Unlocking Value: A Strategic Analysis of the Aluminum Trim Market

Introduction: Navigating the Global Market for aluminum trim

In the dynamic landscape of the global construction and design market, sourcing the right aluminum trim can pose a significant challenge for B2B buyers. The need for durable, low-maintenance, and aesthetically pleasing materials is paramount, especially in regions like Africa, South America, the Middle East, and Europe. This comprehensive guide on aluminum trim addresses these challenges head-on, offering insights into various types of aluminum trim, their applications across different industries, and critical factors for supplier vetting.

From window and door trim to specialized pieces for siding and decorative purposes, understanding the diverse options available is essential for making informed purchasing decisions. Additionally, the guide delves into cost considerations, helping buyers identify budget-friendly solutions without compromising quality. By providing actionable strategies for evaluating suppliers and understanding market trends, this guide empowers international B2B buyers to navigate the complexities of sourcing aluminum trim effectively.

With a focus on practical applications and strategic insights, this resource is designed to enhance your decision-making process, ensuring that you select the best aluminum trim products tailored to your project needs. Whether you’re looking to enhance residential properties or commercial projects, this guide will serve as a valuable tool in your sourcing journey.

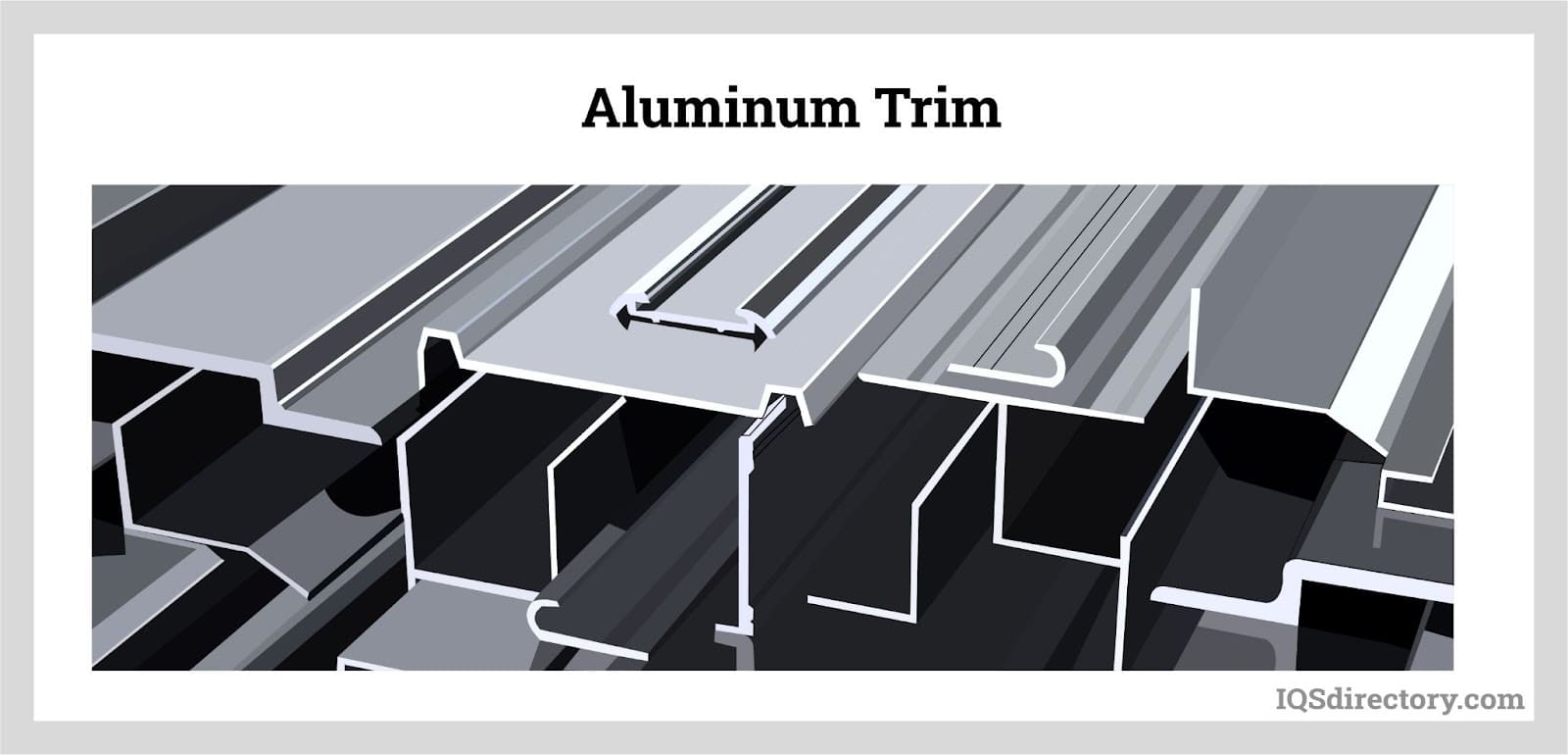

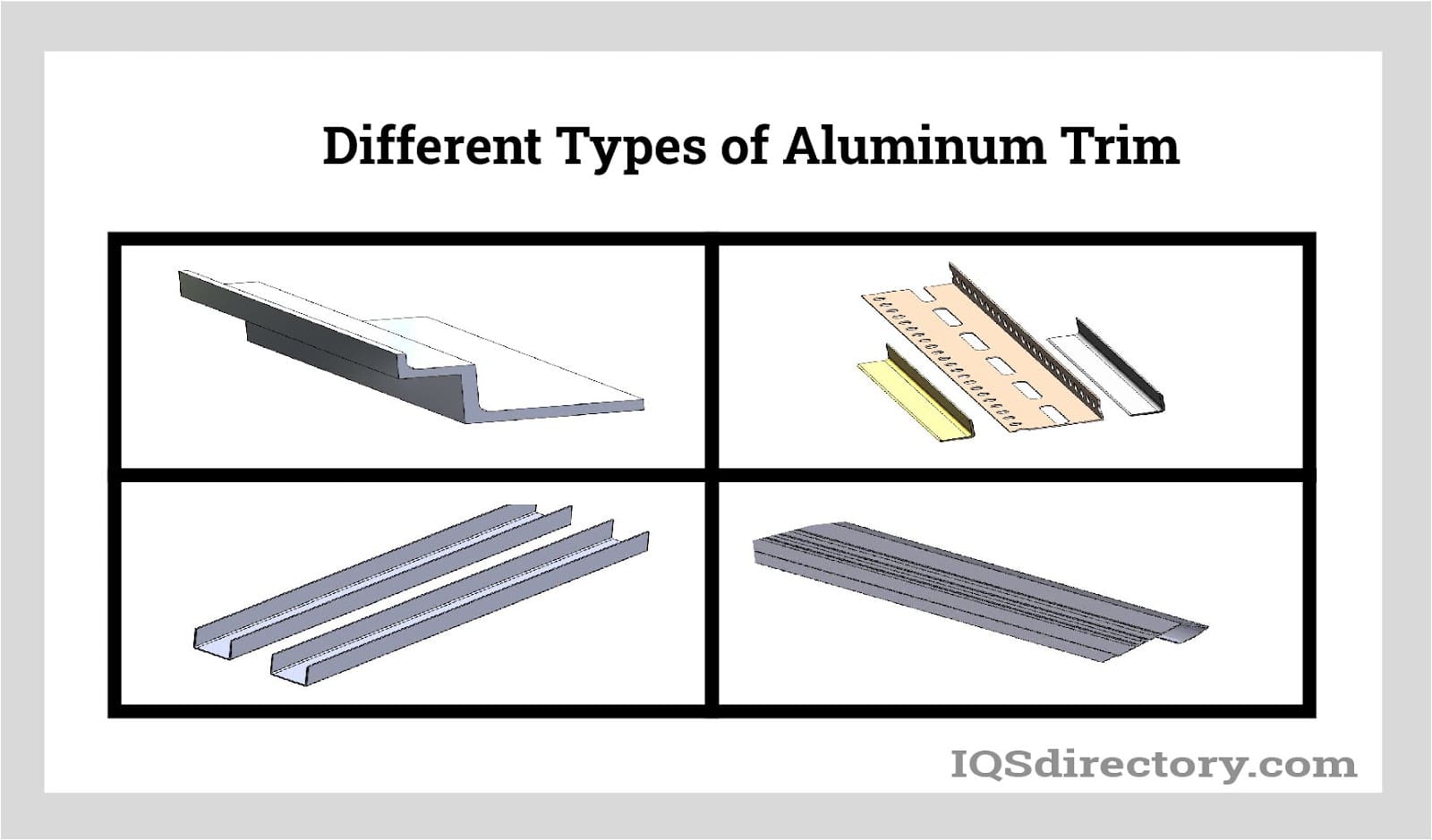

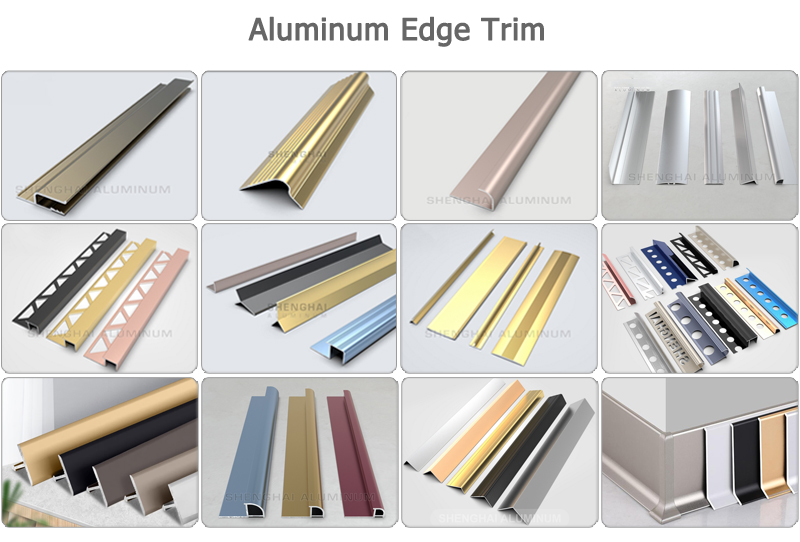

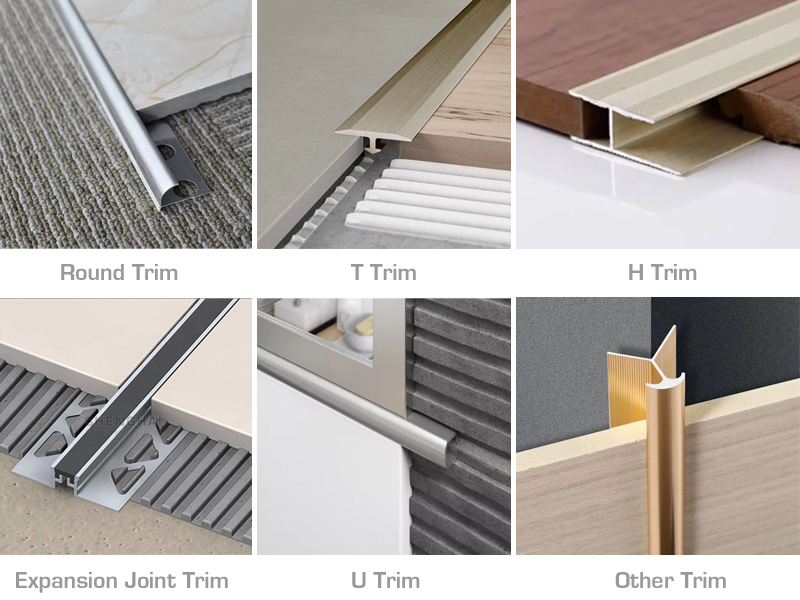

Understanding aluminum trim Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Aluminum Window Trim | Available in various colors, low maintenance | Residential and commercial window projects | Pros: Durable, professional finish. Cons: Limited customizability. |

| Aluminum Siding Trim | Includes J-channel, H-channel, and fascia options | Siding applications for buildings | Pros: Versatile, enhances aesthetics. Cons: May require specific installation techniques. |

| Aluminum Drip Cap | Designed to direct water away from structures | Roofing and eavestrough applications | Pros: Prevents water damage, easy to install. Cons: Potentially higher upfront cost. |

| Aluminum Brick Mold | Used for creating clean edges around brickwork | Masonry and facade applications | Pros: Durable, available in various sizes. Cons: Limited color options compared to other trims. |

| Aluminum Flat Stock | Flat, customizable sheets for various applications | Custom fabrication and detailing | Pros: Highly versatile, can be cut to size. Cons: Requires additional processing for specific uses. |

What are the Key Characteristics of Aluminum Window Trim?

Aluminum window trim is a popular choice for both residential and commercial projects due to its low maintenance requirements and durability. Available in a range of colors and finishes, including wood grain, it provides a professional appearance that lasts the lifetime of the windows. When considering purchasing, B2B buyers should evaluate the specific dimensions and color options available, as well as the ease of installation and compatibility with existing structures.

Illustrative image related to aluminum trim

How Does Aluminum Siding Trim Enhance Building Aesthetics?

Aluminum siding trim includes various profiles such as J-channel, H-channel, and fascia, making it suitable for a wide range of siding applications. This type of trim not only improves the overall aesthetics of a building but also protects against moisture infiltration. Buyers should consider the specific profiles needed for their projects, the available colors, and any installation requirements, as the wrong choice can impact both appearance and functionality.

Why is Aluminum Drip Cap Important for Roofing?

Aluminum drip caps are essential in directing water away from roofing structures, thereby preventing water damage and prolonging the lifespan of roofing materials. They are easy to install and can be customized for specific projects, making them a valuable investment for B2B buyers in the roofing industry. When purchasing, it’s crucial to assess the dimensions and design to ensure compatibility with existing roofing systems.

What Role Does Aluminum Brick Mold Play in Masonry?

Aluminum brick mold is primarily used to create clean, finished edges around brickwork, enhancing the visual appeal of masonry applications. It is available in various sizes and can be painted to match the surrounding structure. B2B buyers should evaluate the specific needs of their masonry projects, including size and finish options, as well as the durability and weather resistance required for their particular applications.

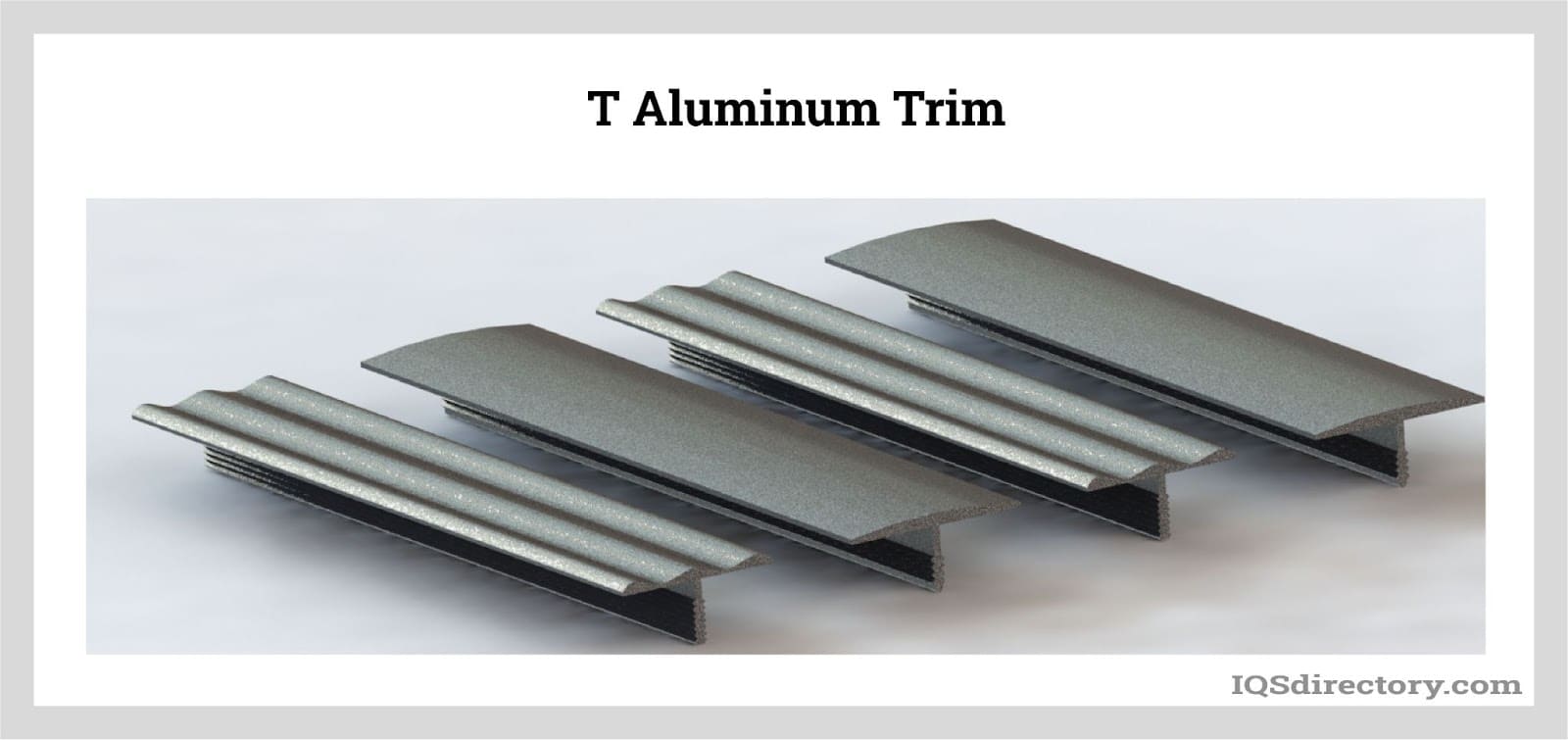

Illustrative image related to aluminum trim

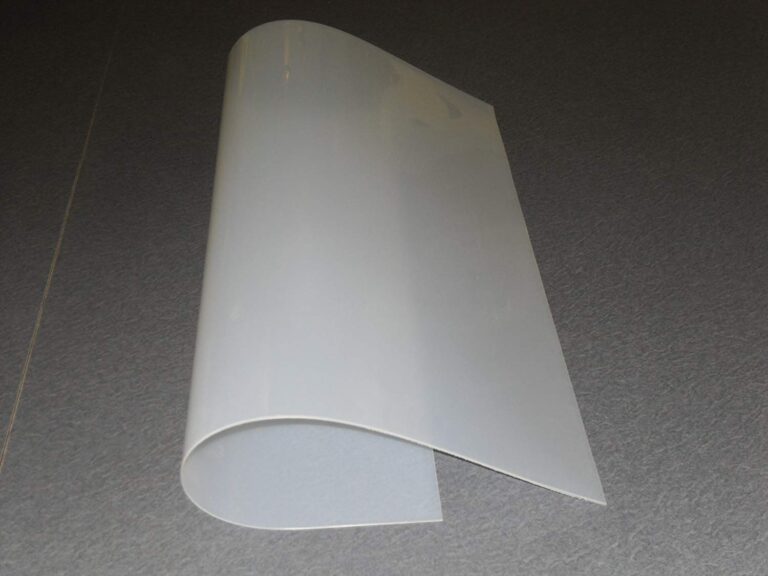

How Can Aluminum Flat Stock Be Utilized in Custom Fabrication?

Aluminum flat stock is a highly versatile option that can be used in a variety of applications, including custom fabrication and detailing. Buyers can order it in different thicknesses and lengths, allowing for tailored solutions that meet specific project requirements. When considering aluminum flat stock, it’s important for B2B buyers to focus on the intended use, the need for cutting or finishing, and overall budget constraints.

Key Industrial Applications of aluminum trim

| Industry/Sector | Specific Application of Aluminum Trim | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Building | Window and Door Trimming | Enhances aesthetic appeal while providing durability | Ensure compatibility with local building codes and standards. |

| Automotive Manufacturing | Edge Finishing for Vehicle Components | Improves safety and finish quality | Focus on weight specifications and corrosion resistance. |

| HVAC Systems | Ductwork and Ventilation Trim | Increases efficiency and reduces maintenance costs | Look for custom sizes to fit specific system requirements. |

| Furniture Manufacturing | Decorative Edging for Aluminum Furniture | Adds a modern touch while ensuring longevity | Consider color options and finishes that align with design themes. |

| Signage & Displays | Trim for Outdoor and Indoor Signage | Enhances visibility and protects signage integrity | Evaluate weather resistance and color retention properties. |

How is Aluminum Trim Used in Construction and Building Projects?

In the construction industry, aluminum trim is commonly utilized for window and door installations. It provides a low-maintenance, durable solution that enhances the aesthetic appeal of buildings. International buyers from regions like Africa and Europe often seek aluminum trim that meets local building codes, ensuring compliance with safety and quality standards. Additionally, the ability to customize colors and finishes allows for a professional look that can elevate property value.

What Role Does Aluminum Trim Play in Automotive Manufacturing?

In automotive manufacturing, aluminum trim is essential for edge finishing on various vehicle components. This application not only enhances the vehicle’s overall appearance but also contributes to safety by providing smooth, finished edges that reduce the risk of injuries. Buyers should prioritize sourcing materials that meet specific weight and corrosion resistance requirements, especially in regions with varying climates, such as South America and the Middle East.

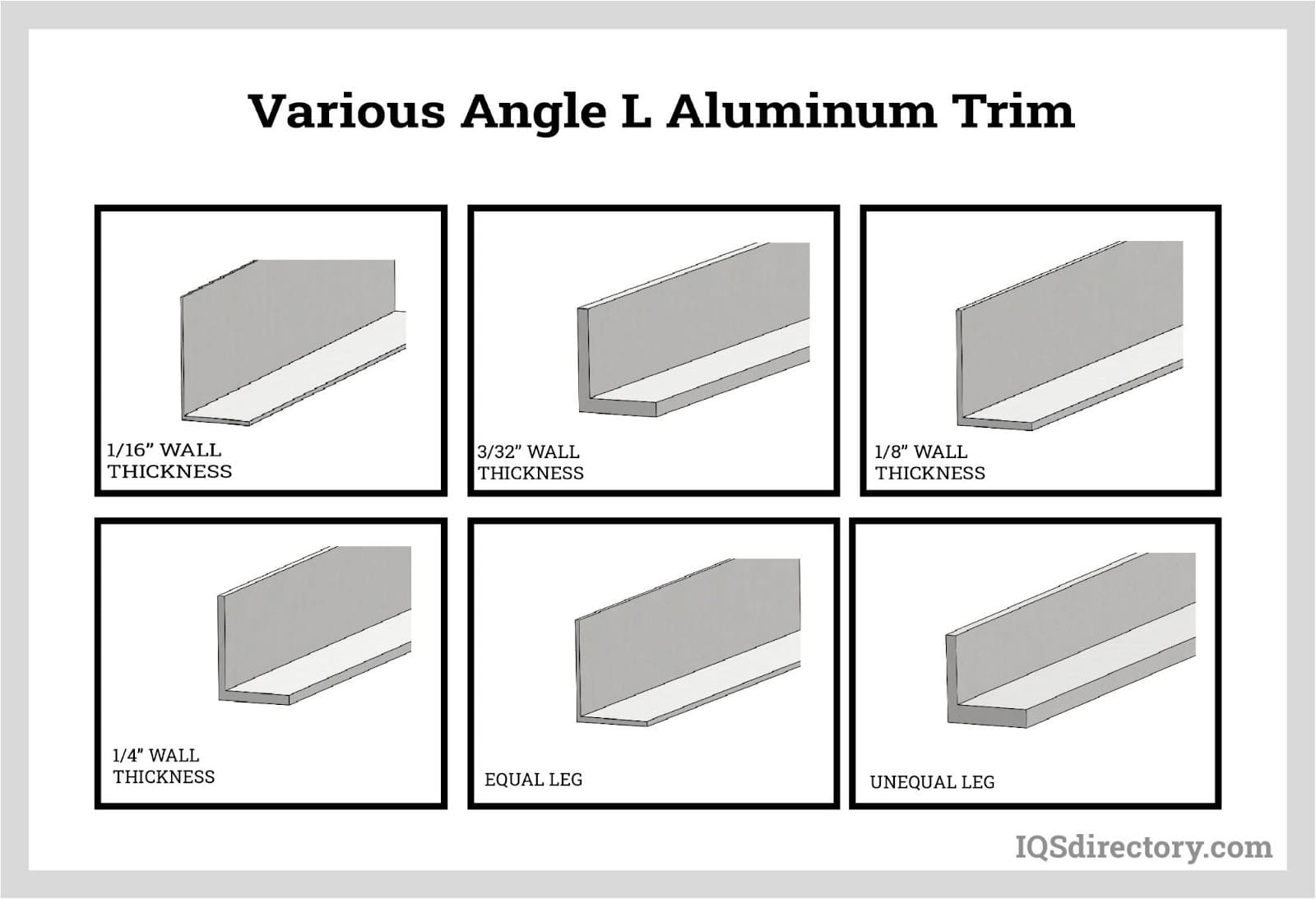

Illustrative image related to aluminum trim

Why is Aluminum Trim Important for HVAC Systems?

Aluminum trim is increasingly used in HVAC systems for ductwork and ventilation applications. It helps to improve system efficiency by providing a clean, finished look that minimizes air leaks and enhances overall performance. Buyers should consider sourcing custom sizes to fit their specific systems, ensuring that the trim integrates seamlessly with existing infrastructure. Additionally, understanding the local market’s preferences for durability and maintenance can guide sourcing decisions.

How is Aluminum Trim Utilized in Furniture Manufacturing?

In the furniture manufacturing sector, aluminum trim serves as decorative edging for aluminum furniture pieces, adding a modern touch while ensuring longevity. This application is particularly appealing to international buyers looking for stylish yet durable options. When sourcing aluminum trim for furniture, businesses should consider color options and finishes that align with current design trends, enabling them to meet customer demands effectively.

What Benefits Does Aluminum Trim Provide in Signage and Displays?

Aluminum trim is widely used in the signage and display industry for both outdoor and indoor applications. It enhances visibility while protecting the integrity of the signage from environmental elements. For international buyers, evaluating the weather resistance and color retention properties of aluminum trim is crucial, especially in regions with extreme weather conditions. This ensures that the signage remains appealing and functional over time, ultimately supporting brand visibility and recognition.

3 Common User Pain Points for ‘aluminum trim’ & Their Solutions

Scenario 1: Sourcing Quality Aluminum Trim for Diverse Projects

The Problem: B2B buyers often face challenges in sourcing high-quality aluminum trim that meets their specific project requirements. This is especially true when dealing with international suppliers, where varying standards and product specifications can lead to inconsistencies. Buyers may experience difficulties in assessing the durability, finish, and compatibility of the trim with existing materials, potentially resulting in costly delays and project overruns.

Illustrative image related to aluminum trim

The Solution: To ensure the procurement of quality aluminum trim, buyers should conduct thorough research on potential suppliers, focusing on those with established reputations in the industry. Requesting samples prior to bulk orders can be invaluable; it allows for hands-on assessment of product quality and finish. Additionally, buyers should specify their project needs clearly, including dimensions, finishes, and load-bearing requirements, which can help suppliers provide the most suitable options. Utilizing platforms that connect B2B buyers with vetted manufacturers can streamline this process, ensuring that the selected aluminum trim meets international standards and project specifications.

Scenario 2: Difficulty in Installation and Customization of Aluminum Trim

The Problem: Another common pain point for B2B buyers is the complexity involved in the installation and customization of aluminum trim. Many projects require specific cuts, bends, or finishes that standard products may not provide. This can lead to frustration among contractors and increased labor costs if modifications are needed on-site, which could compromise the timeline and budget of a project.

The Solution: To mitigate installation issues, it is advisable for buyers to work closely with suppliers who offer customization options. Many reputable manufacturers provide bespoke solutions tailored to unique project requirements. Buyers should take advantage of any available design consultation services that suppliers offer, allowing them to discuss their needs in detail and receive expert advice on how to achieve the desired outcome. Additionally, investing in training for installation teams on the best practices for working with aluminum trim can enhance efficiency and reduce errors during installation.

Scenario 3: Managing Long-Term Maintenance of Aluminum Trim

The Problem: While aluminum trim is often marketed as a low-maintenance solution, many B2B buyers encounter challenges with long-term upkeep. Issues such as fading, discoloration, and corrosion can arise, particularly in harsh climates, leading to unsightly appearances and the potential for premature replacement. Buyers may struggle to find reliable maintenance solutions that extend the life of their aluminum trim investments.

The Solution: To ensure longevity and maintain the aesthetic appeal of aluminum trim, buyers should implement a proactive maintenance strategy. This includes selecting high-quality finishes that are designed to withstand environmental stressors specific to the installation location, such as UV exposure or humidity. Regular cleaning schedules should be established, utilizing non-abrasive cleaners that prevent damage to the trim’s surface. Additionally, buyers can consult with manufacturers about protective coatings that can enhance durability and reduce maintenance needs. Engaging with local contractors who specialize in aluminum products for periodic inspections can also help identify and address potential issues before they escalate, ensuring that the trim remains in optimal condition over time.

Strategic Material Selection Guide for aluminum trim

When selecting aluminum trim materials for various applications, it is essential to analyze their properties, advantages, and limitations from a B2B perspective. This analysis will help international buyers make informed decisions based on their specific needs, compliance requirements, and market conditions.

What are the Key Properties of Common Aluminum Trim Materials?

1. Aluminum Alloy 6061

Aluminum alloy 6061 is one of the most commonly used materials for aluminum trim due to its excellent mechanical properties and corrosion resistance. It can withstand temperatures up to 150°C (302°F) and is known for its good weldability. This alloy is particularly suitable for applications requiring moderate to high strength.

Pros:

– High corrosion resistance, making it ideal for outdoor applications.

– Good machinability and weldability, which simplifies manufacturing processes.

– Relatively lightweight, reducing transportation costs.

Cons:

– Higher cost compared to other aluminum alloys.

– Limited performance at elevated temperatures over prolonged periods.

Impact on Application:

6061 is compatible with various media, including water and chemicals, making it suitable for both residential and industrial applications.

Considerations for International Buyers:

Compliance with standards such as ASTM B221 and EN 573 is crucial. Buyers in Europe and the Middle East may prefer this alloy due to its balance of strength and weight.

2. Aluminum Alloy 3003

Aluminum alloy 3003 is another popular choice for aluminum trim, known for its excellent corrosion resistance and formability. It is suitable for applications where moderate strength is sufficient.

Pros:

– Excellent corrosion resistance, particularly in marine environments.

– High workability allows for easy forming and fabrication.

– Cost-effective, making it a popular choice for budget-sensitive projects.

Cons:

– Lower strength compared to 6061, which may limit its use in structural applications.

– Not suitable for high-temperature applications.

Impact on Application:

3003 is compatible with various media but is primarily used in non-structural applications like decorative trim and siding.

Considerations for International Buyers:

Buyers should ensure compliance with standards like ASTM B209 and JIS H 4000. In regions like Africa and South America, the cost-effectiveness of this alloy can be a significant factor.

3. Aluminum Alloy 5052

Aluminum alloy 5052 offers higher strength than 3003 and is known for its excellent corrosion resistance, especially in marine environments. It can withstand temperatures up to 65°C (149°F).

Pros:

– High fatigue strength, making it suitable for dynamic applications.

– Excellent corrosion resistance, particularly against seawater.

– Good weldability and formability.

Illustrative image related to aluminum trim

Cons:

– More expensive than 3003, which may impact budget considerations.

– Limited machinability compared to 6061.

Impact on Application:

5052 is ideal for applications exposed to harsh environments, such as coastal areas, where durability is essential.

Considerations for International Buyers:

Compliance with ASTM standards is vital. Buyers in Europe may prefer this alloy for its durability in challenging climates.

Summary Table of Aluminum Trim Materials

| Material | Typical Use Case for aluminum trim | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Alloy 6061 | Structural applications, window trim | High strength and corrosion resistance | Higher cost than other alloys | High |

| Aluminum Alloy 3003 | Decorative trim, siding, non-structural | Excellent workability and cost-effective | Lower strength limits application | Low |

| Aluminum Alloy 5052 | Marine applications, dynamic environments | High fatigue strength and corrosion resistance | More expensive than 3003 | Medium |

By carefully considering these materials and their properties, international B2B buyers can make strategic decisions that align with their project requirements and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for aluminum trim

What Are the Main Stages in the Manufacturing Process of Aluminum Trim?

The manufacturing of aluminum trim involves a series of well-defined stages that ensure quality and precision in the final product. These stages typically include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with the selection of high-quality aluminum alloys, which are often chosen for their strength, corrosion resistance, and lightweight properties. These alloys are then cut to specific dimensions and undergo surface treatments to remove impurities and enhance adhesion for subsequent processes.

-

Forming Techniques: Once the aluminum sheets are prepared, they undergo various forming techniques such as extrusion, bending, and stamping. Extrusion involves forcing the aluminum through a die to create long shapes with consistent profiles, while bending allows for the creation of angles and curves. Stamping is used for producing specific shapes and designs, often utilizing precision dies to ensure accuracy.

-

Assembly: After forming, the aluminum components may require assembly, especially for trim pieces that include multiple parts. This stage often involves welding, riveting, or using adhesive bonding to ensure a strong and durable connection between components.

-

Finishing Processes: The final stage is finishing, where the aluminum trim is coated, painted, or anodized. Coating provides additional protection against environmental factors, while anodizing enhances corrosion resistance and allows for a variety of aesthetic finishes. This stage is crucial for achieving the desired appearance and durability of the trim.

How Is Quality Assurance Implemented in Aluminum Trim Manufacturing?

Quality assurance (QA) in aluminum trim manufacturing is critical to ensure that products meet both customer expectations and international standards. The QA process typically encompasses several key components, including adherence to international standards, established checkpoints, and testing methods.

-

International and Industry-Specific Standards: Many manufacturers adhere to international standards such as ISO 9001, which outlines requirements for a quality management system. Additionally, industry-specific certifications like CE (Conformité Européenne) for products sold in Europe or API (American Petroleum Institute) for certain industrial applications are often pursued. These certifications help ensure that products are safe, reliable, and of high quality.

-

Quality Control Checkpoints: Effective QA processes incorporate several checkpoints throughout the manufacturing lifecycle. Incoming Quality Control (IQC) checks raw materials for compliance with specifications. In-Process Quality Control (IPQC) monitors the manufacturing process to identify any deviations in real-time, while Final Quality Control (FQC) involves comprehensive inspections of the finished products before they are shipped. This multi-tiered approach helps identify defects early and reduces the risk of faulty products reaching the market.

-

Common Testing Methods: Various testing methods are employed to validate the quality of aluminum trim. These may include tensile strength tests, corrosion resistance tests, and dimensional inspections. Non-destructive testing methods, such as ultrasonic testing, are also used to assess the integrity of welds and joints without compromising the material.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those from regions such as Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is essential to mitigate risks associated with procurement.

-

Supplier Audits: Conducting on-site audits of suppliers can provide valuable insights into their quality management systems. During these audits, buyers should assess the supplier’s adherence to international standards, evaluate their manufacturing processes, and review their quality control documentation.

-

Requesting Quality Reports: Suppliers should be able to provide detailed quality reports that outline their QA processes, testing results, and any certifications obtained. Buyers should review these documents to ensure that the supplier meets the required standards.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of a supplier’s quality practices. These inspections can be scheduled at various stages of production, providing assurance that the products conform to the agreed-upon specifications.

What Are the Quality Control Nuances for International Buyers?

When sourcing aluminum trim from international suppliers, buyers must consider specific nuances related to quality control that may vary by region or country.

-

Understanding Local Regulations: Buyers should be aware of local regulations and standards that may apply to aluminum products in their target markets. For instance, European buyers must ensure compliance with the CE marking requirements, while buyers in the Middle East may need to adhere to specific Gulf standards.

-

Cultural Differences in Quality Perception: Quality expectations can vary significantly between regions. For example, European manufacturers may prioritize aesthetic finishes and precision, while suppliers in other regions may focus more on functionality and cost. Buyers should communicate their specific quality requirements clearly to avoid misunderstandings.

-

Logistics and Supply Chain Considerations: The quality of aluminum trim can also be affected by transportation and handling during shipping. Buyers should ensure that suppliers have robust packaging and logistics practices to minimize the risk of damage during transit. This includes using appropriate materials to protect the trim from moisture, impact, and other environmental factors.

Conclusion

Understanding the manufacturing processes and quality assurance practices for aluminum trim is crucial for B2B buyers looking to procure high-quality products. By familiarizing themselves with the stages of production, quality control measures, and verification processes, buyers can make informed decisions and establish successful partnerships with suppliers. This knowledge not only enhances procurement strategies but also contributes to achieving long-term business objectives in the competitive aluminum trim market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘aluminum trim’

Introduction

Sourcing aluminum trim for your projects requires a structured approach to ensure quality, durability, and cost-effectiveness. This guide provides a step-by-step checklist designed for B2B buyers, enabling you to make informed decisions when procuring aluminum trim. By following these steps, you can streamline the sourcing process and enhance your project’s overall success.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s essential to clearly outline your technical requirements. Specify the type of aluminum trim needed, including dimensions, finishes, and any particular design elements. This clarity will help you communicate effectively with suppliers and ensure that the products meet your project’s specific needs.

- Considerations:

- Identify the application (e.g., window trim, siding).

- Determine the necessary thickness and alloy type based on environmental factors.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in aluminum trim. Look for manufacturers and distributors with a solid reputation in the industry. Utilize online marketplaces, trade shows, and industry directories to compile a list of candidates.

- Tips:

- Check for supplier reviews and ratings from previous clients.

- Focus on suppliers with experience serving your target markets in Africa, South America, the Middle East, and Europe.

Step 3: Evaluate Supplier Certifications

Ensure that your potential suppliers possess the necessary certifications to guarantee product quality and compliance with international standards. Certifications such as ISO 9001, ASTM, or specific regional quality standards can be indicators of a supplier’s credibility.

- Why It Matters:

- Certifications can help mitigate risks associated with product defects and compliance issues.

- They demonstrate the supplier’s commitment to quality management and customer satisfaction.

Step 4: Request Samples for Quality Assessment

Before placing a bulk order, request samples of the aluminum trim to evaluate the quality firsthand. This step allows you to inspect the material’s finish, durability, and overall craftsmanship.

- What to Look For:

- Assess the color accuracy and texture consistency.

- Verify that the samples meet your technical specifications.

Step 5: Negotiate Pricing and Payment Terms

Once you’ve narrowed down your supplier options, engage in negotiations to secure the best pricing and favorable payment terms. Consider factors such as order volume, delivery timelines, and any potential discounts for bulk purchases.

- Key Points:

- Ensure that the pricing aligns with your budget and market standards.

- Discuss payment methods that offer security for both parties.

Step 6: Verify Delivery and Logistics Capabilities

Confirm that your chosen supplier has reliable logistics and delivery capabilities. Timely delivery is crucial to maintaining project schedules, so inquire about their shipping processes and lead times.

Illustrative image related to aluminum trim

- Important Questions:

- What shipping methods do they use, and what are the expected delivery times?

- Are there provisions for handling delays or damages during transit?

Step 7: Establish a Clear Communication Plan

Finally, set up a communication plan with your supplier to ensure smooth collaboration throughout the procurement process. Regular updates on order status, potential issues, and feedback channels can enhance transparency and foster a strong business relationship.

- Best Practices:

- Designate a primary contact person for both parties.

- Schedule regular check-ins to discuss progress and address any concerns.

By following this checklist, you can effectively navigate the sourcing process for aluminum trim, ensuring that you select the right suppliers and products to meet your project requirements.

Comprehensive Cost and Pricing Analysis for aluminum trim Sourcing

What Are the Key Cost Components of Aluminum Trim Sourcing?

When considering the sourcing of aluminum trim, it’s crucial to understand the various cost components that contribute to the final pricing. The primary cost elements include:

Illustrative image related to aluminum trim

-

Materials: The type of aluminum used directly impacts cost. Higher-grade aluminum alloys may command a premium due to their durability and resistance to corrosion. Additionally, the finish (e.g., anodized, painted) also affects material costs.

-

Labor: Labor costs vary significantly depending on the region and the complexity of the trim pieces. Automated processes may reduce labor costs, but highly customized products will typically require skilled labor, thus increasing expenses.

-

Manufacturing Overhead: This includes the indirect costs associated with production, such as utilities, rent, and equipment maintenance. Manufacturers often pass these costs onto buyers, especially in regions where operational costs are higher.

-

Tooling: Custom tooling for specific trim designs can be a significant upfront cost. This investment is often amortized over the production volume, making it essential for buyers to consider their order size.

-

Quality Control (QC): Implementing stringent QC measures ensures product reliability, which can add to costs but is essential for maintaining standards, particularly for international buyers who may have strict compliance requirements.

-

Logistics: Shipping costs can vary widely based on the distance from the supplier, shipping method, and associated tariffs. International buyers should factor in these logistics costs when evaluating total expenditure.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure viability. This margin can vary based on competition, demand, and the supplier’s market position.

What Influences the Pricing of Aluminum Trim?

Several factors play a crucial role in determining the pricing of aluminum trim:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often provide discounts for larger orders. Understanding the MOQ can help buyers negotiate better terms, especially when planning future projects.

-

Specifications and Customization: Custom designs and specific performance requirements can significantly increase costs. Buyers should assess whether standard products meet their needs or if customization is essential.

-

Material Quality and Certifications: Products that meet specific industry standards or certifications (e.g., ISO, ASTM) may carry a premium. Buyers should ensure that the materials meet their requirements without overpaying for unnecessary certifications.

-

Supplier Factors: The supplier’s reputation, location, and production capabilities can influence pricing. Established suppliers with robust quality control processes may charge more but offer better reliability.

-

Incoterms: The agreed-upon Incoterms can greatly affect the total cost, as they define the responsibilities of buyers and sellers in shipping and logistics. Understanding these terms can help avoid unexpected costs.

How Can Buyers Optimize Costs When Sourcing Aluminum Trim?

International B2B buyers can take several steps to enhance cost-efficiency in their aluminum trim sourcing:

-

Negotiation: Building relationships with suppliers can lead to better pricing and terms. Engaging in open discussions about cost structures can also help in negotiating discounts for larger orders.

-

Total Cost of Ownership (TCO): Rather than focusing solely on purchase price, buyers should consider TCO, which includes installation, maintenance, and potential disposal costs. A slightly higher upfront cost may lead to lower long-term expenses.

-

Pricing Nuances for International Buyers: Buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import duties, and regional pricing strategies that can affect overall costs. Additionally, understanding local market conditions can provide leverage during negotiations.

In conclusion, a comprehensive understanding of the cost components, pricing influencers, and strategic buying practices is essential for B2B buyers in the aluminum trim market. By leveraging this knowledge, buyers can make informed decisions that lead to significant cost savings and optimized supply chain management.

Alternatives Analysis: Comparing aluminum trim With Other Solutions

In the realm of construction and design, selecting the right trim material can significantly impact both aesthetics and functionality. While aluminum trim is a popular choice due to its durability and low maintenance, several alternatives exist that may suit specific project requirements. This analysis compares aluminum trim against two viable alternatives: PVC trim and wood trim, highlighting their respective strengths and weaknesses.

Illustrative image related to aluminum trim

| Comparison Aspect | Aluminum Trim | PVC Trim | Wood Trim |

|---|---|---|---|

| Performance | Highly durable and weather-resistant; suitable for various climates | Resistant to moisture, rot, and insects; less durable than aluminum | Strong and aesthetically pleasing; susceptible to weather damage if untreated |

| Cost | Moderate; typically ranges from $1.50 to $3.00 per foot | Generally lower; ranges from $0.75 to $2.50 per foot | Higher initial cost; varies widely based on type and finish |

| Ease of Implementation | Requires specific tools for cutting and installation; may need professional help | Easy to handle and install; often DIY-friendly | Requires more skill for installation; may need additional finishing |

| Maintenance | Minimal upkeep; occasional cleaning required | Low maintenance; resistant to fading and cracking | Requires regular painting or sealing to protect from elements |

| Best Use Case | Ideal for high-traffic areas or harsh environments | Suitable for moisture-prone areas like bathrooms or exteriors | Best for traditional or rustic designs, often in residential settings |

What Are the Pros and Cons of PVC Trim as an Alternative to Aluminum Trim?

PVC trim offers significant advantages in specific applications, particularly in moisture-prone environments. Its resistance to rot and insects makes it an excellent choice for coastal or humid areas. Furthermore, PVC trim is lightweight, making it easier to install, even for DIY enthusiasts. However, it may not match the durability of aluminum in high-impact situations and can be less aesthetically appealing, especially in traditional designs.

How Does Wood Trim Compare to Aluminum Trim?

Wood trim is favored for its natural beauty and versatility, often enhancing the aesthetic appeal of residential and commercial properties. It provides a warm, inviting look that synthetic materials struggle to replicate. However, wood requires regular maintenance, including painting or sealing, to prevent weather-related deterioration. Additionally, its susceptibility to pests and environmental damage can lead to higher long-term costs, especially if frequent replacements are necessary.

How Can B2B Buyers Choose the Right Trim Solution for Their Needs?

When selecting a trim material, B2B buyers should consider the specific demands of their projects, including the environment, budget, and desired aesthetic. For projects in harsh climates or high-traffic areas, aluminum trim may be the best option due to its durability and low maintenance requirements. Conversely, for moisture-prone locations, PVC trim could provide a cost-effective and resilient solution. Meanwhile, wood trim can be an excellent choice for projects that prioritize aesthetics and traditional designs, provided that the buyer is prepared for the ongoing maintenance it requires. Ultimately, aligning the choice of trim with project specifications and long-term goals will ensure a successful outcome.

Essential Technical Properties and Trade Terminology for aluminum trim

What Are the Key Technical Properties of Aluminum Trim?

Understanding the essential technical properties of aluminum trim is critical for B2B buyers, especially when selecting materials for construction, renovation, or manufacturing projects. Here are some key specifications that should be considered:

-

Material Grade

Aluminum trim is typically categorized by its alloy composition, commonly including grades such as 6061 and 6063. Each grade has unique attributes regarding strength, corrosion resistance, and workability. For B2B buyers, selecting the appropriate grade ensures the durability and longevity of the trim in various applications. -

Thickness and Tolerance

The thickness of aluminum trim can range from 0.015 inches to 0.250 inches, with tolerances generally around ±0.005 inches. This specification is crucial, as it affects the trim’s structural integrity and aesthetic appeal. Buyers should ensure that the thickness meets the requirements of their specific application to prevent issues during installation. -

Finish Options

Aluminum trim can be offered in various finishes, including anodized, painted, or mill finish. Each finish has different aesthetic and performance characteristics, such as enhanced corrosion resistance or visual appeal. For B2B buyers, the right finish can significantly impact the product’s marketability and customer satisfaction. -

Color Availability

The color options for aluminum trim are extensive, ranging from standard white and brown to custom colors. This property allows businesses to match the trim with other architectural elements, thus enhancing the overall design. A diverse color palette can also provide a competitive advantage in markets where aesthetics are paramount. -

Weight

The lightweight nature of aluminum, typically around 2.7 g/cm³, is a significant property for transport and installation. A lighter product reduces shipping costs and simplifies handling, making it an appealing option for international buyers who need to consider logistics in their projects. -

Corrosion Resistance

Aluminum naturally forms a protective oxide layer, making it resistant to corrosion. This property is essential for outdoor applications or in environments with high humidity. For B2B buyers, understanding corrosion resistance helps in choosing the right trim for specific environmental conditions, ensuring long-term performance.

What Are Common Trade Terminology and Jargon Related to Aluminum Trim?

Familiarity with industry jargon is vital for effective communication and negotiation in the aluminum trim market. Here are some key terms that buyers should know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of aluminum trim, understanding OEM relationships can help buyers identify quality sources for their projects. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Knowing the MOQ helps buyers understand their purchasing limits and plan their budgets accordingly, which is particularly important for large-scale projects. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for pricing information on specific products or services. For B2B buyers, issuing RFQs is a common practice to compare offers and negotiate better terms with suppliers. -

Incoterms (International Commercial Terms)

These are predefined commercial terms used in international trade that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms is crucial for international buyers to mitigate risks and ensure smooth transactions. -

Lead Time

This term refers to the time it takes from placing an order to receiving the product. Knowing lead times is essential for project planning and ensures that deadlines are met. -

Custom Fabrication

This refers to the process of creating customized aluminum trim pieces based on specific requirements. For B2B buyers, the ability to order custom fabrications can provide flexibility in design and application, making it a valuable option in competitive markets.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions, enhancing their procurement processes and ensuring successful project outcomes.

Navigating Market Dynamics and Sourcing Trends in the aluminum trim Sector

What Are the Current Market Dynamics and Key Trends in the Aluminum Trim Sector?

The aluminum trim market is experiencing significant growth driven by several global factors. The ongoing urbanization and infrastructure development in emerging markets, particularly in Africa and South America, are fueling demand for durable, low-maintenance building materials. In Europe and the Middle East, there is a growing preference for energy-efficient and sustainable construction practices, which is further driving the use of aluminum trim products. The versatility of aluminum, coupled with its lightweight and corrosion-resistant properties, makes it an attractive option for both residential and commercial applications.

Emerging trends in B2B sourcing include the adoption of digital platforms that facilitate easier access to suppliers and products. Buyers are increasingly leveraging e-commerce platforms and online marketplaces to compare prices, check product availability, and place orders. This shift towards digital sourcing is accompanied by enhanced logistics capabilities, allowing for quicker delivery times and improved inventory management. Additionally, customization is becoming a critical factor as businesses seek tailored solutions to meet specific project requirements, such as custom sizes and finishes.

Furthermore, advancements in manufacturing technologies, including automation and precision engineering, are enhancing the quality and efficiency of aluminum trim production. As international buyers look for reliable suppliers, the ability to demonstrate compliance with quality standards and certifications will be crucial in establishing trust and fostering long-term partnerships.

How Is Sustainability and Ethical Sourcing Impacting the Aluminum Trim Market?

Sustainability is becoming a paramount consideration for B2B buyers in the aluminum trim sector. The environmental impact of aluminum production, particularly in terms of energy consumption and greenhouse gas emissions, has prompted a shift towards more sustainable practices. Buyers are increasingly prioritizing suppliers that adopt eco-friendly manufacturing processes, utilize recycled materials, and adhere to sustainability certifications.

Ethical sourcing is also gaining traction, as companies aim to ensure that their supply chains are transparent and responsible. This includes verifying that suppliers comply with labor laws and environmental regulations. Certifications such as LEED (Leadership in Energy and Environmental Design) and Cradle to Cradle are increasingly important for buyers looking to enhance their own sustainability credentials. By choosing aluminum trim products that carry these certifications, businesses not only contribute to environmental conservation but also strengthen their market position by aligning with consumer preferences for sustainable products.

Incorporating sustainable practices in sourcing can lead to long-term cost savings and improved brand reputation, making it a strategic priority for international buyers in the aluminum trim sector.

What Is the Historical Context of the Aluminum Trim Industry?

The aluminum trim industry has evolved significantly over the past few decades. Initially, the use of aluminum in construction was limited due to perceptions of high cost and limited aesthetic appeal. However, advancements in manufacturing techniques and the development of a wider range of finishes have transformed aluminum into a preferred material for trim applications.

The introduction of anodizing and powder-coating processes has allowed aluminum to offer a variety of colors and textures, making it more visually appealing. As building codes and consumer preferences shifted towards energy efficiency and sustainability, aluminum trim gained popularity for its durability and low maintenance requirements. Today, the aluminum trim market is a vital component of the broader construction industry, serving a diverse range of applications from residential homes to large commercial projects, reflecting a robust and ongoing evolution in response to market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of aluminum trim

1. How do I choose the right aluminum trim for my project?

Selecting the right aluminum trim depends on several factors, including the application, aesthetic preferences, and environmental conditions. Consider the trim’s size, thickness, and finish that align with your design specifications. For exterior applications, ensure the trim is weather-resistant and suitable for your climate. Additionally, review color options and custom finishes that might enhance the overall appearance of your project. Collaborating with suppliers who offer samples can help in making an informed decision.

2. What are the benefits of using aluminum trim over other materials?

Aluminum trim offers numerous advantages, including durability, low maintenance, and resistance to corrosion. Unlike wood, aluminum does not warp or rot, making it ideal for various climates. It is lightweight yet strong, facilitating easier installation and transportation. Additionally, aluminum is available in a wide range of colors and finishes, providing flexibility in design while maintaining a professional look. These benefits make aluminum trim a cost-effective long-term investment for B2B buyers.

3. What customization options are available for aluminum trim?

Customization options for aluminum trim often include size, shape, color, and finish. Many suppliers offer tailored solutions to meet specific project requirements. Custom lengths or profiles can be designed for unique architectural features. Additionally, you may request specific coatings for enhanced durability or aesthetic appeal. Discuss your needs with potential suppliers to understand their capabilities and ensure they can meet your customization requests.

4. What is the minimum order quantity (MOQ) for aluminum trim?

Minimum order quantities for aluminum trim can vary significantly by supplier and product type. Generally, MOQs can range from a few hundred to several thousand units. When sourcing aluminum trim, it’s essential to clarify the MOQ upfront to align with your project budget and scale. Some suppliers may offer flexibility for first-time buyers or smaller projects, so it’s worth negotiating if your order size is below the standard MOQ.

5. How can I ensure quality assurance when sourcing aluminum trim internationally?

To ensure quality assurance when sourcing aluminum trim, start by vetting suppliers thoroughly. Check for certifications, such as ISO 9001, which indicate adherence to quality management standards. Request product samples before placing large orders to evaluate material quality and finish. Additionally, consider implementing third-party inspections during production and before shipping to guarantee that the products meet your specifications and standards.

6. What payment terms should I expect when purchasing aluminum trim?

Payment terms for aluminum trim purchases can vary widely based on the supplier and the size of the order. Common terms include upfront payment, partial payment upon order confirmation, and balance payment prior to shipment. Some suppliers may offer credit terms for established businesses or larger orders. It’s important to negotiate terms that are favorable for your cash flow while ensuring the supplier feels secure in the transaction.

7. What are the logistics considerations for shipping aluminum trim internationally?

When shipping aluminum trim internationally, logistics considerations include shipping methods, lead times, and customs regulations. Choose a reliable freight forwarder who understands the nuances of international shipping and can handle documentation and customs clearance. Consider the weight and dimensions of the trim when selecting shipping methods, as these factors will affect costs. Additionally, be aware of any import duties or tariffs that may apply based on your country’s regulations.

8. How can I find reputable suppliers for aluminum trim in different regions?

Finding reputable suppliers for aluminum trim involves thorough research and networking. Utilize online marketplaces, trade directories, and industry-specific platforms to identify potential suppliers. Attend trade shows and exhibitions to meet suppliers in person and evaluate their offerings. Additionally, seek recommendations from industry peers or join professional associations that can connect you with trusted suppliers. Always conduct due diligence by reviewing company reviews and requesting references before finalizing partnerships.

Top 5 Aluminum Trim Manufacturers & Suppliers List

1. Trimbender – Custom Aluminum Drip Cap

Domain: trimbender.com

Registered: 2008 (17 years)

Introduction: Aluminum window trim for DIY projects, low maintenance, durable exterior trim solution, available in various colors, economical, professional finish. Wood grain finishes available in white and brown. Key products include: Custom Aluminum Drip Cap ($1.55), Aluminum Brick Mold Without Return ($1.85), Aluminum Brick Mold Trim ($1.85), Aluminum Brick Mold with Full Blind Stop ($1.95), Aluminum Flat Br…

2. Orange Aluminum – Edge Trims

Domain: orangealuminum.com

Registered: 2006 (19 years)

Introduction: Aluminum edge trims offer clean, protective finishing for exposed edges on panels, doors, countertops, and displays. Commonly used in cabinetry, architectural millwork, vehicle interiors, and commercial fixtures, they help prevent chipping, wear, and damage while delivering a polished, professional look. Lightweight, corrosion-resistant, and easy to install, these trims are ideal for adding durabi…

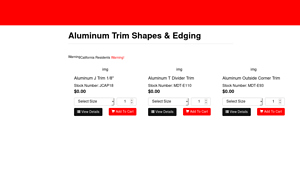

3. Metals Depot – Aluminum Trim Shapes & Edging Products

Domain: metalsdepot.com

Registered: 1999 (26 years)

Introduction: Aluminum Trim Shapes & Edging products include: 1. Aluminum J Trim – Stock Number: JCAP18, Available Sizes: 48″, 96″, 144″ 2. Aluminum T Divider Trim – Stock Number: MDT-E110, Available Sizes: 48″, 96″ 3. Aluminum Outside Corner Trim – Stock Number: MDT-E93, Available Sizes: 48″, 96″ 4. Aluminum Inside Corner Trim – Stock Number: MDT-E85, Available Sizes: 48″, 96″. Pricing is $0.00 for all items.

4. Eagle Aluminum – Stock Extrusions & Trims

Domain: eagle-aluminum.com

Registered: 2010 (15 years)

Introduction: Stock Aluminum Extrusions, Trims & Shapes including: Architectural Trims, Drywall Trims, Millwork Trims, Wallcovering Trims, Aluminum Z Clips, Dock/Decking/Bleacher products, Flat Bars, Floor/Carpet & Thresholds, Tubing, and Custom Extrusions. Various leg types (Equal and Unequal) and thicknesses available. Industries served include Architectural, Marine, Construction, and more.

5. Brand X – Extruded Aluminum Trims

Domain: brandxmetals.com

Registered: 2007 (18 years)

Introduction: Brand X Metals manufactures a wide variety of extruded aluminum trims designed for the lath, plaster, stucco, and drywall construction industry. Key features include:

– Made from 6063 aluminum alloy.

– Products designed for ease of installation and performance.

– Includes money-saving options like the Streamline Channel Reveal Trim and Eliminator Trim Reveal.

– Offers a selection of trims includin…

Strategic Sourcing Conclusion and Outlook for aluminum trim

What Are the Key Takeaways for Sourcing Aluminum Trim?

In summary, strategic sourcing of aluminum trim presents numerous advantages for international B2B buyers. The durability and low maintenance of aluminum make it an economical choice, especially in regions with diverse climatic conditions. Buyers should prioritize suppliers that offer customization options and a wide range of finishes to cater to specific project requirements, ensuring a professional and aesthetically pleasing outcome.

How Can Strategic Sourcing Enhance Your Competitive Edge?

By engaging in strategic sourcing, companies can secure favorable pricing and strengthen supply chain resilience. It is essential to assess potential suppliers not only on cost but also on their ability to deliver quality products consistently and adapt to changing market demands. Building strong partnerships with reliable suppliers can lead to long-term success and innovation in product offerings.

What Does the Future Hold for Aluminum Trim Markets?

Looking ahead, the demand for aluminum trim is expected to grow, driven by increased construction and renovation activities across Africa, South America, the Middle East, and Europe. B2B buyers are encouraged to stay informed about market trends and technological advancements in aluminum production to leverage these developments for competitive advantage. Embrace strategic sourcing today to unlock new opportunities and enhance your business’s operational efficiency.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.