Unlocking Value: A Strategic Analysis of the Caterpillar Truck Price Market

Introduction: Navigating the Global Market for caterpillar truck price

In the competitive landscape of global commerce, sourcing the right caterpillar truck price is a critical challenge for B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and established economies in Europe like Germany and Brazil. As businesses strive to enhance operational efficiency and productivity, understanding the pricing dynamics of these robust vehicles becomes essential. This guide is designed to provide comprehensive insights into the various types of caterpillar trucks available, their applications in different industries, and the intricacies of supplier vetting to ensure quality and reliability.

Throughout this resource, you will discover detailed analyses of cost structures, including factors influencing pricing, such as specifications, features, and market trends. We will also explore the advantages of investing in caterpillar trucks, emphasizing their durability and performance in demanding environments. By equipping international B2B buyers with the knowledge needed to navigate the complexities of caterpillar truck pricing, this guide empowers you to make informed purchasing decisions that align with your operational needs and budgetary constraints. Whether you are managing a fleet for construction projects or seeking reliable transportation solutions in rugged terrains, understanding these elements will enhance your procurement strategy and drive business success.

Understanding caterpillar truck price Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Base Model | Standard features, entry-level pricing | Small businesses, individual contractors | Pros: Lower cost; Cons: Limited features and performance |

| Heavy-Duty Variant | Enhanced towing and payload capacities, reinforced chassis | Construction, logistics, and heavy equipment transport | Pros: High durability; Cons: Higher initial investment |

| Luxury/Loaded Model | Advanced technology, premium materials, superior comfort | Fleet management, high-end construction companies | Pros: Greater comfort and tech; Cons: Higher maintenance costs |

| Electric Model | Eco-friendly, lower operating costs, advanced battery technology | Urban logistics, environmentally conscious businesses | Pros: Reduced emissions; Cons: Limited range and charging infrastructure |

| Specialized Off-Road Model | Superior suspension, off-road capabilities, rugged design | Mining, forestry, and remote construction sites | Pros: Exceptional off-road performance; Cons: Higher price point |

What are the Key Characteristics of the Base Model Caterpillar Truck?

The Base Model Caterpillar Truck serves as an entry-level option for buyers seeking a reliable vehicle without extensive features. It typically includes essential performance specifications suitable for light-duty tasks. Ideal for small businesses and individual contractors, this model offers affordability while still providing Caterpillar’s renowned durability. However, potential buyers should note that while the lower price point is attractive, it may lack advanced technology and performance metrics found in higher-tier models.

How Does the Heavy-Duty Variant Caterpillar Truck Stand Out?

The Heavy-Duty Variant is designed for those requiring maximum towing and payload capabilities. With a reinforced chassis and high-performance engine, this truck is well-suited for construction sites and logistics operations. Companies engaged in heavy equipment transport will find this model particularly beneficial due to its robustness. While it offers exceptional durability and performance, the initial investment is higher, which may be a consideration for budget-conscious buyers.

What Advantages Does the Luxury/Loaded Model Offer?

The Luxury/Loaded Model of the Caterpillar Truck is tailored for businesses that prioritize comfort and advanced technology. It features premium materials, superior infotainment systems, and enhanced safety features. This model is particularly appealing to fleet managers and high-end construction companies that want to impress clients and provide comfort to drivers. While the benefits of advanced technology and comfort are clear, buyers should be aware of the higher maintenance costs associated with these premium features.

Why Consider the Electric Model Caterpillar Truck?

With an increasing focus on sustainability, the Electric Model offers an eco-friendly alternative to traditional trucks. It boasts lower operating costs and reduced emissions, making it an attractive choice for urban logistics and environmentally conscious businesses. However, buyers must consider the limitations in range and the availability of charging infrastructure, which may affect operational efficiency in certain regions.

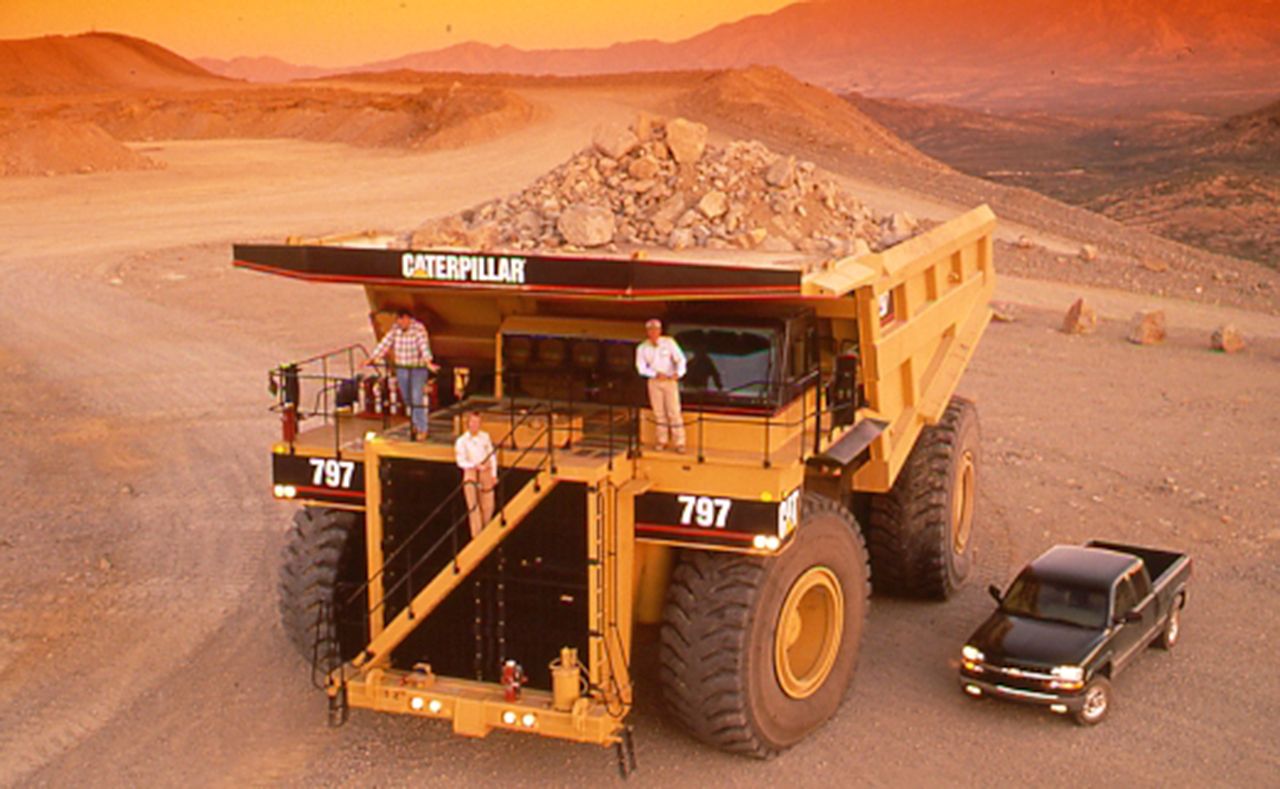

Illustrative image related to caterpillar truck price

What Makes the Specialized Off-Road Model Unique?

The Specialized Off-Road Model is engineered for demanding environments such as mining and forestry. With superior suspension systems and rugged design, it excels in off-road conditions. Companies operating in remote construction sites will benefit from its exceptional performance in harsh terrains. While it provides unparalleled off-road capabilities, its higher price point may deter some buyers who are not focused on extreme applications.

Key Industrial Applications of caterpillar truck price

| Industry/Sector | Specific Application of caterpillar truck price | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Heavy-duty transportation of construction materials | Ensures timely delivery and reduces downtime on job sites | Evaluate local dealer support, financing options, and warranty terms. |

| Agriculture | Transporting equipment and supplies across fields | Enhances operational efficiency and productivity in agricultural tasks | Consider payload capacity and off-road capabilities for diverse terrains. |

| Mining | Hauling raw materials and equipment in rugged terrains | Increases productivity and reduces operational costs | Assess durability and maintenance support in remote locations. |

| Oil & Gas | Transporting personnel and equipment to remote sites | Improves safety and efficiency in challenging environments | Look for features that enhance fuel efficiency and off-road performance. |

| Logistics & Distribution | Moving goods between warehouses and construction sites | Streamlines supply chain operations and reduces transportation costs | Analyze fleet management integration and maintenance accessibility. |

How is the Caterpillar Truck Price Applied in the Construction Industry?

In the construction sector, Caterpillar trucks are crucial for transporting heavy materials like concrete, steel, and machinery to job sites. Their robust design and high towing capacity ensure that construction firms can operate efficiently without delays. Buyers in this industry should prioritize sourcing from local dealers who can provide ongoing support and financing options, especially in developing regions where access to spare parts may be limited.

What Role Does the Caterpillar Truck Price Play in Agriculture?

For agricultural businesses, Caterpillar trucks are essential for transporting equipment and supplies across expansive fields. Their off-road capabilities enable farmers to navigate challenging terrains, enhancing productivity. When sourcing these trucks, agricultural buyers should consider payload capacity and durability to ensure they can withstand the rigors of farm operations. Additionally, local service availability is critical for minimizing downtime.

How Are Caterpillar Trucks Utilized in Mining Operations?

In the mining industry, Caterpillar trucks are utilized for hauling raw materials and heavy equipment across rugged terrains. Their durability and high payload capacity allow mining companies to operate efficiently while minimizing operational costs. Buyers in this sector must evaluate the trucks’ maintenance support, especially in remote locations where access to service may be challenging. Ensuring that the trucks meet safety and environmental regulations is also vital.

Illustrative image related to caterpillar truck price

What Benefits Do Caterpillar Trucks Offer the Oil & Gas Sector?

Caterpillar trucks are instrumental in the oil and gas industry for transporting personnel and equipment to remote drilling sites. Their reliability and advanced safety features enhance operational efficiency in challenging environments. When sourcing these trucks, companies should focus on fuel efficiency and off-road performance to reduce operational costs. Understanding the local regulatory landscape is also essential for compliance and safety standards.

How Do Caterpillar Trucks Enhance Logistics and Distribution?

In logistics and distribution, Caterpillar trucks facilitate the movement of goods between warehouses and construction sites, streamlining supply chain operations. Their robust build and advanced technology help reduce transportation costs and improve delivery times. Buyers in this sector should analyze fleet management integration and maintenance accessibility to ensure long-term operational efficiency. Additionally, understanding the total cost of ownership, including maintenance and fuel consumption, is crucial for informed purchasing decisions.

3 Common User Pain Points for ‘caterpillar truck price’ & Their Solutions

Scenario 1: Navigating High Initial Costs of Caterpillar Trucks

The Problem: One of the most significant challenges for international B2B buyers considering the purchase of a Caterpillar truck is the high initial investment required. With prices starting around $85,000 and potentially exceeding $120,000 for fully loaded models, many businesses, especially small to medium enterprises (SMEs), may struggle to justify or finance this expenditure. This concern is particularly acute in regions like Africa and South America, where budget constraints and economic conditions may limit purchasing power. Buyers may feel overwhelmed by the prospect of such a financial commitment, leading to indecision or the risk of settling for lower-quality alternatives that may not meet their operational needs.

The Solution: To effectively manage the financial implications of purchasing a Caterpillar truck, buyers should consider a phased investment approach. Start by engaging with authorized Caterpillar dealers to discuss financing options, including leasing or installment plans tailored for businesses. Additionally, conduct a total cost of ownership analysis to highlight potential long-term savings from the truck’s durability, lower maintenance costs, and fuel efficiency. By assessing the truck’s ability to reduce downtime and enhance productivity, businesses can build a compelling case for the investment. It’s also beneficial to explore fleet purchase discounts or trade-in programs that can further alleviate upfront costs.

Illustrative image related to caterpillar truck price

Scenario 2: Understanding Variability in Pricing Across Regions

The Problem: Another pain point for B2B buyers is the variability in Caterpillar truck pricing based on geographical location. Prices can fluctuate significantly due to factors such as local taxes, import duties, and dealership markups, creating confusion and frustration among buyers. This variability can lead to uncertainty in budgeting, especially for companies operating in multiple countries or those looking to establish a presence in new markets, such as the Middle East or Europe.

The Solution: To tackle this pricing inconsistency, B2B buyers should adopt a strategic approach by gathering comprehensive market intelligence. Start by reaching out to multiple authorized Caterpillar dealers across different regions to obtain quotes and understand local pricing structures. Leverage online platforms and trade forums to compare prices and gather insights from other businesses that have made similar purchases. Additionally, consider engaging a local purchasing consultant who can navigate regional pricing dynamics and help negotiate better terms. By having a clear understanding of regional market conditions and pricing trends, buyers can make informed decisions that align with their budgetary constraints.

Scenario 3: Evaluating Long-Term Value Against Initial Pricing

The Problem: B2B buyers often grapple with the challenge of evaluating the long-term value of a Caterpillar truck compared to its initial price. In industries where reliability and performance are critical, it can be difficult to quantify the return on investment (ROI) of a higher-priced vehicle. This concern is particularly relevant for companies in competitive sectors, such as construction and logistics, where equipment performance directly impacts profitability. Buyers may struggle to justify the upfront cost without a clear understanding of how the truck’s features translate into operational advantages.

Illustrative image related to caterpillar truck price

The Solution: To effectively assess long-term value, buyers should focus on performance metrics and how they relate to cost efficiency. Start by identifying key performance indicators (KPIs) relevant to your operations, such as fuel consumption, maintenance frequency, and resale value. Utilize Caterpillar’s extensive resources, including case studies and performance data from similar industries, to illustrate the potential ROI of their trucks. Conduct pilot programs or trial purchases to evaluate the truck’s performance in real-world conditions before committing to a full fleet purchase. By emphasizing the potential for increased productivity, reduced downtime, and lower operational costs, buyers can substantiate the initial investment with a compelling long-term value proposition.

Strategic Material Selection Guide for caterpillar truck price

What Materials Are Commonly Used in Caterpillar Trucks and How Do They Affect Pricing?

When considering the pricing of Caterpillar trucks, the selection of materials plays a crucial role in determining performance, durability, and ultimately, cost. Here, we will analyze four common materials used in the construction of Caterpillar trucks: steel, aluminum, composite materials, and rubber. Each material has unique properties and implications for B2B buyers, particularly in international markets.

How Does Steel Impact the Performance and Cost of Caterpillar Trucks?

Steel is a traditional choice for heavy-duty applications, particularly in truck frames and structural components. Its key properties include high tensile strength, excellent durability, and resistance to deformation under heavy loads. However, it can be prone to corrosion if not properly treated, which can affect longevity and maintenance costs.

Illustrative image related to caterpillar truck price

Pros: Steel offers superior strength and impact resistance, making it ideal for rugged environments. It is widely available and relatively low in cost compared to other materials.

Cons: The weight of steel can lead to decreased fuel efficiency and increased operational costs. Additionally, manufacturing processes involving steel can be complex, requiring specialized equipment for cutting and welding.

For international buyers, compliance with standards such as ASTM and DIN is essential. In regions like Africa and South America, where environmental conditions can be harsh, selecting high-grade steel with corrosion resistance is advisable to ensure long-term performance.

What Role Does Aluminum Play in Caterpillar Truck Construction?

Aluminum is increasingly being used in truck manufacturing due to its lightweight properties and resistance to corrosion. This material is particularly beneficial for components like body panels and certain structural elements.

Pros: The primary advantage of aluminum is its reduced weight, which can enhance fuel efficiency and payload capacity. It also has excellent corrosion resistance, making it suitable for diverse environments.

Illustrative image related to caterpillar truck price

Cons: While aluminum is strong, it is not as tough as steel, which may limit its use in high-stress applications. Additionally, aluminum components can be more expensive to manufacture due to the complexities involved in welding and forming.

For B2B buyers in Europe, where regulations around emissions and fuel efficiency are stringent, aluminum’s benefits can translate into cost savings over the vehicle’s lifecycle. However, buyers should ensure that the aluminum used meets local standards for strength and durability.

How Do Composite Materials Enhance Caterpillar Truck Performance?

Composite materials, such as fiberglass and carbon fiber, are becoming more prevalent in truck design, particularly for non-structural components. These materials offer unique properties like high strength-to-weight ratios and resistance to environmental degradation.

Pros: Composites can significantly reduce weight, which enhances fuel efficiency and performance. They are also resistant to corrosion and can be molded into complex shapes, allowing for innovative designs.

Illustrative image related to caterpillar truck price

Cons: The primary drawback is the high cost of composite materials and the complexity of manufacturing processes. Additionally, repair and recycling of composites can be challenging.

For international buyers, especially in technologically advanced markets like Germany, the use of composites may align with trends toward sustainability and innovation. However, understanding the specific applications and limitations of composites is crucial for ensuring they meet performance expectations.

What Is the Importance of Rubber in Caterpillar Trucks?

Rubber is predominantly used in tires and various seals and gaskets in Caterpillar trucks. Its key properties include flexibility, resilience, and excellent traction.

Pros: Rubber provides superior grip and shock absorption, which is essential for off-road capabilities. It is also resistant to wear and can withstand a wide range of temperatures.

Illustrative image related to caterpillar truck price

Cons: Rubber can degrade over time due to UV exposure and extreme temperatures, necessitating regular maintenance and replacement. The cost of high-quality rubber can also be significant.

For B2B buyers in regions with diverse climates, such as the Middle East and South America, selecting the right rubber compound for tires and seals is critical. Compliance with local standards for durability and performance should be a priority to ensure optimal vehicle operation.

Summary Table of Material Considerations for Caterpillar Truck Pricing

| Material | Typical Use Case for caterpillar truck price | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Truck frames and structural components | High strength and durability | Heavy weight affects fuel efficiency | Low |

| Aluminum | Body panels and lightweight structures | Lightweight and corrosion-resistant | Less tough than steel | Medium |

| Composite | Non-structural components | High strength-to-weight ratio | High manufacturing costs | High |

| Rubber | Tires and seals | Excellent traction and shock absorption | Degrades over time | Medium |

This analysis of material selection provides valuable insights for international B2B buyers evaluating Caterpillar trucks. Understanding the properties, pros and cons, and regional considerations will aid in making informed purchasing decisions that align with operational needs and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for caterpillar truck price

What Are the Main Stages in the Manufacturing Process of Caterpillar Trucks?

The manufacturing process for Caterpillar trucks is a complex and meticulous endeavor, designed to ensure that each vehicle meets the high standards expected from the Caterpillar brand. The main stages of manufacturing include material preparation, forming, assembly, and finishing.

Illustrative image related to caterpillar truck price

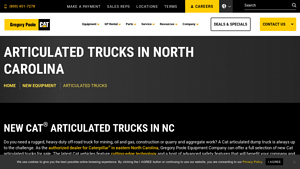

Material Preparation

The process begins with the selection of high-quality materials, primarily focusing on military-grade steel and aluminum alloys. These materials are sourced from certified suppliers to ensure consistency in quality and performance. Each batch of materials undergoes rigorous testing to verify their properties before they are approved for use in production.

Forming

Once the materials are prepared, they are subjected to various forming techniques. Advanced methods such as stamping, bending, and laser cutting are employed to shape the components accurately. Caterpillar utilizes state-of-the-art machinery to ensure precision in forming, allowing for tight tolerances that are crucial for the vehicle’s performance and durability.

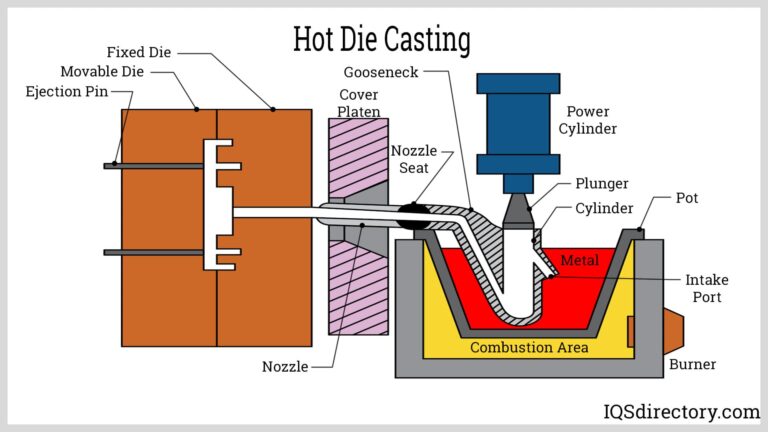

Assembly

The assembly stage involves integrating all the formed components into a cohesive vehicle. Skilled technicians follow detailed assembly protocols to ensure that each part fits perfectly. This stage also includes the installation of complex systems such as the engine, transmission, and electrical components. Caterpillar emphasizes the importance of a well-coordinated assembly process, often employing lean manufacturing principles to minimize waste and improve efficiency.

Illustrative image related to caterpillar truck price

Finishing

The final stage is finishing, where the vehicle undergoes surface treatment, painting, and quality inspections. Advanced robotics are often utilized for painting to ensure an even and durable finish. After painting, each vehicle goes through a series of quality control checks before it is deemed ready for delivery. This stage is crucial for ensuring that the aesthetic and functional aspects of the truck meet Caterpillar’s high standards.

How Does Quality Assurance Work in Caterpillar Truck Manufacturing?

Quality assurance is integral to the manufacturing process of Caterpillar trucks, ensuring that each vehicle not only meets but exceeds international standards. Caterpillar adheres to several internationally recognized quality standards, including ISO 9001, which focuses on effective quality management systems.

International Standards and Certifications

Caterpillar’s commitment to quality is reflected in its compliance with various international standards. ISO 9001 certification ensures that the company maintains a quality management system that is continuously improved. Additionally, industry-specific certifications such as CE (Conformité Européenne) for the European market and API (American Petroleum Institute) standards for equipment used in oil and gas are crucial. These certifications are vital for B2B buyers, particularly in regions like Europe, where compliance with local regulations is mandatory.

Quality Control Checkpoints

Throughout the manufacturing process, multiple quality control checkpoints are established:

Illustrative image related to caterpillar truck price

- Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet the required specifications.

- In-Process Quality Control (IPQC): Quality checks are performed at various stages during the manufacturing process to identify and rectify issues early.

- Final Quality Control (FQC): Once the assembly is complete, the entire vehicle undergoes a comprehensive inspection to ensure it meets all performance and safety standards.

What Testing Methods Are Commonly Used in Caterpillar Truck Manufacturing?

Caterpillar employs a variety of testing methods to ensure that their trucks are robust and reliable. These methods include:

- Performance Testing: Each truck is subjected to rigorous performance tests to evaluate its engine power, towing capacity, and handling under various conditions.

- Durability Testing: Trucks are tested under extreme conditions to ensure they can withstand harsh environments typical in construction and off-road applications.

- Safety Testing: Safety features, such as braking systems and collision avoidance technologies, are thoroughly tested to ensure compliance with safety regulations.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those in international markets, verifying the quality control processes of suppliers is crucial. Here are some actionable steps:

- Audits: Conduct regular audits of the manufacturing facilities to assess compliance with quality standards. This can include both announced and unannounced visits.

- Request Quality Reports: Suppliers should provide detailed quality reports that outline their quality control processes, including any certifications obtained and results from internal audits.

- Third-Party Inspections: Engage third-party inspection agencies to evaluate the quality of the manufacturing processes and finished products. This adds an additional layer of assurance regarding the supplier’s commitment to quality.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, must navigate specific quality control nuances:

- Local Regulations and Compliance: Buyers must be aware of and comply with local regulations regarding vehicle safety, emissions, and import standards. This may require additional certifications or modifications to meet local laws.

- Cultural Considerations: Understanding cultural differences in business practices can facilitate smoother interactions with suppliers. Building relationships based on trust and transparency is vital in many regions.

- Supply Chain Transparency: Ensure that the entire supply chain is transparent and that suppliers maintain high-quality standards throughout their operations. This includes sourcing materials from reputable providers and maintaining ethical labor practices.

Conclusion

Understanding the manufacturing processes and quality assurance measures behind Caterpillar trucks is essential for B2B buyers. By focusing on the key stages of manufacturing and the rigorous quality control practices in place, buyers can make informed decisions that align with their operational needs and regulatory requirements. Ensuring that suppliers adhere to international standards and maintaining a robust verification process will lead to successful partnerships and high-quality purchases.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘caterpillar truck price’

To effectively procure the Caterpillar truck at the best price, follow this structured checklist designed for international B2B buyers. By adhering to these steps, you can ensure a streamlined sourcing process that meets your needs and budget.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline the technical specifications required for the Caterpillar truck. Consider factors such as engine capacity, towing and payload requirements, and off-road capabilities. This clarity will help you communicate your needs effectively to suppliers and ensure you receive accurate quotes tailored to your specifications.

Step 2: Research Market Pricing

Conduct comprehensive market research to understand the pricing landscape for the Caterpillar truck. Look for comparable models and their pricing in different regions, particularly focusing on markets in Africa, South America, the Middle East, and Europe. This step is crucial as it helps you set a realistic budget and negotiates effectively with suppliers.

Step 3: Identify Reputable Suppliers

Finding reliable suppliers is essential for a successful procurement process. Compile a list of authorized Caterpillar dealers and established distributors who specialize in heavy-duty vehicles. Verify their credibility by checking customer reviews, industry certifications, and their history of service in your target region.

Step 4: Request and Compare Quotations

Once you have identified potential suppliers, request detailed quotations that include pricing, delivery timelines, and warranty information. Pay close attention to the inclusions in their offers, such as taxes, shipping fees, and any additional costs. Comparing these quotations will help you identify the best value for your investment.

Step 5: Evaluate Financing Options

Consider your financing options to facilitate the procurement of the Caterpillar truck. Explore various payment methods, including leasing, loans, or direct purchases, and assess the associated costs and benefits. Understanding your financing capabilities will enable you to make informed decisions that align with your budgetary constraints.

Step 6: Negotiate Terms and Conditions

Effective negotiation can significantly impact your final purchase price and terms. Engage with suppliers to discuss pricing, delivery schedules, and after-sales support. Don’t hesitate to ask for discounts, especially for bulk purchases, as many suppliers are willing to accommodate in exchange for larger orders.

Illustrative image related to caterpillar truck price

Step 7: Finalize the Purchase Agreement

Once you have selected a supplier, ensure that all terms are clearly outlined in a purchase agreement. This document should specify the truck’s specifications, pricing, payment terms, warranty, and any service agreements. A well-documented agreement protects both parties and sets clear expectations for the transaction.

By following this checklist, B2B buyers can streamline their procurement process for the Caterpillar truck, ensuring they secure the best possible price while meeting their operational needs.

Comprehensive Cost and Pricing Analysis for caterpillar truck price Sourcing

What Are the Key Cost Components for Caterpillar Truck Pricing?

Understanding the cost structure behind Caterpillar trucks is essential for B2B buyers aiming to make informed purchasing decisions. The primary cost components include:

-

Materials: High-quality materials such as military-grade steel and aluminum-alloy are utilized to ensure durability and performance. The choice of materials directly impacts the cost, with premium materials resulting in higher prices but enhanced longevity and reliability.

-

Labor: Skilled labor is necessary for the assembly of these complex vehicles. Labor costs can vary significantly based on the region and labor market conditions, impacting the final price.

-

Manufacturing Overhead: This includes expenses related to facility operations, utilities, and equipment maintenance. Caterpillar’s advanced manufacturing processes can lead to higher overhead costs, which are reflected in the pricing.

-

Tooling and Equipment: The use of specialized tooling for production can drive up costs. Investments in modern technology and machinery are crucial for maintaining quality and efficiency in manufacturing.

-

Quality Control (QC): Rigorous QC processes ensure that every truck meets Caterpillar’s high standards. While this adds to production costs, it minimizes defects and enhances customer satisfaction, ultimately providing value to buyers.

-

Logistics: Transportation and delivery costs are significant, especially for international buyers. The distance from manufacturing facilities to the end-user and the choice of transportation method can affect logistics expenses.

-

Margin: Caterpillar aims to maintain a healthy profit margin, which is built into the pricing structure. This margin supports ongoing research and development, ensuring continual innovation.

How Do Price Influencers Affect Caterpillar Truck Pricing?

Several factors influence the pricing strategy for Caterpillar trucks:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often lead to volume discounts. Buyers should consider negotiating terms that allow for lower prices based on order size.

-

Specifications and Customization: Trucks can be tailored to meet specific operational needs, which may increase the price based on additional features and specifications.

-

Quality and Certifications: Trucks that meet international quality standards or possess certain certifications may command higher prices. Buyers should weigh the benefits of these certifications against their cost implications.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with proven track records may charge premium prices due to their quality assurance.

-

Incoterms: Understanding international shipping terms is crucial for cost management. Incoterms dictate who is responsible for shipping, insurance, and tariffs, affecting the total landed cost.

What Are the Best Negotiation Tips for International Buyers?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, effective negotiation is key:

Illustrative image related to caterpillar truck price

-

Leverage Total Cost of Ownership (TCO): Focus on the overall value rather than just the initial purchase price. Consider factors like fuel efficiency, maintenance costs, and resale value when evaluating costs.

-

Explore Financing Options: Caterpillar and its dealers may offer financing solutions that can ease upfront costs. Understanding these options can provide flexibility in budgeting.

-

Engage in Direct Discussions: Establishing a relationship with suppliers can lead to better pricing negotiations. Direct communication often allows for more personalized deals and discounts.

-

Stay Informed About Market Trends: Keeping abreast of market trends and competitor pricing can empower buyers during negotiations, enabling them to advocate for more favorable terms.

-

Consider Local Regulations and Duties: Buyers should be aware of local taxes, tariffs, and regulations that may affect the overall cost. This knowledge can be instrumental in negotiating a better deal.

Conclusion: What Should Buyers Keep in Mind?

While the expected starting price for the Caterpillar truck may be around $85,000, various factors can influence this figure. Buyers should approach negotiations with a clear understanding of the cost components, pricing influencers, and their unique needs. By doing so, they can ensure they are making a sound investment in a truck that meets their operational requirements and provides long-term value. Always remember that prices may fluctuate, and it’s essential to verify with authorized dealers for the most accurate and up-to-date pricing information.

Alternatives Analysis: Comparing caterpillar truck price With Other Solutions

In the competitive landscape of heavy-duty vehicles, the Caterpillar truck represents a robust solution for industrial and construction needs. However, B2B buyers should consider various alternatives that might offer comparable performance, cost-effectiveness, and suitability for specific applications. This analysis will delve into alternative solutions to the Caterpillar truck, providing valuable insights for decision-makers.

| Comparison Aspect | Caterpillar Truck Price | Ford F-Series Super Duty | RAM Heavy Duty Trucks |

|---|---|---|---|

| Performance | 500 HP, 25,000 lbs towing | Up to 475 HP, 37,000 lbs towing | Up to 410 HP, 35,100 lbs towing |

| Cost | Starting at $85,000 | Starting at $45,000 | Starting at $40,000 |

| Ease of Implementation | Medium (requires specialized training) | High (widely available) | High (widely available) |

| Maintenance | High (premium parts and service) | Moderate (widely available parts) | Moderate (widely available parts) |

| Best Use Case | Heavy-duty industrial work | Versatile commercial use | Towing and hauling |

What are the Pros and Cons of the Ford F-Series Super Duty as an Alternative?

The Ford F-Series Super Duty trucks are recognized for their versatility and strong performance. With a towing capacity of up to 37,000 lbs, they are suitable for a range of applications, from construction to transportation. One major advantage is the significantly lower starting price of around $45,000, which makes it an attractive option for businesses with budget constraints. The widespread availability of parts and service also enhances ease of maintenance. However, while they offer competitive performance, they may not match the rugged durability of the Caterpillar truck, particularly in extreme conditions.

How Does the RAM Heavy Duty Trucks Compare to the Caterpillar Truck?

RAM Heavy Duty trucks are another viable alternative, offering a balance of power and affordability. With a starting price of approximately $40,000, they present a cost-effective solution for businesses needing reliable hauling and towing capabilities, with a maximum towing capacity of 35,100 lbs. The RAM trucks are known for their comfortable interiors and advanced technology, making them suitable for long-haul jobs. However, like the Ford, they may not provide the same level of durability and specialized features tailored for extreme industrial environments as the Caterpillar truck.

Conclusion: How Can B2B Buyers Choose the Right Solution for Their Needs?

Selecting the right heavy-duty truck is a critical decision that hinges on various factors, including performance, cost, and application. The Caterpillar truck offers exceptional durability and industrial-grade performance but comes at a premium price. Alternatives like the Ford F-Series and RAM Heavy Duty trucks provide strong performance at a lower price point, making them suitable for a broader range of commercial applications. B2B buyers should carefully assess their specific operational needs, budget constraints, and long-term goals to determine which vehicle aligns best with their business strategy. By doing so, they can ensure that their investment maximizes productivity and efficiency in their operations.

Illustrative image related to caterpillar truck price

Essential Technical Properties and Trade Terminology for caterpillar truck price

What Are the Key Technical Properties of Caterpillar Trucks That Impact Pricing?

When evaluating the price of a Caterpillar truck, several technical specifications are crucial to understanding its value and performance. Here are the key properties that B2B buyers should consider:

-

Engine Specifications

The engine is the heart of any truck, particularly in heavy-duty applications. For the Caterpillar pickup truck, the anticipated 6.7L Turbo Diesel engine, capable of producing up to 500 horsepower and 1,200 lb-ft of torque, signifies power and efficiency. This level of performance is essential for industries requiring heavy towing and hauling capabilities, directly influencing the truck’s price. A robust engine ensures lower operational costs and higher productivity, making it a vital consideration for fleet managers. -

Towing and Payload Capacity

Towing capacity (up to 25,000 lbs) and payload capacity (estimated at 7,500 lbs) are critical metrics for businesses that rely on transport. These specifications determine how much weight the truck can safely carry, impacting operational efficiency and safety on the job site. A higher capacity often correlates with a higher price point, but it also translates to increased revenue potential for businesses that need to move heavy materials. -

Build Quality and Materials

The use of military-grade steel for the chassis and aluminum-alloy for the body contributes to the truck’s durability while keeping it lightweight. This combination is essential for maintaining performance under extreme conditions, which is particularly relevant for industries operating in rugged environments. Buyers should assess the material specifications as they directly correlate with the longevity and maintenance costs of the vehicle. -

Off-Road Capability

Features like high ground clearance (estimated at 12-14 inches) and electronic locking differentials enhance the truck’s off-road performance. For businesses in construction and agriculture, these capabilities are critical for accessing challenging terrains. Trucks designed for off-road use typically command a premium price due to the advanced engineering involved. -

Technology Integration

The integration of advanced technology, such as a 12-inch touchscreen infotainment system and smart terrain management, is becoming increasingly important in modern trucks. These features enhance usability and safety, making the truck more appealing to fleet managers. While they may increase the initial purchase price, they can lead to cost savings through improved efficiency and reduced downtime.

What Trade Terminology Should B2B Buyers Understand When Pricing Caterpillar Trucks?

Understanding industry terminology is essential for navigating the purchasing process effectively. Here are some common terms that buyers should familiarize themselves with:

-

OEM (Original Equipment Manufacturer)

This term refers to the company that manufactures the original product, in this case, Caterpillar. Buyers should ensure they are purchasing genuine parts and vehicles from OEMs to guarantee quality and compatibility, which can influence pricing significantly. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For large-scale operations, understanding MOQ can help in negotiating better pricing and ensuring that the purchase aligns with budget constraints. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a quote for specific products or services. For B2B buyers, issuing an RFQ can help compare prices and features from different vendors, leading to more informed purchasing decisions. -

Incoterms (International Commercial Terms)

These are a set of rules that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for determining shipping costs and delivery responsibilities, which can significantly impact the total cost of acquisition. -

TCO (Total Cost of Ownership)

TCO encompasses all costs associated with acquiring and operating a truck over its lifespan, including purchase price, maintenance, fuel, and depreciation. B2B buyers should consider TCO rather than just the initial price to ensure they are making a sound investment. -

Fleet Management

This term refers to the administration of a company’s vehicle fleet. Effective fleet management can optimize vehicle use, reduce costs, and enhance productivity, making it a critical consideration for businesses investing in Caterpillar trucks.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions regarding Caterpillar truck pricing, ultimately ensuring they select the right vehicle for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the caterpillar truck price Sector

What Are the Current Market Dynamics and Key Trends in the Caterpillar Truck Price Sector?

The caterpillar truck price sector is experiencing significant transformation driven by several global factors. First, the increasing demand for heavy-duty vehicles in emerging markets, particularly in Africa and South America, is pushing manufacturers to innovate. Countries like Brazil and Nigeria are investing heavily in infrastructure, leading to a surge in demand for durable, high-performance vehicles capable of handling challenging terrains. Additionally, the shift towards electrification and hybrid solutions is gaining traction, particularly in Europe and the Middle East, where regulatory frameworks are increasingly favoring sustainable transportation solutions.

Another key trend is the integration of technology in sourcing practices. B2B buyers are now leveraging data analytics and AI to optimize procurement processes, ensuring they acquire vehicles that meet specific operational needs while maintaining cost efficiency. Real-time market insights enable buyers to anticipate price fluctuations and availability, which is crucial in a sector characterized by dynamic pricing models influenced by raw material costs and production capabilities.

Moreover, the global supply chain landscape is evolving. Buyers are increasingly looking for suppliers with robust logistics networks to ensure timely delivery and support. This is particularly critical for international buyers who may face customs and importation challenges. Understanding these market dynamics will empower B2B buyers to make informed decisions, aligning their purchasing strategies with current trends.

How Is Sustainability and Ethical Sourcing Impacting the Caterpillar Truck Price Sector?

Sustainability is becoming a cornerstone of business operations in the caterpillar truck price sector. The environmental impact of heavy-duty vehicles is under scrutiny, prompting manufacturers and buyers alike to prioritize eco-friendly practices. Ethical sourcing is now a key consideration, with an emphasis on responsible procurement of materials. Buyers are increasingly favoring suppliers who adhere to sustainable practices, which not only helps in reducing their carbon footprint but also enhances their brand reputation.

The adoption of ‘green’ certifications and materials is gaining momentum. Buyers are encouraged to seek suppliers that utilize recycled materials or innovative technologies that minimize emissions during production. Caterpillar, for instance, is positioning itself to meet these demands by investing in sustainable manufacturing processes and exploring alternative energy sources for its vehicles. By aligning purchasing decisions with sustainability goals, B2B buyers can contribute to a more responsible supply chain, which is becoming increasingly important to stakeholders and consumers alike.

Illustrative image related to caterpillar truck price

Furthermore, regulatory pressures in various regions are shaping sourcing trends. In Europe, for example, stringent emissions standards are driving demand for cleaner technologies, influencing the types of vehicles that are brought to market. Buyers must stay informed about these regulations to ensure compliance and leverage potential incentives for sustainable practices.

What Is the Evolution of the Caterpillar Truck Price Sector and Its Relevance to B2B Buyers?

The caterpillar truck price sector has evolved significantly over the decades, transitioning from traditional heavy machinery to advanced, multi-functional vehicles. Caterpillar, known for its dominance in the construction and heavy equipment market, has leveraged its expertise to enter the pickup truck segment, focusing on durability and performance tailored for demanding work environments. This evolution reflects a broader trend in the automotive industry, where manufacturers are increasingly diversifying their product offerings to cater to specific market needs.

Historically, the focus was primarily on functionality and power, but recent advancements have led to the integration of technology and sustainability into vehicle design. This shift is relevant for B2B buyers, as the modern caterpillar truck not only meets the rigorous demands of heavy-duty tasks but also aligns with evolving market expectations regarding environmental responsibility and technological integration.

As the market continues to evolve, B2B buyers are encouraged to stay ahead of these trends to maximize their procurement strategies, ensuring they invest in vehicles that provide long-term value and support their operational goals in a competitive landscape.

Illustrative image related to caterpillar truck price

Frequently Asked Questions (FAQs) for B2B Buyers of caterpillar truck price

1. How do I determine the right Caterpillar truck for my business needs?

To find the right Caterpillar truck, assess your specific operational requirements such as payload capacity, towing needs, and the terrain where the vehicle will operate. Caterpillar trucks are engineered for durability and performance, so consider factors like engine specifications, off-road capabilities, and technology features. Engage with a Caterpillar dealer to discuss your needs and obtain recommendations based on the latest models available, such as the 2025 Caterpillar pickup, which boasts impressive specs for heavy-duty tasks.

2. What factors influence the pricing of Caterpillar trucks?

The price of Caterpillar trucks is influenced by several factors, including the model, specifications, and optional features. Additional costs may arise from shipping, taxes, and dealer fees. The base model of the 2025 Caterpillar pickup is estimated to start around $85,000, with fully-loaded versions exceeding $120,000. Currency fluctuations and import duties can also affect the final price for international buyers, particularly in regions like Africa and South America.

3. How can I verify the credibility of a Caterpillar truck supplier?

To verify a Caterpillar truck supplier’s credibility, check their business history, customer reviews, and industry reputation. Request references from other businesses that have purchased from them and look for certifications or partnerships with Caterpillar. It’s also beneficial to visit their facilities if possible or arrange a video conference to discuss their operations and customer service practices. Engaging in trade fairs can also provide insights into the supplier’s standing in the industry.

4. Are there customization options available for Caterpillar trucks?

Yes, Caterpillar trucks can often be customized to meet specific business needs. Options may include modifications for payload capacity, specialized equipment integration, and unique aesthetic features. Discuss customization options directly with your dealer to ensure that the modifications align with your operational requirements and comply with local regulations. This flexibility can be particularly advantageous for businesses with unique operational demands.

5. What are the typical payment terms when purchasing Caterpillar trucks?

Payment terms for Caterpillar trucks can vary by dealer and region. Common arrangements include upfront payments, financing options, or installment plans. International buyers should clarify payment methods, such as bank transfers or letters of credit, and understand any associated fees. Additionally, ensure that you are aware of currency exchange rates and potential fluctuations that may impact the final transaction amount.

Illustrative image related to caterpillar truck price

6. What are the logistics involved in importing Caterpillar trucks?

Importing Caterpillar trucks involves several logistical steps, including compliance with local regulations, arranging shipping, and managing customs clearance. Buyers must ensure that all necessary documentation, such as import permits and customs declarations, are prepared in advance. Working with a freight forwarder experienced in heavy machinery can streamline this process, ensuring timely delivery and adherence to local laws in regions like the Middle East and Europe.

7. How do I ensure quality assurance when purchasing Caterpillar trucks?

To ensure quality assurance when purchasing Caterpillar trucks, request detailed specifications and performance history for the model you are considering. It’s advisable to conduct a pre-purchase inspection, especially if buying used trucks. Additionally, inquire about the manufacturer’s warranty and service agreements, which can provide further assurance of the vehicle’s reliability and performance over time.

8. What are the minimum order quantities (MOQ) for Caterpillar trucks in B2B transactions?

Minimum order quantities for Caterpillar trucks can vary based on the dealer and the specific model. Typically, larger orders may qualify for discounts or favorable financing options. If you’re a fleet manager or a construction company, discuss your needs with the dealer to explore bulk purchase options, which may also provide better pricing and availability. Being aware of MOQ can help in planning your procurement strategy effectively.

Top 5 Caterpillar Truck Price Manufacturers & Suppliers List

1. Caterpillar – 2025 Pickup Truck

Domain: arkansashunting.net

Registered: 2003 (22 years)

Introduction: 2025 Caterpillar Pickup Truck

– Entry-model powertrain: 5.0-liter turbocharged V8

– Additional variants: Hybrid and EV options

– Starting price: Approximately $40,000 for the base model

– Distinctive design combining rugged functionality with modern styling elements

– Aimed at a broad range of customers, focusing on performance, fuel efficiency, and sustainability.

2. Caterpillar – Articulated Haul Trucks

Domain: purplewave.com

Registered: 2004 (21 years)

Introduction: Caterpillar Articulated Haul Trucks available for auction include models such as 631D, 725, 730, 730C, 730C2, 735, 740, 740B, 745, and 745C. Recent auction prices range from $101,200 for a 2009 Caterpillar 740 to $567,600 for a 2023 Caterpillar 745 articulated scraper truck. The auction results cover various years including 2023, 2024, and 2025, with multiple units available across states like Kan…

3. Caterpillar – Articulated Dump Trucks

Domain: machineryzone.com

Registered: 2001 (24 years)

Introduction: Used and New Caterpillar Articulated Dump Trucks For Sale – MachineryZone. Types of ads: For sale (429), Auctions (16), Urgent ads. Models available: Caterpillar 740B, 740, 730, 725, 745C, 730C, 745, 725C, 735, 735B, 745-04, 730C2, 725C2, D400E, D250E, 740GC, 735C, 740EJ, 740B EJ, 745 TG. Classified ads sorted by Distance, Trade price, Year, Hours, Model, Make. Locations: USA, with specific states…

4. Caterpillar – CT660

Domain: commercialtrucktrader.com

Registered: 2004 (21 years)

Introduction: Caterpillar Trucks For Sale – Commercial Truck Trader

Key Models:

– CT660 (15 listings)

– CT660S (3 listings)

Types of Trucks Available:

– Dump Truck (20)

– Conventional – Day Cab (5)

– Water Truck (4)

– Glider Kit (2)

– Bucket Truck – Boom Truck (1)

– Cab Chassis (1)

– Dually (1)

– Flatbed Truck (1)

– Mixer Truck – Concrete Truck (1)

– Vacuum Truck (1)

– Water Tank (1)

– Wrecker Tow Truck (1)

…

5. Cat® – 745 & 740 GC Articulated Trucks

Domain: gregorypoole.com

Registered: 1996 (29 years)

Introduction: New Cat® Articulated Trucks for Sale in North Carolina. Key models include: 745 Articulated Truck with Cat® C18 engine, rated payload of 45.2 t, heaped capacity of 33.4 yd³, starting from $823,135.64; 740 GC Articulated Truck with Cat® C15 engine, rated payload of 40 ton, heaped capacity of 29.7 yd³; 740 EJ Articulated Truck with Cat® C18 engine, rated payload of 42 ton, heaped capacity of 30.1 yd…

Strategic Sourcing Conclusion and Outlook for caterpillar truck price

In evaluating the strategic sourcing of the 2025 Caterpillar pickup truck, it is essential for international B2B buyers to recognize the vehicle’s unique value proposition. With an expected starting price of $85,000, this truck is designed to meet the rigorous demands of construction and heavy-duty applications. Its robust specifications, including a powerful engine, exceptional towing capacity, and advanced technology features, make it an attractive investment for fleet managers and contractors alike.

Strategic sourcing allows businesses to leverage Caterpillar’s reputation for durability and performance, ensuring that procurement decisions align with operational needs and budget constraints. Buyers from regions such as Africa, South America, the Middle East, and Europe should consider local availability, financing options, and potential for fleet purchases to maximize value.

Illustrative image related to caterpillar truck price

Looking ahead, as the 2025 Caterpillar pickup truck becomes available for pre-order in mid-2025, now is the time for businesses to assess their requirements and engage with local dealers. By acting strategically, organizations can secure a vehicle that not only enhances productivity but also stands the test of time in challenging environments. Embrace this opportunity to elevate your operations with a Caterpillar truck that embodies strength and reliability.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to caterpillar truck price