Unlocking Value: A Strategic Analysis of the Carbon Fiber Side Fenders Mk5 Supra Market

Introduction: Navigating the Global Market for carbon fiber side fenders mk5 supra

In the competitive landscape of automotive enhancements, sourcing high-quality carbon fiber side fenders for the MK5 Supra presents a critical challenge for international B2B buyers. With an increasing demand for lightweight, durable materials that enhance both performance and aesthetics, navigating the global market can be daunting. This guide offers a comprehensive look into the various types of carbon fiber side fenders available, their applications, and the intricacies of supplier vetting, ensuring that buyers can make informed purchasing decisions.

Our exploration includes insights into material specifications, production timelines, and cost considerations, tailored specifically for businesses operating in diverse regions such as Africa, South America, the Middle East, and Europe, including key markets like Germany and Saudi Arabia. By understanding the nuances of carbon fiber technology and market dynamics, buyers can effectively identify reliable suppliers and negotiate favorable terms.

Furthermore, this guide aims to empower B2B buyers with actionable strategies for enhancing their procurement processes, ensuring that they not only secure premium products but also optimize their supply chain efficiency. Whether you are looking to enhance your automotive offerings or seeking to differentiate your brand in the marketplace, this resource serves as an essential tool for navigating the complexities of sourcing carbon fiber side fenders for the MK5 Supra.

Understanding carbon fiber side fenders mk5 supra Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Vented Carbon Fenders | Enhanced airflow, reduced drag, and improved aerodynamics | Performance racing, custom car builds | Pros: Improved performance, stylish design. Cons: Higher cost, potential fitment issues. |

| OEM Style Carbon Fenders | Designed to match original specifications, lightweight | Restoration projects, OEM replacement | Pros: Seamless integration, reliable quality. Cons: Limited customization options. |

| Widebody Carbon Fenders | Increased width for wider tires, aggressive styling | Motorsport applications, show cars | Pros: Enhanced aesthetics, better handling. Cons: Requires modifications for installation. |

| Dry Carbon Fenders | Lighter than traditional carbon, high durability | High-performance racing, luxury vehicle upgrades | Pros: Superior strength-to-weight ratio. Cons: Premium pricing, less availability. |

| Custom Carbon Fenders | Tailored designs based on specific customer requirements | Bespoke automotive projects, aftermarket upgrades | Pros: Unique aesthetics, tailored fit. Cons: Longer lead times, potentially higher costs. |

What Are Vented Carbon Fenders and Their B2B Suitability?

Vented carbon fenders are designed with strategically placed vents to enhance airflow and reduce drag. This feature is particularly beneficial for performance racing and custom car builds, as it can significantly improve aerodynamic efficiency. For B2B buyers, these fenders represent a blend of functionality and style, appealing to those looking to optimize vehicle performance while maintaining an aggressive aesthetic. However, buyers should consider the higher costs associated with these specialized components and ensure compatibility with their specific models.

How Do OEM Style Carbon Fenders Benefit Restoration Projects?

OEM style carbon fenders replicate the original design of factory parts, making them ideal for restoration projects and OEM replacements. Their lightweight construction enhances performance without compromising the vehicle’s aesthetic integrity. B2B buyers focused on quality and reliability will appreciate these fenders for their seamless integration into existing setups. However, the lack of customization options may limit appeal for those seeking unique styling.

Illustrative image related to carbon fiber side fenders mk5 supra

What Advantages Do Widebody Carbon Fenders Offer?

Widebody carbon fenders are tailored for enthusiasts looking to accommodate wider tires and create a more aggressive stance. These fenders enhance vehicle handling and aesthetics, making them popular in motorsport and show car circles. For B2B buyers, they present an opportunity to cater to a niche market of performance-focused customers. However, installation may require additional modifications, which can complicate the purchasing decision.

Why Choose Dry Carbon Fenders for High-Performance Applications?

Dry carbon fenders are known for their lightweight and high durability, making them a preferred choice for high-performance racing and luxury vehicle upgrades. Their superior strength-to-weight ratio significantly contributes to overall vehicle performance. B2B buyers should be aware of the premium pricing and limited availability of these fenders, but their quality often justifies the investment, especially in competitive racing environments.

What Are the Benefits and Considerations for Custom Carbon Fenders?

Custom carbon fenders allow for tailored designs that meet specific customer requirements, making them ideal for bespoke automotive projects and aftermarket upgrades. They provide unique aesthetics that set vehicles apart in the market. However, B2B buyers should consider longer lead times and potentially higher costs associated with custom orders. Ensuring clear communication with manufacturers about design specifications is crucial for successful procurement.

Key Industrial Applications of carbon fiber side fenders mk5 supra

| Industry/Sector | Specific Application of carbon fiber side fenders mk5 supra | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Customization for Performance Vehicles | Enhances vehicle performance and aesthetics, attracting niche markets. | Need for high-quality materials and precision engineering. |

| Motorsports | Race Vehicle Modifications | Reduces weight for improved speed and handling, crucial for competitive racing. | Compliance with racing regulations and safety standards. |

| Aftermarket Auto Parts | Retail for Performance Upgrades | Expands product offerings, appealing to car enthusiasts and tuners. | Reliable supply chains and competitive pricing for resale. |

| Luxury and Exotic Cars | Upgrades for Exclusive Models | Provides luxury brands with unique, lightweight components that enhance brand value. | Quality assurance and brand reputation are essential. |

| Export and International Trade | Global Distribution of Performance Parts | Access to emerging markets with increasing automotive customization trends. | Understanding of international shipping regulations and tariffs. |

How Are Carbon Fiber Side Fenders Used in Automotive Manufacturing?

In the automotive manufacturing sector, carbon fiber side fenders for the MK5 Supra are primarily utilized for vehicle customization. Manufacturers target performance enthusiasts seeking to enhance both the aesthetic appeal and aerodynamic efficiency of their vehicles. The lightweight nature of carbon fiber contributes to improved fuel efficiency and handling characteristics, which is crucial for attracting niche markets. For international buyers, particularly from regions like Europe and the Middle East, sourcing high-quality materials that meet stringent manufacturing standards is essential to ensure product durability and performance.

What Role Do Carbon Fiber Side Fenders Play in Motorsports?

In motorsports, carbon fiber side fenders are crucial for race vehicle modifications. Their lightweight properties significantly reduce the overall weight of the car, which is a critical factor in enhancing speed and agility on the track. This application is particularly relevant for racing teams looking to gain a competitive edge. Buyers in this sector must ensure compliance with specific racing regulations and safety standards, making it vital to source products from reputable manufacturers that can provide documentation of quality and performance testing.

Illustrative image related to carbon fiber side fenders mk5 supra

How Do Aftermarket Auto Parts Companies Benefit from Carbon Fiber Side Fenders?

Aftermarket auto parts companies leverage carbon fiber side fenders to expand their product offerings for performance upgrades. These components attract car enthusiasts and tuners who prioritize personalization and performance enhancement. For businesses in South America and Africa, establishing reliable supply chains and competitive pricing is key to success in this growing market. They must also focus on marketing strategies that highlight the benefits of carbon fiber, such as weight reduction and aesthetic appeal, to capture the attention of potential customers.

Why Are Carbon Fiber Side Fenders Important for Luxury and Exotic Cars?

In the luxury and exotic car market, carbon fiber side fenders serve to upgrade exclusive models, offering unique, lightweight components that enhance both performance and brand prestige. Luxury brands benefit from incorporating high-quality materials that resonate with their clientele’s expectations for innovation and style. Buyers in this sector should prioritize quality assurance and the reputation of suppliers, as these factors directly influence brand loyalty and customer satisfaction.

How Does the Global Market for Carbon Fiber Side Fenders Evolve?

The global distribution of carbon fiber side fenders opens new avenues for international trade, especially in emerging markets where automotive customization is gaining traction. Businesses looking to export these components must navigate various international shipping regulations and tariffs, which can impact pricing and delivery timelines. Understanding these complexities is essential for B2B buyers from regions such as Africa and South America, where demand for performance parts is on the rise, ensuring they remain competitive in the global marketplace.

3 Common User Pain Points for ‘carbon fiber side fenders mk5 supra’ & Their Solutions

Scenario 1: Navigating Long Lead Times for Carbon Fiber Fenders

The Problem: B2B buyers often face significant delays when sourcing carbon fiber side fenders for the MK5 Supra. Manufacturers may have production times ranging from weeks to months, which can disrupt project timelines and inventory management. This is particularly challenging for businesses in regions like Africa and South America, where access to a diverse supplier network is limited. The potential for lost sales and customer dissatisfaction adds pressure to already tight schedules.

The Solution: To mitigate long lead times, B2B buyers should establish relationships with multiple suppliers and manufacturers who specialize in carbon fiber components. Diversifying the supplier base allows businesses to compare production times and stock availability. Additionally, buyers can pre-order popular items or collaborate with manufacturers to create a forecast for demand. Leveraging local distributors who can expedite shipping or offer ready-to-ship options can also be beneficial. By proactively managing supplier relationships and inventory, businesses can reduce the impact of delays on their operations.

Illustrative image related to carbon fiber side fenders mk5 supra

Scenario 2: Ensuring Quality and Performance Standards

The Problem: Quality assurance is a critical concern when sourcing carbon fiber side fenders. Buyers may encounter products that do not meet the necessary standards for durability, fitment, or aerodynamic performance. This is particularly relevant for businesses in Europe and the Middle East, where regulatory requirements and customer expectations for performance parts are high. A lack of quality can lead to returns, warranty claims, and a damaged reputation.

The Solution: To ensure quality, B2B buyers should prioritize sourcing from manufacturers that provide detailed specifications and certifications for their products. Requesting samples before committing to bulk orders can help assess the quality of the carbon fiber fenders firsthand. Additionally, buyers should look for manufacturers that conduct rigorous testing, such as Computational Fluid Dynamics (CFD) analysis, to validate the aerodynamic performance of their products. Establishing a robust quality assurance process, including regular audits and feedback loops with suppliers, will help maintain high standards and improve overall customer satisfaction.

Scenario 3: Overcoming Compatibility Issues with the MK5 Supra

The Problem: Compatibility with the MK5 Supra’s existing bodywork is a common pain point for B2B buyers. Carbon fiber side fenders must fit seamlessly with the vehicle’s design and integrate with other aftermarket components. Discrepancies in fitment can lead to additional installation costs, increased labor time, and potential damage to the vehicle, ultimately resulting in dissatisfied end customers.

The Solution: To address compatibility issues, B2B buyers should work closely with manufacturers who offer detailed fitment guides and installation instructions. It’s advisable to choose suppliers that provide a guarantee of fitment for their products on specific vehicle models, including the MK5 Supra. Engaging with automotive forums or communities where professionals share their experiences can also provide insights into successful installations. For businesses that install these components, providing training for technicians on best practices for fitting carbon fiber parts can further enhance customer satisfaction and minimize installation errors. By focusing on compatibility from the outset, buyers can ensure a smoother installation process and a better end-user experience.

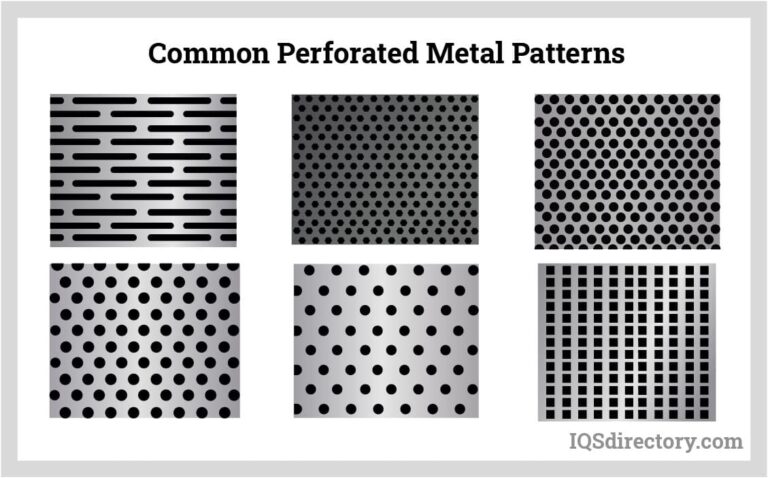

Strategic Material Selection Guide for carbon fiber side fenders mk5 supra

What Are the Key Materials for Carbon Fiber Side Fenders in the MK5 Supra?

When selecting materials for carbon fiber side fenders for the MK5 Supra, it is essential to consider various options that balance performance, durability, and cost. Here, we analyze four common materials: standard carbon fiber, fiberglass, dry carbon fiber, and reinforced carbon fiber composites.

Illustrative image related to carbon fiber side fenders mk5 supra

How Does Standard Carbon Fiber Perform for Side Fenders?

Standard carbon fiber is renowned for its high strength-to-weight ratio and excellent rigidity. It typically withstands temperatures up to 120°C (248°F) and offers good resistance to corrosion and UV degradation. This makes it suitable for automotive applications where performance and aesthetics are crucial.

Pros: The primary advantages include superior strength, lightweight properties, and enhanced aerodynamics, which can improve vehicle performance. Additionally, it can be molded into complex shapes, allowing for innovative designs.

Cons: However, standard carbon fiber can be relatively expensive and may require specialized manufacturing processes, increasing production complexity. It also has lower impact resistance compared to some alternatives, which could be a concern in high-collision scenarios.

Impact on Application: For international buyers, compliance with automotive standards such as ASTM D7264 (for composite materials) is crucial. Buyers from regions with stringent automotive regulations, like Germany, should ensure that the products meet these standards.

What About Fiberglass as an Alternative Material?

Fiberglass is another option that offers a more cost-effective solution for side fenders. It is less rigid than carbon fiber but provides good impact resistance and is generally easier to manufacture.

Pros: The advantages of fiberglass include lower cost, ease of repair, and good durability. It can also be produced in various colors and finishes, making it appealing for aesthetic customization.

Cons: On the downside, fiberglass is heavier than carbon fiber and can be less effective in high-performance applications where weight reduction is critical. It is also more susceptible to UV damage over time.

Impact on Application: Buyers from South America and Africa may find fiberglass more accessible due to lower production costs. However, they should consider local regulations regarding material specifications and environmental impact.

How Does Dry Carbon Fiber Compare?

Dry carbon fiber is a premium option that enhances the performance of standard carbon fiber by using a different manufacturing process that results in lighter and stronger parts.

Pros: The key advantages include exceptional strength, reduced weight, and improved thermal stability. Dry carbon fiber components can also be more aesthetically pleasing due to their glossy finish.

Cons: The primary drawback is the high cost associated with dry carbon fiber production, making it less accessible for budget-conscious buyers. Additionally, the manufacturing process can be more complex, leading to longer lead times.

Illustrative image related to carbon fiber side fenders mk5 supra

Impact on Application: For buyers in the Middle East, where high-performance vehicles are popular, dry carbon fiber could be an attractive option. However, they should be aware of the potential for extended production times and ensure that suppliers can meet their delivery expectations.

What Are the Benefits of Reinforced Carbon Fiber Composites?

Reinforced carbon fiber composites combine carbon fiber with other materials to enhance specific properties, such as impact resistance and durability.

Pros: These composites offer improved toughness and can be tailored for specific applications, making them suitable for high-performance vehicles. They also maintain a lightweight profile while providing enhanced protection against impacts.

Illustrative image related to carbon fiber side fenders mk5 supra

Cons: The complexity of manufacturing reinforced composites can lead to higher costs and longer production times. Additionally, they may not have the same aesthetic appeal as pure carbon fiber options.

Impact on Application: European buyers, particularly in Germany, may appreciate the engineering behind reinforced composites, as they often comply with rigorous automotive standards. However, they should ensure that the material specifications align with their performance needs.

Summary Table of Material Options

| Material | Typical Use Case for carbon fiber side fenders mk5 supra | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Standard Carbon Fiber | High-performance racing and sports cars | High strength-to-weight ratio | Expensive and lower impact resistance | High |

| Fiberglass | Budget-friendly aftermarket fenders | Cost-effective and easy to repair | Heavier and UV susceptible | Low |

| Dry Carbon Fiber | Premium vehicle upgrades | Exceptional strength and lightweight | Very high cost and complex manufacturing | High |

| Reinforced Carbon Fiber Composites | High-impact applications and performance vehicles | Improved toughness and durability | Higher costs and longer production times | Med |

This strategic material selection guide provides valuable insights for international B2B buyers, helping them make informed decisions when sourcing carbon fiber side fenders for the MK5 Supra.

In-depth Look: Manufacturing Processes and Quality Assurance for carbon fiber side fenders mk5 supra

What Are the Main Stages in the Manufacturing Process of Carbon Fiber Side Fenders for the MK5 Supra?

The manufacturing process for carbon fiber side fenders, particularly for high-performance vehicles like the MK5 Supra, involves several critical stages. Each stage is designed to optimize the properties of carbon fiber, ensuring that the final product meets the performance and aesthetic standards expected by automotive enthusiasts.

-

Material Preparation: The first stage involves selecting high-quality carbon fiber materials. Manufacturers typically use pre-preg carbon fiber, which is pre-impregnated with resin, allowing for better control over the curing process. The carbon fiber sheets are cut into specific shapes and sizes according to the design specifications. This preparation phase also includes ensuring that all materials are free from contaminants, as impurities can compromise the integrity of the fender.

-

Forming: In this stage, the prepared carbon fiber is laid into molds that define the shape of the side fenders. Manufacturers often use vacuum bagging techniques, which involve placing the mold and the carbon fiber in a sealed bag and applying vacuum pressure. This process not only enhances the adhesion of the resin but also helps in removing any trapped air, leading to a denser and stronger product.

-

Assembly: After curing, which may involve heating the molds to activate the resin, the individual components are assembled. This can include integrating additional elements such as brackets or mounting points. Careful attention is given to the alignment and fit of each component to ensure that the fenders will fit seamlessly onto the vehicle.

-

Finishing: The final stage involves surface finishing, which may include sanding, painting, or applying a clear coat for aesthetic enhancement. This not only improves the visual appeal of the fenders but also protects them from UV degradation and environmental damage. Quality control checks are conducted at this stage to ensure that the surface finish meets the high standards expected by consumers.

What Key Techniques Are Utilized in Manufacturing Carbon Fiber Side Fenders?

Several advanced techniques are employed throughout the manufacturing process to enhance the performance and quality of carbon fiber side fenders:

Illustrative image related to carbon fiber side fenders mk5 supra

-

Vacuum Infusion: This technique allows for a more uniform distribution of resin, leading to lighter and stronger components. The vacuum pressure pulls the resin through the dry carbon fiber, ensuring complete saturation without excess resin that can add weight.

-

CNC Machining: After the curing process, CNC (Computer Numerical Control) machining may be used to precisely cut and shape the fenders. This ensures that all components are manufactured to exact specifications, allowing for better fit and finish.

-

Quality Assurance Automation: Some manufacturers are increasingly adopting automated systems for quality assurance. This includes the use of sensors and imaging technology to detect defects in real-time during the production process.

How Is Quality Assurance Implemented in the Production of Carbon Fiber Side Fenders?

Quality assurance (QA) is a critical aspect of the manufacturing process, especially in the automotive industry where safety and performance are paramount. Various international and industry-specific standards guide the QA processes:

-

ISO 9001 Certification: This widely recognized international standard ensures that manufacturers adhere to quality management principles. Companies that hold ISO 9001 certification demonstrate their commitment to quality and continuous improvement.

-

CE Marking: For products sold within the European Economic Area, obtaining a CE mark indicates conformity with health, safety, and environmental protection standards.

-

API Standards: Although more common in the oil and gas industry, certain API standards can apply to materials used in automotive manufacturing, ensuring that the materials meet rigorous quality benchmarks.

What Are the Quality Control Checkpoints in the Manufacturing Process?

To maintain high standards of quality, manufacturers implement several checkpoints throughout the production process:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon delivery to ensure they meet specified standards before they enter the production line.

-

In-Process Quality Control (IPQC): During manufacturing, periodic checks are conducted to monitor the process and identify any deviations. This can include measuring resin viscosity and checking for proper vacuum levels during the infusion process.

-

Final Quality Control (FQC): After the components are fully assembled, a comprehensive inspection is carried out. This includes visual inspections for surface defects, dimensional checks, and functional tests to ensure that the fenders perform as intended.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality control processes is essential. Here are some actionable steps:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing environment, review quality control processes, and verify compliance with international standards.

-

Quality Control Reports: Requesting detailed reports on the quality assurance processes, including IQC, IPQC, and FQC, provides insight into the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging independent third-party inspectors can provide an objective assessment of the manufacturing practices and quality control measures in place.

What Are the QC and Certification Nuances for International B2B Buyers?

When sourcing carbon fiber side fenders internationally, buyers should be aware of specific nuances related to quality control and certification:

-

Regional Standards Compliance: Different regions may have varying regulatory requirements. Buyers should familiarize themselves with local standards in their markets, such as the specific automotive regulations in Europe or safety standards in the Middle East.

-

Documentation and Certification: Ensure that suppliers provide all necessary documentation, including certifications, test reports, and compliance statements. This is crucial for importation and market acceptance.

-

Cultural Considerations: Understanding cultural differences in business practices can enhance communication with suppliers and facilitate smoother negotiations regarding quality expectations.

By focusing on these manufacturing processes, quality assurance standards, and verification techniques, B2B buyers can make informed decisions when sourcing carbon fiber side fenders for the MK5 Supra. This comprehensive approach not only ensures product quality but also fosters long-term partnerships with reliable suppliers.

Illustrative image related to carbon fiber side fenders mk5 supra

Practical Sourcing Guide: A Step-by-Step Checklist for ‘carbon fiber side fenders mk5 supra’

Introduction

This practical sourcing guide is designed to assist B2B buyers in the procurement of carbon fiber side fenders for the MK5 Toyota Supra. By following this step-by-step checklist, you can ensure a smooth and efficient purchasing process while minimizing risks associated with sourcing high-performance automotive parts.

Step 1: Define Your Technical Specifications

Before initiating your search for carbon fiber side fenders, clearly outline your technical requirements. This includes specifications such as dimensions, weight limits, and compatibility with the MK5 Supra model. A well-defined specification helps in communicating your needs effectively to potential suppliers.

- Consider aerodynamics: Look for features that enhance vehicle performance, such as designs that reduce drag.

- Material quality: Ensure the carbon fiber used meets industry standards for durability and weight.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers specializing in automotive carbon fiber components. Explore their product offerings, customer reviews, and industry reputation. A strong supplier network is essential for reliable sourcing.

Illustrative image related to carbon fiber side fenders mk5 supra

- Online directories: Utilize platforms like Alibaba or industry-specific forums to find reputable suppliers.

- Trade shows: Attend automotive exhibitions to connect with manufacturers and see products firsthand.

Step 3: Evaluate Supplier Certifications

Verify that your shortlisted suppliers have the necessary certifications and quality assurance processes in place. This ensures that their products meet international standards and regulations.

- ISO certifications: Look for suppliers with ISO 9001 or similar quality management certifications.

- Material certifications: Check for compliance with safety and performance standards relevant to automotive parts.

Step 4: Request Samples

Before placing a bulk order, request samples of the carbon fiber side fenders. This allows you to assess the quality, fit, and finish of the product firsthand.

- Quality assessment: Inspect for uniformity in weave, surface finish, and any defects.

- Fitment testing: Ensure that the fenders fit correctly on the MK5 Supra to avoid costly returns.

Step 5: Understand Pricing and Terms

Analyze the pricing structure of the suppliers and understand the terms of sale, including payment methods, shipping costs, and delivery timelines. Transparent pricing helps you budget accurately and avoid unexpected expenses.

Illustrative image related to carbon fiber side fenders mk5 supra

- Bulk order discounts: Inquire about pricing for larger quantities to maximize savings.

- Shipping options: Consider suppliers that offer full insurance on shipments to protect your investment.

Step 6: Confirm Warranty and After-Sales Support

Ensure that the supplier offers a warranty on their products and provides after-sales support. A solid warranty indicates confidence in the product’s quality and can save you from future headaches.

- Warranty duration: Look for warranties that cover defects and performance issues.

- Customer support: Assess the responsiveness and availability of the supplier’s customer service team for future inquiries.

Step 7: Place Your Order with Confidence

Once all due diligence is completed, proceed to place your order. Confirm all details, including specifications, pricing, and delivery dates, in writing to ensure clarity and avoid misunderstandings.

- Documentation: Keep records of all communications and agreements for reference.

- Follow-up: After placing the order, maintain communication with the supplier to track progress and address any potential issues promptly.

By following this checklist, B2B buyers can effectively navigate the sourcing process for carbon fiber side fenders for the MK5 Supra, ensuring a successful procurement experience.

Comprehensive Cost and Pricing Analysis for carbon fiber side fenders mk5 supra Sourcing

What Are the Key Cost Components in Sourcing Carbon Fiber Side Fenders for the MK5 Supra?

When sourcing carbon fiber side fenders for the MK5 Supra, understanding the cost structure is essential for B2B buyers. The primary cost components include:

Illustrative image related to carbon fiber side fenders mk5 supra

-

Materials: Carbon fiber is generally more expensive than traditional materials like fiberglass. Prices can range from $605 to over $2,450, depending on the specific design and quality. The choice of 2×2 twill carbon fiber versus other weaves can also impact the cost.

-

Labor: Skilled labor is necessary for the manufacturing process, particularly for high-quality carbon fiber products. Labor costs can vary significantly based on geographic location and labor regulations, especially when sourcing from regions like Europe or North America versus South America or Africa.

-

Manufacturing Overhead: This includes costs associated with utilities, equipment maintenance, and facility expenses. Suppliers often embed these costs into the product price, which can vary based on the supplier’s production efficiency.

-

Tooling: Initial tooling costs can be significant, particularly for custom designs. Buyers should consider whether they are purchasing off-the-shelf products or require bespoke solutions, as this will affect the tooling investment needed.

-

Quality Control (QC): Ensuring that products meet specified standards requires a robust QC process, which adds to the overall cost. Certifications for quality assurance can also influence pricing, particularly for buyers from regions with stringent compliance regulations.

-

Logistics: Shipping costs can vary widely based on the origin of the product, destination, and chosen Incoterms. International shipping often entails additional fees, customs duties, and taxes, which should be factored into the total cost.

-

Margin: Suppliers will add a markup to cover their costs and ensure profit. This margin can vary significantly based on the supplier’s market position, competition, and perceived value of the product.

What Factors Influence Pricing for Carbon Fiber Side Fenders?

Several factors can influence the pricing structure for carbon fiber side fenders:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs with suppliers to optimize pricing.

-

Specifications and Customization: Custom designs or specific performance enhancements can increase costs. It’s crucial for buyers to clarify their needs upfront to avoid unexpected price hikes.

-

Material Quality and Certifications: Higher-grade materials and certifications can justify premium pricing. Buyers should assess whether the added cost aligns with their performance requirements.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their brand equity and proven track record.

-

Incoterms: The choice of Incoterms can significantly impact the total landed cost. Buyers should understand the implications of terms like FOB (Free On Board) versus CIF (Cost, Insurance, and Freight) to manage logistics costs effectively.

What Tips Can Help Buyers Achieve Cost-Efficiency in Their Purchases?

For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, there are several strategies to consider:

-

Negotiate with Suppliers: Always engage in discussions regarding pricing, especially for bulk orders. Suppliers may offer discounts or favorable terms for long-term partnerships.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider the long-term costs associated with maintenance, performance, and potential resale value.

-

Understand Pricing Nuances: Different regions may have varying pricing strategies influenced by local demand, shipping costs, and import duties. Buyers should conduct market research to ensure they are making informed decisions.

-

Build Relationships with Multiple Suppliers: Establishing connections with various suppliers can provide leverage in negotiations and offer alternatives if one supplier cannot meet specifications or timelines.

-

Stay Informed on Market Trends: Understanding industry trends, such as advances in manufacturing techniques or shifts in material costs, can aid buyers in anticipating price changes and making timely purchasing decisions.

Disclaimer on Indicative Prices

The prices mentioned in this analysis are indicative and can fluctuate based on market conditions, supplier policies, and other external factors. Buyers are encouraged to obtain detailed quotes and terms directly from suppliers to ensure accurate budgeting.

Alternatives Analysis: Comparing carbon fiber side fenders mk5 supra With Other Solutions

Exploring Alternatives for Carbon Fiber Side Fenders for the MK5 Supra

In the realm of automotive enhancements, particularly for the MK5 Toyota Supra, carbon fiber side fenders are a popular choice among performance enthusiasts. However, there are several alternative solutions that may also meet the needs of international B2B buyers. This analysis will compare carbon fiber side fenders against fiberglass fenders and aluminum fenders, focusing on their performance, cost, ease of implementation, maintenance, and best use cases.

Illustrative image related to carbon fiber side fenders mk5 supra

| Comparison Aspect | Carbon Fiber Side Fenders Mk5 Supra | Fiberglass Fenders | Aluminum Fenders |

|---|---|---|---|

| Performance | Excellent aerodynamic properties, lightweight, and high strength-to-weight ratio | Moderate performance, heavier, less aerodynamic | Good durability and strength, moderate weight |

| Cost | $605 – $2,450 | $200 – $600 | $300 – $800 |

| Ease of Implementation | Professional installation recommended, direct fit | Easier to install, lighter prep work | Requires specialized tools for installation |

| Maintenance | Low maintenance, resistant to corrosion | Moderate maintenance, susceptible to cracks | Low maintenance, corrosion-resistant |

| Best Use Case | High-performance applications, racing, and show cars | Budget-friendly upgrades for daily drivers | Durable options for mixed-use vehicles |

What Are the Benefits of Fiberglass Fenders Compared to Carbon Fiber?

Fiberglass fenders present a budget-friendly alternative for those looking to upgrade their MK5 Supra without the premium price tag of carbon fiber. They are easier to install, often requiring less specialized knowledge. However, fiberglass does not offer the same weight savings or aerodynamic advantages as carbon fiber, making it less suitable for high-performance applications. While they provide decent durability, they can crack under stress, necessitating more frequent repairs.

How Do Aluminum Fenders Stack Up Against Carbon Fiber Options?

Aluminum fenders are known for their strength and durability, making them a solid choice for buyers seeking longevity. They are generally more resistant to corrosion compared to fiberglass, and their moderate weight can still provide a performance boost over stock components. However, they typically lack the aerodynamic benefits of carbon fiber and can be more challenging to install, requiring specialized tools and expertise. Aluminum fenders may be ideal for mixed-use vehicles that require a balance between performance and durability.

Conclusion: How Should B2B Buyers Choose the Right Fender Solution?

When selecting the right fender solution for the MK5 Supra, B2B buyers should consider their specific needs and application. For high-performance racing or show cars where weight and aerodynamics are critical, carbon fiber fenders are the superior choice despite their higher cost. In contrast, those looking for economical solutions for daily driving may find fiberglass fenders more appealing, while aluminum fenders serve well for durability and mixed-use scenarios. Ultimately, evaluating performance requirements, budget constraints, and installation capabilities will guide buyers in making the most informed decision for their automotive enhancement projects.

Essential Technical Properties and Trade Terminology for carbon fiber side fenders mk5 supra

What Are the Key Technical Properties of Carbon Fiber Side Fenders for the MK5 Supra?

When sourcing carbon fiber side fenders for the MK5 Supra, understanding the technical specifications is crucial for ensuring product quality and performance. Here are some critical properties to consider:

-

Material Grade

Carbon fiber is available in various grades, which influence its strength, weight, and durability. Higher-grade carbon fiber, such as T700 or T800, offers superior tensile strength and rigidity, making it ideal for performance applications. For B2B buyers, selecting the right material grade directly impacts the fender’s performance, longevity, and aesthetic appeal. -

Weight Reduction

One of the primary advantages of carbon fiber is its lightweight nature compared to traditional materials like fiberglass or metal. A reduction in weight can enhance vehicle performance, improve fuel efficiency, and increase handling responsiveness. Buyers should evaluate weight specifications to ensure they meet performance criteria, especially for racing or high-performance applications. -

Manufacturing Tolerance

Tolerance refers to the allowable deviation in dimensions during manufacturing. For carbon fiber side fenders, precise tolerances are crucial to ensure proper fitment and alignment with the vehicle’s original design. This precision is particularly important for aftermarket parts, as poor tolerances can lead to installation challenges or performance issues. -

Finish Type

The finish of carbon fiber components can vary, affecting both aesthetics and performance. Options such as matte, gloss, or UV-protected finishes not only enhance the visual appeal but also protect the material from environmental damage. Buyers should consider the intended use and exposure conditions when selecting finish types. -

Impact Resistance

Carbon fiber is known for its high impact resistance, which is vital for automotive applications. Understanding the impact resistance specifications can help buyers gauge how well the fender will withstand road debris, minor collisions, or other hazards. This property is essential for ensuring the longevity and durability of the product. -

Aerodynamic Design Features

Many carbon fiber side fenders are designed with specific aerodynamic features to reduce drag and improve vehicle stability at high speeds. These designs are often tested using Computational Fluid Dynamics (CFD) to validate their effectiveness. B2B buyers should inquire about these features to ensure they meet performance requirements.

What Common Trade Terminology Should B2B Buyers Know When Sourcing Carbon Fiber Products?

Familiarity with industry jargon is vital for effective communication and negotiation in the B2B landscape. Here are some common terms:

Illustrative image related to carbon fiber side fenders mk5 supra

-

OEM (Original Equipment Manufacturer)

Refers to parts made by the same manufacturer that produced the original components for a vehicle. OEM parts are typically synonymous with quality and fitment assurance, making them a preferred choice for many buyers. -

MOQ (Minimum Order Quantity)

This term indicates the smallest number of units a supplier is willing to sell. Understanding MOQ is essential for budgeting and inventory management, particularly for businesses looking to resell or use the components in larger projects. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price estimates from suppliers. It is crucial for comparing costs and ensuring that buyers receive competitive pricing for their required products. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps clarify shipping obligations, risk management, and cost distribution, which are essential for smooth cross-border transactions. -

Lead Time

This refers to the time it takes from placing an order to delivery. Understanding lead times is crucial for inventory planning and project timelines, especially when sourcing specialized components like carbon fiber fenders that may have extended production periods. -

CFD (Computational Fluid Dynamics)

A simulation tool used to analyze and optimize the aerodynamic performance of parts. Knowledge of CFD testing can help buyers assess the effectiveness of design features and make informed decisions regarding product selection.

By grasping these technical properties and trade terms, B2B buyers can enhance their purchasing strategies, ensuring they select the best carbon fiber side fenders for the MK5 Supra that meet their specific needs and performance expectations.

Navigating Market Dynamics and Sourcing Trends in the carbon fiber side fenders mk5 supra Sector

What Are the Current Market Dynamics and Key Trends in the Carbon Fiber Side Fenders Mk5 Supra Sector?

The market for carbon fiber side fenders for the Mk5 Toyota Supra is witnessing significant growth, driven primarily by the increasing demand for lightweight automotive components that enhance performance and fuel efficiency. As global automotive manufacturers pivot towards performance-enhancing materials, carbon fiber’s superior strength-to-weight ratio positions it as a leading choice. This trend is notably evident in regions such as Europe and the Middle East, where consumers prioritize high-performance vehicles.

Emerging technologies such as 3D printing and advanced composites are transforming sourcing strategies, enabling manufacturers to produce complex designs with reduced lead times. Additionally, international buyers are increasingly seeking suppliers who can offer customization options, reflecting the growing trend of personalization in the automotive sector. This customization capability not only enhances vehicle aesthetics but also improves aerodynamic efficiency, a crucial factor for high-performance cars like the Supra.

Moreover, the market is experiencing an uptick in online B2B platforms that facilitate direct connections between manufacturers and international buyers, streamlining the sourcing process. This digital shift is particularly beneficial for buyers from Africa and South America, where access to specialized automotive components may be limited. Buyers are now able to source products globally, ensuring competitive pricing and broader selection.

How Is Sustainability and Ethical Sourcing Influencing the Carbon Fiber Side Fenders Market?

Sustainability has become a paramount concern in the automotive industry, with buyers increasingly prioritizing products that adhere to ethical sourcing practices. The environmental impact of carbon fiber production is significant; however, innovations in recycling and alternative production methods are emerging to mitigate this concern. B2B buyers should look for suppliers who utilize sustainable practices, such as sourcing raw materials from certified suppliers and employing eco-friendly manufacturing processes.

Ethical supply chains are critical, especially for international buyers in regions such as Europe, where regulations regarding environmental impact are stringent. The demand for “green” certifications is rising, as buyers seek assurance that their suppliers are compliant with environmental standards. Materials that boast certifications, such as ISO 14001 for environmental management, can enhance a supplier’s credibility and appeal in the marketplace.

Furthermore, as consumers and businesses alike become more environmentally conscious, the potential for carbon fiber components to be produced from recycled materials is gaining traction. This shift not only reduces waste but also aligns with the values of a growing segment of buyers who prioritize sustainability in their purchasing decisions.

What Is the Brief Evolution and History of Carbon Fiber Side Fenders in the Automotive Industry?

The use of carbon fiber in the automotive industry has evolved significantly since its introduction in the late 20th century. Initially, carbon fiber was primarily employed in motorsports due to its lightweight and high-strength properties. Over the years, advancements in manufacturing techniques have made carbon fiber more accessible, allowing for its integration into mainstream automotive applications, including aftermarket modifications like side fenders.

Illustrative image related to carbon fiber side fenders mk5 supra

In the context of the Mk5 Toyota Supra, the demand for carbon fiber components has surged alongside the car’s popularity among enthusiasts and performance drivers. The introduction of carbon fiber side fenders not only enhances the vehicle’s aesthetic appeal but also contributes to improved aerodynamics and weight reduction, crucial for performance optimization. As the automotive landscape continues to evolve, the trend towards lightweight materials like carbon fiber will likely expand, driven by technological advancements and changing consumer preferences.

This evolution underscores the importance for B2B buyers to stay informed about emerging trends and innovations in the carbon fiber sector to make informed sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of carbon fiber side fenders mk5 supra

-

How do I choose the right supplier for carbon fiber side fenders for the MK5 Supra?

When selecting a supplier, prioritize those with a proven track record in the automotive aftermarket industry, particularly for carbon fiber components. Look for suppliers that offer detailed product specifications, such as material quality and manufacturing processes. Additionally, consider their production capacity, lead times, and customer service responsiveness. Request samples if possible, and check for certifications that ensure compliance with international standards. Engaging in direct communication can also help assess their reliability and willingness to accommodate your specific needs. -

What are the benefits of using carbon fiber side fenders for the MK5 Supra?

Carbon fiber side fenders provide significant advantages, including reduced weight, which enhances vehicle performance and handling. Their aerodynamic design can improve airflow and reduce drag, leading to better fuel efficiency and stability at high speeds. Additionally, the aesthetic appeal of carbon fiber adds a premium look to the vehicle. For B2B buyers, these benefits translate into increased customer satisfaction and potentially higher resale values, making them a worthwhile investment for automotive businesses. -

What is the minimum order quantity (MOQ) for carbon fiber side fenders?

MOQs for carbon fiber side fenders can vary significantly depending on the supplier and the type of product. Typically, manufacturers may set an MOQ ranging from 5 to 20 units. It’s essential to discuss your specific needs with potential suppliers to understand their policies. Some may offer flexibility for smaller orders or provide options for combined shipments of different products to meet MOQ requirements, which can be beneficial for B2B buyers looking to minimize initial investments. -

What are the payment terms commonly offered by suppliers for carbon fiber products?

Payment terms can differ from one supplier to another, but common practices include upfront payments, partial payments upon order confirmation, and balance payments upon shipment. For larger orders, suppliers might offer extended payment terms or financing options. Always clarify payment methods accepted (e.g., bank transfer, credit card) and any associated fees. Establishing clear payment terms can help maintain good relations and ensure timely fulfillment of orders, which is crucial for B2B transactions. -

How can I ensure the quality of carbon fiber side fenders before purchase?

To guarantee product quality, request detailed information about the manufacturing process and materials used. Look for suppliers that conduct rigorous quality assurance checks, including tests for durability, finish, and fitment. Asking for certifications, such as ISO or other industry-specific approvals, can also provide assurance of quality standards. Additionally, consider obtaining product samples or customer testimonials, which can offer insights into the reliability and performance of the fenders. -

What are the typical lead times for ordering carbon fiber side fenders?

Lead times for carbon fiber side fenders can vary based on the supplier’s production capacity, material availability, and customization requests. Standard lead times may range from 2 to 6 weeks for in-stock items, while custom orders could take longer. It’s advisable to confirm lead times during the order process and discuss any urgent requirements. Planning ahead and placing orders well in advance can help mitigate delays and ensure timely delivery to your customers. -

Are there customization options available for carbon fiber side fenders?

Many suppliers offer customization options for carbon fiber side fenders, including variations in design, finish, and fitment. Customization may also extend to branding opportunities, where businesses can add logos or specific styling to the fenders. However, it’s crucial to discuss these options upfront, as they may affect lead times and pricing. Understanding the extent of customization available can help you better cater to your clients’ preferences and enhance your product offerings. -

What logistics considerations should I keep in mind when sourcing carbon fiber side fenders internationally?

When sourcing internationally, consider shipping methods, costs, and import regulations specific to your country. Ensure that the supplier provides adequate packaging to prevent damage during transit. It’s also important to understand customs duties and taxes that may apply to your order. Engaging a reliable logistics partner can facilitate smoother shipping processes and help navigate complex international trade regulations, ensuring that your products arrive on time and in perfect condition.

Top 5 Carbon Fiber Side Fenders Mk5 Supra Manufacturers & Suppliers List

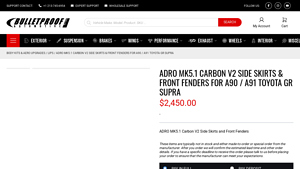

1. ADRO – MK5.1 Carbon V2 Side Skirts & Front Fenders

Domain: bulletproofautomotive.com

Registered: 2000 (25 years)

Introduction: ADRO MK5.1 Carbon V2 Side Skirts & Front Fenders for A90 / A91 Toyota GR Supra

– Price: $2,450.00

– Made-to-order or special order from the manufacturer

– Lead time confirmation after order placement

– Deposit options available (50% deposit per item)

– Features:

– Wet carbon fiber

– Lightweight & durable

– Lower, wider stance for enhanced road presence

– Aggressive angles for a performance…

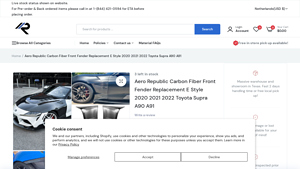

2. Performance SpeedShop – Carbon Front Fender for Toyota Supra A90 A91

Domain: performancespeedshop.com

Registered: 2020 (5 years)

Introduction: Carbon Front Fender Replacement for Toyota Supra A90 A91 – Performance SpeedShop. Live stock status shown on website. For Pre-order & Back ordered items please call in at 1-(844) 421-0594 for ETA before placing order.

3. Supramkv – EOS Performance Package

Domain: supramkv.com

Registered: 2013 (12 years)

Introduction: {“vehicle_type”: “2020-Up Toyota Supra”, “package”: “EOS Performance Package”, “surface_finish”: “Carbon Fiber”, “package_included”: “Toyota Supra Carbon Fiber Front Side Fender”, “features”: {“material”: “3K Twill Weave Real Carbon Fiber”, “benefits”: [“maximizes aerodynamic attributes”, “lightweight and durable”, “enhances appearance”, “improves handling and performance”]}, “installation”: “stra…

4. Adro – Carbon Side Skirts & Fenders for Toyota Supra MK5

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: Adro carbon side skirts and fenders for Toyota Supra MK5 / MKV / A90

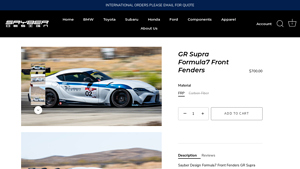

5. Sayber Design – GR Supra Formula7 Front Fenders A90

Domain: sayberdesign.com

Registered: 2020 (5 years)

Introduction: {“product_name”:”GR Supra Formula7 Front Fenders A90″,”price”:”$700.00″,”material”:”FRP / Carbon Fiber”,”description”:”Vented fenders designed to extract heat and high pressure air from wheel wells under heavy braking. Created using 3D scanning technology for fitment and quality.”,”kit_contents”:”Includes (x1) driver side fender and (x1) passenger side fender”,”installation”:”Mounts to OEM locatio…

Strategic Sourcing Conclusion and Outlook for carbon fiber side fenders mk5 supra

As the demand for high-performance automotive components continues to rise, international B2B buyers must prioritize strategic sourcing of carbon fiber side fenders for the MK5 Supra. This lightweight yet durable material offers significant advantages in terms of aerodynamics and vehicle aesthetics, positioning it as a critical investment for performance enhancement. Suppliers like Group A Motoring and ADRO provide a range of options, including custom designs and quick shipping for in-stock items, ensuring that businesses can meet their customers’ needs promptly.

Establishing strong partnerships with manufacturers not only secures quality products but also enhances supply chain resilience, which is vital for navigating global market fluctuations. Buyers from regions such as Africa, South America, the Middle East, and Europe should leverage these opportunities to differentiate their offerings and drive competitive advantage in their markets.

Looking ahead, the potential for innovation in carbon fiber technology presents a compelling opportunity for businesses willing to invest in advanced automotive components. Engage with suppliers now to explore the latest trends and secure your position in this dynamic market. Embrace the future of automotive performance and elevate your product line with high-quality carbon fiber side fenders for the MK5 Supra.

Illustrative image related to carbon fiber side fenders mk5 supra

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.