Unlocking Value: A Strategic Analysis of the Check Swing Valve Market

Introduction: Navigating the Global Market for check swing valve

In the ever-evolving landscape of industrial applications, sourcing reliable check swing valves can pose significant challenges for B2B buyers across diverse regions, including Africa, South America, the Middle East, and Europe. These crucial components play a pivotal role in preventing backflow and ensuring the efficiency of fluid systems in various industries, from water treatment to oil and gas. However, with a multitude of types, materials, and specifications available, navigating the global market requires a strategic approach.

This comprehensive guide delves into the intricacies of check swing valves, encompassing various types—such as metal-to-metal and resilient seated options—and their applications in different sectors. It further addresses critical aspects of the procurement process, including supplier vetting, cost considerations, and performance metrics, empowering international buyers to make informed decisions. By understanding the key features and benefits of each valve type, as well as the unique requirements of their specific applications, B2B purchasers can ensure they select the right solutions for their operational needs.

Equipped with actionable insights and expert recommendations, this guide serves as a valuable resource for companies seeking to optimize their procurement strategies in the competitive global market for check swing valves. Whether you are operating in Brazil, Germany, or elsewhere, the knowledge contained herein will facilitate effective sourcing and enhance the reliability of your fluid management systems.

Understanding check swing valve Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Swing Check Valve | Hinged disc design, full-port body, gravity-assisted closure | Water and wastewater systems | Pros: Simple design, low pressure drop; Cons: Limited to horizontal flow applications. |

| Resilient Seated Swing Check | Rubber or elastomeric seating for positive shutoff | Wastewater, industrial processes | Pros: Effective against debris, ensures tight sealing; Cons: May have higher maintenance needs. |

| Metal-to-Metal Seat Valve | Durable construction, suitable for high-pressure applications | Oil & gas, chemical processing | Pros: Excellent for high-pressure, high-temperature environments; Cons: Can be more expensive. |

| Counterweight Swing Check | Incorporates a counterweight for improved closure control | Pump discharge, high-velocity applications | Pros: Reduces slamming, enhances longevity; Cons: Requires additional space for installation. |

| Vertical Swing Check Valve | Designed for vertical installations, compact design | HVAC systems, vertical pipelines | Pros: Space-saving design; Cons: Limited flow capacity compared to horizontal models. |

What Are the Characteristics of a Swing Check Valve?

Swing check valves feature a simple yet effective design with a hinged disc that swings to block reverse flow. They are primarily used in water and wastewater applications due to their low pressure drop and straightforward construction. Buyers should consider their installation environment, as these valves are typically suited for horizontal flow applications. When selecting a swing check valve, assess the material compatibility and pressure ratings to ensure optimal performance.

Why Choose a Resilient Seated Swing Check Valve?

Resilient seated swing check valves utilize an elastomeric seat to provide a tight seal, making them ideal for wastewater and industrial applications where dirt or particles might be present. These valves are designed for positive shutoff, which is crucial in environments that demand reliability. However, potential buyers should weigh the need for regular maintenance against their effectiveness in preventing leaks and ensuring system integrity.

What Are the Benefits of a Metal-to-Metal Seat Valve?

Metal-to-metal seat swing check valves are engineered for durability and are often used in high-pressure environments such as oil and gas or chemical processing. Their robust construction allows them to withstand harsh conditions, making them a preferred choice for demanding applications. While they offer excellent sealing capabilities, their higher cost may be a consideration for budget-conscious buyers.

How Does a Counterweight Swing Check Valve Enhance Performance?

Counterweight swing check valves are equipped with a counterweight mechanism that aids in the closing of the valve disc, reducing the risk of slamming and subsequent hydraulic shock. This feature is particularly beneficial in applications with high flow velocities. Buyers should consider the additional space required for installation and the potential for enhanced longevity and performance in dynamic systems.

What Makes a Vertical Swing Check Valve Ideal for Specific Applications?

Vertical swing check valves are specifically designed for vertical installations, making them suitable for HVAC systems and vertical pipelines. Their compact design helps save space, but it’s essential to consider their flow capacity, which may be lower compared to horizontal models. B2B buyers should evaluate the specific requirements of their systems to determine if this type of valve meets their operational needs effectively.

Key Industrial Applications of check swing valve

| Industry/Sector | Specific Application of check swing valve | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Water and Wastewater Management | Preventing backflow in pumping stations | Ensures system integrity and protects equipment from damage | Material compatibility, pressure ratings, and certifications |

| Oil and Gas | Flow control in pipelines | Enhances safety by preventing reverse flow | Temperature resistance, size specifications, and durability |

| Chemical Processing | Isolation of fluids in processing systems | Reduces contamination risks and ensures operational efficiency | Chemical compatibility, size, and maintenance requirements |

| HVAC Systems | Controlling flow in heating and cooling systems | Improves energy efficiency and system reliability | Temperature limits, installation orientation, and size |

| Food and Beverage | Preventing contamination in production lines | Ensures product quality and compliance with health standards | Material certifications (FDA/USDA), cleaning requirements |

How Are Check Swing Valves Used in Water and Wastewater Management?

In water and wastewater management, check swing valves are crucial for preventing backflow in pumping stations. By allowing flow in one direction and blocking reverse flow, these valves protect infrastructure from potential damage caused by pressure fluctuations. Buyers in this sector must consider material compatibility with various fluids, pressure ratings to withstand operational demands, and relevant certifications to meet regulatory standards.

What Role Do Check Swing Valves Play in Oil and Gas Operations?

In the oil and gas industry, check swing valves are employed for flow control in pipelines, ensuring that fluids move in the intended direction. This functionality is vital for enhancing safety and preventing hazardous situations resulting from reverse flow. When sourcing valves for this application, buyers should prioritize temperature resistance, size specifications, and overall durability to withstand the demanding conditions typical in oil and gas operations.

How Are Check Swing Valves Essential in Chemical Processing?

Check swing valves in chemical processing systems serve to isolate fluids, thereby minimizing contamination risks and maintaining operational efficiency. These valves facilitate the safe handling of various chemicals, which is critical for compliance with industry standards. Buyers need to ensure that the valves are compatible with the specific chemicals they will handle, pay attention to size and installation requirements, and consider maintenance needs to ensure longevity.

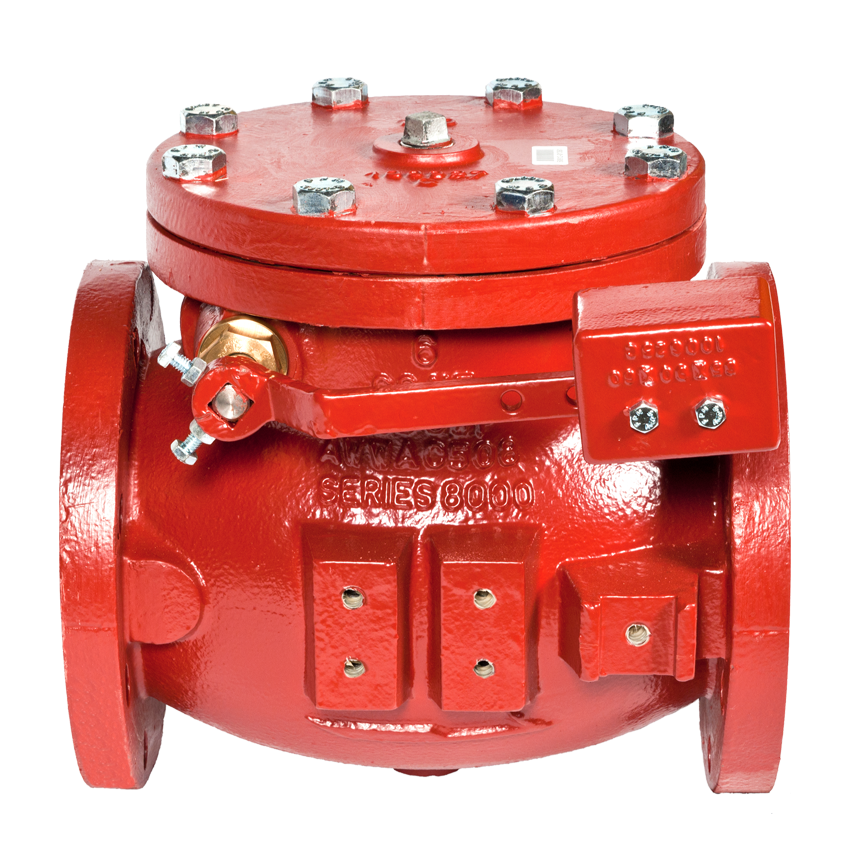

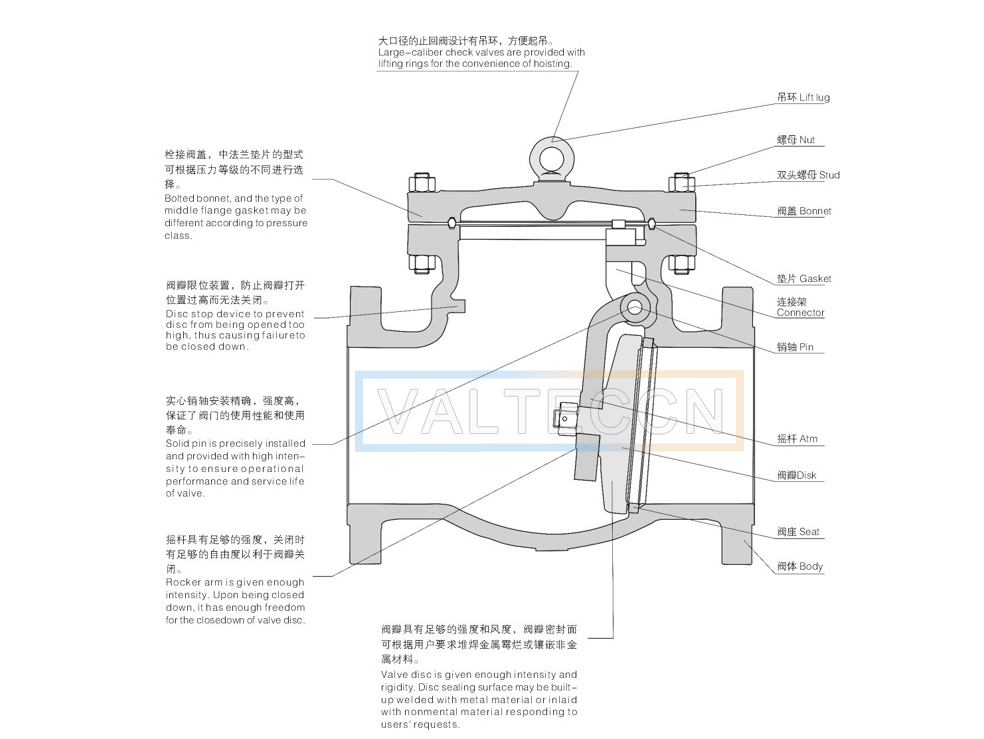

Illustrative image related to check swing valve

Why Are Check Swing Valves Important in HVAC Systems?

In HVAC systems, check swing valves help control the flow of fluids in heating and cooling applications, contributing to improved energy efficiency and system reliability. By preventing backflow, these valves help maintain optimal system performance and reduce wear on components. Buyers should focus on temperature limits for valve operation, installation orientation compatibility, and size to ensure seamless integration into existing systems.

How Do Check Swing Valves Benefit the Food and Beverage Industry?

In the food and beverage sector, check swing valves are critical for preventing contamination during production processes. They help maintain product quality and ensure compliance with health and safety standards. When sourcing these valves, buyers must ensure that materials meet certifications such as FDA or USDA standards and consider cleaning requirements to prevent any cross-contamination during production.

3 Common User Pain Points for ‘check swing valve’ & Their Solutions

Scenario 1: Struggling with Reverse Flow Prevention in Critical Systems

The Problem: In industries such as water treatment and chemical processing, the risk of reverse flow can lead to severe operational issues, including contamination and system failures. B2B buyers often face challenges in ensuring that their check swing valves effectively prevent backflow under varying pressure conditions. This is particularly problematic in systems with fluctuating flow rates, where improper valve selection can result in costly downtime and extensive repairs.

Illustrative image related to check swing valve

The Solution: To mitigate this risk, buyers should prioritize sourcing swing check valves that feature resilient seating and are designed for the specific fluid dynamics of their application. When specifying a valve, consider factors such as the maximum flow rate, pressure ratings, and the physical characteristics of the fluid (e.g., viscosity, particulates). Opt for valves with adjustable closing mechanisms, like external hinge arms with weights or springs, to enhance performance by reducing the risk of slamming and hydraulic shock. Additionally, conducting a thorough assessment of the installation environment—whether vertical or horizontal—will ensure that the selected valves perform optimally and provide reliable backflow prevention.

Scenario 2: Concerns Over Maintenance and Longevity of Swing Check Valves

The Problem: B2B buyers in sectors like wastewater management often worry about the maintenance requirements and lifespan of their check swing valves. Frequent maintenance not only incurs additional labor costs but can also lead to operational interruptions. The presence of dirt or particulates in wastewater can further complicate valve performance and longevity, leading to premature failures and expensive replacements.

The Solution: To enhance longevity and reduce maintenance needs, buyers should consider valves constructed from durable materials such as stainless steel or corrosion-resistant polymers. Resilient seated swing check valves are particularly beneficial for applications with high particulate content, as they provide a better seal and minimize wear over time. Implementing a regular inspection schedule can also help identify wear and tear early, allowing for timely maintenance or replacement. Furthermore, integrating a strainer upstream of the valve can prevent debris from entering the valve, thereby extending its service life and ensuring consistent performance.

Scenario 3: Difficulty in Ensuring Compatibility with Existing Infrastructure

The Problem: Buyers often encounter challenges when integrating new check swing valves into existing systems, especially in retrofitting scenarios. Incompatibility with pipe sizes, material mismatches, or incorrect pressure ratings can lead to operational inefficiencies or even complete system failures. This issue is particularly prevalent in older facilities where legacy systems may not align with modern standards.

The Solution: To navigate these compatibility issues, buyers should conduct a comprehensive analysis of their current infrastructure before purchasing new valves. This involves measuring existing piping dimensions and understanding the specific requirements of the system, including pressure ratings and flow characteristics. Engage with suppliers who offer custom solutions or a wide range of sizes and materials to ensure a perfect fit. When possible, opt for valves with standard flange sizes and configurations to facilitate easier integration. Additionally, consulting with experienced engineers can provide valuable insights into the best practices for retrofitting swing check valves, ensuring a seamless transition and optimal performance.

Strategic Material Selection Guide for check swing valve

When selecting materials for check swing valves, it is essential to consider the specific requirements of the application, including the type of media being handled, temperature and pressure conditions, and environmental factors. Below is an analysis of four common materials used in the manufacturing of check swing valves, highlighting their properties, advantages, disadvantages, and considerations for international B2B buyers.

What Are the Key Properties of PVC in Check Swing Valves?

Polyvinyl Chloride (PVC) is a widely used material for check swing valves, particularly in water and wastewater applications. PVC offers excellent corrosion resistance, making it suitable for handling a variety of fluids, including chemicals and saline solutions. It typically operates effectively at temperatures up to 140°F (60°C) and pressures up to 150 psi.

Pros: PVC is lightweight, cost-effective, and easy to manufacture, which contributes to lower overall costs. Its resistance to corrosion and chemical attack makes it ideal for many industrial applications.

Illustrative image related to check swing valve

Cons: However, PVC has limitations in high-temperature applications and may become brittle over time when exposed to UV light. It is also less suitable for high-pressure environments compared to metal alternatives.

Impact on Application: PVC check swing valves are best suited for low-pressure applications, such as irrigation and drainage systems. Buyers must ensure compatibility with the specific chemicals involved in their processes.

Considerations for International Buyers: Buyers from regions like Europe and South America should verify compliance with ASTM D1784 standards for PVC materials, ensuring they meet local regulations and performance expectations.

How Does CPVC Compare for Check Swing Valve Applications?

Chlorinated Polyvinyl Chloride (CPVC) is an enhanced version of PVC, offering improved temperature and pressure ratings. CPVC can withstand temperatures up to 200°F (93°C) and pressures of 300 psi, making it suitable for higher temperature applications.

Pros: The increased thermal resistance and strength of CPVC make it a preferred choice for hot water systems and certain chemical applications. It also retains the cost-effectiveness and ease of installation associated with PVC.

Cons: The primary drawback of CPVC is its higher cost compared to standard PVC. Additionally, it may still be vulnerable to certain aggressive chemicals, necessitating careful selection based on the media.

Impact on Application: CPVC check swing valves are often used in industrial applications where higher temperatures are common, such as in chemical processing and hot water distribution.

Considerations for International Buyers: Compliance with ASTM D1784 is crucial, and buyers should also consider local regulations regarding the use of CPVC in their specific applications.

What Are the Benefits of Using Stainless Steel in Check Swing Valves?

Stainless steel is a robust material option for check swing valves, particularly in demanding environments. Known for its excellent corrosion resistance and high strength, stainless steel can handle a wide range of temperatures and pressures, often exceeding 300°F (149°C) and 1500 psi.

Pros: The durability and longevity of stainless steel make it ideal for applications involving abrasive materials or extreme conditions. Its resistance to corrosion allows for reliable performance in harsh environments.

Cons: The main limitations are the higher cost and manufacturing complexity associated with stainless steel valves. Additionally, they may require more maintenance compared to plastic alternatives.

Impact on Application: Stainless steel check swing valves are suitable for oil and gas, food processing, and other industries where hygiene and durability are paramount.

Considerations for International Buyers: Buyers must ensure compliance with various standards, including ASTM A351, and consider the specific grades of stainless steel that meet their application needs.

Illustrative image related to check swing valve

Why Choose Cast Iron for Check Swing Valves?

Cast iron is another traditional material used for check swing valves, particularly in heavy-duty applications. It offers good strength and durability, making it suitable for high-pressure systems.

Pros: Cast iron valves are robust and can withstand significant wear and tear, making them ideal for industrial applications. They are also relatively cost-effective compared to stainless steel.

Cons: However, cast iron is susceptible to corrosion, especially in moist environments, which can lead to maintenance challenges. It is also heavier, which can complicate installation.

Impact on Application: Cast iron check swing valves are commonly used in municipal water systems and wastewater treatment facilities where durability is essential.

Considerations for International Buyers: Buyers should check for compliance with relevant standards such as ASTM A126 and consider the environmental conditions in which the valves will operate.

Summary Table of Material Selection for Check Swing Valves

| Material | Typical Use Case for check swing valve | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Water and wastewater applications | Lightweight and cost-effective | Limited high-temperature resistance | Low |

| CPVC | Hot water and chemical processing | Higher temperature and pressure rating | Higher cost than PVC | Medium |

| Stainless Steel | Oil, gas, and food processing | Excellent corrosion resistance | Higher cost and maintenance | High |

| Cast Iron | Municipal water systems | Robust and durable | Susceptible to corrosion | Medium |

This guide provides a comprehensive overview of the materials used in check swing valves, helping international B2B buyers make informed decisions based on their specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for check swing valve

What Are the Key Stages in the Manufacturing Process of Check Swing Valves?

The manufacturing of check swing valves involves several critical stages, each designed to ensure precision and reliability. Understanding these stages can help B2B buyers assess the quality of products they intend to procure.

Material Preparation: How Are Raw Materials Selected and Processed?

The first step in the manufacturing process is the selection and preparation of raw materials. Common materials include PVC, CPVC, and various metals such as stainless steel and aluminum. The selection often depends on the application requirements, such as temperature, pressure, and fluid compatibility.

Illustrative image related to check swing valve

Once materials are chosen, they undergo rigorous quality checks to ensure they meet industry standards (e.g., ASTM, ISO). This may involve chemical analysis and mechanical testing to verify properties such as tensile strength and corrosion resistance. After passing these tests, materials are cut, shaped, or otherwise prepped for the next manufacturing stage.

Forming: What Techniques Are Used to Shape the Valves?

The forming stage involves various techniques tailored to the material type and design specifications. For plastic check swing valves, processes like injection molding or extrusion are commonly employed. These methods allow for intricate designs while maintaining the integrity of the material.

For metal valves, machining processes such as CNC milling, turning, and forging are standard. Each technique has its advantages; for instance, CNC machining offers high precision, while forging enhances the material’s strength. The choice of forming technique impacts the valve’s performance, durability, and cost.

Assembly: How Are Check Swing Valves Assembled for Optimal Performance?

After forming, the next step is assembly, where individual components, such as the valve body, disc, and seals, are brought together. It is crucial that these components are assembled in a clean environment to prevent contamination that could affect valve performance.

Illustrative image related to check swing valve

Assembly may include the use of specialized lubricants that do not interfere with the valve’s operation, such as silicone-free options. Additionally, assembly techniques can vary; some manufacturers may utilize automated assembly lines, while others might prefer manual assembly for greater control.

Finishing: What Processes Ensure a Quality Finish?

The finishing stage is critical for ensuring the valve’s longevity and performance. Common finishing processes include surface treatment, coating, and polishing. For metal valves, processes such as anodizing or galvanizing may be used to enhance corrosion resistance.

For plastic valves, UV stabilizers may be added during manufacturing to protect against degradation from sunlight exposure. The finishing touches not only improve aesthetics but also play a vital role in the functional lifespan of the valve.

Illustrative image related to check swing valve

What Quality Assurance Measures Are Essential for Check Swing Valves?

Quality assurance (QA) is pivotal in the manufacturing of check swing valves, ensuring that the final product meets both industry standards and customer expectations.

Which International Standards Should B2B Buyers Look For?

International standards, such as ISO 9001, serve as benchmarks for quality management systems. Compliance with these standards indicates a commitment to continuous improvement and customer satisfaction. Industry-specific certifications like CE marking for European markets or API standards for oil and gas applications are also crucial.

Buyers should verify that suppliers hold these certifications, as they reflect adherence to rigorous quality and safety protocols.

What Are the Key QC Checkpoints During Manufacturing?

Quality control (QC) checkpoints are implemented at various stages of the manufacturing process to identify and rectify defects early.

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Conducted during the manufacturing process, IPQC checks focus on the quality of individual components and assembly techniques.

- Final Quality Control (FQC): The final inspection ensures that the completed check swing valves meet all specified requirements before shipment.

These checkpoints are designed to catch potential issues, minimizing the risk of defective products reaching the market.

What Testing Methods Are Commonly Used to Ensure Valve Performance?

Testing methods play a crucial role in quality assurance for check swing valves. These methods may include:

- Hydrostatic Testing: This test checks for leaks and assesses the valve’s ability to withstand pressure.

- Functional Testing: Ensures the valve operates correctly under simulated conditions.

- Material Testing: Confirms that the materials used meet the required specifications for strength and durability.

By implementing these testing protocols, manufacturers can ensure that their check swing valves perform reliably in real-world applications.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, should take proactive steps to verify their suppliers’ quality control processes.

- Audits: Conducting supplier audits can provide insights into manufacturing practices and quality management systems. Buyers should look for opportunities to perform on-site inspections or request audit reports.

- Reports: Suppliers should be able to provide detailed reports on their quality control processes, including IQC, IPQC, and FQC findings.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures and product reliability.

What Are the QC and Certification Nuances for International B2B Buyers?

International B2B buyers should be aware of the nuances in quality control and certification requirements across different regions. For instance, compliance with local regulations may differ significantly between Europe and Africa.

Buyers should ensure that suppliers are not only compliant with international standards but also familiar with regional requirements. This understanding can help prevent complications related to customs, import regulations, or product recalls.

Conclusion: Why Understanding Manufacturing and Quality Assurance Is Crucial for B2B Buyers

In conclusion, a thorough understanding of the manufacturing processes and quality assurance measures for check swing valves is vital for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, as well as quality control checkpoints and testing methods, buyers can make informed decisions. Ensuring that suppliers adhere to international standards and provide transparent quality control measures will ultimately lead to successful procurement and long-term satisfaction with the products purchased.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘check swing valve’

In the competitive landscape of industrial procurement, sourcing a check swing valve requires a strategic approach to ensure quality, reliability, and cost-effectiveness. This guide provides a practical checklist to streamline the procurement process for B2B buyers, particularly those in Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Start by clearly outlining the technical requirements for your check swing valve. This includes factors such as size, material (PVC, CPVC, stainless steel, etc.), pressure ratings, and temperature tolerances. By having precise specifications, you can communicate effectively with suppliers and ensure the products meet your operational needs.

- Consider application requirements: Different materials and designs are suited for specific applications, such as wastewater management or high-pressure systems.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers that specialize in check swing valves. Look for manufacturers with a solid track record in your industry and region. Use online resources, industry forums, and trade shows to gather information.

- Evaluate their product range: Ensure the supplier offers a variety of options, such as resilient seating or metal-to-metal seats, to meet diverse application needs.

Step 3: Verify Supplier Certifications

Before moving forward, verify that potential suppliers hold relevant certifications and comply with international standards. Certifications such as ISO 9001 or specific industry certifications demonstrate a commitment to quality and reliability.

- Check for local compliance: Especially for international transactions, ensure the supplier adheres to local regulations and standards in your target market.

Step 4: Request Samples for Testing

Always request product samples before finalizing your order. Testing samples allows you to assess the quality, functionality, and compatibility of the check swing valve with your existing systems.

- Conduct performance tests: Evaluate how the valve performs under real operational conditions, including flow rates and pressure variations.

Step 5: Assess Pricing and Payment Terms

Gather quotes from multiple suppliers to compare pricing structures. While cost is a significant factor, it’s essential to understand the value being offered, including warranty, after-sales support, and delivery timelines.

- Negotiate payment terms: Discuss flexible payment options, such as staggered payments or letters of credit, to mitigate risk.

Step 6: Review Delivery and Lead Times

Confirm the supplier’s lead times and delivery capabilities. Ensure they can meet your timelines without compromising quality. Delays can impact production schedules and lead to additional costs.

Illustrative image related to check swing valve

- Consider logistics: Evaluate shipping methods and costs, especially for international orders, to avoid unexpected expenses.

Step 7: Establish a Communication Plan

Once you’ve selected a supplier, establish a clear communication plan. Regular updates and open lines of communication will help address any issues promptly and ensure the procurement process runs smoothly.

- Set expectations: Define key points of contact and response times for inquiries to maintain a collaborative relationship.

By following these steps, B2B buyers can effectively navigate the complexities of sourcing check swing valves, ensuring they procure reliable products that meet their specific operational needs.

Comprehensive Cost and Pricing Analysis for check swing valve Sourcing

When sourcing check swing valves, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers. This section outlines the key cost components, price influencers, and practical tips to help buyers navigate the procurement process effectively.

Illustrative image related to check swing valve

What Are the Key Cost Components in Check Swing Valve Manufacturing?

The cost structure for check swing valves typically encompasses several components:

-

Materials: The choice of materials significantly affects the overall cost. Common materials include PVC, CPVC, and stainless steel. Specialty materials like aluminum or high-grade alloys may incur higher costs due to their durability and resistance to corrosion.

-

Labor: Manufacturing labor costs can vary based on the geographical location of the supplier. For instance, labor costs in Europe may be higher compared to South America or Africa, influencing the final pricing of the valves.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can reduce overhead costs, which in turn can be passed on to buyers.

-

Tooling: Initial tooling costs can be significant, especially for custom valve designs. These costs are amortized over the production run, impacting unit pricing.

-

Quality Control (QC): Ensuring product quality through rigorous QC processes adds to the cost but is essential for maintaining standards, especially for buyers in regulated industries.

-

Logistics: Shipping costs can vary widely based on distance, mode of transport, and Incoterms. International buyers should account for customs duties and tariffs, which can further affect the total cost.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on market conditions and competition.

How Do Price Influencers Affect Check Swing Valve Costs?

Several factors influence the pricing of check swing valves, including:

-

Volume/MOQ: Bulk orders often lead to lower per-unit costs. Buyers should negotiate minimum order quantities (MOQ) to optimize pricing.

-

Specifications/Customization: Customized valves that meet specific operational needs may come with higher costs. Standardized products generally offer better pricing due to economies of scale.

-

Materials and Quality Certifications: Higher quality materials and certifications (such as ISO or API) can increase costs but ensure reliability and compliance, which is critical for many applications.

-

Supplier Factors: The reputation and reliability of the supplier play a significant role in pricing. Established suppliers may charge a premium for their brand and service guarantees.

-

Incoterms: Understanding Incoterms is vital for pricing negotiations. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly impact the final cost depending on shipping and insurance responsibilities.

What Tips Should International Buyers Consider for Cost-Efficiency?

To maximize cost-efficiency when sourcing check swing valves, consider the following strategies:

-

Negotiate Effectively: Building a strong relationship with suppliers can lead to better pricing and favorable terms. Leverage volume purchases and long-term contracts to negotiate discounts.

-

Evaluate Total Cost of Ownership (TCO): Don’t just focus on the initial purchase price. Consider maintenance, operational efficiency, and potential downtime costs associated with valve performance.

-

Understand Pricing Nuances for Different Regions: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of local market conditions, currency fluctuations, and regional supply chain challenges that may affect pricing.

-

Request Quotations from Multiple Suppliers: Getting quotes from various suppliers allows for better price comparisons and helps identify market trends.

Disclaimer on Indicative Prices

Prices for check swing valves can vary significantly based on numerous factors, including market conditions and specific buyer requirements. The information provided here serves as a guideline, and buyers should conduct thorough market research and supplier evaluations to obtain accurate pricing tailored to their needs.

Alternatives Analysis: Comparing check swing valve With Other Solutions

Understanding the Importance of Alternatives in Valve Selection

When selecting flow control solutions, it’s essential for B2B buyers to consider a range of options. While check swing valves are popular for preventing backflow in various applications, several alternatives may better suit specific operational needs. This analysis compares check swing valves with two viable alternatives: dual plate check valves and ball valves, focusing on their performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | Check Swing Valve | Dual Plate Check Valve | Ball Valve |

|---|---|---|---|

| Performance | Effective for moderate flow rates; relies on gravity for closure | High flow capacity; quick closure, less pressure drop | Excellent sealing, full flow; not ideal for throttling |

| Cost | Moderate initial cost; long-term value | Generally lower cost than swing valves | Varies widely; cost-effective for small sizes |

| Ease of Implementation | Requires careful alignment; may need additional support | Compact design allows for easy installation | Straightforward installation; minimal alignment issues |

| Maintenance | Low maintenance; periodic inspections recommended | Low maintenance; easy access for cleaning | Minimal maintenance; can be automated |

| Best Use Case | Water and wastewater systems; general industrial applications | Water, wastewater, and HVAC applications | Gas and liquid systems requiring quick shut-off |

Detailed Breakdown of Alternatives

Dual Plate Check Valve

Dual plate check valves feature two hinged plates that open and close with flow direction, providing a compact design with minimal pressure drop. These valves excel in applications where space and efficiency are critical. They are generally more cost-effective than check swing valves, making them a popular choice for water and wastewater systems. However, their reliance on flow velocity for closure means they may not perform optimally at lower flow rates, which could lead to operational issues in specific scenarios.

Ball Valve

Ball valves consist of a spherical disc that controls flow, offering excellent sealing capabilities and a straightforward operation. They are ideal for applications requiring quick shut-off and are available in a wide range of sizes and materials. While ball valves are typically more expensive in larger sizes, they offer significant durability and low maintenance costs. However, they are not suitable for throttling, making them less versatile than check swing valves in some applications. Their ease of installation also makes them favorable for various industries, including gas and liquid systems.

Conclusion: Choosing the Right Valve for Your Needs

Selecting the appropriate valve solution depends on various factors, including application requirements, budget constraints, and maintenance capabilities. Check swing valves provide reliable performance in water and wastewater applications but may not be the best fit for every scenario. B2B buyers should carefully evaluate the pros and cons of each alternative, considering factors such as flow rates, installation requirements, and long-term operational costs. By understanding the unique advantages of check swing valves, dual plate check valves, and ball valves, buyers can make informed decisions that align with their specific operational needs and objectives.

Essential Technical Properties and Trade Terminology for check swing valve

What Are the Key Technical Properties of Check Swing Valves?

Understanding the essential technical properties of check swing valves is crucial for B2B buyers to make informed purchasing decisions. Here are some critical specifications:

Illustrative image related to check swing valve

1. Material Grade

Check swing valves are commonly made from materials such as PVC, CPVC, polypropylene (PP), and stainless steel. The choice of material affects the valve’s resistance to corrosion, temperature, and pressure. For instance, PVC is suitable for general applications, while stainless steel is ideal for harsh environments. Selecting the appropriate material grade ensures longevity and reliability in specific applications, which is vital for industries such as wastewater management and chemical processing.

2. Pressure Rating

The pressure rating indicates the maximum pressure the valve can withstand without failure. It is typically measured in pounds per square inch (psi). Higher pressure ratings are essential for industrial applications where fluid dynamics can lead to significant fluctuations in pressure. Understanding the pressure rating helps buyers ensure that the valve can operate safely within their system’s parameters.

3. Temperature Range

The temperature range denotes the operational limits of the valve, indicating the highest and lowest temperatures at which it can function effectively. This property is crucial for applications involving hot fluids or extreme environmental conditions. Buyers must match the valve’s temperature range with their specific use case to prevent premature wear or failure.

4. Flow Coefficient (Cv Rating)

The Cv rating measures the valve’s flow capacity, determining how much fluid can pass through the valve under a specific pressure drop. A higher Cv rating signifies better flow characteristics, which can enhance system efficiency. Buyers should consider the Cv rating to ensure optimal performance in their fluid systems, particularly in applications requiring high flow rates.

5. Installation Orientation

Check swing valves can typically be installed in horizontal or vertical orientations. This flexibility allows for easier integration into existing piping systems. Understanding installation requirements is important for buyers to facilitate proper valve placement, which can affect overall system performance.

What Are Common Trade Terms Related to Check Swing Valves?

Familiarity with industry jargon can enhance communication and negotiation between buyers and suppliers. Here are several important terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of check swing valves, knowing the OEM can help buyers identify the quality and reliability of the products they are sourcing.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for budget planning and inventory management, as it can impact the total cost and logistics of a purchase.

3. RFQ (Request for Quotation)

An RFQ is a formal request for a supplier to provide a quote for the supply of specific goods or services. It is a critical step in the procurement process, allowing buyers to compare pricing and terms across different suppliers.

4. Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers regarding shipping, risk, and costs. Familiarity with these terms is crucial for international buyers to understand their obligations and avoid potential disputes.

Illustrative image related to check swing valve

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. Knowing the lead time helps buyers plan their projects and manage expectations regarding delivery schedules.

In summary, understanding these technical properties and trade terms equips B2B buyers with the knowledge needed to make informed decisions regarding check swing valves, ensuring that they select the right products for their applications while navigating the complexities of international procurement.

Navigating Market Dynamics and Sourcing Trends in the check swing valve Sector

What Are the Key Market Dynamics and Trends Affecting Check Swing Valves?

The global check swing valve market is experiencing significant shifts driven by various factors. The increasing need for efficient fluid control systems in industries such as water treatment, oil and gas, and manufacturing is propelling demand. Notably, the push for automation and smart technologies is leading to the integration of IoT-enabled valves, enhancing operational efficiency and predictive maintenance capabilities. Furthermore, manufacturers are focusing on developing valves that can withstand extreme temperatures and pressures, catering to diverse applications.

Emerging markets in Africa, South America, and the Middle East are witnessing a surge in infrastructure projects, increasing the demand for robust check swing valves. In regions like Brazil and Germany, regulatory frameworks that emphasize quality and safety in industrial applications are influencing sourcing decisions. Buyers are increasingly prioritizing suppliers that can demonstrate compliance with international standards, such as ISO certifications, which are crucial for securing contracts in competitive markets.

Moreover, the trend towards modularity and customization is gaining traction. Buyers are looking for suppliers who can offer tailored solutions that meet specific operational requirements, whether for water treatment facilities or industrial processing plants. The ability to provide comprehensive support, including installation and maintenance services, is becoming a key differentiator for suppliers in this sector.

How Is Sustainability and Ethical Sourcing Shaping the Check Swing Valve Market?

Sustainability is becoming a cornerstone of sourcing strategies for check swing valves, with buyers increasingly demanding environmentally friendly solutions. The production and disposal of traditional valve materials can have significant environmental impacts, prompting a shift towards more sustainable options. Manufacturers are now offering valves made from recycled materials or those that can be fully recycled at the end of their lifecycle.

Ethical sourcing is equally important, as buyers seek to partner with suppliers who adhere to fair labor practices and responsible sourcing standards. Transparency in the supply chain is critical; suppliers are expected to provide evidence of sustainable practices and ethical sourcing certifications. Green certifications, such as those from the Forest Stewardship Council (FSC) or similar organizations, are becoming increasingly relevant in influencing purchasing decisions.

In addition, the use of eco-friendly lubricants and coatings in the manufacturing of check swing valves is gaining attention, as these materials minimize environmental impact while maintaining performance standards. As sustainability becomes a competitive advantage, suppliers who can demonstrate their commitment to ethical sourcing and environmentally friendly practices will be better positioned to meet the demands of international B2B buyers.

What Is the Historical Context of Check Swing Valves in B2B Markets?

The evolution of check swing valves dates back several decades, with their design rooted in the need for efficient fluid control systems. Initially, these valves were predominantly made from cast iron and other metals, designed for basic applications in water and wastewater management. Over time, advancements in materials science have led to the introduction of various alternatives, including PVC, CPVC, and stainless steel, which offer enhanced durability and corrosion resistance.

As industrial processes became more complex, the demand for more sophisticated valve designs grew. This led to innovations such as resilient seating options and self-aligning clapper seals, which improved performance in challenging conditions. Today, the integration of technology, such as IoT for real-time monitoring and maintenance, represents the next phase in the evolution of check swing valves, catering to the increasingly automated landscape of global industries.

This historical context underscores the importance of adaptability and innovation in the check swing valve sector, providing valuable insights for B2B buyers seeking reliable and efficient solutions for their fluid control needs.

Frequently Asked Questions (FAQs) for B2B Buyers of check swing valve

-

How do I determine the appropriate size of a check swing valve for my application?

To select the right size for a check swing valve, assess the pipe diameter, flow rate, and system pressure. The valve size should match the pipe size to minimize pressure drops. Additionally, consider the fluid characteristics and the application environment. Consult with manufacturers or suppliers for specific flow charts and engineering support to ensure optimal performance and compliance with industry standards. -

What materials are best suited for check swing valves in different environments?

Check swing valves are commonly available in materials like PVC, CPVC, stainless steel, and aluminum. For corrosive environments, stainless steel or specialized plastics are ideal. In wastewater applications, resilient seating materials help prevent leaks. Assess the temperature, pressure, and chemical compatibility of your fluid to choose the best material that ensures longevity and reliability in your specific application. -

What are the common applications for check swing valves?

Check swing valves are widely used in water and wastewater treatment, chemical processing, and bulk material handling. They prevent backflow, making them essential in pumping stations and irrigation systems. In industries like oil and gas, they protect equipment from reverse flow, ensuring operational safety. Understanding the specific needs of your application will help in selecting the right valve type. -

What customization options are available for check swing valves?

Many manufacturers offer customization options for check swing valves, including size, material, and sealing configurations. Additional features such as counterweights, limit switches, or position indicators can also be integrated. Discuss your specific requirements with suppliers to explore available options that meet your operational needs and enhance performance. -

What are the minimum order quantities (MOQ) for check swing valves?

Minimum order quantities for check swing valves can vary significantly by supplier and product type. Typically, MOQs range from a few units to several dozen, depending on the valve size and material. It’s advisable to communicate with suppliers early in the sourcing process to understand their MOQ policies, as negotiating smaller orders may be possible for new partnerships. -

What payment terms should I expect when sourcing check swing valves internationally?

Payment terms for international transactions often vary by supplier and region. Common options include advance payment, letters of credit, or payment upon delivery. Some suppliers may offer net payment terms (e.g., 30 or 60 days) based on your business relationship. Always clarify payment terms before placing orders to avoid misunderstandings and to ensure smooth transactions. -

How can I ensure the quality of check swing valves before purchasing?

To ensure the quality of check swing valves, request product certifications and quality assurance documentation from suppliers. Look for compliance with international standards such as ISO or ASTM. Additionally, consider ordering samples for testing or visiting the manufacturing facility if feasible. Engaging with suppliers who have established reputations for quality can also provide peace of mind. -

What logistics considerations should I keep in mind when sourcing check swing valves?

When sourcing check swing valves internationally, consider logistics factors such as shipping methods, lead times, and customs regulations. Evaluate the total cost of ownership, including shipping fees, duties, and taxes. Collaborate with suppliers to establish a reliable shipping schedule and ensure that all necessary documentation is in place to facilitate smooth customs clearance upon arrival in your country.

Top 9 Check Swing Valve Manufacturers & Suppliers List

1. Hayward – SW Series Swing Check Valves

Domain: haywardflowcontrol.com

Registered: 2004 (21 years)

Introduction: {‘description’: ‘SW Series swing check valves are offered in PVC, CPVC and PP. Seals and seats are FPM or EPDM. A counterweight is an option for added stability. Swing check valves are furnished with two o-ring flange seals so no additional gaskets are required for installation. All valves are assembled with silicone free lubricant.’, ‘features’: [‘Available in PVC, CPVC and GFPP’, ‘High Temperatu…

2. Flomatic – Swing Check Valves

Domain: flomatic.com

Registered: 1996 (29 years)

Introduction: Swing Check Valves are designed for water and wastewater applications, featuring a globe style valve body with a hinged valve disc to block reverse flow. They are available in metal-to-metal seat or resilient seating options, with resilient seated valves recommended for wastewater applications where dirt or particles may be present. The operation relies on gravity and reverse flow, with an externa…

3. Electro – Stainless Steel Swing Check Valve

Domain: electricsolenoidvalves.com

Registered: 2013 (12 years)

Introduction: {“Product Name”: “Stainless Steel Swing Check Valve”,”SKU”: “CV-S0-S”,”Availability”: “In Stock”,”Port Sizes Available”: [“1/2”, “3/4”, “1”, “1-1/4”, “1-1/2”, “2”],”Price”: “$19.58″,”Body Material”: “304 Stainless Steel”,”Disc Material”: “304 Stainless Steel”,”Hangar Pin”: “304 Stainless Steel”,”Plug Gasket”: “PTFE”,”Flow”: “Uni-Directional”,”Temperature Range”: “-4 to 356° F / -20 to 180°C”,”Pres…

4. Hirsch – Swing Check Valve

Domain: hirsch.com

Registered: 1995 (30 years)

Introduction: Swing check valve or tilting disc check valve is a check valve in which the disc, the movable part to block the flow, swings on a hinge or trunnion, either onto the seat to block reverse flow or off the seat to allow forward flow.

5. Dixon Valve – Horizontal Swing Check Valve

Domain: dixonvalve.com

Registered: 1996 (29 years)

Introduction: {‘name’: ‘Horizontal Swing Check Valve’, ‘model’: ‘SWCV100’, ‘weight’: ‘0.73 lb’, ‘break_quantity’: ‘1’, ‘size’: ‘1″‘, ‘material’: ‘Brass’, ‘thread_type’: ‘female NPT x female NPT’, ‘temperature_range’: ‘-20°F to 150°F (-29°C to 66°C)’, ‘pressure_rating’: ‘200 PSI WOG’, ‘applications’: ‘Designed to prevent back flow in plumbing and liquid piping systems, offering full flow performance with minimal…

6. pdblowers – 6 Aluminum Check Swing Valve

Domain: pdblowers.com

Registered: 1998 (27 years)

Introduction: {“Product Name”:”6″ Aluminum Check Swing Valve”,”Manufacturer”:”pdblowers, Inc.”,”Description”:”Lightweight Aluminum Swing Check Valves designed to stop flow reversal in air and gas applications for pneumatic and bulk material handling industries. Suitable for installation between two flanges in vertical or horizontal piping systems.”,”Features”:[“American Made – Manufactured in the Midwest”,”Mini…

7. MIFAB – BEECO Swing Check Valve

Domain: mifab.com

Registered: 1997 (28 years)

Introduction: MIFAB BEECO Swing Check Valve is designed to prevent backflow and protect system equipment. It is suitable for use in horizontal or vertical flow upward installations. The valve features low pressure drop and is best suited for moderate velocity applications.

8. Cooney Brothers – Check Valves

Domain: cooneybrothers.com

Registered: 1999 (26 years)

Introduction: Swing Check Valves, Lift Check Valves, Stop Check Valves

9. Valmatic – Swing Check Valves

Domain: valmatic.com

Registered: 1999 (26 years)

Introduction: Swing Check Valves for Water | Municipal & Industrial Check Valve

– Rugged construction and full flow area

– Most specified check valve for municipal/industrial water and wastewater applications

– Smooth, unrestricted flow design for significant savings in pumping costs

– Ductile iron construction with 250 psi rating

– Fusion bonded epoxy coating (interior and exterior)

– Available sizes: 2″ – 48″…

Strategic Sourcing Conclusion and Outlook for check swing valve

What Are the Key Takeaways for Sourcing Check Swing Valves?

In the evolving landscape of industrial operations, strategic sourcing of check swing valves is paramount for ensuring reliability and efficiency in fluid control systems. Buyers should prioritize valves that offer robust material options, such as PVC, CPVC, and stainless steel, which enhance durability and performance across diverse applications. Additionally, understanding the valve’s design features—such as self-aligning clapper seals and built-in flange seals—can significantly impact installation ease and maintenance costs.

How Does Strategic Sourcing Enhance Operational Efficiency?

By engaging in strategic sourcing, B2B buyers not only secure high-quality products but also foster long-term supplier relationships that can lead to better pricing, reliable delivery, and improved service. This proactive approach is essential in regions such as Africa, South America, the Middle East, and Europe, where operational demands and environmental conditions can vary widely.

What’s Next for International Buyers?

As the global market continues to innovate, staying informed about advancements in valve technology and sourcing strategies will be crucial. We encourage international buyers to leverage this guide to make informed purchasing decisions, ensuring they capitalize on the full potential of check swing valves in their operations. Engage with trusted suppliers, evaluate your specific needs, and embrace the future of fluid control with confidence.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.