Unlocking Value: A Strategic Analysis of the Cable Rolls Market

Introduction: Navigating the Global Market for cable rolls

Navigating the complexities of sourcing cable rolls can pose significant challenges for international B2B buyers, particularly those operating in diverse markets across Africa, South America, the Middle East, and Europe. With varying specifications, regulatory requirements, and supplier capabilities, finding reliable solutions that meet your operational needs is crucial. This guide addresses these challenges by providing a comprehensive overview of the global cable roll market, including various types, applications, and critical factors to consider when selecting suppliers.

By delving into essential aspects such as material specifications, cost analysis, and supplier vetting processes, this guide empowers B2B buyers to make informed purchasing decisions. It highlights the importance of understanding regional market dynamics and the specific requirements that may influence your procurement strategy. Whether you are looking for cable rolls for telecommunications, construction, or industrial applications, this resource will equip you with actionable insights to streamline your sourcing process.

Furthermore, we explore best practices for engaging with suppliers, ensuring compliance with international standards, and optimizing logistics to enhance your supply chain efficiency. With this knowledge at your fingertips, you can confidently navigate the global market for cable rolls, ensuring that your business remains competitive and responsive to changing demands.

Understanding cable rolls Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cable Reels | Designed for storage and transportation of various cables. | Telecommunications, construction, utilities. | Pros: Easy mobility; protects cables from damage. Cons: Requires space for storage. |

| Aerial Cable Rollers | Facilitate the installation of overhead cables; lightweight and durable. | Telecom installations, power distribution. | Pros: Reduces installation time; minimizes cable damage. Cons: May require specialized training for use. |

| Cable Spools | Used for winding cables; often custom-sized for specific applications. | Manufacturing, electrical assembly. | Pros: Customizable size; ideal for bulk operations. Cons: Limited mobility; can be cumbersome. |

| Overlash Cable Rollers | Specifically designed for guiding and supporting cables during installation. | Aerial cable installation, maintenance. | Pros: Prevents cable tangling; ensures proper alignment. Cons: Higher cost compared to standard rollers. |

| Heavy-Duty Cable Reels | Sturdy construction for heavy gauge cables; often weather-resistant. | Industrial applications, outdoor installations. | Pros: Durable; suitable for harsh environments. Cons: Heavier and less portable than standard reels. |

What Are Cable Reels and Their Key Features?

Cable reels are essential for the efficient storage and transportation of various types of cables. They come in different sizes and materials, catering to specific needs within industries such as telecommunications and construction. When purchasing cable reels, consider factors such as weight capacity, material durability, and ease of transport. These reels not only protect cables from damage but also streamline the installation process, making them indispensable for B2B operations.

How Do Aerial Cable Rollers Enhance Installation Efficiency?

Aerial cable rollers are designed to simplify the installation of overhead cables, offering lightweight yet robust solutions. These tools are particularly useful in telecommunications and power distribution sectors, where efficiency is critical. When selecting aerial cable rollers, assess their load capacity and compatibility with the types of cables being installed. Proper usage of these rollers can significantly reduce installation time and minimize the risk of cable damage, making them a valuable investment for businesses.

What Are the Advantages of Using Cable Spools?

Cable spools are primarily utilized for winding and storing cables, often tailored to specific dimensions for unique applications in manufacturing and electrical assembly. They provide a convenient way to manage large quantities of cable, ensuring that it remains organized and protected. Buyers should consider the spool’s material, size, and compatibility with the cable type. While spools are effective for bulk operations, they can be cumbersome and may require additional storage space.

What Makes Overlash Cable Rollers Unique?

Overlash cable rollers are specialized tools that guide and support cables during the installation process, particularly in aerial applications. Their design helps prevent tangling and ensures proper alignment of cables, which is crucial for maintaining system integrity. When purchasing these rollers, it’s important to evaluate their cost against the potential savings in time and labor during installation. Although they may be more expensive than standard rollers, their benefits often justify the investment.

Why Choose Heavy-Duty Cable Reels for Industrial Use?

Heavy-duty cable reels are constructed to handle larger, heavier gauge cables and are often designed to withstand harsh outdoor conditions. These reels are ideal for industrial applications where durability and reliability are paramount. When selecting heavy-duty reels, consider their weather resistance, weight capacity, and ease of mobility. While they provide excellent protection and longevity, their weight can make them less portable, which is an important consideration for businesses that require frequent relocation of equipment.

Key Industrial Applications of cable rolls

| Industry/Sector | Specific Application of cable rolls | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Telecommunications | Installation of fiber optic cables | Enhanced network speed and reliability | Ensure compatibility with local standards and environmental conditions. |

| Construction | Power supply for heavy machinery on-site | Increased operational efficiency and reduced downtime | Evaluate the durability and load capacity of the cable rolls. |

| Energy & Utilities | Laying down power lines and cable management | Streamlined operations and improved safety measures | Look for reels that support various cable types and sizes. |

| Event Management & Entertainment | Managing power distribution for events and exhibitions | Improved logistics and reduced risk of power failures | Consider portability and ease of setup for rapid deployment. |

| Manufacturing | Wire management in production processes | Enhanced safety and organization in workspaces | Assess material quality and resistance to wear and tear. |

How Are Cable Rolls Used in Telecommunications?

In the telecommunications sector, cable rolls are critical for the installation of fiber optic cables. These rolls facilitate the efficient handling and deployment of cables, which are essential for establishing high-speed internet and communication networks. International B2B buyers need to consider local regulations and standards, especially in regions like Africa and South America, where infrastructure may vary significantly. Ensuring that the cable rolls can withstand environmental conditions, such as humidity or extreme temperatures, is vital for long-term performance.

What Role Do Cable Rolls Play in Construction?

In construction, cable rolls provide a reliable power supply for heavy machinery and tools on-site. By utilizing cable rolls, companies can enhance operational efficiency and minimize downtime, as they can quickly deploy power wherever it’s needed. Buyers should evaluate the load capacity and durability of the cable rolls, particularly in regions like the Middle East, where construction sites may face harsh conditions. Understanding the specific power requirements of machinery is essential to ensure optimal performance and safety.

Why Are Cable Rolls Important for Energy & Utilities?

Cable rolls are indispensable in the energy and utilities industry for laying down power lines and managing cables during installation. They help streamline operations and improve safety by keeping cables organized and easily accessible. For international buyers, especially in Europe and Africa, it’s crucial to source cable rolls that are compatible with various cable types and sizes, as this can directly impact the efficiency of installation projects. Additionally, understanding local sourcing regulations can facilitate smoother operations.

How Do Cable Rolls Enhance Event Management?

In the event management and entertainment sectors, cable rolls are used to manage power distribution effectively during events and exhibitions. They allow for quick setup and breakdown, which is essential for time-sensitive operations. Buyers should consider the portability and ease of setup of these cable rolls, particularly in dynamic environments where time is of the essence. Ensuring that the rolls can handle high power loads without failure is also a critical factor for maintaining operational integrity.

What Benefits Do Cable Rolls Offer in Manufacturing?

Within manufacturing, cable rolls are utilized for efficient wire management in production processes. They help maintain organization and safety in workplaces, reducing the risk of accidents caused by tangled wires. Buyers in this sector should assess the quality of materials used in cable rolls, ensuring they are resistant to wear and tear, especially in high-traffic areas. Understanding the specific requirements of the manufacturing processes can aid in selecting the most suitable cable rolls for their needs.

3 Common User Pain Points for ‘cable rolls’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Cable Roll for Specific Applications

The Problem: Many B2B buyers struggle with choosing the correct type of cable roll that aligns with their operational requirements. This challenge is particularly acute in sectors like telecommunications and construction, where different cable types (e.g., fiber optic, copper) require specific spool designs to ensure optimal performance and durability. A buyer might select a cable roll that is either too small, leading to overloading and potential damage, or too large, resulting in unnecessary costs and storage issues. This misalignment can disrupt project timelines and inflate budgets, causing frustration and operational inefficiencies.

The Solution: To address this issue, buyers should first conduct a thorough assessment of their specific cable needs, including gauge, length, and environmental conditions. Collaborating closely with manufacturers can provide insights into the appropriate spool sizes and materials. For instance, lightweight, high-strength materials may be ideal for aerial applications, while more robust designs might be necessary for underground installations. Furthermore, utilizing online resources or consulting with industry experts can help buyers understand the nuances of different cable types and their compatibility with various cable rolls. Establishing a standardized specification guide can also streamline the procurement process and minimize the chances of error.

Scenario 2: Managing Cable Roll Storage and Logistics Challenges

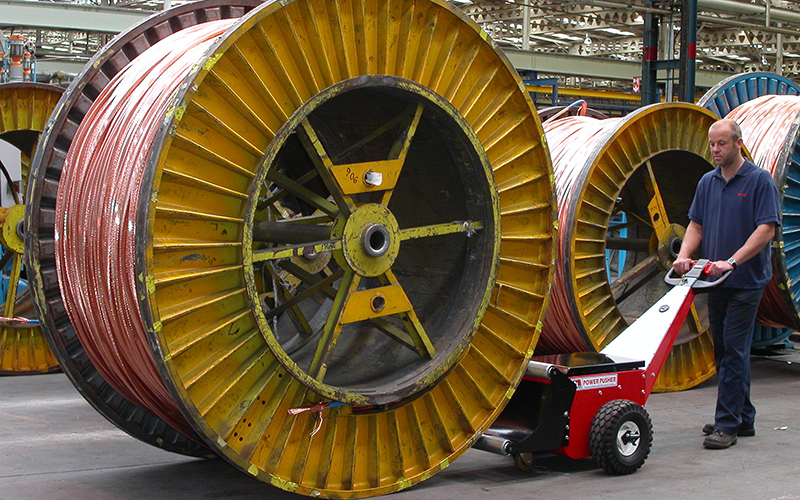

The Problem: Efficient storage and handling of cable rolls can pose significant logistical challenges for B2B buyers. Large, cumbersome rolls can occupy excessive space in warehouses or job sites, leading to clutter and inefficiencies. Additionally, improper storage can result in damage to the cables, such as kinks or abrasions, which can severely impact their functionality. Buyers often face difficulties in tracking inventory, leading to delays in project execution when they cannot quickly access the cables they need.

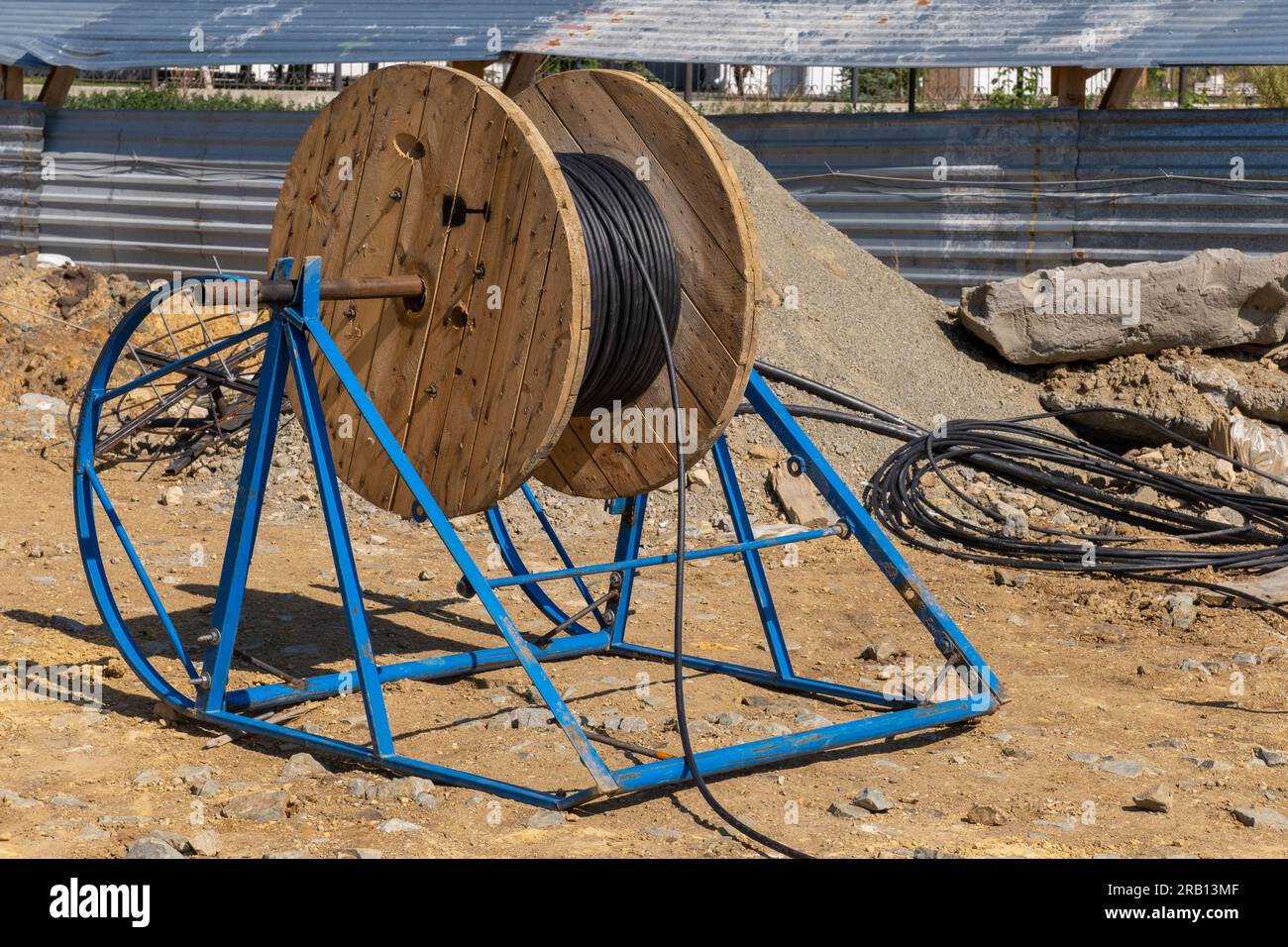

Illustrative image related to cable rolls

The Solution: Implementing a well-organized storage system is essential for managing cable rolls effectively. Buyers should consider utilizing vertical storage solutions or specialized racks that can accommodate various roll sizes while maximizing space efficiency. Additionally, adopting inventory management software can facilitate real-time tracking of cable rolls, ensuring that stock levels are maintained and easily accessible. Incorporating regular audits can help identify damaged rolls before they are deployed, thus maintaining the integrity of the supply. Training staff on proper handling techniques will further reduce the risk of damage and ensure that cables are stored in optimal conditions.

Scenario 3: Ensuring Compliance with Industry Standards and Regulations

The Problem: B2B buyers often grapple with the complexities of ensuring that their cable rolls meet the necessary industry standards and regulations. Non-compliance can result in legal repercussions, project delays, and increased costs due to fines or the need for replacements. This is particularly important in regions where safety and environmental standards are stringent, such as in Europe and parts of the Middle East. Buyers may find it challenging to keep abreast of the latest regulations and certifications, leading to inadvertent oversights.

The Solution: To mitigate compliance issues, buyers should establish a robust compliance management system that includes regular training and updates on relevant regulations. Engaging with suppliers who are transparent about their compliance certifications can streamline the procurement process. Buyers should request documentation proving that cable rolls meet international standards, such as UL or IEC certifications. Furthermore, leveraging industry associations and networks can provide valuable resources and updates on regulatory changes. Conducting periodic compliance audits will ensure ongoing adherence to standards, helping to maintain operational integrity and protect against potential liabilities.

Strategic Material Selection Guide for cable rolls

When selecting materials for cable rolls, it’s essential to consider the properties, advantages, and limitations of each option. This guide analyzes four common materials used in the manufacturing of cable rolls, providing valuable insights for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe.

What are the Key Properties of Polypropylene in Cable Rolls?

Polypropylene (PP) is a thermoplastic polymer known for its excellent chemical resistance and lightweight nature. It typically has a temperature rating of up to 100°C and offers good impact resistance. This makes it suitable for various environments, including those with exposure to moisture and chemicals.

Illustrative image related to cable rolls

Pros and Cons of Polypropylene:

– Pros: Lightweight, cost-effective, and resistant to moisture and chemicals. Its flexibility allows for easy handling and transportation.

– Cons: Limited high-temperature resistance compared to other materials, which may affect performance in extreme conditions. It can also be less durable under constant UV exposure unless treated.

Impact on Application:

Polypropylene is compatible with a wide range of media, making it suitable for various cable types. However, its limitations in high-temperature scenarios may restrict its use in certain industrial applications.

Considerations for International Buyers:

Buyers should ensure compliance with local standards, such as ASTM or DIN, particularly in regions with stringent regulations. In markets like Europe and Germany, where environmental regulations are strict, selecting polypropylene that meets these standards is crucial.

How Does Steel Compare as a Material for Cable Rolls?

Steel, particularly galvanized steel, is known for its strength and durability. It can withstand high temperatures and pressures, making it ideal for heavy-duty applications. Steel cable rolls can handle extreme loads and offer excellent corrosion resistance when treated.

Illustrative image related to cable rolls

Pros and Cons of Steel:

– Pros: Exceptional strength and durability, high-temperature resistance, and longevity. Steel is also recyclable, making it an environmentally friendly option.

– Cons: Heavier than other materials, which can increase shipping costs. It may also be more expensive to manufacture and process, leading to higher initial costs.

Impact on Application:

Steel is particularly suited for applications requiring high load-bearing capacity, such as in construction or heavy machinery. Its robustness ensures that it can handle various environmental stresses.

Considerations for International Buyers:

Steel products must meet specific standards, such as JIS in Japan or ASTM in the U.S. Buyers in regions like the Middle East and Africa should also consider the availability of steel and the associated costs of transportation and logistics.

What Role Does Aluminum Play in Cable Roll Manufacturing?

Aluminum is lightweight and offers good corrosion resistance, making it a popular choice for cable rolls. It has a temperature rating of around 150°C, which allows it to perform well in various applications.

Pros and Cons of Aluminum:

– Pros: Lightweight, corrosion-resistant, and excellent for applications requiring frequent handling. Aluminum’s conductivity also makes it suitable for electrical applications.

– Cons: Less durable than steel, which may limit its use in heavy-duty applications. It can also be more expensive than polypropylene.

Impact on Application:

Aluminum is ideal for applications that require a balance between weight and strength, such as in telecommunications. However, its lower durability compared to steel may necessitate more frequent replacements.

Considerations for International Buyers:

When sourcing aluminum cable rolls, buyers should verify compliance with international standards and consider the material’s recyclability, which is increasingly important in markets focused on sustainability.

What are the Benefits of Using Composite Materials for Cable Rolls?

Composite materials, such as fiberglass-reinforced plastics, offer unique advantages. They are lightweight and resistant to corrosion, with temperature ratings often exceeding 120°C.

Illustrative image related to cable rolls

Pros and Cons of Composites:

– Pros: High strength-to-weight ratio, excellent corrosion resistance, and low thermal conductivity. Composites can be tailored for specific applications, enhancing performance.

– Cons: Higher manufacturing complexity and costs, which can impact pricing. They may also require specialized handling during installation.

Impact on Application:

Composites are particularly beneficial in environments where corrosion is a significant concern, such as coastal areas or chemical plants. Their versatility allows for customization based on specific application needs.

Considerations for International Buyers:

Buyers should ensure that composite materials meet local and international standards, particularly in markets with strict regulations regarding material safety and environmental impact.

Summary Table of Material Selection for Cable Rolls

| Material | Typical Use Case for Cable Rolls | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polypropylene | General-purpose cable rolls | Lightweight and cost-effective | Limited high-temperature resistance | Low |

| Steel | Heavy-duty applications | Exceptional strength and durability | Heavier and more expensive | High |

| Aluminum | Electrical and telecommunications cables | Lightweight and corrosion-resistant | Less durable than steel | Medium |

| Composite | Corrosive environments | High strength-to-weight ratio | Higher manufacturing complexity | High |

This strategic material selection guide aims to equip international B2B buyers with the necessary insights to make informed decisions regarding cable roll materials, ensuring compatibility with their specific applications and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for cable rolls

What Are the Key Stages in the Manufacturing Process of Cable Rolls?

The manufacturing of cable rolls involves several critical stages that ensure the final product meets industry standards and customer expectations. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation

The first step in the manufacturing process is selecting and preparing the raw materials. Common materials used in cable rolls include high-quality plastics, metals (such as aluminum or steel), and various types of wire. The materials undergo inspection to ensure they meet specified standards for durability and conductivity. This phase may also involve cutting the raw materials to predetermined lengths and widths suitable for the intended cable roll design. -

Forming

In the forming stage, the prepared materials are shaped into the components of the cable roll. This can involve processes such as injection molding for plastic parts or stamping and bending for metal components. Advanced techniques like CNC machining may be employed to achieve high precision in the forming process. The goal is to create a robust structure that can withstand the mechanical stresses encountered during use. -

Assembly

Once the individual components are formed, they are assembled into the final cable roll product. This step often involves automated assembly lines where parts are fitted together using adhesives, screws, or welding, depending on the materials used. Quality checks are performed at this stage to ensure alignment and fit, as any discrepancies can affect the roll’s performance. -

Finishing

The finishing stage includes surface treatments, painting, or coating to enhance durability and aesthetics. For example, corrosion-resistant coatings may be applied to metal parts, while plastics may undergo UV stabilization to prevent degradation from sunlight exposure. This stage also involves final inspections to ensure that the cable rolls are free from defects and meet the required specifications.

How Is Quality Assurance Integrated into Cable Roll Manufacturing?

Quality assurance (QA) is a crucial aspect of the manufacturing process, ensuring that the final products meet both international standards and customer requirements. The QA process typically involves several key practices and checkpoints.

-

International Standards for Quality Assurance

Many manufacturers adhere to international standards such as ISO 9001, which outlines criteria for a quality management system. Compliance with ISO 9001 ensures that organizations consistently provide products that meet customer and regulatory requirements. Additionally, certifications like CE marking signify that products meet EU safety, health, and environmental protection standards. For manufacturers targeting specific markets, certifications from industry bodies, such as API for oil and gas applications, may also be relevant. -

Quality Control Checkpoints

The quality control process is often divided into several checkpoints:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival at the manufacturing facility. Materials that do not meet specifications are rejected or returned to suppliers.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, various inspections are conducted to ensure that components meet quality standards. This may include dimensional checks, visual inspections, and functional tests during assembly.

-

Final Quality Control (FQC): After assembly, a thorough inspection is conducted on the finished cable rolls. This includes testing for strength, flexibility, and other performance characteristics, ensuring that the product is ready for distribution.

- Common Testing Methods for Cable Rolls

Various testing methods are employed to validate the quality of cable rolls, including:

- Tensile Testing: Measures the strength and elasticity of materials used in the cable rolls.

- Electrical Testing: Ensures that the cable rolls can handle the intended voltage and current without failure.

- Environmental Testing: Assesses the product’s durability under extreme conditions, such as high temperatures or moisture.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers, especially those sourcing from international suppliers, must take proactive steps to verify the quality control practices of their manufacturers.

-

Conducting Supplier Audits

One of the most effective ways to assess a supplier’s quality control measures is by conducting on-site audits. This allows buyers to inspect the manufacturing process, review quality documentation, and meet with quality assurance personnel. Regular audits can help identify potential issues before they impact product quality. -

Requesting Quality Assurance Documentation

Buyers should request documentation that outlines the supplier’s quality assurance processes, including certifications and test reports. This documentation should detail compliance with relevant standards and provide evidence of testing performed on the products. -

Utilizing Third-Party Inspection Services

Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s quality control practices. These agencies can perform inspections at various stages of production, ensuring that the products meet the agreed-upon specifications before shipment.

What Are the Quality Control Nuances for International Buyers?

International buyers face unique challenges when it comes to quality control in the procurement of cable rolls.

-

Understanding Regional Standards

Different regions may have specific regulations and standards governing cable products. Buyers must familiarize themselves with these standards to ensure compliance. For example, European buyers may prioritize CE marking, while those in North America may look for UL certification. -

Dealing with Language and Cultural Barriers

Communication issues can arise when dealing with international suppliers. It is essential for buyers to establish clear communication channels and possibly engage local representatives who understand the market and the language. -

Managing Logistics and Shipping Challenges

Quality can be compromised during shipping if proper handling protocols are not followed. Buyers should ensure that suppliers implement adequate packaging and shipping procedures to protect the integrity of the cable rolls during transit.

By understanding the manufacturing processes and quality assurance measures in place, B2B buyers can make informed decisions when sourcing cable rolls. This knowledge not only enhances procurement strategies but also helps in establishing long-term partnerships with reliable suppliers across different regions.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cable rolls’

When sourcing cable rolls for your business, it’s essential to approach the procurement process systematically. This guide provides actionable steps to ensure you select the right products from reputable suppliers, ultimately leading to successful project execution and customer satisfaction.

Step 1: Define Your Technical Specifications

Begin by clarifying the specific requirements for the cable rolls you need. Consider factors such as the type of cable (e.g., power, fiber optic), gauge, insulation material, and length. This step is crucial as it sets the foundation for your sourcing process and helps you communicate effectively with suppliers.

- Cable Type: Identify whether you need low-voltage, high-voltage, or specialty cables for specific applications.

- Gauge and Length: Determine the required gauge (AWG) and length to avoid compatibility issues in your projects.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in cable rolls. Look for companies with a proven track record and a strong presence in your target regions, such as Africa, South America, the Middle East, or Europe.

- Industry Experience: Check how long they have been in the industry and their expertise in handling your specific cable types.

- Reputation: Read reviews and testimonials from other B2B buyers to gauge their reliability and product quality.

Step 3: Evaluate Supplier Certifications

Before finalizing a supplier, verify their certifications and compliance with international standards. This step is vital to ensure that the cable rolls meet safety and quality regulations in your region.

- ISO Certifications: Look for suppliers with ISO 9001 certifications, indicating a commitment to quality management.

- Product Certifications: Ensure that the cables are UL-listed or have other relevant certifications based on the intended application.

Step 4: Request Samples

Once you have narrowed down potential suppliers, request samples of the cable rolls. This step allows you to assess the quality of the products first-hand and determine if they meet your specifications.

- Material Quality: Inspect the insulation, flexibility, and overall build quality of the samples.

- Performance Testing: If possible, conduct performance tests to evaluate durability and functionality in real-world conditions.

Step 5: Negotiate Terms and Pricing

Engage in discussions with your shortlisted suppliers to negotiate pricing, payment terms, and delivery schedules. This is an important step to ensure that you receive the best value for your investment.

- Bulk Discounts: Inquire about discounts for bulk orders, which can significantly reduce overall costs.

- Payment Flexibility: Consider negotiating payment terms that align with your cash flow needs.

Step 6: Finalize the Order and Confirm Logistics

After agreeing on terms, finalize the order and confirm the logistics of delivery. This step is critical to ensure timely receipt of your cable rolls and to avoid project delays.

- Delivery Timeline: Establish a clear timeline for when the products will arrive at your location.

- Shipping Costs: Confirm shipping costs and logistics to avoid unexpected expenses.

Step 7: Evaluate After-Sales Support

Finally, assess the after-sales support offered by the supplier. This is essential for addressing any issues that may arise post-purchase.

- Warranty Policies: Understand the warranty terms for the cable rolls to ensure you are covered for any defects.

- Customer Service Availability: Ensure that the supplier has a responsive customer service team to assist with any inquiries or issues.

By following these steps, you can streamline your procurement process for cable rolls and ensure that you make informed decisions that support your business objectives.

Comprehensive Cost and Pricing Analysis for cable rolls Sourcing

What Are the Key Cost Components in Cable Rolls Sourcing?

When sourcing cable rolls, understanding the cost structure is crucial for effective budgeting and negotiation. The primary components include:

-

Materials: The choice of materials significantly impacts cost. Common materials for cable rolls include copper, aluminum, and various plastic compounds. High-quality materials may command a premium but can also enhance durability and performance.

-

Labor: Labor costs vary depending on the region and the complexity of the manufacturing process. Skilled labor is often required for specialized cable production, which can elevate costs.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, including utilities, facility maintenance, and administrative expenses. Efficient manufacturing processes can help reduce overhead costs.

-

Tooling: The initial investment in tooling can be substantial, especially for custom cable rolls. These costs should be factored into the overall pricing, particularly for low-volume orders.

-

Quality Control (QC): Maintaining high quality is essential, particularly for industries that require stringent compliance. Implementing QC measures adds to the cost but is necessary to ensure product reliability and safety.

-

Logistics: Transportation and handling costs can vary widely based on the distance, mode of transport, and shipping conditions. International buyers should be particularly mindful of these costs, which can escalate based on location.

-

Margin: Suppliers typically add a markup to cover their costs and ensure profitability. Understanding the standard margins in your target market can provide leverage during negotiations.

What Influences Pricing in Cable Rolls?

Several factors influence the pricing of cable rolls, including:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often provide better pricing for larger orders. Understanding MOQ requirements can lead to cost savings.

-

Specifications and Customization: Customized cable rolls tailored to specific requirements may incur additional costs. It’s essential to balance customization needs with budget constraints.

-

Material Quality and Certifications: Premium materials and certifications (e.g., UL, CE) can increase costs but may be necessary for compliance and performance assurance in certain markets.

-

Supplier Factors: The reputation, location, and reliability of suppliers can influence pricing. Established suppliers may charge more due to their experience and product quality.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for international transactions. They define the responsibilities of buyers and sellers concerning shipping, insurance, and tariffs, which can affect overall pricing.

What Are Effective Buyer Tips for Sourcing Cable Rolls?

-

How to Negotiate for Better Prices?: Engage in open dialogue with suppliers about pricing structures. Highlight your potential for repeat business or bulk orders to negotiate favorable terms.

-

What Is Total Cost of Ownership (TCO)?: Consider TCO beyond initial pricing. Assess factors such as durability, maintenance, and logistics costs over the product’s lifecycle to make informed purchasing decisions.

-

What Are the Pricing Nuances for International Buyers?: International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of currency fluctuations, import duties, and shipping complexities that can affect pricing.

-

How to Ensure Cost-Efficiency?: Regularly evaluate supplier performance and pricing. Building long-term relationships can lead to better pricing agreements and improved service.

-

What Should Be Your Pricing Strategy?: Be flexible and prepared to adjust your pricing strategy based on market trends and supplier capabilities. Staying informed about industry standards and competitors can enhance your negotiating position.

Disclaimer on Indicative Prices

Please note that prices for cable rolls can vary significantly based on the factors mentioned above. Always request detailed quotes from suppliers to ensure accurate budgeting and financial planning.

Alternatives Analysis: Comparing cable rolls With Other Solutions

Exploring Viable Alternatives to Cable Rolls for B2B Buyers

In the dynamic landscape of cable management solutions, understanding available alternatives to cable rolls is crucial for businesses looking to optimize their operations. This section evaluates two notable alternatives—cable drums and cable trays—against cable rolls, providing insights into their performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Cable Rolls | Cable Drums | Cable Trays |

|---|---|---|---|

| Performance | High efficiency in deployment and storage | Excellent for large cable quantities | Suitable for organized cable management |

| Cost | Moderate initial investment | Higher initial cost | Variable, depending on materials |

| Ease of Implementation | Simple setup and mobility | Requires more handling | Complex installation required |

| Maintenance | Low maintenance | Moderate maintenance needed | Low maintenance |

| Best Use Case | Ideal for temporary setups and installations | Best for long-term storage of heavy cables | Optimal for permanent installations in buildings |

What Are the Advantages and Disadvantages of Cable Drums?

Cable drums are cylindrical containers designed to hold large amounts of cable, often used in industrial settings. Their primary advantage is the ability to store and transport extensive lengths of heavy cables efficiently. However, their initial investment is typically higher than that of cable rolls, and they can be cumbersome to handle, requiring additional equipment for loading and unloading. This can make them less practical for smaller jobs or temporary installations.

Illustrative image related to cable rolls

How Do Cable Trays Compare in Terms of Efficiency?

Cable trays serve as a structural framework for supporting insulated electrical cables. They offer an organized way to manage cables, reducing clutter and improving accessibility. This solution is particularly effective for permanent installations in commercial and industrial buildings. However, the installation process can be complex and labor-intensive, potentially leading to higher costs and longer project timelines. While maintenance is minimal, any modifications to the cable system may require additional labor.

Conclusion: How to Choose the Right Solution for Your Business Needs?

When selecting the most appropriate cable management solution, B2B buyers should consider their specific operational needs, budget constraints, and the nature of their projects. Cable rolls provide an excellent balance of efficiency and mobility for temporary setups, while cable drums and trays cater to more permanent and heavy-duty applications. By assessing performance, cost, ease of implementation, and maintenance, businesses can make informed decisions that align with their operational goals, ensuring optimal cable management solutions that enhance productivity and efficiency.

Essential Technical Properties and Trade Terminology for cable rolls

Understanding the essential technical specifications and trade terminology associated with cable rolls is crucial for B2B buyers, particularly in international markets. This knowledge not only facilitates better purchasing decisions but also ensures compliance with industry standards and enhances operational efficiency.

What are the Key Technical Properties of Cable Rolls?

1. Material Grade

The material used in cable rolls significantly impacts their durability and performance. Common materials include polyethylene, PVC, and various metals. Each material has distinct properties, such as resistance to abrasion, temperature, and environmental factors. Understanding material grade helps buyers select cable rolls that align with their specific application requirements, particularly in challenging environments such as outdoor installations.

2. Voltage Rating

The voltage rating indicates the maximum voltage the cable can safely handle. This specification is critical for ensuring electrical safety and preventing failures. B2B buyers must ensure that the voltage rating of the cable roll matches the requirements of their intended application, as underestimating this can lead to severe operational hazards.

Illustrative image related to cable rolls

3. Wire Gauge (AWG)

The American Wire Gauge (AWG) system measures the diameter of the wire. A lower gauge number indicates a thicker wire, which can carry more current. Selecting the appropriate wire gauge is vital for maintaining optimal current flow and reducing the risk of overheating. Buyers should consider the electrical load and distance of the installation when determining the appropriate gauge.

4. Tensile Strength

Tensile strength measures the maximum stress a material can withstand while being stretched or pulled before breaking. This property is particularly important for cable rolls used in aerial applications or where cables are subjected to tension. High tensile strength ensures longevity and reliability, making it a critical factor in the selection process.

5. Temperature Rating

The temperature rating specifies the range of temperatures within which the cable can operate effectively without degrading. This property is essential for applications in extreme environments, as failure to adhere to temperature limits can lead to insulation breakdown and electrical failures. Buyers should evaluate the operational environment to select cable rolls with suitable temperature ratings.

Illustrative image related to cable rolls

What are Common Trade Terms Related to Cable Rolls?

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components or products that are marketed by another company. In the context of cable rolls, buyers may seek OEM products to ensure compatibility with existing systems or to meet specific industry standards. Understanding OEM relationships can help buyers navigate supplier options more effectively.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is crucial for budgeting and inventory management, especially for B2B buyers who may need to balance their purchasing needs with financial constraints. Buyers should be aware of MOQ requirements to avoid overstocking or incurring additional costs.

3. RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price quotes from suppliers for specific products or services. This process is essential for comparing costs and securing the best deal. B2B buyers should prepare detailed RFQs to ensure they receive accurate and competitive quotes from potential suppliers.

4. Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is critical for B2B buyers engaged in cross-border trade, as they clarify aspects like shipping costs, risk transfer, and delivery obligations. Familiarity with Incoterms can help buyers negotiate better terms and avoid misunderstandings.

5. Lead Time

Lead time refers to the time required from placing an order to receiving the product. This term is vital for project planning and inventory management. Buyers should consider lead times when selecting suppliers to ensure timely delivery and avoid delays in their operations.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions regarding cable rolls, ensuring they meet both operational needs and industry standards effectively.

Navigating Market Dynamics and Sourcing Trends in the cable rolls Sector

What Are the Current Market Dynamics and Key Trends in the Cable Rolls Sector?

The global cable rolls market is experiencing significant growth driven by several factors. Firstly, the increasing demand for reliable electrical infrastructure, particularly in emerging economies across Africa and South America, is propelling investments in power generation and distribution. As these regions continue to urbanize and industrialize, the need for efficient and high-quality cable rolls becomes paramount. Additionally, the global push towards renewable energy sources is fostering demand for specialized cable solutions, including those designed for solar and wind energy applications.

Technological advancements are also reshaping the sourcing landscape. The integration of smart technology in cable management systems is enhancing operational efficiency, reducing downtime, and improving safety. B2B buyers are increasingly looking for suppliers that offer innovative products equipped with features such as RFID tracking and real-time monitoring capabilities. Furthermore, the rise of e-commerce platforms is enabling international buyers to access a broader range of suppliers and products, fostering competitive pricing and improved supply chain transparency.

Illustrative image related to cable rolls

Market dynamics are further influenced by geopolitical factors, including trade agreements and tariffs, which can impact sourcing strategies. Buyers in Europe, particularly Germany, are navigating complex regulatory environments that necessitate compliance with stringent safety and environmental standards. As a result, understanding regional market nuances is essential for successful sourcing in the cable rolls sector.

How Is Sustainability Shaping the Sourcing of Cable Rolls?

Sustainability is becoming a critical factor in the sourcing strategies of B2B buyers in the cable rolls market. The environmental impact of cable production, including resource extraction and energy consumption, has prompted many companies to adopt sustainable practices. Buyers are increasingly prioritizing suppliers that demonstrate a commitment to reducing their carbon footprint and implementing environmentally friendly manufacturing processes.

Ethical sourcing practices are also gaining traction. Companies are now more aware of the importance of maintaining transparent supply chains that uphold labor rights and promote fair working conditions. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) are becoming essential criteria for B2B buyers when evaluating suppliers. Moreover, the adoption of recyclable materials in the production of cable rolls is a growing trend, aligning with global efforts to reduce plastic waste and promote circular economy principles.

Illustrative image related to cable rolls

Incorporating sustainability into sourcing strategies not only enhances brand reputation but also meets the growing consumer demand for ethically produced products. Buyers who prioritize sustainability are likely to establish stronger relationships with suppliers and gain a competitive edge in their respective markets.

What Is the Historical Evolution of the Cable Rolls Sector?

The cable rolls sector has evolved significantly over the past few decades, responding to technological advancements and changing market needs. Initially, cable rolls were primarily made from basic materials and designed for simple applications. However, with the advent of new materials and manufacturing techniques, the industry has seen a transformation towards more specialized and durable products.

The late 20th century marked a turning point as the telecommunications boom increased the demand for high-performance cable solutions. This led to the development of cable rolls that could support a wider range of applications, including fiber optics and high-voltage power lines. Today, the sector continues to innovate, with an emphasis on integrating smart technology and sustainable practices into product development. As the global landscape shifts towards renewable energy and smart infrastructure, the cable rolls sector is poised for further growth and evolution, offering B2B buyers exciting opportunities to explore.

Frequently Asked Questions (FAQs) for B2B Buyers of cable rolls

-

1. How do I choose the right cable roll for my project?

Selecting the appropriate cable roll depends on several factors, including the type of cable (e.g., power, data, or fiber optic), the intended application, and environmental conditions. Consider the cable gauge, insulation type, and length required for your project. Additionally, assess the load capacity and durability of the reel, especially if it will be used in harsh conditions. Consulting with suppliers about their product specifications and your project requirements can help ensure you make the best choice. -

2. What are the key factors to consider when sourcing cable rolls internationally?

When sourcing cable rolls internationally, buyers should consider factors such as the supplier’s reliability, compliance with international standards, and shipping logistics. Verify the supplier’s certifications and reviews, and understand their production capabilities and quality control processes. Additionally, evaluate import regulations and tariffs in your country, as well as potential language barriers and time zones that could affect communication and order fulfillment. -

3. How can I ensure the quality of cable rolls before purchasing?

To ensure the quality of cable rolls, conduct thorough supplier vetting by checking their certifications, customer testimonials, and industry reputation. Request samples to evaluate the material quality and performance. Additionally, consider suppliers who implement strict quality assurance processes and are willing to share testing results. Engaging third-party quality inspection services before shipment can also provide added assurance of product quality. -

4. What are the common minimum order quantities (MOQs) for cable rolls?

Minimum order quantities (MOQs) for cable rolls vary widely based on the manufacturer and product type. Typically, MOQs can range from a few hundred meters to several thousand meters, depending on the specifications and customization options. It’s advisable to discuss your specific needs with suppliers to negotiate MOQs that align with your project requirements, especially if you are looking for customized solutions. -

5. What payment terms should I expect when purchasing cable rolls from international suppliers?

Payment terms can vary significantly between suppliers, but common practices include upfront payments, partial payments before shipment, and payment upon delivery. Some suppliers may offer net 30 or net 60 days terms for established business relationships. It’s essential to clarify payment methods accepted (e.g., bank transfer, credit card, or letter of credit) and ensure that terms are documented in the purchase agreement to avoid misunderstandings. -

6. How can I customize cable rolls to meet specific project needs?

Customization options for cable rolls may include variations in gauge, length, insulation material, and even branding. When discussing your requirements with suppliers, provide detailed specifications and any relevant industry standards that must be met. Some manufacturers may offer bespoke solutions, so it’s beneficial to inquire about their capabilities and lead times for custom orders to ensure your needs are met efficiently. -

7. What logistics considerations should I keep in mind for international shipping of cable rolls?

When planning for international shipping of cable rolls, consider factors such as shipping methods (air vs. sea), lead times, and customs clearance processes. Ensure that the supplier is familiar with shipping regulations in your country and can provide necessary documentation. Additionally, evaluate shipping costs and potential delays due to customs inspections, and consider working with a freight forwarder to streamline logistics and mitigate risks. -

8. How do I handle returns or disputes regarding cable roll orders?

Handling returns or disputes effectively begins with understanding the supplier’s return policy before placing an order. Establish clear communication with the supplier regarding any discrepancies or quality issues upon receipt of goods. Document your concerns with photos and detailed descriptions, and refer to the agreement made at the time of purchase. Many suppliers are willing to negotiate resolutions, such as exchanges or refunds, provided that issues are reported promptly and in accordance with their policies.

Top 3 Cable Rolls Manufacturers & Suppliers List

1. SpoolMaster – Cable Reel Rollers

Domain: spoolmaster.com

Registered: 1996 (29 years)

Introduction: SpoolMaster Cable Reel Rollers: 1. SMP-RP-MPX: 750lb Capacity Unlimited Width Cable Reel Roller – $450.00 2. SMP-RP-BTX: 2000lb Capacity Unlimited Width Cable Reel Roller – $860.00 3. SMP-RP-HDX: 3000lb Capacity Unlimited Width Cable Reel Roller – $920.00 4. SMP-RP-6K: 6000lb Capacity Unlimited Width Cable Reel Roller – $1,065.00 5. SMP-RP-27: 1500lb Capacity Fixed Width Cable Reel Roller – $850.0…

2. Powerwerx – Wire & Cable Reels

Domain: powerwerx.com

Registered: 1999 (26 years)

Introduction: Wire & Cable Reels featuring Red/Black bonded zip cord from 24 to 2 gauge, stranded and solid hookup wire, UL1007, PTFE insulated high temperature wire. Spool sizes range from 25 to 5,000 feet. Additional wire products include welding cable, ultra-flexible power wire, test lead, and magnet wire. Key products include: Red/Black Bonded Zip Cord (starting at $4.69), PTFE High Temperature Stranded Wir…

3. Guillevin – Reels Solutions

Domain: guillevin.com

Registered: 1997 (28 years)

Introduction: This company, Guillevin – Reels Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for cable rolls

What Are the Key Takeaways for International Buyers in Cable Roll Sourcing?

In conclusion, strategic sourcing of cable rolls is essential for optimizing supply chain efficiency and ensuring product quality across diverse markets. Buyers from Africa, South America, the Middle East, and Europe should prioritize suppliers that offer customizable solutions, high-quality materials, and robust logistics support. By leveraging partnerships with reliable manufacturers, businesses can mitigate risks associated with supply chain disruptions and enhance their operational agility.

How Can Strategic Sourcing Enhance Business Operations?

Investing in strategic sourcing not only reduces costs but also improves product availability and accelerates time-to-market. International buyers should consider factors such as supplier certifications, material specifications, and customer service responsiveness when evaluating potential partners. This proactive approach will lead to better procurement outcomes and contribute to sustainable business growth.

What Does the Future Hold for Cable Roll Sourcing?

Looking ahead, the demand for innovative cable solutions will continue to grow, driven by advancements in technology and increasing infrastructure projects globally. Buyers are encouraged to stay informed about market trends and emerging technologies to seize new opportunities. By embracing a strategic sourcing mindset, businesses can position themselves as leaders in their respective markets and ensure long-term success.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.