Unlocking Value: A Strategic Analysis of the 12X12 Stainless Steel Mesh Market

Introduction: Navigating the Global Market for 12×12 stainless steel mesh

In today’s competitive landscape, sourcing high-quality 12×12 stainless steel mesh can present significant challenges for international B2B buyers. As industries ranging from construction to filtration increasingly turn to this versatile material, understanding its applications, properties, and sourcing strategies becomes crucial. This comprehensive guide aims to equip decision-makers from Africa, South America, the Middle East, and Europe—particularly Germany and Saudi Arabia—with the insights needed to make informed purchasing decisions.

Within this guide, readers will find an exploration of different types of 12×12 stainless steel mesh, including variations in wire diameter and material grades, as well as their specific applications across multiple sectors. We will delve into supplier vetting processes, offering practical tips on identifying reliable manufacturers and distributors. Additionally, we will address cost considerations, including bulk purchasing strategies and shipping logistics, enabling buyers to optimize their procurement budgets.

By synthesizing essential information and actionable insights, this guide empowers B2B buyers to navigate the global market effectively, ensuring they select the right stainless steel mesh solutions for their unique operational needs. Whether you are looking to enhance product quality, improve durability, or streamline supply chains, this resource serves as your strategic partner in sourcing success.

Understanding 12×12 stainless steel mesh Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 304 Stainless Steel Mesh | Corrosion-resistant, versatile, cost-effective | Food processing, construction | Pros: Good corrosion resistance; Cons: Limited heat resistance compared to 316. |

| 316 Stainless Steel Mesh | Enhanced corrosion resistance, especially in saline environments | Marine applications, chemical processing | Pros: Superior durability; Cons: Higher cost than 304. |

| Woven Wire Mesh | Interlaced pattern, customizable opening sizes | Filtration, screening | Pros: Flexible applications; Cons: May require precise specifications. |

| Welded Wire Mesh | Rigid structure, uniform openings | Security fencing, reinforcement | Pros: High strength; Cons: Less flexibility in applications. |

| Architectural Mesh | Aesthetic design options, light transmission | Facades, decorative elements | Pros: Enhances visual appeal; Cons: May be costlier due to design complexity. |

What are the characteristics of 304 Stainless Steel Mesh?

304 stainless steel mesh is known for its excellent corrosion resistance and versatility, making it an ideal choice for various applications. Its cost-effectiveness allows businesses to utilize it in food processing and construction without incurring high expenses. Buyers should consider its limitations, particularly its performance in high-temperature environments, where 316 stainless steel might be more suitable. Overall, 304 mesh is a reliable option for companies seeking durability at a reasonable price.

How does 316 Stainless Steel Mesh differ from 304?

316 stainless steel mesh offers enhanced corrosion resistance, particularly in marine and chemical environments. This makes it a preferred choice for industries that require durability against harsh conditions. While it is more expensive than 304, the investment pays off in terms of longevity and reduced maintenance costs. Buyers should evaluate their specific application needs, especially if they operate in environments with high salinity or corrosive substances, to determine if the benefits of 316 justify the higher cost.

What are the advantages of Woven Wire Mesh?

Woven wire mesh features an interlaced pattern that allows for customizable opening sizes, making it suitable for a wide range of filtration and screening applications. Its flexibility in design makes it a popular choice for industries requiring tailored solutions. However, buyers must ensure precise specifications to avoid mismatches in application. This type of mesh is ideal for businesses looking for adaptability without sacrificing structural integrity.

Why choose Welded Wire Mesh for security applications?

Welded wire mesh is characterized by its rigid structure and uniform openings, making it a robust option for security fencing and reinforcement. Its high strength provides enhanced protection, making it suitable for industrial and commercial applications. While it offers less flexibility compared to woven mesh, its durability makes it a reliable choice for buyers focused on security and structural integrity. Companies should assess their specific security needs to determine the best configuration for their projects.

How can Architectural Mesh enhance design projects?

Architectural mesh is designed with aesthetic appeal in mind, offering a variety of designs that enhance visual interest while allowing light transmission. This type of mesh is commonly used in building facades and decorative elements, providing a modern touch to architectural projects. Although it may come at a higher price point due to its design complexity, the benefits of adding visual value to a project can outweigh the costs. Buyers should consider their design goals and budget when selecting architectural mesh to ensure alignment with their overall vision.

Key Industrial Applications of 12×12 stainless steel mesh

| Industry/Sector | Specific Application of 12×12 stainless steel mesh | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Filtration and sieving in food processing | Ensures product purity and safety, compliant with regulations | Need for hygienic materials, resistance to corrosion, and easy cleaning |

| Construction and Architecture | Reinforcement in concrete and plastering | Increases structural integrity and longevity | Sourcing compliant materials that meet local building codes |

| Mining and Minerals | Screening and separation of ores | Improves efficiency in material handling and processing | Durability against abrasive materials and specific mesh openings |

| Agriculture and Horticulture | Crop protection and soil stabilization | Enhances crop yield and reduces pest damage | Requirements for UV resistance and environmental sustainability |

| Automotive | Grille and guard fabrication for vehicles | Provides protection and aesthetic appeal | Consideration for weight, corrosion resistance, and custom sizes |

How is 12×12 Stainless Steel Mesh Utilized in the Food and Beverage Industry?

In the food and beverage sector, 12×12 stainless steel mesh is primarily used for filtration and sieving processes. This mesh type ensures that contaminants are removed, maintaining product purity and adhering to strict food safety regulations. International buyers must prioritize suppliers that provide hygienic materials, as well as those that comply with local health standards, ensuring the mesh can withstand frequent cleaning and exposure to various substances.

What Role Does 12×12 Stainless Steel Mesh Play in Construction and Architecture?

In construction and architecture, 12×12 stainless steel mesh is often employed as reinforcement in concrete and plastering applications. This mesh enhances the structural integrity of buildings, contributing to their longevity and safety. When sourcing, buyers should ensure that the mesh meets local building codes and standards, as well as consider the specific structural requirements of their projects to ensure optimal performance.

How is 12×12 Stainless Steel Mesh Applied in Mining and Minerals?

The mining and minerals industry utilizes 12×12 stainless steel mesh for screening and separating ores. This application is crucial for improving efficiency in material handling and processing, enabling miners to achieve higher yields. Buyers in this sector must focus on the durability of the mesh against abrasive materials and ensure that the mesh openings are tailored to their specific processing needs.

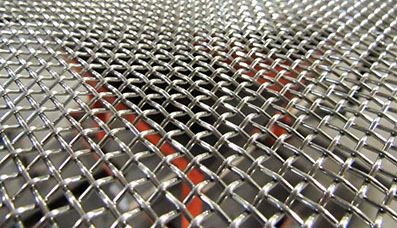

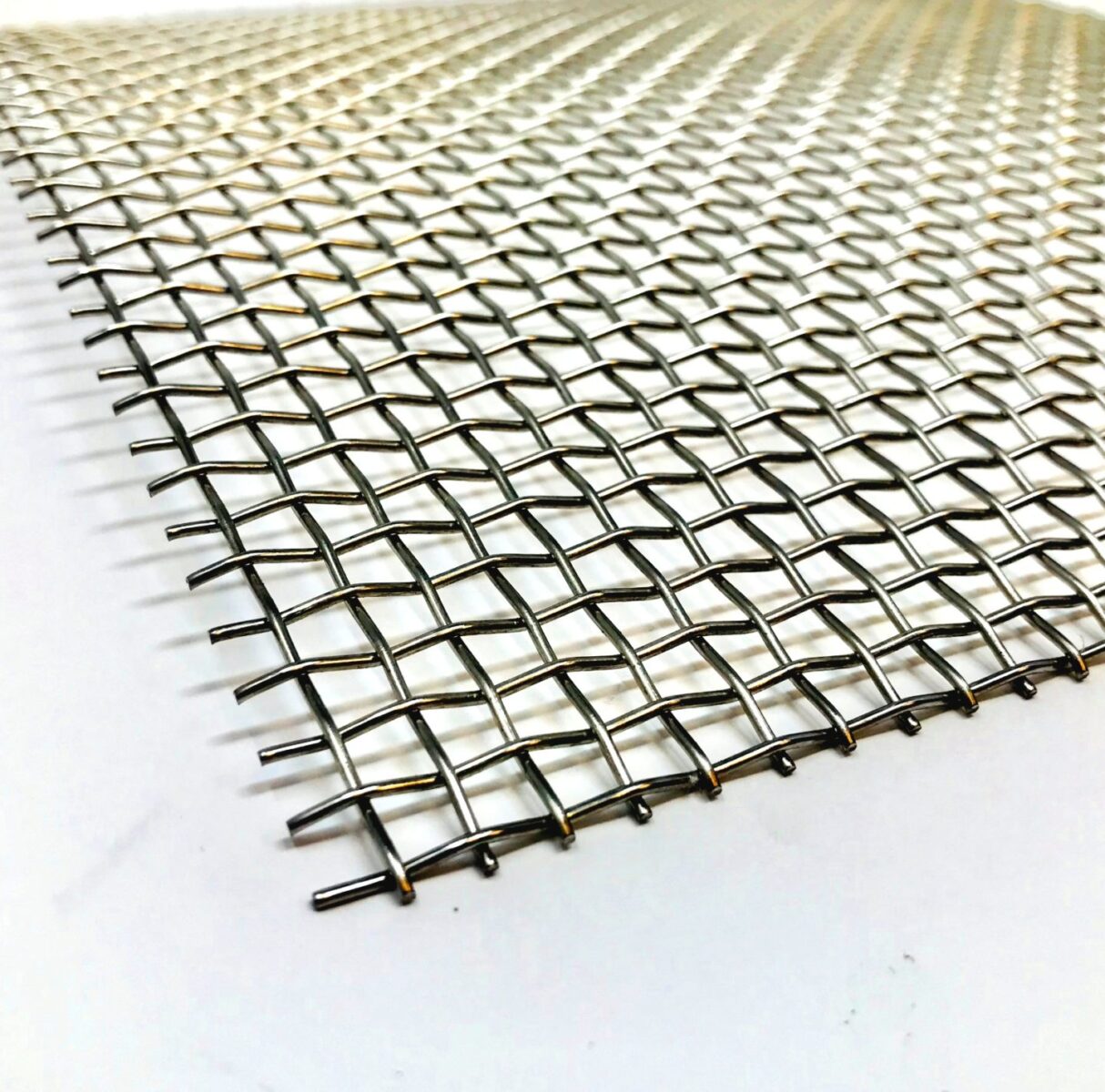

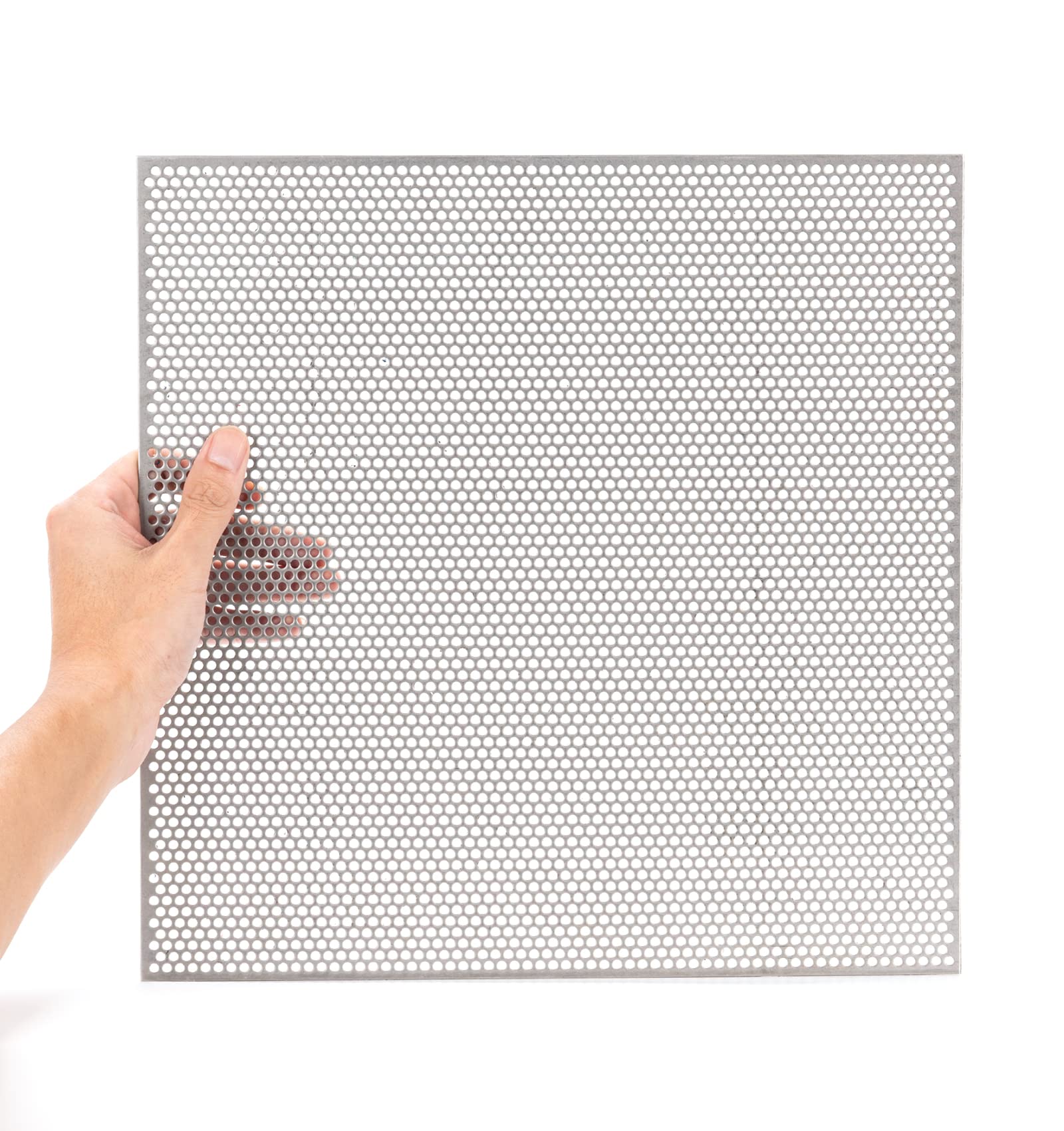

Illustrative image related to 12×12 stainless steel mesh

Why is 12×12 Stainless Steel Mesh Important in Agriculture and Horticulture?

In agriculture and horticulture, 12×12 stainless steel mesh serves as a protective barrier for crops and aids in soil stabilization. By using this mesh, farmers can enhance crop yields while simultaneously reducing pest damage. Buyers should seek mesh that offers UV resistance and aligns with sustainable farming practices, ensuring it can withstand environmental factors while supporting crop health.

How is 12×12 Stainless Steel Mesh Used in the Automotive Sector?

In the automotive industry, 12×12 stainless steel mesh is commonly used for fabricating grilles and guards for vehicles. This application not only provides protection for critical components but also adds an aesthetic appeal to the vehicle design. Buyers need to consider factors such as weight, corrosion resistance, and the possibility of custom sizes to meet specific vehicle requirements, ensuring both functionality and style.

3 Common User Pain Points for ’12×12 stainless steel mesh’ & Their Solutions

Scenario 1: Difficulty in Sourcing High-Quality Mesh for Industrial Applications

The Problem: B2B buyers in industries such as manufacturing, construction, or filtration often encounter challenges when sourcing 12×12 stainless steel mesh that meets specific quality standards. With varying grades of stainless steel available, buyers may struggle to determine which material is most suitable for their applications, leading to potential operational issues, increased costs, and even project delays. For instance, a construction firm might need durable mesh for safety barriers but ends up with a lower-grade product that cannot withstand environmental stressors, compromising safety and increasing liability.

The Solution: To ensure the procurement of high-quality 12×12 stainless steel mesh, buyers should first establish clear specifications based on their project requirements. Considerations should include the grade of stainless steel (e.g., 304 vs. 316), wire diameter, and mesh size to suit the intended use. Engaging with reputable suppliers who provide detailed product information, certifications, and samples can significantly enhance sourcing outcomes. Buyers should also inquire about the manufacturing processes and quality assurance measures the supplier employs. Establishing a reliable supply chain with feedback mechanisms can help ensure consistent quality and performance.

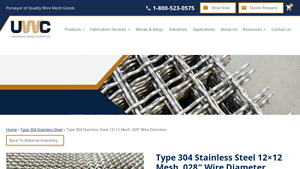

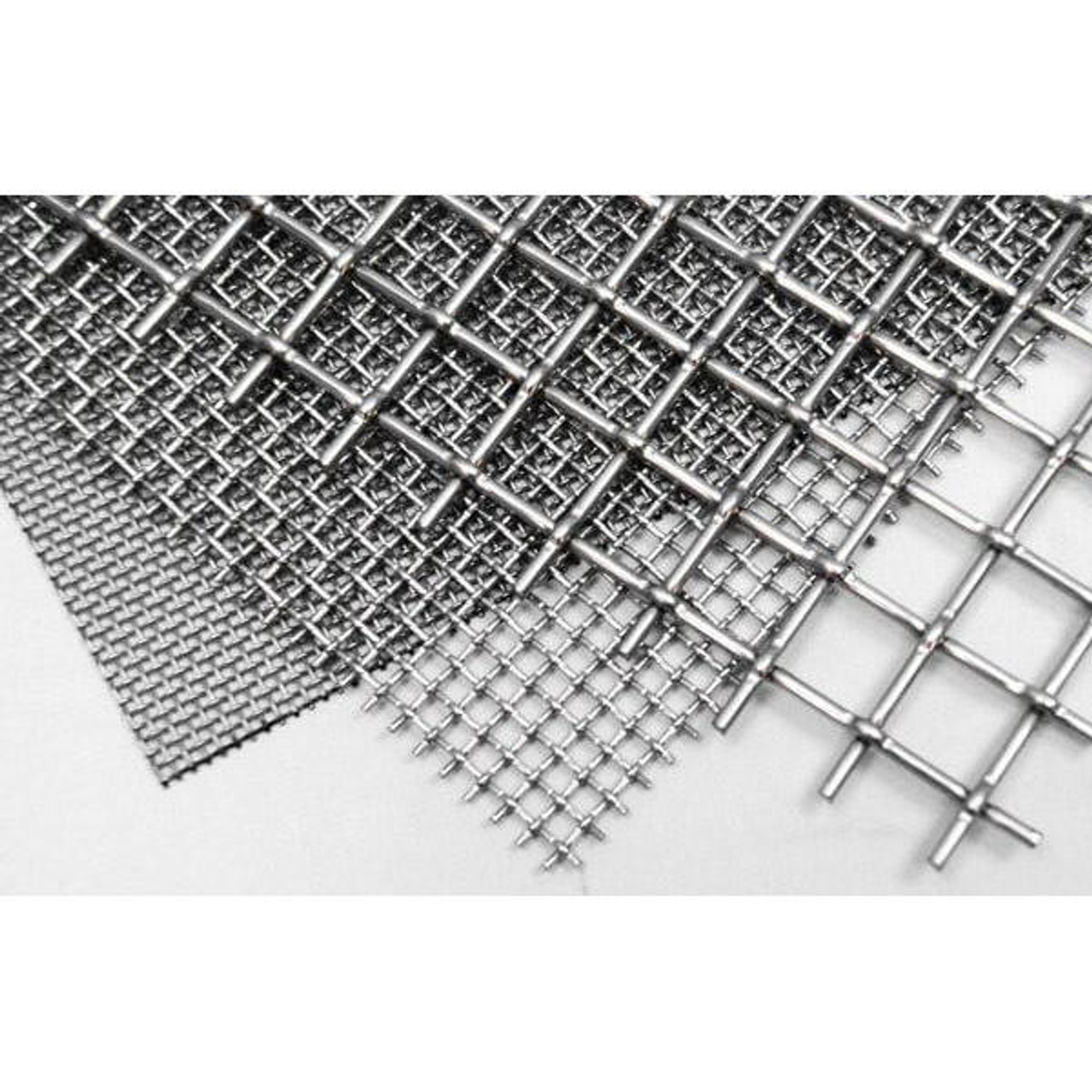

Illustrative image related to 12×12 stainless steel mesh

Scenario 2: Inconsistent Mesh Size Leading to Project Delays

The Problem: B2B buyers often face issues with inconsistent mesh sizes during procurement, which can lead to significant project delays and cost overruns. For example, a manufacturer may order 12×12 stainless steel mesh but receive products that do not conform to the specified dimensions, disrupting their production line and causing frustration among teams that rely on precise specifications for assembly or filtration applications.

The Solution: To mitigate the risk of receiving inconsistent mesh sizes, buyers should implement a robust quality control process at the time of order placement. This includes explicitly stating tolerances and dimensions in purchase orders and requesting a Certificate of Compliance from suppliers. Additionally, conducting pre-shipment inspections or utilizing third-party verification services can ensure the mesh meets the required specifications before leaving the supplier’s facility. Building long-term relationships with suppliers who understand your quality standards can also lead to improved consistency over time.

Scenario 3: Challenges with Mesh Durability and Longevity

The Problem: In various industrial applications, the durability and longevity of 12×12 stainless steel mesh can be a significant concern. Buyers in sectors such as food processing or chemical manufacturing may find that lower-grade mesh degrades quickly under harsh conditions, leading to frequent replacements, increased maintenance costs, and potential contamination risks. For instance, mesh used in a food processing plant must withstand cleaning chemicals while maintaining structural integrity, or else it can lead to product safety issues.

The Solution: To address durability concerns, it is essential for buyers to select the appropriate grade of stainless steel based on environmental factors and application requirements. For high-corrosion environments, opting for a higher-grade stainless steel, such as 316, is advisable due to its enhanced resistance to chemicals and saltwater. Additionally, implementing regular maintenance schedules and inspections can help identify signs of wear and tear early, allowing for timely replacements before failure occurs. Buyers should also consider investing in mesh with protective coatings or treatments designed to enhance longevity in specific applications, thereby reducing overall lifecycle costs.

Strategic Material Selection Guide for 12×12 stainless steel mesh

What Are the Key Properties of 304 Stainless Steel for 12×12 Mesh Applications?

304 stainless steel is the most commonly used grade for woven wire mesh, including 12×12 configurations. It offers excellent corrosion resistance, making it suitable for a variety of applications, from food processing to architectural uses. This material can withstand temperatures up to 870°C (1600°F) in intermittent service and 925°C (1700°F) in continuous service. Its durability is enhanced by its ability to resist oxidation, which is critical in environments exposed to moisture or chemicals.

Pros: The primary advantages of 304 stainless steel include its high corrosion resistance and good formability, which contribute to its versatility across multiple sectors. It is also relatively cost-effective compared to other stainless steel grades.

Cons: However, 304 stainless steel may not be suitable for environments with chlorides, as it can lead to pitting corrosion. Additionally, it is less resistant to high temperatures compared to other alloys such as 316 stainless steel.

How Does 316 Stainless Steel Enhance Performance for 12×12 Mesh?

316 stainless steel is often preferred for applications requiring superior corrosion resistance, especially in marine environments or chemical processing. It contains molybdenum, which significantly enhances its resistance to pitting and crevice corrosion. This material can handle temperatures similar to 304 stainless steel but offers better performance in saline or acidic conditions.

Pros: The key advantage of 316 stainless steel is its exceptional durability and resistance to harsh chemicals, making it ideal for food processing and pharmaceutical applications.

Cons: The primary drawback is its higher cost compared to 304 stainless steel, which can impact budgets for large-scale projects.

What Are the Unique Benefits of Galvanized Steel Mesh for 12×12 Applications?

Galvanized steel mesh is another option, particularly for outdoor applications. The galvanization process provides a protective zinc coating that enhances corrosion resistance. This material is suitable for applications like fencing, drainage, and construction.

Pros: One of the main advantages of galvanized steel is its cost-effectiveness. It offers good durability and a longer lifespan than untreated steel when exposed to the elements.

Cons: However, galvanized steel is not as corrosion-resistant as stainless steel, especially in acidic or saline environments. Additionally, the zinc coating can wear off over time, leading to rust formation.

Why Is Aluminum Mesh a Viable Alternative for 12×12 Mesh Applications?

Aluminum mesh is lightweight and offers excellent corrosion resistance, making it suitable for applications where weight savings are critical, such as in aerospace and automotive industries. It also has a good strength-to-weight ratio and can be anodized for added protection.

Pros: The primary advantage of aluminum mesh is its lightweight nature, which can reduce shipping costs and ease installation. It is also non-magnetic and resistant to corrosion.

Cons: The main limitation is its lower strength compared to stainless steel, which may not be suitable for heavy-duty applications. Additionally, aluminum can be more expensive than galvanized steel.

Summary Table of Material Selection for 12×12 Stainless Steel Mesh

| Material | Typical Use Case for 12×12 Stainless Steel Mesh | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| 304 Stainless Steel | Food processing, architectural applications | High corrosion resistance | Not suitable for chlorides | Medium |

| 316 Stainless Steel | Marine environments, chemical processing | Superior corrosion resistance | Higher cost than 304 | High |

| Galvanized Steel | Fencing, drainage, construction | Cost-effective and durable | Less corrosion resistance than stainless | Low |

| Aluminum | Aerospace, automotive applications | Lightweight and corrosion-resistant | Lower strength compared to stainless | Medium |

This strategic material selection guide provides a comprehensive overview of the various materials available for 12×12 stainless steel mesh, helping B2B buyers make informed decisions based on their specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for 12×12 stainless steel mesh

What Are the Main Manufacturing Processes for 12×12 Stainless Steel Mesh?

The production of 12×12 stainless steel mesh involves a series of well-defined stages that ensure the final product meets the rigorous demands of various applications across industries. Understanding these processes is crucial for B2B buyers looking to procure high-quality mesh for projects in sectors like construction, filtration, and automotive.

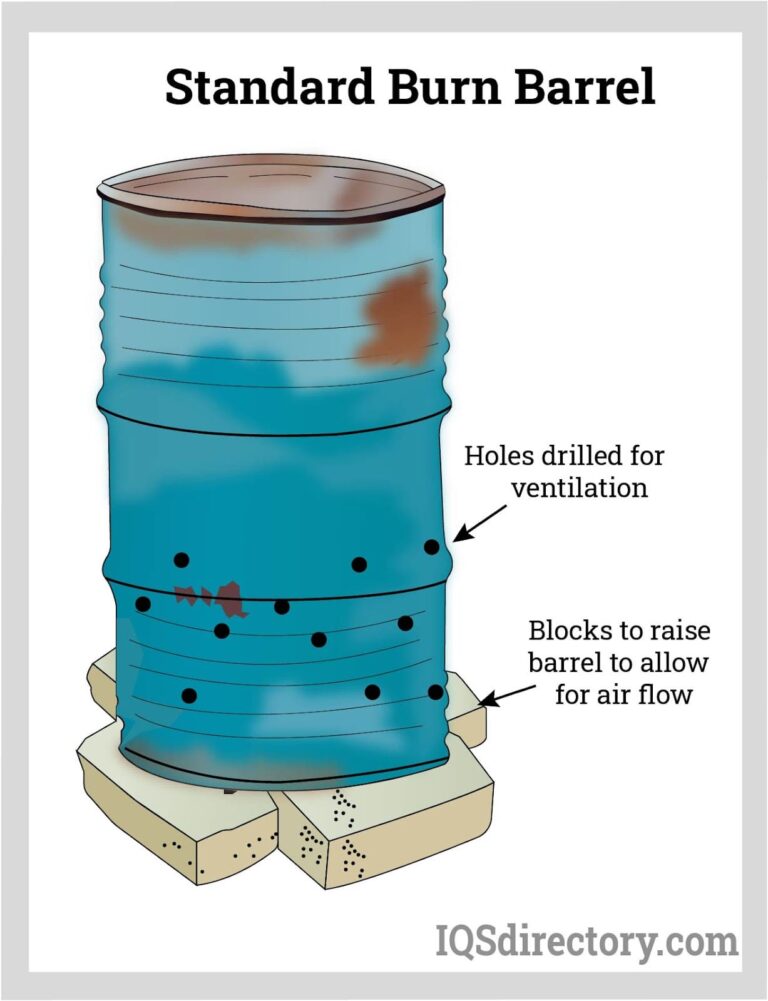

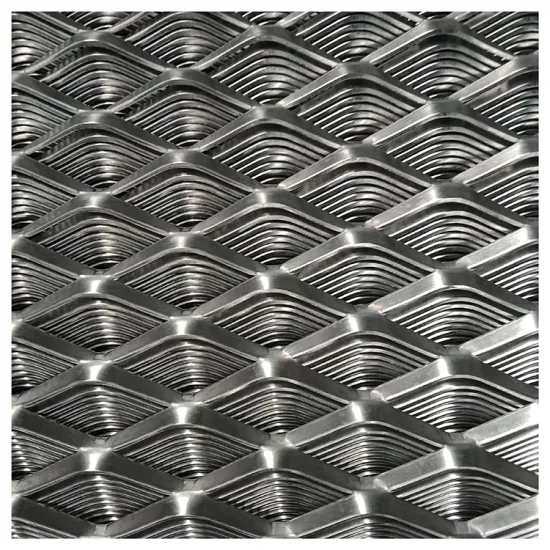

Illustrative image related to 12×12 stainless steel mesh

How Is Material Prepared for 12×12 Stainless Steel Mesh Production?

The manufacturing process begins with the selection of high-grade stainless steel, typically 304 or 316 grades, known for their corrosion resistance and durability. The raw materials undergo stringent quality checks to ensure they meet industry standards. Once approved, the steel is cut into wire forms, often using precision wire drawing techniques. This step involves reducing the diameter of the wire to the desired thickness, which for 12×12 mesh is typically around 0.023 inches.

What Techniques Are Used in Forming the Mesh?

Once the wire is prepared, it is subjected to weaving or welding, depending on the intended application. The weaving process involves interlacing the wires to create the mesh pattern. For 12×12 mesh, the specific weave pattern is designed to provide optimal strength and flexibility. Alternatively, welded mesh is produced by intersecting wires and applying heat at the junctions to bond them together, offering additional structural integrity.

During this stage, advanced machinery is often employed to maintain consistency in mesh size and wire tension, which are crucial for the product’s performance in real-world applications.

How Does Assembly and Finishing Work for Stainless Steel Mesh?

Following the forming stage, the assembled mesh undergoes finishing processes. This may include cleaning to remove any residues from production, followed by surface treatments such as passivation. Passivation enhances the corrosion resistance of stainless steel by removing free iron and promoting the formation of a protective oxide layer.

Quality control checkpoints are integrated into the assembly line to verify that the mesh meets specified dimensional tolerances and surface quality. This proactive approach minimizes defects and ensures that the final product adheres to international standards.

What Quality Assurance Standards Are Relevant for 12×12 Stainless Steel Mesh?

Quality assurance is paramount in the production of stainless steel mesh, particularly for international markets. Adherence to ISO 9001 standards is common, as it outlines the requirements for an effective quality management system. Companies may also seek certifications such as CE marking for compliance with European safety standards or API certifications for oil and gas applications.

How Are Quality Control Checkpoints Established in Manufacturing?

Quality control (QC) is typically structured around several key checkpoints:

-

Incoming Quality Control (IQC): This phase involves inspecting raw materials for compliance with specifications before they enter the production process. This step is vital for ensuring that only the highest quality materials are used.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, continuous monitoring is conducted to detect any deviations from quality standards. This includes checking wire diameter, mesh size, and structural integrity during weaving or welding.

-

Final Quality Control (FQC): Once the mesh is completed, it undergoes rigorous testing to ensure it meets all specified criteria. This may involve visual inspections, dimensional checks, and functional testing under simulated conditions.

What Common Testing Methods Are Employed for Quality Assurance?

To ensure the integrity and performance of 12×12 stainless steel mesh, various testing methods are utilized:

- Tensile Testing: Determines the strength and ductility of the wire used in the mesh.

- Corrosion Resistance Testing: Assesses the mesh’s ability to withstand environmental factors that could lead to degradation.

- Microscopic Examination: Provides insights into the weave quality and any potential defects that could affect performance.

How Can B2B Buyers Verify Supplier Quality Assurance Practices?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality assurance practices is crucial. Here are some effective strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to directly assess the manufacturing processes, quality control measures, and overall operational integrity of the supplier.

-

Requesting Quality Reports: Suppliers should be able to provide documentation detailing their quality control processes, including results from testing and inspections.

-

Third-Party Inspections: Engaging independent inspection agencies can provide an unbiased evaluation of the supplier’s adherence to quality standards, ensuring that the products meet international benchmarks.

What Are the Nuances of Quality Certifications for International Buyers?

Quality certifications can vary significantly across regions, and understanding these nuances is essential for B2B buyers. For instance, while ISO certifications are universally recognized, specific markets may have additional requirements. In Europe, CE marking is crucial for compliance with safety regulations, while in regions like the Middle East, compliance with local standards may also be necessary.

Buyers should conduct thorough research on the relevant certifications for their target markets and ensure that their suppliers are compliant. This diligence not only mitigates risks but also enhances the credibility of the buyer’s own operations.

Conclusion

In summary, the manufacturing processes and quality assurance practices for 12×12 stainless steel mesh are intricate and designed to ensure that the final product meets high standards of performance and durability. For B2B buyers, understanding these processes, quality checkpoints, and verification methods is essential for making informed purchasing decisions. By prioritizing suppliers with robust quality assurance practices, buyers can ensure they receive a product that meets their specific needs and international standards.

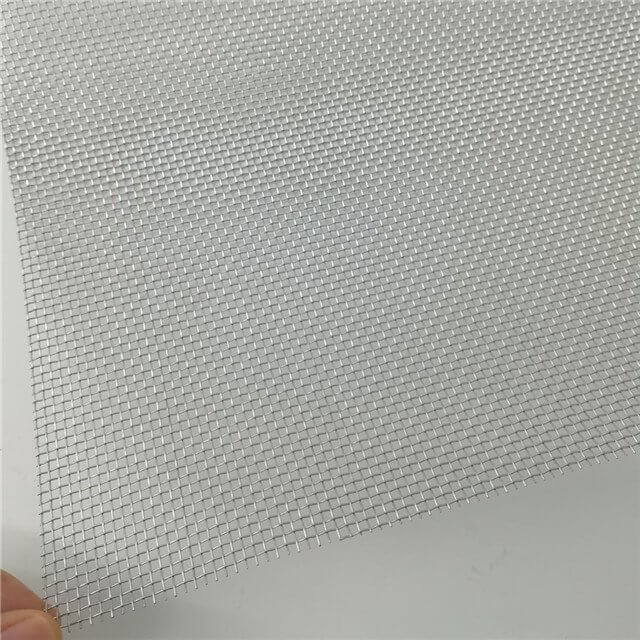

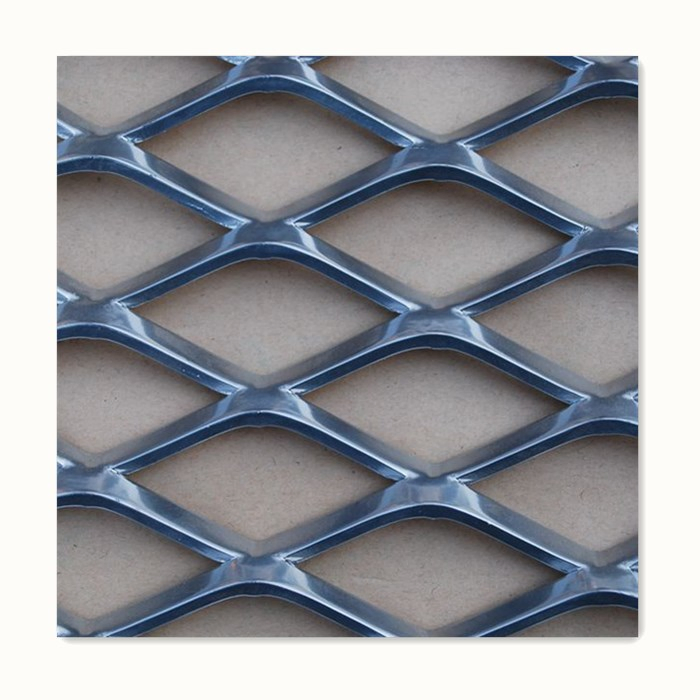

Illustrative image related to 12×12 stainless steel mesh

Practical Sourcing Guide: A Step-by-Step Checklist for ’12×12 stainless steel mesh’

In this practical sourcing guide, we aim to provide international B2B buyers with a comprehensive checklist for procuring 12×12 stainless steel mesh. This guide will help you navigate the essential steps to ensure a successful purchasing process, focusing on key considerations that can affect quality, cost, and delivery.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly define your technical requirements for the 12×12 stainless steel mesh. Specifications may include wire diameter, material grade (such as 304 or 316 stainless steel), and desired mesh openings. Understanding these details ensures that you receive products that meet your operational needs and comply with industry standards.

- Mesh Size: Ensure the mesh size aligns with your project requirements.

- Wire Diameter: Specify the wire thickness to achieve the desired strength and durability.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify reputable suppliers with a proven track record in the production of stainless steel mesh. Look for companies that specialize in industrial materials and have experience serving your specific industry or market.

Illustrative image related to 12×12 stainless steel mesh

- Supplier Reputation: Check reviews, testimonials, and case studies.

- Industry Experience: Prefer suppliers familiar with your geographic region, as they will understand local regulations and logistics.

Step 3: Verify Supplier Certifications

Before proceeding, confirm that potential suppliers hold relevant certifications and adhere to quality control standards. Certifications like ISO 9001 can indicate a commitment to quality management.

- Quality Assurance: Ensure they have processes in place for quality testing.

- Compliance: Verify compliance with regional standards, especially if exporting goods.

Step 4: Request Samples for Evaluation

Request samples of the 12×12 stainless steel mesh before making bulk purchases. Evaluating samples allows you to assess the material quality, finish, and performance characteristics firsthand.

- Material Quality: Inspect for any defects or inconsistencies.

- Performance Testing: If applicable, conduct tests to ensure the mesh meets your operational requirements.

Step 5: Negotiate Pricing and Terms

Once you have identified a suitable supplier, engage in negotiations regarding pricing, payment terms, and delivery timelines. Understanding the cost structure can help you identify potential savings through bulk orders or long-term contracts.

- Bulk Discounts: Inquire about pricing tiers based on order volume.

- Payment Terms: Clarify payment methods and any upfront costs required.

Step 6: Evaluate Logistics and Shipping Options

Consider the logistics involved in shipping the stainless steel mesh to your location. Different suppliers may offer various shipping methods that can affect delivery time and cost.

- Shipping Costs: Get quotes for different shipping options and consider the impact on your budget.

- Lead Times: Ensure the supplier can meet your delivery timeline, especially if you have tight project deadlines.

Step 7: Establish Communication Protocols

Finally, establish clear communication protocols with your chosen supplier. Effective communication can prevent misunderstandings and ensure that any issues are promptly addressed during the sourcing process.

- Point of Contact: Designate a specific contact person for inquiries and updates.

- Regular Updates: Agree on the frequency of updates regarding order status and shipping.

By following this step-by-step checklist, B2B buyers can streamline their procurement process for 12×12 stainless steel mesh, ensuring they receive high-quality products that meet their specific needs while maintaining cost-effectiveness.

Comprehensive Cost and Pricing Analysis for 12×12 stainless steel mesh Sourcing

What are the Key Cost Components in Sourcing 12×12 Stainless Steel Mesh?

When sourcing 12×12 stainless steel mesh, understanding the cost structure is crucial for effective budgeting and negotiation. The main cost components include:

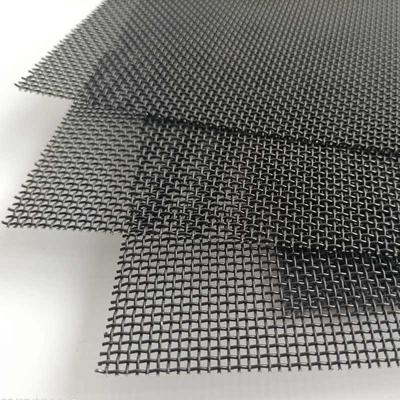

Illustrative image related to 12×12 stainless steel mesh

-

Materials: The primary cost driver is the stainless steel itself, specifically 304 or 316 grades, which vary in price based on market conditions. Prices can fluctuate due to demand, availability, and regional sourcing capabilities.

-

Labor: Labor costs encompass the wages of skilled workers involved in the manufacturing process, including weaving and finishing the mesh. Regions with lower labor costs can provide competitive pricing, making it essential to consider location when sourcing.

-

Manufacturing Overhead: This includes utilities, facility costs, and equipment maintenance. Efficient production processes can help reduce overhead, affecting the overall pricing.

-

Tooling: The initial investment in tools and machinery for producing stainless steel mesh can impact pricing, especially for custom sizes or specifications. Suppliers with advanced machinery may offer better quality at competitive prices.

-

Quality Control (QC): Ensuring that the mesh meets specified standards incurs additional costs. Suppliers that invest in rigorous QC processes may charge more, but this can lead to better long-term value and reliability.

-

Logistics: Transportation costs can significantly affect the final price, especially for international shipments. Factors such as shipping distance, mode of transport, and Incoterms will influence logistics costs.

-

Margin: Suppliers will include a profit margin in their pricing, which can vary widely based on their business model, market positioning, and competition.

How Do Price Influencers Affect Sourcing Decisions for Stainless Steel Mesh?

Several factors influence the pricing of 12×12 stainless steel mesh:

-

Volume/MOQ: Bulk purchases often lead to significant discounts. Understanding a supplier’s minimum order quantity (MOQ) can help buyers negotiate better pricing.

-

Specifications and Customization: Custom features such as wire diameter and mesh size can impact pricing. Suppliers may charge extra for non-standard specifications, so it’s crucial to clearly communicate requirements.

-

Material Quality and Certifications: Higher-grade materials or those with specific certifications (like ISO or ASTM standards) can command higher prices. Buyers should weigh the benefits of premium materials against their application needs.

-

Supplier Factors: Supplier reputation, experience, and production capabilities can all affect pricing. Established suppliers may charge more but offer greater reliability and quality assurance.

-

Incoterms: Understanding the implications of Incoterms (International Commercial Terms) is vital for international buyers. They define responsibilities regarding shipping, insurance, and tariffs, influencing overall costs.

What Buyer Tips Can Help in Sourcing 12×12 Stainless Steel Mesh Cost-Effectively?

To optimize sourcing strategies for 12×12 stainless steel mesh, consider the following tips:

-

Negotiate: Leverage volume commitments and long-term relationships to negotiate better pricing. Suppliers are often willing to provide discounts for larger orders or repeat business.

-

Assess Total Cost of Ownership (TCO): Beyond the initial purchase price, consider costs related to shipping, handling, storage, and potential quality issues. A lower upfront cost may lead to higher long-term expenses if quality or service issues arise.

-

Understand Pricing Nuances: Different regions have varying standards and practices. Buyers from Africa, South America, the Middle East, and Europe should familiarize themselves with local market conditions and supplier expectations to enhance negotiation outcomes.

-

Conduct Market Research: Stay informed about current market trends and prices for stainless steel. This knowledge can empower buyers during negotiations and help identify potential cost-saving opportunities.

Disclaimer on Indicative Pricing

While this analysis provides a framework for understanding the cost and pricing dynamics of 12×12 stainless steel mesh, specific prices may vary based on market conditions, supplier agreements, and regional factors. Always obtain quotes from multiple suppliers to ensure competitive pricing and favorable terms.

Alternatives Analysis: Comparing 12×12 stainless steel mesh With Other Solutions

When considering materials for various industrial applications, it is crucial to evaluate alternatives that can fulfill similar roles as 12×12 stainless steel mesh. This analysis will compare 12×12 stainless steel mesh against two viable alternatives: fiberglass mesh and plastic mesh. Each solution presents unique advantages and challenges depending on the application requirements, cost constraints, and operational environments.

| Comparison Aspect | 12×12 Stainless Steel Mesh | Fiberglass Mesh | Plastic Mesh |

|---|---|---|---|

| Performance | High strength, corrosion resistance, and durability. | Moderate strength; resistant to chemicals but less durable than steel. | Lightweight and flexible; limited strength compared to metal options. |

| Cost | Moderate to high initial investment. | Generally lower cost than stainless steel. | Low cost, but varies with type and quality. |

| Ease of Implementation | Requires tools for cutting and installation; heavier. | Easy to cut and install; lightweight. | Very easy to handle and install; can be cut with basic tools. |

| Maintenance | Low maintenance; resistant to rust and corrosion. | Requires regular checks; can degrade over time. | Low maintenance; can be cleaned easily but may degrade under UV exposure. |

| Best Use Case | Ideal for heavy-duty applications in construction, filtration, and security. | Suitable for applications requiring moderate strength and chemical resistance, like agriculture. | Best for lightweight applications such as garden fencing and temporary structures. |

What Are the Advantages and Disadvantages of Fiberglass Mesh Compared to Stainless Steel Mesh?

Fiberglass mesh is often favored for its lightweight nature and lower cost. It is resistant to a variety of chemicals, making it suitable for agricultural applications and environments where corrosion is a concern. However, fiberglass mesh lacks the structural integrity of stainless steel mesh, making it less suitable for heavy-duty applications. Over time, fiberglass can also degrade due to environmental exposure, necessitating more frequent replacements.

How Does Plastic Mesh Stack Up Against 12×12 Stainless Steel Mesh?

Plastic mesh offers an economical alternative for applications where strength is not the primary concern. It is incredibly lightweight, making installation straightforward and requiring minimal tools. However, plastic mesh generally has a lower tensile strength compared to stainless steel and may not withstand heavy loads or harsh environments. Additionally, while it is resistant to corrosion, prolonged exposure to UV light can weaken plastic mesh, limiting its lifespan in outdoor applications.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting the appropriate mesh solution, B2B buyers should consider the specific requirements of their application, including environmental conditions, load-bearing needs, and budget constraints. For high-performance requirements in harsh environments, 12×12 stainless steel mesh is typically the best choice due to its durability and strength. Conversely, if the project involves lighter applications or budget limitations, fiberglass or plastic mesh may be more suitable. Ultimately, understanding the trade-offs between performance, cost, and maintenance will enable buyers to make informed decisions tailored to their operational needs.

Illustrative image related to 12×12 stainless steel mesh

Essential Technical Properties and Trade Terminology for 12×12 stainless steel mesh

What Are the Key Technical Properties of 12×12 Stainless Steel Mesh?

When sourcing 12×12 stainless steel mesh, understanding its technical properties is essential for making informed purchasing decisions. Here are some critical specifications that can impact your operations:

-

Material Grade

– Definition: The most common grade for stainless steel mesh is 304, which offers good corrosion resistance and formability.

– B2B Importance: Choosing the right material grade ensures durability and performance in various applications, from filtration to architectural elements. For example, 304 stainless steel is suitable for indoor and outdoor uses, making it a versatile choice for diverse industries. -

Wire Diameter

– Definition: This specification indicates the thickness of the wire used in the mesh, typically measured in inches or millimeters. For a 12×12 mesh, the wire diameter is often around 0.023 inches.

– B2B Importance: The wire diameter affects the mesh’s strength, weight, and flow characteristics. A thicker wire provides greater strength and durability, making it suitable for heavy-duty applications, while a thinner wire may be more cost-effective for lighter uses. -

Mesh Size and Opening Size

– Definition: The term “12×12” refers to the number of openings per square inch, while the opening size indicates the physical dimensions of each opening, typically expressed in inches.

– B2B Importance: Understanding mesh and opening sizes is critical for applications requiring specific filtration or separation capabilities. For instance, a smaller opening size allows for finer filtration, which is essential in industries like food processing or pharmaceuticals. -

Open Area Percentage

– Definition: This metric indicates the percentage of the mesh area that is open space, allowing for airflow or fluid passage.

– B2B Importance: A higher open area percentage can enhance the efficiency of filtration systems. When evaluating options, consider how the open area aligns with your operational needs, as it can influence performance and energy consumption. -

Tolerance

– Definition: Tolerance refers to the allowable variation in dimensions, including mesh size and wire diameter.

– B2B Importance: Tighter tolerances ensure consistency and reliability in applications that require precision. In industries such as aerospace or electronics, even minor deviations can lead to significant issues in performance and safety.

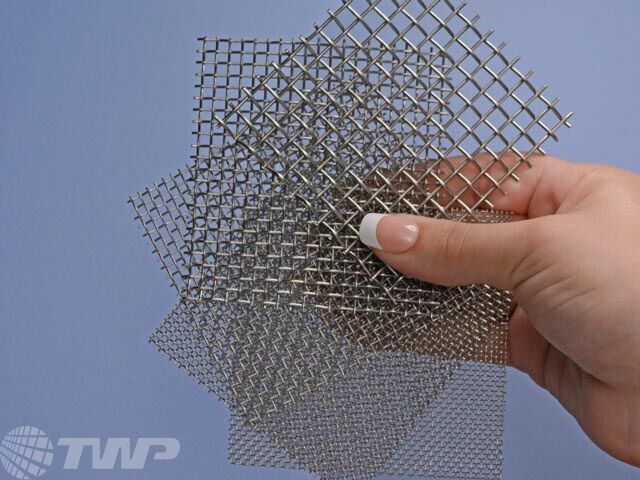

What Common Trade Terms Should You Know When Buying 12×12 Stainless Steel Mesh?

Familiarizing yourself with industry terminology can streamline the purchasing process and facilitate better communication with suppliers. Here are some commonly used trade terms:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships can help in sourcing components that meet specific quality and performance standards for your projects. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ is crucial for budgeting and inventory management. Suppliers may offer better pricing for larger quantities, but it’s essential to balance cost with your actual needs. -

RFQ (Request for Quotation)

– Definition: A formal document requesting price quotes from suppliers for specific products or services.

– Importance: An RFQ helps ensure competitive pricing and provides a basis for negotiation. It’s a standard practice that can lead to better deals and clearer terms. -

Incoterms (International Commercial Terms)

– Definition: A set of international rules that define the responsibilities of sellers and buyers in international transactions.

– Importance: Understanding Incoterms is vital for managing shipping costs, risks, and delivery timelines, especially in global trade where logistics can be complex. -

Lead Time

– Definition: The amount of time required to fulfill an order from the moment it is placed until it is delivered.

– Importance: Knowing lead times helps in planning and ensuring that materials are available when needed, reducing project delays.

By understanding these technical specifications and trade terms, B2B buyers can make more informed decisions when sourcing 12×12 stainless steel mesh, ultimately leading to improved operational efficiency and cost savings.

Navigating Market Dynamics and Sourcing Trends in the 12×12 stainless steel mesh Sector

What Are the Current Market Dynamics and Key Trends Affecting the 12×12 Stainless Steel Mesh Sector?

The global market for 12×12 stainless steel mesh is increasingly influenced by several key drivers, such as the expanding construction industry, heightened demand for filtration and separation technologies, and the rise of advanced manufacturing practices. In regions like Africa and South America, infrastructure development projects, coupled with growing urbanization, are propelling the demand for durable and versatile materials like stainless steel mesh. Meanwhile, in the Middle East and Europe, stringent regulations regarding safety and environmental standards are shaping the sourcing trends, prompting businesses to seek high-quality, compliant materials.

Illustrative image related to 12×12 stainless steel mesh

Emerging B2B technologies are also transforming sourcing strategies. Digital platforms that facilitate online procurement and supply chain visibility are becoming critical. Buyers are leveraging these platforms to streamline their purchasing processes and reduce lead times. Additionally, the integration of data analytics is enabling companies to forecast demand more accurately and optimize inventory management, which is vital for maintaining competitive pricing and ensuring timely delivery.

Furthermore, the trend towards customization is gaining traction, with buyers increasingly looking for suppliers that can offer tailored solutions to meet specific project requirements. This shift highlights the importance of establishing strong relationships with suppliers who can provide both standard and custom sizes of 12×12 stainless steel mesh, ensuring that buyers can meet the unique needs of their projects without compromising on quality.

How Does Sustainability Influence the Sourcing of 12×12 Stainless Steel Mesh?

In today’s business environment, sustainability is no longer a trend but a necessity for B2B buyers. The environmental impact of sourcing materials like 12×12 stainless steel mesh is significant, making it crucial for companies to consider the sustainability practices of their suppliers. Responsible sourcing includes evaluating the lifecycle of the materials, from extraction to production and disposal. Buyers are increasingly prioritizing suppliers who adhere to sustainable practices, such as recycling scrap metal and using energy-efficient manufacturing processes.

Moreover, certifications play a vital role in ensuring that materials meet environmental standards. Buyers are looking for products that carry certifications such as ISO 14001 (Environmental Management Systems) and other green certifications that indicate compliance with eco-friendly practices. By sourcing certified materials, companies not only reduce their carbon footprint but also enhance their brand reputation, appealing to environmentally conscious consumers and partners.

Furthermore, ethical supply chains are becoming a focal point for businesses aiming to improve their corporate social responsibility (CSR). Ensuring that suppliers provide fair labor conditions and adhere to ethical sourcing standards is becoming increasingly important for buyers, especially in regions where labor practices can vary significantly. This emphasis on ethical sourcing aligns with global movements towards sustainability and social responsibility, making it imperative for companies to evaluate their supply chains critically.

Illustrative image related to 12×12 stainless steel mesh

What Is the Historical Context of 12×12 Stainless Steel Mesh in B2B Markets?

The utilization of stainless steel mesh, particularly the 12×12 variety, has evolved significantly over the decades. Initially used primarily in industrial applications such as filtration and separation, advancements in manufacturing technology have broadened its applications across various sectors, including construction, automotive, and food processing. The introduction of high-quality stainless steel alloys, such as 304 and 316, has enhanced the material’s durability and resistance to corrosion, making it a preferred choice for demanding applications.

In the past, sourcing was often limited to local suppliers, leading to challenges in availability and pricing. However, globalization has transformed the landscape, allowing B2B buyers access to a wider range of suppliers and competitive pricing. This shift has prompted a focus on quality, compliance, and sustainability, pushing buyers to demand more from their suppliers as they navigate the complexities of the modern market. As the demand for stainless steel mesh continues to grow, understanding its historical context can provide valuable insights into current trends and future opportunities in the B2B sector.

Frequently Asked Questions (FAQs) for B2B Buyers of 12×12 stainless steel mesh

-

How do I choose the right supplier for 12×12 stainless steel mesh?

Selecting the right supplier is crucial for ensuring quality and reliability. Start by researching suppliers that specialize in stainless steel mesh and have a strong reputation in international markets. Check for certifications such as ISO 9001, which indicates a commitment to quality management. Request samples to assess the material’s quality and ensure it meets your specifications. Additionally, consider suppliers who provide clear and transparent communication regarding lead times, pricing, and payment terms to avoid potential misunderstandings. -

What is the minimum order quantity (MOQ) for 12×12 stainless steel mesh?

Minimum order quantities can vary significantly among suppliers, typically ranging from 10 to 100 units, depending on the supplier’s production capabilities and the specific product. When sourcing internationally, inquire about MOQs early in your discussions, as this can impact your cost-effectiveness and inventory planning. Some suppliers may offer flexible MOQs for established customers or larger orders, so it’s beneficial to negotiate based on your purchasing needs. -

What are the common applications for 12×12 stainless steel mesh?

12×12 stainless steel mesh is versatile and widely used in various industries. Common applications include filtration systems, architectural designs, and safety barriers. In the food and beverage industry, it is often used for sieving and straining. Additionally, it finds use in construction, agriculture, and automotive sectors for protective grilles and reinforcement. Understanding your specific application will help you determine the appropriate wire diameter and mesh specifications. -

What payment terms should I expect when sourcing internationally?

Payment terms vary by supplier and region but typically include options such as advance payment, letter of credit, or payment upon delivery. Many suppliers may request a deposit upfront, especially for custom orders, while others may offer net 30 or net 60 terms. It’s essential to clarify payment terms early in negotiations to avoid any cash flow issues. Consider discussing escrow services for larger transactions to ensure security for both parties. -

How can I ensure quality assurance for my stainless steel mesh order?

To ensure quality assurance, request a detailed quality control process from your supplier. This should include inspection procedures, testing methods, and certifications of materials used. Many reputable suppliers will conduct tests for strength, durability, and corrosion resistance. Additionally, consider employing third-party inspection services to validate product quality before shipment, particularly for large orders or critical applications. -

What shipping options are available for international orders of stainless steel mesh?

Shipping options for international orders typically include air freight and sea freight, with the choice depending on urgency and budget. Air freight is faster but more expensive, while sea freight is cost-effective for larger shipments but takes longer. Be sure to discuss shipping costs, timelines, and customs procedures with your supplier. Additionally, confirm if the supplier offers logistics support or if you need to arrange your own freight forwarding services. -

Can I customize the specifications of 12×12 stainless steel mesh?

Yes, many suppliers offer customization options for stainless steel mesh, including variations in wire diameter, mesh size, and material grade. When discussing customization, clearly outline your specifications and intended application to ensure the product meets your needs. Be aware that custom orders may have longer lead times and potentially higher costs, so factor this into your planning and budgeting. -

What should I consider regarding lead times for international orders?

Lead times for international orders can vary based on the supplier’s location, production capacity, and the complexity of your order. Generally, expect lead times of 3-6 weeks, but this can be longer for customized products. Always confirm lead times during negotiations and factor in additional time for customs clearance and shipping delays. Keeping communication open with your supplier can help manage expectations and mitigate potential delays.

Top 5 12X12 Stainless Steel Mesh Manufacturers & Suppliers List

1. Universal Wire Cloth – Type 304 Stainless Steel 12×12 Mesh

Domain: universalwirecloth.com

Registered: 2001 (24 years)

Introduction: {‘product_name’: ‘Type 304 Stainless Steel 12×12 Mesh .028″ Wire Diameter’, ‘SKU’: ‘12012028’, ‘material’: ‘Type 304 Stainless Steel’, ‘mesh_count’: ’12×12′, ‘wire_diameter_inch’: 0.028, ‘wire_diameter_mm’: 0.711, ‘opening_inch’: 0.055, ‘opening_mm’: 1.397, ‘open_area_percentage’: 43.6, ‘weight_per_sq_ft’: 0.641, ‘chemical_composition’: {‘Carbon (C)’: ‘0.08’, ‘Silicon (Si)’: ‘1’, ‘Manganese (Mn)’:…

2. McNichols – Wire Mesh 12×12 Stainless Steel

Domain: mcnichols.com

Registered: 1996 (29 years)

Introduction: {‘item_number’: ‘3812184810’, ‘product_line’: ‘Wire Mesh’, ‘mesh_type’: ‘Square’, ‘construction_type’: ‘Woven’, ‘primary_material’: ‘Stainless Steel (SS)’, ‘alloy_grade_or_type’: ‘Type 304’, ‘material_finish’: ‘Mill Finish’, ‘weave_or_trim_type’: ‘Woven – Plain Weave’, ‘mesh_size’: ’12 x 12′, ‘opening_size’: ‘0.0653″ x 0.0653″‘, ‘wire_diameter’: ‘0.018″ Thick (26-1/4 Gauge)’, ‘pitch_size’: ‘0.0833…

3. AMZDEPOT – 12X12 Inch Wire Mesh 4 Pack

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“title”: “4 Pack 12X12 Inch Wire Mesh, 20 Mesh Stainless Steel Mesh, Never Rust Sturdy Met”, “condition”: “New”, “quantity”: “1 available”, “item_number”: “157142841036”, “brand”: “AMZDEPOT”, “price”: “$20.17”, “shipping_estimate”: “Sat, Sep 20 – Wed, Sep 24”, “seller”: {“name”: “T trendicarthub”, “feedback_score”: “214”, “positive_feedback_percentage”: “97.8%”}, “returns”: “Accepted within 30 da…

4. Anclas – Heavy Duty Filter Security Screen

Domain: anclasmall.com

Registered: 2019 (6 years)

Introduction: {“product_name”: “Heavy Duty Filter Security Screen”, “dimensions”: “12” x 12″”, “material”: “Heavy Duty”, “usage”: “Filter Security”, “product_id”: “898867”}

5. Segura – High-Temperature Rust-Resistant Wire Mesh

Domain: segura.do

Registered: 2018 (7 years)

Introduction: This company, Segura – High-Temperature Rust-Resistant Wire Mesh, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for 12×12 stainless steel mesh

As the demand for 12×12 stainless steel mesh continues to grow across various industries, strategic sourcing becomes essential for international buyers, particularly in Africa, South America, the Middle East, and Europe. This versatile product, known for its durability and corrosion resistance, plays a crucial role in applications ranging from filtration systems to architectural designs. B2B buyers should focus on sourcing from reputable suppliers who offer transparent pricing structures and flexible order quantities, ensuring both cost efficiency and product quality.

Implementing a strategic sourcing approach allows businesses to leverage bulk purchasing discounts, reducing overall procurement costs. Additionally, establishing long-term relationships with suppliers can enhance supply chain reliability, crucial for maintaining production schedules and meeting customer demands.

Looking ahead, the market for 12×12 stainless steel mesh is expected to expand, driven by innovation in manufacturing processes and increasing applications in emerging markets. International buyers are encouraged to stay proactive in their sourcing strategies, exploring partnerships that not only fulfill immediate needs but also align with future growth opportunities. By doing so, they can ensure a competitive edge in their respective industries while contributing to sustainable practices.

Illustrative image related to 12×12 stainless steel mesh

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.