Unlocking Value: A Strategic Analysis of the Boiler Diagrams Market

Introduction: Navigating the Global Market for boiler diagrams

In the rapidly evolving landscape of industrial heating solutions, sourcing accurate and reliable boiler diagrams is a pivotal challenge for B2B buyers across diverse markets, including Africa, South America, the Middle East, and Europe. These diagrams serve as essential tools for understanding boiler systems, facilitating maintenance, and ensuring compliance with safety regulations. However, the complexity of available diagrams and the varying standards across regions can create obstacles for procurement professionals.

This comprehensive guide delves into the multifaceted world of boiler diagrams, exploring different types, applications, and the critical components that make up these systems. From schematic layouts to detailed installation instructions, we provide insights into how these resources can optimize operational efficiency and reduce downtime. Additionally, we will address supplier vetting processes, cost considerations, and best practices for utilizing boiler diagrams effectively in various industrial contexts.

By equipping international B2B buyers with the knowledge and tools necessary to navigate the global market for boiler diagrams, this guide empowers informed purchasing decisions. Whether you are looking to streamline your procurement strategy or enhance your operational capabilities, understanding the nuances of boiler diagrams will be key to achieving your business objectives in a competitive environment.

Understanding boiler diagrams Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Piping Diagrams | Show the layout of pipes and connections in the system. | Industrial heating, commercial buildings | Pros: Simplifies installation; Cons: May require specialized knowledge for interpretation. |

| Schematic Diagrams | Illustrate the functional relationships between components. | Maintenance, troubleshooting, training | Pros: Offers clear understanding of system; Cons: Can be overly simplified, missing details. |

| Installation Diagrams | Detail specific installation requirements and configurations. | New boiler installations, retrofitting | Pros: Essential for correct setup; Cons: Might not cover all scenarios or variations. |

| Electrical Diagrams | Focus on the electrical connections and control systems. | Automation, controls integration | Pros: Critical for safety and functionality; Cons: Complex for non-electrical professionals. |

| Flow Diagrams | Map the flow of fluids within the system. | Process industries, HVAC applications | Pros: Helps in optimizing flow; Cons: Requires understanding of fluid dynamics. |

What Are the Characteristics of Piping Diagrams in Boiler Systems?

Piping diagrams are essential for illustrating the layout of pipes and connections within a boiler system. They provide a visual representation of how water and steam circulate, highlighting key components such as valves and pumps. These diagrams are particularly useful in industrial heating applications, where complex systems require precise installation and maintenance. Buyers should consider the clarity and detail of the piping diagram, as an accurate representation is crucial for effective troubleshooting and system optimization.

How Do Schematic Diagrams Aid in Boiler Maintenance?

Schematic diagrams depict the functional relationships between various components of a boiler system, making them invaluable for maintenance and troubleshooting. These diagrams help technicians understand how different parts interact, facilitating quicker diagnostics and repairs. While they provide a clear overview, buyers should be cautious, as schematic diagrams can sometimes oversimplify complex systems, potentially omitting critical details necessary for comprehensive understanding.

Why Are Installation Diagrams Important for New Boiler Installations?

Installation diagrams are specifically designed to guide the setup of boiler systems, detailing necessary configurations and requirements. They are essential for both new installations and retrofitting existing systems. Buyers need to ensure that the installation diagram is comprehensive and tailored to their specific boiler model, as incorrect installation can lead to operational inefficiencies and safety hazards.

What Role Do Electrical Diagrams Play in Boiler Systems?

Electrical diagrams focus on the electrical connections and control systems within a boiler setup. They are vital for integrating automation and ensuring safe operation. These diagrams are particularly important for B2B buyers in industries where precise control is necessary for efficiency and safety. However, due to their complexity, buyers may need specialized knowledge to interpret these diagrams effectively.

How Do Flow Diagrams Optimize Boiler System Efficiency?

Flow diagrams illustrate the movement of fluids through a boiler system, providing insights into how to optimize flow rates and system efficiency. They are commonly used in process industries and HVAC applications. Buyers should evaluate the flow diagram for accuracy and detail, as a well-designed flow diagram can significantly enhance system performance and energy efficiency, leading to cost savings over time.

Key Industrial Applications of boiler diagrams

| Industry/Sector | Specific Application of boiler diagrams | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Steam generation for production processes | Enhances operational efficiency and productivity | Availability of spare parts, local support, and compliance with regulations. |

| Food Processing | Heating and sterilization in food production | Ensures safety and quality of food products | Certifications, adherence to food safety standards, and energy efficiency ratings. |

| Chemical Processing | Heating and cooling in chemical reactions | Improves process control and product consistency | Material compatibility, safety standards, and reliability of components. |

| Energy Production | Power generation through steam cycles | Increases energy output and reduces operational costs | Fuel type compatibility, efficiency ratings, and environmental regulations. |

| Healthcare | Providing hot water and steam for sterilization | Supports critical care and hygiene standards | Compliance with health regulations, reliability, and service availability. |

How Are Boiler Diagrams Utilized in the Manufacturing Sector?

In manufacturing, boiler diagrams are essential for understanding steam generation systems used in various production processes. These diagrams provide a visual representation of the boiler’s components, including the firebox, heat exchangers, and water circulation systems. By utilizing these diagrams, manufacturers can troubleshoot issues, optimize performance, and ensure efficient operations, thereby enhancing productivity. Buyers in this sector should prioritize sourcing from suppliers who offer comprehensive technical support and readily available spare parts to minimize downtime.

What Role Do Boiler Diagrams Play in Food Processing?

In the food processing industry, boiler diagrams are critical for ensuring that heating and sterilization processes meet safety and quality standards. These diagrams help operators understand the flow of steam and hot water, which is vital for maintaining the integrity of food products. Accurate boiler diagrams assist in compliance with food safety regulations, preventing contamination and ensuring product quality. International buyers must consider suppliers that provide equipment certified for food applications and that meet local health regulations.

Why Are Boiler Diagrams Important for Chemical Processing?

Chemical processing relies heavily on precise heating and cooling systems, where boiler diagrams illustrate how these systems function. These diagrams help operators maintain optimal conditions for chemical reactions, ensuring product consistency and safety. Moreover, they facilitate quick identification of component failures, leading to reduced downtime and enhanced productivity. Buyers should focus on sourcing boilers that are compatible with the specific chemicals being processed and that adhere to industry safety standards.

How Do Boiler Diagrams Contribute to Energy Production?

In energy production, boiler diagrams are vital for visualizing steam generation systems used in power plants. They enable operators to optimize the steam cycle for maximum efficiency, which is crucial for reducing operational costs and increasing energy output. Additionally, these diagrams help in identifying potential issues before they escalate, ensuring continuous operation. Buyers should evaluate the efficiency ratings of the boilers and consider environmental regulations when sourcing equipment for energy production.

What Is the Importance of Boiler Diagrams in Healthcare Facilities?

In healthcare, boiler diagrams are crucial for providing hot water and steam necessary for sterilization processes in medical facilities. These diagrams help ensure that the systems are operating efficiently and safely, which is vital for maintaining hygiene standards. Accurate boiler diagrams facilitate quick repairs and maintenance, minimizing disruptions in critical care environments. Buyers in this sector must ensure that the boilers comply with health regulations and are backed by reliable service support for maintenance and emergencies.

3 Common User Pain Points for ‘boiler diagrams’ & Their Solutions

Scenario 1: Difficulty in Locating Accurate Boiler Diagrams for Maintenance

The Problem: B2B buyers often encounter challenges when attempting to locate accurate and specific boiler diagrams necessary for maintenance and repairs. This can lead to operational downtime and increased costs, especially in industries reliant on continuous heating solutions. For example, a manufacturing plant may find that the diagrams available online do not match their specific boiler model, resulting in confusion and potential missteps during maintenance. This issue is particularly acute in regions with less access to technical support, such as certain areas in Africa and South America, where local expertise may be limited.

The Solution: To overcome this problem, B2B buyers should prioritize sourcing boiler diagrams from reputable manufacturers or authorized distributors who maintain up-to-date and model-specific documentation. It’s advisable to establish direct communication with the manufacturer’s technical support team to ensure you receive the correct diagrams. Buyers can also leverage comprehensive online platforms that offer searchable databases of boiler diagrams, such as Heating Spare Parts. By using these resources, companies can ensure they have the most accurate and relevant information for their specific boiler models, thus minimizing maintenance errors and downtime.

Scenario 2: Understanding Complex Boiler System Diagrams

The Problem: Many buyers struggle to interpret complex boiler system diagrams, which often contain intricate details about piping, wiring, and component layouts. This difficulty can lead to improper installations or modifications, which can be costly and potentially hazardous. For instance, a contractor in Europe may misinterpret a diagram, leading to incorrect pipe fittings that compromise system efficiency and safety. This issue is exacerbated by the varying standards and practices across different regions, making it hard to find universally applicable guidelines.

The Solution: To alleviate this pain point, B2B buyers should invest in training programs for their staff that focus on understanding boiler diagrams and schematics. Many manufacturers offer training sessions or webinars that provide insights into their specific diagrams, making it easier for teams to grasp the necessary concepts. Additionally, creating a standardized reference guide that summarizes key elements of boiler diagrams can serve as a practical tool for technicians. By enhancing their team’s understanding of these diagrams, businesses can improve installation accuracy and system performance, ultimately saving time and resources.

Scenario 3: Ensuring Compliance with Regional Regulations Through Accurate Diagrams

The Problem: Compliance with local regulations regarding boiler installations and operations can be a significant concern for B2B buyers, particularly in regions with stringent safety and environmental standards. Buyers may find that the boiler diagrams they possess do not align with the latest regulatory requirements, leading to potential fines or safety hazards. For example, a company in the Middle East might use outdated diagrams that do not account for recent changes in emissions standards, putting them at risk of non-compliance.

The Solution: B2B buyers can address this issue by proactively engaging with local regulatory bodies to understand the latest requirements and ensuring that their boiler diagrams reflect these changes. Regularly updating their documentation and sourcing diagrams from manufacturers that prioritize compliance can be crucial. Buyers should also consider implementing a compliance audit process that includes a review of boiler diagrams against current regulations. This approach not only mitigates the risk of non-compliance but also enhances the overall safety and efficiency of boiler operations, fostering trust with clients and stakeholders.

Strategic Material Selection Guide for boiler diagrams

When selecting materials for boiler diagrams, it is crucial to consider their properties, advantages, disadvantages, and suitability for specific applications. This analysis will focus on four common materials: carbon steel, stainless steel, copper, and plastic composites. Each material offers unique characteristics that can significantly impact the performance and longevity of boiler systems.

What Are the Key Properties of Carbon Steel in Boiler Diagrams?

Carbon steel is a widely used material in boiler construction due to its excellent strength and affordability. It typically has a temperature rating of up to 400°F (204°C) and can withstand moderate pressure levels. Its primary advantage lies in its durability and ability to handle high-stress environments. However, carbon steel is susceptible to corrosion, especially in humid or acidic conditions, which can lead to premature failure.

From a B2B perspective, carbon steel is often favored for its cost-effectiveness, making it ideal for large-scale projects. However, international buyers should be aware of compliance with local standards, such as ASTM in the U.S. or EN standards in Europe, to ensure safety and performance.

How Does Stainless Steel Compare for Boiler Diagrams?

Stainless steel is renowned for its corrosion resistance, making it suitable for environments where moisture or aggressive chemicals are present. It can handle higher temperatures (up to 1,500°F or 815°C) and pressures, making it a preferred choice for high-performance boilers. The downside is that stainless steel is generally more expensive than carbon steel and can be more challenging to fabricate.

For international buyers, compliance with standards like DIN in Germany or JIS in Japan is essential, as these specifications often dictate the quality and performance of stainless steel products. Buyers in regions with high humidity or corrosive environments, such as parts of Africa and South America, may find stainless steel to be a worthwhile investment despite the higher upfront costs.

What Role Does Copper Play in Boiler Diagrams?

Copper is another material used in boiler systems, particularly for heat exchangers due to its excellent thermal conductivity. It can efficiently transfer heat, making it ideal for applications requiring rapid heating or cooling. However, copper has a lower temperature and pressure rating compared to steel, typically around 250°F (121°C) and 200 psi, which limits its use in high-pressure systems.

While copper is generally more expensive than carbon steel, its superior heat transfer properties can justify the cost in specific applications. International buyers should consider the availability of copper and any import tariffs, especially in regions like the Middle East and South America, where raw material costs can fluctuate significantly.

Why Are Plastic Composites Emerging in Boiler Diagrams?

Plastic composites are gaining traction in boiler applications due to their lightweight nature and resistance to corrosion. They are particularly useful in low-pressure systems and for components that do not require high-temperature resistance. The primary advantage of plastic composites is their low weight, which can reduce installation costs and complexity.

However, their temperature and pressure ratings are limited, making them unsuitable for high-performance applications. For international buyers, understanding the specific applications and limitations of plastic composites is crucial, especially in regions with varying climate conditions that may affect material performance.

Summary Table of Material Selection for Boiler Diagrams

| Material | Typical Use Case for boiler diagrams | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Structural components in boilers | Cost-effective and durable | Susceptible to corrosion | Low |

| Stainless Steel | High-performance boilers | Excellent corrosion resistance | Higher cost and fabrication complexity | High |

| Copper | Heat exchangers | Superior thermal conductivity | Limited temperature and pressure rating | Med |

| Plastic Composites | Low-pressure systems | Lightweight and corrosion-resistant | Limited thermal and pressure capabilities | Low |

This guide provides a strategic overview of material selection for boiler diagrams, enabling B2B buyers to make informed decisions based on performance, compliance, and cost considerations relevant to their specific markets.

In-depth Look: Manufacturing Processes and Quality Assurance for boiler diagrams

What Are the Key Stages in the Manufacturing Process of Boiler Diagrams?

The manufacturing process of boiler diagrams involves several critical stages that ensure the final product meets industry standards and customer requirements. Understanding these stages can aid B2B buyers in selecting suppliers who maintain high-quality production practices.

Material Preparation: What Materials Are Used and How Are They Processed?

The first stage in manufacturing boiler diagrams is material preparation. This includes selecting high-quality raw materials such as steel, copper, and specialized alloys, which are crucial for the boiler’s durability and efficiency. Suppliers often source materials that comply with international standards, such as ASTM or ISO specifications, to guarantee quality.

Once materials are selected, they undergo various processes such as cutting, shaping, and surface treatment. Advanced technologies like laser cutting and CNC machining are commonly employed to ensure precision and consistency. This stage is essential as any discrepancies can affect the overall performance of the boiler system.

How Are Boiler Diagrams Formed and Assembled?

The forming stage involves shaping the prepared materials into the necessary components outlined in the boiler diagrams. Techniques like stamping, bending, and welding are frequently used. For example, forming the heat exchanger requires precise welding techniques to ensure airtight seals that can withstand high pressure and temperature.

After forming, the assembly stage begins. Components are brought together according to detailed assembly diagrams, which specify the correct order and method for assembling parts like the boiler vessel, heat exchanger, and control systems. This stage is critical, as improper assembly can lead to significant operational failures.

What Finishing Processes Ensure Quality and Durability?

Finishing processes are essential for enhancing the performance and longevity of boiler diagrams. This stage often includes surface treatments such as painting, coating, or galvanizing to protect against corrosion and wear. These treatments not only improve the aesthetic appeal but also ensure the boiler components can withstand harsh operating conditions.

In addition to physical treatments, manufacturers may also conduct tests at this stage to ensure all components function as intended. This includes pressure testing, leak testing, and performance evaluations to validate the integrity of the assembly before it is dispatched.

What Quality Assurance Measures Are Essential for Boiler Diagrams?

Quality assurance is a crucial aspect of the manufacturing process for boiler diagrams. It encompasses various international and industry-specific standards that ensure the final products meet safety and performance expectations.

Which International Standards Should B2B Buyers Be Aware Of?

B2B buyers should be familiar with several international quality standards, such as ISO 9001, which focuses on quality management systems. This certification indicates that the manufacturer has established processes to ensure consistent quality in their products. Additionally, industry-specific standards like CE marking for European markets and API standards for American markets are vital for compliance and safety.

How Are Quality Control Checkpoints Integrated Into the Manufacturing Process?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to monitor and evaluate the quality of the boiler diagrams. The primary QC stages include:

-

Incoming Quality Control (IQC): At this stage, raw materials are inspected upon arrival to ensure they meet specified standards. This prevents subpar materials from entering the production line.

-

In-Process Quality Control (IPQC): During manufacturing, regular checks are conducted to monitor the processes and ensure they comply with quality standards. This includes checking dimensions, tolerances, and assembly accuracy.

-

Final Quality Control (FQC): Before dispatch, the finished product undergoes comprehensive testing to ensure it meets all operational requirements and safety standards. This may include functional testing, endurance testing, and compliance verification.

What Testing Methods Are Commonly Used in Boiler Manufacturing?

Common testing methods include:

-

Hydrostatic Testing: This method checks for leaks and structural integrity by filling the boiler with water and applying pressure beyond normal operating conditions.

-

Non-Destructive Testing (NDT): Techniques such as ultrasonic testing, radiographic testing, and magnetic particle testing are used to identify internal and surface defects without damaging the components.

-

Performance Testing: Final assemblies may undergo performance tests to evaluate efficiency, output capacity, and operational stability.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers have several avenues to verify the quality control practices of potential suppliers:

-

Supplier Audits: Conducting on-site audits can provide insight into a manufacturer’s processes, quality control measures, and compliance with international standards.

-

Quality Reports: Requesting detailed quality reports can help assess a supplier’s historical performance and adherence to quality standards.

-

Third-Party Inspections: Engaging independent inspection agencies can provide an unbiased evaluation of the manufacturing practices and product quality.

What Are the Nuances of Quality Certification for International B2B Buyers?

International buyers, especially from regions like Africa and South America, should be aware of the specific certification requirements in their markets. For instance, certain countries may have additional regulatory requirements beyond ISO or CE certifications. Understanding these nuances can help buyers avoid compliance issues and ensure the boiler systems meet local regulations.

Moreover, cultural and logistical factors can influence the procurement process. Buyers should consider time zones, shipping regulations, and customs procedures when engaging with international suppliers to ensure smooth transactions.

Conclusion: How to Ensure Quality and Compliance in Boiler Diagrams

For B2B buyers, understanding the manufacturing processes and quality assurance measures of boiler diagrams is critical. By focusing on material preparation, assembly processes, and compliance with international standards, buyers can make informed decisions that enhance their operational efficiency and safety. Engaging suppliers who prioritize quality control and have a robust certification framework will ultimately lead to successful and sustainable procurement outcomes.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘boiler diagrams’

In the competitive landscape of B2B procurement, sourcing boiler diagrams requires a strategic approach to ensure that your operations run smoothly and efficiently. This guide provides a practical checklist to help international buyers, particularly in Africa, South America, the Middle East, and Europe, navigate the complexities of acquiring the right boiler diagrams for their needs.

Step 1: Define Your Technical Specifications

Before you begin sourcing, it’s essential to have a clear understanding of your technical requirements. Determine the type of boiler system you need diagrams for—whether industrial, residential, or commercial—and outline the specific components involved.

– Considerations: Include details like the boiler type (e.g., steam, hot water), capacity, and any unique features that may affect the diagram’s design.

Step 2: Research Reputable Suppliers

Identify suppliers who specialize in boiler diagrams. Look for companies with a solid reputation in the industry, ideally with experience serving your specific region.

– Resources: Utilize online directories, industry forums, and trade associations to find credible suppliers. Pay attention to customer reviews and testimonials.

Step 3: Evaluate Supplier Certifications

Ensure that the suppliers you are considering have the necessary certifications and comply with local regulations. This is crucial for both safety and reliability.

– What to Check: Look for certifications from recognized bodies, such as ISO or local equivalents, and verify that they adhere to safety and quality standards specific to your industry.

Step 4: Request Sample Diagrams

Before making a purchase, ask potential suppliers for sample diagrams related to your specifications. This will help you assess the clarity, detail, and usability of the diagrams.

– Key Questions: Inquire about the level of detail provided, including annotations and legends, and whether the diagrams are customizable based on your specific needs.

Step 5: Understand Licensing and Usage Rights

Clarify the licensing terms associated with the boiler diagrams. Understanding your rights regarding the use, reproduction, and modification of these diagrams is essential for compliance and future needs.

– Important Aspects: Confirm whether the diagrams are provided under a one-time purchase, subscription model, or require additional fees for updates or modifications.

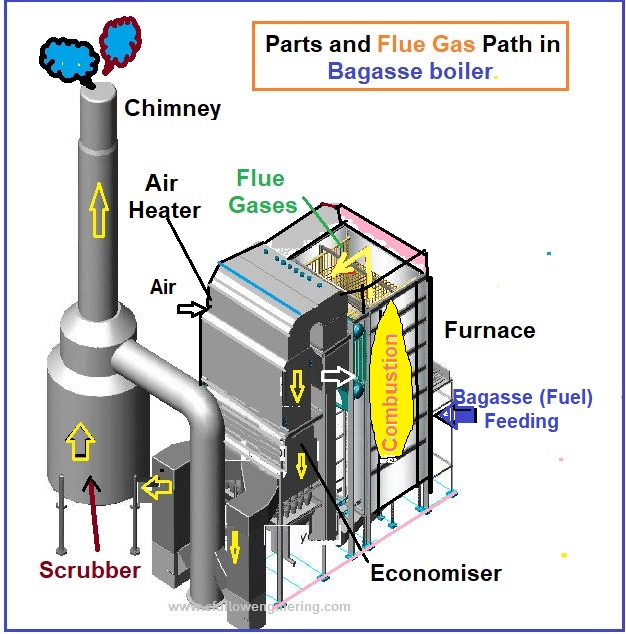

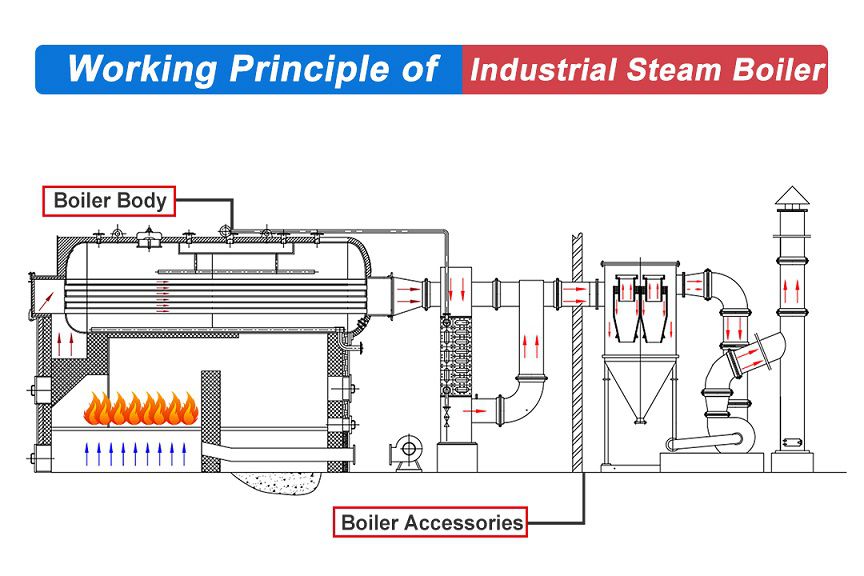

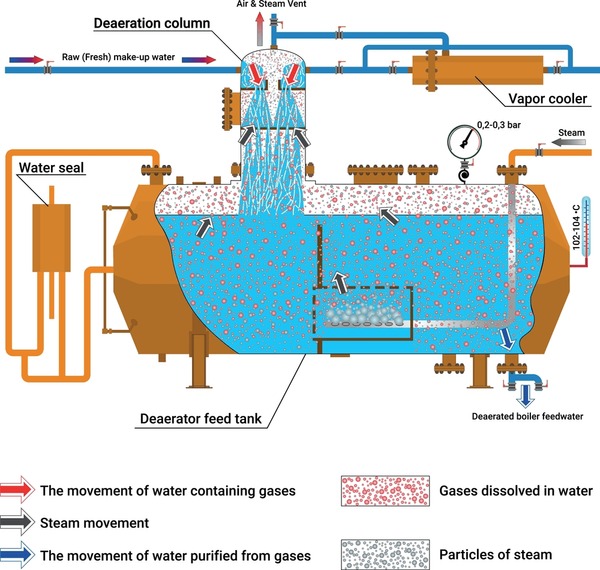

Illustrative image related to boiler diagrams

Step 6: Assess Support and Training Options

Check if the supplier offers support services, such as training on how to read and implement the diagrams. This can be a valuable resource, especially for teams that may be unfamiliar with boiler systems.

– Support Types: Look for options such as online tutorials, manuals, or dedicated customer service representatives who can assist with technical inquiries.

Step 7: Compare Pricing and Terms

Finally, gather quotes from multiple suppliers to compare pricing and terms. Ensure that you are not just looking at the initial cost but also considering factors such as delivery time, after-sales support, and warranty.

– Negotiation Tips: Don’t hesitate to negotiate terms based on your volume requirements or long-term partnership potential.

By following these steps, you can effectively source boiler diagrams that meet your operational needs while ensuring compliance and efficiency in your procurement process.

Comprehensive Cost and Pricing Analysis for boiler diagrams Sourcing

What Are the Key Cost Components for Boiler Diagrams Sourcing?

When sourcing boiler diagrams, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The type of materials used to create the diagrams can significantly impact costs. For instance, high-quality paper and advanced printing technologies may elevate the price. Additionally, diagrams that include digital formats or interactive elements may incur higher material costs.

-

Labor: Labor costs encompass the wages of technical experts who create the diagrams, as well as any additional personnel involved in the production process. Skilled labor, particularly in regions with higher wage standards, can drive up costs.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, facility maintenance, and administrative expenses. Efficient manufacturing processes can help reduce overhead costs.

-

Tooling: Specialized tools and software for creating precise and detailed diagrams are essential. Investment in high-quality tooling can lead to better outputs but may also increase initial costs.

-

Quality Control (QC): Ensuring that diagrams meet industry standards and specifications requires robust quality control measures. This adds to the overall cost but is vital for maintaining product integrity.

-

Logistics: The distribution of diagrams, whether physical or digital, involves shipping costs, customs duties for international orders, and warehousing. These costs can fluctuate based on destination and shipping methods.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the expected margins in different markets can help buyers gauge fair pricing.

How Do Pricing Influencers Affect Boiler Diagrams Costs?

Several factors influence the pricing of boiler diagrams that B2B buyers should consider:

-

Volume/MOQ: Many suppliers offer discounts for bulk orders. Understanding minimum order quantities (MOQs) can lead to cost savings, particularly for organizations that require large volumes of diagrams.

-

Specifications/Customization: Custom diagrams tailored to specific needs or compliance with local regulations may incur higher costs. Buyers should weigh the benefits of customization against their budget.

-

Materials and Quality Certifications: The quality of materials and whether they meet specific certifications can influence pricing. Higher-quality diagrams may cost more but often provide better durability and usability.

-

Supplier Factors: Established suppliers with a strong reputation may command higher prices due to their reliability and service quality. However, working with less-known suppliers can result in cost savings, albeit with potential risks.

-

Incoterms: Understanding shipping terms (like FOB, CIF, etc.) is critical for calculating total costs. Different Incoterms can affect who bears the shipping risk and costs, influencing the final price.

What Buyer Tips Can Lead to Cost-Efficiency in Boiler Diagrams Sourcing?

To maximize cost efficiency, buyers should adopt the following strategies:

-

Negotiate Effectively: Don’t hesitate to negotiate with suppliers. Leverage your purchasing volume and long-term relationship potential to secure better pricing.

-

Consider Total Cost of Ownership (TCO): Evaluate the full lifecycle costs, including maintenance, training, and potential downtime. A lower upfront cost may not always equate to a better deal if the long-term costs are higher.

-

Be Aware of Pricing Nuances for International Purchases: Different regions have varying pricing standards and expectations. For buyers from Africa, South America, the Middle East, and Europe, understanding local market dynamics can help in negotiating better deals.

-

Request Samples and Prototypes: Before committing to a large order, request samples or prototypes to assess quality. This can prevent costly mistakes and ensure that the product meets your needs.

Disclaimer on Indicative Prices

Pricing for boiler diagrams can vary significantly based on the factors mentioned above. It is advisable for buyers to conduct thorough market research and obtain multiple quotes before making purchasing decisions. Always consider the specific needs and context of your organization when evaluating costs.

Alternatives Analysis: Comparing boiler diagrams With Other Solutions

Introduction: Exploring Alternatives to Boiler Diagrams

In the realm of industrial heating solutions, boiler diagrams serve as a critical tool for understanding system components and their interactions. However, there are alternative methods and technologies that can also meet the needs of businesses seeking efficient heating solutions. Understanding these alternatives is essential for B2B buyers to make informed decisions that align with their operational requirements and budget constraints.

Comparison Table

| Comparison Aspect | Boiler Diagrams | 3D Modeling Software | Smart Thermostat Systems |

|---|---|---|---|

| Performance | Provides clear visualizations of system layouts, improving installation and maintenance efficiency. | Offers dynamic and interactive representations, enhancing understanding of complex systems. | Optimizes heating based on real-time data, potentially reducing energy consumption. |

| Cost | Generally low cost; often free or part of boiler purchase. | Higher initial investment; requires software licensing and training. | Moderate cost; savings on energy bills can offset initial expenses. |

| Ease of Implementation | Simple to use for trained professionals; requires minimal training. | Requires skilled personnel for effective use; learning curve involved. | Easy to install and use; often comes with user-friendly interfaces. |

| Maintenance | Helps identify issues quickly, aiding in preventive maintenance. | Can complicate maintenance if not accurately updated. | Provides alerts and diagnostics, facilitating proactive maintenance. |

| Best Use Case | Ideal for traditional boiler systems where clear schematics are needed. | Best for complex installations requiring detailed planning and adjustments. | Suited for modern heating systems needing energy efficiency and remote control. |

Detailed Breakdown of Alternatives

3D Modeling Software

3D modeling software allows engineers to create detailed and interactive representations of boiler systems. This technology provides a comprehensive view, enabling users to visualize components in three dimensions. The primary advantage of 3D modeling is its ability to simulate various scenarios and modifications, which can be invaluable during the design phase. However, the initial cost can be prohibitive, and there is a steep learning curve, necessitating skilled personnel for effective utilization.

Smart Thermostat Systems

Smart thermostat systems represent a modern alternative that focuses on optimizing heating efficiency. By using sensors and algorithms, these systems adjust heating outputs based on occupancy and temperature preferences, which can lead to significant energy savings. The ease of installation and user-friendly interfaces make them accessible to a broad range of users. However, they may not provide the detailed schematics that traditional boiler diagrams offer, which can be a drawback for complex system maintenance.

Illustrative image related to boiler diagrams

Conclusion: How to Choose the Right Solution for Your Needs

When selecting between boiler diagrams and alternative solutions, B2B buyers should consider their specific operational needs, budget, and the complexity of their heating systems. Boiler diagrams remain a reliable choice for straightforward installations, while 3D modeling software can enhance planning for more intricate setups. Smart thermostat systems offer energy efficiency but may lack the detailed insights provided by traditional diagrams. Ultimately, the right solution will depend on a careful assessment of both immediate requirements and long-term operational goals.

Essential Technical Properties and Trade Terminology for boiler diagrams

When navigating the complexities of boiler diagrams, understanding essential technical properties and industry terminology is crucial for effective decision-making. This section outlines key specifications and jargon that B2B buyers should be familiar with to ensure they make informed purchasing choices.

What Are the Key Technical Properties of Boiler Diagrams?

-

Material Grade

– The material grade refers to the quality and type of material used in the construction of boiler components, such as carbon steel, stainless steel, or alloy materials. The choice of material affects durability, corrosion resistance, and heat transfer efficiency. For international buyers, understanding material grades helps assess compatibility with local standards and regulations. -

Pressure Rating

– This specification indicates the maximum pressure a boiler can safely handle during operation, measured in pounds per square inch (psi). A higher pressure rating allows for greater steam generation capacity, which is vital for industries requiring large volumes of steam. Buyers should consider their specific operational needs to select a boiler that meets required pressure ratings. -

Efficiency Rating

– Efficiency ratings, often expressed as a percentage, indicate how effectively a boiler converts fuel into usable energy. High-efficiency boilers reduce fuel consumption and operational costs, making them attractive investments. Buyers must evaluate efficiency against operational costs to ensure long-term savings. -

Heat Transfer Area

– This property represents the surface area within the boiler where heat exchange occurs, impacting the boiler’s performance and capacity. A larger heat transfer area can enhance efficiency and output, which is especially important for high-demand applications. Understanding this specification helps buyers select boilers that align with their production requirements. -

Tolerance Levels

– Tolerance levels define the acceptable deviation from specified dimensions during manufacturing. Proper tolerances ensure that components fit correctly and function optimally, reducing the risk of operational failures. B2B buyers should inquire about tolerance standards to ensure compatibility with existing systems.

What Are Common Trade Terms Associated with Boiler Diagrams?

-

OEM (Original Equipment Manufacturer)

– An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the boiler industry, purchasing from an OEM ensures that the components are made to the original specifications, which is critical for maintaining system integrity and warranty coverage. -

MOQ (Minimum Order Quantity)

– MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers to optimize inventory levels and manage procurement costs, particularly when dealing with specialized boiler components. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers asking for pricing and terms on specific products or services. This process helps buyers compare options and make cost-effective decisions. For boiler components, a well-structured RFQ can lead to better negotiation and procurement outcomes. -

Incoterms (International Commercial Terms)

– Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international shipping. Familiarity with Incoterms helps buyers understand their obligations regarding shipping costs, insurance, and risk during transportation of boiler systems and components. -

Schematic Diagram

– A schematic diagram is a simplified representation of a system that shows the components and their interconnections. These diagrams are essential for understanding the layout and operation of boiler systems, aiding in installation, maintenance, and troubleshooting.

By grasping these technical properties and trade terms, B2B buyers can enhance their understanding of boiler diagrams, leading to more informed purchasing decisions and improved operational efficiency.

Illustrative image related to boiler diagrams

Navigating Market Dynamics and Sourcing Trends in the boiler diagrams Sector

Global drivers in the boiler diagrams sector are increasingly shaped by technological advancements, regulatory changes, and the growing emphasis on sustainability. The demand for efficient and reliable heating solutions across industries in regions like Africa, South America, the Middle East, and Europe is driving innovation in boiler designs. Key trends include the adoption of smart technologies, such as IoT-enabled systems that allow for real-time monitoring and predictive maintenance. This shift not only enhances operational efficiency but also minimizes downtime, a critical factor for international B2B buyers who rely on uninterrupted service.

Moreover, the transition towards renewable energy sources is influencing the design and functionality of boiler systems. Buyers are now looking for diagrams that illustrate compatibility with alternative fuels, such as biomass or solar-assisted systems. As the market evolves, the emphasis on modular designs is also gaining traction, allowing for easier upgrades and maintenance. This flexibility is particularly appealing to buyers in emerging markets, where budget constraints and evolving energy policies often necessitate adaptable solutions.

What Role Does Sustainability and Ethical Sourcing Play in the Boiler Diagrams Sector?

The environmental impact of boiler systems is a pressing concern, making sustainability a key consideration for B2B buyers. As industries globally face increasing pressure to reduce their carbon footprints, sourcing boiler diagrams that emphasize energy efficiency and low emissions is becoming crucial. Ethical sourcing practices are equally important, as they ensure that materials used in boiler systems are acquired responsibly and sustainably. This includes opting for suppliers who provide ‘green’ certifications, which verify that the materials meet environmental standards and contribute to overall sustainability goals.

Furthermore, the use of recycled materials in the production of boiler components is gaining traction. B2B buyers are encouraged to engage with manufacturers that prioritize eco-friendly practices and offer transparency in their supply chains. This not only enhances brand reputation but also aligns with the growing consumer demand for sustainable products. In regions such as Europe, where regulatory frameworks are becoming increasingly stringent, businesses that invest in sustainable practices are likely to gain a competitive edge.

How Has the Boiler Diagrams Sector Evolved Over Time?

The evolution of the boiler diagrams sector has been marked by significant technological advancements and changing market demands. Initially, boiler systems were predominantly mechanical, with simple designs that lacked the efficiency and safety features seen today. Over the decades, the introduction of advanced materials and digital technologies has transformed boiler systems into complex, efficient machines capable of meeting diverse industrial needs.

In the early 2000s, the focus shifted towards energy efficiency and emissions reduction, leading to the development of diagrams that detail innovative designs, such as condensing boilers and hybrid systems. Today, the integration of smart technologies and modular designs reflects the sector’s response to the need for flexibility and sustainability. This historical progression not only informs current practices but also sets the stage for future innovations, making it imperative for international B2B buyers to stay informed about these developments to make strategic sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of boiler diagrams

-

How do I solve issues with identifying the correct boiler diagram for my equipment?

To effectively identify the correct boiler diagram, start by gathering all relevant information about your boiler model, including the manufacturer, model number, and any specifications available. Utilize online databases or resources from official manufacturers that offer searchable schematics and diagrams. If you still face challenges, consider reaching out to customer support teams or technical advisors from the manufacturer or suppliers, as they can provide direct assistance and ensure you receive the right diagram for your needs. -

What is the best source for obtaining boiler diagrams for international projects?

The best sources for obtaining boiler diagrams for international projects include established suppliers with a robust online presence, such as manufacturer websites, specialized spare parts distributors, and industry-specific platforms that offer extensive databases. Look for suppliers that provide user-friendly search tools, comprehensive diagrams, and detailed installation manuals. Additionally, consider suppliers that offer customer support in your preferred language and have experience in international shipping to ensure timely delivery. -

How can I ensure the quality of boiler diagrams and related components?

To ensure the quality of boiler diagrams and components, choose suppliers with a solid reputation and industry certifications. Verify their experience in the market and look for testimonials or reviews from previous customers. Ensure that the diagrams are up-to-date and created by certified engineers or professionals. Additionally, request samples of the components if possible, and inquire about quality assurance processes, including warranties and return policies, to safeguard your investment. -

What are common payment terms for purchasing boiler diagrams and components internationally?

Common payment terms for international purchases typically include options such as advance payment, letters of credit, or net 30/60/90 days, depending on the supplier’s policies. It is essential to clarify payment methods accepted, including wire transfers, credit cards, or PayPal. Be cautious about additional fees related to currency conversion or international transactions. Ensure that all terms are documented in a purchase agreement to avoid misunderstandings and safeguard your financial interests. -

What factors should I consider when vetting suppliers of boiler diagrams?

When vetting suppliers of boiler diagrams, consider factors such as their industry experience, customer reviews, and certifications. Evaluate their product range and whether they offer technical support or consultation services. Additionally, assess their logistics capabilities, including shipping times and costs, especially for international orders. Request references from other clients in your region to gauge their reliability and responsiveness, which can be critical in maintaining smooth operations. -

Can I customize boiler diagrams to suit specific project requirements?

Yes, many suppliers offer customization options for boiler diagrams to align with specific project requirements. When discussing your needs, provide detailed information about your system, including any unique specifications or configurations. Be prepared for potential additional costs associated with customization and ensure that the final diagrams are reviewed for accuracy before implementation. Always confirm that the supplier has the expertise to modify diagrams according to industry standards. -

What are the minimum order quantities (MOQ) for boiler diagrams and components?

Minimum order quantities (MOQ) can vary significantly based on the supplier and the specific components required. Some suppliers may have no MOQ for digital products like diagrams, while physical components may require a minimum order to offset production and shipping costs. It’s advisable to clarify MOQ details during initial discussions with suppliers. If your project requires small quantities, seek suppliers who are flexible with MOQs or consider aggregating orders with other buyers. -

What logistical considerations should I be aware of when sourcing boiler diagrams internationally?

When sourcing boiler diagrams internationally, consider logistical aspects such as shipping times, customs regulations, and import duties that may affect delivery timelines and costs. Verify the supplier’s shipping methods and ensure they can provide tracking information. Additionally, factor in the possibility of delays due to customs clearance, especially in regions with stringent regulations. Engaging a freight forwarder experienced in handling technical equipment can streamline the logistics process and mitigate potential issues.

A Look at Boiler Diagrams Manufacturers & Suppliers

Could not verify enough suppliers for boiler diagrams to create a list at this time.

Strategic Sourcing Conclusion and Outlook for boiler diagrams

How Can Strategic Sourcing Enhance Your Boiler Diagram Procurement?

In the evolving landscape of boiler technology, understanding and utilizing accurate boiler diagrams is essential for optimizing procurement processes. Strategic sourcing allows international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, to streamline their purchasing decisions by ensuring access to high-quality diagrams and components. This not only reduces operational downtime but also enhances the efficiency of installation and maintenance, leading to long-term cost savings.

By leveraging a comprehensive database of schematics and manuals, buyers can pinpoint the exact parts needed for their systems, facilitating quicker repairs and minimizing the risk of equipment failure. Investing in reliable sources of boiler diagrams is crucial for maintaining operational continuity and compliance with industry standards.

Looking ahead, the importance of strategic sourcing in the boiler sector cannot be overstated. As global markets become increasingly interconnected, the ability to source quality materials and diagrams efficiently will provide a competitive edge. We encourage all international buyers to assess their sourcing strategies and embrace the potential of high-quality boiler diagrams to enhance their operational capabilities. By doing so, you not only secure your current projects but also position your business for future growth and success.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.