Unlocking Value: A Strategic Analysis of the Canning Machine Market

Introduction: Navigating the Global Market for canning machine

Navigating the complexities of sourcing canning machines can pose significant challenges for international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. As the demand for canned beverages continues to rise, businesses must identify the right equipment that aligns with their production needs, while also ensuring quality and efficiency. This guide aims to demystify the canning machine market by exploring various types of machines, their applications, and key considerations for supplier vetting.

From compact manual canners ideal for small-scale operations to advanced automatic systems designed for high-volume production, the landscape of canning machinery is diverse. Understanding the unique features, benefits, and costs associated with each type of machine is crucial for making informed purchasing decisions. Additionally, this guide will provide insights into the latest technological advancements and industry trends, helping buyers stay ahead in a competitive market.

By equipping international buyers with actionable knowledge on canning machinery, this guide empowers them to navigate the complexities of sourcing effectively. Whether you are looking to enhance your production capabilities in Saudi Arabia, Germany, or elsewhere, understanding the nuances of canning technology is essential for optimizing your operations and achieving sustainable growth.

Understanding canning machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Manual Can Seamers | Operated by hand; ideal for small batches; cost-effective | Craft breweries, small beverage operations | Pros: Low initial investment, simple operation. Cons: Labor-intensive, slower production rates. |

| Semi-Automatic Canning Systems | Combines manual loading with automated sealing; versatile | Small to mid-sized breweries, cideries | Pros: Increased efficiency, moderate cost. Cons: Requires some operator training, limited scalability. |

| Fully Automatic Canning Lines | High-speed, fully automated processes; can handle large volumes | Large breweries, commercial beverage manufacturers | Pros: High throughput, consistent quality. Cons: High upfront investment, complex maintenance. |

| Counter-Pressure Fillers | Maintains carbonation during filling; suitable for carbonated drinks | Craft breweries, soft drink manufacturers | Pros: Preserves product quality, reduces oxidation. Cons: More expensive, requires specific setup. |

| Compact Canning Machines | Space-saving designs; mobile configurations | Small breweries, on-premise beverage sales | Pros: Flexible placement, easy to move. Cons: Limited production capacity, may require frequent refills. |

What Are the Key Characteristics of Manual Can Seamers?

Manual can seamers are designed for small-scale production, making them ideal for craft breweries and small beverage operations. They are typically operated by hand and are cost-effective, allowing businesses to start canning without a significant financial investment. However, their labor-intensive nature and slower production rates can limit scalability, which is an important consideration for B2B buyers looking to grow their operations.

How Do Semi-Automatic Canning Systems Enhance Efficiency?

Semi-automatic canning systems streamline the canning process by combining manual loading with automated sealing. These machines are suitable for small to mid-sized breweries and cideries, offering a balance between efficiency and cost. While they increase productivity compared to manual systems, operators will need some training to operate the equipment effectively, and they may not be as scalable as fully automated solutions.

Why Are Fully Automatic Canning Lines Ideal for Large Producers?

Fully automatic canning lines are designed for high-speed operations, making them the go-to choice for large breweries and commercial beverage manufacturers. These systems offer consistent quality and can handle large volumes, significantly increasing throughput. However, the high upfront investment and complexity of maintenance may deter smaller operations, highlighting the importance of assessing production needs before purchase.

What Advantages Do Counter-Pressure Fillers Offer?

Counter-pressure fillers are specialized machines that maintain carbonation during the filling process, making them particularly suitable for carbonated beverages. They are popular among craft breweries and soft drink manufacturers who prioritize product quality. While these machines help reduce oxidation and preserve flavor, they come with a higher price tag and require specific setup, which may be a barrier for some buyers.

How Do Compact Canning Machines Benefit Smaller Operations?

Compact canning machines are designed with space-saving features and often come with mobile configurations, allowing small breweries and on-premise beverage sales to operate efficiently. Their flexibility in placement is a significant advantage, especially for businesses with limited space. However, their production capacity may be limited, necessitating frequent refills, which is a critical consideration for B2B buyers focused on operational efficiency.

Key Industrial Applications of canning machine

| Industry/Sector | Specific Application of canning machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Beverage Production | Craft Breweries canning craft beers | Enhances product shelf life and brand visibility | Need for compact, reliable machines with low maintenance costs |

| Food Processing | Canning of sauces, soups, and vegetables | Increases product distribution and market reach | Compliance with food safety regulations and quality standards |

| Pharmaceutical Industry | Canning liquid medications | Ensures product integrity and dosage accuracy | Need for specialized equipment to handle sensitive formulations |

| Coffee and Tea | Canning ready-to-drink coffee and tea products | Expands product offerings and improves shelf stability | Consideration for flavor preservation and can material options |

| Non-Alcoholic Beverages | Canning carbonated soft drinks and juices | Supports scalability and meets rising consumer demand | Requirement for high-speed filling and sealing capabilities |

How Are Canning Machines Used in Beverage Production?

Craft breweries leverage canning machines to package their craft beers efficiently. This process not only extends the shelf life of the product but also enhances brand visibility through appealing can designs. For international B2B buyers, particularly in regions like Europe or South America, sourcing compact and reliable canning machines is essential. These machines should require minimal maintenance to ensure uninterrupted production, especially in markets with varying supply chain challenges.

What Role Do Canning Machines Play in Food Processing?

In the food processing sector, canning machines are crucial for packaging sauces, soups, and vegetables. By using these machines, businesses can significantly increase their product distribution capabilities and market reach. Buyers in regions like Africa or the Middle East must prioritize compliance with local food safety regulations while selecting canning equipment. They also need to ensure that the machinery meets quality standards to maintain the integrity of the food products.

How Are Canning Machines Utilized in the Pharmaceutical Industry?

Canning machines are increasingly being adopted in the pharmaceutical industry for packaging liquid medications. This application is vital for ensuring product integrity and dosage accuracy, which are critical for patient safety. International buyers should consider sourcing machines that can handle sensitive formulations and comply with stringent pharmaceutical regulations. The ability to maintain sterility during the canning process is also a key requirement.

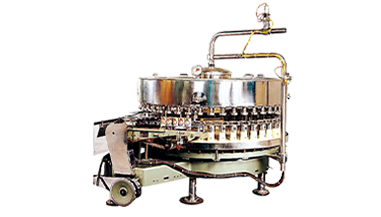

Illustrative image related to canning machine

How Do Canning Machines Benefit the Coffee and Tea Sector?

In the coffee and tea industry, canning machines are used to package ready-to-drink beverages, allowing companies to expand their product offerings. This method improves shelf stability and preserves the flavor profile of the drinks. Buyers need to focus on machines that provide effective sealing to prevent contamination and maintain freshness. Additionally, they should consider can materials that enhance flavor preservation, particularly in regions with diverse climatic conditions.

What Advantages Do Canning Machines Offer for Non-Alcoholic Beverages?

For non-alcoholic beverages like carbonated soft drinks and juices, canning machines enable businesses to scale production and meet growing consumer demand. This application is particularly relevant in emerging markets where demand for packaged beverages is rising. Buyers should look for high-speed filling and sealing capabilities to ensure efficiency and reduce production costs. It is also essential to consider the adaptability of the equipment for different can sizes and types to cater to diverse market preferences.

3 Common User Pain Points for ‘canning machine’ & Their Solutions

Scenario 1: Limited Production Capacity for Growing Businesses

The Problem: Many craft beverage producers, especially in regions like Africa and South America, struggle with scaling their production due to inadequate canning machinery. As demand for their products rises, they find that their current canning machines cannot keep up with the required output. This limitation not only affects their ability to meet market demands but can also lead to lost revenue opportunities. The challenge is further compounded when considering the need for a compact solution that fits within the constraints of their production space.

The Solution: To address this issue, B2B buyers should look for canning machines that offer modularity and scalability. For instance, investing in machines like the Oktober Can Seamers or American Canning Machines that provide various output options can significantly enhance production capacity. These machines often feature compact designs, allowing them to fit into smaller production areas without sacrificing efficiency. Additionally, buyers should consider equipment that allows for easy upgrades or expansions as their production needs grow. Collaborating with suppliers who provide flexible financing options can also help manage initial investments, allowing businesses to scale without financial strain.

Scenario 2: High Maintenance Costs and Downtime

The Problem: Another common pain point for B2B buyers is the high maintenance costs associated with canning machines, which can lead to significant downtime. In the competitive beverage industry, every minute of downtime translates to lost production and revenue. Buyers often find that machines require specialized parts that are difficult to source, leading to extended periods without functionality and increased operational costs.

Illustrative image related to canning machine

The Solution: To mitigate these issues, buyers should prioritize canning machines with readily available parts and robust customer support. Investing in machines like the Gosling 2.0, known for its reliability and ease of maintenance, can minimize downtime. Buyers should also establish relationships with manufacturers that offer comprehensive training for their staff, enabling them to perform basic maintenance tasks. This proactive approach reduces reliance on external technicians and minimizes downtime. Furthermore, implementing a regular maintenance schedule can help identify potential issues before they escalate, ensuring consistent operation.

Scenario 3: Quality Control Challenges During Canning

The Problem: Quality control is a critical concern for beverage producers, particularly when it comes to ensuring that the canning process does not compromise product integrity. Inconsistent sealing or filling can lead to spoilage or customer dissatisfaction, especially in markets with strict quality standards, such as Europe and the Middle East. This challenge can be exacerbated by using outdated equipment or improperly calibrated machines, causing variations in the final product.

The Solution: To enhance quality control, B2B buyers should invest in advanced canning machines that feature integrated quality monitoring systems. For example, machines with automatic counterpressure filling capabilities can ensure consistent fill levels and minimize oxygen exposure, which is crucial for maintaining product freshness. Buyers should also seek equipment that allows for easy calibration and adjustments, enabling operators to fine-tune settings based on the specific product being canned. Regular training sessions for staff on best practices in canning processes can further improve quality outcomes. Establishing a feedback loop from customers can also help producers continuously refine their processes, ensuring they meet evolving quality expectations.

Illustrative image related to canning machine

Strategic Material Selection Guide for canning machine

What Are the Key Materials Used in Canning Machines?

When selecting materials for canning machines, it is crucial to consider their properties, advantages, and limitations. This analysis focuses on four common materials: stainless steel, aluminum, plastic, and composite materials. Each material has unique characteristics that can significantly affect the performance and suitability of canning machines for various applications.

How Does Stainless Steel Perform in Canning Machines?

Key Properties: Stainless steel is known for its high corrosion resistance, strength, and ability to withstand high temperatures and pressures. It typically meets standards such as ASTM A240, ensuring durability in demanding environments.

Pros & Cons: The primary advantage of stainless steel is its durability and resistance to corrosion, making it ideal for handling acidic beverages. However, its high cost and manufacturing complexity can be drawbacks, particularly for smaller operations that may have budget constraints.

Illustrative image related to canning machine

Impact on Application: Stainless steel is suitable for a wide range of beverages, including carbonated drinks, due to its ability to maintain product integrity. Its smooth surface also facilitates easy cleaning and sanitation, which is critical in food and beverage production.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with local standards (e.g., DIN, JIS) when selecting stainless steel grades. Understanding the specific requirements for food-grade materials can help avoid costly compliance issues.

What Role Does Aluminum Play in Canning Machines?

Key Properties: Aluminum is lightweight, resistant to corrosion, and has good thermal conductivity. It typically has a lower melting point than stainless steel, which can influence manufacturing processes.

Pros & Cons: The lightweight nature of aluminum allows for easier handling and transportation. However, its lower strength compared to stainless steel may limit its use in high-pressure applications. Additionally, aluminum can react with certain acidic beverages, potentially affecting product quality.

Impact on Application: Aluminum is commonly used for beverage cans, making it a popular choice for canning machines. Its compatibility with various beverage types, including soft drinks and beers, enhances its appeal.

Considerations for International Buyers: Buyers should be aware of recycling regulations and sustainability practices in their regions, as aluminum is highly recyclable. Compliance with local environmental standards can also influence material selection.

How Do Plastics Fit into Canning Machine Design?

Key Properties: Plastics are lightweight, cost-effective, and can be molded into complex shapes. They offer varying degrees of chemical resistance depending on the type of plastic used.

Pros & Cons: The primary advantage of plastics is their low cost and versatility in design. However, they may not withstand high temperatures or pressures as effectively as metals, limiting their use in certain applications.

Impact on Application: While plastics can be used for non-pressurized containers, they may not be suitable for carbonated beverages. Their compatibility with specific media should be carefully evaluated.

Illustrative image related to canning machine

Considerations for International Buyers: Buyers should consider local regulations regarding food safety and material standards when selecting plastics. Understanding the specific grades of plastic that comply with international food safety standards is essential.

What Are the Benefits of Composite Materials in Canning Machines?

Key Properties: Composite materials combine different materials to achieve superior properties, such as increased strength and reduced weight. They can be engineered to resist corrosion and withstand various environmental conditions.

Pros & Cons: The main advantage of composites is their ability to be tailored for specific applications, offering high strength-to-weight ratios. However, they can be more expensive and complex to manufacture, which may deter some buyers.

Impact on Application: Composites are suitable for specialized applications where weight reduction is critical, such as portable canning machines. Their resistance to corrosion makes them ideal for various beverage types.

Considerations for International Buyers: Buyers should assess the availability of composite materials in their regions and ensure compliance with relevant standards. Understanding the lifecycle and recyclability of composites can also influence purchasing decisions.

Summary Table of Material Selection for Canning Machines

| Material | Typical Use Case for canning machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | High-volume beverage canning | Excellent durability and corrosion resistance | High cost and manufacturing complexity | High |

| Aluminum | Beverage cans | Lightweight and cost-effective | Lower strength and potential reactivity | Medium |

| Plastic | Non-pressurized containers | Low cost and versatile design | Limited temperature/pressure resistance | Low |

| Composite | Specialized portable canning systems | Tailored properties and lightweight | Higher cost and manufacturing complexity | High |

This strategic material selection guide provides B2B buyers with essential insights into the materials used in canning machines, helping them make informed decisions tailored to their specific needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for canning machine

What Are the Main Stages of Manufacturing a Canning Machine?

The manufacturing process of canning machines involves several critical stages, each essential for producing high-quality equipment that meets industry standards. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The manufacturing process begins with the selection of high-grade materials, typically stainless steel or aluminum, chosen for their durability and resistance to corrosion. Suppliers must ensure that materials comply with international standards such as ISO 9001, which emphasizes quality management and consistency.

-

Forming: This stage involves shaping the raw materials into components using techniques like stamping, welding, and machining. Advanced machinery, such as CNC (Computer Numerical Control) machines, is often employed to ensure precision and reduce waste. For canning machines, components like filling heads, seams, and frames are meticulously crafted to ensure they function seamlessly together.

-

Assembly: Once the individual components are formed, they are assembled into the final product. This stage often includes both manual labor and automated processes to ensure a high level of precision. Skilled technicians conduct assembly, ensuring that each part fits correctly and functions as intended. This is also the phase where initial testing of mechanical functions may occur.

-

Finishing: The final stage of manufacturing includes surface treatments such as polishing, anodizing, or coating to enhance durability and aesthetics. Quality assurance checks are performed at this stage to ensure that the canning machines meet the specified design and functionality standards before they are packaged for shipment.

How Is Quality Assurance Implemented in the Canning Machine Industry?

Quality assurance (QA) is a critical aspect of manufacturing canning machines, ensuring that products are reliable, safe, and meet customer expectations. Various international and industry-specific standards guide QA processes.

-

International Standards: Compliance with ISO 9001 is paramount for manufacturers. This standard provides a framework for quality management systems, focusing on continuous improvement and customer satisfaction. It mandates regular audits and documentation of processes, ensuring that all procedures meet the required quality benchmarks.

-

Industry-Specific Certifications: In addition to ISO, manufacturers may also seek certifications such as CE (Conformité Européenne) for compliance with European health, safety, and environmental protection standards. For those targeting markets in the Middle East or Africa, certifications from local standards organizations may also be necessary.

-

Quality Checkpoints: Quality control (QC) processes typically involve several checkpoints:

– Incoming Quality Control (IQC): This phase checks the quality of raw materials before they enter the production line. Suppliers must provide certificates of conformity and test reports to ensure materials meet specifications.

– In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to ensure that processes are followed correctly and that any defects are identified early.

– Final Quality Control (FQC): Before shipping, a comprehensive inspection of the final product is conducted. This includes functional testing, performance assessments, and visual inspections to verify that the canning machines meet all design specifications.

What Common Testing Methods Are Used for Canning Machines?

Manufacturers employ various testing methods to ensure the reliability and performance of canning machines. Common methods include:

-

Functional Testing: This involves operating the machine under normal conditions to evaluate its performance. Tests may include checking the filling accuracy, seam integrity, and speed of operation.

-

Pressure Testing: For machines that handle carbonated beverages, pressure testing is crucial. This method evaluates the machine’s ability to maintain pressure without leaks, ensuring product quality and safety.

-

Durability Testing: Canning machines undergo stress tests to simulate long-term use. This helps manufacturers identify potential failure points and address them before products reach the market.

-

Hygiene and Cleanability Testing: Given the food and beverage industry’s stringent hygiene requirements, machines are tested for ease of cleaning and sanitation compliance.

How Can B2B Buyers Verify Supplier Quality Control Processes?

When sourcing canning machines, B2B buyers must ensure that their suppliers have robust quality control processes in place. Here are some effective methods to verify QC:

-

Supplier Audits: Conducting on-site audits of potential suppliers allows buyers to assess their manufacturing processes, quality management systems, and adherence to international standards. This provides insight into the supplier’s commitment to quality.

-

Requesting Quality Reports: Buyers should ask for detailed QC reports that document the results of various tests conducted during the manufacturing process. These reports should outline compliance with international standards and any corrective actions taken for non-conformance.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the manufacturing facility and its processes. Inspectors can verify that the supplier meets both international and industry-specific standards.

-

Understanding QC Certifications: Buyers should familiarize themselves with the relevant certifications held by suppliers, such as ISO or CE certifications. These certifications indicate that the supplier adheres to established quality management practices and regulatory requirements.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, particularly from diverse markets like Africa, South America, the Middle East, and Europe, face unique challenges in ensuring quality control. Here are key considerations:

-

Cultural and Regulatory Differences: Understanding the local regulations and standards in different regions is crucial. Buyers must ensure that suppliers comply with both international standards and any local requirements that may apply.

-

Logistics and Supply Chain Management: The international supply chain can introduce complexities related to shipping and handling. Ensuring that suppliers have robust logistics practices can mitigate risks associated with damage or delays.

-

Communication and Support: Buyers should establish clear lines of communication with suppliers, particularly regarding quality issues. A responsive supplier will facilitate quicker resolutions to any concerns that arise.

-

Monitoring Supply Chain Performance: Regularly reviewing supplier performance metrics can help buyers identify trends or issues in quality over time. This proactive approach enables buyers to make informed decisions about their supply chain partners.

By understanding the manufacturing processes and quality assurance mechanisms in place for canning machines, B2B buyers can make informed decisions that align with their operational needs and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘canning machine’

Introduction

When sourcing a canning machine, it’s essential to navigate the complexities of equipment selection, supplier vetting, and operational needs. This practical checklist serves as a guide for B2B buyers, ensuring that you make informed decisions that align with your production goals, operational efficiency, and budget. By following these steps, you can streamline your procurement process and select the right canning machine for your business.

Step 1: Define Your Technical Specifications

Start by outlining the specific requirements for your canning operation. Consider factors such as the type of beverages you will be canning (carbonated vs. non-carbonated), the can sizes you plan to use, and your expected production volume. This clarity will help you identify machines that can meet your needs and prevent over- or under-investing in equipment.

- Capacity Needs: Determine how many cans you need to produce per minute or hour.

- Can Sizes: Decide on standard sizes, such as 12oz or 16oz, and ensure the machine can accommodate these.

Step 2: Assess Your Budget Constraints

Establish a realistic budget that includes not only the cost of the canning machine but also installation, maintenance, and operational expenses. Understanding your financial limits will guide your options and prevent unexpected costs down the line.

- Initial Costs vs. Long-Term Investment: Consider the total cost of ownership, including potential savings from efficiency and labor reduction.

- Financing Options: Look into leasing versus purchasing to see which aligns better with your cash flow.

Step 3: Evaluate Potential Suppliers

Conduct thorough research on potential suppliers before making a commitment. Request detailed company profiles, case studies, and references from other businesses in your industry or region. This due diligence ensures you partner with reliable manufacturers who can deliver quality equipment and support.

- Supplier Reputation: Investigate online reviews and testimonials to gauge customer satisfaction.

- After-Sales Support: Ensure that the supplier offers robust support, including maintenance services and readily available spare parts.

Step 4: Verify Compliance and Certifications

Ensure that the canning machines you are considering comply with international safety and quality standards. Certification can be indicative of a supplier’s commitment to quality and reliability, which is critical for maintaining your production standards.

- Quality Certifications: Look for certifications like ISO, CE, or local equivalents relevant to your region.

- Safety Standards: Confirm that machines adhere to safety regulations applicable in your operational area.

Step 5: Request Demonstrations or Trials

Before finalizing your purchase, request a demonstration of the canning machine. This allows you to see the machine in action and assess its performance, ease of use, and how it fits within your production workflow.

Illustrative image related to canning machine

- Operational Fit: Ensure the machine integrates seamlessly with your existing processes and equipment.

- User Experience: Evaluate how intuitive the controls are and whether training is required for your staff.

Step 6: Consider Scalability and Future Needs

Think about your long-term production goals and ensure the canning machine can scale with your business. A machine that can accommodate future growth will save you from needing to replace equipment as your production demands increase.

- Modular Options: Look for machines with modular capabilities that allow for upgrades or expansions.

- Flexibility: Ensure the machine can handle different can sizes and types as your product range evolves.

Step 7: Finalize Your Purchase Agreement

Once you have selected a supplier and a machine, carefully review and finalize the purchase agreement. Pay attention to warranty terms, payment schedules, and delivery timelines to avoid misunderstandings.

- Warranty and Service Agreements: Ensure you understand the terms of the warranty and what services are included.

- Delivery and Installation: Confirm the timeline for delivery and the installation process to align with your operational schedule.

By following this checklist, you can make a well-informed decision when sourcing a canning machine that meets your specific needs and supports your business growth.

Illustrative image related to canning machine

Comprehensive Cost and Pricing Analysis for canning machine Sourcing

What Are the Key Cost Components in Canning Machine Sourcing?

When sourcing canning machines, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The type of materials used significantly impacts the overall cost. High-grade stainless steel, for instance, offers durability and resistance to corrosion but comes at a higher price. Buyers should evaluate material options based on their specific operational needs and budget constraints.

-

Labor: Labor costs can vary based on the complexity of the machine and the skill level required for assembly and operation. Automated machines generally require less labor for operation but may necessitate skilled technicians for maintenance.

-

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and administrative expenses associated with production. Efficient manufacturers often have streamlined processes that can help reduce overhead costs.

-

Tooling: The initial investment in tooling can be significant, especially for customized machines. Buyers should inquire about tooling costs when requesting quotes, as these can be a one-time expense that affects the total cost.

-

Quality Control: Ensuring that machines meet industry standards incurs costs related to testing and certification. Machines with recognized certifications (like CE marking) may command a higher price but also provide assurance of quality and compliance.

-

Logistics: Shipping costs, including freight and insurance, are significant for international buyers. Understanding Incoterms is essential, as they dictate who is responsible for costs at various stages of shipping.

-

Margin: Finally, suppliers will include a margin that reflects their business model and market conditions. This margin can be negotiated, particularly for larger orders or long-term contracts.

How Do Price Influencers Affect Canning Machine Costs?

Several factors influence the pricing of canning machines, and savvy buyers can leverage these for better deals.

-

Volume/MOQ: Higher order volumes often lead to better pricing. Suppliers are more likely to offer discounts or favorable terms for bulk orders, making it vital for buyers to assess their projected needs accurately.

-

Specifications/Customization: Customized machines tailored to specific operational requirements can increase costs. Buyers should balance their need for customization with the potential for cost savings from standard models.

-

Quality and Certifications: Machines with higher quality standards and certifications typically come at a premium. However, investing in quality equipment can reduce long-term operational costs and maintenance issues.

-

Supplier Factors: The supplier’s reputation, reliability, and service offerings can influence pricing. Established suppliers may charge more due to their proven track record and customer support.

-

Incoterms: Understanding delivery terms can help manage logistics costs effectively. Buyers should clarify which party is responsible for shipping, insurance, and customs duties to avoid unexpected expenses.

What Are the Best Buyer Tips for Cost-Efficiency in Canning Machines?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, the following tips can enhance cost-efficiency:

-

Negotiation: Always negotiate pricing and terms. Suppliers often have flexibility, especially for large orders or repeat business. Building a relationship can also lead to better long-term pricing.

-

Total Cost of Ownership (TCO): Consider not just the purchase price but the total cost of ownership, including maintenance, operational costs, and potential downtime. A lower upfront cost may not always result in overall savings.

-

Understand Pricing Nuances: Be aware of currency fluctuations, tariffs, and taxes that can affect pricing. Buyers should factor these into their budget to avoid surprises.

-

Research Suppliers: Conduct thorough research on potential suppliers. Look for reviews, testimonials, and case studies to ensure they meet your quality and service expectations.

-

Plan for Scalability: Choose machines that can grow with your business. Investing in scalable technology may have a higher initial cost but can save money in the long run as your production needs increase.

Disclaimer

Prices mentioned in this analysis are indicative and may vary based on supplier, specifications, and market conditions. Always request detailed quotes and conduct due diligence before making purchasing decisions.

Alternatives Analysis: Comparing canning machine With Other Solutions

Exploring Alternative Solutions to Canning Machines

In the beverage production industry, canning machines play a crucial role in packaging and preserving products. However, various alternatives exist that can also meet the packaging needs of businesses. These alternatives can vary in terms of performance, cost, and usability, making it essential for B2B buyers to evaluate their options carefully.

Comparison Table

| Comparison Aspect | Canning Machine | Manual Filling Systems | Bottling Line Systems |

|---|---|---|---|

| Performance | High-speed, automated | Moderate, labor-intensive | High-speed, fully automated |

| Cost | Medium to high investment | Low initial cost | High initial investment |

| Ease of Implementation | Requires some training | Simple setup | Complex, requires professional installation |

| Maintenance | Moderate maintenance needs | Low maintenance | High maintenance demands |

| Best Use Case | Craft breweries, small to medium production | Small-scale operations, startups | Large-scale production facilities |

What Are the Pros and Cons of Manual Filling Systems?

Manual filling systems are often chosen for their low initial investment and straightforward operation. These systems are ideal for small-scale operations or startups where budget constraints are significant. They allow for flexibility in production quantities and can be easily adjusted to meet varying demands. However, the labor-intensive nature of manual filling can lead to slower production rates and inconsistencies in fill levels, which may affect product quality.

What Are the Advantages and Disadvantages of Bottling Line Systems?

Bottling line systems represent a fully automated approach to beverage packaging. They are designed for high-volume production, making them suitable for large-scale facilities. These systems can deliver exceptional speed and efficiency, significantly reducing labor costs over time. However, the initial investment is substantial, and they often require professional installation and ongoing maintenance. Additionally, their complexity can be a barrier for smaller operations or those just starting in the beverage industry.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When selecting between a canning machine and its alternatives, B2B buyers should consider their production scale, budget, and operational capabilities. For businesses looking to maintain high-quality standards with moderate production needs, a canning machine may offer the best balance of performance and flexibility. Conversely, startups may benefit from manual filling systems to minimize upfront costs, while larger producers should evaluate bottling line systems for their efficiency and speed. Ultimately, aligning the choice with the specific operational goals and production demands will ensure the most effective investment.

Essential Technical Properties and Trade Terminology for canning machine

What Are the Key Technical Properties of Canning Machines?

When considering a canning machine for your business, understanding its technical properties is crucial for ensuring efficient operation and product quality. Here are several key specifications that buyers should prioritize:

-

Filling Method

Canning machines typically utilize either atmospheric or counter-pressure filling methods. Atmospheric filling is suitable for non-carbonated beverages, while counter-pressure filling is essential for carbonated products to minimize foaming and ensure product integrity. Selecting the appropriate filling method can significantly impact product quality and shelf life. -

Production Rate

Measured in cans per minute (CPM), the production rate indicates how quickly a machine can fill and seal cans. Machines like the AT-1 can process 12 cans per minute, while high-speed options can handle over 60 CPM. Understanding your production needs helps in selecting a machine that aligns with your operational capacity and growth plans. -

Can Compatibility

Canning machines must accommodate various can sizes and shapes, including standard, sleek, and crowler cans. Models equipped with adjustable adapters offer versatility, which is particularly beneficial for businesses that plan to expand their product lines or packaging options. Ensuring the machine can handle your desired can types is vital for maintaining flexibility in production. -

Material and Build Quality

The material grade of a canning machine affects its durability and maintenance requirements. Stainless steel is often preferred for its resistance to corrosion and ease of cleaning. A robust build ensures longevity and can reduce downtime, which is critical for maintaining production schedules. -

Footprint and Mobility

For businesses with limited space, the footprint of a canning machine is an important consideration. Compact and mobile designs allow for efficient use of space and can facilitate closer placement to production tanks, which reduces the risk of product loss during transfer. Assessing the physical dimensions and mobility features is essential for optimizing your production layout. -

Automation Level

Canning machines range from fully automated systems to semi-automated options. Higher automation levels typically reduce labor costs and enhance efficiency. However, they may require a higher initial investment. Evaluate your staffing capabilities and production goals to determine the right level of automation for your operations.

What Are Common Trade Terminology and Jargon in the Canning Machine Industry?

Familiarizing yourself with industry-specific terminology is key to navigating the procurement process effectively. Here are several common terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding the role of OEMs is crucial when sourcing canning machines, as it affects warranty and service options. -

MOQ (Minimum Order Quantity)

MOQ signifies the smallest quantity of a product that a supplier is willing to sell. This term is particularly relevant when purchasing raw materials or components for canning machines. Knowing the MOQ helps buyers plan their inventory and budget. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers for specific products or services. Utilizing RFQs can ensure competitive pricing and help buyers make informed purchasing decisions based on detailed cost analysis. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of sellers and buyers in international transactions. Familiarity with these terms can prevent misunderstandings related to shipping costs, risks, and delivery responsibilities. -

TCO (Total Cost of Ownership)

TCO encompasses all costs associated with acquiring and operating a canning machine over its lifetime, including purchase price, maintenance, and operating costs. Understanding TCO is critical for assessing the long-term value of a canning machine investment. -

Lead Time

Lead time refers to the time it takes from placing an order to the delivery of the product. Knowing the lead time is vital for planning production schedules and ensuring timely availability of canning equipment.

Understanding these technical properties and industry terms will empower B2B buyers to make informed decisions when selecting canning machines, ultimately enhancing operational efficiency and product quality.

Navigating Market Dynamics and Sourcing Trends in the canning machine Sector

What Are the Current Market Dynamics and Key Trends in the Canning Machine Sector?

The global canning machine market is experiencing significant growth driven by the rising demand for canned beverages, including craft beers, soft drinks, and ready-to-drink cocktails. This trend is particularly pronounced in regions such as Africa, South America, the Middle East, and Europe, where urbanization and changing consumer preferences are leading to increased consumption of packaged beverages. International B2B buyers are also seeking automation solutions to enhance production efficiency and reduce labor costs, especially in markets like Germany and Saudi Arabia, where operational efficiency is paramount.

Emerging technologies in canning machinery are reshaping the landscape. Manufacturers are increasingly adopting smart technologies, such as IoT-enabled machines that allow for real-time monitoring and predictive maintenance. Additionally, the trend towards compact and mobile canning systems is gaining traction, offering flexibility for small and medium-sized enterprises (SMEs) in various production environments. Sustainability is also becoming a focal point, with buyers prioritizing machines that minimize waste and energy consumption while maximizing product quality.

The competitive landscape is further influenced by the rise of e-commerce platforms, allowing manufacturers to reach a broader audience. B2B buyers are now able to access a diverse range of canning solutions and suppliers from different regions, facilitating informed sourcing decisions based on pricing, technology, and service capabilities. Overall, the canning machine sector is evolving rapidly, presenting numerous opportunities for international buyers to enhance their operations and product offerings.

How Are Sustainability and Ethical Sourcing Influencing the Canning Machine Industry?

Sustainability is becoming a critical concern for businesses in the canning machine sector, with environmental impacts driving the demand for greener solutions. As consumers become more environmentally conscious, B2B buyers are increasingly looking for canning machines that utilize eco-friendly materials and processes. This includes sourcing equipment that reduces energy consumption and waste during production, as well as those that support the use of recyclable or biodegradable packaging materials.

The importance of ethical supply chains cannot be overstated. B2B buyers are now prioritizing suppliers who demonstrate a commitment to ethical sourcing practices, including fair labor standards and responsible resource management. Certifications such as ISO 14001 for environmental management and other green certifications are becoming key factors in the decision-making process for buyers. These certifications not only enhance a company’s reputation but also align with global sustainability goals, making them attractive to environmentally conscious consumers.

Illustrative image related to canning machine

Moreover, the integration of sustainable practices in the production of canning machines can lead to long-term cost savings. By investing in energy-efficient machines and sustainable materials, companies can reduce operational costs and enhance their market competitiveness. As sustainability continues to shape industry standards, B2B buyers must remain vigilant in selecting suppliers that align with their values and operational goals.

What Is the Brief Evolution of Canning Machines and Its Relevance to B2B Buyers?

The evolution of canning machines dates back to the early 19th century, when the canning process was first commercialized to preserve food and beverages. Initially, canning involved manual processes, which limited production capacity and efficiency. However, with advancements in technology, the introduction of automated canning machines revolutionized the industry, allowing for higher output and better product quality.

In recent years, the focus has shifted towards compact and versatile machines that cater to the needs of craft brewers and small beverage producers. These innovations have made canning accessible to a broader range of businesses, enabling them to enter the market without significant capital investment. For B2B buyers, understanding the historical context of canning technology provides valuable insights into the current landscape, highlighting the importance of flexibility, scalability, and sustainability in equipment choices.

As the market continues to evolve, international buyers must stay informed about the latest developments in canning technology and practices to ensure they are making strategic investments that will enhance their production capabilities and meet consumer demands.

Frequently Asked Questions (FAQs) for B2B Buyers of canning machine

-

How do I select the right canning machine for my production needs?

Choosing the right canning machine hinges on your production volume, the type of beverage, and the desired can size. Evaluate machines based on their filling speed (cans per minute), adaptability to different can sizes, and compatibility with your existing production setup. Additionally, consider features like automatic rinsing and carbonation management for enhanced efficiency. It’s also wise to consult with manufacturers to understand how their machines can scale with your business growth. -

What are the key features to look for in a canning machine?

When assessing canning machines, prioritize features such as ease of operation, maintenance requirements, and the ability to accommodate various can sizes. Look for automated filling and seaming processes, which reduce labor costs and enhance consistency. Additionally, consider the machine’s footprint, especially if space is a constraint, and ensure it has a robust support system for spare parts and service. -

What customization options are available for canning machines?

Many manufacturers offer customization options to meet specific production requirements. This can include modifications for different can sizes, labeling capabilities, and specialized filling techniques (like counter-pressure filling for carbonated beverages). Discuss your unique needs with suppliers to explore available options that can enhance your operational efficiency and product quality. -

What is the typical minimum order quantity (MOQ) for canning machines?

The minimum order quantity for canning machines can vary significantly between manufacturers. Typically, MOQs can range from one machine for smaller manufacturers to several units for larger suppliers. It’s essential to communicate your production goals and volume requirements to potential suppliers to negotiate terms that align with your business needs. -

What payment terms should I expect when purchasing a canning machine?

Payment terms can vary widely depending on the supplier and the size of the order. Commonly, you may encounter options such as a deposit upfront (often 30-50% of the total cost) with the balance due upon delivery or installation. Some suppliers may offer financing options or extended payment plans, particularly for larger orders. Always clarify terms before finalizing your purchase to avoid unexpected costs. -

How can I ensure the quality of the canning machine I am purchasing?

To ensure quality, research the manufacturer’s reputation through reviews, testimonials, and case studies. Verify their certifications, such as ISO or CE, which indicate adherence to international quality standards. Request product samples or demonstrations if possible, and inquire about warranty and support services. Additionally, consider visiting the manufacturer’s facility to witness their production processes firsthand. -

What logistics should I consider when importing a canning machine?

When importing a canning machine, factor in shipping costs, customs duties, and import regulations specific to your country. Understand the estimated delivery timeline and ensure that the supplier provides all necessary documentation for customs clearance. Consider working with a freight forwarder who specializes in industrial equipment to streamline the import process and mitigate potential delays. -

What are the common maintenance requirements for canning machines?

Regular maintenance is crucial for optimal performance and longevity of canning machines. Common maintenance tasks include cleaning components, checking for wear and tear, and ensuring proper lubrication of moving parts. Establish a maintenance schedule based on the manufacturer’s recommendations and consider training your staff to perform basic upkeep. Additionally, maintain a relationship with the supplier for any necessary repairs or replacement parts.

Top 4 Canning Machine Manufacturers & Suppliers List

1. Can With A Can – Filler/Seamer AT-3

Domain: canwithacm.com

Registered: 2024 (1 years)

Introduction: {“products”:[{“model”:”AT-1″,”type”:”Filler/Seamer”,”fill_type”:”Atmospheric Filling”,”capacity”:”12 Cans Per Minute”},{“model”:”AT-3″,”type”:”Filler/Seamer”,”fill_type”:”Atmospheric Filling”,”capacity”:”60 Cans Per Minute”},{“model”:”AT-6″,”type”:”Filler/Seamer”,”fill_type”:”Atmospheric Filling”,”capacity”:”60 Cans Per Minute”},{“model”:”CP-4″,”type”:”Filler/Seamer”,”fill_type”:”Counter-pressure …

2. Northern Brewer – Beer Canning Equipment

Domain: northernbrewer.com

Registered: 1999 (26 years)

Introduction: Beer Canning equipment selection includes can seamers, fillers, cans, canning accessories, and everything needed to can homebrewed beer. Current promotions include 30% off all Fall Beer Kits and Hard Cider Recipe Kits, as well as a variety pack called “Fireside Favorites.” The Malt of the Month is Rahr Pale Ale, with discounts up to 33% off. Free shipping is available on orders over $99.

3. Wild Goose – Gosling™ 2.0 Automated Canning System

Domain: wildgoosefilling.com

Registered: 2019 (6 years)

Introduction: Gosling™ 2.0 is an automated, entry-level beverage canning system designed for packaging small product volumes from tank or keg. It features:

– Filling speed: Up to 12 cans per minute

– Integrated control interface

– Automatic counterpressure filling with 2, 4, or 6 fill heads

– Automatic crowning

– Semi-automatic rinsing

– Dimensions: 5.5′ L x 3.5″ W (1.7 m L x 1.1 m W)

– Power: Single-phase 17A …

4. MoreBeer – Home Brewing Kits & Canning Supplies

Domain: morebeer.com

Registered: 1997 (28 years)

Introduction: Food Canning products available at MoreBeer include various home brewing kits, fermentation equipment, brewing ingredients, and canning supplies. Key offerings include 2-Gallon Flash Kits, Five Gallon Home Brewing Starter Kits, All Grain Brewing Equipment, and various beer recipe kits. The site also features brewing hardware, cleaning and sanitizing products, and equipment for other beverages like…

Strategic Sourcing Conclusion and Outlook for canning machine

In the rapidly evolving landscape of beverage packaging, strategic sourcing of canning machines is crucial for businesses aiming to enhance operational efficiency and product quality. With diverse options available—from compact manual seamers to sophisticated automated systems—international buyers must carefully assess their production needs, space constraints, and scalability potential. The right canning equipment not only streamlines operations but also allows for customization, ensuring that brands can present their products effectively with custom labeling and packaging.

Investing in reliable canning machines can lead to significant cost savings over time, especially when considering maintenance accessibility and the availability of spare parts. Moreover, as the demand for canned beverages continues to rise globally, particularly in regions like Africa and South America, businesses that prioritize quality and efficiency in their packaging processes are likely to gain a competitive edge.

Looking ahead, the focus should be on integrating innovative technologies that support sustainability and adaptability in production. International buyers are encouraged to explore partnerships with reputable manufacturers that offer robust support and guidance throughout the sourcing process. Taking these steps will not only position your business for immediate success but also foster long-term growth in a dynamic market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to canning machine

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.