Unlocking Value: A Strategic Analysis of the Baby Oil Bottle Market

Introduction: Navigating the Global Market for baby oil bottle

In the ever-evolving landscape of personal care products, sourcing high-quality baby oil bottles presents a significant challenge for international B2B buyers. Whether you are looking to supply retailers in Nigeria or Germany, understanding the diverse options available in the market is crucial. This comprehensive guide delves into the intricacies of the baby oil bottle market, covering essential aspects such as types of bottles, material options, applications, supplier vetting processes, and cost considerations.

As the demand for baby care products continues to rise globally, buyers must navigate a myriad of choices that cater to both safety and functionality. From PET plastic to glass options, the materials used in baby oil bottles can greatly influence product quality and consumer satisfaction. Additionally, understanding the regulatory requirements specific to different regions is vital for compliance and successful market entry.

By equipping B2B buyers with actionable insights and expert recommendations, this guide empowers informed purchasing decisions tailored to the unique needs of markets in Africa, South America, the Middle East, and Europe. It aims to enhance your sourcing strategy, streamline supplier selection, and ultimately contribute to the success of your business in the competitive baby care sector.

Understanding baby oil bottle Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| PET Plastic Bottles | Lightweight, recyclable, and resistant to impact; available in various sizes. | Personal care products, baby oil, cosmetics | Pros: Cost-effective, versatile; Cons: Limited barrier properties compared to glass. |

| Glass Bottles | Durable, non-reactive, and premium appearance; available in various shapes and sizes. | High-end baby oil, organic products | Pros: Excellent preservation of product quality; Cons: Heavier and more fragile. |

| Squeeze Bottles | Easy dispensing with a controlled flow; often made from flexible plastic. | Baby oil, lotions, and other liquid products | Pros: User-friendly, minimizes waste; Cons: May not be suitable for all oil viscosities. |

| Pump Dispenser Bottles | Convenient one-handed operation; typically made from plastic or glass. | Baby oil, lotions, and creams | Pros: Reduces contamination risk; Cons: Higher initial cost than standard bottles. |

| Roll-On Bottles | Designed for targeted application; usually made from glass or plastic. | Baby oil, essential oils, and therapeutic oils | Pros: Precise application; Cons: Limited volume capacity. |

What Are the Characteristics of PET Plastic Bottles for Baby Oil?

PET plastic bottles are a popular choice for baby oil packaging due to their lightweight and shatter-resistant nature. These bottles are recyclable, making them an eco-friendly option for brands looking to promote sustainability. They come in various sizes, catering to different market segments, from small travel sizes to larger family-friendly options. When considering PET bottles, B2B buyers should evaluate factors such as cost-effectiveness, customization options, and supplier reliability to ensure they meet their brand’s needs.

Why Choose Glass Bottles for High-End Baby Oil Products?

Glass bottles offer a premium packaging solution for baby oil products, providing an upscale aesthetic that appeals to discerning consumers. They are non-reactive, ensuring that the product’s quality is preserved over time. Glass is also recyclable, which aligns with growing consumer demand for sustainable packaging. For B2B buyers, key considerations include the weight and fragility of glass, potential shipping costs, and the availability of various designs that can enhance brand identity.

How Do Squeeze Bottles Enhance User Experience?

Squeeze bottles are designed for easy dispensing, allowing users to control the flow of baby oil effectively. This feature minimizes product waste and enhances the user experience, making them a practical choice for both consumers and retailers. Typically made from flexible plastic, these bottles can be customized in terms of size and design. B2B buyers should consider the viscosity of the oil being packaged, as thicker oils may require specialized designs to ensure effective dispensing.

What Are the Benefits of Pump Dispenser Bottles?

Pump dispenser bottles provide a convenient and hygienic way to dispense baby oil, reducing the risk of contamination. They are available in both plastic and glass formats, allowing brands to select materials that align with their product positioning. The one-handed operation is particularly appealing for busy parents. B2B buyers should assess the cost implications of pump dispensers compared to traditional caps, as well as the potential for product differentiation through innovative designs.

Why Consider Roll-On Bottles for Targeted Application?

Roll-on bottles are ideal for baby oils that require targeted application, such as those designed for massage or therapeutic use. They typically come in glass or plastic formats, offering a compact and portable solution. The precision of application can enhance the consumer experience, especially for products aimed at soothing or calming. When purchasing roll-on bottles, B2B buyers should evaluate the capacity, material suitability, and potential for customization to meet branding requirements.

Key Industrial Applications of baby oil bottle

| Industry/Sector | Specific Application of Baby Oil Bottle | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Personal Care Products | Packaging for baby oil and skincare products | Enhances brand image with attractive packaging | Material safety, compliance with regulations, customization options |

| Healthcare | Use in hospitals for baby care and skincare | Ensures safe and gentle care for infants | Sterilization capabilities, volume requirements, supply chain reliability |

| Cosmetics | Bottling for massage oils and aromatherapy products | Appeals to consumers looking for high-quality oils | Sustainability of materials, design flexibility, branding options |

| Educational Products | Sensory bottles for educational tools | Provides sensory engagement for early childhood development | Safety standards, durability, ease of use for children |

| Household Products | Multi-purpose oil for general household use | Versatile application across various household needs | Cost-effectiveness, packaging sizes, user-friendly design |

How Are Baby Oil Bottles Used in Personal Care Products?

In the personal care industry, baby oil bottles are primarily used for packaging baby oil and other skincare products. The design of these bottles can significantly influence consumer perception and brand loyalty. Buyers should prioritize materials that ensure product safety and compliance with local regulations, especially in regions like Africa and South America where standards may vary. Customization options for branding can also enhance market appeal.

What Role Do Baby Oil Bottles Play in Healthcare Settings?

In healthcare settings, particularly in neonatal care, baby oil bottles are essential for providing gentle skincare to infants. Hospitals utilize these bottles for both baby oil and moisturizing creams, ensuring that products are safe for delicate skin. Key considerations for sourcing include the ability to sterilize bottles and maintain a reliable supply chain to avoid stockouts, especially in critical care environments.

How Are Baby Oil Bottles Utilized in the Cosmetics Industry?

The cosmetics sector employs baby oil bottles to package massage oils and aromatherapy products. These bottles must be visually appealing to attract consumers while also ensuring the integrity of the product. Buyers should consider the sustainability of the materials used, as eco-friendly packaging is increasingly important to consumers in Europe and the Middle East. Design flexibility is also crucial to accommodate various product lines.

In What Ways Are Baby Oil Bottles Used in Educational Products?

Baby oil bottles are creatively repurposed in educational settings as sensory bottles, which are used to engage infants and toddlers in sensory play. These bottles can be filled with colorful liquids and glitter to stimulate visual and tactile senses. When sourcing for this application, businesses must ensure that the bottles meet safety standards and are durable enough for frequent handling by young children.

How Do Baby Oil Bottles Serve Household Needs?

In the household products sector, baby oil bottles can be utilized for multi-purpose oils that cater to various needs, including moisturizing skin, removing makeup, or even as a lubricant. The versatility of these bottles allows consumers to use them for multiple applications, enhancing their value. Buyers should focus on cost-effectiveness and user-friendly designs that make the products accessible to a wider audience, particularly in emerging markets.

3 Common User Pain Points for ‘baby oil bottle’ & Their Solutions

Scenario 1: Difficulty in Ensuring Product Safety and Compliance

The Problem: For B2B buyers in the baby care industry, sourcing baby oil bottles that meet safety regulations can be a daunting task. Buyers often grapple with ensuring that the packaging materials comply with local and international safety standards, particularly in regions like Africa and Europe, where regulations may vary significantly. Concerns about harmful chemicals, such as phthalates and parabens, can lead to costly delays or even product recalls if the materials are not compliant. This situation not only affects brand reputation but also poses risks to consumer safety.

The Solution: To mitigate these risks, B2B buyers should prioritize suppliers that provide transparent information regarding their materials and safety certifications. It is crucial to request documentation that confirms compliance with regulations such as REACH in Europe or the FDA standards in the United States. Engaging with manufacturers who specialize in baby care products is advisable, as they are likely to be more knowledgeable about safety requirements. Additionally, conducting regular audits of suppliers and implementing a quality assurance program can further ensure that the bottles sourced are safe for use. Establishing a collaborative relationship with suppliers can also facilitate ongoing compliance with evolving regulations.

Scenario 2: Managing Supply Chain Disruptions and Costs

The Problem: Fluctuations in global supply chains have become a common pain point for B2B buyers, especially in the wake of recent global events. Buyers face challenges in securing consistent supplies of baby oil bottles due to production delays, increased shipping costs, or geopolitical tensions. These disruptions can lead to inventory shortages and delays in product launches, ultimately affecting sales and customer satisfaction.

The Solution: To address supply chain issues, B2B buyers should adopt a diversified sourcing strategy. This involves identifying multiple suppliers across different regions to reduce dependency on a single source. Utilizing local suppliers can also help mitigate international shipping delays and tariffs. Implementing inventory management software can provide real-time data on stock levels and lead times, enabling buyers to make informed decisions and place orders proactively. Additionally, negotiating long-term contracts with suppliers can lock in prices and ensure availability, thereby stabilizing costs and reducing the impact of sudden disruptions.

Scenario 3: Differentiating in a Competitive Market

The Problem: The baby oil market is saturated with various brands and products, making it challenging for B2B buyers to stand out. Buyers need to offer unique value propositions that resonate with consumers, such as organic ingredients or eco-friendly packaging, to differentiate their products from competitors. Without a clear differentiation strategy, products may become undistinguishable in a crowded marketplace, leading to lower sales and brand loyalty.

The Solution: To create a competitive edge, B2B buyers should invest in innovative product development and branding strategies. This includes selecting baby oil bottles that not only serve functional purposes but also align with current consumer trends, such as sustainability. For instance, sourcing recyclable or biodegradable bottles can appeal to environmentally conscious consumers. Additionally, customizing labels and packaging designs can enhance brand identity and attract attention on retail shelves. Collaborating with marketing teams to conduct consumer research can provide insights into preferences and help tailor products to meet market demands. By focusing on unique selling propositions and leveraging storytelling in marketing efforts, buyers can effectively differentiate their offerings in the market.

Strategic Material Selection Guide for baby oil bottle

What Are the Key Properties of Common Materials for Baby Oil Bottles?

When selecting materials for baby oil bottles, it is essential to consider their properties, performance, and suitability for the intended application. The following analysis covers four common materials: PET (Polyethylene Terephthalate), HDPE (High-Density Polyethylene), glass, and LDPE (Low-Density Polyethylene). Each material has unique characteristics that influence its performance, cost, and compliance with international standards.

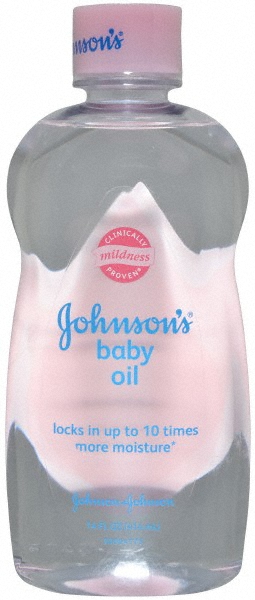

Illustrative image related to baby oil bottle

How Does PET Perform in Baby Oil Bottle Applications?

PET is a widely used plastic for baby oil bottles due to its excellent clarity, strength, and barrier properties. It can withstand moderate temperature variations, making it suitable for various storage conditions. PET bottles are also lightweight, which reduces shipping costs.

Pros: PET is durable, offers good chemical resistance, and is recyclable. It is also less expensive than glass, making it a cost-effective option for manufacturers.

Cons: While PET has good moisture barrier properties, it is less resistant to high temperatures compared to glass. Additionally, it may not provide the same premium feel that glass does, which can be a consideration for branding.

Impact on Application: PET is compatible with baby oil formulations, ensuring that the product remains stable during storage. However, buyers should ensure compliance with local regulations regarding food-grade plastics.

Why Choose HDPE for Baby Oil Bottles?

HDPE is another popular choice for baby oil bottles due to its high strength-to-density ratio. It is resistant to impact and can withstand a wide range of temperatures, making it suitable for various environments.

Pros: HDPE is cost-effective and resistant to many chemicals, ensuring the integrity of the baby oil inside. Its recyclability is also an advantage for environmentally conscious brands.

Cons: HDPE can be less transparent than PET, which may affect the visual appeal of the product. Additionally, it is not as rigid as glass, which can lead to deformation under pressure.

Impact on Application: HDPE is compatible with baby oil and can help maintain product quality. Buyers should consider local recycling capabilities, as HDPE recycling can vary by region.

What Are the Benefits of Glass for Baby Oil Bottles?

Glass is often viewed as a premium material for baby oil bottles due to its aesthetic appeal and excellent barrier properties. It is inert, meaning it does not react with the contents, ensuring product integrity.

Pros: Glass provides a high-end look and feel, which can enhance brand perception. It is also recyclable and environmentally friendly.

Cons: The primary drawback of glass is its weight, which increases shipping costs. It is also more prone to breakage compared to plastic options, posing a risk during transportation and handling.

Impact on Application: Glass is highly compatible with baby oil, providing an excellent barrier against moisture and air. However, international buyers must consider local regulations regarding glass packaging and potential safety concerns.

How Does LDPE Compare in Baby Oil Bottle Production?

LDPE is less commonly used for baby oil bottles but can be suitable for certain applications. It is flexible and has good chemical resistance, making it a viable option for some formulations.

Pros: LDPE is lightweight and offers excellent moisture barrier properties. It is also easy to mold, which simplifies manufacturing processes.

Illustrative image related to baby oil bottle

Cons: LDPE is less rigid than PET or glass, which can affect the bottle’s structural integrity. Additionally, it may not provide the same level of protection against UV light.

Impact on Application: LDPE can be used for baby oil, but buyers should evaluate its compatibility with specific formulations. Compliance with international standards for plastic materials is also essential.

Summary Table of Material Selection for Baby Oil Bottles

| Material | Typical Use Case for baby oil bottle | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PET | Commonly used for mass-produced baby oil bottles | Lightweight and cost-effective | Less temperature resistant than glass | Medium |

| HDPE | Ideal for bulk packaging and distribution | Strong and impact-resistant | Less transparent than PET | Low |

| Glass | Premium packaging for high-end baby oil products | Excellent barrier properties and aesthetic appeal | Heavy and prone to breakage | High |

| LDPE | Flexible packaging for specific formulations | Lightweight and easy to mold | Less rigid, affecting structural integrity | Medium |

This guide provides B2B buyers with essential insights into the strategic selection of materials for baby oil bottles, emphasizing the importance of compliance and performance in various international markets.

Illustrative image related to baby oil bottle

In-depth Look: Manufacturing Processes and Quality Assurance for baby oil bottle

What Are the Main Stages in the Manufacturing Process of Baby Oil Bottles?

The manufacturing process for baby oil bottles generally involves several key stages: material preparation, forming, assembly, and finishing. Each stage is critical to ensuring that the final product meets the safety and quality standards required for baby care products.

Material Preparation

The first step involves selecting appropriate materials, typically polyethylene terephthalate (PET) or high-density polyethylene (HDPE), which are favored for their durability, safety, and recyclability. Suppliers must ensure that the raw materials meet international safety standards, particularly those relevant to products intended for children. This may involve sourcing materials that are free from harmful chemicals such as phthalates and bisphenol A (BPA).

Before production, materials undergo rigorous testing for purity and compliance with regulations, including REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) in Europe and similar frameworks in other regions. The preparation stage also includes drying and conditioning the materials to achieve optimal processing conditions.

How Are Baby Oil Bottles Formed?

The forming stage typically utilizes extrusion blow molding or injection molding techniques. In extrusion blow molding, molten plastic is extruded into a mold, which is then inflated to achieve the desired shape. This method is efficient for producing bottles with consistent wall thickness and allows for the creation of complex shapes.

In contrast, injection molding involves injecting molten plastic into a pre-designed mold. This technique is ideal for producing precise and intricate designs, which can include unique bottle shapes or integrated dispensing systems. Both methods are highly automated, ensuring consistency and reducing the likelihood of human error.

What Quality Control Measures Are in Place During Manufacturing?

Quality control (QC) is a cornerstone of the manufacturing process, particularly for baby products. Implementing a robust QC system ensures that every batch of bottles meets both safety and quality standards.

Relevant International Standards

International standards such as ISO 9001 are essential benchmarks for quality management systems. This standard emphasizes the importance of continuous improvement and customer satisfaction. In addition to ISO certifications, industry-specific certifications such as CE marking for the European market and the American Society for Testing and Materials (ASTM) standards are critical for compliance and safety.

What Are the Key QC Checkpoints?

Quality control in the manufacturing of baby oil bottles typically includes several checkpoints:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified requirements.

-

In-Process Quality Control (IPQC): During production, samples are taken at regular intervals to ensure that the manufacturing processes are functioning correctly and that the products are within the desired specifications.

-

Final Quality Control (FQC): After production, a comprehensive inspection of the finished products is conducted. This includes checking for defects, ensuring proper labeling, and verifying that the bottles meet all safety standards.

What Common Testing Methods Are Used for Baby Oil Bottles?

Testing methods for baby oil bottles are crucial for ensuring safety and compliance. Common tests include:

- Material Testing: This assesses the physical and chemical properties of the materials used, ensuring they are suitable for baby products.

- Leak Testing: Bottles are tested for leaks under various conditions to ensure they maintain their integrity during use.

- Drop Testing: This simulates the potential impact of drops and falls, evaluating the bottle’s durability.

- Chemical Migration Testing: This checks for any harmful substances that may leach from the bottle into the oil, ensuring safety for infants.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must be proactive in verifying the quality control processes of their suppliers, especially when sourcing products for sensitive markets such as baby care. Here are several strategies:

Illustrative image related to baby oil bottle

-

Conduct Audits: Regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. This can include onsite visits to assess operations firsthand.

-

Request Quality Reports: Suppliers should provide documentation detailing their QC processes, results from testing, and certifications. This transparency is vital for establishing trust.

-

Utilize Third-Party Inspections: Engaging independent third-party inspection services can help verify that products meet the required standards. These services can provide unbiased assessments of both materials and finished products.

What Are the QC and Certification Nuances for International B2B Buyers?

International buyers must navigate various certification requirements and quality control standards that may differ by region. For instance, regulations in Europe might necessitate compliance with the European Union’s General Product Safety Directive, while buyers in Africa may need to consider local standards that can vary significantly between countries.

Additionally, it’s essential for buyers to understand the supply chain dynamics in their respective regions. For example, certain materials may be more readily available in South America compared to Europe, affecting the sourcing process. Buyers should also be mindful of potential tariffs and trade regulations that could impact the cost and availability of products.

By understanding these nuances and implementing rigorous verification processes, B2B buyers can ensure they partner with reliable suppliers who adhere to the highest standards of quality and safety in the manufacturing of baby oil bottles.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘baby oil bottle’

The following checklist provides a practical approach for B2B buyers looking to source baby oil bottles. This guide outlines essential steps to ensure the procurement process is efficient and meets quality standards.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for sourcing baby oil bottles that meet your product requirements. Consider factors such as material (e.g., PET, glass), size (e.g., 3 fl oz, 14 fl oz), and design (e.g., narrow neck, wide mouth) to ensure the bottles align with your product’s needs. Defining these specifications upfront will streamline the supplier selection process and minimize potential compatibility issues later on.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers that specialize in baby oil bottles. Utilize online directories, industry trade shows, and B2B marketplaces to compile a list of manufacturers. Pay attention to supplier reputation, customer reviews, and their experience in producing baby care products, as these factors significantly impact the quality and reliability of your sourcing decision.

Step 3: Evaluate Supplier Certifications

Before finalizing any supplier, it’s essential to verify their certifications. Look for certifications that demonstrate compliance with international safety and quality standards, such as ISO 9001 for quality management systems or FDA approval for materials used in baby products. These certifications provide assurance that the supplier adheres to stringent safety guidelines, which is particularly important when dealing with products for infants.

Step 4: Request Samples

Once you’ve narrowed down your list of suppliers, request product samples to evaluate quality firsthand. Assess the bottles for consistency in size, weight, and material integrity. Testing samples allows you to check for any defects and ensures that the bottles can effectively hold baby oil without leakage or degradation over time.

Step 5: Understand Pricing and Payment Terms

Negotiate pricing and payment terms with potential suppliers to ensure they fit within your budget. Consider factors such as minimum order quantities, bulk discounts, and shipping costs. Clear payment terms are crucial to avoiding misunderstandings that could impact cash flow or delay delivery times.

Step 6: Assess Supply Chain Logistics

Evaluate the logistics capabilities of your chosen supplier. Consider their production lead times, shipping methods, and ability to handle international shipping, especially if you’re sourcing from regions like Africa or South America. A supplier with robust logistics can help ensure timely delivery and maintain your inventory levels.

Step 7: Establish a Quality Control Process

Finally, establish a quality control process to monitor the quality of the bottles upon receipt. Implement inspection protocols to check for defects, proper labeling, and compliance with specifications. This step is vital for maintaining product quality and protecting your brand reputation in the competitive baby care market.

By following this structured checklist, B2B buyers can navigate the complexities of sourcing baby oil bottles effectively, ensuring that they partner with reliable suppliers and procure high-quality products for their customers.

Comprehensive Cost and Pricing Analysis for baby oil bottle Sourcing

What Are the Key Cost Components in Sourcing Baby Oil Bottles?

When sourcing baby oil bottles, understanding the cost structure is crucial for effective budgeting and financial planning. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly impacts costs. Common materials for baby oil bottles are PET and HDPE plastics, which are favored for their durability and safety. Premium materials, such as glass, may offer a higher perceived value but will increase costs.

-

Labor: Labor costs vary based on geographic location and the complexity of the manufacturing process. In regions with higher wages, such as Europe, labor costs may account for a larger percentage of the total price.

-

Manufacturing Overhead: This includes costs associated with facility operation, utilities, and administrative expenses. Efficient manufacturing processes can help reduce overhead costs, which can be passed on to buyers.

-

Tooling: Initial tooling costs can be substantial, especially for custom-designed bottles. Buyers should consider how many units will be produced to amortize these costs effectively over a larger volume.

-

Quality Control: Ensuring product safety and compliance with international standards is essential, particularly for baby products. Quality assurance processes may add to production costs but can prevent costly recalls and damage to brand reputation.

-

Logistics: Shipping and handling costs vary widely depending on the destination and the chosen Incoterms. International shipping can introduce tariffs and customs duties that affect the total landed cost.

-

Margin: Suppliers will typically add a profit margin to cover their risks and operational costs. Understanding the market landscape can help buyers negotiate better margins.

How Do Price Influencers Impact the Cost of Baby Oil Bottles?

Several factors influence the pricing of baby oil bottles, making it essential for buyers to evaluate their specific needs.

-

Volume/MOQ: Bulk purchasing often leads to lower per-unit costs. Suppliers may have minimum order quantities (MOQs), so buyers should assess their ability to meet these requirements to take advantage of volume discounts.

-

Specifications and Customization: Custom designs, such as unique shapes or branding, can significantly increase costs. Buyers should weigh the benefits of customization against the added expense.

-

Materials and Quality Certifications: Bottles that meet higher safety and environmental standards, such as being BPA-free or recyclable, may incur additional costs. Buyers should ensure that the materials align with their brand values and market demands.

-

Supplier Factors: The reliability and reputation of the supplier can also affect pricing. Established suppliers may offer more consistent quality but at a premium price.

-

Incoterms: The choice of Incoterms (International Commercial Terms) can impact the total cost. For example, choosing DDP (Delivered Duty Paid) may seem more expensive upfront but can simplify logistics and reduce unexpected costs.

What Negotiation Tips Can Help Buyers Optimize Costs?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider several strategies to optimize costs when sourcing baby oil bottles.

-

Total Cost of Ownership (TCO): Evaluate not just the purchase price but the entire lifecycle cost, including shipping, storage, and potential disposal costs. This holistic view will help identify the most cost-effective options.

-

Leverage Relationships: Building strong relationships with suppliers can facilitate negotiations. Suppliers may be more willing to offer discounts or better terms to long-term partners.

-

Market Research: Understanding the competitive landscape can provide leverage in negotiations. Buyers should research alternative suppliers and pricing structures to make informed decisions.

-

Flexibility in Specifications: If possible, being flexible with bottle specifications can lead to significant cost savings. Standard designs often come with lower production costs compared to custom orders.

-

Timing of Orders: Strategically timing orders can also influence pricing, especially during off-peak seasons when suppliers may be more willing to negotiate.

Conclusion: What Should Buyers Keep in Mind?

While indicative prices for baby oil bottles can vary widely based on the aforementioned factors, buyers should approach sourcing with a comprehensive understanding of cost structures and price influencers. By leveraging negotiation strategies and being mindful of the total cost of ownership, B2B buyers can optimize their sourcing decisions and ensure they secure the best value for their investment.

Alternatives Analysis: Comparing baby oil bottle With Other Solutions

Understanding Alternatives to Baby Oil Bottles

When considering the best options for moisturizing and protecting delicate skin, especially in the context of baby care, various alternatives to traditional baby oil bottles exist. These alternatives may offer distinct benefits in terms of formulation, packaging, and application methods. Understanding these options can help B2B buyers make informed decisions that align with their specific market needs.

Comparison of Baby Oil Bottle with Alternatives

| Comparison Aspect | Baby Oil Bottle | Natural Oils | Cream-Based Moisturizers |

|---|---|---|---|

| Performance | Locks in moisture effectively, gentle on skin | Provides deep hydration, may have additional benefits (e.g., anti-inflammatory) | Provides a barrier to moisture loss, often richer texture |

| Cost | Moderate (varies by brand) | Generally lower, but can vary widely based on source | Typically higher due to formulation complexity |

| Ease of Implementation | Easy to use, convenient packaging | Requires knowledge of application techniques | May require more steps in application, such as warming or spreading |

| Maintenance | Low maintenance; shelf-stable | Requires proper storage to maintain quality | Can have a shorter shelf life, needs proper sealing |

| Best Use Case | Daily moisturizing for babies | Ideal for sensitive skin or specific conditions (e.g., eczema) | Suitable for long-lasting hydration and protection |

Detailed Breakdown of Alternatives

Natural Oils

Natural oils, such as coconut oil or almond oil, present a compelling alternative to baby oil. They not only moisturize but also often provide additional benefits like anti-inflammatory properties and vitamins that nourish the skin. The cost of natural oils can be lower than that of branded baby oil products, making them attractive for businesses looking to offer budget-friendly options. However, the application may require more knowledge about the appropriate use and skin compatibility, which could complicate the consumer experience.

Illustrative image related to baby oil bottle

Cream-Based Moisturizers

Cream-based moisturizers, formulated specifically for babies, offer a richer texture that can provide long-lasting hydration and create a protective barrier on the skin. These products typically contain a blend of emollients and occlusives that enhance their moisturizing effects. While they may be more expensive than baby oil, their effectiveness in treating dry skin conditions makes them a preferred choice for many parents. However, they may require a more involved application process, which could deter some consumers seeking convenience.

Conclusion: Choosing the Right Solution for Your Needs

For B2B buyers, selecting the right solution involves evaluating the specific needs of their target market. If ease of use and moisture retention are top priorities, baby oil bottles might be the best fit. However, if the market leans towards natural and holistic solutions, promoting natural oils could resonate more with consumers. Conversely, for those targeting parents seeking comprehensive skincare solutions, cream-based moisturizers might be ideal. Ultimately, understanding these alternatives’ performance, cost, and application will enable buyers to align their product offerings with customer expectations and market trends.

Essential Technical Properties and Trade Terminology for baby oil bottle

What Are the Key Technical Properties of Baby Oil Bottles?

When sourcing baby oil bottles for distribution or production, understanding the essential technical properties is crucial for ensuring product quality and compliance with market standards. Here are some critical specifications to consider:

1. Material Grade

Baby oil bottles are primarily manufactured from materials like PET (Polyethylene Terephthalate) and HDPE (High-Density Polyethylene). PET is favored for its clarity and strength, making it ideal for showcasing product quality, while HDPE offers excellent chemical resistance and durability. Selecting the right material is vital for maintaining product integrity and ensuring safety, especially for sensitive items like baby oil.

2. Capacity

The capacity of baby oil bottles typically ranges from 3 fl oz (89 mL) to 20 fl oz (591 mL). Understanding the capacity is essential for market positioning and meeting consumer needs. Smaller sizes may cater to travel markets or samples, while larger sizes can appeal to families looking for value.

3. Closure Type

The type of closure, whether a flip-top, pump, or screw cap, significantly impacts user experience and product functionality. A secure closure ensures that the product remains uncontaminated and prevents leakage during transport. B2B buyers should consider which closure types are most popular in their target markets, as this can affect sales and customer satisfaction.

4. Tolerance and Dimensional Specifications

Tolerance refers to the allowable variation in dimensions during manufacturing. For baby oil bottles, maintaining precise tolerances is crucial to ensure compatibility with caps and prevent leakage. Buyers should inquire about the manufacturing tolerances to avoid potential quality issues that could lead to product recalls or customer dissatisfaction.

5. Safety and Compliance Standards

Baby oil bottles must meet stringent safety and compliance standards, particularly those related to chemical safety and child-proofing. Certifications such as ISO 9001 for quality management and compliance with FDA regulations for packaging materials are essential. Buyers must ensure that suppliers provide documentation proving compliance to safeguard their business against legal liabilities.

6. Recyclability

With increasing environmental concerns, the recyclability of packaging materials is becoming a significant selling point. PET and HDPE are widely recyclable, which aligns with global trends towards sustainable packaging. Buyers should prioritize suppliers who offer eco-friendly options and provide clear recycling information to consumers.

Illustrative image related to baby oil bottle

What Are Common Trade Terms Used in the Baby Oil Bottle Industry?

Navigating the B2B landscape involves familiarizing oneself with industry jargon. Here are some common terms relevant to baby oil bottle procurement:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or products that are sold by another company under its brand name. In the context of baby oil bottles, OEMs can provide custom bottle designs and manufacturing services, allowing brands to focus on marketing and distribution.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQs is crucial for buyers to manage inventory costs effectively and ensure they meet production demands without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers for specific products. This process helps buyers compare pricing, terms, and conditions across multiple suppliers, enabling informed decision-making.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers regarding the delivery of goods. They specify who is responsible for shipping, insurance, and tariffs. Familiarity with Incoterms is essential for international transactions, as it helps avoid misunderstandings and disputes.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. Understanding lead times helps businesses plan their inventory and manage customer expectations, particularly in industries with rapid demand fluctuations.

6. Product Lifecycle Management (PLM)

PLM encompasses the processes of managing a product’s lifecycle from inception to disposal. For baby oil bottles, effective PLM can enhance product development, streamline operations, and ensure compliance with safety regulations throughout the product’s life.

By mastering these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing baby oil bottles, leading to improved product offerings and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the baby oil bottle Sector

What Are the Key Market Dynamics and Trends in the Baby Oil Bottle Sector?

The global baby oil bottle market is experiencing significant growth, driven by increasing awareness of baby skin care and the rising demand for high-quality personal care products. In regions such as Africa, South America, the Middle East, and Europe, factors such as urbanization, improved living standards, and increased disposable income are propelling market expansion. Notably, B2B buyers are increasingly focused on sourcing products that emphasize safety, efficacy, and sustainability, leading to a surge in demand for bottles designed with advanced materials such as PET and HDPE that ensure product integrity.

Emerging technologies in packaging are revolutionizing the sourcing landscape. Innovations such as smart packaging that integrates QR codes for consumer education and product tracking are becoming prevalent. Furthermore, automation in manufacturing processes is enhancing efficiency and reducing costs, making it attractive for international buyers. The shift towards online procurement platforms has also simplified sourcing, allowing buyers to compare products and suppliers effortlessly.

Additionally, the market is witnessing a trend toward customization, with suppliers offering tailored designs and sizes to meet specific regional demands. The emergence of eco-friendly options, such as biodegradable and recyclable packaging, aligns with consumer preferences for sustainable products, which is becoming a critical differentiator in the competitive landscape.

How Can B2B Buyers Ensure Sustainability and Ethical Sourcing in Baby Oil Bottles?

Sustainability is a paramount concern for B2B buyers in the baby oil bottle sector. The environmental impact of plastic waste and the growing emphasis on responsible consumption have prompted buyers to prioritize suppliers who implement sustainable practices. This includes sourcing materials that are recyclable, biodegradable, or derived from renewable resources. For instance, bottles made from post-consumer recycled (PCR) plastic are gaining traction, offering a more sustainable option without compromising product quality.

Illustrative image related to baby oil bottle

Ethical sourcing extends beyond materials to encompass the entire supply chain. Buyers should consider suppliers who adhere to fair labor practices and transparency in their operations. Certifications such as ISO 14001 for environmental management and FSC certification for sustainable forestry can provide assurance of a supplier’s commitment to ethical practices.

Moreover, companies are increasingly adopting life cycle assessments (LCAs) to evaluate the environmental impact of their products throughout their lifespan. This data-driven approach not only aids in making informed sourcing decisions but also resonates with eco-conscious consumers. By prioritizing sustainability and ethical sourcing, B2B buyers can enhance their brand reputation and meet the growing consumer demand for responsible products.

What Is the Evolution of the Baby Oil Bottle Market?

The baby oil bottle market has evolved significantly over the past few decades. Initially dominated by glass containers, the introduction of plastic bottles in the late 20th century revolutionized the industry due to their lightweight and shatter-resistant properties. As consumer preferences shifted towards convenience and safety, manufacturers began developing specialized plastic formulations that are safe for baby care products.

In recent years, the market has also seen a shift towards more user-friendly designs, such as ergonomic shapes and easy-to-use dispensing mechanisms. Alongside this, heightened awareness of ingredient safety has led to stringent regulations governing product formulations, ensuring that bottles are not only functional but also safe for infants. This evolution reflects the ongoing commitment of manufacturers and suppliers to meet the changing needs of consumers while adhering to regulatory standards and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of baby oil bottle

-

How do I choose the right baby oil bottle supplier?

When selecting a supplier for baby oil bottles, consider their reputation, production capacity, and quality control processes. Look for suppliers that provide certifications for their products, such as ISO standards, and check reviews or testimonials from other B2B buyers. It’s beneficial to request samples to assess the quality firsthand. Additionally, ensure they have experience in international trade, as this will facilitate smoother transactions and compliance with import regulations in your region. -

What materials are commonly used for baby oil bottles?

Baby oil bottles are typically made from materials like PET (Polyethylene Terephthalate) and HDPE (High-Density Polyethylene). PET is lightweight, transparent, and resistant to impact, making it ideal for consumer products. HDPE is known for its durability and resistance to moisture, ensuring that the baby oil remains uncontaminated. When sourcing, consider the material’s safety standards, especially for products intended for babies, and inquire about recyclability to align with sustainability goals. -

What customization options are available for baby oil bottles?

Many suppliers offer customization options such as bottle shapes, sizes, colors, and labeling. Custom labeling can enhance your brand visibility and appeal to your target market. Additionally, you might want to discuss options for child-resistant caps or special dispensing mechanisms to improve safety and usability. Ensure to communicate your specific requirements early in the negotiation process to avoid delays in production. -

What are the minimum order quantities (MOQ) for baby oil bottles?

MOQs for baby oil bottles can vary significantly depending on the supplier and the level of customization required. Generally, standard products may have lower MOQs, while customized bottles might require larger orders. It is advisable to discuss your needs with potential suppliers to understand their policies. If you are a smaller business, some suppliers may be willing to negotiate or offer flexibility in order sizes. -

What payment terms should I expect when sourcing baby oil bottles?

Payment terms can vary by supplier and region. Common options include upfront payments, letters of credit, or payment upon delivery. Ensure to clarify payment methods accepted, such as bank transfers or credit cards, and inquire about any potential discounts for early payments. Establishing clear payment terms upfront can help avoid misunderstandings and foster a reliable partnership. -

How do I ensure quality assurance for baby oil bottles?

To ensure quality assurance, request documentation of the supplier’s quality control processes and certifications. Consider implementing third-party quality inspections at various stages of production, especially before shipment. Also, establish clear specifications and standards for your order, and discuss the consequences of failing to meet these standards. Regular communication with your supplier can help address any issues proactively. -

What logistics should I consider when importing baby oil bottles?

When importing baby oil bottles, consider shipping methods, customs regulations, and potential tariffs. Work with a freight forwarder who understands the complexities of international shipping to streamline the process. Additionally, account for lead times, storage solutions, and distribution strategies once the products arrive in your country. Understanding these logistics can help avoid delays and additional costs. -

How can I navigate regulatory compliance for baby oil products in different markets?

Navigating regulatory compliance requires thorough research on the specific requirements for baby products in your target markets. Each region may have different safety standards, labeling requirements, and permissible ingredients. Engage with local authorities or compliance consultants to ensure your products meet all necessary regulations. Staying informed about changes in regulations will help you maintain compliance and avoid potential legal issues.

Top 6 Baby Oil Bottle Manufacturers & Suppliers List

1. Johnson’s – Baby Oil

Domain: johnsonsbaby.com

Registered: 1996 (29 years)

Introduction: Product Name: Johnson’s® Baby Oil

Purpose: Designed for baby massage and moisturizing skin.

Key Benefits:

– Locks in up to 10x more moisture on wet skin than ordinary lotion on dry skin.

– Leaves skin smooth and feeling baby soft.

– Dermatologist-tested.

– Clinically Proven Mildness formula for delicate skin.

– Free from parabens, phthalates, and dyes.

– Effective moisturization for the whole fam…

2. Pretium Packaging – PET Baby Oil Bottles

Domain: pretiumpkg.com

Registered: 1997 (28 years)

Introduction: {“product_name”: “PET Baby Oil Bottles”, “sizes_available”: [“14oz”, “20oz”], “type”: “Narrow Neck Oblong Plastic Bottles”, “company”: “Pretium Packaging”, “contact_info”: {“address”: “1555 Page Industrial Blvd St. Louis, MO 63132”, “phone”: “+1 (314) 727-8200”, “fax”: “+1 (314) 427-5445”}}

3. Diddy’s Baby Oil – Bulk Supply

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 1 standard baby oil bottle = 14oz; 1000 baby oil bottles = 14,000oz; 1 gallon = 128oz; Total gallons of baby oil at Diddy’s house = Approximately 110 gallons.

4. Getty Images – Baby Oil Bottle Stock Photos

Domain: gettyimages.com

Registered: 1999 (26 years)

Introduction: This company, Getty Images – Baby Oil Bottle Stock Photos, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. SKS – Baby Oil Bottles

Domain: sks-bottle.com

Registered: 1997 (28 years)

Introduction: Baby Oil Bottles: Cosmo round style, ergonomic design, snap top caps for one-handed dispensing. Available in clear PET plastic. Cap options: white or black snap top caps with small opening for pouring and attached lid for safe transport. Custom labeling area for product differentiation. Dimensions: 159 mm (H), 44 mm (D); Case pack: 507/cs; Price: $177.45 per case ($0.35 each). Additional cap optio…

6. JOHNSON’S – Diddy’s Personal Collection Baby Oil

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“title”: “A Bottle Of Diddy’s Personal Collection Of Baby Oil”, “condition”: “New”, “price”: “$5,000.00 or Best Offer”, “shipping”: “$16.58”, “estimated_delivery”: “Thu, Sep 11 – Wed, Sep 17”, “quantity_available”: “1”, “item_number”: “296720689675”, “UPC”: “0381370033394”, “brand”: “JOHNSON’S”, “description”: “No lowballs I know what I got. If you know, you know may have been partially up Rihann…

Strategic Sourcing Conclusion and Outlook for baby oil bottle

What Are the Key Takeaways for Strategic Sourcing of Baby Oil Bottles?

In the evolving landscape of baby care products, the strategic sourcing of baby oil bottles presents significant opportunities for international B2B buyers. As consumer demand increases for high-quality, safe, and environmentally-friendly packaging options, prioritizing suppliers that offer materials free from harmful additives is crucial. Bottles made from PET and other recyclable materials not only enhance brand reputation but also align with sustainability goals. Moreover, understanding regional preferences—whether in Africa, South America, the Middle East, or Europe—can drive product differentiation and market success.

How Can B2B Buyers Prepare for Future Trends in Baby Oil Bottles?

The outlook for the baby oil bottle market is optimistic, with rising awareness of skincare needs and the increasing importance of bonding experiences through baby massage. Buyers should actively seek partnerships with manufacturers that provide customizable solutions, such as different sizes and dispensing options, to meet diverse market demands. Emphasizing innovation in packaging design can also create a competitive edge in a crowded marketplace.

What Steps Should International Buyers Take Now?

As you navigate this dynamic market, consider leveraging strategic sourcing to enhance your supply chain resilience. Engage with suppliers who prioritize quality, sustainability, and compliance with international safety standards. By taking these proactive steps, you can position your business to capitalize on emerging trends and meet the evolving needs of consumers across various regions. Embrace the opportunity to forge strong partnerships that will drive growth and innovation in the baby care industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.