U Shaped Brackets For Mounting: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for u shaped brackets for mounting

In the intricate world of industrial and commercial construction, sourcing reliable U-shaped brackets for mounting can pose significant challenges for B2B buyers. Whether you are in Africa, South America, the Middle East, or Europe, understanding the diverse applications and specifications of these mounting solutions is critical. This comprehensive guide delves into the various types of U-shaped brackets, their applications across multiple industries, and essential factors to consider when selecting suppliers.

From heavy-duty brackets designed for structural support in construction projects to lightweight options for shelving and display systems, the market offers a wide array of choices. We will explore how to effectively vet suppliers, ensuring that you partner with those who meet quality standards and provide competitive pricing. Additionally, this guide addresses cost considerations, including shipping and bulk order discounts, which are particularly relevant for international buyers operating on tight budgets.

By equipping you with in-depth insights and actionable information, this guide empowers B2B buyers to make informed purchasing decisions. Whether you’re a purchasing manager in Vietnam or a project coordinator in Brazil, you will find valuable strategies for navigating the global market for U-shaped brackets, ultimately leading to more efficient project execution and enhanced operational success.

Understanding u shaped brackets for mounting Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard U-Bracket | Simple design, multiple hole options for mounting | General construction, shelving, and support systems | Pros: Cost-effective, versatile; Cons: May lack heavy-duty support. |

| Heavy-Duty U-Bracket | Made from thicker steel, designed for high-load applications | Industrial shelving, heavy machinery mounting | Pros: High strength, durable; Cons: Higher cost, may be overkill for light applications. |

| Adjustable U-Bracket | Features adjustable arms for varying widths | Custom shelving, modular displays | Pros: Flexibility in installation; Cons: More complex installation process. |

| Marine U-Bracket | Corrosion-resistant materials, designed for harsh environments | Marine equipment mounting, outdoor installations | Pros: Long-lasting in wet conditions; Cons: Limited to specific applications. |

| Decorative U-Bracket | Aesthetic finishes, often used in visible applications | Retail displays, furniture assembly | Pros: Enhances appearance; Cons: May sacrifice strength for style. |

What Are the Characteristics of Standard U-Brackets?

Standard U-brackets are characterized by their straightforward design and versatility. Typically made from mild steel or aluminum, they feature multiple holes for easy mounting. These brackets are widely used in general construction and shelving applications, making them a staple for B2B buyers looking for reliable support solutions. When considering these brackets, buyers should evaluate their load requirements and installation environment to ensure compatibility.

How Do Heavy-Duty U-Brackets Differ from Standard Options?

Heavy-duty U-brackets are constructed from thicker steel, making them suitable for high-load applications. These brackets are ideal for industrial settings, where strength and durability are paramount. They can support heavy machinery and shelving units, providing a robust solution for demanding environments. Buyers should weigh the higher cost against the necessity for strength, as these brackets may be excessive for lighter applications.

Why Choose Adjustable U-Brackets for Custom Solutions?

Adjustable U-brackets stand out due to their ability to modify width and accommodate various shelf sizes. This flexibility makes them perfect for custom shelving or modular displays in retail environments. While they offer significant installation versatility, the complexity involved in their setup may be a consideration for some buyers. Evaluating the specific needs of a project can help in deciding if these brackets are the right fit.

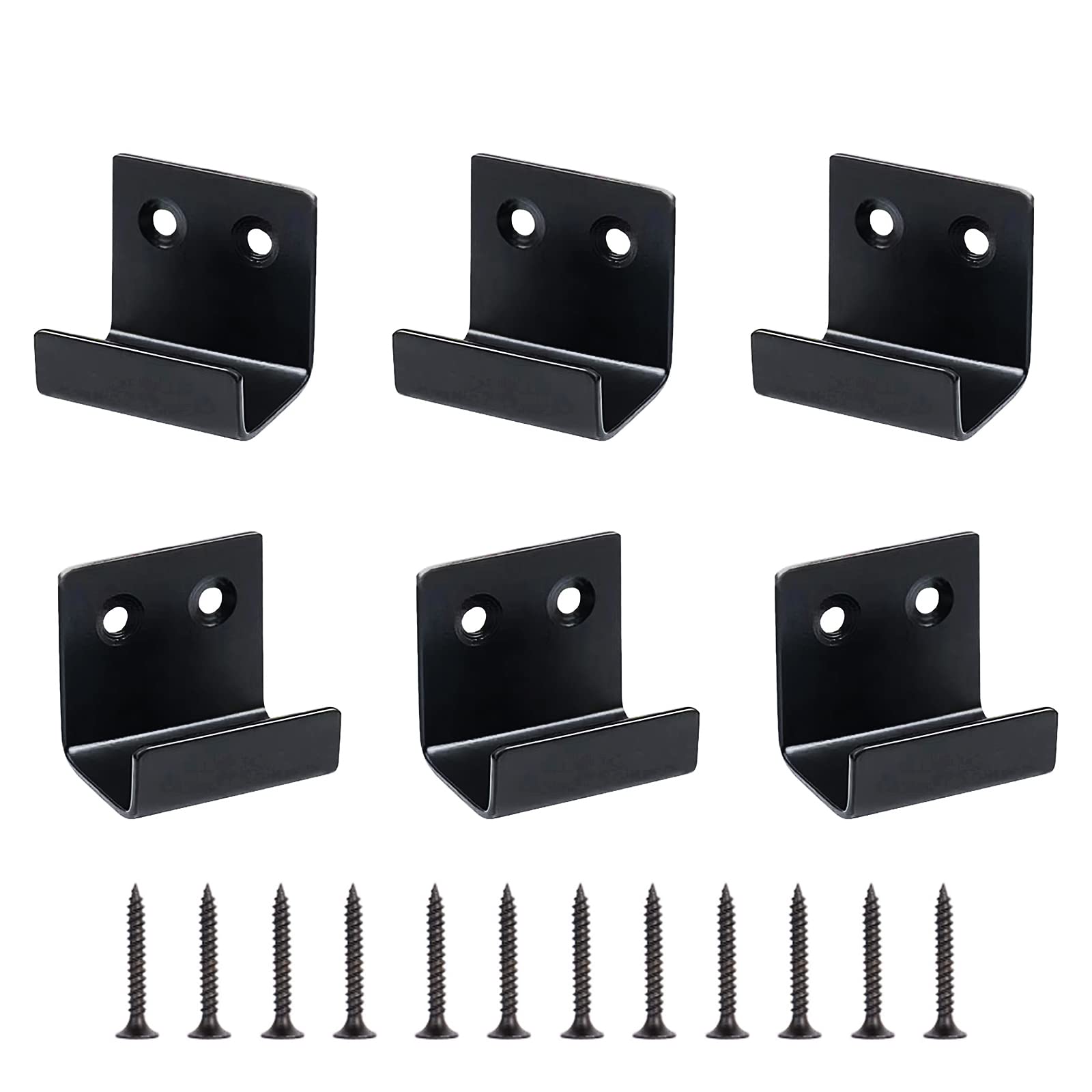

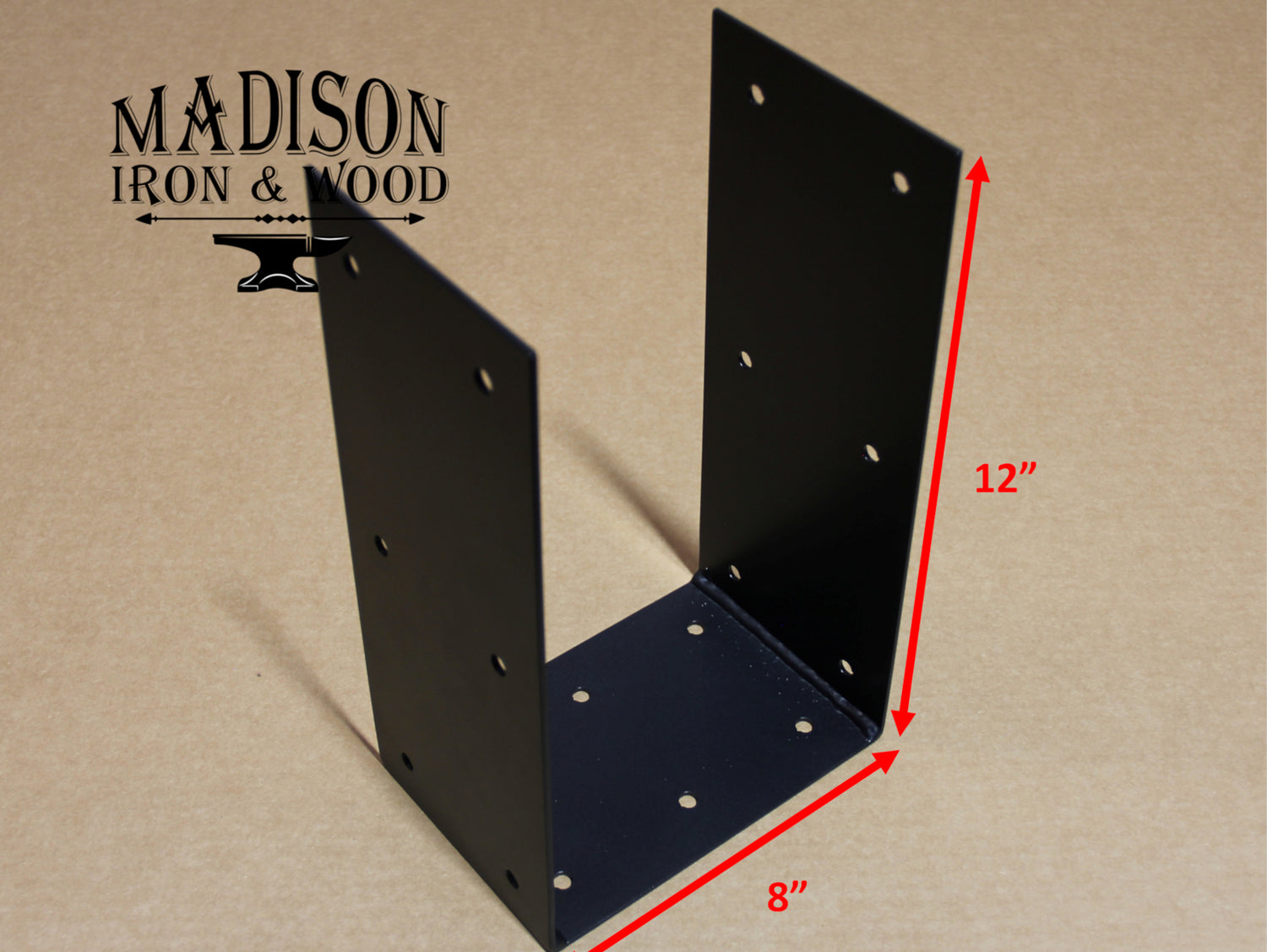

Illustrative image related to u shaped brackets for mounting

What Makes Marine U-Brackets Suitable for Outdoor Use?

Marine U-brackets are specifically designed to resist corrosion and withstand harsh environmental conditions, making them ideal for marine applications. Constructed from materials like aluminum or stainless steel, they are perfect for mounting marine equipment or outdoor installations. B2B buyers in the marine sector should prioritize these brackets to ensure longevity and reliability in wet conditions, although their specialized nature limits their use to specific applications.

How Do Decorative U-Brackets Enhance Aesthetic Appeal?

Decorative U-brackets combine functionality with aesthetic appeal, often featuring various finishes that enhance their visual impact. These brackets are commonly used in retail displays and furniture assembly, where appearance is as crucial as strength. While they provide a stylish solution, buyers should consider that decorative options may not offer the same level of strength as their standard counterparts. Balancing aesthetics with structural needs is vital for making the right purchasing decision.

Key Industrial Applications of u shaped brackets for mounting

| Industry/Sector | Specific Application of u shaped brackets for mounting | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Supporting machinery and equipment in assembly lines | Enhances equipment stability and safety, reducing downtime | Durability under heavy loads, corrosion resistance, and size options |

| Construction | Mounting structural components like beams and panels | Provides robust support, ensuring structural integrity | Compliance with local building codes and load-bearing capacity |

| Marine | Securing pumps and valves in marine systems | Ensures reliable operation in harsh environments | Material durability against saltwater and ease of installation |

| Retail Display | Creating shelving systems for product displays | Maximizes retail space and enhances product visibility | Aesthetic finishes and weight capacity for various product sizes |

| Telecommunications | Mounting antennas and communication devices | Ensures optimal signal transmission and device stability | Compatibility with various mounting surfaces and environmental resistance |

How are U-Shaped Brackets Utilized in the Manufacturing Sector?

In the manufacturing sector, U-shaped brackets are vital for supporting machinery and equipment along assembly lines. These brackets enhance stability, which is crucial for maintaining safety and productivity. They are designed to withstand heavy loads, ensuring that machinery operates efficiently without risk of failure. International buyers should prioritize sourcing brackets that meet specific durability standards and can resist corrosion, especially in environments with high humidity or exposure to chemicals.

What Role Do U-Shaped Brackets Play in Construction?

In construction, U-shaped brackets are extensively used to mount structural components such as beams and panels. Their robust design allows for reliable support, which is essential for maintaining the structural integrity of buildings. Buyers in this sector must consider local building codes, load-bearing capacity, and the environmental conditions of the installation site when sourcing these brackets. Ensuring that the brackets meet regulatory standards is critical for compliance and safety.

Illustrative image related to u shaped brackets for mounting

Why are U-Shaped Brackets Important in Marine Applications?

U-shaped brackets serve a critical role in marine applications, particularly for securing pumps and valves within various systems. These brackets are engineered to resist corrosion and wear, ensuring long-term reliability even in harsh marine environments. For international buyers, especially those in coastal regions, sourcing brackets made from high-strength materials that can withstand saltwater exposure is essential. Additionally, easy installation and maintenance access are key considerations for effective operation.

How Do U-Shaped Brackets Enhance Retail Display Solutions?

In the retail sector, U-shaped brackets are used to create effective shelving systems for product displays. They maximize available retail space while enhancing product visibility, which can lead to increased sales. Businesses should focus on sourcing brackets that offer aesthetic finishes and sufficient weight capacity to support diverse product ranges. Moreover, considerations for ease of installation and adaptability to various shelving designs can further enhance the effectiveness of retail displays.

What is the Importance of U-Shaped Brackets in Telecommunications?

In telecommunications, U-shaped brackets are crucial for mounting antennas and communication devices securely. They ensure optimal signal transmission and device stability, which are vital for maintaining communication quality. When sourcing these brackets, international buyers should consider compatibility with different mounting surfaces and the brackets’ ability to withstand environmental factors such as wind and rain. Ensuring that the brackets are designed for quick installation can also facilitate efficient deployment of telecommunications infrastructure.

3 Common User Pain Points for ‘u shaped brackets for mounting’ & Their Solutions

Scenario 1: Sourcing Quality U-Shaped Brackets for Diverse Applications

The Problem: Many B2B buyers encounter challenges when sourcing u-shaped brackets that meet specific project requirements. In regions like Africa or South America, access to high-quality materials can be inconsistent, leading to concerns about durability and performance. Buyers often struggle to find suppliers who offer a wide range of sizes and finishes suitable for their diverse applications, such as mounting heavy machinery or constructing shelving systems. This can result in delays, increased costs, and ultimately, project setbacks.

The Solution: To overcome sourcing challenges, B2B buyers should establish relationships with multiple suppliers that specialize in u-shaped brackets. It is essential to conduct thorough research on suppliers and their product offerings. Request samples before committing to larger orders to assess the quality and durability of the brackets. Utilizing platforms like Alibaba or local manufacturers can provide additional options. Additionally, buyers should clearly define the specifications needed for their projects—such as load capacity, material type (e.g., stainless steel for corrosion resistance), and finish—when communicating with suppliers. This proactive approach will ensure that the right products are sourced efficiently, minimizing project delays.

Scenario 2: Ensuring Proper Installation for Maximum Load Capacity

The Problem: A common issue faced by B2B buyers is the improper installation of u-shaped brackets, which can lead to structural failures and safety hazards. This is particularly critical in commercial settings where brackets are used to support heavy loads, such as shelving or equipment. Misalignment during installation or the use of inadequate fasteners can compromise the integrity of the mounting system, resulting in costly repairs and potential liability issues.

The Solution: To ensure proper installation, it is imperative to provide comprehensive training for installation teams. Develop detailed installation guidelines that outline the steps for aligning and securing u-shaped brackets correctly. This should include specifications on the type and size of fasteners to be used, as well as recommended torque settings for securing the brackets. Consider utilizing installation aids, such as templates or jigs, to facilitate accurate placement. Additionally, conducting on-site inspections during the installation process can help catch potential issues early, ensuring that brackets are mounted securely and safely for maximum load capacity.

Illustrative image related to u shaped brackets for mounting

Scenario 3: Navigating Regulatory Compliance and Safety Standards

The Problem: B2B buyers often face the challenge of ensuring that their use of u-shaped brackets complies with local regulations and industry safety standards. This is particularly pertinent in sectors such as construction and manufacturing, where non-compliance can lead to legal ramifications, project delays, and increased costs. In regions like the Middle East and Europe, regulatory frameworks can be complex and vary significantly between countries, adding to the confusion.

The Solution: To navigate compliance challenges, B2B buyers should familiarize themselves with the relevant regulations and standards governing their industry. This includes understanding load requirements, material specifications, and safety certifications for mounting hardware. Collaborating with local engineering firms or consultants can provide valuable insights into compliance matters. It is also beneficial to source brackets that come with certifications or meet specific standards, such as ISO or ASTM, which can simplify the compliance process. Regularly reviewing and updating knowledge on regulatory changes will ensure that businesses remain compliant and avoid costly penalties.

Strategic Material Selection Guide for u shaped brackets for mounting

When selecting materials for U-shaped brackets for mounting, it is essential to consider the specific requirements of the application, including environmental conditions, load-bearing capacity, and compliance with international standards. Below, we analyze four common materials used in manufacturing U-shaped brackets, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

What are the Key Properties of Steel for U-Shaped Brackets?

Steel, particularly carbon steel, is a prevalent choice for U-shaped brackets due to its strength and durability. Key properties include high tensile strength, making it suitable for heavy loads, and good weldability, which facilitates manufacturing. However, steel is susceptible to corrosion unless treated with protective coatings such as galvanization or powder coating.

Pros: Steel brackets are robust and can support significant weight, making them ideal for structural applications in construction and industrial settings. They are also relatively cost-effective compared to other materials.

Cons: The primary disadvantage is their susceptibility to rust and corrosion, especially in humid or marine environments. This necessitates additional treatments, which can increase manufacturing complexity and costs.

Impact on Application: Steel brackets are suitable for a variety of applications, including construction and industrial machinery. However, they may not be ideal for environments with high moisture or corrosive agents unless properly treated.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM A36 for structural steel. In regions like Africa and South America, local sourcing of treated steel may be preferred to reduce costs.

How Does Aluminum Compare as a Material for U-Shaped Brackets?

Aluminum is another popular material for U-shaped brackets, particularly in applications requiring lightweight solutions. It offers excellent corrosion resistance due to its natural oxide layer, making it suitable for marine and outdoor applications.

Pros: Aluminum is lightweight, which can reduce shipping costs and facilitate easier installation. It is also resistant to corrosion, ensuring longevity in harsh environments.

Cons: The main drawback is its lower strength compared to steel, which may limit its use in heavy-load applications. Additionally, aluminum can be more expensive than steel, depending on the alloy used.

Impact on Application: Aluminum brackets are ideal for applications in the aerospace and automotive industries, as well as for mounting in marine environments. They excel in situations where weight savings are critical.

Considerations for International Buyers: Compliance with standards such as ASTM B221 for aluminum extrusions is crucial. Buyers in Europe may prefer aluminum brackets that meet EN standards for quality assurance.

What are the Benefits of Stainless Steel for U-Shaped Brackets?

Stainless Steel is favored for applications requiring high corrosion resistance and aesthetic appeal. Key properties include excellent strength, durability, and resistance to staining and rust.

Pros: Stainless steel brackets are highly durable and can withstand harsh environments, making them suitable for both indoor and outdoor applications. They also require minimal maintenance due to their corrosion resistance.

Cons: The primary disadvantage is the higher cost compared to carbon steel and aluminum. Manufacturing processes for stainless steel can also be more complex, which may lead to increased production times.

Impact on Application: Stainless steel brackets are ideal for use in food processing, pharmaceuticals, and marine applications where hygiene and corrosion resistance are paramount.

Considerations for International Buyers: Buyers should look for compliance with standards such as ASTM A240 for stainless steel. In the Middle East, local regulations may dictate specific grades of stainless steel for construction applications.

How Does Plastic Fit into the Material Selection for U-Shaped Brackets?

Plastic, particularly high-density polyethylene (HDPE) or polycarbonate, is used for lightweight applications where corrosion resistance is essential. These materials are non-conductive and resistant to many chemicals.

Pros: Plastic brackets are lightweight, resistant to corrosion, and can be manufactured in various colors, making them suitable for aesthetic applications. They are also generally less expensive than metal options.

Cons: The main limitation is their lower load-bearing capacity compared to metals, which may restrict their use in heavy-duty applications. Additionally, plastics can degrade under UV exposure unless treated.

Impact on Application: Plastic brackets are commonly used in electrical applications and in environments where moisture resistance is critical, such as in food processing.

Illustrative image related to u shaped brackets for mounting

Considerations for International Buyers: Compliance with international standards such as ASTM D638 for plastics is essential. Buyers should also consider the environmental impact of plastic materials, particularly in regions with stringent regulations.

Summary Table

| Material | Typical Use Case for U Shaped Brackets for Mounting | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty construction and industrial applications | High strength and load-bearing capacity | Susceptible to corrosion without treatment | Medium |

| Aluminum | Aerospace, automotive, and marine applications | Lightweight and corrosion-resistant | Lower strength compared to steel | High |

| Stainless Steel | Food processing, pharmaceuticals, and marine use | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| Plastic | Electrical applications and moisture-prone environments | Lightweight and corrosion-resistant | Lower load-bearing capacity | Low |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of various materials for U-shaped brackets, helping them make informed decisions tailored to their specific applications and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for u shaped brackets for mounting

What Are the Key Stages in the Manufacturing Process of U-Shaped Brackets?

The manufacturing of U-shaped brackets involves several critical stages that ensure the final product meets the required specifications for strength, durability, and functionality.

Material Preparation

The first step in the manufacturing process is material selection and preparation. Common materials for U-shaped brackets include stainless steel, carbon steel, aluminum, and various alloys, chosen for their strength-to-weight ratios and corrosion resistance. The materials are typically sourced from certified suppliers, and a thorough inspection (Incoming Quality Control, IQC) is conducted to ensure they meet specific standards.

Once the materials are verified, they are cut to the required dimensions using techniques such as laser cutting or CNC machining. This ensures precision and consistency across batches, which is vital for assembly and structural integrity.

Forming Techniques

The next stage involves the forming of the U-shaped brackets. This can be achieved through various methods, including:

-

Bending: The cut sheets are bent into the desired U-shape using hydraulic or mechanical presses. This process must be carefully controlled to avoid material fatigue or failure.

-

Stamping: For higher volume production, stamping can be employed. This method uses a die to cut and form the brackets in one operation, which enhances efficiency and reduces waste.

-

Welding: In instances where additional components are required (e.g., flanges for mounting), welding techniques like MIG or TIG welding may be used to assemble parts securely.

Assembly and Finishing

After forming, the brackets undergo assembly if they consist of multiple components. This is followed by finishing processes, which may include:

-

Surface Treatment: To enhance corrosion resistance, brackets often undergo treatments such as galvanization, powder coating, or anodizing. These finishes not only protect the product but can also provide aesthetic value.

-

Quality Checks: Throughout the production process, quality checks are implemented to ensure adherence to specifications. This includes dimensional checks and visual inspections.

How Is Quality Assurance Managed in U-Shaped Bracket Manufacturing?

Quality assurance (QA) is a critical component of the manufacturing process for U-shaped brackets, particularly for B2B buyers who require reliability and compliance with international standards.

Which International Standards Are Relevant for U-Shaped Brackets?

Manufacturers often adhere to internationally recognized standards such as ISO 9001, which outlines the criteria for quality management systems. Compliance with these standards demonstrates a commitment to quality and consistency. Additionally, industry-specific certifications like CE marking for products sold in Europe and API standards for oil and gas applications may apply.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to identify and mitigate defects:

-

Incoming Quality Control (IQC): This checkpoint involves the inspection of raw materials to ensure they meet specified requirements before production begins.

-

In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor processes and ensure that they adhere to quality standards. This can include dimensional checks and visual inspections.

-

Final Quality Control (FQC): Once the brackets are completed, a final inspection is performed to assess overall quality, ensuring that each product meets the required specifications before shipment.

What Common Testing Methods Are Used for U-Shaped Brackets?

Various testing methods are employed to verify the performance and durability of U-shaped brackets:

-

Load Testing: This method assesses the strength and capacity of the brackets by applying weight until failure occurs, ensuring they can withstand specified loads.

-

Corrosion Testing: To evaluate the effectiveness of surface treatments, brackets may undergo salt spray tests or other corrosion resistance tests.

-

Dimensional Inspection: Using calipers or other measuring devices, manufacturers ensure that the dimensions of each bracket conform to design specifications.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying the quality control processes of suppliers is essential to ensure product reliability:

-

Supplier Audits: Conducting audits of suppliers’ facilities allows buyers to assess their quality management systems and adherence to industry standards. This can include checking documentation, processes, and overall production practices.

-

Quality Reports: Requesting regular quality reports can provide insights into the supplier’s performance, including defect rates and corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can add an extra layer of assurance. These independent entities evaluate the products and processes to ensure compliance with specified standards.

What Are the Nuances of Quality Control for International B2B Buyers?

For buyers from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is crucial:

Illustrative image related to u shaped brackets for mounting

-

Cultural Differences: Awareness of cultural differences in business practices can impact communication and expectations regarding quality. Establishing clear agreements on quality standards upfront can mitigate misunderstandings.

-

Logistics and Shipping: International shipping can introduce risks related to product handling and transportation. Ensuring that suppliers package products appropriately and provide necessary documentation can help maintain quality.

-

Regulatory Compliance: Different regions may have specific regulatory requirements. Buyers should ensure that suppliers are compliant with local laws and international standards relevant to their market.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions, ensuring they procure high-quality U-shaped brackets that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘u shaped brackets for mounting’

When sourcing U-shaped brackets for mounting, it’s essential to follow a structured approach to ensure you select the right products for your specific needs. This guide outlines key steps to help international B2B buyers navigate the procurement process effectively.

Step 1: Define Your Technical Specifications

Before starting your search, clarify the technical requirements of the U-shaped brackets needed for your project. Consider factors such as load capacity, material type (e.g., stainless steel, galvanized steel, or aluminum), and environmental conditions (e.g., corrosion resistance for marine applications). Documenting these specifications will streamline your sourcing process and help you communicate your needs clearly to potential suppliers.

Illustrative image related to u shaped brackets for mounting

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers who specialize in U-shaped brackets. Look for companies with a proven track record in your industry and positive customer reviews. Utilize online platforms, industry directories, and trade shows to discover suppliers who meet your criteria.

- Focus on Regions: Given your location, prioritize suppliers in regions known for high-quality manufacturing, such as Europe or North America, while also considering local suppliers in Africa or South America for logistics advantages.

Step 3: Evaluate Product Varieties

Not all U-shaped brackets are created equal; they come in various designs and finishes to suit different applications. Examine the product range offered by potential suppliers, paying attention to the number of holes, dimensions, and finishes available. Ensure the brackets can accommodate your specific mounting needs.

- Check for Customization: If standard options do not meet your requirements, inquire about customization capabilities for size, finish, or additional features.

Step 4: Request Samples

Before finalizing your order, request samples from shortlisted suppliers. This step allows you to assess the quality and durability of the brackets firsthand. Evaluate the samples based on your defined specifications and consider conducting stress tests if applicable.

Illustrative image related to u shaped brackets for mounting

- Assess Fit and Finish: Pay attention to the craftsmanship, including any protective coatings that enhance corrosion resistance or aesthetic appeal.

Step 5: Verify Supplier Certifications

Ensure that your chosen suppliers adhere to industry standards and possess relevant certifications. This may include ISO certifications, quality management systems, or compliance with safety regulations. Certifications provide assurance of product quality and reliability.

- Documentation Review: Request copies of certifications and any test reports to validate the supplier’s claims regarding their products.

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, negotiate favorable terms, including pricing, payment terms, and delivery schedules. Clear agreements on these aspects will help prevent misunderstandings and ensure timely project execution.

- Consider Bulk Discounts: If your project requires a large quantity of brackets, inquire about bulk pricing to maximize cost efficiency.

Step 7: Establish a Communication Plan

Effective communication is key to a successful procurement process. Establish a clear communication plan with your supplier to discuss project timelines, updates, and any potential issues that may arise during production or shipping.

- Regular Check-ins: Schedule regular updates to stay informed about your order status and address any concerns promptly.

By following this structured checklist, B2B buyers can enhance their procurement process for U-shaped brackets, ensuring they secure high-quality products that meet their project requirements efficiently.

Comprehensive Cost and Pricing Analysis for u shaped brackets for mounting Sourcing

What Are the Key Cost Components of U-Shaped Brackets for Mounting?

When sourcing U-shaped brackets for mounting, understanding the cost structure is critical for B2B buyers. The primary cost components include:

-

Materials: The choice of material significantly impacts cost. Common materials include stainless steel, aluminum, and galvanized steel. Higher-grade materials, like stainless steel, provide better corrosion resistance but also come at a premium.

-

Labor: Labor costs vary depending on the complexity of the manufacturing process and the region. Automated production can reduce labor costs, but highly customized solutions may require more skilled labor.

-

Manufacturing Overhead: This encompasses the indirect costs of production, such as utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can help minimize these overhead costs.

-

Tooling: Initial tooling costs can be substantial, especially for custom designs. These costs are typically amortized over the production run, making them less significant for larger orders.

-

Quality Control (QC): Ensuring that products meet industry standards requires investment in QC processes. Certifications can also add to costs but are essential for industries where safety and reliability are paramount.

-

Logistics: Shipping costs, which can fluctuate based on distance, weight, and volume, play a vital role in the total cost. Additionally, international shipping may involve tariffs and customs duties.

-

Margin: Suppliers will add a profit margin on top of their costs. This can vary widely based on market conditions, competition, and perceived value.

How Do Price Influencers Affect U-Shaped Bracket Sourcing?

Several factors influence the pricing of U-shaped brackets, making it essential for buyers to be aware of these nuances:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to better pricing due to economies of scale. Understanding the supplier’s MOQ is crucial for optimizing costs.

-

Specifications and Customization: Custom designs or specific specifications can increase costs. Suppliers may charge extra for unique sizes, finishes, or load-bearing capabilities.

-

Material Quality and Certifications: Higher quality materials and necessary certifications (such as ISO or ASTM) can raise prices. Buyers should evaluate whether these certifications are essential for their application.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more but offer better assurance in terms of quality and service.

-

Incoterms: These terms define the responsibilities of buyers and sellers in international shipping. Understanding Incoterms (like FOB or CIF) can help buyers manage costs and risks effectively.

What Are the Best Buyer Tips for Cost-Efficiency in U-Shaped Bracket Procurement?

To optimize sourcing strategies for U-shaped brackets, consider the following actionable tips:

-

Negotiate Pricing: Don’t hesitate to negotiate terms with suppliers. Leveraging volume or long-term contracts can lead to better pricing.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider long-term factors such as durability, maintenance, and lifecycle costs. A lower upfront cost may lead to higher TCO if the product has a shorter lifespan.

-

Understand Pricing Nuances for International Sourcing: Be aware of fluctuations in shipping costs and potential tariffs when sourcing from different regions. For buyers in Africa, South America, the Middle East, and Europe, these factors can greatly affect the final cost.

-

Request Multiple Quotes: Always seek quotes from multiple suppliers to compare prices and service levels. This can reveal significant differences in pricing and help identify the best value.

-

Stay Informed on Market Trends: Prices can be influenced by raw material costs and geopolitical factors. Staying informed can help buyers make timely purchasing decisions.

Conclusion: What Should Buyers Keep in Mind Regarding Indicative Pricing?

While pricing can vary widely based on the factors mentioned, it is essential to recognize that the figures provided by suppliers are often indicative. Market conditions, material availability, and supplier capacity can all impact final prices. Buyers should approach sourcing with a thorough understanding of their specific needs and the broader market dynamics. This strategic perspective will empower them to make informed purchasing decisions that align with their business objectives.

Alternatives Analysis: Comparing u shaped brackets for mounting With Other Solutions

Exploring Alternatives for U-Shaped Brackets in Mounting Applications

When considering mounting solutions, it’s essential to evaluate various alternatives to U-shaped brackets. While these brackets offer reliability and versatility for structural applications, other solutions may provide distinct advantages depending on the specific needs of a project. This analysis compares U-shaped brackets with two alternative mounting solutions: L-brackets and Cable Management Systems.

| Comparison Aspect | U Shaped Brackets For Mounting | L-Brackets | Cable Management Systems |

|---|---|---|---|

| Performance | Strong load-bearing capability | High strength but limited to corners | Effective for organizing and securing cables |

| Cost | Moderate cost | Generally lower cost | Variable cost, depending on complexity |

| Ease of Implementation | Straightforward installation | Easy installation | Can be complex, especially in large setups |

| Maintenance | Low maintenance | Low maintenance | Moderate maintenance for adjustments |

| Best Use Case | Multi-purpose structural support | Corner reinforcement | Cable management in electrical installations |

L-Brackets: A Corner Reinforcement Solution

L-brackets are a popular alternative for mounting applications, particularly for securing items at right angles. Their design allows for easy installation in corners, making them ideal for framing and shelving systems. The primary advantage of L-brackets is their lower cost compared to U-shaped brackets, making them a budget-friendly option for projects with tight financial constraints. However, they may not offer the same load-bearing capacity as U-shaped brackets when used in standalone applications, limiting their use in heavy-duty scenarios.

Cable Management Systems: Organizing and Securing Cables

Cable management systems serve a different purpose but are essential in environments where organized wiring is crucial, such as in industrial or commercial settings. These systems can include cable trays, raceways, and ties, designed to keep cables neatly arranged and secure. The advantage of cable management systems is their ability to accommodate extensive networks of cables, reducing clutter and improving safety. However, they require more effort to install and maintain, especially in larger setups, making them less suitable for simple mounting needs.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the appropriate mounting solution depends on specific project requirements. U-shaped brackets excel in providing robust support for various applications, particularly where high load capacity is essential. If budget constraints are a priority, L-brackets may offer an economical alternative for corner reinforcements. Conversely, for projects requiring extensive cable management, investing in a dedicated cable management system could enhance organization and safety.

Ultimately, B2B buyers should assess the performance, cost, and ease of implementation of each solution against their project goals. Understanding these factors will ensure the selection of the most suitable mounting solution tailored to their operational needs.

Essential Technical Properties and Trade Terminology for u shaped brackets for mounting

What Are the Key Technical Properties of U-Shaped Brackets for Mounting?

When selecting U-shaped brackets for mounting, understanding their technical specifications is crucial for ensuring compatibility and reliability in various applications. Here are some critical specifications to consider:

-

Material Grade

The material grade of U-shaped brackets typically includes options like stainless steel, galvanized steel, and aluminum. Stainless steel (Type 304) is ideal for environments prone to corrosion, while galvanized steel offers a cost-effective solution with moderate corrosion resistance. Aluminum is lightweight and corrosion-resistant, making it suitable for applications where weight is a concern. Choosing the right material impacts durability, strength, and overall performance. -

Load Capacity

Load capacity refers to the maximum weight a bracket can support without failure. This specification is essential for determining how many brackets are needed for a specific application, such as shelving or structural support. Load capacities can vary significantly, often ranging from 50 lbs to over 500 lbs per bracket, depending on the design and material. Understanding load capacity helps ensure safety and stability in installations. -

Hole Configuration

The hole configuration (number of holes and their spacing) is vital for installation flexibility. Most U-shaped brackets come with multiple pre-drilled holes to accommodate various mounting options. This feature allows for secure attachment to different surfaces, such as walls or beams, and is particularly important in industrial settings where precise alignment is necessary. -

Finish Type

The finish of a U-shaped bracket affects both its aesthetic appeal and its resistance to environmental factors. Common finishes include electro-galvanized, hot-dip galvanized, and powder-coated options. Each finish offers different levels of protection against rust and corrosion, influencing the bracket’s longevity in outdoor or harsh environments. Selecting the appropriate finish is essential for maintaining the integrity of the installation over time. -

Dimensions and Tolerances

Dimensions (length, width, and thickness) and tolerances (the permissible limit of variation) are critical for ensuring that the brackets fit properly in their intended applications. Accurate dimensions ensure compatibility with channels and other mounting hardware. Tolerances are particularly important in precision engineering, where even minor deviations can affect performance.

What Trade Terms Should B2B Buyers Understand When Purchasing U-Shaped Brackets?

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B space. Here are some common terms relevant to purchasing U-shaped brackets:

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of U-shaped brackets, an OEM might supply brackets specifically designed for a particular application or brand. Understanding OEM relationships can aid in sourcing high-quality components that meet specific industry standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is significant for B2B buyers as it influences purchasing decisions and inventory management. Understanding the MOQ helps companies plan their procurement strategies and manage costs effectively. -

RFQ (Request for Quotation)

An RFQ is a formal document that a buyer sends to suppliers to request pricing and terms for specific products. For U-shaped brackets, an RFQ can help buyers obtain competitive quotes, compare suppliers, and ensure they receive the best value for their investment. -

Incoterms (International Commercial Terms)

Incoterms are international rules that define the responsibilities of buyers and sellers in international transactions. They outline who is responsible for shipping, insurance, and tariffs. Familiarity with Incoterms is crucial for B2B buyers engaging in cross-border procurement of U-shaped brackets, as it helps clarify costs and responsibilities. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. Understanding lead times is vital for project planning and inventory management. B2B buyers should consider lead times when sourcing U-shaped brackets to ensure timely delivery for their projects.

By comprehensively understanding these technical properties and trade terms, B2B buyers can make informed decisions, ensuring they select the right U-shaped brackets for their mounting needs while fostering effective supplier relationships.

Navigating Market Dynamics and Sourcing Trends in the u shaped brackets for mounting Sector

What Are the Current Market Dynamics and Key Trends for U-Shaped Brackets for Mounting?

The global market for U-shaped brackets for mounting is experiencing significant growth, driven by various factors including the expansion of industrial sectors, the rise of construction activities, and increasing demand for versatile mounting solutions. In regions such as Africa, South America, the Middle East, and Europe, international B2B buyers are increasingly seeking reliable and durable mounting hardware that can adapt to diverse applications, from industrial installations to commercial projects.

Emerging technologies in manufacturing, such as automated production and advanced materials, are reshaping the sourcing landscape. These innovations not only enhance product quality but also reduce lead times, allowing buyers to respond swiftly to market demands. Additionally, there is a noticeable trend towards customization, as businesses look for brackets that can accommodate specific project requirements, ensuring compatibility with various mounting surfaces and structural frameworks.

The shift towards digital sourcing platforms is another significant trend. B2B buyers are leveraging online marketplaces and specialized suppliers to access a wider range of products, compare prices, and evaluate supplier credentials. This transition is particularly beneficial for international buyers, who can easily navigate logistics and shipping options to secure the best deals while ensuring quality and compliance with local standards.

How Is Sustainability and Ethical Sourcing Changing the U-Shaped Brackets Market?

The environmental impact of manufacturing practices is increasingly influencing purchasing decisions among B2B buyers. In the U-shaped bracket sector, sustainability is becoming a key consideration, with companies seeking products made from recycled or sustainably sourced materials. These efforts not only minimize the ecological footprint but also enhance brand reputation in an era where consumers and businesses alike prioritize environmental responsibility.

Ethical sourcing is also gaining traction, as buyers demand transparency in supply chains. Suppliers that adhere to ethical practices—such as fair labor conditions and responsible sourcing—are more likely to secure contracts with conscientious businesses. Certifications like ISO 14001 (Environmental Management) and other green credentials are becoming essential for suppliers aiming to attract international clients, particularly in regions where environmental regulations are stringent.

Moreover, the emphasis on sustainability is prompting manufacturers to innovate. For instance, some companies are developing U-shaped brackets using biodegradable coatings or rust-resistant finishes that reduce the need for frequent replacements, thus contributing to a circular economy.

What Is the Brief Evolution and History of U-Shaped Brackets for Mounting?

The evolution of U-shaped brackets can be traced back to the early days of construction and manufacturing when the need for reliable mounting solutions became apparent. Initially crafted from basic metals, these brackets evolved in design and material as construction techniques advanced.

With the industrial revolution and the subsequent expansion of the construction sector, the demand for more durable and versatile mounting solutions surged. Today, U-shaped brackets are available in various materials—ranging from standard steel to corrosion-resistant alloys—allowing them to meet the diverse needs of different industries, including automotive, marine, and general construction.

In recent decades, the introduction of computer-aided design (CAD) and automated manufacturing processes has revolutionized the production of U-shaped brackets. This technological advancement has enabled manufacturers to produce customized solutions at scale, further solidifying the relevance of U-shaped brackets in modern construction and industrial applications. As markets continue to evolve, the adaptability of these brackets remains a cornerstone of their enduring popularity.

Frequently Asked Questions (FAQs) for B2B Buyers of u shaped brackets for mounting

-

How do I determine the right size of U-shaped bracket for my mounting needs?

To select the appropriate size of U-shaped bracket, first assess the weight and dimensions of the items you plan to mount. Consider the load-bearing capacity of the bracket, which is typically indicated by the manufacturer. It’s also essential to evaluate the mounting surface and ensure the bracket size matches the required spacing and fit for your application. Lastly, consult technical specifications or a supplier for guidance tailored to your specific project requirements. -

What is the best material for U-shaped brackets in outdoor applications?

For outdoor applications, stainless steel or hot-dip galvanized brackets are highly recommended due to their superior resistance to corrosion and rust. Stainless steel, particularly Type 304, offers excellent durability and aesthetic appeal, while hot-dip galvanized options provide a protective zinc coating that withstands harsh weather conditions. Always consider the environmental factors, such as humidity and exposure to chemicals, to ensure longevity and performance. -

How can I ensure the quality of U-shaped brackets from international suppliers?

To ensure quality when sourcing U-shaped brackets from international suppliers, it’s essential to conduct thorough due diligence. Start by verifying the supplier’s certifications, such as ISO 9001, which indicates a commitment to quality management systems. Request samples to assess material and manufacturing quality firsthand. Additionally, consider suppliers with positive reviews and a proven track record in your industry. Establishing clear communication regarding your quality standards can further mitigate risks. -

What customization options are typically available for U-shaped brackets?

Many manufacturers offer customization options for U-shaped brackets, including variations in size, material, and finish. You can often request specific hole placements, thicknesses, or additional features like powder coating for enhanced protection. It’s advisable to communicate your exact requirements during the initial discussions with suppliers to ensure they can meet your specifications. Be prepared to provide detailed drawings or prototypes to facilitate the customization process. -

What are the typical minimum order quantities (MOQs) for U-shaped brackets?

Minimum order quantities (MOQs) for U-shaped brackets can vary significantly based on the supplier and the complexity of the customization. Generally, MOQs range from 50 to 500 pieces for standard products, while custom orders may have higher thresholds. Discussing your project needs with the supplier can sometimes lead to flexibility in MOQs, especially if you’re willing to negotiate pricing or future order commitments. -

What payment terms should I expect when purchasing U-shaped brackets internationally?

Payment terms can vary widely among international suppliers. Common practices include advance payment, letters of credit, or net 30/60/90 days after delivery. It’s crucial to clarify these terms before placing an order to avoid misunderstandings. Additionally, consider the payment methods that offer protection, such as escrow services, which ensure that funds are only released once you receive and approve the goods. -

How can I manage logistics and shipping for U-shaped brackets sourced internationally?

To effectively manage logistics for international sourcing, collaborate closely with your supplier to understand shipping options, costs, and timelines. Utilize freight forwarders who specialize in your destination region to streamline customs clearance and ensure compliance with local regulations. It’s also wise to account for potential delays due to customs or shipping issues in your planning. Additionally, consider insurance for your shipment to protect against losses during transit. -

What quality assurance practices should I implement when sourcing U-shaped brackets?

Implementing quality assurance (QA) practices involves several steps. Start with defining your quality specifications and communicate these to your supplier. Conduct inspections during production or upon receipt to verify that the brackets meet your standards. Additionally, consider third-party inspection services for larger orders or complex products. Regularly reviewing supplier performance and maintaining an open line of communication can further enhance QA processes and ensure ongoing product reliability.

Top 6 U Shaped Brackets For Mounting Manufacturers & Suppliers List

1. Unistrut Store – U Brackets

Domain: unistrutstore.com

Registered: 2018 (7 years)

Introduction: U Brackets are designed to securely join multiple pieces of Unistrut Channel or mount channels to walls or other surfaces. They ensure strong, reliable connections for a variety of structural applications. Available in multiple sizes, they offer flexible mounting solutions for both industrial and commercial projects. Free shipping on orders over $35 (some conditions apply).

2. Wagner – Steel U-Bracket 3755

Domain: shop.wagnercompanies.com

Registered: 1999 (26 years)

Introduction: This company, Wagner – Steel U-Bracket 3755, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Freshwater Systems – Metal U-Shaped Mounting Bracket

Domain: freshwatersystems.com

Registered: 1998 (27 years)

Introduction: Mounting Bracket – TWO Housing METAL “U” Shaped

4. Cascade Iron Co – Heavy Duty U Shaped Bracket

Domain: cascadeironco.com

Registered: 2018 (7 years)

Introduction: Product Name: Heavy Duty U Shaped Bracket for Double Shelves

Price: $26.00 – $32.00 USD depending on size and finish

Sizes Available: 5″, 7″, 9″, 11″

Weight Capacity: Each bracket holds 100 lbs

Material: .25″ thick x 2″ wide premium US steel

Finish Options: Clear Coated Raw Steel, Black, Brass, White, Silver

Included Hardware: Matching lag bolt hardware for wall attachment and short bolts for atta…

5. Etsy – Heavy Duty Channel Stabilizer

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: U Bracket – Etsy

– Price Range: $18.15 – $26.00

– Product Types:

– Heavy Duty Channel Stabilizer with Powder Coating, C Channel Support, Slab Stabilizer, Wood Slab, Metal Bracket

– Modern Industrial Concave Shelf Brackets (Raw Steel, Heavy-Duty, Handmade in USA, Powder-Coat Option)

– Heavy-Duty Black Iron Shelf Bracket Pair (Wall Mounted, U-Shaped, Rustic Industrial, Farmhouse Decor)

– H…

6. Reddit – Underground Sprinkling Control Unit

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Control unit for homemade underground sprinkling system; requires mounting bracket for U Post; no mounting holes on the control unit; needs to be suspended by tube or tension.

Strategic Sourcing Conclusion and Outlook for u shaped brackets for mounting

In today’s competitive marketplace, strategic sourcing of U-shaped brackets for mounting is essential for international B2B buyers. These brackets provide versatile solutions for various applications, from industrial to commercial projects, ensuring robust connections and structural integrity. By leveraging a wide range of sizes and finishes, businesses can tailor their sourcing strategies to meet specific needs, enhancing project efficiency and performance.

Moreover, the availability of free shipping options and competitive pricing across suppliers can significantly reduce overall costs. Engaging with reliable manufacturers and distributors not only streamlines procurement processes but also fosters long-term partnerships that can yield additional benefits, such as bulk discounts and priority service.

Looking ahead, the demand for durable and adaptable mounting solutions is set to rise, driven by infrastructural developments and technological advancements in various sectors. International buyers from Africa, South America, the Middle East, and Europe should seize this opportunity to optimize their supply chains and invest in high-quality U-shaped brackets. By doing so, they position themselves for future growth and success in an increasingly interconnected global market. Explore your sourcing options today to ensure your projects are built on a foundation of strength and reliability.

Illustrative image related to u shaped brackets for mounting

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.