Unlocking Value: A Strategic Analysis of the 220632 Hypertherm Market

Introduction: Navigating the Global Market for 220632 hypertherm

In today’s competitive landscape, sourcing reliable components like the Hypertherm 220632 nozzle can be a daunting challenge for international B2B buyers. With varying quality standards and supplier reliability across regions, ensuring optimal performance for your plasma cutting operations is essential. This guide offers a comprehensive overview of the 220632 hypertherm, exploring its specifications, applications, and compatibility with various materials.

We delve into critical aspects such as supplier vetting processes, cost considerations, and the nuances of international shipping logistics, tailored specifically for buyers in Africa, South America, the Middle East, and Europe, including key markets like Saudi Arabia and Germany. By addressing these pivotal concerns, this guide empowers businesses to make informed purchasing decisions, enhancing operational efficiency and reducing downtime.

Whether you’re looking to upgrade existing equipment or expand your production capabilities, understanding the intricacies of sourcing the Hypertherm 220632 nozzle will equip you with the knowledge necessary to navigate the global market confidently. This guide serves as a strategic resource, ensuring that you not only procure the best products but also foster long-lasting relationships with trusted suppliers.

Understanding 220632 hypertherm Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hypertherm HPR 400 Amp Nozzle | High-capacity, designed for mild steel | Heavy manufacturing, metal fabrication | Pros: High efficiency, excellent cut quality. Cons: Higher initial cost. |

| Hypertherm HPR 130 Amp Nozzle | Lower amperage, suitable for thinner materials | Light manufacturing, small workshops | Pros: Cost-effective, versatile for lighter tasks. Cons: Limited cutting thickness. |

| Hypertherm HPR 200 Amp Nozzle | Mid-range capacity, good for various metals | General metalworking | Pros: Balanced performance and cost. Cons: May not handle extreme thicknesses well. |

| Hypertherm HPR 260 Amp Nozzle | Enhanced performance for thicker materials | Industrial applications, fabrication | Pros: Great for heavy-duty applications. Cons: More expensive than lower amperage options. |

| Hypertherm HPR 50 Amp Nozzle | Designed for very thin materials | Precision cutting, automotive repair | Pros: Ideal for precision cuts, lower cost. Cons: Not suitable for thicker materials. |

What Are the Key Characteristics of Hypertherm HPR 400 Amp Nozzle?

The Hypertherm HPR 400 Amp Nozzle is engineered for high-capacity operations, primarily focusing on cutting mild steel. This nozzle is ideal for heavy manufacturing and metal fabrication settings where efficiency and quality are paramount. Buyers should consider its higher initial investment but can expect a significant return through increased productivity and superior cut quality over time.

How Does the Hypertherm HPR 130 Amp Nozzle Differ?

The Hypertherm HPR 130 Amp Nozzle is tailored for lighter applications, making it suitable for thinner materials. It finds its place in light manufacturing and small workshops, offering a cost-effective solution for businesses that do not require high-capacity cutting. Its versatility allows it to handle a variety of tasks, although buyers should note its limitations regarding cutting thickness.

What Makes the Hypertherm HPR 200 Amp Nozzle a Popular Choice?

The Hypertherm HPR 200 Amp Nozzle strikes a balance between performance and cost, making it a popular choice for general metalworking. It is versatile enough for various metals and applications, providing a reliable option for businesses looking to optimize their cutting capabilities. While it offers good performance, buyers must be aware that it may not effectively handle extreme thicknesses.

Why Choose the Hypertherm HPR 260 Amp Nozzle for Heavy-Duty Applications?

The Hypertherm HPR 260 Amp Nozzle is designed for enhanced performance, particularly in industrial applications that require cutting thicker materials. It is ideal for heavy-duty fabrication and manufacturing environments. While it comes with a higher price tag, its capabilities can justify the investment for businesses needing robust cutting solutions.

What Are the Advantages of Using the Hypertherm HPR 50 Amp Nozzle?

The Hypertherm HPR 50 Amp Nozzle is specifically designed for precision cutting of very thin materials, making it an excellent choice for applications in automotive repair and detailed work. Its lower cost and effectiveness in precision tasks make it appealing to businesses focused on high-quality cuts. However, its limitations in cutting thickness should be considered when making a purchasing decision.

Key Industrial Applications of 220632 hypertherm

| Industry/Sector | Specific Application of 220632 hypertherm | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Metal Fabrication | Plasma cutting of mild steel components | Enhances precision and efficiency in cutting tasks | Ensure compatibility with existing machinery and power supply. |

| Shipbuilding | Bevel cutting for ship hulls | Reduces material wastage and improves structural integrity | Consider local regulations on emissions and safety standards. |

| Construction | Fabrication of structural steel beams | Increases speed of construction and reduces labor costs | Look for suppliers with reliable delivery times and support. |

| Automotive Manufacturing | Cutting and shaping automotive parts | Supports high-volume production with minimal downtime | Verify quality certifications and after-sales service options. |

| Oil & Gas | Maintenance and repair of pipelines | Ensures safety and compliance with industry standards | Source from suppliers with a strong track record in the sector. |

How is the 220632 hypertherm Used in Metal Fabrication?

In the metal fabrication industry, the 220632 hypertherm nozzle is primarily utilized for plasma cutting of mild steel components. This application is crucial for creating intricate designs and precise cuts necessary in fabrication projects. The efficiency of the nozzle helps in reducing operational costs and improving output quality. International buyers should ensure that the nozzle is compatible with their existing plasma cutting systems and that they have access to local support and maintenance services.

What Role Does the 220632 Hypertherm Play in Shipbuilding?

The shipbuilding sector employs the 220632 hypertherm for bevel cutting of ship hulls, which is essential for achieving the necessary angles and edges for structural integrity. This application not only minimizes material waste but also enhances the overall strength of the vessel. Buyers from regions like the Middle East, where shipbuilding is prominent, must consider local regulations regarding emissions and safety standards when sourcing this equipment.

How is the 220632 Hypertherm Beneficial in Construction?

In construction, the 220632 hypertherm is used for the fabrication of structural steel beams, facilitating efficient assembly on-site. This application accelerates construction timelines and reduces labor costs, making projects more economically viable. B2B buyers should prioritize suppliers who can guarantee timely delivery and offer comprehensive customer support to ensure seamless integration into their operations.

Why is the 220632 Hypertherm Important for Automotive Manufacturing?

The automotive manufacturing industry relies on the 220632 hypertherm for cutting and shaping various automotive parts. The precision offered by this nozzle ensures high-quality output while supporting high-volume production demands. Buyers should focus on verifying the quality certifications of the nozzle and seek suppliers who provide robust after-sales service to maintain operational efficiency.

How Does the 220632 Hypertherm Assist in the Oil & Gas Sector?

In the oil and gas industry, the 220632 hypertherm nozzle is vital for the maintenance and repair of pipelines. This application is crucial for ensuring safety and compliance with stringent industry standards. When sourcing this equipment, international buyers should look for suppliers with a proven track record in the oil and gas sector, as reliability and quality are paramount in such critical applications.

3 Common User Pain Points for ‘220632 hypertherm’ & Their Solutions

Scenario 1: Difficulty in Sourcing Compatible Nozzles for Different Applications

The Problem: B2B buyers in the metal fabrication industry often face challenges when sourcing nozzles that are compatible with various materials and specific amperage requirements. For instance, a company may primarily work with mild steel at 400 amps but occasionally needs to switch to stainless steel or different amperage levels. This variability can lead to confusion about which nozzle assembly to purchase, risking downtime due to incorrect orders.

The Solution: To ensure seamless operations, it’s crucial to establish a reliable supply chain with multiple suppliers who understand your specific needs. When sourcing the Hypertherm 220632 nozzle assembly, always confirm compatibility with the materials and amperage you plan to use. Consider creating a standardized checklist that includes required specifications and vendor recommendations. Additionally, utilize suppliers that offer comprehensive product catalogs and the ability to order in bulk, which can reduce lead times and ensure that you have the right nozzle available when needed. Regularly review your inventory and reorder components before they run out to avoid project delays.

Scenario 2: High Replacement Costs Due to Frequent Wear and Tear

The Problem: Frequent use of plasma cutting equipment can lead to accelerated wear and tear on nozzles, particularly in high-volume production environments. Buyers may find themselves facing high replacement costs and unexpected downtime, negatively impacting their bottom line and operational efficiency. This scenario is especially prevalent in regions where procurement logistics can be challenging and costly.

The Solution: To mitigate replacement costs, it’s essential to implement a proactive maintenance schedule that includes regular inspections of the Hypertherm 220632 nozzle. Educate your operators on the signs of wear and the importance of routine checks. Consider investing in training sessions for your team to help them understand how to extend the life of nozzles through proper usage techniques, such as optimal cutting speeds and coolant use. Additionally, explore options for bulk purchasing or subscription services with suppliers that can offer discounts on high-volume orders, reducing per-unit costs while ensuring you have a ready supply of replacements.

Scenario 3: Inconsistent Performance Leading to Quality Control Issues

The Problem: B2B buyers often encounter quality control issues when the performance of the Hypertherm 220632 nozzle is inconsistent, leading to subpar cuts that do not meet industry standards. This inconsistency can stem from using incorrect or incompatible nozzles, improper setup, or insufficient maintenance practices, ultimately jeopardizing the quality of the finished product and customer satisfaction.

The Solution: To enhance cutting performance and maintain quality standards, buyers should invest in training for their operators focusing on the correct installation and adjustment of the Hypertherm 220632 nozzle. Implementing a quality assurance protocol that includes testing cuts at the beginning of each shift can help identify potential issues early on. Additionally, consider working closely with your suppliers to ensure you receive genuine Hypertherm products and technical support. Regularly consult with manufacturer guidelines and engage in online forums or local workshops to share best practices with industry peers. By creating a culture of quality and accountability, your team can improve cutting precision and reduce the incidence of defects.

Strategic Material Selection Guide for 220632 hypertherm

What Are the Key Materials for the 220632 Hypertherm Nozzle?

When selecting materials for the Hypertherm 220632 nozzle, it’s crucial to consider their properties, advantages, and limitations. This selection directly impacts performance, durability, and compatibility with various applications. Below, we analyze four common materials used in the construction of the 220632 nozzle, focusing on their relevance to international B2B buyers.

1. Mild Steel

Key Properties:

Mild steel is known for its excellent weldability and machinability. It typically has a temperature rating of up to 400°C and offers good strength under pressure. However, it has limited corrosion resistance, which can be a concern in humid or corrosive environments.

Pros & Cons:

Mild steel is cost-effective and readily available, making it a popular choice for many applications. Its durability is suitable for high-stress environments, but it may require additional coatings for enhanced corrosion resistance, increasing manufacturing complexity.

Impact on Application:

Mild steel is compatible with various media, particularly in industrial settings where cost is a primary concern. However, its susceptibility to rust can be a significant drawback in regions with high humidity, such as parts of Africa and South America.

Considerations for International Buyers:

Buyers in Europe and the Middle East should ensure compliance with relevant standards like DIN and ASTM for quality assurance. Additionally, they may need to consider protective coatings to enhance durability in specific climates.

2. Stainless Steel

Key Properties:

Stainless steel is recognized for its superior corrosion resistance and ability to withstand high temperatures, typically rated up to 800°C. It maintains its strength and integrity even in harsh environments.

Pros & Cons:

The primary advantage of stainless steel is its longevity and resistance to corrosion, making it ideal for applications exposed to moisture or chemicals. However, it is more expensive than mild steel and may require specialized manufacturing processes.

Impact on Application:

Stainless steel is highly compatible with a range of media, including corrosive substances, making it suitable for diverse industrial applications. Its durability enhances the lifespan of the nozzle, reducing the frequency of replacements.

Considerations for International Buyers:

International buyers should verify that the stainless steel used meets ASTM standards, particularly in regions like Germany where quality control is stringent. The higher initial cost may be offset by lower maintenance and replacement costs.

3. Copper

Key Properties:

Copper offers excellent thermal and electrical conductivity, making it beneficial in applications requiring efficient heat dissipation. It can withstand temperatures up to 300°C and is highly resistant to corrosion.

Pros & Cons:

The primary advantage of copper is its thermal efficiency, which can enhance the performance of plasma cutting applications. However, it is more expensive than steel and can be more challenging to machine.

Impact on Application:

Copper is particularly effective in applications that involve high temperatures and require rapid heat transfer. This makes it suitable for specific industrial processes, although it may not be ideal for environments with abrasive materials.

Considerations for International Buyers:

Buyers should consider the availability of copper and its compliance with international standards. In regions like the Middle East, where copper is often imported, costs can fluctuate based on market conditions.

4. Brass

Key Properties:

Brass combines copper and zinc, providing good corrosion resistance and strength. It typically operates effectively at temperatures up to 350°C and offers moderate thermal conductivity.

Pros & Cons:

Brass is less expensive than pure copper and offers excellent machinability. However, it may not perform as well in high-temperature applications compared to stainless steel or copper.

Impact on Application:

Brass is suitable for applications where moderate thermal conductivity is acceptable. It is often used in fittings and connectors but may not be the best choice for high-stress or high-temperature environments.

Considerations for International Buyers:

International buyers should ensure that brass components meet relevant standards, as different regions may have varying quality expectations. In Europe, for example, compliance with EU regulations is essential.

Summary Table of Material Selection for 220632 Hypertherm

| Material | Typical Use Case for 220632 hypertherm | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Mild Steel | General industrial applications | Cost-effective and durable | Limited corrosion resistance | Low |

| Stainless Steel | Harsh environments and corrosive media | Superior corrosion resistance | Higher cost and manufacturing complexity | High |

| Copper | High-temperature applications | Excellent thermal conductivity | Expensive and challenging to machine | Med |

| Brass | Connectors and fittings | Good machinability and moderate cost | Not ideal for high-temperature use | Med |

This strategic material selection guide provides valuable insights for B2B buyers, ensuring informed decisions that meet both operational and regulatory requirements across diverse international markets.

In-depth Look: Manufacturing Processes and Quality Assurance for 220632 hypertherm

What Are the Key Stages in the Manufacturing Process for the 220632 Hypertherm Nozzle?

The manufacturing process of the Hypertherm nozzle assembly (220632) involves several critical stages, ensuring that each component meets high standards for performance and reliability. Understanding these stages is essential for B2B buyers looking to source quality products.

Material Preparation: Selecting and Sourcing High-Quality Materials

The first step in the manufacturing process is the selection of raw materials. For the 220632 nozzle, materials such as mild steel are commonly used due to their durability and resistance to thermal stress. Suppliers typically source materials that meet specific industry standards to ensure compatibility with high-temperature applications.

Once sourced, the materials undergo rigorous quality checks to verify their composition and properties. This step ensures that the materials will perform reliably under operational conditions, which is particularly important for B2B buyers in industries such as welding and metal fabrication.

Forming: Precision Techniques for Component Shaping

Following material preparation, the forming stage involves shaping the raw materials into the desired nozzle components. Advanced techniques such as CNC machining and laser cutting are often employed to achieve precise dimensions and intricate designs.

These processes not only enhance the aesthetic quality of the nozzle but also ensure that the components fit together seamlessly during assembly. For B2B buyers, understanding the manufacturing techniques used can provide insights into the potential longevity and performance of the final product.

Assembly: Bringing Components Together with Care

The assembly stage is critical for ensuring that each component of the nozzle fits together correctly. Skilled technicians carefully assemble parts such as the nozzle body, retaining cap, and swirl ring.

During this phase, manufacturers often employ automated systems to enhance efficiency and reduce human error. Quality assurance personnel monitor this stage closely to ensure that each assembly meets the required specifications. For international B2B buyers, this level of attention to detail is essential for maintaining operational reliability.

Finishing: Ensuring Surface Quality and Performance

The final stage of manufacturing involves finishing processes, which may include surface treatments such as coating or polishing. These treatments not only enhance the visual appeal of the nozzle but also improve its resistance to wear and corrosion.

Quality checks are performed post-finishing to ensure that the nozzle meets aesthetic and functional standards. B2B buyers should inquire about the specific finishing techniques used, as these can significantly impact the durability and performance of the nozzle in demanding applications.

What Quality Assurance Standards Are Relevant for the 220632 Hypertherm?

Quality assurance is a crucial aspect of the manufacturing process, especially for products used in high-stakes environments like welding and metal cutting. Understanding the relevant international and industry-specific standards can help B2B buyers make informed purchasing decisions.

Which International Standards Are Commonly Applied?

ISO 9001 is one of the most recognized international standards for quality management systems. Manufacturers of the 220632 nozzle typically implement ISO 9001 principles to ensure consistent quality throughout the production process. Compliance with this standard signifies that the manufacturer adheres to best practices in quality management, which is essential for international buyers.

In addition to ISO standards, other certifications such as CE marking or API (American Petroleum Institute) standards may be relevant, depending on the application of the nozzle. These certifications indicate compliance with specific regulatory requirements and industry standards, which can be particularly important for buyers in the Middle East and Europe.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is integral to ensuring that products meet required specifications. Manufacturers typically implement several checkpoints throughout the production process:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon receipt to verify their quality before they enter the production process.

-

In-Process Quality Control (IPQC): During manufacturing, IPQC is conducted to monitor ongoing processes and identify any deviations from quality standards. This helps to mitigate issues before they escalate.

-

Final Quality Control (FQC): After assembly and finishing, FQC ensures that the final product meets all specifications and is ready for shipment. This step often involves functional testing and dimensional checks.

B2B buyers should inquire about the QC processes employed by suppliers to ensure that they are receiving high-quality products.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those from diverse regions such as Africa, South America, and the Middle East, verifying supplier quality control practices is crucial. Here are some actionable steps to ensure quality compliance:

What Are Effective Methods for Supplier Audits?

Conducting supplier audits is one of the most effective ways to assess a manufacturer’s quality control processes. Buyers should consider:

-

On-Site Audits: Visiting the manufacturing facility allows buyers to observe the production process firsthand, evaluate equipment, and review documentation related to quality management systems.

-

Third-Party Inspections: Engaging independent inspection agencies can provide an unbiased assessment of the supplier’s quality practices. These agencies often offer detailed reports that can be used for decision-making.

How Can Buyers Access Quality Assurance Documentation?

Buyers should request access to quality assurance documentation, including:

-

Certificates of Compliance: These documents verify that the products meet specific standards and regulations, providing assurance of quality.

-

Test Reports: Manufacturers often conduct various tests on products before shipment. Access to these reports can provide insights into the performance and reliability of the nozzle.

-

Quality Management System Documentation: Understanding the manufacturer’s quality management processes can help buyers gauge their commitment to quality assurance.

What Are the Quality Control Nuances for International B2B Buyers?

Navigating the complexities of international quality control can be challenging. B2B buyers from different regions should be aware of the following nuances:

-

Regional Standards: Different regions may have varying quality standards and certifications. Buyers should familiarize themselves with local requirements to ensure compliance.

-

Cultural Considerations: Building strong relationships with suppliers can facilitate better communication regarding quality expectations. Understanding cultural differences can enhance collaboration and minimize misunderstandings.

-

Supply Chain Transparency: Buyers should prioritize suppliers who maintain transparency throughout the supply chain. This includes clear communication regarding sourcing, manufacturing, and quality assurance practices.

By understanding the manufacturing processes and quality assurance measures associated with the Hypertherm 220632 nozzle, international B2B buyers can make informed decisions and secure high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘220632 hypertherm’

This guide aims to equip B2B buyers with a systematic approach to sourcing the Hypertherm 220632 nozzle assembly. By following these steps, you can ensure that you acquire high-quality products that meet your operational requirements.

Step 1: Define Your Technical Specifications

Understanding the technical requirements for the Hypertherm 220632 is essential. This nozzle assembly is designed for 400 Amp applications, predominantly used with mild steel. Clearly outline the specifications needed for your projects, including compatibility with existing equipment, to avoid costly mistakes.

Step 2: Identify Reliable Suppliers

Research potential suppliers specializing in Hypertherm products. Look for distributors or manufacturers with a strong reputation in the industry. Key indicators of reliability include:

– Years of operation: Suppliers with a long history often have proven track records.

– Customer reviews: Check testimonials and ratings from previous clients to gauge satisfaction and service quality.

Step 3: Evaluate Supplier Certifications

Before proceeding with a supplier, verify their certifications and compliance with industry standards. This is particularly crucial for products like the Hypertherm nozzle, which must meet safety and quality regulations. Look for:

– ISO certifications: Indicate adherence to international quality management standards.

– Industry-specific certifications: Ensure the supplier meets specific requirements relevant to your region or industry.

Step 4: Request Samples or Demonstrations

Whenever possible, request samples or product demonstrations to evaluate the quality and performance of the 220632 nozzle. This step allows you to:

– Assess the product: Ensure it meets your specifications and quality standards.

– Test compatibility: Confirm that the nozzle works seamlessly with your existing equipment.

Step 5: Negotiate Pricing and Terms

Once you’ve identified a suitable supplier, engage in negotiations regarding pricing and payment terms. Consider the following:

– Bulk discounts: Inquire about price breaks for larger orders, which can significantly reduce costs.

– Payment terms: Establish clear payment terms to manage cash flow effectively.

Step 6: Confirm Shipping and Delivery Options

Understanding the logistics of shipping is vital for timely operations. Confirm the following details with your supplier:

– Shipping costs: Request a detailed breakdown of shipping fees to avoid surprises.

– Delivery timelines: Establish clear expectations for when the product will arrive, factoring in potential delays.

Step 7: Establish Post-Purchase Support

Finally, inquire about post-purchase support, which is crucial for long-term satisfaction. Ensure your supplier offers:

– Technical assistance: Access to support for installation and troubleshooting.

– Return policies: Understand the return process in case the product does not meet your expectations.

By following these steps, you can confidently navigate the procurement process for the Hypertherm 220632 nozzle assembly, ensuring a successful purchase that aligns with your business needs.

Comprehensive Cost and Pricing Analysis for 220632 hypertherm Sourcing

What Are the Key Cost Components for Sourcing the 220632 Hypertherm?

When evaluating the cost structure for the 220632 Hypertherm nozzle assembly, several components play a critical role. These include:

-

Materials: The primary material for the 220632 is typically mild steel, which influences the base cost. Suppliers may also offer alternatives, such as stainless steel, which can increase the price due to higher material costs.

-

Labor: Labor costs can vary significantly based on the region of manufacture. Regions with lower labor costs may provide a more competitive price, but this could also affect the quality of craftsmanship.

-

Manufacturing Overhead: This includes costs associated with facility maintenance, utilities, and indirect labor. Suppliers with advanced manufacturing capabilities may have higher overhead but can produce items more efficiently.

-

Tooling: Specialized tooling for manufacturing the nozzle can represent a significant upfront cost, particularly if the design requires precision engineering. This cost is often amortized over the production volume.

-

Quality Control (QC): Rigorous QC processes ensure the reliability and performance of the nozzle, which can increase costs. Certifications and testing protocols may also add to the price.

-

Logistics: Shipping costs depend on the distance from the supplier to the buyer, the weight of the product, and the chosen shipping method. International buyers should consider potential customs duties and tariffs.

-

Margin: Suppliers will add a profit margin to cover their costs and ensure sustainability. This margin can vary widely based on the supplier’s market positioning and competitive landscape.

How Do Pricing Influencers Affect the Cost of the 220632 Hypertherm?

Several factors influence the pricing of the 220632 Hypertherm nozzle assembly:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes typically lead to lower per-unit costs due to economies of scale. Suppliers are often willing to negotiate prices for bulk purchases.

-

Specifications and Customization: Customization options can significantly affect pricing. Standard products are generally less expensive than customized versions, which may require additional engineering and production time.

-

Quality and Certifications: Products that meet specific industry standards or certifications often command higher prices. Buyers should assess whether these certifications are necessary for their applications.

-

Supplier Factors: The reputation and reliability of the supplier can influence cost. Established suppliers may charge a premium for their products due to their proven track record, while newer suppliers may offer lower prices to gain market share.

-

Incoterms: Understanding the chosen Incoterms is crucial for international transactions. They dictate who bears the costs and risks during shipping, which can significantly impact total costs.

What Buyer Tips Can Enhance Cost-Efficiency for International Procurement?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, consider the following strategies to enhance cost-efficiency:

-

Negotiation: Always engage in negotiations with suppliers. Understanding market rates and competitor pricing can provide leverage during discussions. Building a strong relationship may also lead to better terms over time.

-

Total Cost of Ownership (TCO): Evaluate not only the purchase price but also the long-term costs associated with the product, including maintenance, replacement, and operational efficiencies. A lower initial price may not always translate to savings in the long run.

-

Pricing Nuances: Be aware of pricing trends in different regions. For instance, suppliers in Europe may have different pricing strategies compared to those in the Middle East, influenced by local demand and economic conditions.

-

Shipping and Handling: Consider shipping methods and logistics providers carefully. Opting for slower shipping can reduce costs, while express services might be necessary for urgent needs. Always factor in potential delays at customs.

Disclaimer on Indicative Prices

Prices for the 220632 Hypertherm nozzle assembly can vary widely based on the factors discussed above. The indicative prices noted in various sources range from approximately $27.95 to $290.00, depending on the supplier, specifications, and additional components required. Buyers should conduct thorough market research and direct inquiries to obtain accurate pricing tailored to their needs.

Alternatives Analysis: Comparing 220632 hypertherm With Other Solutions

Understanding Alternative Solutions for 220632 Hypertherm

In the dynamic world of industrial applications, particularly in welding and cutting, the selection of the right tools and technologies is paramount. The Hypertherm 220632 nozzle assembly is a leading product designed for high-performance plasma cutting, specifically for mild steel applications at 400 amps. However, businesses often seek alternatives that may align better with their specific operational needs or budget constraints. This section explores viable alternatives to the 220632 Hypertherm nozzle, comparing their performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | 220632 Hypertherm | Alternative 1: Koike Aronson Nozzle | Alternative 2: Thermal Dynamics Nozzle |

|---|---|---|---|

| Performance | High-quality cut with precision at 400 amps | Comparable performance for mild steel | Moderate performance, varies by model |

| Cost | Approximately $27.95 | Approximately $35.50 | Approximately $25.00 |

| Ease of Implementation | Simple installation and use | User-friendly setup | Requires more technical knowledge |

| Maintenance | Low maintenance required | Moderate maintenance, easy to clean | Higher maintenance due to varied parts |

| Best Use Case | Industrial cutting of thick mild steel | General industrial applications | Budget-friendly projects and lighter metals |

Detailed Breakdown of Alternatives

Koike Aronson Nozzle

The Koike Aronson nozzle is a strong alternative to the Hypertherm 220632, priced slightly higher but offering comparable performance for cutting mild steel. Its user-friendly installation process makes it a suitable option for businesses looking to minimize downtime. However, maintenance is moderate; while it is easy to clean, users may find that certain components wear out more quickly than those in the Hypertherm nozzle. It is best used in general industrial applications where precision is important but not the sole factor.

Thermal Dynamics Nozzle

The Thermal Dynamics nozzle offers a budget-friendly alternative, typically priced lower than the Hypertherm option. It is suitable for lighter metal cutting and can handle various applications, making it a versatile choice for small to medium-sized projects. However, its performance may not match the precision of the Hypertherm nozzle, especially in high-demand environments. Additionally, this nozzle may require more frequent maintenance and technical knowledge to ensure optimal performance, which could lead to higher overall costs in complex operations.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting a nozzle assembly for plasma cutting, B2B buyers should carefully consider their specific operational requirements and budget constraints. The Hypertherm 220632 is ideal for those who prioritize high performance and low maintenance, particularly in demanding industrial applications. On the other hand, the Koike Aronson nozzle offers a solid alternative with user-friendly features for general applications, while the Thermal Dynamics nozzle can serve budget-conscious businesses needing flexibility for lighter tasks. By evaluating these aspects, buyers can make informed decisions that align with their operational goals and ensure efficient use of resources.

Essential Technical Properties and Trade Terminology for 220632 hypertherm

What Are the Key Technical Properties of the 220632 Hypertherm Nozzle?

When considering the Hypertherm Nozzle Assembly 220632, several technical specifications are crucial for understanding its performance and suitability for various applications in the metalworking industry. Here are the most relevant properties:

-

Current Rating (400 Amps): This nozzle is rated for a maximum output of 400 amps, which indicates its capacity to handle high power levels without overheating. For B2B buyers, this means the nozzle can efficiently cut through thicker materials, making it ideal for industrial applications involving heavy metal fabrication.

-

Material Composition (Mild Steel): The 220632 nozzle is designed primarily for use with mild steel. This specification is important for ensuring compatibility with the materials being worked on. B2B buyers must consider the material properties to prevent premature wear and ensure optimal cutting performance.

-

Compatibility with Plasma Systems: The nozzle is specifically designed for use with Hypertherm’s HPR400XD plasma systems. This ensures seamless integration into existing equipment. For businesses, this compatibility can reduce downtime and maintenance costs, as they can rely on standardized parts.

-

Bevel Cutting Capability: The nozzle supports bevel cutting at 400 amps, which enhances its versatility in various applications. Bevel cuts are often required for weld preparation, and having this capability allows buyers to streamline their operations and reduce the need for additional equipment.

-

Retention Cap Design: The nozzle assembly includes a retention cap (model 220635), which plays a vital role in securing the nozzle during operation. This feature is crucial for maintaining cutting accuracy and preventing damage to the nozzle, thereby reducing replacement costs for buyers.

-

Durability and Longevity: The construction of the nozzle is designed to withstand the harsh conditions of plasma cutting, ensuring a longer lifespan. For B2B buyers, investing in durable components like the 220632 nozzle can lead to lower operational costs and improved productivity over time.

Which Trade Terms Are Essential for Understanding the 220632 Hypertherm Nozzle?

Understanding the specific trade terminology associated with the 220632 Hypertherm nozzle can significantly enhance communication between buyers and suppliers. Here are some key terms:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In this context, Hypertherm is the OEM for the 220632 nozzle, ensuring that buyers receive parts specifically designed for their systems.

-

MOQ (Minimum Order Quantity): This term signifies the smallest quantity of a product that a supplier is willing to sell. B2B buyers should be aware of MOQ requirements to plan their inventory and purchasing strategies effectively.

-

RFQ (Request for Quotation): An RFQ is a formal request from a buyer to suppliers to provide pricing and terms for specific products. This process is critical for B2B transactions, allowing buyers to compare offers and negotiate better deals.

-

Incoterms (International Commercial Terms): These are standardized terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping, insurance, and risk management associated with their purchases.

-

Lead Time: This term refers to the time taken from placing an order to delivery. Understanding lead times is essential for planning production schedules and inventory management, especially for businesses that rely on timely deliveries for operational efficiency.

-

Warranty: A warranty is a guarantee provided by the manufacturer regarding the quality and lifespan of a product. Knowing the warranty terms for the 220632 nozzle is important for buyers to ensure they are covered in case of defects or premature failure.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing the Hypertherm Nozzle Assembly 220632, ensuring they select the right components for their specific operational needs.

Navigating Market Dynamics and Sourcing Trends in the 220632 hypertherm Sector

What Are the Current Market Trends Influencing the 220632 Hypertherm Sector?

The global demand for high-performance plasma cutting technologies, such as the Hypertherm 220632 nozzle assembly, is being driven by several key factors. One major driver is the increasing need for precision in industrial applications across various sectors, including manufacturing, automotive, and construction. As businesses seek to enhance operational efficiency and reduce production costs, the adoption of advanced cutting technologies becomes essential. Furthermore, the rise of automation and Industry 4.0 is shaping the way companies approach sourcing, prompting them to seek suppliers that offer innovative technologies and integrated solutions.

Emerging trends in B2B sourcing highlight the importance of digital transformation. International buyers are increasingly relying on e-commerce platforms and digital marketplaces to streamline procurement processes. This shift not only improves accessibility to products like the Hypertherm 220632 but also enables buyers to compare prices, assess supplier credibility, and make informed purchasing decisions quickly. Additionally, regional dynamics play a crucial role; for instance, the Middle East and Africa are seeing substantial investments in infrastructure, creating a surge in demand for reliable cutting equipment.

In Europe, particularly in countries like Germany, there is a growing emphasis on high-quality standards and certifications, which can significantly impact sourcing decisions. Buyers are more inclined to partner with manufacturers who can demonstrate compliance with international quality and safety regulations, ensuring that products like the 220632 nozzle meet the required performance criteria.

How Are Sustainability and Ethical Sourcing Shaping the 220632 Hypertherm Market?

Sustainability has become a pivotal concern for B2B buyers globally, influencing sourcing strategies across industries. The environmental impact of manufacturing processes, particularly in sectors reliant on heavy machinery and cutting technologies, cannot be overlooked. For buyers in regions such as Africa and South America, there is a pressing need to align procurement practices with sustainable development goals.

The importance of ethical supply chains is increasingly recognized, with businesses striving to ensure that their suppliers adhere to environmentally responsible practices. This includes sourcing materials for products like the Hypertherm 220632 that are recyclable or produced with reduced carbon footprints. Certifications such as ISO 14001 or adherence to the Global Reporting Initiative (GRI) can serve as indicators of a supplier’s commitment to sustainability, making them more attractive to conscientious buyers.

Incorporating ‘green’ materials not only supports environmental goals but can also enhance a company’s brand reputation. For instance, using eco-friendly packaging for the delivery of Hypertherm products can resonate well with customers who prioritize sustainability. As a result, buyers should actively seek suppliers that prioritize sustainable practices and can provide transparency in their sourcing processes.

What Is the Historical Context Behind the 220632 Hypertherm Nozzle Assembly?

The Hypertherm 220632 nozzle assembly has evolved alongside advancements in plasma cutting technology, reflecting a broader trend of innovation within the industry. Initially developed to meet the growing demands of metal fabrication and other industrial applications, the design and functionality of the 220632 have been optimized over the years to enhance cutting speed and precision.

As industries began to prioritize efficiency and accuracy, Hypertherm responded by investing in research and development, leading to the creation of more sophisticated nozzle designs. This evolution has positioned the 220632 as a reliable choice for international buyers seeking high-quality cutting solutions. Its compatibility with various materials, including mild steel, and its ability to handle significant amperage demonstrate its versatility and effectiveness in diverse applications.

In summary, the historical development of the 220632 nozzle assembly underscores the importance of continuous improvement in meeting the evolving needs of B2B buyers worldwide. By understanding these trends, buyers can make informed decisions that align with their operational goals and sustainability objectives.

Frequently Asked Questions (FAQs) for B2B Buyers of 220632 hypertherm

-

How do I solve issues with the Hypertherm 220632 nozzle assembly?

If you’re experiencing problems with the Hypertherm 220632 nozzle assembly, first ensure that it is properly installed and compatible with your equipment. Check for any signs of wear or damage, such as cracks or excessive buildup of materials that could obstruct airflow. Regular maintenance, including cleaning and timely replacement of worn parts, is crucial to prevent operational issues. For persistent problems, consult the manufacturer’s guidelines or contact your supplier for technical support. -

What is the best nozzle type for cutting mild steel?

The Hypertherm 220632 nozzle assembly is specifically designed for cutting mild steel at 400 amps. It offers excellent performance in terms of cutting speed and quality. When selecting a nozzle, consider factors like material thickness and cutting speed requirements. Always refer to the manufacturer’s specifications to ensure optimal results and compatibility with your plasma cutting system. -

What are the minimum order quantities (MOQ) for the Hypertherm 220632?

Minimum order quantities can vary significantly between suppliers. Typically, for the Hypertherm 220632 nozzle assembly, MOQs may range from one to several units, depending on the supplier’s policies and your geographical location. It’s advisable to communicate directly with suppliers to understand their specific MOQ requirements and negotiate terms that suit your business needs. -

What payment terms should I expect when purchasing Hypertherm products internationally?

Payment terms can differ based on the supplier and the region. Common terms for international transactions include advance payment, letter of credit, or payment upon delivery. Some suppliers might offer net payment terms (e.g., net 30 or net 60 days). Always clarify payment methods and terms before finalizing your order to avoid any misunderstandings during the transaction process. -

How can I ensure the quality of the Hypertherm 220632 I am purchasing?

To ensure quality, source the Hypertherm 220632 nozzle assembly from reputable suppliers with established track records. Request product certifications and quality assurance documentation to verify that the products meet industry standards. Additionally, consider suppliers that offer warranties or return policies, which can provide added assurance regarding product quality and performance. -

What logistics considerations should I keep in mind for international shipping of Hypertherm products?

When arranging international shipping for Hypertherm products, consider factors like shipping costs, customs duties, and transit times. Choose a reliable logistics partner experienced in handling industrial equipment. Ensure that all necessary documentation, such as invoices and packing lists, is in order to facilitate smooth customs clearance. Tracking options can also help you monitor your shipment’s progress. -

Can I customize the Hypertherm 220632 nozzle assembly for my specific needs?

Customization options may be available depending on the supplier. If you have specific requirements, such as modifications for different materials or cutting speeds, discuss these with your supplier. They may offer tailored solutions or alternative products that better meet your operational needs. Always verify that any customization will not compromise the product’s integrity or performance. -

What support can I expect after purchasing the Hypertherm 220632 nozzle assembly?

Post-purchase support varies by supplier but typically includes customer service for inquiries and troubleshooting. Many suppliers also offer technical assistance, installation guidance, and maintenance tips. Additionally, some manufacturers provide online resources, such as manuals and video tutorials, to help you maximize the use of the Hypertherm 220632. Always inquire about available support options before making your purchase.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 220632 Hypertherm Manufacturers & Suppliers List

1. Hypertherm – HPR 400 Amp Nozzle

Domain: harrisweldingsupplies.com

Registered: 2000 (25 years)

Introduction: {‘name’: ‘Hypertherm HPR 400 Amp Nozzle’, ‘sku’: ‘220632’, ‘price’: ‘$28.58’, ‘original_price’: ‘$35.50’, ‘savings’: ‘$6.92’, ‘compatible_with’: ‘Mild Steel 400 Amp and 400 Amp Bevel’}

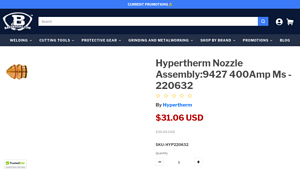

2. Hypertherm – Nozzle Assembly 9427

Domain: shop.arcsolinc.com

Registered: 2012 (13 years)

Introduction: {“name”:”Hypertherm Nozzle Assembly:9427 400AMP MS 220632″,”price”:”$27.95″,”sku”:”220632″,”weight”:”4″,”description”:”Mild Steel 400 A”,”shipping_info”:”Free 3 Day Shipping on Orders over $99″,”return_policy”:”Free returns”}

3. Airgas – HYP220632

4. Hypertherm – Mild Steel Nozzle & Bevel

Domain: lindedirect.com

Registered: 2020 (5 years)

Introduction: This company, Hypertherm – Mild Steel Nozzle & Bevel, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

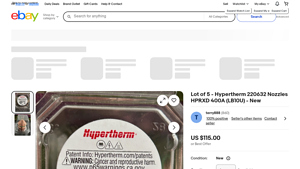

5. Hypertherm – Lot of 5 Plasma Cutter Nozzles

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“title”:”Lot of 5 – Hypertherm 220632 Nozzles HPRXD 400A (LB10U) – New”,”condition”:”New”,”brand”:”Hypertherm”,”MPN”:”220632″,”item_type”:”Plasma Cutter Nozzle”,”quantity_available”:3,”price”:”US $115.00″,”shipping_cost”:”US $20.00″,”shipping_method”:”FedEx Ground Economy”,”location”:”North York, Ontario, Canada”,”estimated_delivery_dates”:”between Tue, Sep 23 and Thu, Oct 16 to 10118″,”returns”:…

6. Hypertherm – 220632 Nozzle Assembly

Domain: weldfabulous.com

Registered: 2003 (22 years)

Introduction: Hypertherm 220632 Nozzle Assembly, 9427 400 Amp MS

7. Hypertherm – Nozzle Assembly 9427 400Amp Ms

Domain: bakersgas.com

Registered: 1999 (26 years)

Introduction: Hypertherm Nozzle Assembly: 9427 400Amp Ms – 220632

Strategic Sourcing Conclusion and Outlook for 220632 hypertherm

In the realm of strategic sourcing for Hypertherm products, particularly the 220632 nozzle assembly, understanding the nuances of compatibility and pricing is essential for international B2B buyers. The 220632 nozzle is designed for high-performance applications, notably with mild steel at 400 amps, making it a critical component for businesses focused on efficiency and quality in plasma cutting operations.

By prioritizing strategic sourcing, companies can optimize their supply chains, ensuring not only cost-effectiveness but also reliability in product availability. Engaging with trusted suppliers who offer transparent pricing and timely delivery can significantly enhance operational workflows, especially in regions like Africa, South America, the Middle East, and Europe.

As you consider your sourcing strategies, remember that the right nozzle can improve not just the quality of your cuts but also the longevity of your equipment, ultimately contributing to lower operational costs. Looking ahead, we encourage you to explore partnerships with reputable suppliers to secure the best pricing and support for your Hypertherm needs. Investing in quality sourcing now will position your business for success in a competitive global market.