Unlocking Value: A Strategic Analysis of the Bevel Gear Drive Market

Introduction: Navigating the Global Market for bevel gear drive

In today’s competitive landscape, sourcing efficient bevel gear drives can present a significant challenge for international B2B buyers, particularly those in emerging markets such as Africa, South America, the Middle East, and Europe. These essential components are crucial for applications requiring reliable power transmission, yet navigating the complexities of supply chains, varying quality standards, and price fluctuations can be daunting. This guide is designed to empower buyers with the knowledge they need to make informed purchasing decisions regarding bevel gear drives.

Our comprehensive exploration covers various types of bevel gear drives, including right-angle configurations, and their specific applications across diverse industries. We delve into critical factors such as supplier vetting processes, cost considerations, and the latest technological advancements influencing gear drive performance. By providing actionable insights and best practices, this guide equips buyers with the tools necessary to optimize their sourcing strategies.

Whether you are a manufacturer in Brazil seeking to enhance operational efficiency or a distributor in Nigeria aiming to meet the demands of your customers, understanding the intricacies of bevel gear drives is essential. This guide not only simplifies the decision-making process but also positions your business for success in the global market, ensuring you can confidently select the right bevel gear drives that meet your specific requirements.

Understanding bevel gear drive Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Straight Bevel Gears | Teeth are straight and cut at a 45-degree angle. | Automotive, aerospace, and industrial machinery | Pros: Simple design, efficient power transfer. Cons: Limited to low-speed applications. |

| Spiral Bevel Gears | Teeth are curved, allowing for smoother engagement. | High-speed applications, such as turbines | Pros: Quieter operation, higher load capacity. Cons: More complex and expensive to manufacture. |

| Hypoid Bevel Gears | Shaft axes are offset, providing unique angles. | Heavy machinery, automotive differentials | Pros: Greater efficiency, smoother operation. Cons: Requires precise alignment and installation. |

| Crown Bevel Gears | Cone-shaped with teeth on the crown surface. | Robotics, conveyor systems | Pros: High torque capacity, compact design. Cons: Limited to specific applications. |

| Miter Gears | 1:1 gear ratio, often used in pairs. | Optical devices, small machinery | Pros: Simple design, easy to install. Cons: Limited speed and torque capabilities. |

What Are the Characteristics of Straight Bevel Gears?

Straight bevel gears feature teeth that are straight and aligned at a 45-degree angle, making them ideal for low-speed applications. They are commonly used in automotive and industrial machinery where simplicity and reliability are paramount. When considering straight bevel gears, buyers should focus on load capacity and gear ratios that suit their specific machinery needs, as these gears excel in straightforward power transfer but may not perform well under high-speed conditions.

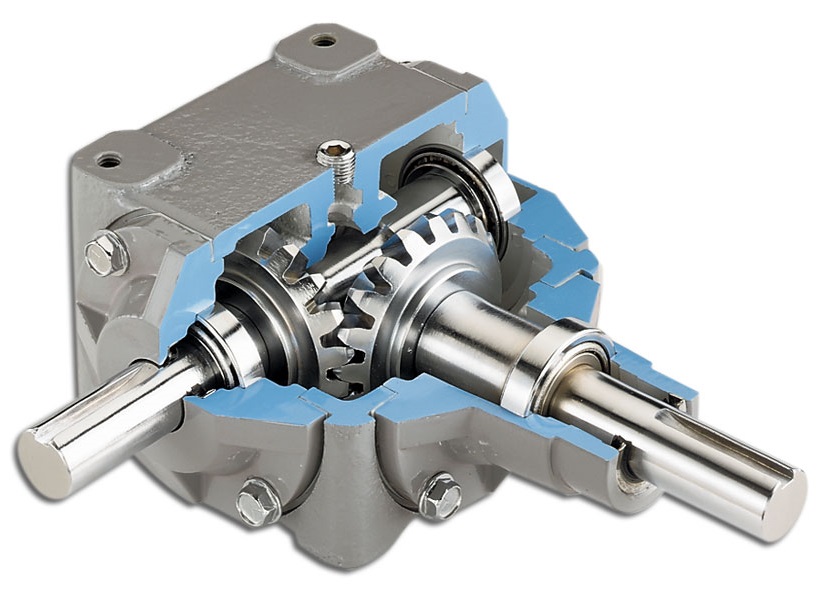

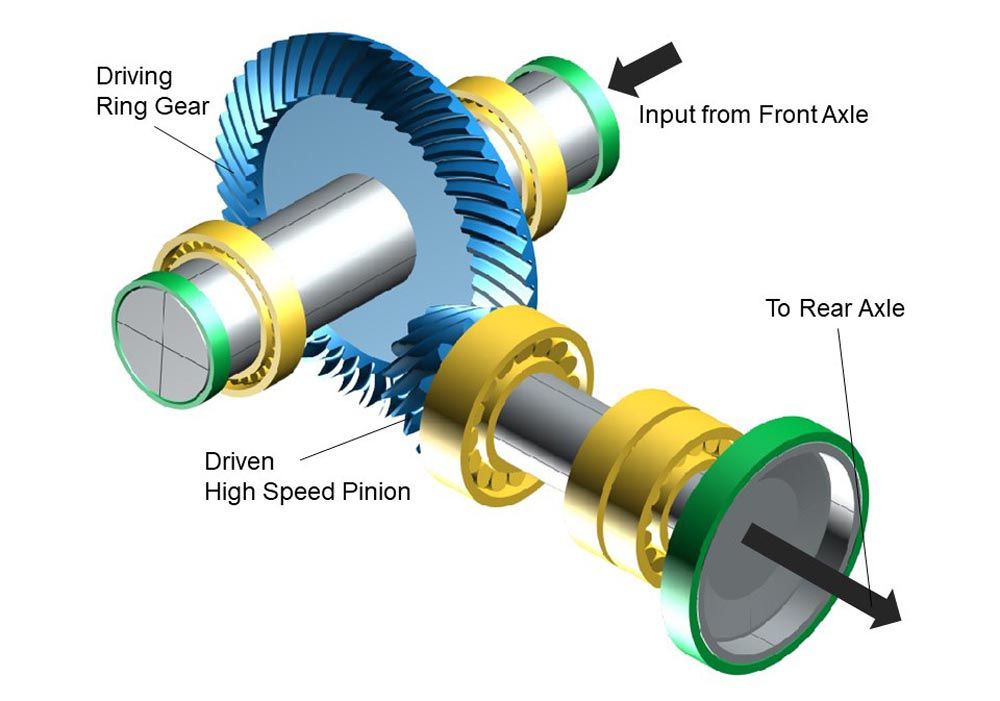

Illustrative image related to bevel gear drive

How Do Spiral Bevel Gears Differ in Performance?

Spiral bevel gears are characterized by their curved teeth, which provide smoother engagement and quieter operation compared to straight bevel gears. They are often found in high-speed applications, such as turbines and high-performance automotive systems, where noise reduction and load capacity are critical. Buyers should evaluate the manufacturing quality and material of spiral bevel gears, as these factors can significantly impact performance and longevity, particularly in demanding environments.

What Advantages Do Hypoid Bevel Gears Offer?

Hypoid bevel gears are distinguished by their offset shafts, allowing for unique angles that enhance efficiency. They are widely used in heavy machinery and automotive differentials due to their ability to handle higher loads and provide smoother operation. B2B buyers must consider the alignment and installation requirements of hypoid gears, as improper setup can lead to performance issues. Additionally, they should assess the specific application demands to ensure optimal gear selection.

In Which Applications Are Crown Bevel Gears Most Effective?

Crown bevel gears, with their cone-shaped design and teeth on the crown surface, are particularly suited for compact applications like robotics and conveyor systems. They offer high torque capacity while maintaining a small footprint, making them an excellent choice for space-constrained environments. Buyers should evaluate the torque requirements and compatibility with existing systems when considering crown bevel gears, as their unique design may not fit all machinery.

Why Choose Miter Gears for Your Applications?

Miter gears have a 1:1 gear ratio and are typically used in pairs to change the direction of rotation. They are common in optical devices and small machinery where simplicity and ease of installation are beneficial. While miter gears are straightforward and cost-effective, buyers should be aware of their limitations in speed and torque capabilities, ensuring that their application aligns with these parameters for optimal performance.

Key Industrial Applications of bevel gear drive

| Industry/Sector | Specific Application of bevel gear drive | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Conveyor systems for material handling | Efficient power transmission, space-saving design | Durability, load capacity, maintenance requirements |

| Automotive | Drive systems in electric vehicles | Enhanced torque control, compact design | Precision engineering, compatibility with electric systems |

| Agriculture | Drive mechanisms in agricultural machinery | Increased reliability, reduced downtime | Resistance to environmental factors, ease of installation |

| Oil & Gas | Directional drilling equipment | Improved power transfer at varied angles | Corrosion resistance, high load handling capabilities |

| Marine | Propulsion systems in ships and submarines | Enhanced maneuverability, efficient space utilization | Material strength, marine-grade specifications |

How is Bevel Gear Drive Used in Manufacturing Applications?

In the manufacturing sector, bevel gear drives are essential for conveyor systems used in material handling. These systems require efficient power transmission to move heavy materials over distances while maintaining a compact design. Bevel gears facilitate a right-angle drive, allowing for flexible layouts in tight spaces. Buyers from regions like Africa and South America should consider sourcing gears that offer high durability and load capacity to withstand the demands of continuous operation, particularly in environments with varying temperatures and humidity levels.

What Role Does Bevel Gear Drive Play in the Automotive Industry?

In the automotive industry, bevel gear drives are pivotal in the drive systems of electric vehicles (EVs). They provide enhanced torque control and support the compact design necessary for modern EV architectures. This is particularly important for international buyers looking to invest in sustainable technologies. Key sourcing considerations include precision engineering to ensure compatibility with electric systems and the ability to handle high torque outputs without compromising performance, which is crucial for market competitiveness in Europe and the Middle East.

How is Bevel Gear Drive Applied in Agriculture?

Agricultural machinery relies heavily on bevel gear drives for their drive mechanisms. These components enhance the reliability of equipment like tractors and harvesters, which are crucial for efficient farming operations. By ensuring smooth power transfer at various angles, bevel gears help reduce downtime caused by mechanical failures. Buyers in regions like Nigeria and Brazil should prioritize sourcing gears that are resistant to environmental factors, such as dust and moisture, to ensure longevity and consistent performance in challenging agricultural conditions.

Why is Bevel Gear Drive Important for Oil & Gas Applications?

In the oil and gas sector, bevel gear drives are used in directional drilling equipment, where they are essential for improving power transfer at varied angles. This capability allows for more efficient drilling operations, which is critical in maximizing productivity. For international buyers, particularly in the Middle East, sourcing gears that offer high load handling capabilities and corrosion resistance is vital due to the harsh operational environments typical in this industry.

How Does Bevel Gear Drive Enhance Marine Propulsion Systems?

Bevel gear drives are integral to propulsion systems in ships and submarines, allowing for enhanced maneuverability and efficient space utilization. These drives enable the transfer of power from the engine to the propeller at right angles, which is essential for vessel design. Marine buyers should focus on sourcing materials that meet marine-grade specifications to ensure resilience against saltwater corrosion and mechanical stresses, thus ensuring the safety and efficiency of their vessels in international waters.

3 Common User Pain Points for ‘bevel gear drive’ & Their Solutions

Scenario 1: Misalignment Issues in Bevel Gear Drives

The Problem: One common challenge B2B buyers face when implementing bevel gear drives is the misalignment of gears. Misalignment can occur during installation or due to wear over time, leading to increased friction, noise, and ultimately, premature failure of the gear system. This not only hampers operational efficiency but can also result in costly downtimes and repairs, which is particularly detrimental in industries where precision and reliability are critical.

The Solution: To mitigate misalignment issues, it is crucial to employ precise installation techniques. Buyers should invest in alignment tools such as laser alignment systems to ensure that the high-speed and low-speed shafts are perfectly aligned during installation. Additionally, regular maintenance checks should be scheduled to monitor gear wear and alignment over time. When sourcing bevel gear drives, consider suppliers who offer alignment services or technical support to guide installation. This proactive approach can significantly reduce the risk of misalignment-related failures and extend the lifespan of the gear drive.

Scenario 2: Inadequate Load Capacity for Application Needs

The Problem: Another prevalent pain point is the selection of bevel gear drives with inadequate load capacity for specific applications. This often stems from a lack of understanding of the operational demands of the machinery involved. If the gear drive is not rated for the required load, it may lead to overheating, excessive wear, and catastrophic failure, resulting in significant operational interruptions and increased costs.

The Solution: To avoid this scenario, it is essential for buyers to conduct a thorough analysis of their application’s load requirements before purchasing bevel gear drives. This includes understanding the torque, speed, and environmental conditions the gear drive will operate under. Collaborating with manufacturers or suppliers who specialize in bevel gear drives can provide insights into the appropriate load ratings. Buyers should also consider custom solutions that offer tailored load capacities to meet specific operational demands. By ensuring that the selected gear drive is adequately rated, businesses can enhance reliability and reduce the risk of unexpected failures.

Scenario 3: Difficulty in Sourcing Replacement Parts

The Problem: Many B2B buyers experience challenges in sourcing replacement parts for bevel gear drives. This issue can arise from several factors, including the obsolescence of specific gear models, limited availability of components, or long lead times from suppliers. Such difficulties can lead to extended downtimes, affecting production schedules and overall business performance.

The Solution: To address this sourcing challenge, buyers should establish a robust relationship with reliable suppliers who offer a wide range of replacement parts and components for bevel gear drives. It is beneficial to inquire about the availability of spare parts at the time of purchase and to choose suppliers who maintain inventories of critical components. Additionally, consider opting for gear drives from manufacturers known for their commitment to ongoing product support and availability of parts, even for older models. Implementing a preventive maintenance strategy that includes keeping a stock of essential spare parts can also minimize downtime. This foresight can help ensure that any necessary repairs can be executed swiftly, maintaining operational continuity.

By understanding these pain points and implementing the recommended solutions, B2B buyers can enhance the performance, reliability, and longevity of their bevel gear drive systems, ultimately contributing to better operational efficiency and cost savings.

Strategic Material Selection Guide for bevel gear drive

What Materials are Commonly Used for Bevel Gear Drives?

When selecting materials for bevel gear drives, it is crucial to consider properties such as strength, durability, and resistance to wear and corrosion. The choice of material can significantly influence the performance, longevity, and cost-effectiveness of the gear drive. Below, we analyze four common materials used in bevel gear drives: steel, cast iron, aluminum, and plastic.

How Does Steel Perform in Bevel Gear Drives?

Steel is the most widely used material for bevel gear drives due to its exceptional strength and durability. Key properties include high tensile strength, excellent wear resistance, and good machinability. Steel can withstand high temperatures and pressures, making it suitable for heavy-duty applications.

Pros: Steel bevel gears offer high load-bearing capacity and longevity, making them ideal for demanding environments. Their resistance to deformation under stress ensures reliable performance over time.

Cons: The main drawbacks of steel are its susceptibility to corrosion and the higher manufacturing complexity associated with heat treatment processes. Additionally, steel gears can be heavier, which may not be suitable for applications where weight is a critical factor.

Impact on Application: Steel gears are compatible with a wide range of media, including oils and greases, which enhances their performance in various industrial settings.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is essential. Buyers from regions like Africa and South America should also consider the availability of quality steel and the associated costs.

What Role Does Cast Iron Play in Bevel Gear Drives?

Cast iron is another popular choice for bevel gear drives, particularly in applications where vibration dampening is crucial. Its properties include good wear resistance and the ability to absorb shock, which can prolong the life of the gear.

Pros: Cast iron gears are cost-effective and can be produced in complex shapes, making them suitable for various applications. Their inherent damping properties also reduce noise during operation.

Cons: However, cast iron is brittle and can fracture under high stress. It is also less suitable for high-speed applications due to its lower strength compared to steel.

Impact on Application: Cast iron gears are often used in machinery where shock loads are present, but they may not perform well in high-temperature environments.

Considerations for International Buyers: Buyers should ensure that cast iron components meet relevant standards to avoid quality issues. In regions like the Middle East, where high temperatures are common, it is vital to assess the specific grade of cast iron used.

How Does Aluminum Compare for Bevel Gear Drives?

Aluminum is increasingly being used in bevel gear drives, especially in lightweight applications. It offers a good strength-to-weight ratio and excellent corrosion resistance.

Pros: Aluminum gears are lightweight, which reduces the overall weight of the machinery. They are also resistant to oxidation, making them suitable for environments exposed to moisture.

Cons: The primary limitation of aluminum is its lower strength compared to steel and cast iron, which may restrict its use in heavy-duty applications. Additionally, aluminum gears can be more expensive than their steel counterparts.

Impact on Application: Aluminum gears are ideal for applications where weight is a concern, such as in aerospace and automotive industries.

Considerations for International Buyers: Compliance with international standards is crucial, and buyers must consider the availability and cost of aluminum in their regions, particularly in South America and Africa.

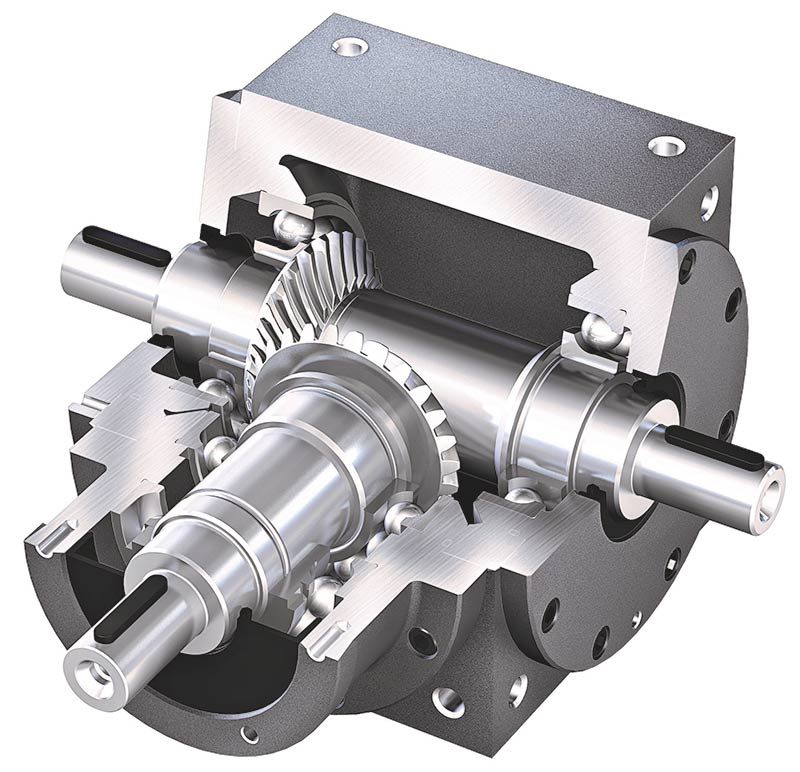

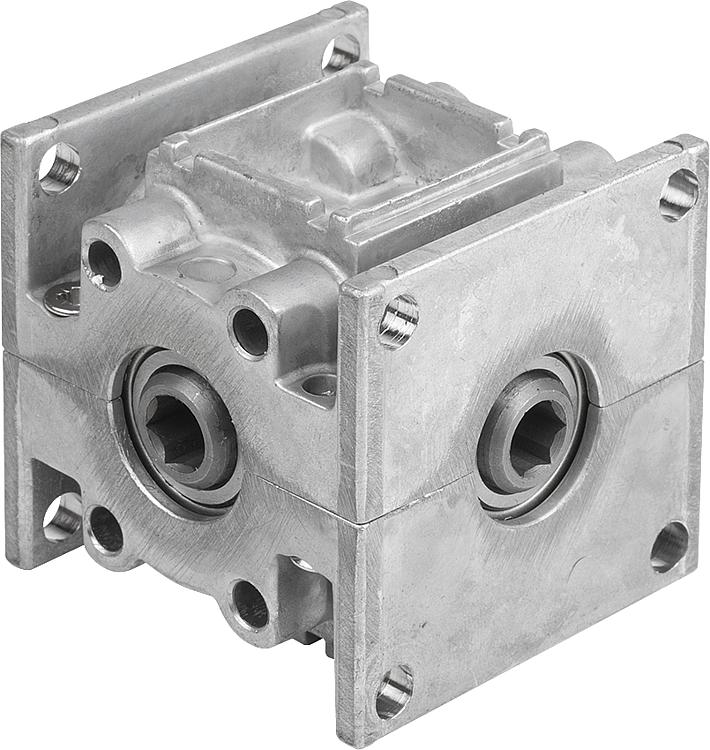

Illustrative image related to bevel gear drive

What Advantages Do Plastic Gears Offer in Bevel Gear Drives?

Plastic gears are often overlooked but can be highly effective in specific applications. They are lightweight, resistant to corrosion, and can operate quietly.

Pros: Plastic gears are cost-effective and can be manufactured with precision. They also offer good chemical resistance, making them suitable for various environments.

Cons: However, plastic gears may not withstand high loads or temperatures as well as metal gears. Their lifespan may also be shorter in demanding applications.

Impact on Application: Plastic gears are ideal for low-load applications, such as in consumer products or where noise reduction is essential.

Considerations for International Buyers: Buyers should ensure that the plastic materials used comply with relevant standards, especially in industries where safety and reliability are paramount.

Summary Table of Material Selection for Bevel Gear Drives

| Material | Typical Use Case for bevel gear drive | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy machinery, automotive | High strength and durability | Susceptible to corrosion | High |

| Cast Iron | Industrial machinery | Cost-effective, good shock absorption | Brittle, lower strength | Medium |

| Aluminum | Aerospace, automotive | Lightweight, corrosion-resistant | Lower strength compared to steel | High |

| Plastic | Consumer products, low-load applications | Cost-effective, quiet operation | Shorter lifespan under load | Low |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of various materials for bevel gear drives. By understanding these factors, buyers can make informed decisions that align with their specific application requirements and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for bevel gear drive

What Are the Main Stages in the Manufacturing Process of Bevel Gear Drives?

The manufacturing of bevel gear drives involves several critical stages, each designed to ensure the final product meets high standards of quality and performance. Understanding these stages is essential for B2B buyers looking to source bevel gear drives effectively.

Material Preparation: What Raw Materials Are Used?

The first step in manufacturing bevel gear drives is material selection. Common materials include high-carbon steel, stainless steel, and sometimes advanced alloys for specialized applications. The choice of material affects the strength, durability, and resistance to wear of the bevel gears. Once selected, the materials undergo processes such as heat treatment to improve their mechanical properties. This preparation is crucial as it sets the foundation for a reliable gear drive.

How Are Bevel Gears Formed?

The forming process typically involves several key techniques:

-

Machining: This is the primary method used to shape the gear teeth and achieve precise dimensions. CNC (Computer Numerical Control) machines are commonly employed for their accuracy and repeatability.

-

Hobbing: This technique is used to produce the gear teeth by rotating a hob cutter against the workpiece. It is efficient for creating complex tooth profiles and is widely used in the production of bevel gears.

-

Grinding: After hobbing, gears may be ground to achieve finer tolerances and surface finishes. This step is essential for reducing noise and wear during operation.

Each of these processes plays a vital role in ensuring that the bevel gear drives meet the required specifications.

What Does the Assembly Process Involve?

Once individual components are manufactured, the assembly process begins. This stage includes:

-

Alignment: Proper alignment of the gears is critical for optimal performance and longevity. Misalignment can lead to increased wear and potential failure.

-

Lubrication: Adequate lubrication is applied to minimize friction between moving parts, enhancing efficiency and reducing heat generation.

-

Final Assembly: Components are assembled according to precise specifications, ensuring that the gear drive functions as intended in its application.

What Finishing Techniques Are Used for Bevel Gear Drives?

Finishing is the final step in the manufacturing process, which enhances the aesthetic and functional properties of bevel gear drives. Techniques include:

-

Surface Treatment: Processes such as shot peening or coating with anti-corrosive materials enhance surface durability and resistance to environmental factors.

-

Quality Inspection: This is where the gears are subjected to rigorous quality checks to ensure they meet the specified tolerances and performance criteria.

What Are the Quality Assurance Standards for Bevel Gear Drives?

Quality assurance is paramount in the production of bevel gear drives, particularly for international B2B buyers. Compliance with international standards is essential for ensuring product reliability and safety.

What International Standards Should Buyers Be Aware Of?

One of the most recognized international standards is ISO 9001, which outlines the requirements for a quality management system (QMS). Adherence to this standard signifies that the manufacturer has established processes to ensure consistent quality in products and services.

In addition to ISO 9001, industry-specific certifications such as CE (Conformité Européenne) for European markets and API (American Petroleum Institute) standards for applications in the oil and gas sector may also be relevant. These certifications indicate compliance with rigorous safety and performance standards.

How Are Quality Control Checkpoints Implemented?

Quality control (QC) is integrated throughout the manufacturing process, with several key checkpoints:

Illustrative image related to bevel gear drive

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon delivery to ensure they meet specified standards before production begins.

-

In-Process Quality Control (IPQC): During manufacturing, QC measures are taken at various stages to monitor processes and identify any deviations from specifications.

-

Final Quality Control (FQC): After assembly and finishing, a comprehensive inspection is conducted to ensure the final product meets all requirements before shipping.

What Common Testing Methods Are Used for Bevel Gear Drives?

To ensure reliability and performance, various testing methods are employed:

-

Load Testing: Bevel gears are subjected to operational loads to assess their performance under real-world conditions.

-

Noise and Vibration Testing: Excessive noise or vibration can indicate issues with alignment or wear, making these tests crucial for quality assurance.

-

Fatigue Testing: This assesses the gears’ durability over time, simulating prolonged use to identify potential failure points.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, verifying a supplier’s quality control processes is crucial. Here are effective strategies:

-

Supplier Audits: Conducting audits allows buyers to assess the manufacturer’s quality management practices firsthand, ensuring they align with expected standards.

-

Quality Reports: Requesting detailed quality reports can provide insights into the supplier’s QC processes and any issues encountered during production.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality assurance practices, enhancing trust in the procurement process.

What Are the QC and Certification Nuances for International B2B Buyers?

When sourcing bevel gear drives from manufacturers in different regions, B2B buyers should be aware of specific nuances:

-

Regional Certifications: Understanding local certifications and compliance requirements is essential, especially in regions like Africa and South America where standards may differ significantly from Europe and North America.

-

Cultural Differences in Manufacturing Practices: Awareness of cultural attitudes towards quality and production can influence supplier relationships and expectations.

-

Documentation and Traceability: Buyers should ensure that suppliers maintain detailed documentation of quality processes and traceability of materials, which is particularly important for industries with stringent regulatory requirements.

In conclusion, a thorough understanding of manufacturing processes and quality assurance for bevel gear drives is essential for B2B buyers. By focusing on the details of manufacturing stages, quality standards, and verification methods, buyers can make informed sourcing decisions that align with their operational needs and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bevel gear drive’

In this guide, we provide a practical sourcing checklist specifically designed for B2B buyers looking to procure bevel gear drives. These components are essential for effective power transmission in various industrial applications. By following these steps, you can ensure that your sourcing process is efficient, reliable, and aligned with your operational needs.

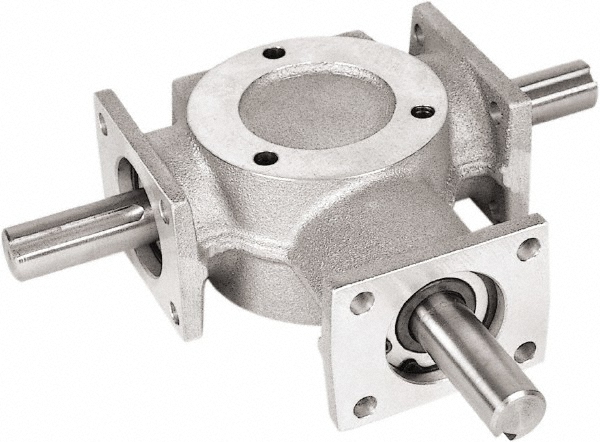

Step 1: Define Your Technical Specifications

Begin by establishing the technical requirements for your bevel gear drive. This includes understanding the power transmission needs, gear ratios, and the specific configurations (inline, parallel, or right-angle) that suit your application. Clearly defined specifications will help you communicate effectively with suppliers and ensure that the products meet your operational demands.

Illustrative image related to bevel gear drive

- Consider the load requirements: Analyze the torque and speed requirements to select the appropriate gear ratio.

- Identify the mounting configuration: Determine if your application requires a specific shaft orientation.

Step 2: Conduct Market Research

Research potential suppliers and manufacturers of bevel gear drives. Investigate their market presence, product offerings, and industry reputation. This step is crucial for identifying reliable partners who can meet your specific needs.

- Utilize online platforms: Look for industry-specific directories and trade platforms to find reputable suppliers.

- Assess geographical advantages: Consider suppliers from regions with established manufacturing expertise in bevel gears, such as Europe or North America.

Step 3: Evaluate Potential Suppliers

Before making a commitment, thoroughly vet potential suppliers. Request company profiles, product catalogs, and case studies that demonstrate their capability in producing bevel gear drives. It’s vital to validate their experience and reliability in your specific industry.

- Seek customer testimonials: Ask for references from other businesses that have purchased similar products.

- Review certifications: Ensure that the suppliers adhere to relevant quality standards (e.g., ISO certification).

Step 4: Request Quotes and Compare Pricing

Once you have a shortlist of suppliers, request detailed quotes that include pricing, delivery times, and terms of service. Comparing quotes will help you understand the market rate and identify the best value for your budget.

- Consider total cost of ownership: Factor in shipping, import duties, and potential maintenance costs when evaluating quotes.

- Negotiate terms: Don’t hesitate to discuss pricing and payment terms to get the best deal.

Step 5: Examine Product Quality and Performance

Before finalizing your purchase, assess the quality and performance of the bevel gear drives. Request samples or conduct tests to ensure they meet your specified requirements.

- Evaluate material quality: Check if the materials used are durable and suitable for your application.

- Review performance data: Look for performance metrics such as efficiency, noise levels, and heat generation under load.

Step 6: Verify After-Sales Support and Warranty

Inquire about the after-sales support and warranty options provided by the supplier. Strong after-sales service can significantly impact the longevity and reliability of your bevel gear drives.

- Check for technical support: Ensure that the supplier offers assistance for installation and troubleshooting.

- Understand warranty terms: A comprehensive warranty can provide peace of mind and protect your investment.

Step 7: Finalize Your Order and Establish Communication

Once you have selected a supplier, finalize your order by confirming all details, including specifications, pricing, and delivery timelines. Establish clear communication channels for ongoing support and updates throughout the procurement process.

- Document agreements: Keep a written record of all terms agreed upon to avoid misunderstandings.

- Set up regular check-ins: Maintain communication with the supplier to monitor progress and address any potential issues proactively.

By following this checklist, B2B buyers can ensure a systematic approach to sourcing bevel gear drives, ultimately leading to improved operational efficiency and reduced downtime.

Comprehensive Cost and Pricing Analysis for bevel gear drive Sourcing

What Are the Key Cost Components in Bevel Gear Drive Manufacturing?

When sourcing bevel gear drives, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The choice of materials significantly impacts costs. Common materials for bevel gears include carbon steel, stainless steel, and alloy steels, each varying in price based on quality and market availability. High-performance materials may incur higher upfront costs but can lead to reduced wear and longer service life.

-

Labor: Labor costs vary by region and the complexity of the manufacturing process. Skilled labor is often necessary for precision machining and assembly, particularly for custom bevel gear drives. This is a key consideration for international buyers, as labor costs can differ dramatically across countries.

-

Manufacturing Overhead: This encompasses indirect costs such as utilities, equipment depreciation, and facility expenses. Buyers should inquire about a supplier’s overhead rate to better understand the overall pricing structure.

-

Tooling: The initial investment in tooling can be significant, especially for custom gear designs. Tooling costs are typically amortized over the production run, so larger orders may yield lower per-unit costs.

-

Quality Control (QC): Implementing rigorous QC processes ensures reliability and performance. However, these processes add to the overall cost. Buyers should weigh the importance of certifications and testing against the potential risks of inferior products.

-

Logistics: Shipping and handling costs can vary based on the distance, mode of transport, and packaging requirements. International buyers must consider tariffs, customs duties, and freight charges, which can significantly impact total costs.

-

Supplier Margin: Each supplier will have their own markup based on their business model, market position, and the level of service provided. Understanding these margins can aid in negotiations.

What Factors Influence Pricing for Bevel Gear Drives?

Several factors can influence the pricing of bevel gear drives, especially for B2B transactions:

-

Volume and Minimum Order Quantity (MOQ): Higher volumes often lead to reduced per-unit costs due to economies of scale. Buyers should negotiate MOQs to find a balance between cost efficiency and inventory management.

-

Specifications and Customization: Custom bevel gear drives tailored to specific applications may incur additional costs. Buyers should clearly outline their specifications to avoid unexpected price increases.

-

Materials and Quality Certifications: The choice of materials and the existence of quality certifications can affect both cost and price. Higher-quality materials typically command higher prices, but they may also reduce maintenance costs over time.

-

Supplier Factors: The supplier’s reputation, production capabilities, and geographic location can influence pricing. Established suppliers may offer more reliability but at a premium.

-

Incoterms: Understanding Incoterms is vital for international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, directly impacting the total landed cost.

What Buyer Tips Can Enhance Cost Efficiency?

International B2B buyers can employ several strategies to enhance cost efficiency when sourcing bevel gear drives:

-

Negotiate Effectively: Leverage volume commitments or long-term contracts to negotiate better pricing. Building strong relationships with suppliers can also facilitate favorable terms.

-

Evaluate Total Cost of Ownership (TCO): Instead of focusing solely on initial purchase price, consider the TCO, which includes installation, maintenance, and operational costs. This approach can lead to more informed purchasing decisions.

-

Understand Pricing Nuances in Different Markets: Be aware of regional pricing variations due to labor costs, local materials, and market competition. Buyers in Africa and South America, for instance, may face different logistical challenges compared to those in Europe.

-

Request Detailed Quotes: Ensure that suppliers provide comprehensive quotes that break down costs. This transparency allows for better comparison and negotiation.

-

Stay Informed on Market Trends: Keeping abreast of fluctuations in raw material prices and market demand can provide leverage in negotiations and purchasing strategies.

By understanding the cost structure and pricing influencers, international B2B buyers can make informed decisions, optimize procurement strategies, and ultimately enhance their operational efficiency.

Alternatives Analysis: Comparing bevel gear drive With Other Solutions

When considering the best mechanical power transmission solutions, it’s essential to evaluate various alternatives to bevel gear drives. These alternatives can provide different advantages and disadvantages depending on specific applications and operational requirements. This analysis will compare bevel gear drives with worm gear drives and planetary gear systems, which are common alternatives in industrial settings.

| Comparison Aspect | Bevel Gear Drive | Worm Gear Drive | Planetary Gear System |

|---|---|---|---|

| Performance | High efficiency; good for right-angle power transmission | Lower efficiency due to sliding friction; excellent for high torque applications | Very high efficiency; compact design for multi-speed applications |

| Cost | Moderate initial investment; long-term durability can justify cost | Generally lower initial cost; may require more frequent replacements | Higher initial investment; long-term savings through efficiency |

| Ease of Implementation | Moderate; requires precise alignment | Relatively easy to install; less precise alignment needed | Complex installation; requires careful design and assembly |

| Maintenance | Low maintenance; durable under proper use | Higher maintenance; can wear out faster due to friction | Low maintenance; robust design leads to longer lifespan |

| Best Use Case | Applications requiring direction change in compact spaces | High-torque applications with limited space; ideal for conveyor systems | High-performance applications needing compact solutions with high torque and speed variability |

What are the Advantages and Disadvantages of Worm Gear Drives?

Worm gear drives are characterized by their ability to provide high torque and a significant speed reduction in a compact form factor. They are often used in conveyor systems and applications where space is at a premium. The primary advantage of worm gears is their ability to transmit motion at right angles and their self-locking capabilities, which prevent back-driving. However, they tend to have lower efficiency compared to bevel gears due to higher friction losses and may require more frequent maintenance due to wear on the worm and gear teeth.

How Do Planetary Gear Systems Compare to Bevel Gear Drives?

Planetary gear systems, also known as epicyclic gears, offer unique advantages, particularly in applications requiring compactness and high power density. They consist of multiple gears (sun, planet, and ring gears) that distribute load evenly, resulting in high efficiency and torque output. This makes them suitable for applications such as automotive transmissions and robotics. However, the complexity of their design can lead to higher initial costs and installation challenges, which may deter some buyers.

How Can B2B Buyers Choose the Right Solution?

When selecting a power transmission solution, B2B buyers should first assess their specific operational needs, including performance requirements, space constraints, and budget. Bevel gear drives are ideal for applications needing efficient right-angle power transmission with low maintenance, while worm gears are more suited for high-torque scenarios where compactness is critical. On the other hand, planetary gear systems are excellent for applications needing high efficiency and compact design, albeit at a higher cost.

Ultimately, understanding the unique advantages and limitations of each solution allows buyers to make informed decisions that align with their operational goals, ensuring optimal performance and cost-effectiveness in their machinery and equipment.

Essential Technical Properties and Trade Terminology for bevel gear drive

When engaging with bevel gear drives, understanding their technical properties and associated terminology is crucial for informed decision-making. Below, we explore key specifications and trade terms that are essential for B2B buyers looking to procure bevel gear drives effectively.

What Are the Key Technical Properties of Bevel Gear Drives?

1. Material Grade

The material used in bevel gear drives significantly impacts their performance and longevity. Common materials include steel, cast iron, and alloyed metals. Steel, for instance, is favored for its high tensile strength and wear resistance, making it suitable for high-load applications. Buyers should ensure that the material grade aligns with their specific operational demands to avoid premature wear or failure.

2. Gear Ratio

The gear ratio determines the output speed and torque of the bevel gear drive. It is calculated by dividing the number of teeth on the driven gear by the number of teeth on the driving gear. A higher gear ratio typically means increased torque but reduced speed, and vice versa. Understanding gear ratios is vital for selecting a bevel gear drive that meets the application’s power transmission requirements.

3. Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension. In bevel gear drives, precise tolerances are critical for ensuring smooth operation and reducing noise and wear. Tighter tolerances generally lead to better performance, but they may also increase manufacturing costs. Buyers should balance the need for precision with budget considerations.

Illustrative image related to bevel gear drive

4. Load Capacity

Load capacity indicates the maximum load a bevel gear drive can handle without failure. This property is crucial for applications involving heavy machinery or high-speed operations. Understanding load capacity helps buyers select drives that can withstand operational stresses while ensuring reliability and safety.

5. Efficiency

Efficiency is a measure of how effectively a bevel gear drive transmits power. Higher efficiency means less energy loss due to friction and heat, resulting in lower operational costs. For B2B buyers, selecting a high-efficiency bevel gear drive can lead to significant savings in energy costs over time.

What Are Common Trade Terms Related to Bevel Gear Drives?

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts and equipment that may be marketed by another manufacturer. Understanding this term is crucial for B2B buyers, as it often indicates the quality and compatibility of bevel gear drives with existing machinery.

2. MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units a buyer must purchase in a single order. This term is vital for budget planning and inventory management, especially for businesses looking to procure bevel gear drives in bulk.

3. RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers. It typically includes specifications and quantities for the desired products. For B2B buyers, issuing an RFQ for bevel gear drives can help in comparing prices and terms from multiple suppliers, facilitating better purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international trade rules that define the responsibilities of buyers and sellers for the delivery of goods. Familiarity with Incoterms is crucial for B2B transactions involving bevel gear drives, as they clarify shipping costs, risk allocation, and delivery timelines.

5. Lead Time

Lead time is the period between the initiation of an order and its completion. Understanding lead times for bevel gear drives is essential for project planning and ensuring that equipment is available when needed.

By familiarizing themselves with these technical properties and trade terminologies, B2B buyers can make more informed purchasing decisions regarding bevel gear drives, ensuring they select the right products for their specific applications and operational needs.

Navigating Market Dynamics and Sourcing Trends in the bevel gear drive Sector

What Are the Global Drivers Shaping the Bevel Gear Drive Market?

The bevel gear drive market is experiencing robust growth, driven by increasing automation across industries, demand for energy-efficient solutions, and advancements in manufacturing technology. Key sectors such as automotive, aerospace, and industrial machinery are pushing the need for more compact, reliable, and efficient power transmission systems. In regions like Africa and South America, where industrialization is accelerating, the demand for bevel gear drives is surging as businesses seek to modernize their operations. In Europe and the Middle East, stringent regulations on energy efficiency are further propelling the adoption of high-performance gear systems that meet both operational and environmental standards.

Emerging B2B technologies, such as Industry 4.0 and IoT, are reshaping sourcing trends in the bevel gear drive sector. Smart manufacturing practices are leading to the integration of predictive maintenance and real-time monitoring, enhancing the performance and lifespan of gear drives. Buyers are increasingly looking for suppliers who can offer these advanced technological solutions alongside traditional products. Additionally, the move towards digital procurement processes is streamlining sourcing, allowing international buyers to access a broader range of suppliers and innovations efficiently.

How Is Sustainability Influencing Bevel Gear Drive Sourcing Decisions?

Sustainability is becoming a critical consideration for B2B buyers in the bevel gear drive sector. The environmental impact of manufacturing processes, including energy consumption and waste generation, is under scrutiny, and companies are increasingly prioritizing suppliers with strong sustainability credentials. The importance of ethical supply chains cannot be overstated, as businesses seek to align with partners who share their commitment to environmental responsibility.

In response to this demand, manufacturers are adopting ‘green’ certifications and utilizing sustainable materials in their production processes. For instance, the use of recyclable materials and eco-friendly lubricants in bevel gear drives can significantly reduce environmental footprints. Buyers in regions such as Europe and North America are particularly attuned to these trends, often requiring suppliers to provide proof of sustainability practices and certifications. This shift not only enhances corporate responsibility but can also lead to cost savings and improved brand reputation for businesses committed to sustainable practices.

What Is the Historical Context of Bevel Gear Drives for Modern B2B Applications?

The evolution of bevel gear drives dates back to the late 19th century when they were first introduced to facilitate efficient power transmission at right angles. Initially employed in various mechanical applications, bevel gears have since undergone significant advancements, incorporating new materials and manufacturing techniques that enhance their performance and reliability. As industries have evolved, so too have the applications of bevel gear drives, adapting to the needs of modern machinery and automation.

Historically, the shift towards precision engineering has led to the development of specialized bevel gear designs that cater to specific industry requirements. Today, these drives are integral to many high-tech applications, from robotics to renewable energy systems, demonstrating their versatility and importance in contemporary B2B environments. Understanding this evolution provides buyers with context for the ongoing innovations and trends that shape the bevel gear drive market today, ensuring they make informed sourcing decisions aligned with their operational needs.

Frequently Asked Questions (FAQs) for B2B Buyers of bevel gear drive

-

How do I select the right bevel gear drive for my application?

Selecting the right bevel gear drive involves understanding your specific application requirements, such as load capacity, speed, torque, and space constraints. Begin by identifying the gear ratio needed for your operation, as this will directly impact performance. Evaluate the materials used in construction, as they affect durability and weight. Consult with suppliers to discuss your needs, and request samples or detailed specifications to ensure the gear drive meets your operational demands. -

What factors should I consider when vetting suppliers for bevel gear drives?

When vetting suppliers, consider their industry experience, reputation, and manufacturing capabilities. Check for certifications like ISO to ensure quality standards. It’s beneficial to review customer testimonials and case studies to gauge their reliability. Additionally, assess their ability to provide customization options and after-sales support. Establish communication channels to discuss your specific requirements and ensure they can meet your lead times and logistical needs. -

What are the minimum order quantities (MOQs) for bevel gear drives?

Minimum order quantities (MOQs) for bevel gear drives can vary significantly between suppliers. Some may offer flexible MOQs for custom orders, while others might have strict minimums due to production constraints. It’s essential to discuss your needs with potential suppliers to negotiate MOQs that align with your purchasing plans. Consider your budget and storage capacity when deciding on the quantity to order, especially if you are entering a new market. -

Can bevel gear drives be customized to fit my specific needs?

Yes, many manufacturers offer customization options for bevel gear drives to meet specific application requirements. Customizations may include variations in gear ratios, sizes, materials, and mounting configurations. When seeking customization, provide detailed specifications and discuss your operational challenges with the supplier. Collaborating with an experienced manufacturer can lead to tailored solutions that enhance performance and efficiency in your applications. -

What payment terms should I expect when sourcing bevel gear drives internationally?

Payment terms for international orders can vary widely depending on the supplier and the buyer’s relationship. Common terms include payment in advance, letters of credit, or net terms (e.g., 30, 60, or 90 days). Always clarify payment methods accepted, including wire transfers, credit cards, or PayPal. Establishing clear terms upfront can prevent misunderstandings and ensure a smooth transaction process, especially when dealing with international logistics. -

What quality assurance measures should I look for in bevel gear drives?

Quality assurance is critical when sourcing bevel gear drives. Look for suppliers who implement rigorous quality control processes, including testing for durability, precision, and performance under load. Certifications such as ISO 9001 can indicate a commitment to quality management. Request documentation of quality tests and inspection reports for the bevel gear drives you intend to purchase. Ensuring quality will help mitigate risks associated with equipment failure and downtime. -

How do I handle logistics and shipping for international orders of bevel gear drives?

Managing logistics for international orders involves coordinating shipping methods, customs clearance, and delivery timelines. Discuss shipping options with your supplier, considering factors like cost, speed, and reliability. Ensure you understand any import duties or tariffs that may apply to your shipment. Partnering with a freight forwarder can streamline the process, providing expertise in navigating international shipping regulations and ensuring timely delivery of your bevel gear drives. -

What are the common applications for bevel gear drives across different industries?

Bevel gear drives are used in various industries due to their ability to transmit power efficiently at right angles. Common applications include automotive systems, industrial machinery, conveyor systems, and agricultural equipment. In the oil and gas sector, they are often employed in drilling rigs and pumps. Understanding the specific applications relevant to your industry can help you identify the most suitable bevel gear drives for your operational needs.

Top 7 Bevel Gear Drive Manufacturers & Suppliers List

1. Boston Gear – Bevel Gear Drives

Domain: bostongear.com

Registered: 1997 (28 years)

Introduction: Bevel Gear Drives from Boston Gear are part of their enclosed gear drives and motors product line. They cater to various industries including Aerospace, Amusement Rides, Elevators, Agriculture, Food and Beverage, Forestry, Marine, Material Handling, Medical, Mining, Motion Control, Oil & Gas, Packaging, Power Generation, Stage & Theater, and Wastewater.

2. McMaster – Bevel Gear Drives

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Bevel Gear Drives, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Superior Gearbox – Bevel Gear Drives

Domain: superiorgearbox.com

Registered: 1997 (28 years)

Introduction: Bevel Gear Drives from Superior Gearbox Company offer various configurations including inline, parallel, and right-angle gear drives. Key features include:

– Two-piece aluminum housing for strength, corrosion resistance, and thermal capacity.

– Precision machined for exact gear mesh and bearing preload.

– Precision-forged gears with ratios ranging from 2.92:1 to 1:2.

– Tapered roller bearings for …

4. IQS Directory – Bevel Gears

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Bevel gears are toothed, rotating devices designed to transmit mechanical energy or power between intersecting shafts, often at right angles. They alter the axis of rotation and can adjust torque levels, either enhancing or reducing it, while inversely impacting angular speed. Bevel gears come in various types, including straight bevel gears, spiral bevel gears, zerol bevel gears, and hypoid gears…

5. GoBilda – MOD 1.5 Bevel Gears (2:1 Ratio)

Domain: gobilda.com

Registered: 2015 (10 years)

Introduction: Bevel gears are designed to drive a shaft at a 90° angle, available in ratios of 1:1 (miter gears) and 2:1 for speed and torque tuning. Key products include:

– MOD 1.5 Bevel Gears (2:1 Ratio): Creates a 2:1 reduction; specific tooth profile; compatible only with pinion gear.

– MOD 1 Miter Gears (1:1 Ratio): Two-piece steel construction; pinch bolts for secure locking; titanium nitride finish for…

6. Ducati – Bevel Drive Mechanism

Domain: ducati.ms

Registered: 2003 (22 years)

Introduction: Bevel drive is a mechanism used in vintage Ducati motorcycles to drive the cams. It involves bevel gears that connect the crankshaft to a shaft, which then spins the cam for ignition or other functions. The design includes a timing chest where the cam is driven off the bevel gear, and it may also involve components like an oil pump. The setup requires careful adjustment with shims, and the timing …

7. Regal Rexnord – Hub City Bevel Gear Drives

Domain: regalrexnord.com

Registered: 2021 (4 years)

Introduction: Hub City Bevel Gear Drives Ductile Iron Bevel Reducer

Strategic Sourcing Conclusion and Outlook for bevel gear drive

In the dynamic landscape of industrial applications, bevel gear drives stand out as crucial components for effective power transmission. Their efficiency in converting rotational motion at right angles makes them ideal for various machinery across sectors, including automotive, aerospace, and manufacturing. Strategic sourcing of bevel gear drives not only ensures access to high-quality products but also fosters long-term partnerships with reliable suppliers. This can lead to reduced operational costs, improved product performance, and enhanced safety standards.

For international B2B buyers in regions such as Africa, South America, the Middle East, and Europe, leveraging strategic sourcing practices is essential. Understanding the specific needs of your operational environment, alongside the advantages of local and global suppliers, can provide a competitive edge. As the market evolves, staying informed about advancements in bevel gear technology and manufacturing processes will be vital.

Illustrative image related to bevel gear drive

Looking ahead, the demand for innovative and efficient bevel gear solutions is set to rise. Buyers are encouraged to actively engage with manufacturers and suppliers to explore cutting-edge options that meet their unique operational requirements. By prioritizing strategic sourcing, businesses can position themselves for success in an increasingly competitive marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.