global logistics and has a track record of efficient shipping practices. Look for warehouses that offer multiple shipping options (air, sea, express) to suit different urgency levels and budgets. Additionally, establishing a clear logistics plan in collaboration with your warehouse provider is essential. This plan should include contingency strategies for potential delays, such as alternative shipping routes or methods. Furthermore, consider utilizing a warehouse that provides real-time tracking and updates on shipment status, enabling you to communicate proactively with your customers about their orders. Building a strong partnership with your warehouse can lead to improved delivery performance and enhanced customer satisfaction.

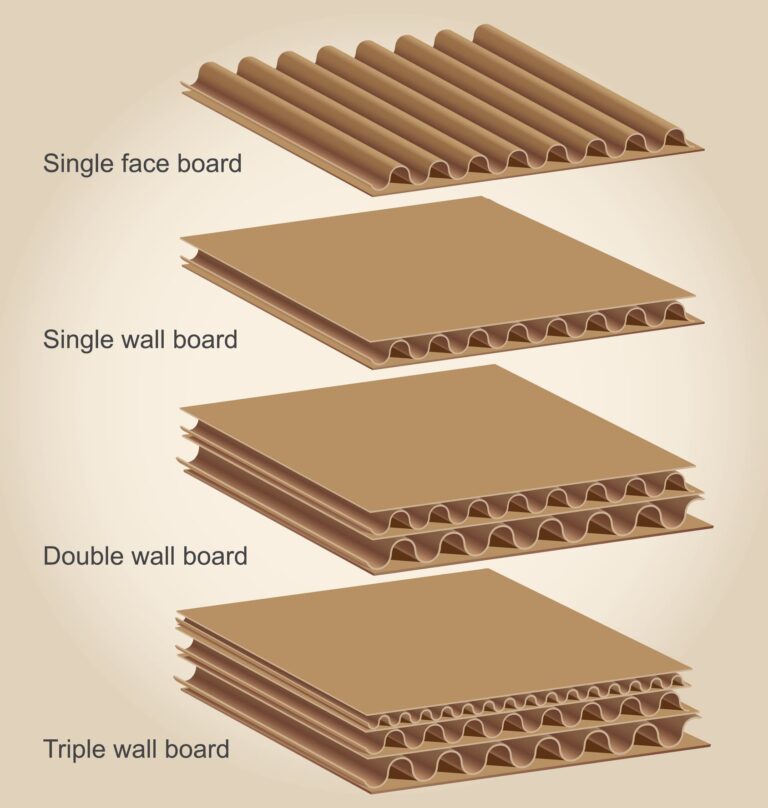

Strategic Material Selection Guide for china warehouse

What Are the Key Materials Used in China Warehousing?

When selecting materials for warehousing in China, particularly for international B2B operations, it is essential to consider the properties, advantages, and limitations of various materials. This guide analyzes four common materials used in warehouse applications, focusing on their performance, suitability, and compliance with international standards.

How Does Steel Perform in Warehouse Applications?

Steel is a widely used material in warehouse construction, known for its strength and durability. Key properties include high tensile strength, excellent load-bearing capacity, and resistance to deformation under pressure. Steel structures can withstand extreme temperatures, making them suitable for various climates.

Pros: Steel’s durability ensures a long lifespan, reducing the need for frequent replacements. It is also recyclable, aligning with sustainability goals. However, the initial costs can be high due to manufacturing and transportation expenses.

Illustrative image related to china warehouse

Cons: Steel is prone to corrosion if not properly treated, particularly in humid environments. This necessitates additional protective coatings, which can increase costs and complexity.

Impact on Application: Steel is ideal for heavy-duty shelving and racking systems, providing excellent support for high-density storage solutions. For international buyers, compliance with standards like ASTM A36 or EN 10025 is critical, especially in regions with strict building codes.

Why Choose Plastic for Warehouse Solutions?

Plastic materials, particularly high-density polyethylene (HDPE) and polypropylene, are increasingly popular in warehouse settings due to their lightweight and corrosion-resistant properties. They can withstand a wide range of temperatures and are often used in shelving, bins, and pallets.

Illustrative image related to china warehouse

Pros: The lightweight nature of plastic reduces shipping costs and makes handling easier. Additionally, plastic is resistant to chemicals and moisture, making it suitable for various media.

Cons: While plastic is durable, it may not support as much weight as steel or wood, limiting its application in heavy-duty scenarios. Moreover, the environmental impact of plastic waste can be a concern for eco-conscious companies.

Impact on Application: Plastic is particularly effective for storing non-perishable goods and in environments where moisture is a concern. International buyers should consider compliance with standards such as FDA regulations for food-grade plastics.

What Advantages Does Wood Offer in Warehousing?

Wood is a traditional material used in warehouse construction and storage solutions. It offers natural insulation properties and is often used for pallets, crates, and shelving units.

Illustrative image related to china warehouse

Pros: Wood is relatively inexpensive and easy to work with, allowing for custom solutions. Its aesthetic appeal can also enhance the warehouse environment.

Cons: Wood is susceptible to pests, rot, and warping, particularly in humid conditions. This can lead to increased maintenance costs over time.

Impact on Application: Wood is suitable for lighter loads and is often used in environments where aesthetics are important. International buyers should ensure compliance with standards such as ISPM 15 for treated wood to prevent pest infestations during shipping.

How Does Aluminum Compare in Warehouse Settings?

Aluminum is another versatile material used in warehouse applications, known for its lightweight and corrosion-resistant properties. It is often used in shelving, conveyor systems, and structural components.

Illustrative image related to china warehouse

Pros: Aluminum’s lightweight nature allows for easy installation and reduces transportation costs. It is also resistant to corrosion, making it ideal for various environments.

Cons: While aluminum is strong, it is generally more expensive than steel and may not support as much weight, limiting its use in heavy-duty applications.

Impact on Application: Aluminum is excellent for modular shelving systems and lightweight structures. International buyers should consider compliance with standards such as ASTM B221 for aluminum extrusions.

Summary Table of Material Selection for China Warehousing

| Material | Typical Use Case for china warehouse | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty shelving and racking | High strength and durability | Prone to corrosion without treatment | High |

| Plastic | Bins and pallets | Lightweight and corrosion-resistant | Limited weight capacity | Medium |

| Wood | Custom pallets and crates | Inexpensive and easy to work with | Susceptible to pests and rot | Low |

| Aluminum | Modular shelving and conveyor systems | Lightweight and corrosion-resistant | Higher cost compared to steel | Medium |

This comprehensive overview of material selection provides actionable insights for international B2B buyers, ensuring informed decisions that align with operational needs and compliance requirements.

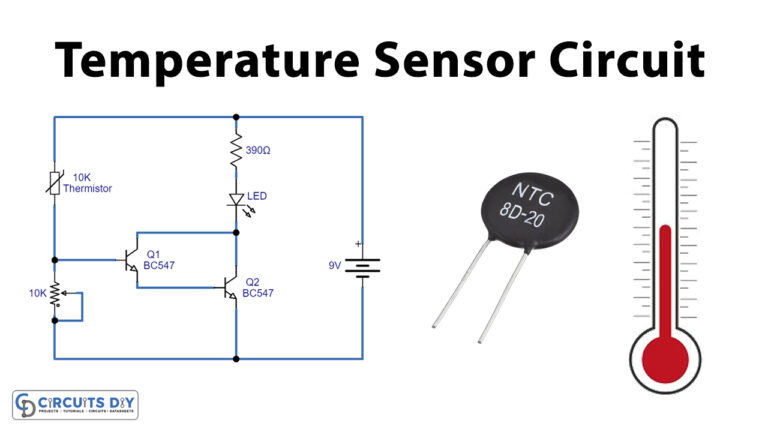

In-depth Look: Manufacturing Processes and Quality Assurance for china warehouse

What Are the Main Stages of Manufacturing Processes in Chinese Warehouses?

When considering manufacturing processes within Chinese warehouses, it’s crucial to understand the key stages involved: material preparation, forming, assembly, and finishing. Each stage plays a vital role in ensuring that products meet the required specifications for quality and functionality.

Illustrative image related to china warehouse

-

Material Preparation: This initial stage involves sourcing and preparing raw materials for production. Suppliers typically ensure that materials meet specified standards, which is critical for maintaining quality. In China, materials may undergo rigorous testing to confirm their compliance with international standards. This stage sets the foundation for the subsequent processes.

-

Forming: This stage transforms raw materials into semi-finished products. Techniques such as molding, machining, and welding are commonly employed. Advanced technologies like CNC (Computer Numerical Control) machining are often used for precision, which is essential for high-quality outputs. Proper equipment calibration and maintenance during this stage are vital to avoid defects.

-

Assembly: Once the components are formed, they are assembled into the final product. This may involve manual labor or automated assembly lines, depending on the complexity and volume of production. Quality control checks are often integrated into the assembly process to catch any defects before the final product is completed.

-

Finishing: The finishing stage includes surface treatments, painting, and packaging. This step enhances the product’s aesthetics and protects it from environmental factors. Techniques such as powder coating or anodizing can be employed to improve durability. Quality checks during this stage focus on both appearance and functionality.

What Are the Key Techniques Used in Chinese Manufacturing?

Chinese warehouses leverage a variety of manufacturing techniques to optimize efficiency and quality. These include:

-

Lean Manufacturing: This method focuses on minimizing waste while maximizing productivity. By streamlining processes and reducing excess inventory, companies can respond more quickly to market demands.

-

Just-In-Time (JIT): JIT manufacturing reduces inventory costs by producing only what is needed when it is needed. This technique requires precise coordination with suppliers and logistics partners.

-

Automation and Robotics: Increasingly, warehouses in China are adopting automated systems for tasks such as sorting, packing, and inventory management. Robotics can significantly enhance speed and accuracy, reducing human error.

-

Quality Management Systems (QMS): Many manufacturers implement QMS, such as ISO 9001, to ensure consistent quality throughout the manufacturing process. These systems include documented procedures and continuous improvement protocols.

How Is Quality Assurance Implemented in Chinese Warehouses?

Quality assurance (QA) is a critical aspect of manufacturing in Chinese warehouses, designed to ensure that products meet specific quality standards. Various international and industry-specific standards guide these practices.

-

International Standards: ISO 9001 is the most recognized quality management standard, focusing on process efficiency and customer satisfaction. Compliance with ISO standards indicates that a warehouse has a systematic approach to managing quality.

-

Industry-Specific Standards: Depending on the products being manufactured, additional certifications may be relevant. For instance, CE marking is essential for products sold in the European Economic Area, while API standards are crucial for manufacturers in the petroleum and natural gas industries.

What Are the Key Quality Control Checkpoints in Chinese Warehousing?

Quality control (QC) checkpoints are essential for maintaining product integrity throughout the manufacturing process. The main QC checkpoints include:

-

Incoming Quality Control (IQC): This initial checkpoint inspects raw materials upon arrival at the warehouse. Suppliers must provide documentation proving compliance with required specifications.

-

In-Process Quality Control (IPQC): Conducted during the manufacturing process, IPQC involves monitoring production stages to detect and correct defects early. This can include visual inspections and functional testing.

-

Final Quality Control (FQC): FQC occurs after production and before shipment. This comprehensive check ensures that the final product meets all specifications and standards. Random sampling is often used to assess quality.

What Testing Methods Are Commonly Used in Chinese Warehouses?

Testing methods in Chinese warehouses vary depending on the product type and industry standards. Common testing methodologies include:

-

Destructive Testing: This method evaluates the material’s strength and durability by subjecting it to conditions that will ultimately lead to failure. It’s often used for metals and construction materials.

-

Non-Destructive Testing (NDT): Techniques like ultrasonic, magnetic particle, and radiographic testing allow for the assessment of materials without damaging them. NDT is crucial for products where integrity is paramount.

-

Functional Testing: This ensures that the product performs as intended under specified conditions. It may include stress tests, usability tests, and performance evaluations.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential to mitigate risks. Here are some strategies to consider:

Illustrative image related to china warehouse

-

Audits: Conducting on-site audits provides an in-depth understanding of the supplier’s operations and quality control measures. These audits can reveal compliance with international standards and internal quality practices.

-

Quality Reports: Requesting detailed quality reports from suppliers can provide insights into their QC processes, including the frequency of inspections and the results of previous tests.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures. These services often include factory audits, product inspections, and compliance checks.

-

Certifications: Checking for relevant certifications like ISO 9001 or industry-specific standards can offer additional assurance that the supplier adheres to recognized quality practices.

What Are the QC and Certification Nuances for International B2B Buyers?

International buyers should be aware of certain nuances related to quality control and certification:

-

Cultural Differences: Understanding local business practices and cultural norms can aid in effective communication with suppliers regarding quality expectations.

-

Regulatory Compliance: Different regions have varying regulatory requirements that must be met for products to be imported. Buyers should ensure that their suppliers are compliant with both local and international regulations.

-

Documentation: Ensure that all quality control processes and certifications are well-documented. This documentation can be crucial for customs clearance and compliance verification.

By understanding the manufacturing processes and quality assurance practices in Chinese warehouses, international B2B buyers can make informed decisions that enhance their supply chain efficiency and product quality.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘china warehouse’

Introduction

Navigating the complexities of sourcing warehousing solutions in China is crucial for international B2B buyers looking to optimize their supply chain. This guide provides a systematic checklist to assist you in identifying, evaluating, and securing the right warehouse services to meet your business needs. By following these steps, you can streamline your logistics operations and enhance your overall efficiency.

Step 1: Identify Your Storage and Distribution Needs

Understanding your specific storage and distribution requirements is the foundation of effective warehouse sourcing. Consider factors such as product volume, type, and turnover rate.

– Sub-bullets:

– Determine if you need short-term or long-term storage.

– Assess whether you require specialized handling for fragile or perishable items.

Illustrative image related to china warehouse

Step 2: Research Potential Warehousing Partners

Conduct comprehensive research to identify potential warehouse providers in China that align with your needs. Utilize industry directories, online reviews, and trade shows to gather information.

– Sub-bullets:

– Look for warehouses with proven experience in your industry.

– Pay attention to their geographical location and proximity to major transport hubs.

Step 3: Evaluate Facility Capabilities and Technology

Once you have a shortlist of potential partners, assess their facility capabilities and technological infrastructure. A modern warehouse should incorporate advanced systems for inventory management and logistics.

– Sub-bullets:

– Inquire about automation and real-time tracking capabilities.

– Check if they offer value-added services like kitting, bundling, or customization.

Step 4: Verify Compliance and Certifications

Ensuring that your chosen warehouse complies with local regulations and international standards is non-negotiable. Verify their certifications and compliance with customs regulations.

– Sub-bullets:

– Request documentation related to safety, environmental standards, and quality management systems.

– Ensure they have experience handling customs clearance for your target markets.

Illustrative image related to china warehouse

Step 5: Assess Logistics and Shipping Options

Evaluate the logistics and shipping solutions provided by the warehouse. A reliable partner should offer multiple shipping methods and efficient last-mile delivery services.

– Sub-bullets:

– Ask about their partnerships with freight forwarders and courier services.

– Consider their capacity for handling both B2B and B2C shipments.

Step 6: Request Quotes and Compare Costs

Once you have narrowed down your options, request detailed quotes from your selected warehouses. Comparing costs will help you identify the most cost-effective solution without compromising quality.

– Sub-bullets:

– Look for transparency in pricing, including any hidden fees.

– Evaluate service levels included in the pricing structure.

Step 7: Engage in a Trial Period

Before making a long-term commitment, consider engaging in a trial period with the selected warehouse. This will allow you to assess their performance and reliability in real-time.

– Sub-bullets:

– Monitor key performance indicators such as order accuracy and turnaround time.

– Use this period to establish communication protocols and operational workflows.

By following this checklist, you can make informed decisions that will enhance your supply chain efficiency and ultimately contribute to your business’s success in the competitive global marketplace.

Comprehensive Cost and Pricing Analysis for china warehouse Sourcing

What Are the Key Cost Components of Sourcing from a China Warehouse?

When sourcing products from China, understanding the cost structure is essential for effective budgeting and pricing strategy. The main cost components include:

Illustrative image related to china warehouse

-

Materials: The cost of raw materials can vary significantly based on quality and sourcing location. Prices may fluctuate due to market demand or seasonal changes. B2B buyers should engage suppliers early to secure favorable rates.

-

Labor: Labor costs in China are generally lower than in Western countries, but they can vary by region and skill level. Factories in coastal cities like Shenzhen may have higher labor costs compared to inland areas. It’s crucial to consider the skill set required for your product when evaluating labor expenses.

-

Manufacturing Overhead: This includes costs associated with factory operations, such as utilities, equipment depreciation, and facility maintenance. Understanding these costs can provide insight into the overall pricing strategy of your supplier.

-

Tooling: Tooling costs are significant for custom products and can include molds, dies, and specialized equipment. Buyers should factor in these expenses for new product launches or custom designs.

-

Quality Control (QC): Investing in QC is vital to ensure product standards meet international regulations. Costs for QC inspections and certifications can vary based on the complexity of the product and the required quality standards.

-

Logistics: Shipping costs can be a major expense, influenced by the chosen transportation method (air vs. sea), distance, and the volume of goods. Buyers should also consider warehousing and distribution costs, particularly if using a third-party logistics provider.

-

Margin: Suppliers typically include a margin in their pricing to ensure profitability. Understanding the typical margins in your industry can help you negotiate better prices.

How Do Price Influencers Impact Sourcing from China?

Several factors influence pricing when sourcing from China, including:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to lower per-unit costs. Many suppliers set MOQs to ensure production efficiency, which may require buyers to adjust their ordering strategy to meet these thresholds.

-

Specifications and Customization: Customized products usually incur additional costs for design and tooling. When requesting quotes, be clear about specifications to avoid unexpected price increases.

-

Materials: The choice of materials can significantly affect pricing. Premium materials will increase costs, while more economical options can reduce them, but may impact product quality.

-

Quality and Certifications: Products requiring certifications (e.g., CE, ISO) may have higher costs due to the necessary testing and compliance processes. Buyers should factor these into their total cost calculations.

-

Supplier Factors: A supplier’s experience, reputation, and production capacity can influence pricing. Established suppliers may charge a premium for reliability and quality assurance.

-

Incoterms: The chosen Incoterm affects the division of costs and responsibilities between buyer and supplier. Understanding terms like FOB (Free On Board) or CIF (Cost Insurance and Freight) is crucial for accurate cost assessments.

What Are the Best Practices for Negotiating Costs with China Warehouses?

To optimize your sourcing strategy, consider these negotiation tips:

-

Build Relationships: Establishing a strong rapport with suppliers can lead to better pricing and terms. Regular communication and transparency can foster trust.

-

Leverage Volume Discounts: If possible, consolidate orders to meet MOQ requirements and negotiate discounts based on larger volumes.

-

Assess Total Cost of Ownership (TCO): Look beyond initial pricing to consider logistics, QC, and potential risks. This holistic view will help in making informed decisions.

-

Stay Informed on Market Trends: Knowledge of current market conditions can provide leverage during negotiations. Understanding fluctuations in material costs or labor rates can help you negotiate better terms.

-

Be Prepared for Cultural Differences: Understanding Chinese business culture can aid negotiations. Respect for hierarchy and the importance of face can impact discussions.

Conclusion: Why Is Understanding Costs Crucial for International Buyers?

For B2B buyers from regions like Africa, South America, the Middle East, and Europe, comprehending the cost structure of sourcing from China is vital. Each component contributes to the overall pricing, impacting profitability and competitiveness. As you navigate this landscape, remember to account for all variables and remain flexible to adapt to changing conditions. Always seek multiple quotes and engage in thorough due diligence to ensure you’re making the best sourcing decisions.

Disclaimer: Prices and costs mentioned are indicative and can vary based on market conditions and specific supplier agreements.

Alternatives Analysis: Comparing china warehouse With Other Solutions

In the dynamic world of global logistics, B2B buyers often seek alternatives to traditional warehouse solutions in China. Understanding the various options available can help businesses optimize their supply chains, reduce costs, and enhance overall efficiency. Below, we compare ‘China Warehouse’ services against two viable alternatives: Local Warehousing and Dropshipping.

Comparison Table

| Comparison Aspect | China Warehouse | Local Warehousing | Dropshipping |

|---|---|---|---|

| Performance | High efficiency, fast shipping | Moderate efficiency, regionally limited | Variable, dependent on supplier |

| Cost | Competitive, with no minimum fees | Higher overhead costs (rent, utilities) | Low upfront costs, variable margins |

| Ease of Implementation | Quick onboarding, integration with e-commerce | Time-consuming setup and contracts | Simple, requires minimal setup |

| Maintenance | Managed by warehouse provider | Requires active management and staffing | Minimal, managed by suppliers |

| Best Use Case | High-volume e-commerce businesses | Regional distribution needs | Startups, small businesses with limited inventory |

What Are the Pros and Cons of Local Warehousing?

Local warehousing involves storing inventory close to the customer base, which can significantly reduce shipping times and costs. This method is particularly beneficial for businesses that operate in specific geographic areas or require quick fulfillment. However, local warehousing often comes with higher overhead costs, including rent and utilities. Additionally, managing a warehouse requires staffing, which can lead to complexities in operations. This solution is ideal for businesses that prioritize speed and regional distribution but may not be feasible for those looking to scale quickly or manage international orders efficiently.

How Does Dropshipping Compare to China Warehousing?

Dropshipping is a model where retailers sell products without holding inventory, instead relying on suppliers to ship directly to customers. This approach minimizes upfront investment and inventory risks, making it attractive for startups or smaller businesses. However, dropshipping can lead to variable performance and customer satisfaction issues, as shipping times and product quality depend on the supplier. While it offers flexibility and low operational costs, reliance on third-party suppliers can complicate logistics and fulfillment. Dropshipping is best suited for businesses testing new markets or products without committing to large inventories.

Illustrative image related to china warehouse

Conclusion: How Should B2B Buyers Choose the Right Solution?

When selecting a logistics solution, B2B buyers must consider their specific needs, including shipping speed, cost structure, and scalability. China warehouses offer a robust solution for high-volume e-commerce businesses looking for efficiency and integration with global shipping networks. In contrast, local warehousing may serve businesses with regional focus, while dropshipping caters to those with limited inventory management capabilities. By evaluating these alternatives against their operational goals, businesses can make informed decisions that align with their growth strategies and customer demands.

Essential Technical Properties and Trade Terminology for china warehouse

What Are the Key Technical Properties of a Warehouse in China?

When selecting a warehouse in China for your business needs, understanding specific technical properties is vital for ensuring efficiency and reliability in your supply chain. Here are some critical specifications to consider:

-

Storage Capacity

– Definition: The total volume of goods a warehouse can hold, typically measured in cubic meters or square footage.

– Importance: Adequate storage capacity is essential for managing inventory effectively, especially for businesses with fluctuating demand. A warehouse that can accommodate growth allows for smoother operations and better response times to market changes. -

Location Proximity

– Definition: The warehouse’s geographical closeness to key transportation hubs, such as ports, airports, and major roadways.

– Importance: A strategically located warehouse reduces shipping times and costs. For international buyers, being near logistics hubs like Shenzhen or Guangzhou can facilitate quicker customs clearance and delivery to global markets. -

Inventory Management System (IMS)

– Definition: A software system that tracks inventory levels, orders, sales, and deliveries in real time.

– Importance: An effective IMS ensures accurate stock levels, minimizes errors, and enhances operational efficiency. For B2B buyers, this means better control over inventory and the ability to quickly respond to customer demands. -

Temperature Control

– Definition: The capability of a warehouse to maintain specific temperature ranges for sensitive products.

– Importance: For businesses dealing with perishable goods or items requiring special handling, temperature control is crucial. It ensures product integrity during storage and transport, reducing spoilage and losses. -

Security Features

– Definition: Measures implemented to protect goods from theft, damage, or loss, including surveillance systems, access controls, and fire safety protocols.

– Importance: Strong security features are essential for safeguarding inventory, particularly for high-value items. They enhance buyer confidence and ensure compliance with insurance requirements.

What Are Common Trade Terminology and Jargon Related to Warehousing in China?

Navigating the logistics landscape requires familiarity with industry-specific terminology. Here are some common terms every B2B buyer should know:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships is crucial for businesses looking to source products or components from China. This term often indicates the quality and reliability of products, impacting purchasing decisions. -

MOQ (Minimum Order Quantity)

– Definition: The smallest number of units a supplier is willing to sell.

– Importance: Knowing the MOQ is vital for budgeting and inventory planning. It can affect cash flow and storage costs, particularly for smaller businesses or those testing new products. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers to request pricing and terms for specific goods or services.

– Importance: An RFQ helps buyers compare offers from multiple suppliers, ensuring they secure the best deal for their needs. This is especially important in competitive markets. -

Incoterms (International Commercial Terms)

– Definition: A set of standardized trade terms published by the International Chamber of Commerce that define the responsibilities of buyers and sellers in international transactions.

– Importance: Familiarity with Incoterms helps buyers understand shipping costs, risk transfers, and delivery obligations. This clarity can prevent costly misunderstandings and disputes. -

3PL (Third-Party Logistics)

– Definition: A logistics service provider that manages logistics and fulfillment services for businesses.

– Importance: Engaging a 3PL can streamline operations, allowing businesses to focus on core activities. Understanding the role of 3PLs is essential for optimizing supply chain efficiency. -

Kitting

– Definition: The process of assembling various products into a single package or kit for sale.

– Importance: Kitting can enhance product offerings and improve shipping efficiency. For B2B buyers, it simplifies inventory management by consolidating multiple SKUs into one, reducing handling costs.

By grasping these properties and terms, international B2B buyers can make informed decisions when selecting warehouse services in China, leading to smoother operations and enhanced competitiveness in their respective markets.

Illustrative image related to china warehouse

Navigating Market Dynamics and Sourcing Trends in the china warehouse Sector

What Are the Key Market Trends Influencing the China Warehouse Sector?

The China warehouse sector is undergoing significant transformation, driven by global demand for efficient and reliable supply chain solutions. As international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, expand their sourcing strategies, several key trends emerge. First, the rise of e-commerce has created a pressing need for advanced logistics capabilities, particularly for sellers on platforms like Amazon and Alibaba. This has led to an increase in tech-driven warehouses that leverage AI and IoT for inventory management and order fulfillment.

Another critical trend is the shift towards direct-to-consumer (D2C) models. Businesses are increasingly seeking fulfillment centers that allow for streamlined shipping directly to customers, reducing transit times and enhancing customer satisfaction. This demand for agility in logistics is further amplified by the need for cost-effective solutions, prompting many companies to centralize their operations in key logistics hubs like Shenzhen and Guangzhou.

Moreover, as geopolitical tensions and supply chain disruptions become more common, buyers are looking for warehouse partners that offer flexibility and resilience. This includes the ability to adapt to changing regulations and customs requirements, making it imperative for B2B buyers to select warehouses with established compliance protocols and robust management systems.

How Is Sustainability and Ethical Sourcing Shaping B2B Decisions in the China Warehouse Sector?

As environmental concerns take center stage, sustainability and ethical sourcing are becoming pivotal in the decision-making processes of international B2B buyers. The China warehouse sector is increasingly adopting green practices, driven by both regulatory pressures and consumer expectations. Many warehouse operators are now implementing energy-efficient systems, waste reduction initiatives, and sustainable packaging solutions.

For B2B buyers, partnering with warehouses that hold certifications for green practices, such as ISO 14001, can provide a competitive edge. These certifications demonstrate a commitment to minimizing environmental impact, which is increasingly important for consumers and businesses alike. Additionally, using recycled materials and minimizing carbon footprints in logistics operations can enhance brand reputation and foster loyalty among eco-conscious customers.

Moreover, ethical sourcing practices are essential in the context of labor standards and fair trade. Buyers must ensure that their warehouse partners adhere to ethical labor practices and support local communities. This not only mitigates risk but also aligns with the growing demand for transparency in supply chains, making it crucial for B2B buyers to conduct thorough due diligence when selecting warehouse partners.

What Historical Developments Have Shaped the Current Landscape of China Warehousing?

The evolution of the China warehouse sector is closely tied to the country’s rapid industrialization and its emergence as a global manufacturing hub. Initially, warehouses in China primarily served domestic markets, focusing on basic storage and distribution. However, the advent of globalization in the late 20th century catalyzed significant changes, leading to the establishment of sophisticated logistics infrastructures designed to support international trade.

The rise of e-commerce in the early 2000s marked a turning point for the sector. As online shopping gained popularity, warehouses began adopting advanced technologies to enhance efficiency and speed. The establishment of major logistics players like Cainiao and JD Logistics further revolutionized the industry, introducing AI-driven solutions and automated systems that significantly improved operational capabilities.

Today, the China warehouse sector stands at the forefront of technological innovation, making it an indispensable asset for international B2B buyers. As the demand for rapid, reliable, and sustainable logistics continues to grow, understanding the historical context helps buyers navigate the complexities of the current landscape, ensuring they choose the right partners for their business needs.

Illustrative image related to china warehouse

Frequently Asked Questions (FAQs) for B2B Buyers of china warehouse

-

How do I choose the right warehouse in China for my business needs?

Selecting the right warehouse in China involves evaluating several factors. Consider the warehouse’s location relative to your suppliers and target markets to minimize shipping costs. Assess the range of services offered, such as inventory management, kitting, and customs clearance, to ensure they align with your operational needs. Additionally, check their technology capabilities for tracking shipments and managing inventory. Finally, review client testimonials and case studies to gauge their reliability and service quality, ensuring they have a proven track record with businesses similar to yours. -

What are the key services offered by warehouses in China for international buyers?

Chinese warehouses typically offer a variety of services tailored for international buyers, including inventory storage, order fulfillment, shipping coordination, and customs clearance. Many also provide value-added services like kitting, labeling, and product assembly, which can streamline your supply chain. Some warehouses specialize in e-commerce fulfillment, catering to platforms like Amazon FBA, while others may focus on B2B shipping solutions. It’s essential to choose a warehouse that can handle your specific product types and shipping requirements efficiently. -

What are the minimum order quantities (MOQ) for using a warehouse in China?

Minimum order quantities can vary significantly by warehouse and the type of products being stored or shipped. Some warehouses may have no MOQ, especially for e-commerce operations, while others may require a certain volume to optimize storage costs. It’s advisable to inquire directly with potential warehouses about their MOQ policies and whether they offer flexibility based on your business’s scale. Understanding these requirements upfront can help you plan your inventory and cash flow more effectively. -

How do I ensure the quality of products stored and shipped from a Chinese warehouse?

To ensure product quality, first, select a warehouse that implements rigorous quality assurance protocols. This includes regular inspections, inventory audits, and adherence to international shipping standards. Consider conducting initial quality checks before products are stored and implementing a system for ongoing quality assessments throughout the storage period. Additionally, establish clear communication with the warehouse management about your quality expectations and any specific requirements for handling your products. -

What are the payment terms typically offered by warehouses in China?

Payment terms for warehouses in China vary widely and are often negotiable. Common arrangements include upfront payments, partial payments upon order placement, and balance payments before shipment. Some warehouses may also offer credit terms based on your relationship and order volume. It’s crucial to clarify payment terms in advance and ensure they align with your cash flow strategy. Additionally, always request a formal contract that outlines payment schedules and any penalties for late payments to avoid misunderstandings. -

How can I manage logistics effectively when using a warehouse in China?

Effective logistics management begins with clear communication with your chosen warehouse. Utilize their expertise in local transportation and customs processes to streamline shipping. Implement a robust inventory management system that integrates with the warehouse’s software for real-time tracking and updates. Regularly review your logistics strategy, adjusting as necessary to accommodate changes in demand or shipping conditions. Collaborating with a logistics partner experienced in international shipping can also enhance your overall efficiency. -

What should I consider when vetting suppliers for warehouse services in China?

When vetting suppliers, consider their experience and reputation in the industry. Look for warehouses with proven track records in handling products similar to yours and check for certifications that demonstrate compliance with international standards. Request references and feedback from current or past clients to gauge reliability and service quality. Additionally, assess their technological capabilities, such as inventory management systems, to ensure they can meet your operational needs efficiently. -

How do customs and compliance work when shipping from a warehouse in China?

Customs and compliance are critical when shipping internationally from a Chinese warehouse. Ensure the warehouse has expertise in customs regulations for your target market, as they can assist with proper documentation and compliance checks. They should also be familiar with tariffs, duties, and any restrictions related to your products. Collaborating with a warehouse that offers customs clearance services can simplify the process, helping you avoid delays and additional costs associated with non-compliance.

Top 6 China Warehouse Manufacturers & Suppliers List

1. Easy China Warehouse – Comprehensive Logistics Services for eCommerce

Domain: easychinawarehouse.com

Registered: 2018 (7 years)

Introduction: Easy China Warehouse offers comprehensive logistics services for eCommerce sellers, including shipping to Amazon FBA warehouses worldwide. Key features include:

– Location: 3500 m2 warehouse in Shenzhen, China, with access to Hong Kong and Guangzhou.

– Services: FBA prep, kitting, bundling, assembly, logistics planning, global D2C and B2B shipments.

– Shipping Methods: Air and sea freight options …

2. China Division – Global Order Fulfillment Solutions

Domain: chinadivision.com

Registered: 2015 (10 years)

Introduction: Global Order Fulfillment & Shipping from China Warehouse Company Solutions include: Order Fulfillment, Crowdfunding Projects, Amazon Order Fulfillment (FBA PREP), Product Sourcing, Warehousing, Value-Added Integrations, Fulfillment Integration/plugins, and API. Key features include: 3 advantageous transportation routes (Middle East India Pakistan Red Sea Line, European Basic Port Line, US and Cana…

3. DHgate – B2B Wholesale Marketplace

Domain: dhgate.com

Registered: 2004 (21 years)

Introduction: DHgate is a B2B cross-border e-commerce wholesale marketplace established in 2004, connecting over 2 million registered buyers from more than 220 countries. The platform offers over 30 million products across 26 categories, including electronics, home goods, toys, outdoor items, renewable energy products, and custom products. Key features include worldwide shipping, low prices starting from US $0….

4. SendFromChina – Fulfillment Services

Domain: sendfromchina.com

Registered: 2007 (18 years)

Introduction: SendFromChina offers a range of fulfillment services including:

– Warehouse Fulfillment

– Pick & Pack

– Kitting & Assembly

– Multi-Channel Logistics

– Amazon Prep Service

– eCommerce Fulfillment

– Crowdfunding Fulfillment

– Board Game Fulfillment

– Value-Added Services

– Consolidated Shipping

Key features include:

– Door-to-door shipping from China to 220+ countries and regions

– No …

5. Ecommerce Express – Global Fulfillment Solutions

Domain: ecommerce-express.com

Registered: 2020 (5 years)

Introduction: Fulfilment Warehouse in China, 5000 m2 space, Global fulfillment for DTC & B2B, 30 days free storage, Shenzhen Fulfillment Center, Dongguan Fulfillment Center, automated order fulfillment system, shipping worldwide in 4~10 days, 24 hours dock-to-stock, 100% free quality control, multimodal routing orders, flexibility in bundling, kitting and assembly, returns management, on-time delivery record of…

6. Sino Shipping – Fulfillment & Warehousing Services

Domain: sino-shipping.com

Registered: 2017 (8 years)

Introduction: China Fulfillment Center & Warehousing services including: Warehouse and Fulfillment Services in Hong Kong, Shanghai, Shenzhen, Ningbo, Xiamen, Tianjin, and Qingdao. Additional services include logistics support, customs clearance, freight insurance, cold chain logistics, and export licensing.

Strategic Sourcing Conclusion and Outlook for china warehouse

In navigating the complexities of global supply chains, strategic sourcing from China’s warehouses emerges as a critical factor for international B2B buyers. By leveraging advanced logistics capabilities and efficient inventory management systems, businesses can significantly reduce costs and improve delivery times. The integration of technology, such as AI and IoT, in leading Chinese warehouses not only enhances operational efficiency but also provides a seamless experience for managing shipments across borders.

International buyers, particularly from Africa, South America, the Middle East, and Europe, must recognize the value of establishing strong partnerships with reliable warehousing providers. This strategic approach allows for streamlined logistics processes, ensuring compliance and timely fulfillment of orders. As global trade continues to evolve, staying informed about the latest developments in China’s warehousing landscape will be essential for maintaining a competitive edge.

Looking ahead, the opportunities for growth are vast. By tapping into the capabilities of top-tier Chinese warehouses, you can optimize your supply chain and better serve your customers. Take the next step towards enhancing your logistics strategy—connect with a trusted warehouse partner today to capitalize on these advantages and position your business for success in the global market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to china warehouse

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.