Unlocking Value: A Strategic Analysis of the Big Lots Dining Table Market

Introduction: Navigating the Global Market for big lots dining table

In the dynamic landscape of global commerce, sourcing big lots dining tables presents a unique challenge for B2B buyers. As international markets become increasingly interconnected, finding high-quality, cost-effective dining solutions that cater to diverse consumer preferences is essential. This guide aims to equip businesses from Africa, South America, the Middle East, and Europe—including key markets like Brazil and Germany—with the insights necessary to make informed purchasing decisions.

Within this comprehensive resource, you will discover various types of big lots dining tables suited for different applications, from family dining to commercial settings. We delve into supplier vetting processes, ensuring you partner with reputable manufacturers that meet your quality standards. Additionally, we provide a thorough analysis of cost considerations, helping you navigate pricing structures across different markets.

By the end of this guide, you will be empowered to identify the best dining solutions that align with your business objectives, enhance customer satisfaction, and ultimately drive profitability. Understanding the nuances of sourcing big lots dining tables will not only streamline your procurement process but also enable you to stay competitive in an ever-evolving marketplace.

Understanding big lots dining table Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Rectangular Dining Tables | Traditional shape; accommodates larger groups; often extendable | Restaurants, banquet halls, corporate dining | Pros: Versatile, space-efficient; Cons: May require more space for movement. |

| Round Dining Tables | Circular shape; encourages conversation; ideal for smaller spaces | Cafés, small restaurants, family dining | Pros: Space-saving, aesthetic appeal; Cons: Limited seating capacity. |

| Oval Dining Tables | Combines features of rectangular and round; often extendable | Event venues, upscale dining establishments | Pros: Elegant design, flexible seating; Cons: Can be less stable than rectangular tables. |

| Counter Height Tables | Taller than standard dining tables; often paired with bar stools | Casual dining, bars, and modern homes | Pros: Stylish and trendy; Cons: Not suitable for all dining preferences. |

| Patio Dining Tables | Weather-resistant materials; designed for outdoor use | Outdoor dining areas, resorts, and cafés | Pros: Durable and versatile; Cons: Limited usability in colder climates. |

What Are the Characteristics of Rectangular Dining Tables for B2B Buyers?

Rectangular dining tables are a staple in the commercial furniture sector, particularly for businesses that require seating for larger groups, such as restaurants and corporate dining facilities. These tables often feature extendable designs, allowing for flexibility in accommodating varying group sizes. When sourcing these tables, B2B buyers should consider durability, ease of maintenance, and the capacity to fit within the layout of their establishments.

How Do Round Dining Tables Enhance Customer Experience?

Round dining tables are favored for their ability to foster conversation and connection among diners, making them ideal for smaller cafés and family-oriented restaurants. Their design often allows for a more intimate dining experience. B2B buyers should evaluate the materials used, as well as the size and shape options, to ensure they meet the needs of their clientele while maximizing space efficiency.

What Advantages Do Oval Dining Tables Offer for Upscale Venues?

Oval dining tables strike a balance between the formality of rectangular tables and the intimacy of round ones, making them a popular choice for upscale dining establishments and event venues. Their aesthetic appeal can enhance the dining experience, but B2B buyers must consider stability and the potential need for additional support mechanisms, especially for larger models.

Why Choose Counter Height Tables for Modern Dining Spaces?

Counter height tables are increasingly popular in casual dining settings and modern homes, as they provide a trendy alternative to traditional dining arrangements. These tables are typically taller and paired with bar stools, making them suitable for informal gatherings. B2B buyers should assess the style and comfort of accompanying seating options, as well as the table’s construction to ensure longevity in high-traffic areas.

How Do Patio Dining Tables Meet Outdoor Dining Needs?

Patio dining tables are specifically designed for outdoor use, constructed from weather-resistant materials to withstand the elements. They are essential for businesses with outdoor dining areas, such as resorts and cafés. B2B buyers should prioritize durability and ease of cleaning when selecting these tables, as well as consider the aesthetic appeal to attract customers looking for a pleasant outdoor dining experience.

Key Industrial Applications of big lots dining table

| Industry/Sector | Specific Application of big lots dining table | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Restaurant dining areas | Enhances customer experience and encourages longer visits | Durability, style, and ease of maintenance are critical |

| Corporate Offices | Breakrooms and meeting spaces | Promotes employee collaboration and comfort during meals | Size, material quality, and ergonomic design are essential |

| Educational Institutions | Cafeterias and student lounges | Supports social interaction and provides a casual dining environment | Safety, ease of cleaning, and space optimization are key |

| Event Management | Banquet and conference settings | Versatile setup for various events and enhances ambiance | Flexibility in design and size, along with transportability, is crucial |

| Retail Spaces | In-store cafes or dining areas | Drives foot traffic and increases dwell time in stores | Alignment with store branding, durability, and aesthetics are vital |

How are Big Lots Dining Tables Utilized in the Hospitality Sector?

In the hospitality sector, Big Lots dining tables are frequently employed in restaurant dining areas to create inviting spaces for customers. These tables enhance the overall dining experience, allowing restaurants to accommodate various group sizes while maintaining aesthetic appeal. B2B buyers in this sector should prioritize durability and ease of maintenance, as high foot traffic can lead to wear and tear. The ability to clean surfaces easily is crucial for maintaining hygiene standards, especially in regions with strict health regulations.

Illustrative image related to big lots dining table

What Role do Big Lots Dining Tables Play in Corporate Offices?

In corporate offices, Big Lots dining tables are ideal for breakrooms and meeting spaces, where they facilitate informal gatherings and promote collaboration among employees. These tables create comfortable environments for meals and discussions, thereby enhancing workplace morale. Buyers must consider the size and ergonomic design of the tables to ensure they fit the office layout while providing comfort. Additionally, selecting materials that withstand daily use without compromising style is essential for maintaining a professional atmosphere.

How are Big Lots Dining Tables Applied in Educational Institutions?

Educational institutions utilize Big Lots dining tables in cafeterias and student lounges to foster social interaction among students. These tables provide a casual dining experience that encourages students to gather, share meals, and engage in discussions. Buyers in this sector need to focus on safety features, such as rounded edges, and materials that are easy to clean and maintain. Space optimization is also a key consideration, as many institutions require tables that can accommodate varying group sizes while fitting within limited spaces.

Why are Big Lots Dining Tables Important for Event Management?

In event management, Big Lots dining tables serve as versatile solutions for banquet and conference settings. Their adaptability allows for various configurations, catering to different event sizes and styles, which enhances the overall ambiance. Buyers should prioritize flexibility in design and size, ensuring that tables can be easily transported and set up for different occasions. The aesthetic appeal of the tables can significantly influence the event’s atmosphere, making it crucial to select styles that align with the event’s theme.

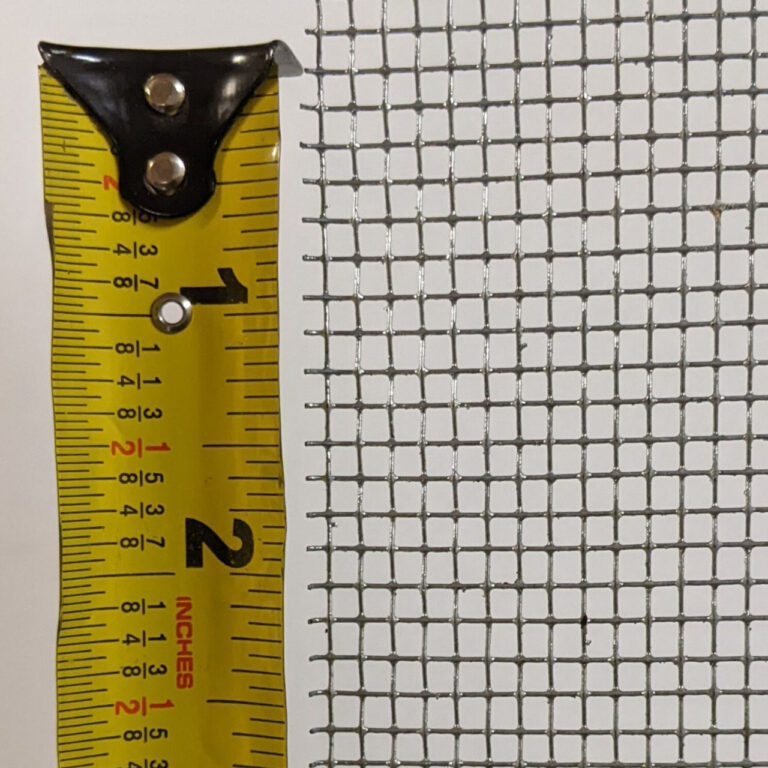

Illustrative image related to big lots dining table

How Can Retail Spaces Benefit from Big Lots Dining Tables?

Retail spaces increasingly incorporate Big Lots dining tables in in-store cafes or dining areas to drive foot traffic and increase customer dwell time. These tables create a welcoming environment that encourages shoppers to relax and enjoy refreshments, ultimately enhancing the shopping experience. B2B buyers in this sector should align table styles with their brand’s aesthetic while ensuring durability to withstand the demands of a retail environment. A focus on aesthetics and functionality can significantly impact customer satisfaction and sales.

3 Common User Pain Points for ‘big lots dining table’ & Their Solutions

Scenario 1: Difficulty in Sourcing Durable Dining Tables for Commercial Use

The Problem: B2B buyers often struggle to find dining tables that can withstand heavy usage in commercial settings such as restaurants, cafes, or corporate dining rooms. Many tables on the market are designed primarily for residential use, leading to issues like premature wear and tear, instability, and safety hazards. This challenge is especially pronounced for buyers in regions where high foot traffic and varied climates can affect furniture longevity.

The Solution: When sourcing ‘big lots dining tables,’ it’s crucial to prioritize models specifically labeled as commercial-grade or those that feature robust materials such as solid wood or reinforced metal frames. Buyers should inquire about the weight capacity and durability ratings, ensuring that the tables can handle the demands of a busy environment. Additionally, consider opting for tables with finishes that are easy to clean and resistant to stains, which can prolong their lifespan. For bulk purchases, negotiating with suppliers for warranties or service agreements can also mitigate the risk of investing in tables that may not hold up over time.

Scenario 2: Navigating Space Constraints in Dining Areas

The Problem: In many commercial dining environments, space is at a premium. Buyers often find themselves needing dining tables that can accommodate varying numbers of guests without taking up too much room. The challenge lies in selecting tables that are both functional and stylish while fitting into the designated space without creating a cramped atmosphere.

Illustrative image related to big lots dining table

The Solution: To tackle space constraints, buyers should look for ‘big lots dining tables’ that offer versatility, such as extendable or collapsible options. Tables with built-in storage or those that can be easily pushed together to create larger surfaces for events can be particularly useful. When evaluating options, consider the layout of the dining area and the flow of traffic, ensuring that tables can be arranged in a way that maximizes seating while allowing for easy movement. Consulting with interior design experts can also provide tailored solutions to optimize space usage effectively.

Scenario 3: Managing Budget Constraints While Seeking Quality

The Problem: Many B2B buyers face budget limitations when it comes to furnishing dining areas, particularly in competitive markets. The challenge is to find high-quality dining tables that offer good value without compromising on aesthetics or durability. Buyers often feel pressured to choose lower-cost options that may lead to higher replacement costs in the long run.

The Solution: To navigate budget constraints effectively, buyers should take a strategic approach when selecting ‘big lots dining tables.’ First, conduct thorough market research to compare prices and features across various suppliers. Look for seasonal sales, bulk purchase discounts, or financing options that can ease immediate financial burdens. Prioritize tables that combine style with functionality, such as those that are easy to maintain and have multi-purpose uses. Additionally, consider the long-term value of investing in higher-quality materials, as they may reduce replacement costs and provide better overall customer satisfaction. Engaging in discussions with suppliers about your budget and needs can also lead to customized solutions that align with your financial parameters.

Strategic Material Selection Guide for big lots dining table

What are the Key Properties of Common Materials Used in Big Lots Dining Tables?

When selecting materials for dining tables, it is crucial to understand the properties and characteristics of each option. Below is an analysis of four common materials used in big lots dining tables: wood, metal, glass, and engineered wood. Each material has unique properties that affect performance, cost, and suitability for various applications.

Illustrative image related to big lots dining table

Wood: A Classic Choice for Dining Tables

Key Properties: Wood is known for its natural beauty, strength, and versatility. It can withstand moderate temperature and pressure but is susceptible to moisture and pests. Different types of wood, such as oak, walnut, and pine, offer varying levels of durability and aesthetic appeal.

Pros & Cons: The primary advantage of wood is its aesthetic appeal and warmth, making it a popular choice for dining spaces. However, it can be more expensive than other materials and may require regular maintenance to prevent warping and scratches. Additionally, wood can be heavy, complicating shipping and assembly.

Impact on Application: Wood is compatible with various finishes and can be treated for enhanced durability. However, it may not be suitable for humid environments without proper sealing.

Considerations for International Buyers: Buyers from regions with high humidity, such as parts of Africa and South America, should consider moisture-resistant treatments. Compliance with local standards for wood sourcing and sustainability (e.g., FSC certification) is also essential.

Illustrative image related to big lots dining table

Metal: Durability and Modern Aesthetics

Key Properties: Metal, often used in frames and legs, offers high strength and resistance to corrosion. Common metals include steel and aluminum, which can withstand significant weight and pressure.

Pros & Cons: Metal is highly durable and can be designed in various styles, making it suitable for modern aesthetics. However, it can be prone to scratches and may require protective coatings to prevent rust, especially in humid environments.

Impact on Application: Metal tables are often used in commercial settings due to their robustness. They are less likely to warp under temperature changes compared to wood.

Considerations for International Buyers: Buyers should ensure compliance with local regulations regarding metal content and coatings. In regions like Europe, adherence to standards such as EN 10025 for structural steel may be necessary.

Glass: Elegance Meets Practicality

Key Properties: Glass is prized for its sleek appearance and ability to create a sense of space. Tempered glass is commonly used for dining tables due to its strength and resistance to thermal stress.

Pros & Cons: The key advantage of glass is its modern aesthetic and ease of cleaning. However, it is more fragile than other materials and can be prone to scratches and chipping. Additionally, glass tables can be heavy, complicating transport.

Impact on Application: Glass surfaces can be combined with metal or wood bases, providing versatility in design. They are particularly suitable for contemporary dining environments.

Considerations for International Buyers: Buyers should be aware of regulations regarding glass safety standards (e.g., ANSI Z97.1 in the U.S. or EN 12150 in Europe). Import duties on glass products may also vary by region.

Engineered Wood: A Cost-Effective Alternative

Key Properties: Engineered wood, such as MDF or particleboard, is made from wood fibers and adhesives. It offers a stable surface and is less prone to warping compared to solid wood.

Illustrative image related to big lots dining table

Pros & Cons: The primary advantage of engineered wood is its cost-effectiveness and uniformity. However, it may not have the same aesthetic appeal as solid wood and can be less durable over time.

Impact on Application: Engineered wood is often used in budget-friendly dining tables and can be finished to mimic the look of solid wood. It is suitable for indoor use but may not withstand high humidity.

Considerations for International Buyers: Buyers should check for compliance with emission standards for formaldehyde and other VOCs, especially in regions with strict environmental regulations.

Illustrative image related to big lots dining table

Summary Table of Material Selection for Big Lots Dining Tables

| Material | Typical Use Case for big lots dining table | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Wood | Residential and commercial dining tables | Aesthetic appeal and warmth | Requires maintenance and heavy | High |

| Metal | Modern and commercial dining environments | High durability and strength | Prone to scratches and rust | Medium |

| Glass | Contemporary dining settings | Sleek appearance and easy to clean | Fragile and heavy | Medium |

| Engineered Wood | Budget-friendly dining tables | Cost-effective and stable | Less durable and aesthetic appeal | Low |

This guide provides valuable insights for international B2B buyers looking to select the right materials for big lots dining tables, ensuring they meet both functional and aesthetic requirements while adhering to local standards and preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for big lots dining table

What Are the Key Stages in the Manufacturing Process of Big Lots Dining Tables?

The manufacturing process of dining tables at Big Lots involves several critical stages, ensuring that each piece meets quality standards while maintaining cost-effectiveness. The primary stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Big Lots Dining Tables?

Material preparation is the first stage, where high-quality raw materials, predominantly wood, metal, and upholstery fabrics, are sourced. Suppliers are often selected based on their ability to meet sustainability criteria and industry standards. Wood is typically dried to a specific moisture content to prevent warping and splitting, while metals are treated to resist corrosion.

During this stage, manufacturers also perform a thorough inspection of the materials to ensure they meet predetermined specifications. This includes checking for defects, consistency in color and grain, and verifying that all materials are compliant with international standards, such as FSC (Forest Stewardship Council) for wood.

Illustrative image related to big lots dining table

What Techniques Are Used in the Forming Stage?

The forming stage involves shaping the prepared materials into the desired components of the dining table. Techniques such as cutting, milling, and bending are employed to achieve precise dimensions and designs. Computer Numerical Control (CNC) machines are commonly used for their accuracy and efficiency, allowing for intricate designs to be created with minimal waste.

This stage also includes the creation of components like tabletops, legs, and supports. Advanced technology ensures that pieces fit together seamlessly, which is essential for both aesthetics and structural integrity.

How Are Big Lots Dining Tables Assembled?

Assembly is the next crucial step, where individual components come together to form the final product. Skilled workers, often supported by automated systems, join the pieces using various methods, including doweling, screws, and adhesives. This hybrid approach enhances durability while allowing for flexibility in design.

Quality control checks are integrated into the assembly process. Workers are trained to spot inconsistencies or flaws, which can be addressed immediately, reducing the likelihood of defective products reaching the market.

What Finishing Techniques Are Applied to Dining Tables?

Finishing is the final stage of manufacturing, where tables are treated for aesthetics and protection. Techniques such as sanding, staining, and varnishing are employed to enhance the wood’s natural beauty while providing a durable surface that can withstand daily use.

During this stage, manufacturers also apply coatings that meet international safety standards, ensuring that finishes are non-toxic and safe for consumers. The finishing process is vital, as it not only impacts the appearance but also the longevity of the product.

What Quality Assurance Measures Are Implemented in Dining Table Manufacturing?

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that each dining table meets the required standards before it reaches the buyer. This involves adhering to international standards such as ISO 9001 and industry-specific certifications like CE and API.

Which International Standards Are Relevant for Quality Assurance?

ISO 9001 provides a framework for quality management systems, ensuring that manufacturers consistently meet customer and regulatory requirements. Compliance with CE marking signifies that products meet European safety, health, and environmental protection standards.

B2B buyers should ensure that their suppliers maintain these certifications, as they reflect the manufacturer’s commitment to quality and continuous improvement.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are strategically placed throughout the manufacturing process to catch defects early. These checkpoints include:

-

Incoming Quality Control (IQC): This is the first line of defense where raw materials are inspected upon arrival. Only materials that meet quality standards are accepted for production.

-

In-Process Quality Control (IPQC): During production, random checks are performed to ensure that components are being manufactured according to specifications. This includes checking dimensions, finishes, and assembly integrity.

-

Final Quality Control (FQC): Once the dining tables are fully assembled and finished, they undergo a final inspection. This includes testing for stability, finish quality, and overall appearance to ensure they meet the set standards.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can verify the quality control processes of their suppliers through various means:

-

Supplier Audits: Conducting on-site audits of the manufacturing facility can provide insights into the operational processes and quality control measures in place. This is particularly useful for buyers from regions like Africa and South America, where standards may vary significantly.

-

Quality Reports: Suppliers should provide detailed quality reports that outline their QC processes, test results, and any corrective actions taken in the event of defects. These reports can serve as a basis for assessing supplier reliability.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the manufacturing processes and quality control measures. This is especially important for international buyers who may not have the capacity to conduct audits themselves.

What Nuances Should International Buyers Consider Regarding Quality Control?

International B2B buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, must navigate various nuances in quality control. Understanding local regulations and standards is crucial, as compliance requirements may differ significantly between countries.

Additionally, cultural differences may impact communication regarding quality expectations. It is essential for buyers to establish clear lines of communication with suppliers, outlining specific quality requirements and expectations upfront. This proactive approach can help mitigate misunderstandings and ensure that the final products meet the buyer’s standards.

Illustrative image related to big lots dining table

Conclusion

The manufacturing processes and quality assurance measures for Big Lots dining tables are designed to ensure a consistent, high-quality product that meets the diverse needs of B2B buyers across various international markets. By understanding these processes and implementing robust quality control verification methods, buyers can make informed decisions and foster successful partnerships with manufacturers. This comprehensive approach not only enhances buyer confidence but also contributes to long-term business success.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘big lots dining table’

In the competitive landscape of international procurement, sourcing a ‘big lots dining table’ requires a strategic approach to ensure quality, cost-effectiveness, and supplier reliability. This guide provides a step-by-step checklist tailored for B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Clearly outline the specifications of the dining table you intend to procure. This includes dimensions, materials (e.g., wood type, metal components), and design features (e.g., extendable options, color finishes). Defining these parameters helps in narrowing down potential suppliers and ensuring that the products meet your operational needs.

Illustrative image related to big lots dining table

- Consider Market Preferences: Research regional preferences in design and materials to ensure your selection resonates with local consumers.

- Quality Standards: Establish quality benchmarks, including durability and aesthetic appeal, to maintain your brand’s reputation.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in dining tables, particularly those with a reputation for reliability and quality. Look for suppliers who have a history of working with international buyers, as this often indicates experience with export regulations and logistics.

- Supplier Directories: Utilize platforms like Alibaba or Global Sources to find verified suppliers.

- Trade Shows: Attend relevant trade shows to meet potential suppliers in person and evaluate their products firsthand.

Step 3: Evaluate Supplier Certifications

Before making a commitment, verify that suppliers have the necessary certifications that demonstrate compliance with international quality and safety standards. Certifications such as ISO 9001 for quality management systems or FSC for sustainable wood sourcing are crucial indicators of reliability.

- Request Documentation: Ask suppliers for copies of their certifications and any recent audits or inspections.

- Assess Compliance: Ensure that the certifications align with your industry’s standards and regulations in your target market.

Step 4: Request Samples

Always request product samples before placing a bulk order. This allows you to assess the quality and craftsmanship of the dining tables firsthand and determine if they meet your specifications.

- Evaluate Functionality: Check for ease of assembly, stability, and finish quality.

- Test Durability: Conduct simple tests to evaluate the material’s durability and how it holds up under typical use conditions.

Step 5: Negotiate Pricing and Terms

Engage in discussions with your chosen suppliers to negotiate pricing, payment terms, and delivery schedules. Effective negotiation can lead to cost savings and more favorable terms, which can enhance your overall procurement strategy.

- Bulk Discounts: Inquire about pricing structures for larger orders, as many suppliers offer discounts for bulk purchases.

- Payment Flexibility: Discuss payment terms, such as a deposit upfront and the balance upon delivery, to manage cash flow effectively.

Step 6: Assess Logistics and Shipping Options

Evaluate the logistics involved in shipping the dining tables from the supplier to your location. Understanding shipping costs, timelines, and customs requirements is vital for ensuring a smooth delivery process.

- Shipping Partners: Check if the supplier has partnerships with reliable logistics companies to facilitate shipping.

- Customs Regulations: Familiarize yourself with import regulations in your country to avoid delays and additional costs.

Step 7: Establish a Quality Control Process

Implement a quality control process for received goods to ensure they meet your specifications and standards. This step is crucial to maintain customer satisfaction and reduce return rates.

- Inspection Protocols: Develop clear inspection protocols, including visual checks and functionality tests.

- Feedback Mechanism: Create a system for providing feedback to suppliers, which can help them improve their products and services over time.

By following this checklist, B2B buyers can effectively navigate the sourcing process for ‘big lots dining tables,’ ensuring they find reliable suppliers that meet their specific needs while optimizing costs and quality.

Comprehensive Cost and Pricing Analysis for big lots dining table Sourcing

What Are the Key Cost Components in Sourcing Big Lots Dining Tables?

When analyzing the cost structure of sourcing dining tables from Big Lots, several key components must be considered. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Illustrative image related to big lots dining table

-

Materials: The type of materials used significantly impacts the cost. Dining tables can be made from solid wood, engineered wood, metal, or glass. Each material has its own cost implications, with solid wood typically being more expensive due to its durability and aesthetic appeal.

-

Labor: Labor costs can vary based on the region where the manufacturing takes place. Countries with lower labor costs may provide a competitive edge, but it’s essential to balance this with quality standards.

-

Manufacturing Overhead: This includes costs associated with running the manufacturing facility, such as utilities, rent, and equipment maintenance. Overhead can significantly affect pricing, especially if production processes are inefficient.

-

Tooling: Initial tooling costs for custom designs can be high, particularly for unique dining table styles or sizes. Buyers should inquire about these costs when considering customized options.

-

Quality Control (QC): Ensuring the dining tables meet quality standards involves additional costs. Rigorous QC processes can mitigate defects but will influence the overall cost structure.

-

Logistics: Shipping and handling costs are crucial, especially for international buyers. Factors such as shipping distance, mode of transport, and insurance can all add to the final cost.

-

Margin: Suppliers typically apply a margin to cover their costs and generate profit. Understanding the expected margin can help buyers negotiate better pricing.

How Do Price Influencers Affect Big Lots Dining Tables?

Several factors influence the pricing of dining tables sourced from Big Lots. These include volume or minimum order quantities (MOQs), specifications and customization, materials, quality certifications, supplier reputation, and Incoterms.

-

Volume/MOQ: Purchasing in bulk can lead to significant discounts. Many suppliers offer better pricing tiers for larger orders, which can benefit B2B buyers looking to stock inventory.

-

Specifications/Customization: Custom designs or specific requirements (like size or color) may incur additional costs. It’s essential to weigh the benefits of customization against the potential price increase.

-

Materials: The choice of materials will directly affect the price. High-quality materials can enhance durability and aesthetics but will increase the cost.

-

Quality/Certifications: Products that meet specific quality standards or have certifications (like eco-friendliness) may command higher prices. Buyers should consider whether the certifications align with their market demands.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their proven track record of quality and service.

-

Incoterms: Understanding the terms of trade (Incoterms) is vital for international transactions. These terms define responsibilities for shipping costs, insurance, and risk, which can significantly affect the total landed cost of the dining tables.

What Tips Can Help B2B Buyers Optimize Costs When Sourcing Dining Tables?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several strategies can help optimize costs.

-

Negotiation: Always approach pricing discussions with a clear understanding of market rates and your budget. Leverage the volume of your order to negotiate better terms.

-

Cost-Efficiency: Consider the total cost of ownership (TCO), which includes initial purchase price, shipping, handling, and potential maintenance costs. A lower upfront price may not always result in the best long-term value.

-

Pricing Nuances: Be aware of currency fluctuations and import tariffs that may affect overall costs. Understanding local regulations can also aid in making informed purchasing decisions.

-

Supplier Relationships: Building strong relationships with suppliers can lead to better pricing and more favorable terms in the long run. Regular communication and feedback can foster loyalty and trust.

-

Market Research: Regularly conducting market research can provide insights into pricing trends and help buyers make informed decisions about when to purchase.

Disclaimer on Indicative Prices

The pricing mentioned in this analysis is indicative and can vary based on factors such as order size, specific requirements, and market conditions. It is advisable for buyers to conduct thorough market research and obtain quotes from multiple suppliers to ensure competitive pricing.

Illustrative image related to big lots dining table

Alternatives Analysis: Comparing big lots dining table With Other Solutions

When considering dining solutions for business environments, it is essential to evaluate various options that suit different operational needs. The ‘Big Lots Dining Table’ is a popular choice among B2B buyers, but several alternatives may provide better alignment with specific requirements or budgets. This analysis aims to compare the Big Lots dining table with other viable solutions in the market, focusing on performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | ‘Big Lots Dining Table’ | Alternative 1 Name (IKEA Dining Table) | Alternative 2 Name (Custom-Built Dining Table) |

|---|---|---|---|

| Performance | Durable, stylish design suitable for various settings | Functional and versatile with modular options | Tailored design for specific requirements and aesthetics |

| Cost | Moderate, generally under $1,000 | Affordable, typically $200 to $600 | High initial investment, ranging from $1,000 to $5,000 |

| Ease of Implementation | Ready to assemble; straightforward setup | Easy assembly with pre-cut parts | Requires professional design and installation |

| Maintenance | Low maintenance; easy to clean | Low maintenance; durable materials | Varies based on materials used; may require more upkeep |

| Best Use Case | Ideal for casual dining and break rooms | Suitable for modern, minimalist spaces | Perfect for bespoke dining experiences in high-end venues |

What are the Pros and Cons of an IKEA Dining Table as an Alternative?

The IKEA dining table is known for its affordability and modular design, making it an excellent alternative for businesses seeking budget-friendly options. The tables are easy to assemble and can fit various settings, from offices to cafes. However, while they offer a stylish and functional solution, their durability may not match that of more expensive counterparts. Additionally, the limited customization options may not suit businesses looking for a unique aesthetic.

How Does a Custom-Built Dining Table Compare?

Custom-built dining tables offer a tailored solution that can meet specific business needs and design preferences. Businesses can choose materials, sizes, and styles that align with their brand identity and operational requirements. This option is ideal for high-end restaurants or corporate dining areas where aesthetics and functionality are critical. However, the cost of custom tables can be significantly higher, and the implementation process may require a longer lead time, as professional design and installation are often necessary.

Conclusion: How Can B2B Buyers Choose the Right Dining Solution?

Selecting the appropriate dining solution for your business hinges on several factors, including budget, aesthetic preference, and intended use. The Big Lots dining table stands out for its affordability and practicality, making it suitable for casual dining environments. Conversely, if cost is a primary concern, IKEA tables offer a budget-friendly alternative with modern design elements. For those looking to create a distinctive dining experience, a custom-built table may provide the flexibility and uniqueness required, albeit at a higher price point. Ultimately, B2B buyers should assess their specific needs and constraints to determine which option aligns best with their operational goals and brand image.

Essential Technical Properties and Trade Terminology for big lots dining table

What Are the Key Technical Properties of Big Lots Dining Tables?

When considering big lots dining tables, several technical properties are crucial for international B2B buyers. Understanding these specifications helps in making informed purchasing decisions, ensuring product quality and suitability for diverse markets.

1. Material Grade

The material grade defines the quality and durability of the dining table. Common materials include solid wood, engineered wood, metal, and glass. For instance, solid wood tables, often made from hardwoods like oak or maple, offer longevity and robustness. In contrast, engineered wood, like MDF or particleboard, provides cost-effective alternatives but may be less durable. Buyers must evaluate the expected lifespan and maintenance needs of the materials to align with market demands.

2. Tolerance Levels

Tolerance levels indicate the permissible deviations from specified dimensions during manufacturing. This is crucial for ensuring that components fit together correctly and that the final product meets quality standards. For example, a tolerance of ±2mm on table dimensions may be acceptable for a dining table. Understanding tolerance levels helps buyers assess the manufacturing precision and potential assembly challenges, ensuring a smoother delivery and installation process.

3. Weight Capacity

The weight capacity refers to the maximum load a dining table can support safely. This specification is vital for B2B buyers, especially those in hospitality or retail, where tables may need to accommodate heavier loads during service or display. A standard dining table should support at least 200-300 pounds. Evaluating weight capacity ensures that the table will meet the functional needs of its intended use, preventing potential safety hazards.

4. Finish Type

Finish type affects both the aesthetic appeal and durability of the dining table. Options include natural wood finishes, laminate, or high-gloss coatings. Each finish has unique properties regarding maintenance, stain resistance, and overall appearance. For example, high-gloss finishes are easier to clean but may show scratches more readily. Buyers should consider the target market’s preferences and the table’s intended environment when selecting the finish type.

5. Assembly Requirements

Assembly requirements indicate whether the dining table comes pre-assembled or requires assembly upon delivery. This factor influences shipping costs and ease of installation. Products that require minimal assembly are often more attractive to buyers, as they can reduce labor costs and installation time. Clear assembly instructions and necessary tools should accompany the product to facilitate a seamless experience for end-users.

What Trade Terminology Should B2B Buyers Know for Dining Tables?

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B sector. Here are some common trade terms relevant to big lots dining tables.

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of dining tables, buyers may work with OEMs to create custom designs or modifications. Understanding OEM relationships can lead to cost savings and tailored products that meet specific market needs.

Illustrative image related to big lots dining table

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Knowing the MOQ is crucial for buyers to manage inventory effectively and ensure they can meet market demand without overcommitting resources. Negotiating MOQs can help buyers balance their purchasing strategies with budget constraints.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specified products. For dining tables, an RFQ can outline desired specifications, quantities, and delivery timelines. This process helps buyers compare offers from different suppliers and make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms used in international contracts to clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B buyers to understand their obligations and risks during the transport of dining tables across borders.

Understanding these technical properties and trade terms equips international B2B buyers with the knowledge necessary to navigate the market for big lots dining tables effectively, ensuring they make informed decisions that align with their business needs.

Navigating Market Dynamics and Sourcing Trends in the big lots dining table Sector

What are the Current Market Dynamics and Key Trends Influencing the Big Lots Dining Table Sector?

The big lots dining table sector is experiencing significant transformations driven by global economic trends, consumer preferences, and technological advancements. As international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, navigate this landscape, several key drivers emerge. Firstly, the rise of remote work has led to an increased demand for multifunctional furniture, including dining tables that can serve as workspaces. This trend aligns with the growing consumer preference for space-efficient designs, particularly in urban areas.

Illustrative image related to big lots dining table

Moreover, e-commerce continues to reshape the sourcing process. Online platforms are becoming vital for B2B buyers, offering access to a wider range of products and suppliers. This digital shift also facilitates quicker procurement processes and enhanced product visibility. Additionally, international trade dynamics, influenced by tariffs and regulations, are prompting buyers to seek local suppliers to mitigate costs and ensure faster delivery times.

Emerging technologies, such as AI and data analytics, are also changing how businesses source products. These tools provide insights into consumer behavior, enabling suppliers to tailor their offerings effectively. For instance, predictive analytics can help identify which dining table designs are likely to trend based on regional preferences, thus allowing buyers to make informed purchasing decisions.

How is Sustainability and Ethical Sourcing Shaping the Big Lots Dining Table Market?

Sustainability is no longer a niche consideration but a fundamental aspect of the big lots dining table sector. International B2B buyers are increasingly prioritizing environmentally friendly products, leading to a rise in demand for dining tables constructed from sustainable materials. Wood sourced from responsibly managed forests and recycled materials are gaining traction, as they offer both aesthetic appeal and reduced environmental impact.

The importance of ethical supply chains cannot be overstated. Buyers are scrutinizing the sourcing practices of manufacturers to ensure compliance with labor standards and environmental regulations. This shift is creating opportunities for suppliers that can demonstrate transparency and ethical sourcing practices, such as certifications from recognized organizations like the Forest Stewardship Council (FSC) or the Global Organic Textile Standard (GOTS).

Furthermore, the push for sustainability is driving innovation in materials. For example, dining tables featuring biodegradable finishes or using reclaimed wood not only meet consumer demand for green products but also appeal to a growing segment of eco-conscious buyers. As these trends continue to evolve, B2B buyers must align their sourcing strategies with sustainable practices to maintain competitiveness in the market.

Illustrative image related to big lots dining table

What is the Brief Evolution and History of the Big Lots Dining Table Sector?

The evolution of the big lots dining table sector reflects broader changes in consumer lifestyles and economic conditions. Traditionally, dining tables were viewed as standalone pieces of furniture primarily used for meals. However, the advent of modern living spaces has transformed dining tables into multifunctional furniture that caters to diverse needs, from dining to working or socializing.

In the past two decades, there has been a significant shift towards customizable options, allowing consumers to select styles, sizes, and materials that suit their specific requirements. This customization trend is particularly appealing to B2B buyers looking to furnish commercial spaces such as restaurants, cafes, and hotels, where aesthetics and functionality are crucial.

The introduction of e-commerce has also played a pivotal role in this evolution, making it easier for buyers to access a wide range of dining tables from various suppliers. As the market continues to adapt to changing consumer preferences and technological advancements, international B2B buyers must remain agile and informed to capitalize on the opportunities presented by these trends.

Frequently Asked Questions (FAQs) for B2B Buyers of big lots dining table

-

How do I ensure the quality of big lots dining tables before purchasing?

To ensure quality, request samples or visit the manufacturing facility if possible. Evaluate the materials used, such as the type of wood or metal, and check for certifications like ISO or FSC that indicate sustainability and quality standards. Additionally, inquire about the manufacturer’s quality assurance processes, including testing procedures for durability and safety. It’s also beneficial to read reviews or testimonials from other buyers to gain insights into the product’s performance and longevity. -

What are the best materials for big lots dining tables in different climates?

When selecting materials for dining tables, consider the climate of your target market. For humid areas, solid woods treated for moisture resistance, such as teak or mahogany, are ideal. In contrast, metal or glass tables may work well in arid regions, as they are less prone to warping. Additionally, look for finishes that offer UV protection if the tables will be exposed to sunlight, ensuring they maintain their aesthetic appeal and structural integrity over time. -

What customization options are available for big lots dining tables?

Most manufacturers offer various customization options, including size, shape, and finish. You can often choose from different wood types, colors, and styles to match your brand’s aesthetic. Additionally, inquire about adding features like extendable leaves for larger gatherings or built-in storage. It’s essential to discuss your specific requirements with the supplier upfront to ensure they can accommodate your needs and deliver the desired product. -

What is the typical minimum order quantity (MOQ) for big lots dining tables?

MOQs can vary widely depending on the manufacturer, ranging from as low as 10 units to several hundred. When sourcing, clarify the MOQ with potential suppliers early in the negotiation process. Some manufacturers may be willing to offer lower MOQs for new customers or larger orders in the future. Understanding the MOQ helps you plan your inventory and manage your cash flow effectively. -

What payment terms should I expect when sourcing big lots dining tables?

Payment terms can vary based on the supplier’s policies and your negotiation. Common terms include a deposit (often 30-50%) upon order confirmation, with the balance due before shipment or upon delivery. Additionally, consider using secure payment methods such as letters of credit or escrow services to mitigate risks. Always clarify payment terms in the contract to ensure both parties have a mutual understanding and protect your investment. -

How can I vet suppliers for big lots dining tables effectively?

To vet suppliers, start by researching their business history, customer reviews, and reputation in the industry. Request references from previous clients and check their responsiveness and willingness to provide information. Additionally, consider visiting the supplier’s facility if feasible, or utilize third-party inspection services to assess their production capabilities. Certifications such as ISO standards and membership in industry associations can also indicate a reliable supplier. -

What logistics considerations should I keep in mind when importing big lots dining tables?

When importing, consider shipping methods, costs, and delivery timelines. Assess whether air freight or ocean freight is more suitable based on your budget and urgency. Additionally, factor in customs duties, taxes, and compliance with local regulations in your country. Partnering with a logistics provider experienced in furniture shipping can streamline the process, ensuring your products arrive safely and on time. -

What are common issues faced during the importation of big lots dining tables, and how can they be resolved?

Common issues include delays in shipping, customs clearance complications, and damages during transport. To mitigate these risks, ensure accurate documentation is prepared, including invoices, packing lists, and certificates of origin. Consider purchasing insurance for your shipment to cover potential damages. Establishing a good relationship with your logistics provider and staying informed about customs regulations can help address and resolve issues promptly.

Top 4 Big Lots Dining Table Manufacturers & Suppliers List

1. Big Lots – Breakfast Nook

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Dining furniture from BigLots, specifically a breakfast nook, is being considered for durability. Users report that the quality is comparable to Ikea and Target, with prices being more affordable. There are mixed reviews on durability, with some users suggesting that while the furniture is good enough for the price, it may not last long-term. One user mentioned a positive experience with a glass i…

2. Big Lots – Farmhouse-Style Table

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: The farmhouse-style table you always dreamed of, now at Big Lots for a limited time.

3. Broyhill – Castillo Round Dining Table

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Broyhill Castillo Round Dining Table, model WS540T, features a charming farmhouse style, sturdy round tabletop, classic timber-beam base, two-tone finish with light wire-brushing, seats up to six people, suitable for dining room or eat-in kitchen.

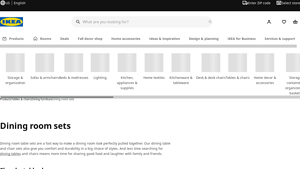

4. IKEA – HÄGERNÄS Table and 4 chairs

Domain: ikea.com

Registered: 1995 (30 years)

Introduction: Dining Room Sets – Affordable and Modern. Options available for small dining table sets for 2, dining table sets for 4, and dining table sets for 6. Key products include: HÄGERNÄS Table and 4 chairs ($259.99), SANDSBERG Table and 4 chairs ($169.99), SKOGSTA / NORDVIKEN Table and 6 chairs ($1,039.99), NÄSINGE Table and 4 chairs ($479.99), TONSTAD Table and 6 chairs ($919.99), MÖRBYLÅNGA Table and 4…

Strategic Sourcing Conclusion and Outlook for big lots dining table

The importance of strategic sourcing in acquiring Big Lots dining tables cannot be overstated. By leveraging insights into product quality, price points, and customer preferences, international B2B buyers can make informed decisions that align with their market needs. The diverse range of dining table options—from contemporary glass tops to traditional wooden designs—ensures that buyers can find products that cater to various demographics and aesthetic preferences.

Moreover, understanding the supply chain dynamics and potential partnerships with suppliers can significantly enhance procurement efficiency. Buyers from Africa, South America, the Middle East, and Europe are positioned to capitalize on competitive pricing and unique designs that resonate with their local markets. This strategic approach will not only foster robust relationships with suppliers but also enhance the overall value proposition to end consumers.

Illustrative image related to big lots dining table

As you explore the possibilities with Big Lots dining tables, consider integrating these insights into your sourcing strategy. The future of your business relies on making calculated, informed decisions that prioritize quality and customer satisfaction. Engage with suppliers today to unlock the potential of your dining furniture offerings and elevate your brand in the competitive marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.