Unlocking Value: A Strategic Analysis of the Automatic Extension Cord Reel Market

Introduction: Navigating the Global Market for automatic extension cord reel

In today’s fast-paced industrial landscape, sourcing the right automatic extension cord reel can pose significant challenges for international B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. The need for reliable power solutions is paramount, especially as businesses expand and demand for efficient equipment grows. This comprehensive guide addresses the complexities of selecting the ideal extension cord reel by exploring various types, applications, and essential features.

Our in-depth analysis will cover critical aspects such as supplier vetting, pricing strategies, and compliance with international safety standards. By delving into the specifications that matter—like cord gauge, reel capacity, and durability—this guide empowers buyers to make informed purchasing decisions. Whether you are in Nigeria seeking robust solutions for heavy-duty applications or in Brazil looking for versatile options for commercial use, our insights will help you navigate the global market with confidence.

Moreover, we will provide actionable tips on evaluating suppliers and understanding market trends, ensuring that you can secure products that not only meet your operational needs but also align with your budget. With this guide, B2B buyers can streamline their procurement process and invest in high-quality extension cord reels that enhance productivity and safety in their workplaces.

Understanding automatic extension cord reel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Retractable Cord Reel | Automatically winds up the cord; often includes a locking system | Manufacturing, construction, workshops | Pros: Reduces trip hazards; easy to store. Cons: May require wall or ceiling installation. |

| Heavy-Duty Cord Reel | Built with robust materials; higher gauge cords for heavy loads | Industrial sites, outdoor events | Pros: Can handle significant power loads; durable. Cons: Higher initial cost; bulkier design. |

| Multi-Outlet Cord Reel | Features multiple outlets; often includes surge protection | Offices, commercial spaces | Pros: Convenient for powering multiple devices; protects against surges. Cons: Limited to specific environments; may not be portable. |

| Portable Cord Reel | Lightweight, compact design; often battery-operated | Outdoor events, temporary setups | Pros: Easy to transport; ideal for temporary use. Cons: Limited cord length; may not support high wattage. |

| Wall-Mounted Cord Reel | Fixed installation; maximizes space efficiency | Warehouses, garages | Pros: Saves floor space; keeps cords organized. Cons: Less flexible in terms of reach; installation required. |

What Are the Characteristics of Retractable Cord Reels?

Retractable cord reels are designed for convenience, automatically winding the cord when not in use. This feature minimizes trip hazards and keeps workspaces organized, making them ideal for manufacturing and construction environments where safety is paramount. Buyers should consider the length and gauge of the cord, as well as the ease of installation, to ensure they meet their specific operational needs.

Illustrative image related to automatic extension cord reel

Why Choose Heavy-Duty Cord Reels for Industrial Applications?

Heavy-duty cord reels are constructed with robust materials and higher gauge cords, allowing them to handle significant power loads. They are particularly suitable for industrial sites and outdoor events where equipment demands are high. B2B buyers should assess the reel’s durability, cord length, and compatibility with their power requirements to ensure optimal performance in demanding environments.

How Do Multi-Outlet Cord Reels Enhance Office Efficiency?

Multi-outlet cord reels come equipped with several outlets, often featuring surge protection to safeguard sensitive equipment. They are particularly beneficial in offices and commercial spaces where multiple devices need to be powered simultaneously. When purchasing, businesses should evaluate the total wattage capacity and the length of the cord to ensure that it meets their workspace layout and electrical needs.

What Makes Portable Cord Reels Ideal for Temporary Setups?

Portable cord reels are lightweight and designed for ease of transport, often featuring battery operation for flexibility at outdoor events or temporary setups. They are ideal for businesses that require mobility and quick setup. However, buyers should be mindful of the cord length and the wattage capacity, as these reels may not support high-power equipment.

Why Consider Wall-Mounted Cord Reels for Space Efficiency?

Wall-mounted cord reels are fixed installations that maximize space efficiency, making them ideal for warehouses and garages. They keep cords organized and out of the way, reducing clutter in high-traffic areas. Buyers should consider the installation requirements and the reach of the cord to ensure it fits their operational layout and provides sufficient coverage for their equipment.

Key Industrial Applications of automatic extension cord reel

| Industry/Sector | Specific Application of automatic extension cord reel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction and Engineering | Powering tools and equipment on job sites | Enhances efficiency and reduces downtime | Heavy-duty cord specifications, weather resistance |

| Manufacturing | Machinery operation in factories | Ensures consistent power supply for production | Voltage compatibility, overload protection features |

| Event Management | Power supply for temporary installations | Facilitates quick setup and teardown of events | Portability, length of cord, ease of retraction |

| Agriculture | Powering irrigation systems and farm equipment | Increases productivity and reduces manual handling | Durability against environmental factors, cord length |

| Maintenance and Repair Services | Powering equipment in repair shops and facilities | Streamlines operations and minimizes tripping hazards | Safety features, ease of installation, cord gauge |

How is the automatic extension cord reel utilized in the construction and engineering sector?

In the construction and engineering sector, automatic extension cord reels are essential for powering various tools and equipment at job sites. These reels provide a flexible and organized way to manage electrical cords, reducing the risk of tripping hazards and improving site safety. Heavy-duty options are preferred, ensuring that the reels can handle the demanding power requirements of equipment like drills and saws. Buyers must consider weather-resistant features to ensure functionality in diverse climates, particularly in regions like Africa and South America.

What role do automatic extension cord reels play in manufacturing facilities?

Manufacturing facilities rely heavily on automatic extension cord reels to maintain a consistent power supply to machinery. These reels facilitate the operation of various machines, ensuring that production lines run smoothly without interruptions. The need for overload protection and voltage compatibility is critical, as equipment specifications can vary widely. International buyers should prioritize sourcing reels that meet local electrical standards, particularly in the Middle East and Europe, to avoid operational disruptions.

How do automatic extension cord reels enhance event management processes?

In event management, automatic extension cord reels are used to provide power for temporary installations such as lighting, audio systems, and catering equipment. Their retractable design allows for quick setup and teardown, essential for maintaining tight schedules during events. Portability and the length of the cord are significant considerations for buyers, as they need flexibility to adapt to various venue layouts. Additionally, reels with safety features can mitigate risks associated with high foot traffic at events, crucial for ensuring guest safety.

In what ways are automatic extension cord reels beneficial for agricultural applications?

Automatic extension cord reels are increasingly utilized in agriculture to power irrigation systems and farm equipment. By providing a reliable power source, these reels enhance productivity and minimize the need for manual handling of cords in outdoor environments. Durability against environmental factors such as moisture and dirt is vital when sourcing these products. Buyers from agricultural sectors in regions like Africa should look for reels that can withstand harsh conditions while maintaining performance.

How do automatic extension cord reels improve maintenance and repair services?

In maintenance and repair services, automatic extension cord reels streamline operations by providing easy access to power for various tools and equipment. This organization reduces clutter and minimizes tripping hazards, enhancing workplace safety. Key sourcing considerations include the safety features of the reels, ease of installation, and the appropriate cord gauge to match the power requirements of the tools used. This is particularly important for service providers operating in diverse environments across Europe and South America, where electrical standards may vary.

3 Common User Pain Points for ‘automatic extension cord reel’ & Their Solutions

Scenario 1: Managing Cord Clutter in Busy Work Environments

The Problem: In bustling industrial settings, the accumulation of extension cords can lead to significant clutter and safety hazards. B2B buyers often face the challenge of managing long cords that are either tangled or improperly stored, creating trip hazards and inefficiencies. This issue is particularly acute in environments where space is limited, such as warehouses or construction sites in regions like Brazil or Nigeria, where workers may need to navigate tight areas while operating heavy machinery.

The Solution: To mitigate cord clutter, investing in a high-quality automatic extension cord reel is essential. These reels not only facilitate the organized storage of cords but also feature self-retracting mechanisms that eliminate tangles. When sourcing these products, buyers should prioritize models with a durable, impact-resistant housing and a self-leveling system that ensures even winding. Additionally, features such as adjustable cord stoppers can allow users to lock the cord at specific lengths, making it easier to access power sources without unnecessary excess cord lying around. Regular maintenance checks on the reels can also help prevent wear and prolong their lifespan, ensuring that the workspace remains safe and organized.

Scenario 2: Ensuring Electrical Safety and Compliance

The Problem: Compliance with electrical safety standards is a critical concern for B2B buyers in industries such as construction and manufacturing. Automatic extension cord reels can pose risks if not properly specified or used. Issues such as overheating, tripped breakers, and electrical fires can arise from using the wrong type of cord or failing to adhere to local regulations, especially in regions with varying safety standards like the Middle East and Europe.

The Solution: To ensure safety and compliance, buyers should look for automatic extension cord reels that are specifically rated for their intended use. This includes evaluating the cord’s gauge and amperage rating to match the equipment it will power. Opting for reels that come with built-in circuit breakers and overload protection features can provide an added layer of safety. Additionally, it is advisable to review local electrical codes and regulations before purchasing, to ensure that the products meet all necessary standards. Regular training sessions for employees on the correct usage of these reels can further enhance safety, reducing the risk of accidents and ensuring compliance with regulations.

Scenario 3: Adapting to Varied Work Conditions

The Problem: Different work environments present unique challenges, especially when it comes to weather and terrain. For instance, outdoor construction sites in South America may face extreme temperatures or wet conditions that can damage standard extension cords. B2B buyers often struggle to find reliable automatic extension cord reels that can withstand such conditions without compromising performance.

The Solution: Buyers should select automatic extension cord reels made from materials designed to endure harsh environments. Look for cords rated for cold weather or those that are oil and water-resistant, ensuring they remain functional under adverse conditions. Additionally, it’s beneficial to choose reels with features like swivel mounting brackets that provide flexibility in positioning the outlet where it is most needed, regardless of terrain. Understanding the specific environmental requirements of their projects can guide buyers in selecting the most appropriate reels, thereby maximizing efficiency and minimizing downtime due to equipment failure. Regular inspections and proper storage when not in use can also help maintain the integrity of the equipment, ensuring longevity and reliability in various conditions.

Strategic Material Selection Guide for automatic extension cord reel

What Are the Common Materials Used in Automatic Extension Cord Reels?

When selecting materials for automatic extension cord reels, several factors come into play, including performance, durability, and cost. The choice of materials can significantly impact the functionality and longevity of the product, making it essential for international B2B buyers to understand the characteristics of each material.

How Does Plastic Compare for Automatic Extension Cord Reels?

Plastic is a commonly used material in the housing of automatic extension cord reels. Key properties include lightweight characteristics, good electrical insulation, and resistance to corrosion and moisture. However, plastics can be less durable under extreme temperatures and UV exposure, which may lead to brittleness over time.

Pros:

– Cost-effective and lightweight, facilitating easier handling and installation.

– Good electrical insulation properties, enhancing safety.

Cons:

– Limited temperature resistance, which can affect performance in extreme environments.

– Potential for degradation under UV exposure, especially in outdoor applications.

For international buyers, compliance with safety standards such as ASTM or IEC is crucial, particularly in regions with stringent electrical safety regulations.

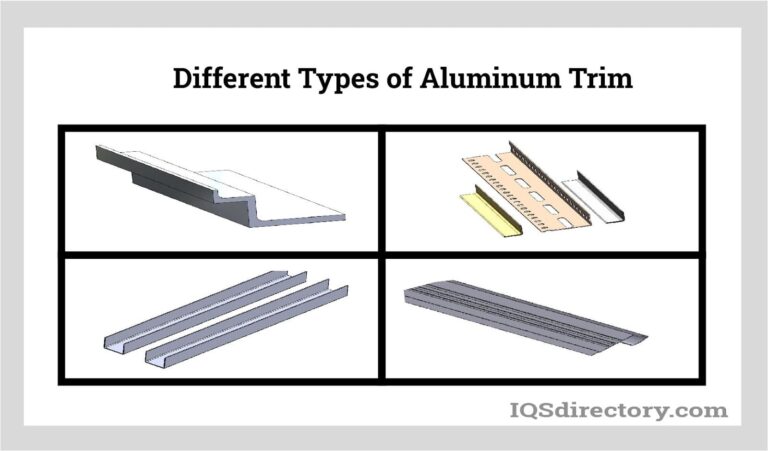

What Role Does Metal Play in Automatic Extension Cord Reel Construction?

Metals, particularly steel and aluminum, are often used for structural components due to their strength and durability. Key properties include high tensile strength and resistance to impact and deformation, making them suitable for heavy-duty applications.

Pros:

– Exceptional durability and resistance to wear and tear, ideal for industrial environments.

– High-temperature resistance, ensuring performance in hot conditions.

Illustrative image related to automatic extension cord reel

Cons:

– Heavier than plastic, which may complicate installation and handling.

– Higher manufacturing costs, impacting overall product pricing.

For buyers in regions like Africa and South America, the availability of quality metals may vary, and understanding local manufacturing capabilities is essential for sourcing.

How Do Rubber and Elastomers Enhance Performance in Automatic Extension Cord Reels?

Rubber and elastomers are often used for cord insulation and protective coverings. They offer excellent flexibility, abrasion resistance, and can withstand a wide range of temperatures. These materials are particularly beneficial in environments where movement and bending are common.

Pros:

– High flexibility and resilience, reducing the risk of cord damage during use.

– Good resistance to oil and chemicals, enhancing longevity in industrial settings.

Cons:

– Can be more expensive than plastic options.

– May degrade over time if exposed to excessive UV light without proper additives.

International buyers should consider the specific environmental conditions of their regions, as rubber’s performance can vary significantly based on climate.

What Are the Benefits of Using Composite Materials in Automatic Extension Cord Reels?

Composite materials, often a blend of plastics and metals, are gaining traction in the manufacturing of automatic extension cord reels. They combine the lightweight properties of plastics with the strength of metals, providing a balanced solution.

Pros:

– Lightweight yet strong, offering ease of use without sacrificing durability.

– Can be engineered to meet specific performance criteria, such as temperature resistance and impact strength.

Cons:

– Higher manufacturing complexity can lead to increased costs.

– Availability may be limited in some regions, affecting supply chains.

For global buyers, understanding the local market for composite materials is essential, especially in regions where advanced manufacturing processes are less common.

Summary Table of Material Selection for Automatic Extension Cord Reels

| Material | Typical Use Case for automatic extension cord reel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Housing and lightweight components | Cost-effective and lightweight | Limited temperature resistance | Low |

| Metal | Structural components in heavy-duty applications | Exceptional durability | Heavier and higher manufacturing costs | High |

| Rubber/Elastomers | Cord insulation and protective coverings | High flexibility and abrasion resistance | Can degrade under UV exposure | Medium |

| Composite | Advanced applications requiring strength and lightness | Lightweight yet strong | Higher manufacturing complexity | High |

By understanding the properties, advantages, and limitations of these materials, international B2B buyers can make informed decisions that align with their specific needs and compliance requirements.

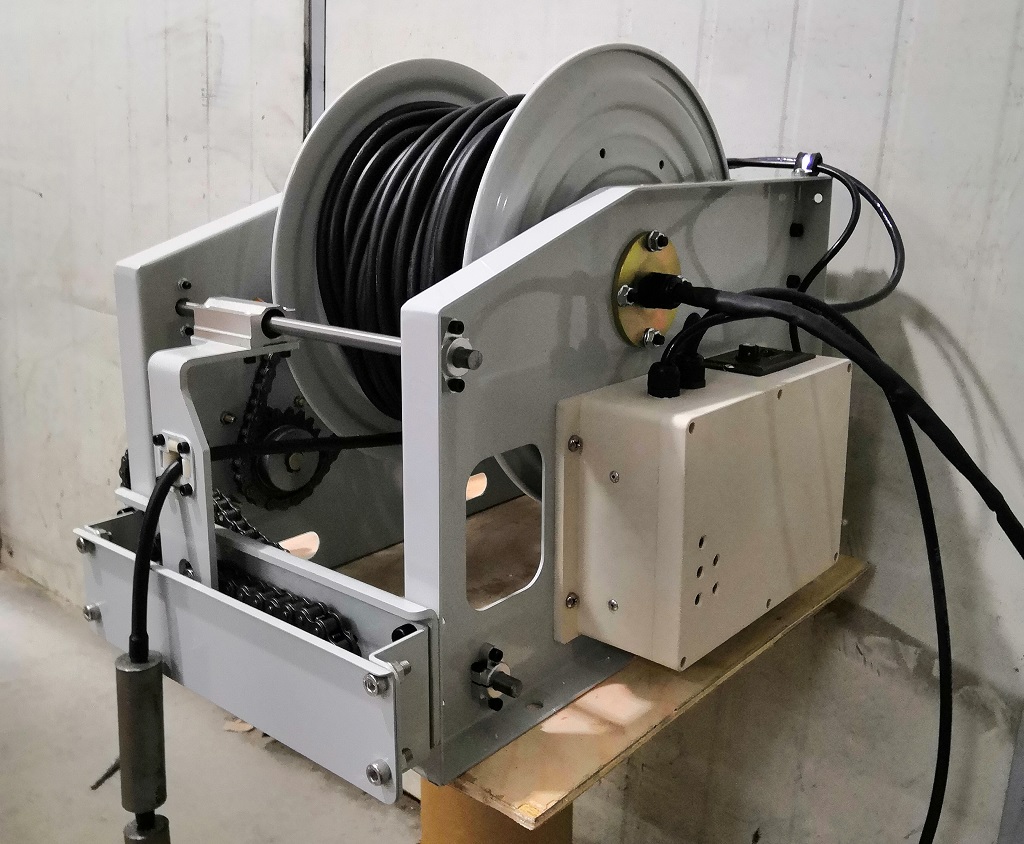

In-depth Look: Manufacturing Processes and Quality Assurance for automatic extension cord reel

What Are the Key Stages in the Manufacturing Process of Automatic Extension Cord Reels?

The manufacturing process of automatic extension cord reels involves several critical stages, each designed to ensure that the final product meets stringent quality and performance standards. Understanding these stages will help B2B buyers make informed decisions when sourcing these products.

Material Preparation: What Materials Are Used in Automatic Extension Cord Reels?

The first step in the manufacturing process is material preparation. Commonly used materials include high-quality thermoplastics for the housing, copper for the wiring, and durable rubber or thermoplastic elastomer for the cords. Each material is chosen based on its properties—thermoplastics provide impact resistance, while copper ensures excellent conductivity.

Illustrative image related to automatic extension cord reel

During this stage, raw materials undergo inspection to verify their compliance with international quality standards. This includes checks for material strength, flexibility, and resistance to environmental factors such as oil, water, and UV radiation.

How Is Forming Done in the Production of Automatic Extension Cord Reels?

The forming stage typically involves several techniques, including injection molding and extrusion. Injection molding is used to create the plastic housing and internal components, ensuring precise shapes and dimensional accuracy. Extrusion is often employed for producing cords, where thermoplastic materials are heated and forced through a die to create continuous lengths of cable.

Advanced forming technologies may also be utilized, such as robotic arms for automated assembly lines, which enhance precision and reduce human error. This stage is crucial for ensuring that all components fit together seamlessly, which is vital for the proper functioning of the reel.

What Happens During the Assembly Stage of Automatic Extension Cord Reel Production?

Assembly is where all the prepared components come together. Key parts include the cord, electrical outlets, circuit breakers, and the housing. Automated assembly lines may be employed to improve efficiency and consistency, with workers focusing on quality checks at various points.

During this stage, the incorporation of features such as self-leveling mechanisms and adjustable cord stoppers is crucial. Each assembly line typically has specific quality control checkpoints to ensure that each unit is assembled according to the design specifications.

Illustrative image related to automatic extension cord reel

How Is Finishing Achieved in the Production of Automatic Extension Cord Reels?

Finishing processes include painting, coating, and additional treatments that enhance the durability and aesthetic appeal of the extension cord reels. The application of protective coatings, such as those that resist oil and UV rays, is particularly important for products intended for outdoor or industrial use.

Finishing also involves final inspections to ensure that there are no cosmetic defects and that all functional components operate as intended. This stage is vital for presenting a polished product to the market.

What Quality Assurance Standards Are Relevant for Automatic Extension Cord Reels?

Quality assurance is a critical aspect of the manufacturing process, particularly for B2B buyers seeking reliable products. International standards such as ISO 9001 focus on establishing a quality management system that ensures consistency in production and customer satisfaction. Compliance with these standards is often a prerequisite for business partnerships.

Which Industry-Specific Certifications Should B2B Buyers Look For?

In addition to ISO 9001, B2B buyers should be aware of industry-specific certifications such as CE marking in Europe and UL certification in North America. These certifications indicate that products meet regulatory and safety requirements, which is crucial for ensuring the reliability of automatic extension cord reels in various applications.

For buyers in Africa and South America, understanding local compliance requirements is equally important. Buyers should inquire about certifications that are recognized in their respective markets to avoid regulatory issues.

Illustrative image related to automatic extension cord reel

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is integrated throughout the manufacturing process and typically involves several checkpoints:

-

Incoming Quality Control (IQC): This checkpoint assesses raw materials upon arrival to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): Conducted during manufacturing, this involves monitoring processes and equipment to catch defects early.

-

Final Quality Control (FQC): At this stage, finished products undergo thorough testing to verify functionality, safety, and compliance with specifications.

Common testing methods include electrical testing for safety, functional tests to ensure the retractable mechanism works correctly, and environmental tests to verify resistance to various conditions.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers can take several steps to verify the quality control practices of potential suppliers:

-

Conduct Supplier Audits: Regular audits can provide insights into a supplier’s manufacturing processes and quality assurance practices. Buyers should assess whether the supplier adheres to international standards and industry best practices.

-

Request Quality Assurance Documentation: Suppliers should be able to provide documents that outline their quality management systems, certifications, and testing methodologies.

-

Engage Third-Party Inspection Services: Utilizing third-party services for product inspections can offer an unbiased evaluation of the supplier’s quality control practices. This is particularly valuable for buyers operating in regions with specific compliance requirements.

-

Review Quality Control Reports: Buyers should request and review reports that detail the results of quality inspections and tests conducted on finished products.

What Nuances Should International B2B Buyers Be Aware Of Regarding Quality Control?

For international B2B buyers, particularly from diverse regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control can be crucial:

-

Cultural Differences in Quality Standards: Different regions may have varying expectations regarding quality and compliance. Buyers should familiarize themselves with local standards to ensure alignment with supplier practices.

-

Logistical Considerations: The supply chain can affect product quality; therefore, buyers should consider the entire logistics process, including transportation and storage, which can impact product performance.

-

Market-Specific Regulations: Each market may have unique regulations that impact quality assurance. Staying informed about these regulations can help buyers navigate compliance more effectively.

By understanding the manufacturing processes and quality assurance measures associated with automatic extension cord reels, B2B buyers can make more informed sourcing decisions and select suppliers that meet their quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘automatic extension cord reel’

Introduction

This sourcing guide is designed to assist B2B buyers in procuring automatic extension cord reels effectively. By following this checklist, businesses can ensure they select high-quality products that meet their operational needs while also aligning with safety standards and budget considerations.

Illustrative image related to automatic extension cord reel

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s essential to establish clear technical specifications for the extension cord reel. Consider factors such as cord length, gauge, and power capacity to ensure the product meets the demands of your applications. For instance, a heavy-duty reel may require a thicker gauge cord to handle higher amperage.

Step 2: Research Compliance and Safety Standards

Verify that the automatic extension cord reels comply with relevant safety standards and certifications applicable in your region. For example, look for cULus listings or CE markings, which indicate that the product meets North American or European safety requirements. Ensuring compliance not only mitigates risk but also enhances the reliability of the equipment in your operations.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations to ensure their credibility and reliability. Request company profiles, client testimonials, and case studies from similar industries or regions. Engaging with suppliers who have a proven track record can significantly reduce the risk of delays or quality issues.

Illustrative image related to automatic extension cord reel

Step 4: Request Samples for Testing

Once you have shortlisted suppliers, request samples of the automatic extension cord reels for testing. This step allows you to assess the product’s quality, durability, and functionality firsthand. Pay attention to features such as cord retraction mechanisms, ease of installation, and overall user experience.

Step 5: Assess Warranty and After-Sales Support

Review the warranty terms and after-sales support offered by potential suppliers. A robust warranty can provide peace of mind, indicating that the supplier stands behind their product. Additionally, responsive customer service is crucial for resolving any issues that may arise after purchase, ensuring minimal disruption to your operations.

Step 6: Compare Pricing and Payment Terms

Gather detailed pricing information from multiple suppliers and compare it against the specifications and features offered. Look for any hidden costs such as shipping fees or taxes that could affect your overall budget. Also, inquire about payment terms to find a solution that aligns with your financial practices.

Step 7: Finalize the Purchase Agreement

After selecting a supplier, finalize the purchase agreement with clear terms regarding delivery timelines, payment schedules, and return policies. Ensure that all parties understand their responsibilities to avoid misunderstandings. A well-structured agreement can help facilitate smooth transactions and foster a positive supplier relationship.

By following these steps, B2B buyers can navigate the complexities of sourcing automatic extension cord reels, ensuring they make informed decisions that support their business objectives.

Comprehensive Cost and Pricing Analysis for automatic extension cord reel Sourcing

What Are the Key Cost Components in Sourcing Automatic Extension Cord Reels?

When sourcing automatic extension cord reels, understanding the cost structure is crucial for effective budgeting and pricing negotiations. The primary cost components include:

-

Materials: The core materials used in manufacturing, such as high-quality plastics for housing, copper for wiring, and rubber for cords, significantly impact the overall cost. Suppliers that source materials sustainably may charge a premium, but this often results in better durability and performance.

-

Labor: Labor costs can vary widely based on the region and the complexity of the manufacturing process. In countries with higher labor costs, such as those in Europe, you might find that automation reduces labor expenses, while in regions like Africa or South America, manual labor might be cheaper but less efficient.

-

Manufacturing Overhead: This includes the costs associated with the production environment, such as utilities, equipment maintenance, and facility costs. Factories with advanced technology may have higher overhead but can produce higher-quality products more efficiently.

-

Tooling: The initial investment in molds and machinery for producing specific designs or customizations can be significant. Buyers should consider whether they need customized reels, as this will increase tooling costs.

-

Quality Control (QC): Implementing stringent QC processes ensures that products meet safety and performance standards. The costs associated with QC can vary, but they are essential for maintaining quality, especially for international buyers who must comply with various certifications.

-

Logistics: Shipping and handling costs are often overlooked but can significantly affect the total cost. Factors like distance, shipping method, and customs fees play a role in determining logistics costs.

-

Margin: Suppliers will include a profit margin in their pricing, which can vary based on market demand and competition. Understanding the supplier’s cost structure can provide leverage in negotiations.

How Do Price Influencers Affect Sourcing Automatic Extension Cord Reels?

Several factors can influence the pricing of automatic extension cord reels:

-

Volume and Minimum Order Quantity (MOQ): Ordering in bulk typically leads to lower per-unit costs. Suppliers often offer discounts for larger orders, making it beneficial for businesses to assess their needs and plan accordingly.

-

Specifications and Customization: Customized products tend to cost more due to the additional resources required for production. Buyers should weigh the benefits of customization against the increased costs.

-

Materials and Quality Certifications: Higher-quality materials and certifications (such as UL or CE) can increase the price. However, investing in quality can reduce the total cost of ownership by minimizing the need for replacements or repairs.

-

Supplier Factors: The reputation and reliability of suppliers can also affect pricing. Established suppliers with proven track records may charge more, but they often provide better service and quality assurance.

-

Incoterms: Understanding Incoterms is critical for international transactions. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can shift the cost burden between buyer and seller, impacting overall pricing.

What Are the Best Buyer Tips for Cost-Efficiency in Automatic Extension Cord Reel Sourcing?

To maximize cost-efficiency when sourcing automatic extension cord reels, consider the following tips:

Illustrative image related to automatic extension cord reel

-

Negotiate Terms: Always negotiate pricing and terms with suppliers. Many are willing to adjust prices based on order size or long-term contracts.

-

Assess Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider maintenance, warranty, and longevity to understand the true cost of a product over its lifecycle.

-

Understand Pricing Nuances for International Buyers: Different regions may have varying pricing structures due to labor costs, material availability, and local demand. For buyers in Africa, South America, and the Middle East, it’s essential to research local suppliers who may offer more competitive prices.

-

Stay Informed on Market Trends: Keeping abreast of market changes can provide insights into when to buy or negotiate. Economic fluctuations can impact material costs and availability.

-

Utilize Local Partnerships: Establishing relationships with local distributors can reduce shipping costs and provide quicker access to products, thus enhancing supply chain efficiency.

In conclusion, a comprehensive understanding of the cost components, price influencers, and strategic buyer tips can empower businesses to make informed decisions when sourcing automatic extension cord reels, ultimately leading to better financial outcomes.

Alternatives Analysis: Comparing automatic extension cord reel With Other Solutions

When considering the procurement of electrical solutions for industrial or commercial environments, it’s essential to evaluate various options available in the market. The automatic extension cord reel is a popular choice due to its convenience and efficiency in managing electrical cords. However, alternatives exist that may better suit specific operational needs, budget constraints, or environmental conditions. This analysis will compare the automatic extension cord reel against two viable alternatives: traditional extension cords and cord management systems.

| Comparison Aspect | Automatic Extension Cord Reel | Traditional Extension Cords | Cord Management Systems |

|---|---|---|---|

| Performance | High; retracts automatically, reducing tangles and wear. | Variable; prone to tangling and damage. | Moderate; depends on design; can be effective in organized settings. |

| Cost | Higher upfront cost, but reduces long-term replacement costs. | Lower initial cost, but may require frequent replacements. | Mid-range; initial setup can be costly, but offers long-term savings. |

| Ease of Implementation | Simple installation; mounts to walls or ceilings. | Very easy to use; no installation required. | May require professional installation for optimal setup. |

| Maintenance | Low; minimal upkeep required. | Moderate; needs periodic checks for wear. | Low to moderate; depends on the complexity of the system. |

| Best Use Case | Ideal for workshops, garages, and areas with heavy equipment. | Suitable for home or temporary setups. | Best for environments where cord organization is critical, like offices or large facilities. |

What Are the Pros and Cons of Traditional Extension Cords?

Traditional extension cords are widely used due to their affordability and ease of access. They can be plugged directly into a power source without the need for installation, making them a convenient option for temporary setups. However, their performance is limited as they can easily become tangled or damaged over time, leading to potential safety hazards. Additionally, constant handling can result in wear and tear, necessitating frequent replacements, which can increase long-term costs.

Illustrative image related to automatic extension cord reel

How Do Cord Management Systems Compare?

Cord management systems offer a structured approach to organizing multiple cords within a workspace. These systems can include cable trays, clips, and ties designed to keep cords in place and out of the way, which can enhance safety and aesthetics. While they help prevent tangling and damage, their effectiveness is contingent upon proper installation and regular upkeep. The initial investment may be significant, but for organizations dealing with numerous cords, the system could yield substantial savings by reducing clutter and enhancing efficiency.

Conclusion: How Should B2B Buyers Choose the Right Solution?

In selecting the appropriate cord management solution, B2B buyers should assess their specific operational needs, budget, and workspace environment. The automatic extension cord reel excels in performance and ease of use, making it ideal for environments where heavy equipment is frequently used. Traditional extension cords may suffice for less demanding applications, while cord management systems are best suited for organized environments requiring a high degree of cord control. Ultimately, the decision should align with both immediate needs and long-term operational goals, ensuring that the chosen solution enhances productivity and safety.

Essential Technical Properties and Trade Terminology for automatic extension cord reel

What Are the Key Technical Properties of Automatic Extension Cord Reels?

Understanding the essential specifications of automatic extension cord reels is crucial for B2B buyers seeking reliable and efficient equipment. Here are some critical technical properties that should be considered:

-

Cord Gauge and Length

The cord gauge, typically ranging from 12 to 16 AWG (American Wire Gauge), indicates the thickness and capacity of the wire to handle electrical loads. A lower AWG number means a thicker wire, which is essential for high-power applications. The length of the cord, often available in options like 30 ft, 50 ft, or 100 ft, determines how far electrical power can be extended, impacting usability in various environments. -

Material Grade

The materials used in the construction of the reel and cord significantly influence durability and performance. High-quality, oil-resistant, and weather-resistant materials are essential for outdoor or industrial applications. The housing should ideally be impact-resistant to withstand harsh working conditions, ensuring longevity and reliability. -

Retractable Mechanism

A robust retractable mechanism, often featuring a self-leveling system, allows for smooth and even winding of the cord. This feature not only enhances usability but also minimizes wear and tear on the cord, reducing maintenance costs. Buyers should look for reels that lock the cord in increments, facilitating controlled extension. -

Safety Features

Safety is paramount in electrical equipment. Key safety features include circuit breakers that prevent overloads, grounded plugs for added protection, and power indicator lights. These features are vital for ensuring safe operation, particularly in commercial and industrial settings where the risk of electrical hazards is higher. -

Mounting Options

The versatility of mounting options, such as wall or ceiling installations, is critical for optimizing workspace efficiency. A swivel mounting bracket can enhance accessibility and ease of use, especially in dynamic work environments. -

Amperage Rating

The amperage rating, often specified as maximum amperage (e.g., 10A, 15A), indicates the maximum electrical load the reel can handle safely. Selecting a reel with the appropriate amperage rating for specific applications is crucial for avoiding electrical failures or hazards.

What Are Common Trade Terms Related to Automatic Extension Cord Reels?

Familiarity with industry jargon can streamline purchasing and negotiation processes for B2B buyers. Here are some common terms used in the automatic extension cord reel market:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify quality products and establish reliable supply chains. -

MOQ (Minimum Order Quantity)

MOQ specifies the smallest quantity of a product that a supplier is willing to sell. This term is significant for buyers as it influences inventory management and cost-efficiency in procurement. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. It is a critical tool for B2B buyers to compare pricing and terms across multiple suppliers. -

Incoterms (International Commercial Terms)

These terms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and delivery obligations. Familiarity with Incoterms helps mitigate risks and clarify contractual obligations in cross-border purchases. -

Lead Time

Lead time refers to the amount of time it takes for an order to be fulfilled after it has been placed. Understanding lead times is essential for effective project planning and inventory management. -

Certification Standards

Certification standards, such as cULus or CE marking, indicate that products meet specific safety and performance criteria. Compliance with these standards is crucial for ensuring product reliability and regulatory adherence.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when purchasing automatic extension cord reels, ultimately leading to improved operational efficiency and safety.

Navigating Market Dynamics and Sourcing Trends in the automatic extension cord reel Sector

What Are the Current Market Dynamics and Key Trends in the Automatic Extension Cord Reel Sector?

The automatic extension cord reel market is experiencing robust growth driven by the increasing demand for efficient power solutions across various industries. The expansion of sectors such as construction, manufacturing, and automotive, particularly in emerging economies like Brazil, Nigeria, and across the Middle East, highlights a significant shift towards automated and user-friendly equipment. These regions are witnessing a rise in infrastructure projects and industrial activities, necessitating reliable power supply solutions. As businesses seek to enhance operational efficiency, the incorporation of retractable and automatic extension cord reels becomes paramount.

Additionally, technological advancements are shaping the market dynamics. Features such as self-leveling mechanisms, integrated circuit breakers, and oil-resistant cords are becoming standard, meeting the needs of heavy-duty applications. The trend toward smart technology integration, including remote control and IoT connectivity, is also gaining traction, enabling businesses to monitor and manage power usage effectively. For B2B buyers, understanding these technological trends is critical to sourcing products that align with their operational requirements and enhance productivity.

How Is Sustainability Influencing Sourcing Decisions in the Automatic Extension Cord Reel Market?

Sustainability is increasingly becoming a focal point for B2B buyers in the automatic extension cord reel sector. The environmental impact of manufacturing processes and product life cycles is under scrutiny, prompting companies to adopt more responsible sourcing practices. Buyers are prioritizing suppliers who demonstrate a commitment to sustainability through ethical supply chains and eco-friendly materials. This shift not only aligns with global environmental goals but also resonates with consumers who are increasingly demanding sustainable products.

Illustrative image related to automatic extension cord reel

Moreover, certifications such as Energy Star and RoHS (Restriction of Hazardous Substances) are becoming essential in the procurement process. These certifications ensure that products meet specific environmental standards, which can significantly enhance a company’s reputation and appeal in the marketplace. B2B buyers are encouraged to evaluate potential suppliers based on their sustainability practices, including the use of recyclable materials and energy-efficient manufacturing processes. This focus on green sourcing not only contributes to environmental conservation but also presents opportunities for businesses to differentiate themselves in competitive markets.

What Is the Evolution of Automatic Extension Cord Reels and Its Relevance to Current B2B Trends?

The evolution of automatic extension cord reels has been marked by significant technological advancements and a growing understanding of user needs. Initially, extension cords were simple, unwieldy tools that posed safety risks and were challenging to manage. The introduction of retractable designs revolutionized this market, allowing for more organized and safer use in various settings.

As industries have evolved, so too have the demands placed on these products. The contemporary automatic extension cord reel now incorporates features such as overload protection, multiple outlets, and compatibility with heavy-duty applications. This evolution is crucial for B2B buyers as it reflects a broader trend towards automation and efficiency in industrial settings. Understanding this historical context enables buyers to make informed decisions about which products will best serve their operational needs while ensuring safety and reliability.

In conclusion, the automatic extension cord reel market presents a dynamic landscape for international B2B buyers. By staying informed about current trends, sustainability considerations, and the historical evolution of these products, businesses can strategically source solutions that not only meet their immediate operational needs but also align with long-term sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of automatic extension cord reel

-

How do I choose the right automatic extension cord reel for my business needs?

Selecting the right automatic extension cord reel involves assessing your specific power requirements, work environment, and the type of equipment you will be using. Consider factors such as the reel’s cord length, gauge, and amperage rating to ensure it meets the demands of your applications. Additionally, evaluate the reel’s features, such as overload protection, retraction mechanism, and durability, especially if it will be used in harsh conditions. It’s also advisable to consult with suppliers about customization options to better fit your operational needs. -

What are the key features to look for in an automatic extension cord reel?

When sourcing an automatic extension cord reel, prioritize features such as a self-leveling retraction system, adjustable cord stopper, and built-in circuit breakers for safety. Consider reels with oil-resistant and weather-resistant cords for outdoor use or industrial environments. Also, check for multiple outlet configurations and power indicators for enhanced functionality. Lastly, ensure that the reel has a robust mounting system for stability and ease of use in your workspace. -

What is the typical lead time for ordering automatic extension cord reels internationally?

Lead times for international orders of automatic extension cord reels can vary significantly based on factors such as the supplier’s location, production capacity, and shipping methods. Generally, expect lead times of 4 to 12 weeks, which includes manufacturing and shipping. It is crucial to discuss timelines with your supplier during the negotiation phase to align with your project schedules and ensure timely delivery. -

How can I ensure the quality of automatic extension cord reels from suppliers?

To ensure the quality of automatic extension cord reels, conduct thorough supplier vetting by checking certifications, product reviews, and references. Request samples for testing before placing a bulk order, and inquire about the supplier’s quality assurance processes, including any guarantees or warranties. Additionally, consider suppliers that comply with international safety standards, which can provide an extra layer of confidence in their product reliability. -

What are the minimum order quantities (MOQs) for automatic extension cord reels?

Minimum order quantities (MOQs) for automatic extension cord reels typically range from 50 to 200 units, depending on the supplier and product specifications. Some suppliers may offer lower MOQs for customized products, while others may require higher quantities for bulk pricing. It’s beneficial to negotiate MOQs with suppliers, particularly if you are exploring a long-term partnership or require a variety of models. -

What payment terms should I expect when sourcing automatic extension cord reels?

Payment terms can vary widely among suppliers but commonly include options such as a deposit upfront (typically 30-50%) with the balance due upon shipment or delivery. Some suppliers may offer net payment terms (e.g., net 30 or net 60) for established businesses. Be sure to discuss and agree upon payment terms before finalizing your order to avoid any misunderstandings and ensure a smooth transaction. -

How do I handle logistics and shipping for international orders of automatic extension cord reels?

Handling logistics for international orders involves coordinating with freight forwarders to determine the best shipping methods, which can include air freight for speed or ocean freight for cost-effectiveness. Ensure that you understand the customs regulations and duties applicable in your destination country. Collaborate with your supplier to prepare all necessary documentation, such as commercial invoices and packing lists, to streamline the customs clearance process. -

Can I customize the design or features of an automatic extension cord reel?

Many manufacturers offer customization options for automatic extension cord reels, allowing you to specify features such as cord length, gauge, outlet configurations, and color. Customization may also include branding options for your company logo. It’s advisable to discuss your specific requirements with potential suppliers to determine the feasibility, associated costs, and impact on lead times for customized orders.

Top 5 Automatic Extension Cord Reel Manufacturers & Suppliers List

1. Flexzilla – Pro Retractable Extension Cord Reel

Domain: flexzilla.com

Registered: 2008 (17 years)

Introduction: Pro Retractable Extension Cord Reel SKU: FZ8120603

– Pre-loaded with 60 feet of cord

– Lighted triple tap outlet

– Grounded 4.5 foot lead-in cord

– 12 gauge oil resistant cord, flexible in low temperatures

– Self-leveling system for even winding

– Circuit breaker with reset button

– Adjustable cord stopper

– Power indicator light

– Cord locks out in 2 foot increments

– Swivel mounting bracket for …

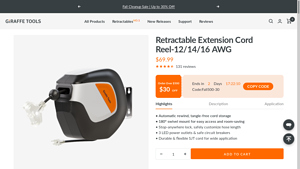

2. Giraffe Tools – Retractable Extension Cord Reel

Domain: giraffetools.com

Registered: 2018 (7 years)

Introduction: Retractable Extension Cord Reel available in 12AWG-50ft, 14AWG-50ft, and 16AWG-40ft options.

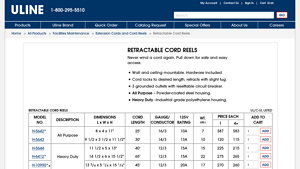

3. ULINE – Retractable Cord Reels

Domain: uline.com

Registered: 1995 (30 years)

Introduction: Retractable Cord Reels – ULINE

– Features: Never wind a cord again, pull down for safe and easy access, wall and ceiling mountable, hardware included, cord locks to desired length, retracts with slight tug.

– Outlets: 3 grounded outlets with resettable circuit breaker.

– Housing: All Purpose – Powder-coated steel housing; Heavy Duty – Industrial grade polyethylene housing.

– UL/C-UL Listed.

Model…

4. KH Industries – Retractable Cord Reels

Domain: khindustries.com

Registered: 2002 (23 years)

Introduction: Retractable Cord Reels for Industrial & Commercial Use; Available in various colors, amps, and standards; Options include small retractable power cord reels for indoor applications and heavy duty extension cord reels for harsh outdoor conditions; Amperage options: Up to 15 Amp, 16-20 Amp, 21-25 Amp, 26-65+ Amp; Color options: Black, White, Yellow; Types: NEMA 3R, UL Listed, NEMA 2, NEMA 4, NEMA 4X…

5. Flexzilla – Retractable Cord Reel

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: User is looking for a retractable cord reel for their garage with a 12/3 cable, built to last. Recommendations include Reelcraft, known for quality and durability, and ReelWorks as a comparable option. User ultimately purchased a Flexzilla cord reel that uses 12 gauge wire with sjtow rating, priced around $150. User noted that Reelcraft is considered a high-end option, while other brands may vary …

Strategic Sourcing Conclusion and Outlook for automatic extension cord reel

In conclusion, the strategic sourcing of automatic extension cord reels offers significant advantages for businesses operating in diverse sectors, from construction to manufacturing. Key considerations include evaluating product specifications such as cord gauge, durability, and safety features, which directly impact the efficiency and safety of operations. Buyers must also recognize the importance of selecting reliable suppliers who provide quality assurance and after-sales support to enhance operational continuity.

Moreover, understanding regional market dynamics is crucial for buyers from Africa, South America, the Middle East, and Europe. Adapting sourcing strategies to local requirements—such as voltage standards and environmental conditions—can lead to better product performance and customer satisfaction. By leveraging strategic sourcing principles, businesses can minimize costs while maximizing productivity and safety.

Looking ahead, the demand for automatic extension cord reels is poised to grow, driven by the increasing need for flexible and efficient power solutions in various industries. We encourage international B2B buyers to engage with reputable manufacturers and distributors to explore innovative solutions that can support their operational goals. Investing in quality sourcing today will pave the way for enhanced operational success tomorrow.

Illustrative image related to automatic extension cord reel

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.