Unlocking Value: A Strategic Analysis of the Ac Motor Parts Market

Introduction: Navigating the Global Market for ac motor parts

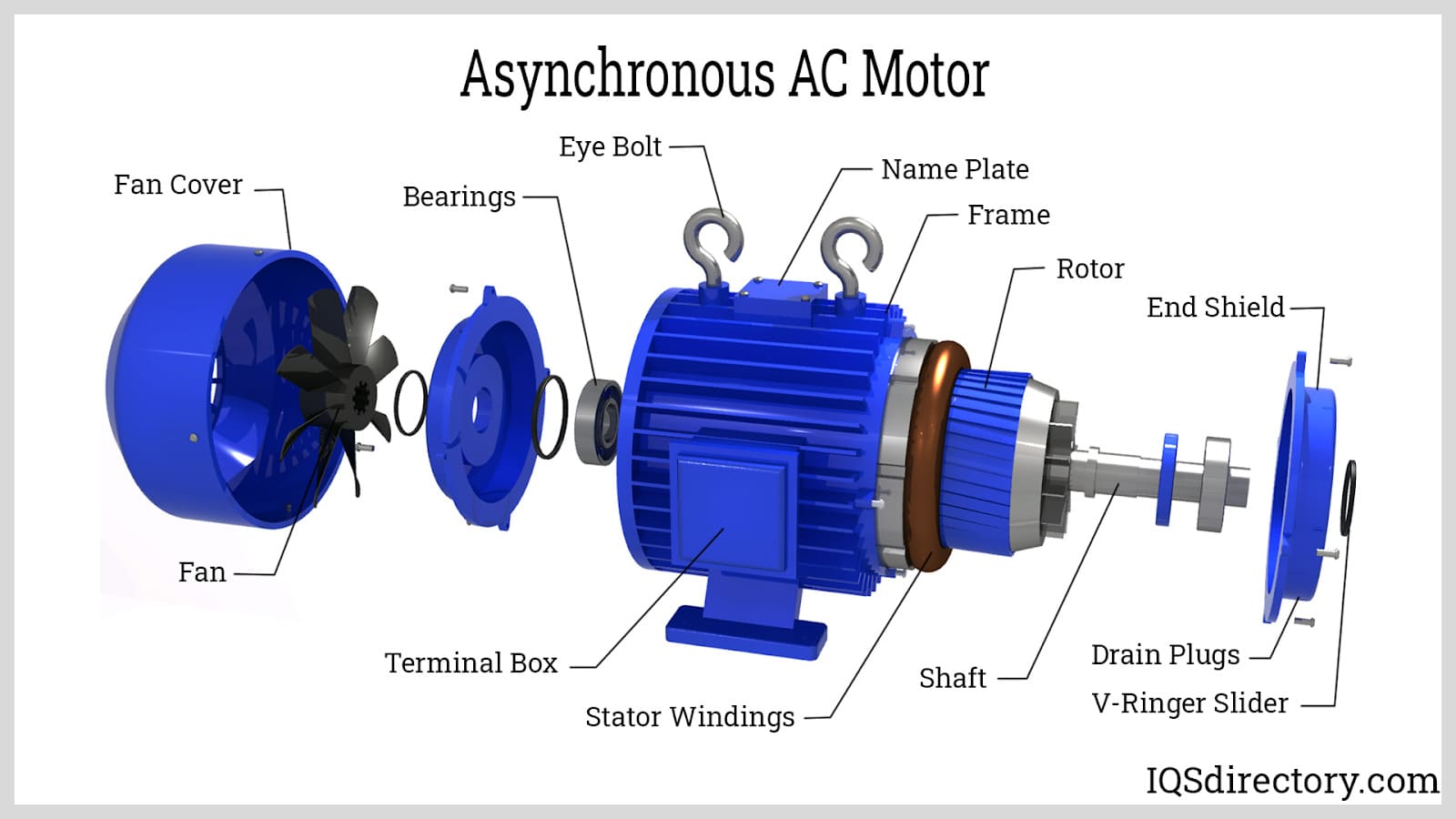

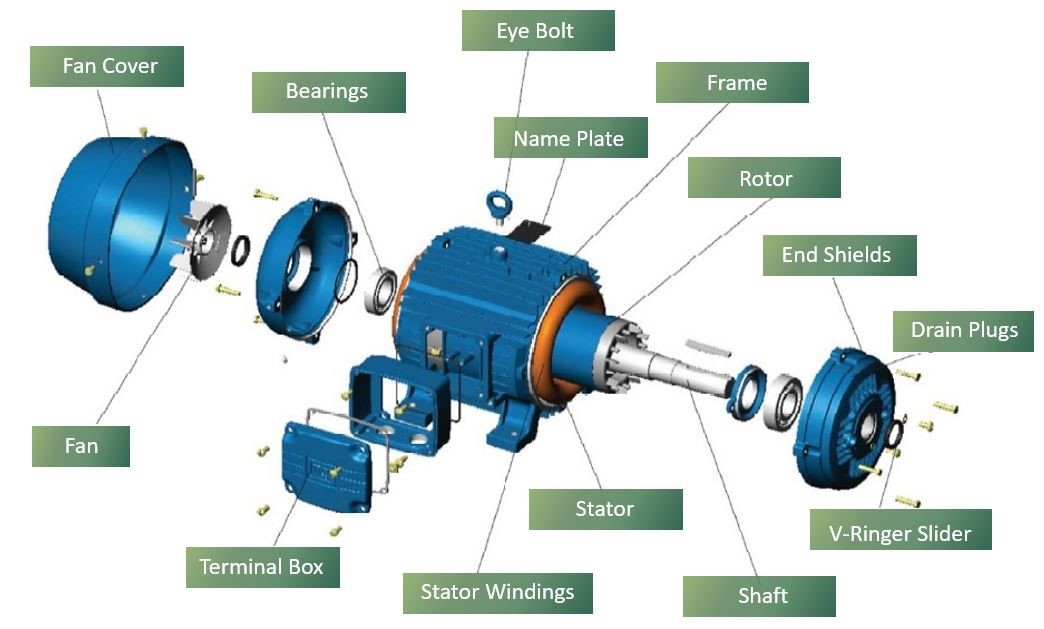

In today’s global market, sourcing high-quality AC motor parts can be a daunting challenge for B2B buyers, particularly those operating in diverse environments such as Africa, South America, the Middle East, and Europe. The sheer variety of components—ranging from stators and rotors to bearings and cooling systems—requires a comprehensive understanding of both the technical specifications and the marketplace dynamics. This guide is designed to equip international buyers with the essential knowledge to navigate this complex landscape, addressing key considerations such as types of AC motors, their applications across various industries, and the critical process of vetting suppliers.

Understanding the intricacies of AC motor components is vital for making informed purchasing decisions that not only meet operational needs but also adhere to budget constraints. Our guide delves into the nuances of cost structures, supplier reliability, and the importance of quality assurance, helping you mitigate risks associated with procurement. By highlighting best practices and providing actionable insights, we empower B2B buyers to enhance their purchasing strategies, ensuring that they can confidently source AC motor parts that align with their business objectives. Whether you are looking to optimize machinery in a manufacturing plant or improve energy efficiency in HVAC systems, this guide serves as your trusted resource for navigating the global market for AC motor parts.

Understanding ac motor parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Induction Motors | Operate using electromagnetic induction; typically asynchronous | Manufacturing, HVAC systems | Pros: Durable, low maintenance. Cons: Lower efficiency compared to synchronous motors. |

| Synchronous Motors | Rotate at synchronous speed; require an external power source for excitation | Robotics, precision applications | Pros: High efficiency, constant speed. Cons: More complex control systems needed. |

| Universal Motors | Operate on both AC and DC; high-speed capabilities | Power tools, small appliances | Pros: Versatile, compact size. Cons: Limited lifespan under continuous use. |

| Permanent Magnet Motors | Use permanent magnets for rotor excitation; compact design | Electric vehicles, robotics | Pros: High torque density, energy-efficient. Cons: Higher initial cost, sensitive to temperature. |

| Split-phase Motors | Utilize a starting winding for torque; simple design | Fans, pumps, small machinery | Pros: Cost-effective, easy to install. Cons: Limited starting torque, not suitable for heavy loads. |

What Are the Characteristics of Induction Motors and Their Suitability for B2B Applications?

Induction motors are the most common type of AC motors, widely used in industrial applications due to their robustness and simplicity. They function through electromagnetic induction, producing a rotating magnetic field that induces current in the rotor. Ideal for manufacturing and HVAC systems, these motors require minimal maintenance and are known for their durability. Buyers should consider the motor’s efficiency ratings and operational environment, as these factors can impact long-term performance.

How Do Synchronous Motors Stand Out in Precision Applications?

Synchronous motors are distinguished by their ability to run at a constant speed, synchronized with the supply frequency. This makes them particularly suitable for applications requiring precise control, such as robotics and conveyor systems. While they offer high efficiency and performance, the complexity of their control systems can pose challenges for some businesses. Buyers must evaluate their capacity for advanced control technologies when considering synchronous motors for their operations.

Why Choose Universal Motors for Versatile Applications?

Universal motors are designed to operate on both AC and DC power sources, making them highly versatile. Their compact size and ability to achieve high speeds make them ideal for power tools and small appliances. However, their lifespan can be limited under continuous use, which is an important consideration for buyers looking for long-term reliability. Businesses should assess their specific needs to determine if the flexibility of universal motors outweighs potential durability concerns.

What Advantages Do Permanent Magnet Motors Offer for Modern Technology?

Permanent magnet motors utilize magnets for rotor excitation, resulting in a compact design and high efficiency. They are increasingly used in electric vehicles and robotics due to their high torque density and energy-saving capabilities. However, these motors come with a higher initial cost and can be sensitive to temperature variations. B2B buyers should weigh the benefits of energy efficiency against the upfront investment when considering permanent magnet motors.

How Do Split-phase Motors Provide Cost-Effective Solutions for Small Machinery?

Split-phase motors are characterized by their simple design, which includes a starting winding to provide the necessary torque for startup. They are commonly found in fans, pumps, and small machinery, offering a cost-effective solution for many applications. However, their limited starting torque may not be suitable for heavier loads. Buyers should consider the specific requirements of their applications and the motor’s torque ratings to ensure optimal performance.

Key Industrial Applications of ac motor parts

| Industry/Sector | Specific Application of ac motor parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food & Beverage | Conveyor Systems for Processing and Packaging | Increases efficiency and reduces downtime | Ensure compliance with food safety standards |

| HVAC | Blower Motors for Air Conditioning Systems | Enhances energy efficiency and indoor air quality | Look for high-temperature tolerance and durability |

| Automotive | Electric Power Steering Systems | Improves vehicle control and safety | Focus on precision and reliability of components |

| Material Handling | Automated Guided Vehicles (AGVs) | Streamlines logistics and reduces labor costs | Assess compatibility with existing systems |

| Mining and Minerals | Hoisting and Lifting Equipment | Enhances safety and productivity in extraction | Verify load capacity and environmental resilience |

How Are AC Motor Parts Used in the Food & Beverage Industry?

In the food and beverage sector, AC motor parts are crucial for conveyor systems that transport raw materials and finished products through processing and packaging stages. These motors ensure consistent and efficient movement, minimizing downtime and maximizing throughput. Buyers should prioritize sourcing motors that meet stringent food safety standards, including materials that are resistant to corrosion and easy to clean. Reliability is essential to prevent disruptions in production, making quality assurance a key consideration.

Why Are AC Motors Essential for HVAC Applications?

AC motors are integral to HVAC systems, powering blower motors that circulate air in heating and cooling applications. These motors improve energy efficiency, which is vital for reducing operational costs in commercial buildings. International buyers should seek motors capable of operating in high-temperature environments, particularly in regions with extreme climates, such as the Middle East and parts of Africa. Durability and energy efficiency ratings should be top priorities to ensure long-term performance and compliance with local regulations.

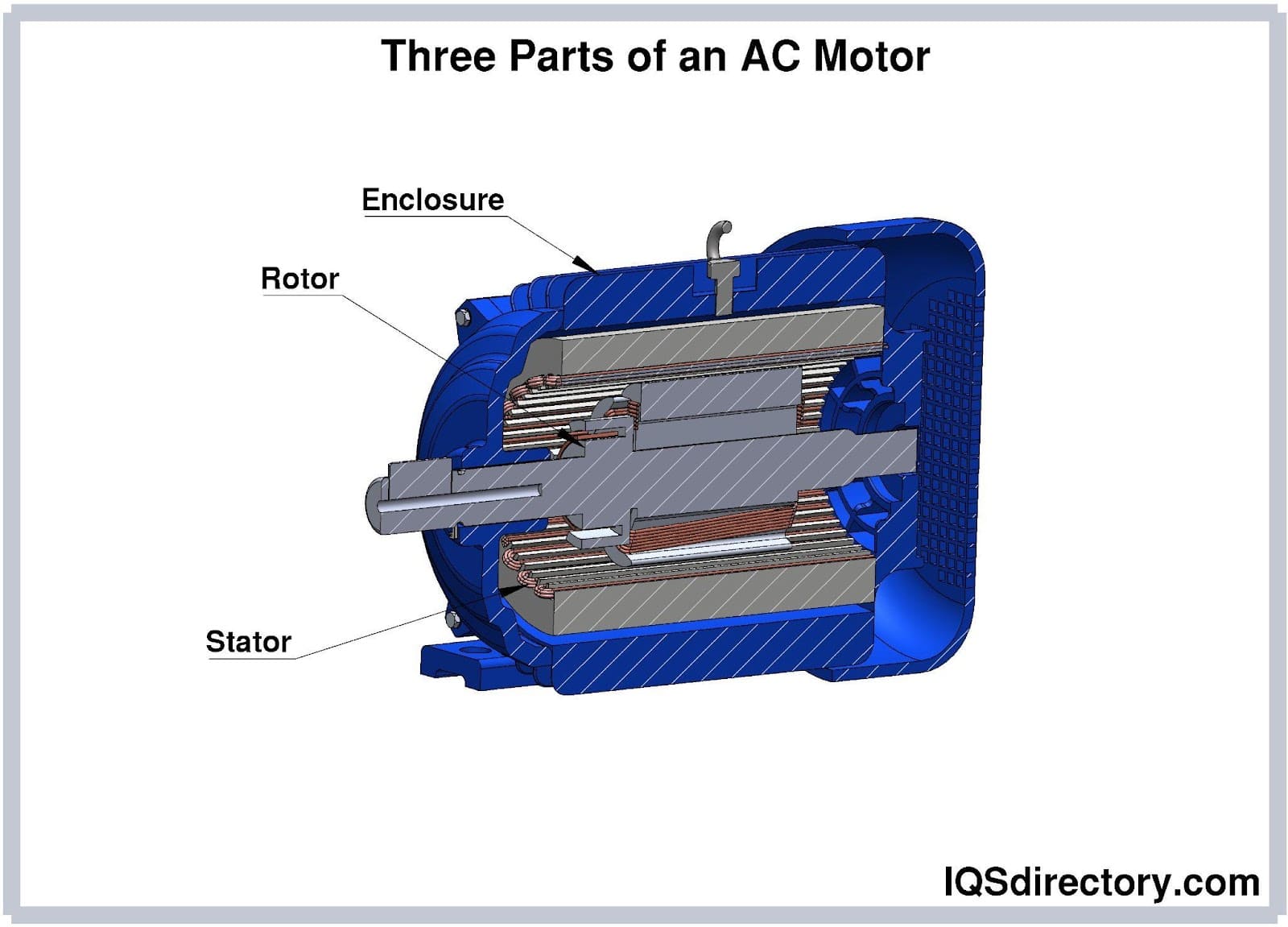

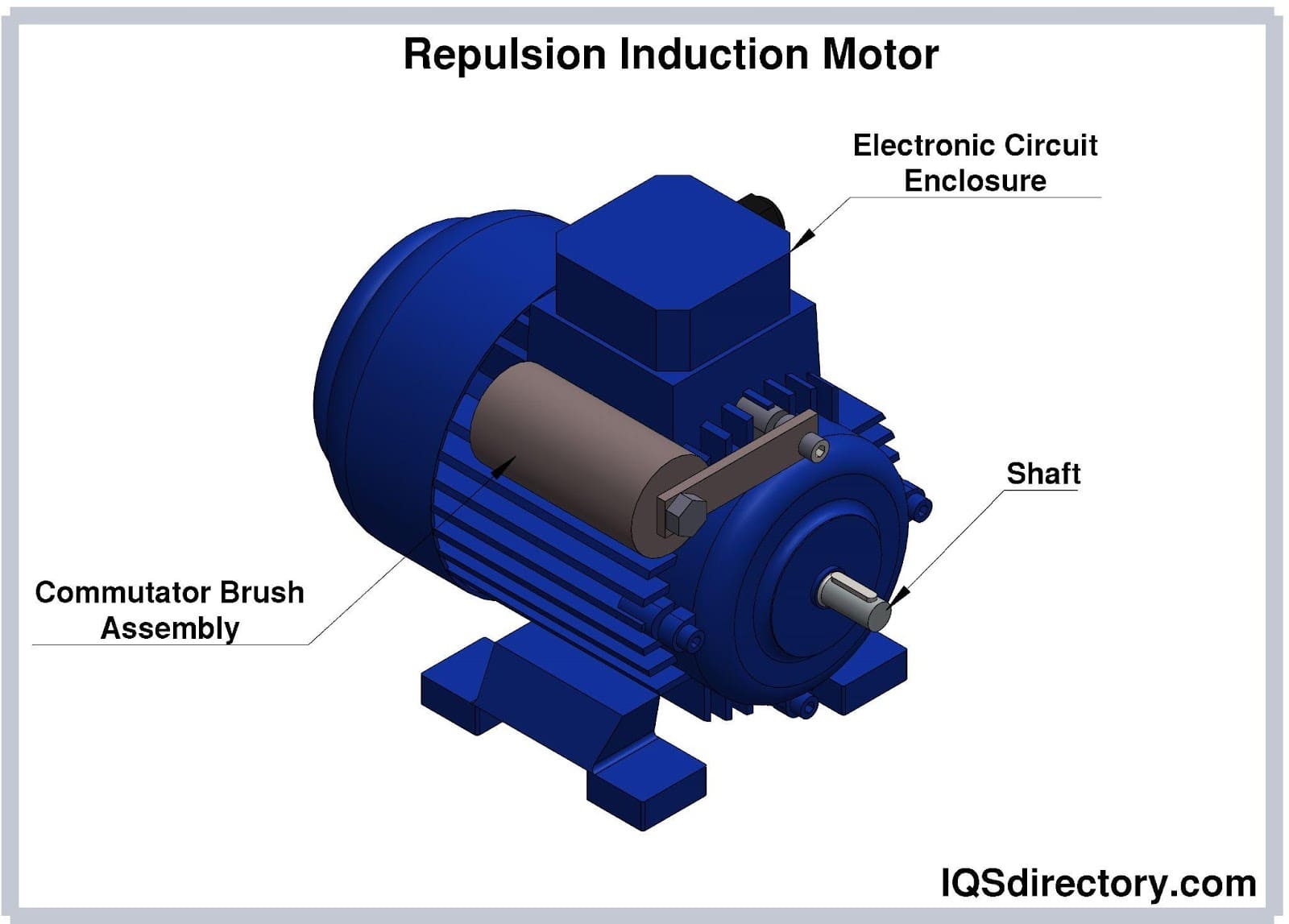

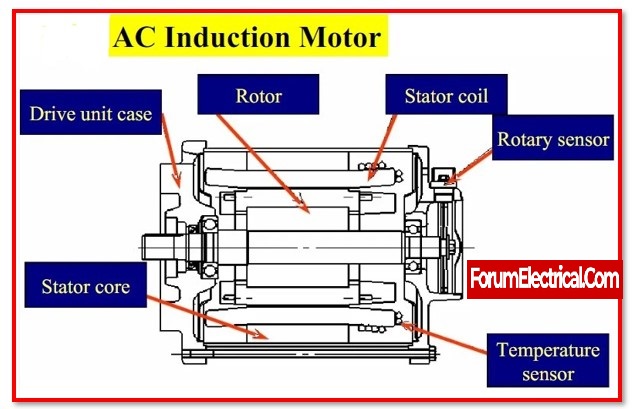

Illustrative image related to ac motor parts

What Role Do AC Motors Play in the Automotive Sector?

In the automotive industry, AC motor parts are utilized in electric power steering systems, enhancing vehicle control and safety. These motors provide precise steering assistance, contributing to improved driver experience and vehicle responsiveness. Buyers in this sector must focus on sourcing high-quality, reliable components that meet automotive standards and can withstand varying operating conditions. The ability to customize motors for specific vehicle models is also a significant advantage.

How Are AC Motor Parts Transforming Material Handling?

Material handling applications, such as Automated Guided Vehicles (AGVs), heavily rely on AC motor parts for efficient logistics and inventory management. These motors facilitate smooth and reliable operation of AGVs, which help reduce labor costs and enhance productivity in warehouses and distribution centers. Buyers should evaluate the compatibility of AC motors with existing systems and consider the technological advancements that can enhance automation and efficiency, especially in emerging markets in South America and Africa.

Why Are AC Motors Important in Mining and Minerals?

In the mining and minerals industry, AC motors are essential for hoisting and lifting equipment, enabling the safe extraction of materials from great depths. The reliability and efficiency of these motors directly affect safety and productivity levels. Buyers must ensure that sourced motors have the necessary load capacity and resilience to operate in harsh environments, where dust and moisture can significantly impact performance. Compliance with safety regulations and certifications is also critical in this high-risk industry.

3 Common User Pain Points for ‘ac motor parts’ & Their Solutions

Scenario 1: Sourcing Quality AC Motor Parts in Emerging Markets

The Problem: B2B buyers in regions like Africa and South America often face significant challenges when sourcing high-quality AC motor parts. Local suppliers may lack the necessary inventory or offer components that do not meet international standards. As a result, buyers may be forced to settle for inferior parts that can lead to operational inefficiencies, increased maintenance costs, and potential downtime, severely impacting production schedules.

The Solution: To ensure the procurement of reliable AC motor parts, buyers should establish relationships with reputable manufacturers and suppliers who specialize in high-quality components. Conducting thorough due diligence, including verifying certifications and previous customer reviews, is crucial. Consider leveraging digital platforms that connect buyers with verified suppliers globally. Additionally, requesting samples before placing bulk orders can help assess the quality of the parts. Engaging in long-term contracts with suppliers may also provide price stability and ensure a consistent supply of quality components, mitigating the risk of disruptions.

Illustrative image related to ac motor parts

Scenario 2: Understanding Technical Specifications for Compatibility

The Problem: A common frustration among B2B buyers is the complexity of technical specifications associated with AC motor parts. Buyers often struggle to understand the compatibility of various components, such as stators, rotors, and bearings, with their existing systems. This lack of clarity can lead to incorrect orders, wasted resources, and delays in project timelines, as mismatched components can’t be easily returned or exchanged.

The Solution: To navigate the technical landscape effectively, buyers should invest time in training and upskilling their purchasing teams on AC motor technologies. Detailed specifications should be compiled for each motor type in use, including dimensions, power ratings, and operational requirements. Utilizing comprehensive product catalogs and datasheets from manufacturers can provide clarity on compatibility. Additionally, fostering a dialogue with suppliers can yield insights into best practices for selecting the right parts. Implementing a robust inventory management system that tracks existing components can further streamline the ordering process, reducing the likelihood of errors.

Scenario 3: Managing Lead Times and Supply Chain Disruptions

The Problem: Buyers often experience frustration due to unpredictable lead times and supply chain disruptions for AC motor parts, exacerbated by global events or regional logistical challenges. These delays can halt production lines, resulting in significant financial losses and missed deadlines. For businesses in competitive markets, such interruptions can lead to a loss of clients and damage to reputation.

The Solution: To mitigate risks associated with lead times, B2B buyers should adopt a proactive approach to supply chain management. Establishing multiple sourcing options can provide alternative pathways in case of disruption. Buyers should consider maintaining a buffer stock of critical components to manage short-term shortages. Collaborating with suppliers to gain insights into their production schedules and potential bottlenecks can also enhance planning and forecasting. Furthermore, leveraging technologies like predictive analytics can help anticipate demand fluctuations and adjust orders accordingly. Building strong relationships with logistics providers can ensure more reliable transport and delivery timelines, ultimately enhancing operational resilience.

By addressing these common pain points with actionable solutions, B2B buyers can navigate the complexities of sourcing AC motor parts more effectively, ensuring smoother operations and greater reliability in their supply chains.

Strategic Material Selection Guide for ac motor parts

What Are the Key Materials Used in AC Motor Parts?

When selecting materials for AC motor components, it’s essential to consider properties that directly affect performance, durability, and cost. Here, we analyze four common materials used in AC motor parts: aluminum, steel, copper, and plastic. Each material has unique characteristics that cater to different applications and market needs.

How Does Aluminum Benefit AC Motor Parts?

Aluminum is widely used for various AC motor components, particularly in the stator and rotor assemblies. Its key properties include a high strength-to-weight ratio, excellent thermal conductivity, and corrosion resistance. Aluminum can withstand temperatures up to 150°C, making it suitable for many operating conditions.

Illustrative image related to ac motor parts

Pros: Aluminum is lightweight, which enhances efficiency and reduces energy consumption. It is also cost-effective and easy to manufacture, allowing for complex shapes and designs.

Cons: While aluminum is resistant to corrosion, it can be less durable than steel under heavy stress or impact. This can limit its use in high-torque applications.

Impact on Application: Aluminum is suitable for applications in environments with moderate temperatures and humidity, such as HVAC systems in tropical regions of Africa and South America.

International Considerations: Buyers from regions like the Middle East and Europe should ensure compliance with standards such as ASTM B221 for aluminum extrusions, which can affect sourcing and manufacturing processes.

Why Choose Steel for AC Motor Components?

Steel, particularly carbon steel, is another prevalent material for AC motor parts, especially in the rotor and stator cores. Its high tensile strength and ability to withstand high temperatures (up to 300°C) make it ideal for heavy-duty applications.

Pros: Steel offers superior durability and resistance to deformation under load. It is also readily available and tends to be less expensive than other metals.

Cons: Steel is heavier than aluminum, which can lead to increased energy consumption. It is also prone to corrosion if not properly treated or coated.

Illustrative image related to ac motor parts

Impact on Application: Steel is often used in industrial applications where robustness is crucial, such as in manufacturing plants in Nigeria and Brazil.

International Considerations: Compliance with standards like DIN 17100 is essential for buyers in Europe, ensuring that the steel used meets specific quality and performance criteria.

What Role Does Copper Play in AC Motor Parts?

Copper is primarily used in windings and electrical connections within AC motors due to its excellent electrical conductivity. It can operate efficiently at temperatures up to 200°C, making it suitable for high-performance applications.

Pros: Copper’s superior conductivity minimizes energy losses, enhancing motor efficiency. It is also resistant to corrosion, which contributes to longevity.

Cons: The high cost of copper can be a significant drawback, especially for large-scale applications. Additionally, its weight can be a concern in lightweight motor designs.

Impact on Application: Copper is ideal for applications requiring high efficiency and reliability, such as in electric vehicles and renewable energy systems.

International Considerations: Buyers should be aware of the fluctuating global copper prices and ensure compliance with standards like ASTM B170 to guarantee quality.

How Does Plastic Enhance AC Motor Components?

Plastic materials, such as polycarbonate and nylon, are increasingly used in non-structural components of AC motors, including housings and insulators. They offer good thermal and electrical insulation properties.

Pros: Plastics are lightweight, cost-effective, and resistant to corrosion and chemicals. They can also be molded into complex shapes, providing design flexibility.

Cons: Plastics have lower thermal resistance compared to metals, typically operating safely up to 100°C. They may also be less durable under mechanical stress.

Impact on Application: Plastic components are beneficial in applications where weight savings and insulation are critical, such as in consumer electronics and portable devices.

International Considerations: Compliance with standards like ISO 9001 for quality management can help ensure that plastic parts meet the necessary performance specifications.

Summary Table of Material Selection for AC Motor Parts

| Material | Typical Use Case for AC Motor Parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Stator and rotor assemblies | Lightweight and corrosion-resistant | Less durable under heavy stress | Medium |

| Steel | Rotor and stator cores | High durability and strength | Heavier and prone to corrosion | Low |

| Copper | Windings and electrical connections | Excellent conductivity | High cost and weight | High |

| Plastic | Housings and insulators | Lightweight and design flexibility | Lower thermal resistance | Low |

This strategic material selection guide provides essential insights for B2B buyers looking to optimize their procurement of AC motor parts, ensuring they make informed decisions that align with their operational needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for ac motor parts

What Are the Main Stages of Manufacturing AC Motor Parts?

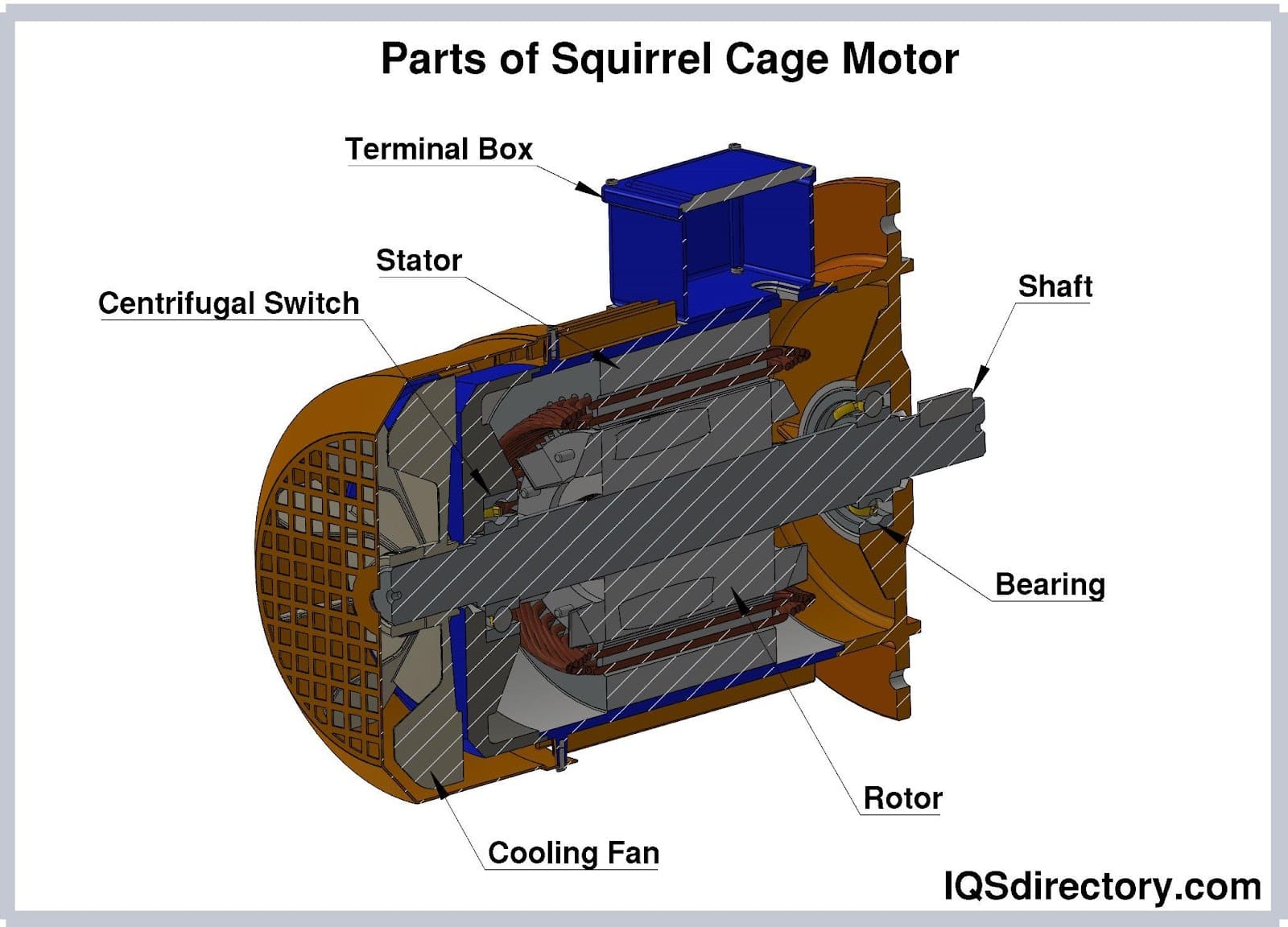

The manufacturing process for AC motor parts is intricate and requires precision at every stage. The primary stages include material preparation, forming, assembly, and finishing, each crucial for ensuring the quality and reliability of the final product.

Material Preparation

The first step involves selecting high-quality materials, such as copper for windings and steel for the stator and rotor. Manufacturers often source these materials based on specific performance criteria and international standards. They must conduct rigorous inspections to verify material quality, ensuring they meet specifications that enhance electrical conductivity and durability.

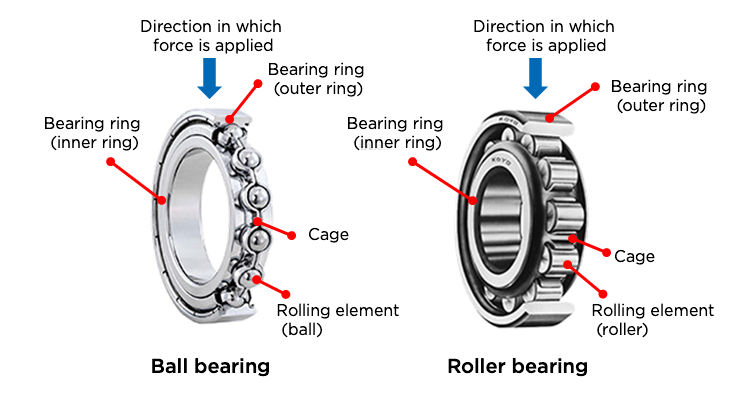

Forming Techniques

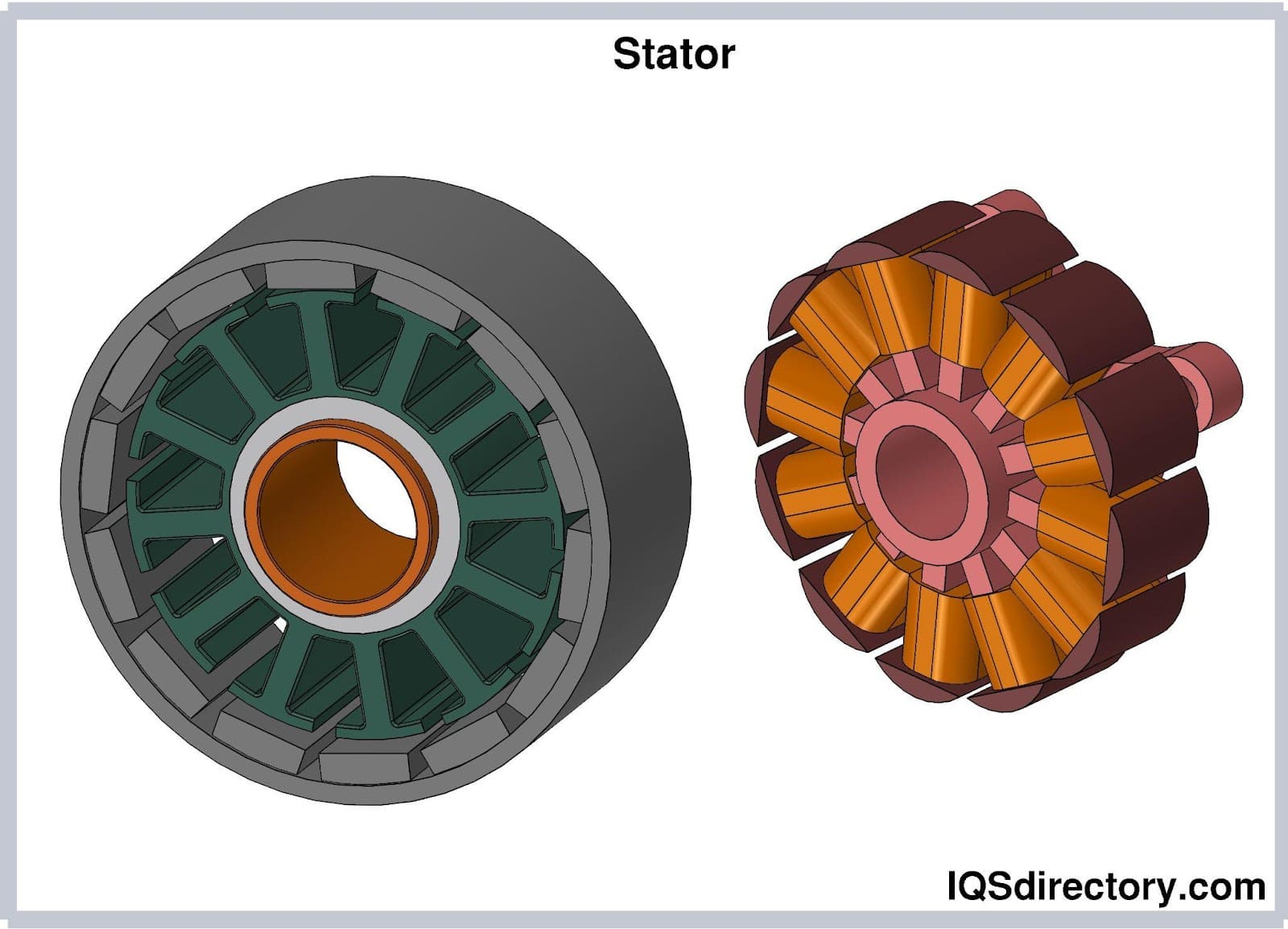

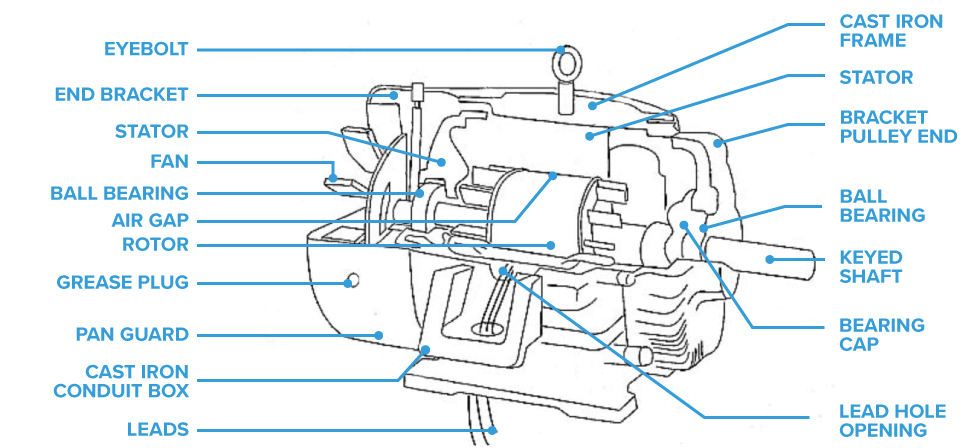

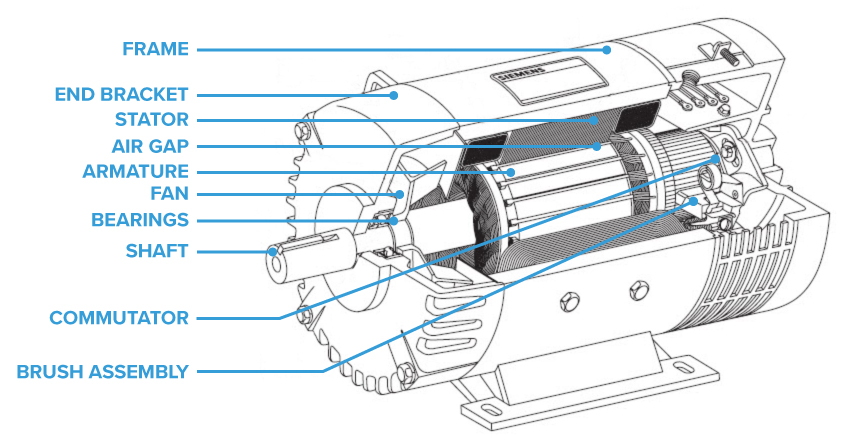

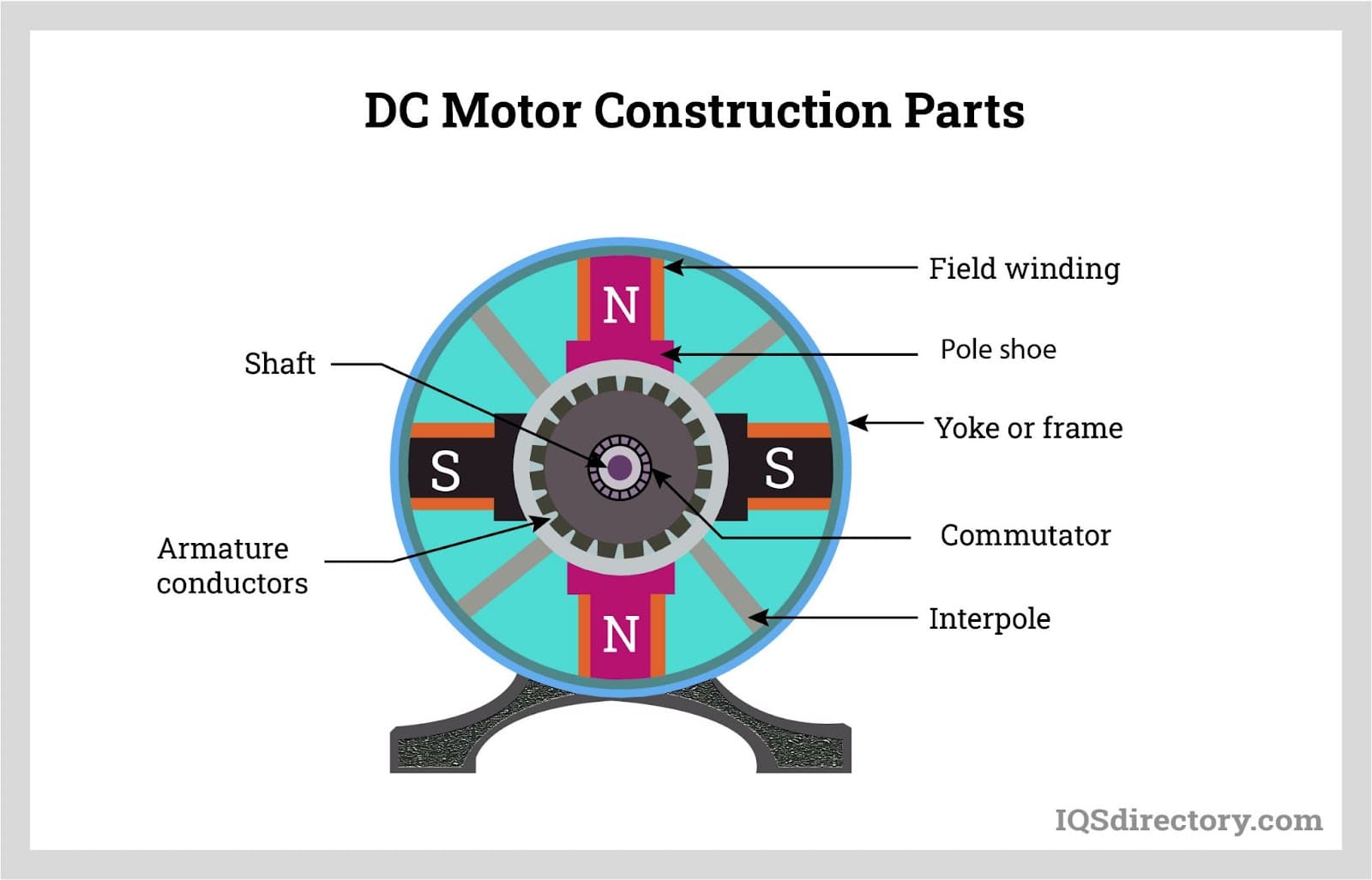

After preparing the materials, the forming stage begins. This typically involves processes such as stamping, machining, and winding. For instance, stator and rotor laminations are stamped from sheets of electrical steel to reduce energy loss. Winding involves wrapping copper wire around the stator and rotor, which is critical for creating the magnetic fields necessary for motor operation. Advanced techniques such as automated winding and laser cutting are increasingly employed to enhance precision and reduce production times.

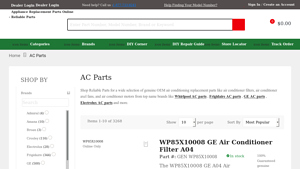

Assembly Process

The assembly stage is where various components come together. This includes fitting the rotor into the stator and attaching the bearings and cooling systems. Each assembly process is performed under strict guidelines to ensure alignment and fit, which are vital for the motor’s efficiency and lifespan. Automation plays a significant role here, with robotic arms often used to improve accuracy and reduce human error.

Finishing Touches

The finishing stage involves applying protective coatings, conducting electrical tests, and ensuring that all components are securely fastened. Surface treatments like painting or galvanizing protect against corrosion and improve aesthetics. This stage also includes balancing the rotor to minimize vibrations during operation.

How Is Quality Assurance Implemented in AC Motor Parts Manufacturing?

Quality assurance (QA) is a critical aspect of manufacturing AC motor parts, ensuring that products meet or exceed industry standards. Various international and industry-specific standards guide these QA processes.

Illustrative image related to ac motor parts

International Standards and Certifications

Many manufacturers adhere to ISO 9001, which outlines requirements for a quality management system (QMS). This standard helps ensure consistent quality in products and services. Other relevant certifications include CE marking for compliance with European health, safety, and environmental protection standards, and API standards for motors used in the oil and gas industry. These certifications are essential for B2B buyers, particularly in regions like Europe and the Middle East, where regulatory compliance is strictly enforced.

Quality Control Checkpoints

Quality control (QC) is implemented at various checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials before they enter production. Suppliers must provide certificates of compliance, and materials are often subjected to random sampling tests.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections ensure that each step adheres to quality standards. This includes monitoring dimensions, tolerances, and the integrity of components as they are formed and assembled.

-

Final Quality Control (FQC): After assembly, motors undergo rigorous testing. This includes performance tests, electrical tests, and thermal tests to ensure they function correctly under specified conditions.

What Testing Methods Are Commonly Used for AC Motor Parts?

Testing methods are essential to verify the performance and reliability of AC motor parts. Common methods include:

-

Electrical Testing: This assesses the electrical characteristics of the motor, including resistance, inductance, and insulation integrity. High-voltage tests are often conducted to ensure that the motor can handle operational stresses.

-

Vibration Testing: Vibration analysis helps identify potential issues with balance and alignment, which can lead to premature failure if not addressed.

-

Thermal Testing: Motors are subjected to elevated temperatures to ensure that they can operate effectively in various environmental conditions without overheating.

-

Load Testing: This simulates real-world operating conditions, allowing manufacturers to assess how the motor performs under load and to detect any anomalies.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those from regions like Africa and South America, verifying supplier quality control is crucial in establishing reliable partnerships. Here are some strategies to ensure suppliers maintain high-quality standards:

-

Conduct Supplier Audits: Regular audits allow buyers to assess a supplier’s manufacturing processes, quality control measures, and compliance with industry standards. This can be done in person or through third-party auditing services.

-

Request Quality Reports: Suppliers should provide detailed reports on their quality control processes, including IQC, IPQC, and FQC findings. This transparency is vital for building trust.

-

Utilize Third-Party Inspection Services: Engaging independent inspection agencies can offer unbiased assessments of a supplier’s operations. These agencies can conduct inspections at various stages of production and provide certification that confirms adherence to specified standards.

-

Evaluate Certifications: Buyers should verify the authenticity of certifications claimed by suppliers. This can often be done through the issuing authority or relevant industry associations.

What Are the Nuances of Quality Control for International B2B Buyers?

International B2B buyers face unique challenges when it comes to quality control. These include:

-

Understanding Regional Standards: Different regions may have varying standards and regulations. Buyers must be familiar with local compliance requirements, particularly when importing goods.

-

Language Barriers and Communication: Effective communication with suppliers is essential. Language barriers can lead to misunderstandings about quality expectations. It’s advisable to use clear, documented specifications and requirements.

-

Cultural Differences: Awareness of cultural differences can impact negotiations and relationships with suppliers. Building rapport and understanding local business practices can facilitate smoother transactions.

In conclusion, understanding the manufacturing processes and quality assurance practices for AC motor parts is essential for B2B buyers looking to source reliable components. By focusing on these key areas, buyers can make informed decisions that align with their operational needs and quality expectations.

Illustrative image related to ac motor parts

Practical Sourcing Guide: A Step-by-Step Checklist for ‘ac motor parts’

Introduction

Sourcing AC motor parts can be a complex process that requires careful consideration and strategic planning. This checklist is designed to guide international B2B buyers through the procurement process, ensuring that they make informed decisions that align with their operational needs and compliance standards. By following these steps, you will enhance your ability to source reliable and efficient components for your applications.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for ensuring that the AC motor parts meet your operational requirements. Consider factors such as voltage, horsepower, RPM, and environmental conditions (e.g., temperature extremes).

– Identify compatibility with existing systems to avoid costly modifications later.

– Document the required features to communicate effectively with suppliers.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers who specialize in AC motor parts. Look for companies with a strong track record in your industry and positive reviews from past clients.

– Check online directories and trade platforms to find established manufacturers.

– Network with industry peers to gain insights into reliable sources.

Step 3: Verify Supplier Certifications

Before making a commitment, ensure that potential suppliers hold relevant certifications and comply with international standards. This is vital for maintaining quality and reliability in your supply chain.

– Request documentation for ISO certifications or other quality assurance processes.

– Understand the supplier’s compliance with local regulations, especially if sourcing from different regions.

Step 4: Evaluate Product Quality

Quality should be a top priority when sourcing AC motor parts. Conduct a quality assessment by requesting samples or visiting the supplier’s facility if possible.

– Inquire about the materials used in production to ensure durability.

– Review warranty terms and service agreements to gauge the supplier’s commitment to quality.

Step 5: Compare Pricing and Terms

Once you have shortlisted suppliers, compare their pricing structures and payment terms. This step is essential to ensure that you receive the best value without compromising on quality.

– Request detailed quotes that outline costs for each component, including shipping and handling.

– Negotiate terms that align with your budget and cash flow needs.

Step 6: Assess After-Sales Support

Strong after-sales support can significantly impact your long-term satisfaction with a supplier. Evaluate the level of support they offer post-purchase.

– Inquire about technical support for installation and troubleshooting.

– Understand return policies and procedures for defective parts to safeguard your investment.

Step 7: Establish Long-Term Relationships

Building a long-term partnership with a reliable supplier can lead to better pricing, priority service, and insights into new products.

– Maintain open lines of communication to foster trust and collaboration.

– Regularly review performance and address any issues promptly to strengthen the relationship.

By following this checklist, B2B buyers can navigate the complexities of sourcing AC motor parts with confidence, ensuring they select high-quality components that meet their specific needs.

Illustrative image related to ac motor parts

Comprehensive Cost and Pricing Analysis for ac motor parts Sourcing

What Are the Key Cost Components for AC Motor Parts?

When sourcing AC motor parts, understanding the cost structure is crucial for B2B buyers. The main cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly influences the cost. High-quality copper windings, for instance, are essential for efficiency but can be costly. Buyers should assess whether lower-grade materials could suffice for their specific applications without compromising performance.

-

Labor: Labor costs can vary based on geographic location. Regions with lower labor costs might offer more competitive pricing, but buyers should consider the trade-off with quality and reliability.

-

Manufacturing Overhead: This encompasses the costs of facilities, equipment maintenance, and utilities. Efficient manufacturing processes can lower these overhead costs, allowing suppliers to offer better prices.

-

Tooling: The initial investment in tooling can be substantial, especially for custom parts. However, this cost is often amortized over large production runs, which can lead to more favorable pricing for bulk orders.

-

Quality Control (QC): Implementing stringent QC measures ensures that products meet required standards, which can add to the cost. Buyers should weigh the benefits of quality assurance against potential losses from defective components.

-

Logistics: Transportation costs, including freight and insurance, can significantly impact the total cost. Buyers should consider proximity to suppliers and shipping methods that can reduce these expenses.

-

Margin: Suppliers will include a profit margin in their pricing. Understanding the typical margins in the industry can help buyers negotiate better deals.

How Do Price Influencers Affect AC Motor Parts Pricing?

Several factors can influence pricing, which is essential for international B2B buyers to consider.

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically result in lower per-unit costs due to economies of scale. Negotiating for favorable MOQs can lead to significant savings.

-

Specifications and Customization: Custom parts or those with specific specifications can incur additional costs. Clear communication about requirements can help avoid unexpected expenses.

-

Materials: The type of materials used directly affects the price. High-performance materials may be necessary for certain applications but can significantly increase costs.

-

Quality Certifications: Products that meet international quality standards (like ISO certifications) may come at a premium. Buyers should evaluate the necessity of these certifications based on their market requirements.

-

Supplier Factors: The reputation, reliability, and financial stability of suppliers can influence pricing. Engaging with well-established suppliers may result in higher initial costs but can lead to long-term savings due to quality and reliability.

-

Incoterms: Understanding Incoterms is crucial for calculating total landed costs. Different terms (e.g., FOB, CIF) can lead to variations in pricing based on who bears the shipping and insurance costs.

What Are Some Effective Buyer Tips for AC Motor Parts Sourcing?

To ensure a cost-effective sourcing process, B2B buyers should consider the following strategies:

-

Negotiation: Always negotiate terms, especially for larger orders. Suppliers may have room to adjust pricing based on volume or long-term commitments.

-

Focus on Total Cost of Ownership (TCO): Consider not just the initial purchase price but also the long-term costs associated with maintenance, energy consumption, and potential downtime.

-

Pricing Nuances for International Buyers: When sourcing from different regions, be mindful of currency fluctuations, tariffs, and trade regulations. These factors can affect overall pricing and should be factored into your budget.

-

Supplier Relationships: Building strong relationships with suppliers can lead to better pricing and service. Consider establishing partnerships rather than one-off transactions to gain advantages over time.

-

Market Research: Stay informed about market trends and pricing benchmarks in different regions, particularly in Africa, South America, the Middle East, and Europe. Understanding local market conditions can empower buyers during negotiations.

Disclaimer on Indicative Prices

Prices for AC motor parts can vary widely based on the factors discussed above. Buyers should consider this analysis as a guideline rather than a definitive pricing structure. Always request quotes from multiple suppliers to ensure competitive pricing and terms that meet your specific needs.

Alternatives Analysis: Comparing ac motor parts With Other Solutions

Exploring Alternative Solutions to AC Motor Parts

In the realm of electric motors, specifically AC motors, various alternatives exist that can fulfill similar roles in industrial applications. Understanding these alternatives can help B2B buyers make informed decisions about which solutions best meet their operational needs. Below, we compare AC motor parts to two viable alternatives: DC motors and stepper motors.

| Comparison Aspect | Ac Motor Parts | DC Motors | Stepper Motors |

|---|---|---|---|

| Performance | High efficiency with good torque | Excellent speed control, moderate efficiency | Precise positioning and control |

| Cost | Generally moderate to high | Typically lower initial cost | Higher initial cost but low operating cost |

| Ease of Implementation | Standardized installation processes | Straightforward wiring, but may require a controller | Requires specific drivers for control |

| Maintenance | Low maintenance with long lifespan | Moderate maintenance needs | More frequent maintenance due to wear |

| Best Use Case | General industrial applications | Battery-operated devices, robotics | CNC machinery, 3D printers |

What Are the Advantages and Disadvantages of DC Motors?

DC motors are an alternative to AC motors that provide exceptional speed control, making them ideal for applications requiring variable speed. They typically have a lower initial cost, which can be appealing for budget-conscious projects. However, they require a controller for operation and can have a shorter lifespan due to brush wear, necessitating more frequent maintenance. Additionally, their efficiency may not match that of high-quality AC motors in continuous operation scenarios.

How Do Stepper Motors Compare to AC Motor Parts?

Stepper motors offer precise control over positioning and speed, making them suitable for applications like CNC machinery and 3D printers. They excel in environments where accuracy is paramount, as they can move in fixed increments without feedback systems. However, stepper motors generally have a higher upfront cost and require specific drivers for operation, complicating the implementation process. Moreover, they may necessitate more frequent maintenance due to mechanical wear, which can impact long-term operational efficiency.

How Can B2B Buyers Choose the Right Solution?

When selecting between AC motor parts and their alternatives, B2B buyers should consider their specific operational requirements. Factors such as performance needs, budget constraints, and maintenance capabilities play a critical role in this decision-making process. For general industrial applications, AC motors often provide the best balance of efficiency and longevity. Conversely, if precise control and lower initial costs are more critical, DC or stepper motors may be more suitable. Ultimately, understanding the nuances of each option empowers buyers to make informed choices that align with their operational goals.

Essential Technical Properties and Trade Terminology for ac motor parts

What Are the Key Technical Properties of AC Motor Parts That Buyers Should Consider?

When sourcing AC motor parts, understanding the technical specifications is crucial for making informed purchasing decisions. Here are several essential properties to keep in mind:

1. Material Grade

The material grade of components, such as the rotor and stator, affects the motor’s performance and longevity. Common materials include copper for windings due to its high conductivity, and silicon steel for magnetic cores, which minimizes energy losses. Selecting the right material grade is vital, as it directly influences efficiency, durability, and resistance to environmental factors such as humidity and temperature.

2. Power Rating (HP or kW)

Power rating, typically measured in horsepower (HP) or kilowatts (kW), indicates the motor’s output capacity. This specification is essential for matching the motor to the intended application, whether it be for household appliances or industrial machinery. An incorrect power rating can lead to underperformance or premature failure, resulting in costly downtimes and repairs.

3. Speed (RPM)

The speed of an AC motor, measured in revolutions per minute (RPM), is another critical property. Different applications require specific speeds for optimal performance. Understanding the required RPM helps in selecting the right motor type, whether synchronous or induction, ensuring that the motor can effectively meet operational needs.

Illustrative image related to ac motor parts

4. Efficiency Rating

Efficiency ratings indicate how well a motor converts electrical energy into mechanical energy. Motors with higher efficiency ratings consume less power, leading to lower operational costs and reduced environmental impact. This property is particularly important for businesses looking to optimize energy usage and comply with sustainability regulations.

5. Torque

Torque is the rotational force generated by the motor and is crucial for determining how well the motor can handle various loads. High torque is necessary for applications involving heavy machinery, while lower torque may suffice for lighter tasks. Understanding torque requirements helps buyers choose motors that can deliver the necessary performance without risk of overload.

What Are the Common Trade Terms Related to AC Motor Parts That Buyers Should Know?

Navigating the procurement process involves familiarity with specific trade terminology that can impact negotiations and agreements. Here are several key terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts that are used in the manufacturing of a final product. When sourcing AC motor parts, working with OEMs ensures compatibility and quality assurance, as these parts are designed to meet specific standards required by original manufacturers.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for budgeting and inventory management, especially for businesses that may not need large quantities of parts at once. Negotiating MOQs can lead to more favorable purchasing terms.

Illustrative image related to ac motor parts

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to request pricing and other details from suppliers. Including detailed specifications in an RFQ helps suppliers provide accurate quotes, ultimately streamlining the procurement process and ensuring that all parties are aligned on expectations.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, covering aspects like shipping, insurance, and delivery. Familiarity with these terms is crucial for international B2B buyers, as they dictate the risk and cost associated with transporting AC motor parts across borders.

5. Lead Time

Lead time refers to the time taken from placing an order until the goods are received. Understanding lead times helps businesses plan their production schedules effectively and avoid delays that could disrupt operations.

By comprehensively understanding these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing AC motor parts, optimizing their procurement process while ensuring compatibility and performance for their applications.

Illustrative image related to ac motor parts

Navigating Market Dynamics and Sourcing Trends in the ac motor parts Sector

What Are the Key Market Dynamics and Trends in the AC Motor Parts Sector?

The global AC motor parts market is experiencing a robust transformation driven by several factors. As industries across the globe increasingly prioritize automation and efficiency, the demand for high-quality AC motors is surging. Key markets such as Africa, South America, the Middle East, and Europe are witnessing significant growth due to the expansion of manufacturing sectors, infrastructure development, and increased investment in renewable energy. For international B2B buyers, understanding these dynamics is essential for making informed sourcing decisions.

Emerging technologies are reshaping the sourcing landscape. The integration of IoT in motor components enables real-time monitoring and predictive maintenance, significantly enhancing operational efficiency. Additionally, the rise of e-commerce platforms is facilitating easier access to suppliers, allowing buyers to compare prices, quality, and delivery times from various manufacturers globally. In regions like Saudi Arabia and Nigeria, local regulations are increasingly favoring the procurement of energy-efficient and environmentally friendly motor parts, further influencing purchasing choices.

Moreover, the trend towards modularity in motor design is gaining traction. Buyers are now looking for components that can be easily integrated or replaced, reducing downtime and maintenance costs. This shift is particularly pertinent for sectors such as automotive and food processing, where operational efficiency is paramount.

How Does Sustainability Influence Sourcing Decisions for AC Motor Parts?

Sustainability is becoming a crucial factor in sourcing strategies for AC motor parts. Environmental concerns are prompting companies to seek components that minimize ecological impact, aligning with global sustainability goals. This shift is particularly relevant for international buyers in regions like Europe, where stringent regulations and consumer preferences are pushing for greener solutions.

Ethical sourcing practices are gaining importance as businesses recognize the long-term benefits of sustainable supply chains. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to reducing carbon footprints, utilizing renewable materials, and ensuring fair labor practices. Certifications such as ISO 14001 (Environmental Management) and RoHS (Restriction of Hazardous Substances) are becoming essential for suppliers aiming to establish credibility in the marketplace.

Furthermore, the use of eco-friendly materials in the production of AC motor parts is on the rise. For instance, manufacturers are exploring biodegradable composites and recycled metals, which not only reduce environmental impact but can also enhance brand reputation among eco-conscious consumers. By prioritizing sustainability, B2B buyers can not only comply with regulations but also differentiate themselves in competitive markets.

How Has the AC Motor Parts Market Evolved Over Time?

The evolution of the AC motor parts market reflects significant technological advancements and changing industrial needs. Initially, AC motors were primarily used in basic applications, with limited focus on efficiency and sustainability. However, as industries advanced, the demand for more efficient, durable, and adaptable motors grew.

The introduction of variable frequency drives (VFDs) in the 1990s marked a pivotal shift, allowing for better control over motor speed and efficiency. This innovation led to the widespread adoption of AC motors in various sectors, including HVAC, manufacturing, and renewable energy.

As the market continues to evolve, the focus is now on integrating smart technologies and sustainable practices, positioning AC motor parts as critical components in the push towards automation and environmental responsibility. For international B2B buyers, staying abreast of these historical trends is essential for making strategic sourcing decisions that align with both current market demands and future innovations.

Illustrative image related to ac motor parts

Frequently Asked Questions (FAQs) for B2B Buyers of ac motor parts

-

How do I solve issues with AC motor part compatibility?

To resolve compatibility issues with AC motor parts, first, identify the specific requirements of your application, including voltage, horsepower, and RPM. Check the specifications of both the motor and the parts you are considering. It’s advisable to consult with manufacturers or suppliers to ensure that the components are compatible. Additionally, consider using universal parts where applicable, but always verify that they meet the performance criteria for your specific setup. -

What is the best type of AC motor for industrial applications?

The best type of AC motor for industrial applications typically depends on the specific operational needs. Induction motors are widely favored due to their robustness and efficiency in various environments. Synchronous motors can be ideal for applications requiring precise speed control. Evaluate the load requirements, operational conditions, and energy efficiency standards to determine the most suitable motor type for your operations. -

How can I vet AC motor parts suppliers for international purchases?

When vetting suppliers for international purchases of AC motor parts, conduct thorough research into their reputation and reliability. Look for suppliers with a proven track record in the industry, verified certifications, and positive customer reviews. Request references and inquire about their quality assurance processes. Additionally, consider suppliers who offer guarantees or warranties on their products, as this can indicate confidence in their offerings. -

What are the common minimum order quantities (MOQ) for AC motor parts?

Minimum order quantities (MOQ) for AC motor parts can vary significantly based on the supplier and the type of part. Many suppliers establish an MOQ to ensure cost-effectiveness in production and shipping. Typically, MOQs can range from as low as 10 units to several hundred. It’s beneficial to communicate directly with suppliers to negotiate MOQs that align with your purchasing needs while considering potential bulk discounts. -

What payment terms should I expect when sourcing AC motor parts internationally?

Payment terms for international sourcing of AC motor parts often include options such as advance payment, letter of credit, or payment upon delivery. Many suppliers may require a deposit upfront, particularly for custom orders. Be sure to clarify payment terms before finalizing any agreements to avoid misunderstandings. Additionally, consider using secure payment methods that offer buyer protection, especially when dealing with new suppliers. -

How can I ensure quality assurance (QA) for AC motor parts?

To ensure quality assurance for AC motor parts, establish clear quality standards and specifications before placing an order. Request documentation of quality control processes from suppliers, including certifications such as ISO 9001. Consider conducting factory audits or requesting third-party inspections for large orders. Establishing a strong communication channel with suppliers can also facilitate addressing any quality concerns promptly. -

What logistics considerations should I keep in mind when importing AC motor parts?

When importing AC motor parts, logistics considerations include shipping methods, customs clearance, and delivery timelines. Choose a reliable freight forwarder familiar with international shipping regulations to streamline the process. Ensure that you have all necessary documentation, such as invoices and certificates of origin, to avoid delays during customs clearance. Additionally, factor in potential tariffs and duties that may affect overall costs. -

Can I customize AC motor parts to meet specific requirements?

Yes, many suppliers offer customization options for AC motor parts to meet specific application requirements. Customization can include alterations in size, voltage ratings, and performance characteristics. When seeking custom parts, provide detailed specifications and discuss your needs with the supplier early in the process. Be aware that custom orders may have longer lead times and higher costs compared to standard parts.

Top 5 Ac Motor Parts Manufacturers & Suppliers List

1. Baldor – OEM Electric Motor Parts

Domain: electricmotorwholesale.com

Registered: 2005 (20 years)

Introduction: This company, Baldor – OEM Electric Motor Parts, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Bauer GMC – AC Motors

Domain: bauergmc.com

Registered: 2015 (10 years)

Introduction: An AC motor, also known as an alternating current motor, operates on alternating current and is found in various applications from household appliances to heavy industrial machinery. The key components of an AC motor include: 1. Stator: A stationary coil winding that produces a rotating magnetic field when connected to an AC source. 2. Rotor: The moving part of the motor, containing conductive bar…

3. Home Depot – Air Conditioner Motor Parts

Domain: appliancerepair.homedepot.com

Registered: 1992 (33 years)

Introduction: This company, Home Depot – Air Conditioner Motor Parts, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Indoor Comfort Supply – A/C Motors

Domain: indoorcomfortsupply.com

Registered: 2007 (18 years)

Introduction: A/C Motors include: 1. A/C and Furnace Blower Motor – 1/6 – 1/2 Horse Power, 1075 RPM, 230 Volt, 4 speed, MSRP: $181.84. 2. A/C Condenser Fan Motor – Bracket 3 Ear Clamp Style, MSRP: $39.99. 3. Motor Shaft Adapter 1/2 X 5/8 – Adapts 5/8″ pulley to a standard 1/2″ cooler motor shaft, MSRP: $4.99.

5. GE – A04 Air Conditioner Filter

Domain: reliableparts.com

Registered: 1996 (29 years)

Introduction: [{‘part_number’: ‘WP85X10008’, ‘brand’: ‘GE’, ‘description’: ‘GE A04 Air Conditioner Filter’, ‘special_price’: ‘$20.97’, ‘regular_price’: ‘$23.30’, ‘savings’: ‘$2.33’, ‘in_stock’: ‘Yes’}, {‘part_number’: ‘4681A20169B’, ‘brand’: ‘LG’, ‘description’: ‘Indoor DC Motor Assembly’, ‘special_price’: ‘$524.44’, ‘regular_price’: ‘$582.71’, ‘savings’: ‘$58.27’, ‘in_stock’: ‘Yes’}, {‘part_number’: ‘WP94X1030…

Strategic Sourcing Conclusion and Outlook for ac motor parts

In the evolving landscape of AC motor parts, strategic sourcing remains paramount for international B2B buyers. Emphasizing quality components such as stators, rotors, and cooling systems is essential for ensuring operational efficiency and durability. By prioritizing reliable suppliers who adhere to rigorous quality standards, businesses can mitigate risks associated with equipment failure and maximize their return on investment.

Furthermore, understanding regional market dynamics in areas like Africa, South America, the Middle East, and Europe enables buyers to tailor their sourcing strategies effectively. This localized approach not only enhances supply chain resilience but also fosters long-term partnerships with manufacturers who comprehend specific regional needs.

As the demand for energy-efficient solutions rises, staying ahead of technological advancements in AC motors will be crucial. International buyers are encouraged to engage in proactive sourcing strategies that align with sustainability goals while also exploring innovative product offerings. By taking these steps, companies can secure their competitive advantage in an increasingly complex market landscape. Embrace the opportunity to refine your sourcing strategy today and position your business for future success in the AC motor parts industry.

Illustrative image related to ac motor parts

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.