Unlocking Value: A Strategic Analysis of the Caster Gate Wheel Market

Introduction: Navigating the Global Market for caster gate wheel

In the ever-evolving landscape of global commerce, sourcing high-quality caster gate wheels presents a significant challenge for B2B buyers across diverse markets, particularly in Africa, South America, the Middle East, and Europe. These essential components not only enhance the functionality of gates and barriers but also contribute to operational efficiency and safety in various applications. This comprehensive guide aims to equip international buyers with the knowledge necessary to navigate the complexities of the caster gate wheel market, addressing critical aspects such as types, applications, supplier vetting, and pricing strategies.

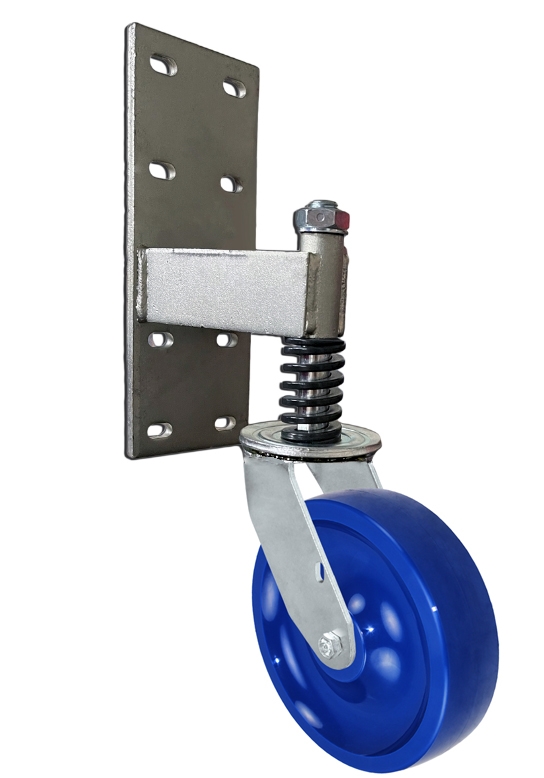

Understanding the distinct features and benefits of different caster gate wheels is crucial for making informed purchasing decisions. From spring-loaded designs that adapt to uneven terrains to heavy-duty options capable of supporting substantial weight, the variety available can be overwhelming. Moreover, the guide offers insights into how to evaluate suppliers effectively, ensuring that you partner with manufacturers who prioritize quality and compliance with international standards.

By exploring this resource, B2B buyers will gain actionable insights into optimizing their procurement processes, enhancing their gate systems, and ultimately driving greater efficiency in their operations. Whether you are looking to upgrade your existing setups or seeking reliable solutions for new projects, this guide serves as an essential tool for making strategic, informed decisions in the global market for caster gate wheels.

Understanding caster gate wheel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Spring-Loaded Gate Casters | Equipped with a spring mechanism for shock absorption | Swing gates, bi-fold gates, metal fence gates | Pros: Enhances gate longevity; suitable for uneven terrain. Cons: May require regular maintenance. |

| Heavy-Duty Gate Casters | High load capacity (up to 700 lbs) with robust construction | Industrial gates, heavy-duty applications | Pros: Durable; supports heavy gates. Cons: Higher initial investment. |

| Pneumatic Gate Casters | Air-filled wheels for enhanced cushioning and traction | Outdoor gates, areas with rough terrain | Pros: Excellent shock absorption; smooth operation. Cons: Prone to punctures. |

| Polyurethane Gate Casters | Durable, non-marking wheels resistant to wear and tear | Commercial and residential gates | Pros: Long-lasting; low rolling resistance. Cons: Limited load capacity compared to heavy-duty options. |

| Locking Spring-Loaded Gate Casters | Features brakes for added security and stability | High-traffic areas, security gates | Pros: Prevents unintentional movement; enhances safety. Cons: More complex installation. |

What are Spring-Loaded Gate Casters and Why Use Them?

Spring-loaded gate casters are designed to maintain a level gate as it rolls over uneven surfaces, absorbing shocks and reducing strain on hinges. Their versatility makes them ideal for a variety of applications, including residential and commercial swing gates, bi-fold gates, and metal fence gates. When sourcing these casters, consider the load capacity and the materials used in construction, as these factors will influence durability and performance, especially in regions with varying terrain.

How Do Heavy-Duty Gate Casters Differ from Standard Options?

Heavy-duty gate casters are engineered for robust performance, capable of supporting loads up to 700 lbs. Their reinforced construction makes them suitable for industrial applications where gates are frequently used or subject to heavy traffic. Buyers should evaluate their specific load requirements and the environment in which the casters will be used, as this will dictate the best choice for long-term reliability and safety.

What Advantages Do Pneumatic Gate Casters Offer?

Pneumatic gate casters feature air-filled wheels, providing superior cushioning and traction on rough terrain. This makes them particularly beneficial for outdoor applications where surfaces may be uneven. However, buyers should be aware of the potential for punctures and ensure that their operational environment minimizes this risk. Regular checks and maintenance will help extend the lifespan of pneumatic casters.

Why Choose Polyurethane Gate Casters?

Polyurethane gate casters are known for their resistance to wear and tear, making them a popular choice for both commercial and residential gates. They offer low rolling resistance, which can enhance maneuverability and reduce physical strain on users. When purchasing, consider the specific application and load requirements, as these casters may not support as much weight as heavy-duty options.

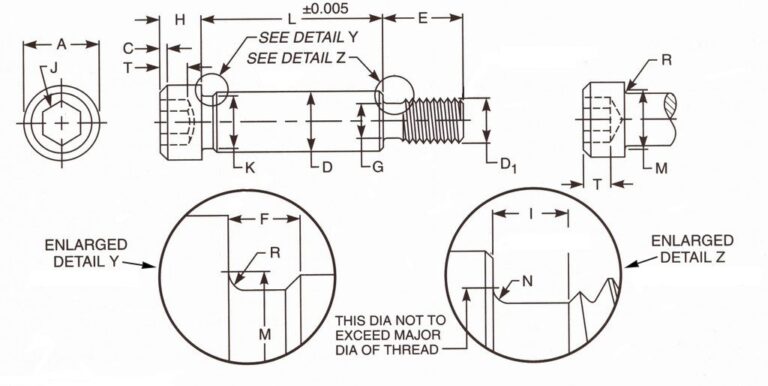

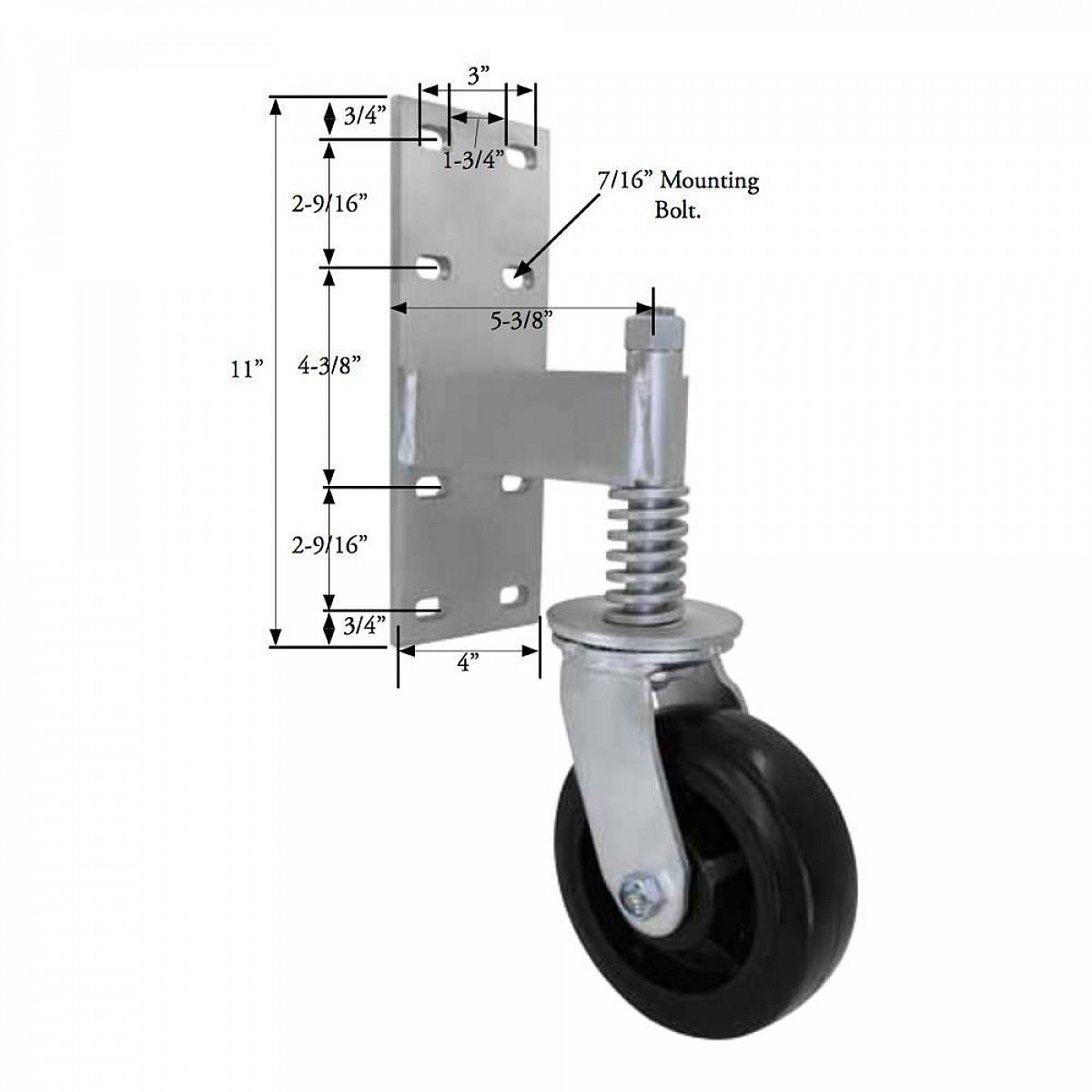

Illustrative image related to caster gate wheel

What are the Benefits of Locking Spring-Loaded Gate Casters?

Locking spring-loaded gate casters combine the shock-absorbing benefits of spring-loaded designs with the added security of brakes. This makes them ideal for high-traffic areas or gates that need to remain stationary when not in use. Buyers should assess the installation complexity and ensure that their gates can accommodate these casters, as the locking mechanism may require additional modifications.

Key Industrial Applications of caster gate wheel

| Industry/Sector | Specific Application of caster gate wheel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Heavy-duty gates for loading docks | Enhances gate maneuverability, reducing downtime. | Load capacity, material durability, and weather resistance. |

| Agriculture | Access gates for livestock pens | Facilitates easy access and minimizes wear on gates. | Terrain adaptability, wheel material for shock absorption. |

| Construction | Site access gates for construction sites | Improves safety and efficiency in site operations. | Customization options for different gate types and weights. |

| Warehousing | Security gates for inventory areas | Increases security while allowing easy access for staff. | Compatibility with existing gate structures and load ratings. |

| Residential & Commercial | Garden and patio gates | Enhances aesthetic appeal and functionality. | Design options, ease of installation, and weather resistance. |

How Are Caster Gate Wheels Used in Manufacturing Environments?

In manufacturing settings, caster gate wheels are essential for heavy-duty gates at loading docks. These wheels enable gates to open and close smoothly, facilitating the movement of goods and reducing downtime. The durability of the wheels is crucial, as they must withstand significant loads and frequent use. International buyers should prioritize sourcing options that offer high load capacities and materials resistant to wear and tear, ensuring long-term performance in diverse conditions.

What Role Do Caster Gate Wheels Play in Agriculture?

In agriculture, caster gate wheels are utilized for access gates in livestock pens and fields. These wheels allow for easy maneuverability, which is vital for farmers needing to transport feed or equipment quickly. The ability to handle uneven terrain is critical, so buyers should look for wheels with shock-absorbing properties. Selecting the right wheel material can also prevent damage to both the gate and the surrounding environment, ensuring operational efficiency.

How Are Caster Gate Wheels Implemented in Construction?

Construction sites often require temporary access gates, and caster gate wheels provide a practical solution. These wheels facilitate the opening and closing of gates, promoting safety and efficiency during site operations. Buyers in this sector should consider customization options, as construction gates vary significantly in size and weight. The ability to adapt to various terrains and conditions is also a key consideration, ensuring that the gates remain functional throughout the project.

Why Are Caster Gate Wheels Important in Warehousing?

In warehousing, caster gate wheels are crucial for securing inventory areas with high-traffic gates. These wheels enhance security while allowing quick access for staff, streamlining operations. Buyers should focus on compatibility with existing gate structures and ensure that the wheels can handle the expected load ratings. The choice of materials is also significant, as they must be robust enough to withstand the warehouse environment, including exposure to moisture and heavy equipment.

What Benefits Do Caster Gate Wheels Offer for Residential and Commercial Applications?

In residential and commercial settings, caster gate wheels are commonly used for garden and patio gates. They improve both the aesthetic appeal and functionality of outdoor spaces, making it easier for homeowners and businesses to manage access. Buyers should consider design options that align with their property styles and prioritize ease of installation. Weather resistance is another important factor, as these gates are exposed to the elements, impacting their longevity and performance.

Illustrative image related to caster gate wheel

3 Common User Pain Points for ‘caster gate wheel’ & Their Solutions

Scenario 1: Difficulty in Ensuring Smooth Gate Operation on Uneven Surfaces

The Problem: Many B2B buyers encounter the challenge of installing gate systems in environments with uneven terrain. This scenario is common in outdoor settings, such as agricultural fields or warehouses, where gates are subjected to rough surfaces. As a result, gates may drag or become misaligned, causing operational inefficiencies and increasing wear on gate structures. Buyers often struggle to find a reliable solution that allows gates to open and close smoothly, which can lead to frustrations and additional maintenance costs.

The Solution: To overcome this challenge, sourcing high-quality spring-loaded caster gate wheels is essential. These casters are designed to absorb shocks and adjust to uneven surfaces, ensuring that the gates remain level during operation. When selecting caster wheels, consider those made from durable materials like polyurethane or rubber, which provide excellent grip and shock absorption. Additionally, opting for casters with a higher load capacity will accommodate heavier gates without compromising performance. Ensure proper installation by following manufacturer guidelines and regularly inspecting the casters for wear. This proactive approach will significantly enhance gate functionality and longevity.

Scenario 2: Frequent Gate Sagging Leading to Operational Issues

The Problem: Gate sagging is a prevalent issue for many businesses, especially those managing heavy gates in industrial settings. Over time, the weight of the gate can cause it to droop, resulting in misalignment with the latch or locking mechanism. This not only complicates the opening and closing process but can also pose security risks, as gates may not close properly. B2B buyers often find themselves dealing with increased maintenance efforts and potential safety hazards due to this issue.

The Solution: The installation of heavy-duty caster gate wheels is a practical solution to mitigate sagging. These casters, particularly those with a spring-loaded mechanism, provide necessary support and stability to the gate structure. When selecting the right casters, it’s crucial to match the load capacity to the weight of the gate, ensuring optimal performance. Consider casters with adjustable height features to fine-tune the alignment as needed. Regular maintenance checks should include inspecting the caster wheels for any signs of wear or damage, which can exacerbate sagging issues. By investing in quality casters and adhering to a maintenance schedule, businesses can maintain gate functionality and security effectively.

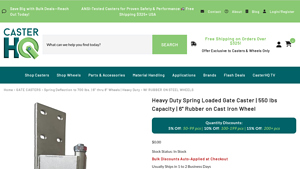

Illustrative image related to caster gate wheel

Scenario 3: Noise and Friction Disrupting Work Environments

The Problem: In industrial or commercial settings, noise can be a significant distraction, affecting productivity and worker comfort. Gates that operate with standard casters may generate excessive noise due to friction as they move, leading to a disruptive environment. B2B buyers often seek solutions that not only enhance functionality but also contribute to a quieter workspace.

The Solution: Selecting precision-engineered caster gate wheels can address the noise issue effectively. Casters equipped with high-quality ball bearings reduce friction, allowing for smoother and quieter operation. When sourcing these wheels, prioritize those designed for low rolling resistance and minimal debris retention, which can contribute to noise. Additionally, consider casters with shock-absorbing features that dampen vibrations during movement. Implementing regular cleaning and maintenance routines will also help prevent debris buildup that can lead to increased noise and friction. By focusing on quality and maintenance, businesses can create a more pleasant working atmosphere while ensuring efficient gate operation.

Strategic Material Selection Guide for caster gate wheel

What Are the Key Properties of Common Materials Used in Caster Gate Wheels?

When selecting materials for caster gate wheels, it is essential to consider the specific properties that impact performance under various conditions. Here, we analyze four common materials: rubber, polyurethane, cast iron, and stainless steel. Each material presents unique characteristics that can significantly influence the functionality and durability of caster gate wheels.

How Does Rubber Perform in Caster Gate Wheel Applications?

Rubber is widely used in caster gate wheels due to its excellent shock-absorbing properties and flexibility. Key properties include a good temperature range, typically from -30°F to 180°F, and moderate pressure resistance. Rubber is also resistant to wear and provides a non-marking surface, making it suitable for indoor applications.

Pros: Rubber wheels offer durability and a smooth, quiet operation. They are cost-effective and easy to manufacture, making them a popular choice for various applications.

Cons: However, rubber can degrade over time when exposed to UV light or extreme temperatures, limiting its outdoor applicability. Additionally, rubber wheels may not support heavy loads effectively.

Impact on Application: Rubber wheels are ideal for residential gates and light commercial applications where noise reduction and shock absorption are crucial.

Considerations for International Buyers: Buyers should ensure compliance with local standards, such as ASTM or DIN, especially in regions with varying climate conditions.

What Advantages Does Polyurethane Offer for Caster Gate Wheels?

Polyurethane is increasingly favored for caster gate wheels due to its superior abrasion resistance and load-bearing capabilities. This material can handle a temperature range of -40°F to 200°F and has excellent chemical resistance.

Pros: Polyurethane wheels combine the benefits of rubber and plastic, providing a durable, long-lasting option that can support heavier loads. They also maintain a quieter operation than harder materials.

Cons: The manufacturing process for polyurethane can be more complex and costly compared to rubber. Additionally, while they are more resistant to outdoor conditions, they can still be susceptible to certain chemicals.

Impact on Application: These wheels are well-suited for industrial gates and environments where chemical exposure is a concern.

Illustrative image related to caster gate wheel

Considerations for International Buyers: Compliance with international standards is critical, particularly in industries with strict safety regulations. Buyers should also consider the availability of polyurethane in their region.

Why Choose Cast Iron for Heavy-Duty Caster Gate Wheels?

Cast iron is often used for heavy-duty applications due to its strength and durability. With a high load capacity, cast iron wheels can withstand significant pressure and are often used in environments where heavy gates are common.

Pros: Cast iron wheels are robust and can handle extreme loads, making them ideal for industrial applications. They are also relatively low-cost compared to other heavy-duty materials.

Cons: The major drawback is that cast iron is prone to rust and corrosion, particularly in humid or wet environments. This limits its suitability for outdoor use unless properly treated.

Illustrative image related to caster gate wheel

Impact on Application: Cast iron wheels are best suited for heavy industrial gates and environments where durability is paramount.

Considerations for International Buyers: Buyers in humid regions should prioritize corrosion-resistant treatments or coatings. Compliance with relevant standards is also essential.

How Does Stainless Steel Compare in Caster Gate Wheel Materials?

Stainless steel is renowned for its corrosion resistance and strength, making it an excellent choice for environments exposed to moisture or chemicals. It typically withstands temperatures up to 1,500°F, providing versatility in various applications.

Pros: Stainless steel wheels offer exceptional durability and longevity, making them suitable for both indoor and outdoor applications. They are easy to clean and maintain.

Illustrative image related to caster gate wheel

Cons: The main disadvantage is the higher cost associated with stainless steel compared to other materials. Additionally, they can be heavier, which may not be ideal for all applications.

Impact on Application: Stainless steel wheels are ideal for gates in food processing plants, chemical facilities, or any environment where hygiene and corrosion resistance are critical.

Considerations for International Buyers: Buyers should verify compliance with international standards, especially in industries where safety and hygiene are paramount.

Summary Table of Material Selection for Caster Gate Wheels

| Material | Typical Use Case for Caster Gate Wheel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Rubber | Residential gates | Excellent shock absorption | Degrades under UV exposure | Low |

| Polyurethane | Industrial gates | High abrasion resistance | Higher manufacturing complexity | Medium |

| Cast Iron | Heavy-duty industrial gates | Exceptional load capacity | Prone to rust without treatment | Low |

| Stainless Steel | Food processing or chemical facilities | Corrosion resistance | Higher cost | High |

This guide provides a comprehensive overview of materials for caster gate wheels, enabling B2B buyers to make informed decisions based on their specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for caster gate wheel

What Are the Main Stages in the Manufacturing Process of Caster Gate Wheels?

The manufacturing process of caster gate wheels involves several key stages that ensure the final product meets industry standards and customer requirements. Understanding these stages can help B2B buyers identify quality suppliers and make informed purchasing decisions.

Material Preparation: What Materials Are Commonly Used?

The first step in manufacturing caster gate wheels is material preparation. Common materials include rubber, polyurethane, and metal (such as cast iron or steel). Each material offers distinct advantages—rubber provides excellent shock absorption, while metal components enhance durability and load-bearing capacity.

Manufacturers often source raw materials from reputable suppliers, ensuring they comply with international quality standards. This phase may also involve the inspection of materials for defects, which is crucial for maintaining product integrity.

How Are Caster Gate Wheels Formed?

Once materials are prepared, the next stage is forming. This can involve several techniques, including molding, machining, and welding.

-

Molding: For rubber and polyurethane wheels, molding is the predominant method. The raw material is heated and shaped into the desired wheel form using molds. This technique allows for mass production and consistent quality.

-

Machining: For metal components, machining processes like turning or milling are used to achieve precise dimensions. This is essential for ensuring that parts fit together seamlessly during assembly.

-

Welding: In cases where metal components need to be joined, welding techniques ensure strong, durable connections.

Each of these methods requires skilled labor and precise machinery, contributing to the overall quality of the final product.

What Does the Assembly Process Entail?

After forming, the assembly stage brings together all the components of the caster gate wheel. This includes attaching the wheel to the mounting bracket and integrating any additional features such as springs or locking mechanisms.

Quality manufacturers often employ automated assembly lines to enhance efficiency and consistency. Additionally, manual assembly may be used for complex designs requiring meticulous attention to detail.

What Finishing Techniques Are Commonly Applied?

Finishing processes enhance the aesthetic and functional qualities of caster gate wheels. Common techniques include painting, coating, or polishing to improve corrosion resistance and appearance.

Manufacturers may also conduct surface treatments, such as galvanization for metal parts, to further protect against wear and tear. These finishing touches not only improve the product’s lifespan but also increase its market appeal.

How Is Quality Assurance Implemented in Caster Gate Wheel Manufacturing?

Quality assurance is a critical aspect of the manufacturing process, ensuring that products meet specified standards before they reach the market. For B2B buyers, understanding the quality control measures in place can help assess supplier reliability.

What International Standards Should B2B Buyers Look For?

Manufacturers often adhere to international standards such as ISO 9001, which outlines criteria for a quality management system. Compliance with these standards indicates that a manufacturer is committed to quality and continuous improvement.

In addition to ISO certifications, industry-specific certifications such as CE (Conformité Européenne) for products sold in Europe or API (American Petroleum Institute) for products used in the petroleum sector may also be relevant. These certifications assure buyers that the products have been rigorously tested and comply with regulatory requirements.

Illustrative image related to caster gate wheel

What Are the Key Quality Control Checkpoints?

Quality control (QC) typically involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): At this stage, raw materials are inspected upon arrival to ensure they meet specified quality standards. This step is vital for preventing defects in the final product.

-

In-Process Quality Control (IPQC): During manufacturing, various checks are performed to monitor the production process. This may include verifying dimensions, material properties, and assembly integrity at different stages.

-

Final Quality Control (FQC): Before products are shipped, they undergo final inspections to ensure they meet all specifications. This may include functionality tests, load capacity assessments, and visual inspections for defects.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers looking to ensure the quality of caster gate wheels should consider several strategies:

-

Supplier Audits: Conducting on-site audits of potential suppliers allows buyers to assess their manufacturing processes, quality control measures, and adherence to international standards. This firsthand insight is invaluable for making informed decisions.

-

Requesting Quality Reports: Suppliers should be able to provide documentation of their quality control processes, including test results and compliance certificates. Reviewing these reports can provide additional assurance of product quality.

-

Engaging Third-Party Inspectors: For larger orders, hiring third-party inspection services can provide unbiased evaluations of product quality. These inspectors can conduct random checks and provide detailed reports on compliance with specifications.

What Are the Quality Control Nuances for International B2B Buyers?

For international buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential. Different regions may have varying standards and regulations that affect product quality and compliance.

-

Cultural Differences: Buyers should be aware of the cultural differences in business practices that may impact communication and negotiation regarding quality expectations.

-

Regulatory Compliance: Understanding the specific regulatory requirements in their own countries can help buyers ensure that imported products meet local laws. This is especially important in industries where safety and compliance are critical.

-

Supply Chain Considerations: Buyers should consider the reliability of the entire supply chain, including logistics and transportation, as these factors can also impact product quality upon arrival.

By grasping the intricacies of the manufacturing and quality assurance processes for caster gate wheels, B2B buyers can make more informed decisions, ensuring they partner with suppliers that meet their quality standards and operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘caster gate wheel’

To assist international B2B buyers in sourcing caster gate wheels effectively, this guide offers a detailed checklist. By following these steps, you can ensure that your procurement process is thorough and aligned with your operational needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential for selecting the right caster gate wheels. Consider factors such as load capacity, wheel diameter, tread material, and spring mechanism. For instance, if your gates will be exposed to uneven terrain, opt for spring-loaded casters that can adapt to varying surfaces.

- Load Capacity: Determine the maximum weight the caster will support.

- Wheel Material: Choose from options like rubber or polyurethane based on durability and environmental conditions.

Step 2: Identify Application Requirements

Understand the specific applications for which the caster gate wheels will be used. Different environments, such as industrial, commercial, or residential settings, may require unique features.

- Indoor vs. Outdoor Use: Wheels for outdoor gates should be weather-resistant.

- Gate Type Compatibility: Ensure that the casters are suitable for swing, bi-fold, or sliding gates.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct a thorough evaluation. Request company profiles, product catalogs, and references from similar industries or regions to gauge their reliability and expertise.

- Supplier Reputation: Look for reviews and testimonials from other B2B clients.

- Product Range: A supplier with a diverse product range can better accommodate your specific needs.

Step 4: Request Samples for Testing

Once you have shortlisted potential suppliers, request samples to assess their products firsthand. Testing the casters in your operational environment will help you evaluate their performance under real conditions.

- Performance Assessment: Check for smooth operation, load handling, and durability.

- Compatibility Check: Ensure the samples fit your gate structures without modification.

Step 5: Verify Compliance and Certifications

Ensure that the caster gate wheels meet relevant industry standards and certifications. Compliance with safety and quality regulations is crucial for maintaining operational integrity.

- Quality Assurance: Verify if the supplier adheres to ISO standards or equivalent.

- Safety Certifications: Check for certifications that ensure the products are safe for use in your intended applications.

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, engage in negotiations regarding pricing, delivery schedules, and payment terms. Establishing clear agreements will help prevent misunderstandings later.

- Bulk Discounts: Inquire about pricing tiers for larger orders.

- Lead Times: Confirm delivery timelines to ensure they align with your project schedules.

Step 7: Plan for Long-Term Support and Maintenance

Finally, consider the long-term support and maintenance aspects of your caster gate wheels. Establish a relationship with your supplier for ongoing service and parts availability.

- Maintenance Guidelines: Request information on how to maintain the casters for optimal performance.

- Warranty Terms: Understand the warranty coverage for your purchased products.

By following this structured checklist, B2B buyers can make informed decisions when sourcing caster gate wheels, ensuring they select products that meet their operational needs and enhance efficiency.

Illustrative image related to caster gate wheel

Comprehensive Cost and Pricing Analysis for caster gate wheel Sourcing

What Are the Key Cost Components in Sourcing Caster Gate Wheels?

When sourcing caster gate wheels, understanding the cost structure is essential for making informed purchasing decisions. The primary components influencing costs include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the supplier’s profit margin.

-

Materials: The choice of materials significantly impacts the cost. Common options like rubber and polyurethane offer varying levels of durability and performance. For instance, rubber wheels may be more affordable but might not withstand heavy loads compared to polyurethane options, which can increase upfront costs but offer better longevity.

-

Labor: Labor costs are influenced by the region of production. Countries with lower labor costs may provide a price advantage, but this can sometimes compromise quality. Understanding the labor market in the supplier’s location is crucial for evaluating total costs.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and equipment maintenance. Suppliers with efficient production processes may offer better pricing due to lower overheads.

-

Tooling: Customization often requires specific tooling, which can be a significant upfront cost. Buyers should consider whether the supplier has the necessary tooling capabilities or if they will incur additional charges for custom designs.

-

Quality Control: Ensuring product quality through rigorous QC processes can add to costs. However, investing in quality control can reduce long-term expenses by minimizing defects and returns.

-

Logistics: Shipping costs can vary based on the mode of transport, distance, and Incoterms. International buyers need to consider these factors as they can significantly affect the final price.

-

Margin: Suppliers will typically mark up their prices to ensure profitability. Understanding a supplier’s pricing strategy can help buyers negotiate better deals.

How Do Price Influencers Affect Caster Gate Wheel Costs?

Several factors can influence the pricing of caster gate wheels beyond the basic cost components.

-

Volume and Minimum Order Quantity (MOQ): Purchasing in bulk often leads to discounts. Suppliers typically offer tiered pricing structures that incentivize larger orders, which can significantly lower the per-unit cost.

-

Specifications and Customization: Custom specifications can lead to higher costs due to additional tooling and production complexities. Buyers should weigh the necessity of custom features against the potential price increase.

-

Quality and Certifications: Products meeting specific industry certifications may come at a premium. However, these certifications can enhance product reliability and safety, which may justify the higher costs.

-

Supplier Factors: The supplier’s reputation, manufacturing capabilities, and customer service can influence pricing. Established suppliers with a track record of quality may charge more, but the assurance of reliability can be worth the investment.

-

Incoterms: Understanding the shipping and delivery terms outlined by Incoterms is crucial. These terms dictate who bears the costs and risks associated with shipping, which can significantly impact the total cost of ownership.

What Tips Can Help Buyers Negotiate Better Prices for Caster Gate Wheels?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, effective negotiation and strategic sourcing can lead to significant savings.

-

Negotiate Terms: Always engage in negotiations regarding price, payment terms, and delivery schedules. Suppliers may be open to adjusting prices based on order size or payment upfront.

-

Focus on Total Cost of Ownership: Consider not only the purchase price but also the long-term costs associated with the caster wheels, including maintenance, replacement, and operational efficiency.

-

Research Market Prices: Understanding market trends and competitor pricing can provide leverage during negotiations. Be informed about pricing variations based on regions and quality.

-

Build Relationships: Establishing a strong relationship with suppliers can lead to better terms and pricing. Suppliers are often more willing to negotiate with repeat customers or those who demonstrate loyalty.

-

Consider Local Suppliers: Sourcing from local suppliers can sometimes reduce shipping costs and lead times, making it a more cost-effective option.

Disclaimer on Pricing

Pricing for caster gate wheels is highly variable and subject to change based on market conditions, supplier dynamics, and specific buyer requirements. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing caster gate wheel With Other Solutions

Introduction to Alternative Solutions for Gate Mobility

When considering mobility solutions for gates, businesses often face the challenge of selecting the most efficient and cost-effective option. Caster gate wheels are widely recognized for their ability to facilitate smooth gate operation, but several alternative solutions exist that can achieve similar goals. This analysis will compare caster gate wheels with two viable alternatives: pneumatic wheels and sliding gate tracks. Each option has its unique features and applications, making it essential for B2B buyers to understand their differences.

Illustrative image related to caster gate wheel

Comparison Table

| Comparison Aspect | Caster Gate Wheel | Pneumatic Wheels | Sliding Gate Tracks |

|---|---|---|---|

| Performance | Excellent for uneven surfaces | Superior shock absorption | Smooth operation on level surfaces |

| Cost | Moderate (varies by load capacity) | Generally higher due to material costs | Initial installation may be high |

| Ease of Implementation | Easy to install on various gates | Requires precise mounting and alignment | Complex installation requiring tracks |

| Maintenance | Low; occasional lubrication needed | Moderate; check for air pressure | Low; minimal upkeep once installed |

| Best Use Case | Residential and light to medium duty | Heavy-duty gates and outdoor conditions | Commercial and industrial sliding gates |

Detailed Breakdown of Alternatives

Pneumatic Wheels

Pneumatic wheels are designed for maximum shock absorption, making them ideal for heavy-duty applications where uneven terrain is prevalent. The air-filled design allows for flexibility and resilience, which can help to prevent damage to both the gate and the surrounding structures. However, they tend to be more expensive than traditional caster wheels due to the material costs and may require regular maintenance checks for air pressure. Businesses that operate in rugged environments or require frequent gate mobility may find pneumatic wheels to be a suitable option, despite the higher initial investment.

Sliding Gate Tracks

Sliding gate tracks provide a robust solution for larger gates that require a smooth and stable operation. This system allows gates to glide along a fixed path, minimizing the wear and tear associated with dragging on the ground. While sliding gate tracks can be more costly to install initially, they require minimal maintenance once in place. This makes them an excellent choice for commercial and industrial applications where durability and longevity are critical. However, they may not be suitable for all settings, particularly in areas with uneven surfaces where tracks cannot be laid effectively.

Conclusion: Choosing the Right Solution for Your Needs

When selecting a mobility solution for gates, B2B buyers should carefully evaluate their specific operational requirements. Caster gate wheels are highly versatile and offer a balance between performance and cost, making them ideal for light to medium-duty applications. Alternatively, pneumatic wheels are better suited for heavy-duty needs, while sliding gate tracks excel in commercial environments with a focus on durability and minimal maintenance. By assessing factors such as terrain, load requirements, and budget, buyers can make an informed decision that aligns with their operational objectives and enhances their gate functionality.

Essential Technical Properties and Trade Terminology for caster gate wheel

What Are the Key Technical Properties of Caster Gate Wheels?

When selecting caster gate wheels for various applications, it is crucial for B2B buyers to understand specific technical properties that determine performance, durability, and suitability for their intended use. Here are some essential specifications:

-

Material Composition

Caster gate wheels are primarily made from materials such as rubber, polyurethane, or nylon. Rubber offers excellent shock absorption, making it ideal for uneven terrains, while polyurethane provides durability and resistance to wear. Understanding material properties helps in selecting the right wheel for specific environments, such as outdoor gates exposed to harsh weather or indoor settings requiring minimal noise. -

Load Capacity

Each caster wheel is rated for a specific load capacity, typically ranging from light to heavy-duty classifications. For example, a heavy-duty caster may support loads exceeding 1,500 lbs, making it suitable for industrial applications. Buyers must assess the weight of the gates and any additional forces they may encounter to ensure the selected caster can handle the load without compromising safety or performance. -

Wheel Diameter and Width

The diameter and width of the wheel significantly influence maneuverability and stability. A larger diameter wheel can roll over obstacles more easily, while a wider wheel provides greater surface area, distributing weight more evenly. This is particularly important for gates that operate on uneven ground or require frequent use, as it enhances both performance and longevity. -

Spring Mechanism

Many caster gate wheels feature a spring-loaded design that allows for vertical deflection. This mechanism absorbs shocks and helps maintain the gate’s level during operation, preventing sagging and enhancing the gate’s lifespan. Buyers should consider whether their gates will encounter rough surfaces, as spring-loaded casters can significantly improve functionality. -

Mounting Options

Different mounting configurations, such as plate mounts or stem mounts, determine how easily a caster can be installed or replaced. Standardized mounting options facilitate compatibility with various gate types and materials. Understanding mounting specifications helps streamline installation processes and reduces potential downtime during upgrades or repairs. -

Noise and Debris Retention

Caster wheels designed with low rolling resistance and noise-reducing features contribute to a quieter operation, which is particularly beneficial in residential or commercial settings. Additionally, non-marking wheels help prevent scuffing on floors and minimize maintenance needs. Evaluating these features can lead to long-term cost savings and improved user experience.

What Are Common Trade Terms Related to Caster Gate Wheels?

Familiarity with industry terminology is vital for B2B buyers to navigate purchasing processes effectively. Here are several key terms frequently encountered in the caster wheel industry:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products that are sold under another company’s brand name. Understanding OEM relationships is important for buyers seeking quality assurance and reliability in their caster wheel selections. -

MOQ (Minimum Order Quantity)

MOQ signifies the minimum quantity of a product that a supplier is willing to sell. It is crucial for buyers to know this figure to manage inventory levels and ensure they are meeting supplier requirements without overcommitting resources. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price offers for specific products. For B2B buyers, issuing an RFQ can facilitate competitive pricing and help secure favorable terms for bulk purchases of caster gate wheels. -

Incoterms (International Commercial Terms)

These are internationally recognized rules that define the responsibilities of buyers and sellers in shipping agreements. Familiarity with Incoterms helps buyers understand shipping costs, risks, and obligations, which is essential when sourcing products from global suppliers. -

Load Rating

This term indicates the maximum weight a caster can safely support. It is vital for buyers to match the load rating with their specific application to ensure safety and functionality. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the product. Understanding lead times is crucial for project planning and inventory management, particularly for businesses that rely on timely deliveries to maintain operations.

By grasping these technical specifications and trade terms, B2B buyers can make informed decisions when sourcing caster gate wheels, ultimately enhancing operational efficiency and reducing costs.

Navigating Market Dynamics and Sourcing Trends in the caster gate wheel Sector

What Are the Key Market Trends Influencing the Caster Gate Wheel Sector?

The global caster gate wheel market is witnessing significant growth driven by various factors, including increased industrial automation, the rise of e-commerce, and a growing emphasis on efficient logistics and material handling. In regions like Africa, South America, the Middle East, and Europe, the demand for gate casters is rising due to urbanization and infrastructure development. Specifically, countries like Saudi Arabia and Vietnam are focusing on enhancing their logistics capabilities, which directly correlates with the need for high-quality caster solutions.

Emerging technologies are reshaping sourcing trends within the sector. The integration of IoT (Internet of Things) in industrial applications allows for real-time monitoring of caster performance and load management, which improves operational efficiency. Additionally, digital procurement platforms are gaining traction, enabling international buyers to access a wider range of suppliers and products while comparing prices and quality easily.

Market dynamics are further influenced by customization demands. Buyers are increasingly seeking tailored solutions to meet specific operational needs, leading manufacturers to offer a variety of wheel materials, sizes, and load capacities. The versatility of caster gate wheels is also being recognized in non-traditional applications, expanding their market reach. As buyers prioritize performance and reliability, manufacturers are focusing on developing durable products that can withstand harsh conditions, particularly in outdoor settings.

How Can Sustainability and Ethical Sourcing Impact the Caster Gate Wheel Market?

Sustainability is becoming a pivotal concern in the caster gate wheel market. As environmental regulations tighten globally, B2B buyers are increasingly prioritizing products that minimize ecological footprints. This shift is prompting manufacturers to adopt sustainable materials, such as recycled rubber and eco-friendly polyurethane, that not only meet performance standards but also appeal to environmentally conscious buyers.

The importance of ethical supply chains cannot be overstated. Buyers are now more inclined to partner with suppliers who demonstrate transparency in their sourcing processes and labor practices. This includes ensuring that raw materials are sourced responsibly, thereby reducing the environmental impact associated with production. Certifications such as ISO 14001 for environmental management and products labeled with ‘green’ certifications are becoming critical factors in the purchasing decision process.

Furthermore, the adoption of lifecycle assessment tools is helping manufacturers and buyers understand the environmental impacts of caster products throughout their lifespan. By focusing on sustainability and ethical sourcing, companies can enhance their brand reputation, attract a loyal customer base, and potentially benefit from cost savings through efficient resource use.

What Is the Brief Evolution of the Caster Gate Wheel Industry?

The evolution of the caster gate wheel industry can be traced back to the early days of industrialization, where the need for mobility in heavy machinery and equipment emerged. Initially, casters were rudimentary, primarily made from wood or basic metals, lacking the advanced engineering seen today. As industries evolved, so did the demand for more durable and efficient caster solutions.

In the mid-20th century, the introduction of synthetic materials like polyurethane revolutionized the caster market, providing enhanced durability and shock absorption capabilities. The late 20th and early 21st centuries saw a shift towards specialization, with manufacturers developing various types of gate casters tailored for specific applications, including residential, commercial, and industrial uses.

Today, the caster gate wheel sector is characterized by innovation, with an increasing focus on performance, customization, and sustainability. As technology continues to advance, the sector is poised for further growth, driven by the demands of a globalized market and the need for efficient mobility solutions across various industries.

Frequently Asked Questions (FAQs) for B2B Buyers of caster gate wheel

-

How do I solve sagging gate issues with caster wheels?

To address sagging gate issues, consider using heavy-duty spring-loaded gate casters. These casters feature a shock-absorbing design that adjusts to uneven surfaces, allowing the gate to maintain an even height as it opens and closes. Ensure the caster’s load capacity matches your gate’s weight, and opt for materials like rubber or polyurethane for better shock absorption. Proper installation on the gate’s mounting plate will also enhance functionality and durability, reducing the need for frequent repairs. -

What is the best caster gate wheel for outdoor applications?

For outdoor applications, select caster gate wheels made from durable materials like solid rubber or polyurethane, as they provide excellent weather resistance and shock absorption. A spring-loaded design is crucial for adapting to uneven terrain, ensuring smooth operation. Heavy-duty options with a load capacity of 550 lbs or more are recommended for larger gates. Additionally, consider non-marking wheels to prevent damage to surfaces and reduce maintenance costs. -

How can I customize caster wheels for specific gate requirements?

Customization options for caster wheels typically include selecting the wheel diameter, tread material, and load capacity. Many suppliers offer bespoke solutions to accommodate unique gate designs or operational needs. When discussing customization with suppliers, provide detailed specifications, including the weight of the gate, surface conditions, and desired wheel features. This will help ensure the caster wheels meet your operational requirements effectively. -

What are the minimum order quantities (MOQs) for caster gate wheels?

Minimum order quantities for caster gate wheels can vary significantly between suppliers. Typically, MOQs range from 10 to 100 units, depending on the product type and customization requirements. Some suppliers may offer discounts for larger orders, which can be beneficial for businesses looking to stock up. It’s advisable to discuss your needs with potential suppliers to understand their MOQ policies and explore possible negotiation options. -

What payment terms should I expect when sourcing caster gate wheels internationally?

Payment terms for international orders of caster gate wheels usually include options like advance payment, partial payment before shipping, or payment upon delivery. Common methods include bank transfers, letters of credit, or online payment platforms. It’s essential to review the supplier’s payment policies and ensure they align with your financial practices. Establishing clear terms upfront can help avoid misunderstandings and facilitate smoother transactions. -

How do I ensure quality assurance for caster gate wheels?

To ensure quality assurance, request samples before placing a large order to evaluate the caster wheels’ performance and durability. Additionally, inquire about the supplier’s quality control processes, certifications, and warranty policies. It’s beneficial to review customer feedback and case studies to gauge the supplier’s reliability. Establishing a clear agreement on quality standards and conducting regular inspections can further enhance confidence in the product’s quality. -

What logistics considerations should I keep in mind when sourcing caster wheels internationally?

When sourcing caster wheels internationally, consider shipping methods, delivery times, and customs regulations. Opt for suppliers who provide detailed shipping options, including freight forwarding services. It’s crucial to factor in lead times for manufacturing and shipping, especially if you have tight deadlines. Additionally, understanding import duties and taxes in your country can help manage costs effectively and avoid unexpected expenses. -

How do I vet suppliers for caster gate wheels?

To vet suppliers for caster gate wheels, conduct thorough research by checking their credentials, industry experience, and customer reviews. Request references from previous clients to assess their reliability and product quality. Additionally, consider suppliers who provide transparency regarding their manufacturing processes and quality control measures. Engaging in direct communication can also help you evaluate their responsiveness and willingness to address your specific needs.

Top 5 Caster Gate Wheel Manufacturers & Suppliers List

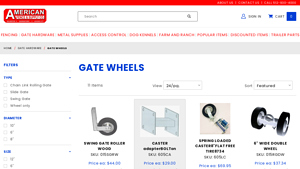

1. Caster Connection – Spring-Loaded Gate Casters

Domain: casterconnection.com

Registered: 1999 (26 years)

Introduction: {“Caster Type”:”Spring-Loaded Gate Caster”,”Wheel Diameter”:[“3 inch”,”4 inch”,”6 inch”],”Wheel Material”:”Rubber”,”Wheel Width”:[“1 inch”,”1-1/4 inch”,”2 inch”],”Fork Finish”:”Zinc Plated”,”Weight Capacity Range”:[“50 – 250 lbs.”,”501 – 1,000 lbs.”],”Color”:”Black”,”Core Material”:”Cast Iron”,”Tread Style”:”Flat Tread”,”Wheel Configuration”:”Single Wheel”,”Application”:”Gates/Sliding Doors”}

2. Mapp Caster – Casters & Wheels for Gates

Domain: mappcaster.com

Registered: 1997 (28 years)

Introduction: Casters & Wheels for Sliding Gates & Swinging Gates – Mapp Caster offers a variety of casters and wheels categorized by duty ratings: Light Duty (up to 350 lbs), Medium Duty (up to 1,500 lbs), and Heavy Duty (up to 40,000 lbs). Types include Track Casters, Stem Casters (all stem types), Stainless Steel, Pneumatic, High Temp (up to 550 ˚F), Metric, Leveling, and Spring Loaded Wheels. Wheel types av…

3. Caster HQ – Heavy Duty Spring Loaded Gate Caster

Domain: casterhq.com

Registered: 2017 (8 years)

Introduction: {“Product Name”: “Heavy Duty Spring Loaded Gate Caster”, “Load Capacity”: “550 lbs”, “Wheel Diameter”: “6 inches”, “Tread Width”: “2 inches”, “Wheel Material”: “Rubber on Cast Iron”, “Rotating Space”: “6-1/2 inches”, “Spring Deflection Range”: “180-700 lbs”, “Overall Mounting Plate Size”: “4 x 11 inches”, “Bolt Size”: “7/16 inches”, “Bolt Hole Patterns”: “1-7/8 x 2-9/16 & 4-3/8 x 9-1/2”, “Price”: …

4. Source 4 Industries – Gate Casters

Domain: source4industries.com

Registered: 1998 (27 years)

Introduction: Gate casters are essential for smooth operation of gates, providing mobility and support. They are designed to handle various gate weights and sizes, ensuring durability and stability. Available in different materials and styles, these casters can accommodate both residential and commercial applications. Key features include easy installation, adjustable height, and corrosion resistance. Ideal for…

5. Afence – Swing Gate Roller Wood

Domain: afence.com

Registered: 1997 (28 years)

Introduction: Products available: 1. SWING GATE ROLLER WOOD – SKU: 015SGRW, Price: $44.00 2. CASTER adapterBOLTon – SKU: 605CA, Price: $29.00 3. SPRING LOADED CASTER 8″ FLAT FREE TIRE 8734 – SKU: 605LC, Price: $69.95 4. 6″ WIDE DOUBLE WHEEL – SKU: 015RGDW, Price: $37.34 5. 12″ WIDE DOUBLE WHEEL – SKU: 015RGDW12, Price: $53.90 6. 10″ SOLID DOUBLE ROLLER ASSEMBLY – SKU: 015ATR, Price: $101.22 7. CANTILEVER WHEEL …

Strategic Sourcing Conclusion and Outlook for caster gate wheel

In the competitive landscape of global sourcing, strategic procurement of caster gate wheels emerges as a critical factor for enhancing operational efficiency and durability. Key takeaways include the importance of selecting high-quality materials—such as rubber or polyurethane for shock absorption—and ensuring that the casters are designed for specific applications, whether for residential, commercial, or industrial use. By investing in durable, spring-loaded gate casters, businesses can mitigate maintenance costs and extend the lifespan of their gates, ultimately leading to improved workflow and reduced downtime.

As B2B buyers from regions like Africa, South America, the Middle East, and Europe evaluate their sourcing strategies, it is vital to consider suppliers that offer a diverse range of customizable options tailored to specific needs. The evolving market demands a proactive approach to sourcing, emphasizing the significance of reliable partnerships that can deliver innovative mobility solutions.

Looking ahead, now is the time to capitalize on the advantages of strategic sourcing in your operations. Engage with reputable suppliers, explore the latest product offerings, and leverage the expertise available in the market to drive value and efficiency in your gate systems. Your commitment to quality and strategic partnerships will position your business for sustainable growth in an increasingly globalized economy.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.