Unlocking Value: A Strategic Analysis of the Bending Wire Tool Market

Introduction: Navigating the Global Market for bending wire tool

In today’s competitive landscape, sourcing the right bending wire tool can be a daunting challenge for international B2B buyers, especially when considering factors such as quality, cost, and application versatility. Whether you’re operating in the construction, manufacturing, or hobby industries, the need for precise wire bending solutions is universal. This comprehensive guide delves into the various types of bending wire tools available on the market, from heavy-duty benders designed for large cables to precision tools for intricate tasks.

Our exploration extends beyond mere product descriptions; we provide actionable insights into supplier vetting processes, enabling buyers to identify reliable manufacturers and distributors. Additionally, we analyze cost considerations, ensuring that businesses can make informed decisions that align with their budgets and operational needs.

By focusing on the specific needs of B2B buyers from diverse regions—including Africa, South America, the Middle East, and Europe—this guide is tailored to empower you with the knowledge necessary to navigate the global market effectively. With a clear understanding of the options available, along with practical advice on selecting the right tool for your unique applications, you’ll be equipped to enhance productivity and achieve superior results in your projects.

Understanding bending wire tool Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Bulldog Bender | Heavy-duty design, suitable for large cable sizes (up to 750 MCM) | Electrical installations, industrial wiring | Pros: High durability, ease of use; Cons: Higher initial investment. |

| E/Z Bender | Versatile, accommodates various wire sizes with interchangeable dies | Hobby modeling, small-scale manufacturing | Pros: Compact, precise bends; Cons: Limited to lighter wire applications. |

| Wire Bending Jig | Simple design, ideal for bending mild steel wire up to 5mm | Custom tool fabrication, DIY projects | Pros: Affordable, easy to use; Cons: Less suitable for heavy gauge wire. |

| Bend-All Tool | Designed for tight spaces, capable of bending large wires | Electrical and construction applications | Pros: Excellent for limited space; Cons: May require more manual effort. |

| Manual Wire Bender | Handheld tool, suitable for small to medium wire diameters | Crafting, light industrial applications | Pros: Portable, cost-effective; Cons: Labor-intensive for large projects. |

What are the key characteristics of Bulldog Benders for B2B buyers?

Bulldog Benders are designed for heavy-duty applications, capable of bending large cables up to 750 MCM. Their robust construction makes them ideal for electrical installations and industrial wiring, ensuring precise bends without damaging the wire. When considering a Bulldog Bender, buyers should evaluate the initial cost against the long-term durability and efficiency it offers, particularly in high-volume settings.

How does the E/Z Bender cater to diverse wire bending needs?

The E/Z Bender is known for its versatility, accommodating wire sizes ranging from .015″ to .093″. It is particularly useful in the hobby modeling sector and small-scale manufacturing, where precision and flexibility are paramount. This tool’s interchangeable forming dies allow for various bend types, making it suitable for intricate designs. Buyers should consider the specific wire types they will be working with, as this tool is best suited for lighter materials.

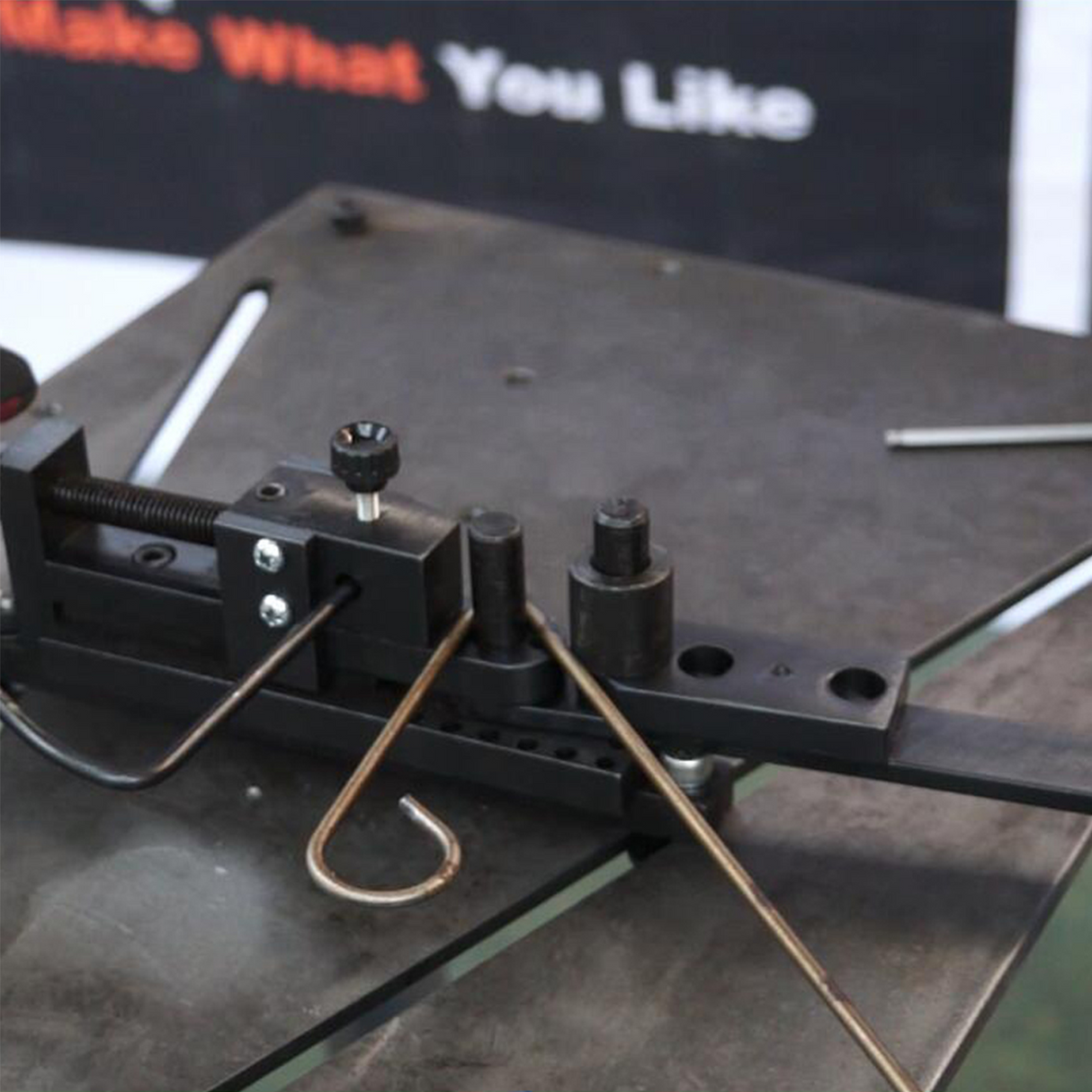

In what scenarios is a Wire Bending Jig most effective?

A Wire Bending Jig is an economical choice for businesses engaged in custom tool fabrication or DIY projects. It allows users to bend mild steel wire up to 5mm in diameter with ease. While it is highly affordable and user-friendly, its limitations in handling heavy gauge wires may restrict its application in more demanding environments. Businesses should assess their wire requirements to determine if this tool meets their needs.

What advantages does the Bend-All Tool provide in tight spaces?

The Bend-All Tool is specifically designed for bending large wires in confined areas, making it invaluable for electrical and construction applications. Its ability to perform precise bends without compromising the wire’s integrity is a significant advantage. However, users should be prepared for a more manual bending process, which may require additional effort compared to powered tools. Evaluating the workspace layout is crucial for potential buyers.

Why should buyers consider a Manual Wire Bender?

Manual Wire Benders are portable tools suitable for small to medium wire diameters, often used in crafting and light industrial applications. Their cost-effectiveness and ease of use make them appealing to small businesses and hobbyists. However, the labor-intensive nature of these tools can be a drawback for larger projects, prompting buyers to consider the volume of work they expect to undertake.

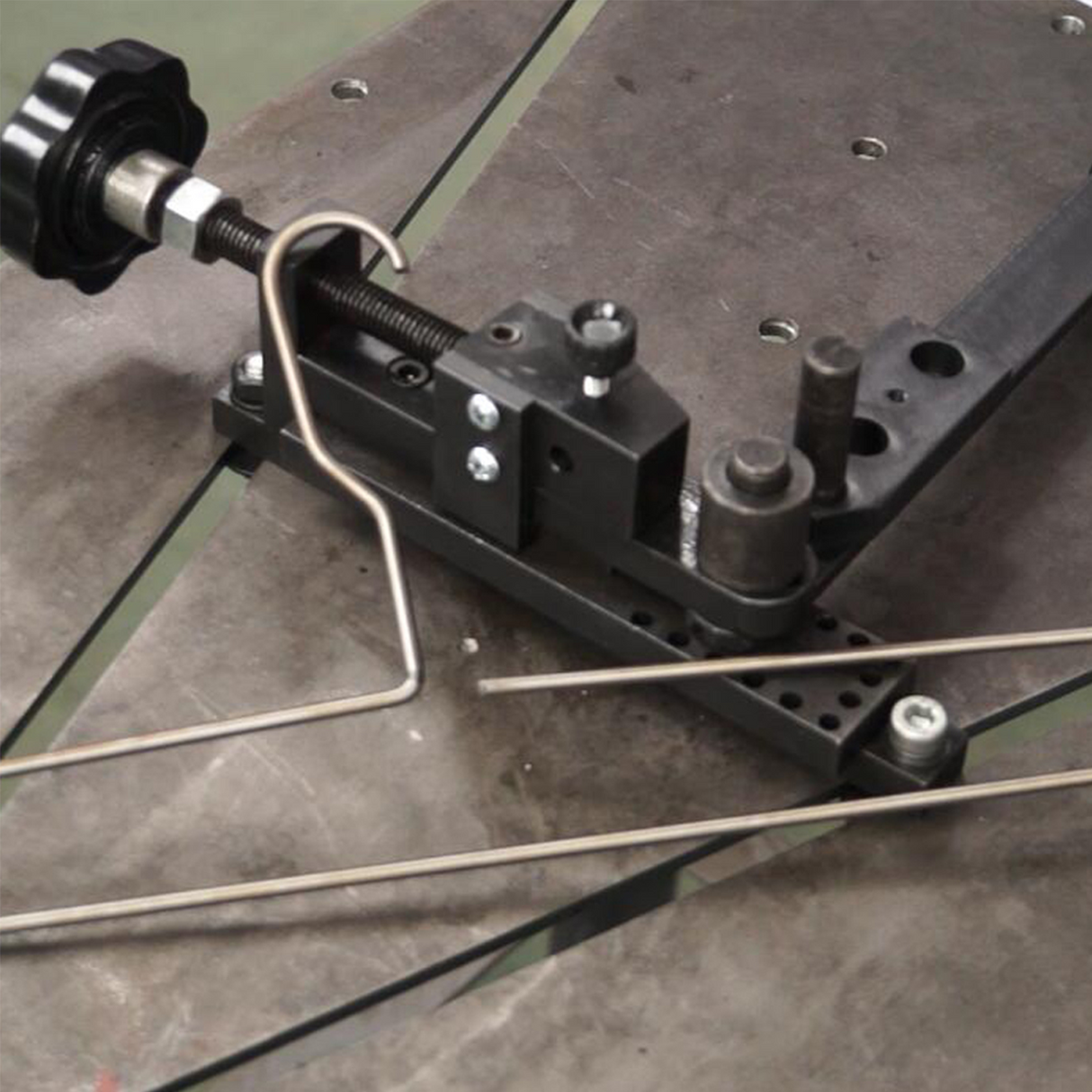

Illustrative image related to bending wire tool

Key Industrial Applications of bending wire tool

| Industry/Sector | Specific Application of bending wire tool | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Electrical wiring and conduit bending | Ensures proper installation and minimizes damage to cables | Quality of materials, adaptability for different wire sizes, and ergonomic design for ease of use |

| Manufacturing | Custom wire forms for machinery and equipment | Increases efficiency by reducing production time and waste | Precision in bending angles, durability of tools, and compatibility with various wire types |

| Automotive | Creating wire harnesses and brackets | Enhances product reliability and safety | Availability of specialized tools for different wire gauges and materials, as well as after-sales support |

| Hobby and Crafts | Model making and custom designs | Allows for creativity and precision in crafting | Range of bending options, ease of use for beginners, and availability of replacement parts |

| Agriculture | Fabrication of fencing and support structures | Improves operational efficiency and longevity of installations | Robustness of tools, ability to handle heavy-duty wire, and local availability of service and support |

How is Bending Wire Tool Used in Construction?

In the construction sector, bending wire tools are essential for shaping electrical wiring and conduits. These tools enable workers to create precise bends, ensuring that cables fit seamlessly into structures without risking damage. This is particularly important in regions with stringent safety regulations, as improper installation can lead to electrical hazards. Buyers in this sector should prioritize tools that can accommodate various wire sizes and are ergonomically designed to reduce worker fatigue, especially in high-volume settings.

What Role Does Bending Wire Tool Play in Manufacturing?

Manufacturers utilize bending wire tools to create custom wire forms essential for machinery and equipment. These tools streamline production processes by allowing for quick adjustments and modifications, which significantly reduces material waste and enhances efficiency. For international buyers, especially in developing regions, sourcing tools that offer precision and durability is critical, as these factors directly impact production quality and operational costs.

How is Bending Wire Tool Applied in the Automotive Industry?

In the automotive industry, bending wire tools are vital for fabricating wire harnesses and brackets that ensure vehicle reliability and safety. These tools allow manufacturers to create complex shapes that fit specific designs, which is crucial for modern automotive engineering. Buyers should consider tools that cater to different wire gauges and materials, as well as those that offer robust after-sales support, to maintain productivity and reduce downtime.

What is the Importance of Bending Wire Tool in Hobby and Crafts?

For hobbyists and crafters, bending wire tools are indispensable for model making and custom designs. These tools enable users to create intricate shapes and structures, enhancing the overall quality of their projects. When sourcing these tools, buyers should look for options that provide a variety of bending capabilities and ease of use, particularly for beginners. Availability of replacement parts is also a significant consideration to ensure long-term usability.

How Does Bending Wire Tool Benefit the Agriculture Sector?

In agriculture, bending wire tools are utilized for the fabrication of fencing and support structures, which are crucial for crop protection and livestock management. These tools enhance operational efficiency by enabling farmers to create durable installations that withstand environmental stressors. Buyers in this sector should focus on the robustness of the tools, ensuring they can handle heavy-duty wire while also considering the availability of local service and support to minimize downtime.

3 Common User Pain Points for ‘bending wire tool’ & Their Solutions

Scenario 1: Difficulty in Achieving Precise Wire Bends for Complex Projects

The Problem:

B2B buyers in industries such as construction and manufacturing often face challenges when bending wire for intricate applications. For instance, when creating custom fixtures or structural supports, achieving the right angles and bends can be crucial. Traditional methods, like using pliers, can lead to inconsistent results, damaging the wire or causing wastage. This not only affects project timelines but can also escalate costs due to the need for additional materials and rework.

The Solution:

Investing in high-quality wire bending tools specifically designed for precision can significantly alleviate this issue. Tools like the Bulldog Bender or the E/Z Bender offer adjustable settings that cater to various wire sizes and bending angles. To properly source these tools, buyers should look for options that include multiple forming dies to accommodate different wire gauges. Additionally, understanding the specifications of the wire being used is essential; for instance, softer wires are easier to bend accurately. Training staff on using these tools effectively can further enhance precision, ensuring that projects meet specifications without excessive trial and error.

Scenario 2: Strain and Fatigue from Manual Bending Processes

The Problem:

Manual wire bending can be physically taxing, leading to strain and fatigue among workers, particularly in high-volume environments. This not only affects productivity but can also lead to injuries, increasing the risk of workplace accidents. Companies operating in sectors like electrical installation or metal fabrication may find that their employees experience discomfort or even chronic pain from repetitive bending tasks, which can result in higher turnover rates and increased training costs for new hires.

The Solution:

To mitigate these ergonomic challenges, businesses should consider investing in ergonomic wire bending tools. Tools designed with user comfort in mind can minimize strain, allowing workers to perform bending tasks more efficiently. For example, tools that can be operated with one hand or that feature grips designed to reduce hand fatigue are ideal. Additionally, implementing regular breaks and ergonomic assessments can help ensure that workers maintain proper posture and avoid repetitive strain injuries. Educating employees on the importance of ergonomic practices and providing training on tool usage can further enhance workplace safety and productivity.

Scenario 3: Limited Versatility of Existing Tools for Different Wire Types

The Problem:

Many companies find that the wire bending tools they currently use are not versatile enough to handle various wire types and sizes. This limitation can lead to delays when switching between different projects, as workers may need to source additional tools or adjust their techniques. For example, a company that frequently uses both soft copper wire and harder steel wire may struggle to find a single tool that performs well for both materials, leading to inefficiencies and increased operational costs.

The Solution:

To address this pain point, B2B buyers should look for multifunctional wire bending tools that can accommodate a range of wire types and diameters. Tools like the E/Z Bender come with multiple forming dies that can be easily interchanged, allowing for quick adjustments based on project requirements. Buyers should also consider the material specifications of the tools to ensure they can handle both soft and hard wires without compromising performance. Additionally, investing in tools with a good warranty and customer support can provide peace of mind, ensuring that any issues can be resolved quickly, thus maintaining workflow continuity. By selecting versatile tools, companies can streamline their operations and reduce downtime associated with tool changes.

Strategic Material Selection Guide for bending wire tool

What Materials Are Commonly Used for Bending Wire Tools?

When selecting a bending wire tool, the choice of material is critical to ensure optimal performance, durability, and cost-effectiveness. Here, we analyze four common materials used in the manufacturing of bending wire tools: carbon steel, stainless steel, aluminum, and plastic composites.

How Does Carbon Steel Perform in Bending Wire Tools?

Carbon steel is a popular choice for bending wire tools due to its excellent strength and hardness. It typically exhibits high tensile strength, making it suitable for bending thicker wires. However, carbon steel is prone to corrosion if not properly treated, which can limit its lifespan, especially in humid or corrosive environments.

Pros:

– High durability and strength, making it ideal for heavy-duty applications.

– Cost-effective compared to other metals.

Cons:

– Requires protective coatings to prevent rust and corrosion.

– Heavier than other materials, which can affect handling.

For international buyers, particularly in regions like Africa and South America, it’s essential to consider local environmental conditions that may affect the longevity of carbon steel tools. Compliance with local standards, such as ASTM for the U.S. or DIN for Europe, is also crucial.

What Are the Advantages of Stainless Steel in Bending Wire Tools?

Stainless steel is renowned for its corrosion resistance and aesthetic appeal. It maintains strength at high temperatures and is less susceptible to wear and tear, making it an excellent option for industrial applications.

Pros:

– Exceptional corrosion resistance, ideal for various climates.

– Long-lasting and requires minimal maintenance.

Cons:

– Higher cost compared to carbon steel.

– More challenging to machine, which can increase manufacturing complexity.

For buyers in the Middle East and Europe, stainless steel tools often comply with stringent quality standards, making them a reliable choice for industries requiring high durability and performance.

Why Choose Aluminum for Bending Wire Tools?

Aluminum is lightweight and offers good corrosion resistance, making it a suitable choice for portable bending tools. Its lower density compared to steel makes it easier to handle, especially in field applications. However, aluminum is not as strong as steel, which may limit its use for heavy-duty tasks.

Pros:

– Lightweight, facilitating ease of use and transport.

– Corrosion-resistant, suitable for outdoor applications.

Cons:

– Lower tensile strength compared to steel, limiting its use for thicker wires.

– Can be more expensive than carbon steel depending on the alloy.

International buyers should consider the specific applications for which they need bending tools. In regions like Nigeria and Vietnam, where portability may be prioritized, aluminum tools can be advantageous.

How Do Plastic Composites Stack Up for Bending Wire Tools?

Plastic composites are increasingly being used in bending wire tools due to their lightweight nature and resistance to corrosion. They can be molded into complex shapes, providing versatility in design. However, their strength and durability may not match that of metal options.

Pros:

– Lightweight and easy to handle.

– Resistant to corrosion and chemicals.

Cons:

– Generally less durable than metal options, especially under heavy loads.

– Limited temperature resistance compared to metals.

For B2B buyers in regions with varying climates, such as South America and Africa, understanding the limitations of plastic composites is vital. Compliance with local manufacturing standards can also impact the choice of materials.

Summary Table of Material Selection for Bending Wire Tools

| Material | Typical Use Case for bending wire tool | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Heavy-duty wire bending | High strength and durability | Prone to corrosion | Medium |

| Stainless Steel | Industrial applications | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Aluminum | Portable bending tools | Lightweight and easy to handle | Lower strength than steel | Medium |

| Plastic Composites | Versatile design applications | Corrosion-resistant and lightweight | Less durable under heavy loads | Low |

This guide provides a comprehensive overview of the materials used in bending wire tools, enabling international B2B buyers to make informed decisions based on their specific needs and regional conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for bending wire tool

The manufacturing of bending wire tools encompasses several critical processes designed to ensure the tools are durable, precise, and efficient. For international B2B buyers, understanding these processes, along with the quality assurance protocols in place, is essential for making informed purchasing decisions. Here’s an in-depth look at the typical manufacturing stages and quality control measures relevant to bending wire tools.

What Are the Main Stages of Manufacturing Bending Wire Tools?

1. Material Preparation: How Is Raw Material Selected and Processed?

The manufacturing process begins with the selection of high-quality raw materials, typically steel or aluminum alloys, chosen for their strength and flexibility. Suppliers often conduct rigorous testing of the raw materials to ensure they meet specific mechanical properties required for bending applications.

Once the materials are sourced, they undergo processes such as cutting, shearing, or rolling to achieve the desired dimensions. This stage is crucial, as any defects in the raw materials can compromise the integrity of the final product.

2. Forming: What Techniques Are Used to Shape the Tools?

The forming stage involves several techniques that transform the prepared materials into bending wire tools. Common methods include:

-

Die Casting: This technique allows for the production of complex shapes with high precision. It is particularly useful for creating parts that require intricate designs.

-

Forging: This process involves shaping the metal using compressive forces, resulting in a denser and more durable product. Forging is favored for tools that must withstand high levels of stress during use.

-

Machining: Precision machining processes, such as CNC (Computer Numerical Control) machining, are employed to achieve exact dimensions and surface finishes. This is particularly important for components like forming dies that require high accuracy.

The choice of technique depends on the specific design requirements and the material being used.

3. Assembly: How Are Different Components Integrated?

After forming, the various components of the bending wire tool are assembled. This may involve welding, bolting, or fastening parts together to create a complete unit. The assembly process is critical, as improper alignment or fitting can lead to malfunction or reduced performance.

Quality control during assembly is vital. Manufacturers may use jigs and fixtures to ensure that components are positioned accurately. This minimizes human error and enhances the consistency of the final product.

4. Finishing: What Processes Ensure Durability and Aesthetic Quality?

Finishing processes serve both functional and aesthetic purposes. Common finishing techniques include:

-

Surface Treatment: Techniques such as anodizing, galvanizing, or powder coating protect the tools from corrosion and wear while improving their appearance.

-

Polishing and Grinding: These processes enhance the surface smoothness, which can reduce friction during operation and increase the tool’s lifespan.

-

Quality Inspection: Each finished tool typically undergoes a final inspection to ensure it meets the specified standards before packaging and shipping.

What Quality Assurance Standards Are Relevant for Bending Wire Tools?

Quality assurance is a critical aspect of the manufacturing process, especially for international buyers who must adhere to various regulations and standards. The following are key quality assurance standards and practices relevant to bending wire tools:

1. International Standards: How Do ISO Standards Apply?

ISO 9001 is one of the most recognized international standards for quality management systems. Manufacturers of bending wire tools often implement ISO 9001 to ensure consistent quality and continuous improvement. Compliance with this standard signals to buyers that the manufacturer follows best practices in quality management, from material sourcing to production processes.

2. Industry-Specific Certifications: What Are the Key Certifications to Look For?

In addition to ISO 9001, other certifications may be relevant depending on the market and application. For example:

-

CE Marking: This indicates compliance with European health, safety, and environmental protection standards. It is essential for products sold in the European market.

-

API Certification: For manufacturers producing tools used in the oil and gas industry, API (American Petroleum Institute) certification is crucial. It ensures that products meet stringent industry standards.

These certifications not only enhance product credibility but also help in navigating regulatory requirements in various regions.

What Quality Control Checkpoints Are Critical During Manufacturing?

Quality control checkpoints are vital throughout the manufacturing process to ensure that the tools meet required specifications. The following checkpoints are commonly implemented:

1. Incoming Quality Control (IQC): How Are Raw Materials Assessed?

IQC involves the inspection of raw materials upon arrival at the manufacturing facility. Suppliers may conduct tests such as tensile strength tests or chemical composition analysis to verify the quality of materials before they enter the production line.

2. In-Process Quality Control (IPQC): What Monitoring Techniques Are Used?

During the manufacturing process, IPQC involves real-time monitoring of production techniques. This could include:

- Regular measurements of tool dimensions to ensure they conform to specifications.

- Checks for defects during the forming process, such as cracks or misalignment.

Implementing IPQC reduces the likelihood of defects in the final product and ensures that any issues are addressed promptly.

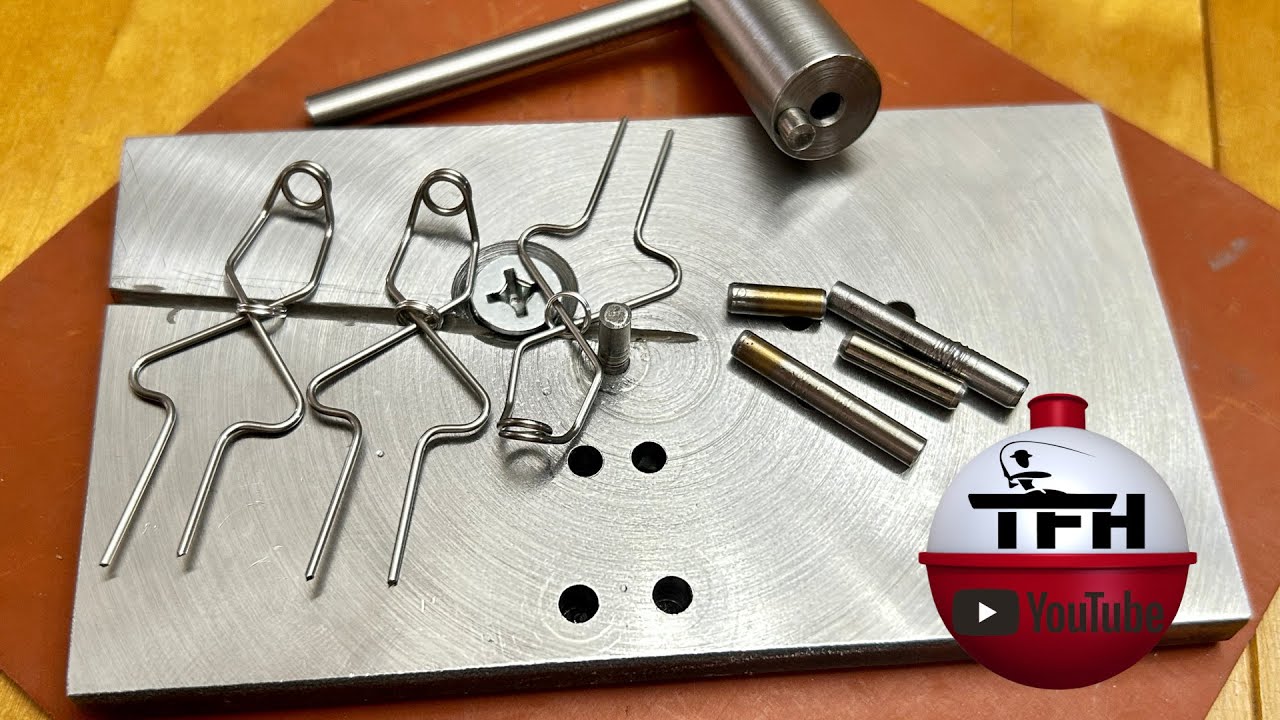

Illustrative image related to bending wire tool

3. Final Quality Control (FQC): How Is the Finished Product Verified?

FQC is the last stage of quality control and involves comprehensive testing of the finished tools. Common testing methods include:

- Functional Testing: Ensuring that the tools perform as intended under operational conditions.

- Durability Testing: Assessing the tools’ resistance to wear and tear over time.

Manufacturers often maintain detailed records of these tests, which can be invaluable for B2B buyers looking to verify product quality.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, especially in regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is crucial. Here are some strategies:

Illustrative image related to bending wire tool

-

Supplier Audits: Conducting audits of suppliers can provide insights into their manufacturing processes and quality control measures. This can be done by the buyer or through third-party auditing firms.

-

Quality Reports: Requesting quality assurance reports from suppliers can help buyers assess the consistency and reliability of the manufacturing process.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the product quality before shipment. This is particularly important for larger orders where the risk of defects can be significant.

What Are the Nuances of Quality Control for International B2B Buyers?

Understanding the nuances of quality control in the context of international trade is essential. Buyers should be aware of the following:

-

Cultural Differences: Different countries may have varying standards and practices regarding quality assurance. Understanding these differences can help in negotiating terms and expectations.

-

Regulatory Compliance: Buyers must ensure that products comply with local regulations in their respective markets. This may involve additional testing or certification processes.

-

Supply Chain Transparency: Establishing transparency in the supply chain can help buyers monitor quality and compliance effectively. This is particularly crucial when sourcing from multiple regions or suppliers.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance protocols for bending wire tools is vital for B2B buyers. By leveraging this knowledge, buyers can make informed decisions, ensuring they procure high-quality tools that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bending wire tool’

The following practical sourcing guide serves as a comprehensive checklist for B2B buyers looking to procure wire bending tools. This guide will help you navigate the complexities of sourcing by ensuring that you consider all critical factors to make an informed purchasing decision.

Step 1: Define Your Technical Specifications

Start by identifying the specific requirements for the wire bending tool you need. Consider factors such as the wire diameter range, bending angles, and material compatibility. For example, tools designed for heavy gauge wire like the Bulldog bender can handle larger diameters, while smaller tools may be more suited for precision work.

Step 2: Research Potential Suppliers

Conduct thorough research to compile a list of potential suppliers. Look for companies with a strong reputation in the industry, positive customer feedback, and a history of reliability. Utilize platforms such as trade shows, online directories, and industry forums to gather information and insights about various suppliers.

Illustrative image related to bending wire tool

Step 3: Evaluate Supplier Certifications

Before engaging with suppliers, ensure they have the necessary certifications and compliance with international standards. Certifications such as ISO 9001 can indicate quality management practices. This step is crucial as it assures you that the products meet safety and performance criteria relevant to your region.

Step 4: Request Samples for Testing

Once you have shortlisted potential suppliers, request samples of the wire bending tools. Testing samples allows you to evaluate the tool’s performance, durability, and ease of use. Pay attention to how well the tool meets your technical specifications and whether it is user-friendly for your team.

Step 5: Assess Pricing and Payment Terms

Compare pricing across different suppliers to ensure you are getting a competitive rate. Additionally, review payment terms and conditions, including any discounts for bulk purchases. Understanding the total cost of ownership, including shipping and potential import duties, is essential for accurate budgeting.

Step 6: Inquire About After-Sales Support

After-sales support can significantly impact your overall satisfaction with the purchase. Inquire about warranty terms, repair services, and availability of spare parts. A supplier that offers robust after-sales support can save you time and money in the long run.

Step 7: Verify Delivery Times and Logistics

Confirm the lead times for delivery and the logistics involved in shipping the tools to your location. Delays in delivery can disrupt your operations, so it’s vital to have a clear understanding of the timeline. Check if the supplier has experience shipping to your region, as this can also affect reliability.

By following this checklist, B2B buyers can approach the procurement of wire bending tools with confidence, ensuring that they select the best product for their needs while minimizing risks associated with the purchasing process.

Comprehensive Cost and Pricing Analysis for bending wire tool Sourcing

What Are the Key Cost Components in Bending Wire Tool Production?

When sourcing bending wire tools, understanding the cost structure is crucial. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The type of materials used significantly affects pricing. Common materials include steel, aluminum, and specialized alloys. Higher-grade materials that offer better durability and performance will typically incur a higher cost.

-

Labor: Labor costs vary based on geographic location and skill levels. In regions with higher wages, such as Europe, labor costs will be a significant portion of the overall expense. Conversely, countries in Africa or South America may have lower labor costs, which can impact the final pricing.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, including utilities, rent, and administrative expenses. Efficient manufacturing processes can help reduce these costs, positively influencing the final price.

-

Tooling: Initial tooling costs for custom designs can be significant. If a bending wire tool requires specialized molds or dies, these costs must be factored into the overall pricing strategy.

-

Quality Control: Ensuring that products meet industry standards and certifications is essential. The costs associated with QC processes can vary, impacting the final price. Tools with higher quality certifications may command a premium.

-

Logistics: Transportation and warehousing costs are crucial, especially for international shipping. The choice of Incoterms will also affect these costs, influencing the buyer’s total expenditure.

-

Margin: Finally, suppliers will add a profit margin to cover their expenses and achieve profitability. This margin can vary widely based on competition and market demand.

How Do Price Influencers Affect Bending Wire Tool Costs?

Several factors influence the pricing of bending wire tools, which B2B buyers should consider:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes typically lead to lower per-unit costs due to economies of scale. Negotiating lower MOQs can be beneficial for smaller businesses.

-

Specifications and Customization: Custom tools tailored to specific applications may incur additional costs. Buyers should evaluate whether the added functionality justifies the expense.

-

Material Quality and Certifications: Tools made from higher-quality materials or certified for specific industry standards will generally be more expensive. Buyers should balance their need for quality with budget constraints.

-

Supplier Factors: Supplier reputation, reliability, and production capabilities can influence pricing. Established suppliers may charge more due to their track record, while new entrants might offer competitive pricing to capture market share.

-

Incoterms: The choice of shipping terms can significantly impact the total cost. Understanding responsibilities for freight, insurance, and customs duties is crucial for accurate budgeting.

What Buyer Tips Can Help in Negotiating Bending Wire Tool Prices?

To optimize sourcing costs, B2B buyers should consider the following strategies:

-

Negotiation: Engage suppliers in discussions about pricing, especially for larger orders. Building a relationship can sometimes lead to better terms or discounts.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO) rather than just the upfront price. Consider factors such as durability, maintenance costs, and potential downtime.

-

Pricing Nuances for International Buyers: Buyers from regions such as Africa, South America, the Middle East, and Europe should account for currency fluctuations, import tariffs, and shipping costs. These can significantly alter the final cost of tools.

-

Supplier Diversification: Avoid reliance on a single supplier. Exploring multiple suppliers can provide leverage during negotiations and help identify the best pricing options.

-

Market Research: Regularly review market trends and competitor pricing to stay informed. This knowledge can empower buyers during negotiations and sourcing decisions.

Disclaimer on Pricing

Prices mentioned in reference sources are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always confirm current pricing directly with suppliers for the most accurate quotes.

Alternatives Analysis: Comparing bending wire tool With Other Solutions

Understanding the Alternatives to Bending Wire Tools

In the realm of wire manipulation, selecting the appropriate tool or method is crucial for achieving optimal results. While dedicated bending wire tools are popular for their precision and ease of use, several alternatives exist that may suit different needs, budgets, and applications. This analysis will compare the traditional bending wire tool with alternative solutions, enabling B2B buyers to make informed decisions.

| Comparison Aspect | Bending Wire Tool | E/Z Bender Wire Forming Tool | Wire Bender Jig (Lee Valley Tools) |

|---|---|---|---|

| Performance | High precision for various wire sizes | Versatile for small wire diameters | Simple, effective for mild steel |

| Cost | $198.99 – $976.99 | $39.95 | $13.90 |

| Ease of Implementation | Requires some skill for optimal use | User-friendly, quick setup | Easy to mount and use |

| Maintenance | Minimal, durable construction | Low, replaceable forming dies | Low, simple design |

| Best Use Case | Heavy-duty applications, large wire sizes | Hobbyist projects, model making | Custom tool holders, light tasks |

What Are the Advantages and Disadvantages of the E/Z Bender Wire Forming Tool?

The E/Z Bender Wire Forming Tool is designed for hobbyists and light industrial use, making it an attractive alternative for those working with smaller wire diameters (0.015″ to 0.093″). Its compact design allows for easy handling and quick setup, and it can produce precise bends for applications like model building. However, its limitations include a maximum wire thickness and reduced effectiveness for larger or more rigid materials, which may necessitate a more robust tool for heavy-duty tasks.

How Does the Wire Bender Jig from Lee Valley Tools Compare?

The Wire Bender Jig offers an economical option for bending mild steel wire up to 5mm in diameter. This jig is especially beneficial for those creating custom tool holders or pegboard hooks, as it allows for a high degree of flexibility in shaping. Its low cost makes it accessible for small-scale projects or DIY enthusiasts. However, it is less suited for industrial applications and larger wire sizes, limiting its utility in more demanding environments.

Making the Right Choice for Your Bending Needs

When evaluating the best wire bending solution for your business, it is essential to consider your specific requirements. If your operations involve heavy gauge wire and demand precision, investing in a dedicated bending wire tool may be the most effective route. For hobbyists or smaller projects, the E/Z Bender or the Wire Bender Jig can offer satisfactory results at a fraction of the cost. Ultimately, understanding the nuances of each option will empower B2B buyers to select the solution that aligns with their operational demands and budget constraints.

Essential Technical Properties and Trade Terminology for bending wire tool

What Are the Key Technical Properties of Bending Wire Tools?

When selecting a wire bending tool for your business, understanding its technical properties is crucial. Here are several critical specifications that can significantly impact performance and usability:

-

Material Grade

The material used in the construction of wire bending tools typically ranges from high-carbon steel to stainless steel. High-carbon steel offers strength and durability, making it suitable for heavy-duty applications. Conversely, stainless steel is corrosion-resistant, ideal for environments with moisture or chemicals. Selecting the right material ensures longevity and reliability, reducing the need for frequent replacements. -

Bending Capacity

This specification indicates the maximum wire diameter the tool can accommodate. For instance, tools may be rated for wire sizes from 0.015 inches (0.38 mm) to 750 MCM (thousands of circular mils). Understanding bending capacity is essential for ensuring the tool meets your specific project requirements, especially in industries such as construction, automotive, and manufacturing. -

Bend Radius

The minimum bend radius defines how tightly the wire can be bent without risking damage. A proper bend radius is critical to prevent kinking or weakening the wire, which can lead to failure in applications. Knowing the bend radius helps in selecting tools that will maintain the structural integrity of the wire being manipulated. -

Tolerance Levels

Tolerance refers to the acceptable range of deviation from a specified measurement. High precision is vital in industries where exact dimensions are required, such as aerospace or electronics. Understanding the tolerance levels of bending tools can help ensure the final product meets the necessary specifications, enhancing quality control processes. -

Ergonomics and Design

The ergonomic design of wire bending tools can significantly influence user efficiency and comfort. Features such as cushioned grips, adjustable handles, and lightweight materials reduce fatigue during prolonged use. Selecting ergonomically designed tools can lead to improved productivity and less risk of workplace injuries.

What Are Common Trade Terms Associated with Bending Wire Tools?

Familiarizing yourself with industry jargon can facilitate smoother communication and negotiations in B2B transactions. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of bending wire tools, an OEM might supply components that are incorporated into a larger assembly, allowing businesses to ensure compatibility and quality. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQs is crucial for inventory management and cost control, especially for businesses looking to stock bending wire tools or components without overcommitting financially. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for pricing and terms for specific products or services. It is a vital step in the procurement process, allowing businesses to compare costs and terms from multiple suppliers before making purchasing decisions. -

Incoterms

International Commercial Terms (Incoterms) are a set of rules that define responsibilities and risks between buyers and sellers during the shipping process. Familiarity with Incoterms can help businesses negotiate shipping costs and clarify liability, ensuring smoother transactions across borders. -

Lead Time

Lead time refers to the time taken from placing an order until the delivery of the product. Understanding lead times is essential for effective project planning and inventory management, particularly in industries with tight deadlines. -

Technical Specifications

This term encompasses detailed descriptions of a product’s characteristics, including dimensions, materials, and performance standards. Clear technical specifications are vital for ensuring that the selected bending wire tool meets the operational needs of your business.

By understanding these essential properties and trade terminologies, B2B buyers can make informed decisions that align with their operational requirements and strategic goals.

Navigating Market Dynamics and Sourcing Trends in the bending wire tool Sector

What Are the Current Market Trends Influencing the Bending Wire Tool Sector?

The bending wire tool market is experiencing significant transformation driven by globalization, technological advancements, and evolving consumer preferences. One of the primary drivers is the increasing demand for precision in manufacturing processes, particularly in sectors such as construction, automotive, and electronics. B2B buyers from regions like Africa, South America, the Middle East, and Europe are increasingly seeking tools that offer versatility and efficiency, enabling them to adapt to diverse project requirements.

Illustrative image related to bending wire tool

Emerging technologies such as automation and smart manufacturing are reshaping sourcing trends. For instance, manufacturers are adopting advanced materials and production techniques that enhance durability and performance. Buyers are now looking for tools that not only meet their immediate needs but also integrate well with automated systems, thereby reducing labor costs and increasing output. Additionally, the trend towards customization is gaining momentum, with suppliers offering bespoke solutions tailored to specific industry demands.

International buyers must also consider logistical factors, such as shipping times and costs, which can vary significantly across regions. Establishing partnerships with reliable suppliers who understand local market dynamics can streamline procurement processes and enhance competitiveness.

How Important Is Sustainability and Ethical Sourcing in the Bending Wire Tool Market?

Sustainability and ethical sourcing have become critical considerations for B2B buyers in the bending wire tool sector. The environmental impact of manufacturing processes is under increasing scrutiny, prompting companies to adopt greener practices. Buyers are now looking for tools made from recycled materials or those that utilize sustainable production techniques. For example, tools that minimize waste during manufacturing or that have longer lifespans contribute to a reduced ecological footprint.

Moreover, ethical supply chains are essential for building brand reputation and ensuring compliance with international standards. Buyers are encouraged to seek suppliers who have certifications indicating adherence to environmental and social governance (ESG) criteria. Such certifications not only demonstrate a commitment to sustainability but also assure buyers that the products they procure align with their corporate values.

Furthermore, incorporating sustainability into purchasing decisions can lead to cost savings in the long run. Tools designed for longevity can reduce the need for frequent replacements, and those that are energy-efficient can decrease operational costs. Therefore, integrating sustainability into sourcing strategies is not just a trend but a necessity for forward-thinking B2B buyers.

What Is the Historical Evolution of Bending Wire Tools?

The evolution of bending wire tools has been shaped by advancements in metallurgy and manufacturing techniques over the centuries. Initially, wire bending was a manual process, relying on simple tools and skilled artisans. As industries began to expand during the Industrial Revolution, the demand for more precise and efficient wire bending tools grew, leading to the development of specialized equipment.

In the mid-20th century, the introduction of electric and pneumatic tools revolutionized wire bending, allowing for faster production rates and improved accuracy. This shift not only increased the efficiency of manufacturing processes but also made wire bending accessible to a broader range of industries, from construction to hobbyist applications.

Today, the market continues to evolve with the integration of digital technologies, such as computer-aided design (CAD) and automation, paving the way for innovative solutions that enhance precision and reduce labor costs. This historical trajectory underscores the importance of staying abreast of technological advancements to remain competitive in the global marketplace.

Illustrative image related to bending wire tool

Frequently Asked Questions (FAQs) for B2B Buyers of bending wire tool

-

How do I choose the right bending wire tool for my business needs?

Selecting the right bending wire tool involves assessing the specific applications within your operations. Consider factors such as wire diameter, material type, and the degree of bends required. For heavy-duty applications, tools like the Bulldog Bender are ideal for larger cables, while lighter models may suffice for smaller, more intricate tasks. Additionally, evaluate the tool’s ease of use and durability, as well as any customization options that may enhance its functionality for your specific needs. -

What is the best wire bending tool for industrial applications?

For industrial applications, the Bulldog Bender series stands out due to its capacity to handle large wire sizes, up to 750 MCM. This tool is designed for efficiency and precision, making it perfect for jobs requiring repeated heavy bending. If your operations involve smaller wire diameters, consider the E/Z Bender, which offers versatility and can create precise bends for various configurations. Always ensure that the selected tool meets your specific operational requirements and industry standards. -

What factors should I consider when sourcing bending wire tools internationally?

When sourcing bending wire tools internationally, consider the supplier’s reputation, product quality, and compliance with international standards. Verify certifications and inspect product samples if possible. Additionally, assess the supplier’s logistics capabilities to ensure timely delivery. Payment terms and warranty policies are also critical; look for suppliers who offer favorable terms and robust support for their products. Lastly, understanding local regulations and import duties is essential to avoid unexpected costs. -

What are the typical minimum order quantities (MOQs) for bending wire tools?

Minimum order quantities (MOQs) for bending wire tools can vary widely depending on the supplier and the type of tool. Many manufacturers set MOQs ranging from 50 to several hundred units, especially for specialized tools. It’s beneficial to negotiate MOQs, particularly if you are testing the market or require a smaller initial inventory. Always clarify MOQs before finalizing an order to ensure alignment with your business strategy. -

How can I customize bending wire tools to fit my specific requirements?

Customization options for bending wire tools often include adjustments to size, shape, and materials used in the tool’s construction. Many manufacturers offer bespoke solutions to meet unique operational demands, such as special dies or modified bending angles. It’s advisable to communicate your specific needs clearly during the sourcing process. Discuss potential prototypes with suppliers to ensure that the final product meets your expectations and operational requirements. -

What payment terms should I expect when purchasing bending wire tools from international suppliers?

Payment terms can vary significantly among international suppliers. Common terms include payment in advance, letters of credit, or net payment terms (e.g., 30, 60, or 90 days after delivery). When negotiating terms, consider your cash flow and risk tolerance. Some suppliers may offer discounts for early payment or bulk orders, so explore these options to optimize your costs. Ensure all payment terms are documented clearly in your purchase agreement. -

How do I ensure quality assurance when buying bending wire tools?

To ensure quality assurance, always request certifications and quality control documentation from suppliers. Conduct thorough research on the supplier’s quality management practices and previous customer reviews. If possible, arrange for a third-party inspection of the tools before shipment. Establish clear quality expectations in your contract, including specifications for performance and durability. Additionally, consider a trial order to assess the product quality before committing to larger purchases. -

What logistical considerations should I keep in mind when importing bending wire tools?

Logistical considerations when importing bending wire tools include shipping methods, lead times, and customs clearance processes. Choose a reliable freight forwarder familiar with your destination country to navigate potential challenges effectively. Be aware of import duties and taxes that may apply, and ensure all paperwork is in order to avoid delays. Planning for lead times is crucial; factor in both production and shipping durations to align with your inventory needs.

Top 5 Bending Wire Tool Manufacturers & Suppliers List

1. Rack-A-Tiers – Wire Bending Tools

Domain: rack-a-tiers.com

Registered: 1997 (28 years)

Introduction: Wire Bending Tools from Rack-A-Tiers include various models designed for bending heavy gauge wires. Key products include: 1. 1/2″ Ratchet Wire Bending Attachment – $49.99 USD 2. Bulldog “Pup 3 Piece” Set – Wire bending tool for up to 4/0 – $523.49 USD 3. Bulldog “Pup Pro” 2 Piece Set – Wire bending tool for up to 4/0 – $435.99 USD 4. The Bulldog 3 Piece Set (Original & Pro) – Wire bending set for …

2. Dubro – E/Z Bender Wire Forming Tool

3. Lee Valley Tools – Wire Bender

Domain: leevalley.com

Registered: 1996 (29 years)

Introduction: {“name”: “Wire Bender”, “brand”: “Lee Valley Tools”, “description”: “A jig for bending mild steel wire up to 3/16″ or 5mm diameter to any shape, ideal for making custom tool holders or pegboard hooks from coat-hanger wire.”, “material”: “Mild steel”, “dimensions”: “up to 3/16″ or 5mm diameter”, “origin”: “Made in Japan”, “price”: “$13.90”, “variations”: [{“code”: “92W6701”, “name”: “Wire Bender”, …

4. Reddit – Handheld Wire Bender for Jewelry and Bike Spokes

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Handheld wire bender, suitable for bending spokes into jewelry, ideally used with one hand, capable of bending wire at tight angles. User is looking for pliers rather than a jig, specifically for bending bike spokes.

5. Facebook – Bending and Stripping Pliers

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: Simplify your wire work with bending and stripping pliers.

Strategic Sourcing Conclusion and Outlook for bending wire tool

What Are the Key Takeaways for B2B Buyers in the Wire Bending Tool Market?

In the evolving landscape of wire bending tools, strategic sourcing remains paramount for B2B buyers. The diverse range of tools available—from heavy-duty Bulldog Benders to specialized E/Z Benders—highlights the necessity for tailored solutions that meet specific operational demands. Buyers should prioritize tools that not only enhance efficiency but also ensure safety and precision, particularly when handling large cables or intricate designs.

How Can Strategic Sourcing Drive Value in Your Operations?

By engaging in strategic sourcing, businesses can leverage supplier relationships to obtain high-quality tools at competitive prices. This approach enables companies to optimize their procurement processes, thereby reducing costs and improving operational workflows. For buyers in Africa, South America, the Middle East, and Europe, understanding local market dynamics and supplier capabilities can further enhance sourcing strategies.

What’s Next for International B2B Buyers?

Looking ahead, international B2B buyers are encouraged to explore innovative bending solutions that align with industry trends, such as sustainability and automation. Investing in advanced wire bending tools not only boosts productivity but also positions businesses for long-term growth. As you navigate the global market, consider establishing partnerships with reputable suppliers to ensure access to the latest technologies and best practices. Embrace the future of wire bending—your operational success depends on it.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.