Types Of Shelving: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for types of shelving

In today’s rapidly evolving global market, sourcing the right types of shelving can be a daunting challenge for B2B buyers, particularly when it comes to optimizing space and enhancing organizational efficiency. With diverse applications ranging from retail display to industrial storage, the variety of shelving options available can overwhelm even the most seasoned procurement professionals. This guide serves as a comprehensive resource, offering insights into the myriad types of shelving, including freestanding, wall-mounted, and adjustable solutions, along with their specific applications across various industries.

International buyers from regions such as Africa, South America, the Middle East, and Europe—including countries like Nigeria and Vietnam—face unique considerations in their purchasing decisions. Factors such as local market trends, supplier reliability, and cost-effectiveness play a critical role in ensuring the right fit for business needs. This guide empowers decision-makers by providing actionable insights into supplier vetting processes, cost analysis, and market trends, allowing for informed and strategic purchasing decisions.

By addressing these key challenges and outlining the essential elements of effective shelving solutions, this guide aims to streamline the decision-making process for international B2B buyers, ensuring they can confidently navigate the complexities of the global shelving market.

Understanding types of shelving Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Freestanding Shelving | Versatile, available in various materials and sizes | Warehouses, retail stores, offices | Pros: Easy to assemble, adaptable; Cons: May require more floor space. |

| Wall-Mounted Shelving | Attached directly to walls, saving floor space | Showrooms, kitchens, and offices | Pros: Space-saving, visually appealing; Cons: Limited weight capacity depending on wall structure. |

| Adjustable Slotted Shelves | Flexible height settings, typically made of metal | Industrial storage, libraries, retail | Pros: Customizable, efficient use of vertical space; Cons: Installation can be complex. |

| Floating Shelves | No visible brackets, creates a clean aesthetic | Home decor, boutiques, and galleries | Pros: Stylish, maximizes floor space; Cons: Limited load-bearing capacity. |

| Mobile Shelving | Equipped with wheels for easy relocation | Hospitals, libraries, and warehouses | Pros: Flexible storage solutions, easy to reposition; Cons: Stability can be an issue if overloaded. |

What Are the Characteristics and Suitability of Freestanding Shelving?

Freestanding shelving is a classic storage solution characterized by its independence from walls or other structures. Available in a myriad of materials like wood, metal, and plastic, these shelves can accommodate diverse storage needs across various sectors. B2B buyers often choose freestanding shelving for warehouses, retail environments, and offices due to its adaptability and ease of assembly. However, it typically requires a larger footprint, which may be a drawback in space-constrained environments.

How Do Wall-Mounted Shelving Solutions Optimize Space?

Wall-mounted shelving is designed to attach directly to walls, making it an excellent choice for businesses looking to save floor space. This type of shelving is commonly used in showrooms, kitchens, and offices, where aesthetics and functionality are paramount. Buyers appreciate the stylish appearance of wall-mounted shelves, but they must consider the weight capacity, as it depends on the wall structure. Proper installation is crucial to ensure safety and durability.

Why Are Adjustable Slotted Shelves Ideal for Industrial Settings?

Adjustable slotted shelves feature a design that allows for customizable height settings, making them suitable for various applications, particularly in industrial settings like warehouses and libraries. Their metal construction provides durability, and the ability to reposition shelves easily makes them a favorite among B2B buyers looking for flexibility. However, installation can be more complex compared to other shelving types, necessitating careful planning.

What Advantages Do Floating Shelves Offer in Terms of Aesthetics?

Floating shelves are known for their sleek, modern design, as they have no visible brackets, creating a minimalist aesthetic. They are often used in home decor, boutiques, and galleries to display products or art without taking up floor space. While floating shelves can enhance the visual appeal of a space, buyers should be aware of their limited load-bearing capacity, which may restrict their use for heavier items.

How Do Mobile Shelving Solutions Enhance Flexibility in Storage?

Mobile shelving is equipped with wheels, allowing for easy relocation and reconfiguration of storage spaces. This type of shelving is particularly beneficial in dynamic environments such as hospitals, libraries, and warehouses, where space usage may frequently change. B2B buyers value the flexibility mobile shelving provides, but they must also consider the stability and weight limitations to ensure it meets their storage requirements effectively.

Key Industrial Applications of types of shelving

| Industry/Sector | Specific Application of types of shelving | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Adjustable Slotted Shelves in Stock Rooms | Maximizes storage efficiency and flexibility in inventory management | Durability, weight capacity, and ease of reconfiguration |

| Healthcare | Mobile High-Density Shelving for Medical Supplies | Optimizes space in medical facilities, ensuring quick access to critical supplies | Compliance with health regulations, mobility, and accessibility |

| Automotive | Heavy-Duty Freestanding Shelving for Tools | Increases organization and safety in workshops, reducing downtime | Load capacity, corrosion resistance, and modularity |

| Warehousing | Industrial Racking Systems | Enhances storage density and retrieval speed, improving logistics | Compatibility with forklifts, load rating, and scalability |

| Education | Library Shelving Solutions | Facilitates efficient use of space for books and materials, enhancing learning environments | Customization options, material quality, and aesthetic appeal |

How Are Adjustable Slotted Shelves Used in Retail Stock Rooms?

In retail environments, adjustable slotted shelves are essential for stock rooms where inventory management is crucial. These shelves allow for the customization of height and spacing, accommodating various product sizes and ensuring optimal organization. Retailers benefit from increased space efficiency and improved accessibility to stock, which can enhance customer service. For international buyers, sourcing should consider the material’s durability to withstand frequent use and the ease of assembly to facilitate quick setup.

What Role Do Mobile High-Density Shelving Systems Play in Healthcare Facilities?

Mobile high-density shelving is a vital solution for healthcare facilities aiming to maximize their limited space while ensuring quick access to medical supplies. These systems allow for compact storage, reducing the footprint of storage areas while maintaining compliance with health regulations. International buyers should focus on mobility features, ensuring that the shelving can be easily maneuvered and meets stringent safety standards. The ability to customize these systems to fit specific spaces and needs is also a significant consideration.

How Does Heavy-Duty Freestanding Shelving Benefit Automotive Workshops?

In automotive workshops, heavy-duty freestanding shelving is crucial for storing tools and parts securely. These shelving units are designed to handle substantial weight, providing a safe and organized environment that minimizes downtime due to misplaced tools. B2B buyers in this sector should evaluate the load capacity and corrosion resistance of the shelving, particularly in environments where exposure to oils and chemicals is common. Modular designs that allow for easy rearrangement can also enhance workflow efficiency.

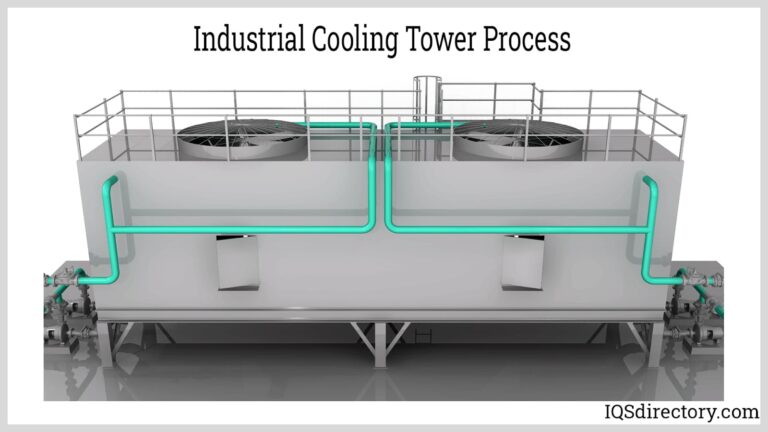

Why Are Industrial Racking Systems Important in Warehousing?

Industrial racking systems are fundamental in warehousing operations, significantly enhancing storage density and retrieval speed. By utilizing vertical space effectively, these systems allow businesses to manage larger inventories without expanding their physical footprint. Buyers should consider compatibility with forklifts and other material handling equipment, as well as the load ratings of the racking. Scalability is also a key factor, enabling businesses to adapt their storage solutions as inventory needs change.

How Can Library Shelving Solutions Enhance Educational Environments?

Library shelving solutions are vital in educational settings, providing structured storage for books and learning materials. These systems facilitate easy access to resources, promoting better learning outcomes. For international buyers, customization options to fit unique space requirements and aesthetic considerations are essential. The quality of materials is also critical, ensuring durability and safety in high-traffic environments.

3 Common User Pain Points for ‘types of shelving’ & Their Solutions

Scenario 1: Inadequate Weight Capacity for Heavy Items

The Problem: A logistics company in Nigeria needs to optimize its warehouse storage but finds that their existing shelving solutions cannot accommodate the weight of heavy equipment and supplies. This not only limits their storage capabilities but also poses safety risks, as shelves may collapse under excess weight. B2B buyers in similar industries often struggle to find shelving that balances strength, durability, and space efficiency, leading to inefficiencies and potential accidents.

The Solution: To address this issue, B2B buyers should consider investing in heavy-duty shelving options specifically designed for industrial use, such as steel or reinforced metal shelving. These types of shelving offer higher weight capacities and are engineered to withstand the rigors of warehouse environments. When sourcing, look for suppliers who provide detailed specifications, including load ratings and materials used. Additionally, consider modular shelving systems that can be customized to fit specific storage needs and can be reconfigured as inventory changes. This not only enhances safety but also maximizes vertical space, allowing for more efficient storage solutions.

Scenario 2: Difficulty in Organizing and Accessing Inventory

The Problem: A retail business in South America is facing challenges with cluttered storage areas where products are difficult to access. Shelving that lacks adjustable heights or compartmentalized sections can lead to inefficiencies in stock retrieval, resulting in longer wait times for customers and potentially lost sales. B2B buyers often encounter this pain point, which can significantly affect operational efficiency and customer satisfaction.

The Solution: Implementing adjustable shelving systems can greatly improve organization and accessibility. These systems allow for the customization of shelf heights based on the size of the products being stored, providing flexibility as inventory changes. Buyers should prioritize shelving solutions that include features such as pull-out shelves or bin shelving, which facilitate easier access to items. Additionally, integrating labeling systems with the shelving can enhance inventory management. When sourcing, it’s crucial to select a supplier who offers comprehensive installation support and training to ensure that staff can effectively utilize the shelving for optimal organization.

Scenario 3: Space Constraints in Smaller Facilities

The Problem: A small manufacturing company in Europe is struggling with limited floor space, making it challenging to store materials efficiently. Traditional shelving solutions consume too much room, leading to a cluttered environment that hinders productivity. B2B buyers in similar situations often find themselves torn between maximizing storage capacity and maintaining a safe and navigable workspace.

The Solution: For companies dealing with space constraints, vertical storage solutions like wall-mounted shelving or ceiling-mounted racks can be game-changers. These options utilize otherwise wasted vertical space, allowing for more floor area to remain clear and accessible. When selecting shelving, consider compact, modular designs that can be adjusted or reconfigured as needed. Buyers should also look for suppliers who provide space-saving solutions tailored to specific industry needs, as well as those who can offer expert consultation on layout design. Investing in such shelving not only enhances space efficiency but also contributes to a safer, more organized work environment.

Strategic Material Selection Guide for types of shelving

What Are the Key Properties of Common Shelving Materials?

When selecting shelving materials for various applications, it is essential to consider their key properties, particularly in terms of durability, load capacity, and environmental resistance.

Steel Shelving is renowned for its strength and durability. With a high-temperature rating and excellent corrosion resistance when treated, steel shelving can withstand heavy loads, making it ideal for industrial settings. However, the manufacturing complexity and higher costs associated with steel can be a concern for some buyers. Steel is suitable for environments where heavy items are stored, such as warehouses and factories.

Wood Shelving offers aesthetic appeal and versatility, making it a popular choice for retail and office environments. It can be treated to enhance durability and resistance to moisture, but it may not withstand extreme temperatures or heavy loads as well as metal options. The cost can vary based on the type of wood used, and while it is generally easy to manufacture, it may require additional treatments for longevity. Wood is particularly suitable for decorative applications or where a warm aesthetic is desired.

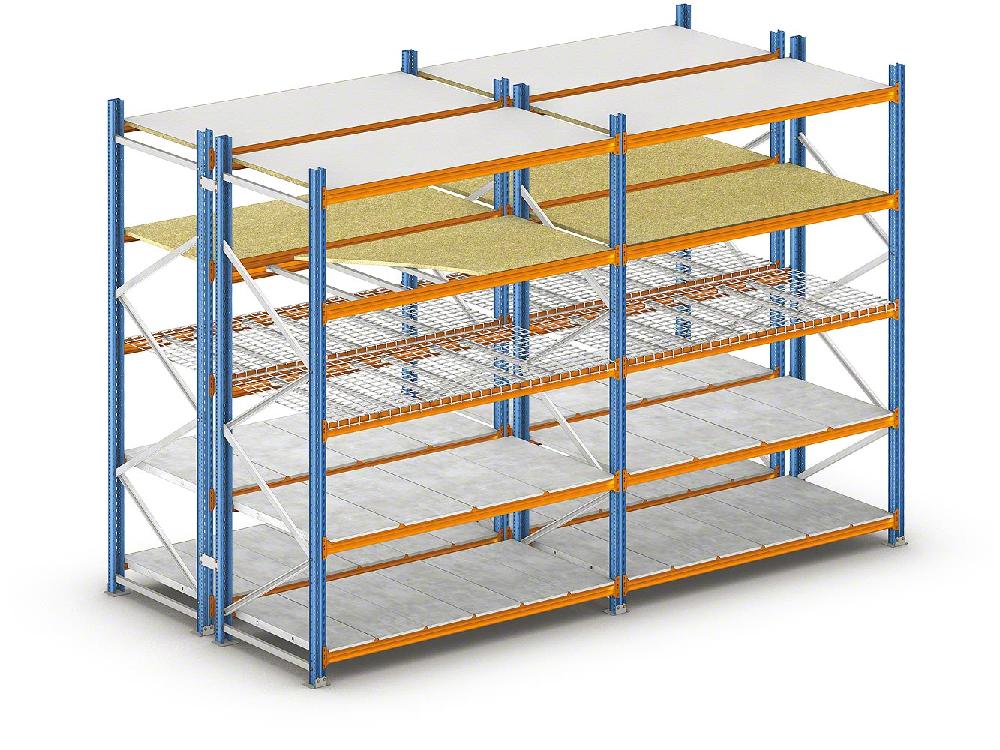

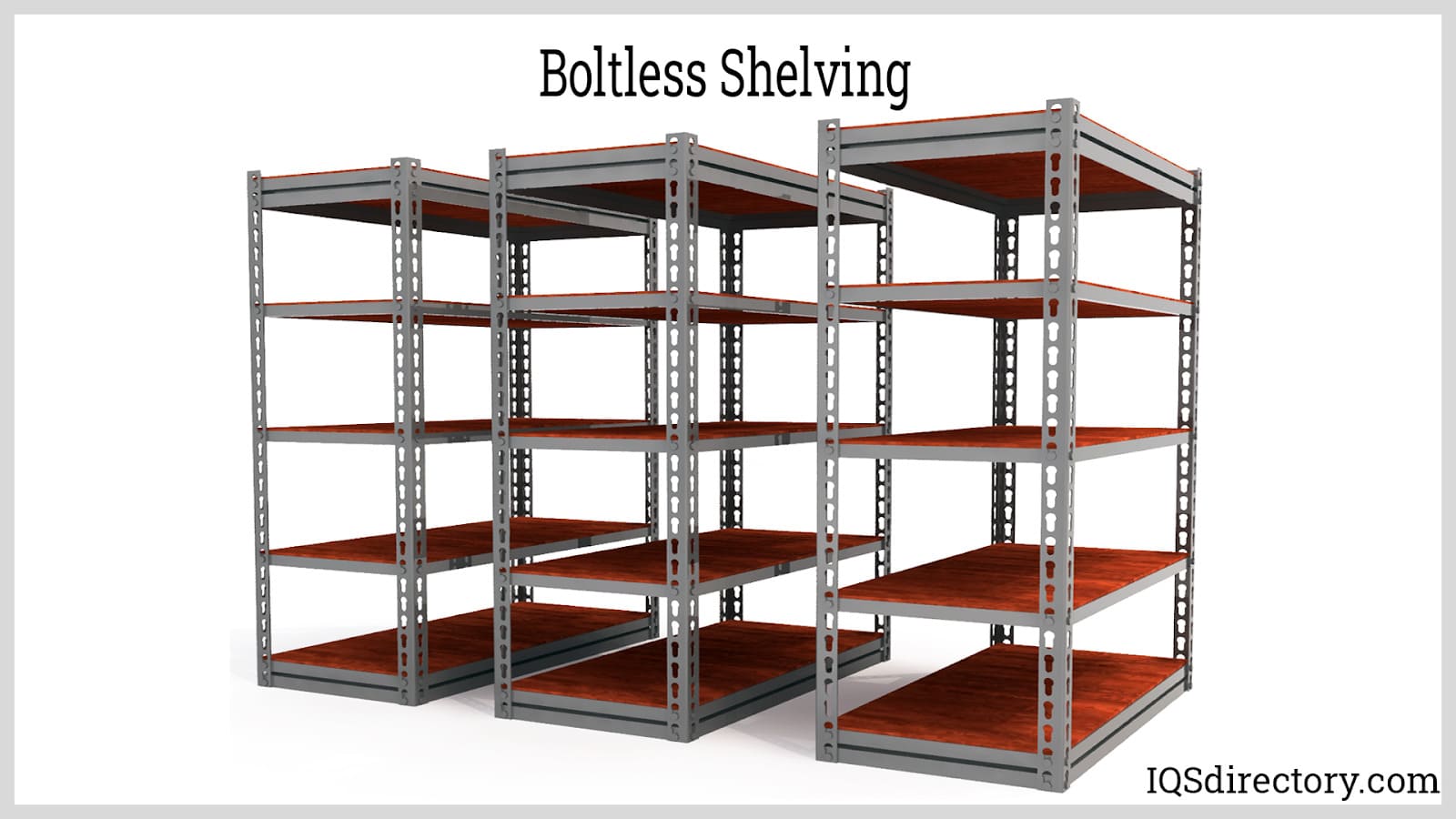

Illustrative image related to types of shelving

Plastic Shelving is lightweight, corrosion-resistant, and often less expensive than metal or wood. It is particularly suitable for environments where moisture is a concern, such as in laboratories or food storage areas. However, it may not support as much weight as metal or wood, limiting its use in heavy-duty applications. For international buyers, the availability of recycled plastic options can be a significant advantage, aligning with sustainability goals.

Wire Shelving combines the benefits of metal with a lightweight design. It is highly versatile and often adjustable, making it suitable for various applications, from retail displays to industrial storage. Wire shelving allows for airflow, which is beneficial in environments where moisture control is crucial. However, it may not be suitable for very small items unless additional containers are used. The cost is generally moderate, making it accessible for many buyers.

What Should International Buyers Consider When Selecting Shelving Materials?

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, must consider local compliance and standards when selecting shelving materials. For instance, adherence to standards like ASTM (American Society for Testing and Materials), DIN (Deutsches Institut für Normung), or JIS (Japanese Industrial Standards) can be crucial for ensuring product quality and safety. Additionally, regional preferences for materials—such as the sustainability of wood or the robustness of steel—can influence purchasing decisions. Understanding local market conditions and material availability is essential for making informed choices.

Summary Table of Material Selection for Shelving

| Material | Typical Use Case for types of shelving | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Industrial storage, warehouses | High strength and durability | Higher cost and manufacturing complexity | High |

| Wood | Retail displays, offices | Aesthetic appeal and versatility | Limited load capacity and moisture sensitivity | Medium |

| Plastic | Laboratories, food storage | Lightweight and corrosion-resistant | Lower weight capacity | Low |

| Wire | Retail displays, industrial storage | Adjustable and allows airflow | Not suitable for very small items | Medium |

This analysis provides a comprehensive overview of the strategic material selection for shelving, assisting international B2B buyers in making informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for types of shelving

What Are the Key Stages in the Manufacturing Process of Shelving?

The manufacturing process for shelving systems typically involves several critical stages: material preparation, forming, assembly, and finishing. Each stage is crucial for ensuring the quality and durability of the final product.

Illustrative image related to types of shelving

Material Preparation: How Are Raw Materials Selected and Processed?

The first step in manufacturing shelving involves selecting high-quality raw materials such as wood, metal, or plastic. The choice of material directly impacts the shelf’s strength, weight capacity, and aesthetic appeal. For metal shelving, for instance, steel is often preferred due to its robustness and longevity.

Once materials are chosen, they undergo preparation processes, including cutting, shaping, and treating. Metals may be coated with anti-corrosive treatments, while wood might be sanded or treated to prevent warping. The preparation phase is vital as it sets the foundation for the entire shelving system.

What Techniques Are Commonly Used in the Forming Stage?

During the forming stage, the prepared materials are manipulated into the desired shapes. For metal shelving, techniques such as stamping, bending, and welding are commonly employed. These methods allow for the creation of complex designs and ensure that the shelves can bear significant weight.

In the case of wooden shelves, processes like routing or milling may be used to create grooves for adjustable shelving systems. This stage is critical for achieving the exact specifications required by B2B buyers, who often need customized solutions for their storage needs.

How Is Assembly Conducted to Ensure Structural Integrity?

Assembly is the next step, where individual components are brought together to form the final shelving unit. This can involve mechanical fasteners such as screws and bolts or adhesive bonding for certain materials. Automated assembly lines are increasingly common, allowing for faster production rates without compromising quality.

For B2B buyers, the assembly process should include checks to ensure that all parts fit correctly and securely. A well-assembled shelving unit will not only perform better but will also have a longer lifespan, which is a critical factor for businesses looking to invest in durable storage solutions.

What Finishing Processes Are Essential for Aesthetic and Protective Qualities?

The final stage in manufacturing shelving involves finishing processes that enhance both aesthetics and durability. This may include painting, powder coating, or varnishing, depending on the material used. For metal shelves, powder coating provides a tough, protective layer that is resistant to scratches and corrosion, making it ideal for industrial settings.

In wood shelving, applying a finish can improve the look while also protecting against moisture and wear. Quality finishes can significantly influence the marketability of shelving products, especially for B2B buyers who may require specific colors or textures to match their branding.

Illustrative image related to types of shelving

What Quality Assurance Standards Are Important for Shelving Manufacturers?

Quality assurance (QA) is a vital component of the manufacturing process, ensuring that shelving products meet international standards and customer expectations. For B2B buyers, understanding these standards can help in selecting reliable suppliers.

Which International Standards Should Buyers Be Aware Of?

International standards such as ISO 9001 are essential for manufacturers as they outline the requirements for a quality management system. Compliance with ISO standards ensures that manufacturers consistently provide products that meet customer and regulatory requirements. Other relevant certifications may include CE marking for products sold in Europe, which indicates conformity with health, safety, and environmental protection standards.

How Are Quality Control Checkpoints Established Throughout the Manufacturing Process?

Quality control (QC) checkpoints are integral to maintaining high standards during the manufacturing process. Common checkpoints include:

Illustrative image related to types of shelving

- Incoming Quality Control (IQC): This involves inspecting raw materials upon delivery to ensure they meet specified quality standards.

- In-Process Quality Control (IPQC): This is conducted during the manufacturing process to monitor and verify that production parameters are being adhered to.

- Final Quality Control (FQC): This final inspection ensures that the finished products meet all specifications before they are shipped.

Each checkpoint is designed to catch defects early in the production process, thereby reducing waste and ensuring that only high-quality shelving reaches the market.

What Testing Methods Are Commonly Used to Ensure Product Quality?

Various testing methods are employed to assess the durability and performance of shelving products. These may include:

- Load Testing: This evaluates the weight capacity of shelves under various conditions to ensure they can handle the intended loads.

- Environmental Testing: Shelving units may be subjected to humidity and temperature variations to assess their durability in different environments.

- Finish Testing: This assesses the resilience of coatings against scratches, chemicals, and environmental factors.

Such testing is crucial for B2B buyers, particularly in sectors like retail and warehousing, where the integrity of storage solutions is paramount.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying the quality control practices of suppliers is essential to ensure product reliability. Here are some actionable steps:

What Should Buyers Look for in Supplier Audits and Reports?

Buyers should request copies of quality control reports and audit results from potential suppliers. These documents can provide insights into the supplier’s manufacturing processes and adherence to quality standards. Regular audits conducted by third parties can also serve as an assurance of the supplier’s commitment to quality.

How Can Third-Party Inspections Enhance Supplier Trustworthiness?

Engaging third-party inspection services can provide an unbiased evaluation of the manufacturing processes and product quality. This is especially important for buyers in regions like Africa and South America, where local regulations may differ significantly from international standards. Third-party inspections can help mitigate risks associated with sourcing from unfamiliar suppliers.

What Are the QC and Certification Nuances for International B2B Buyers?

Understanding the nuances of quality control and certification is particularly critical for international B2B buyers. Different regions may have varying regulations and standards, which can affect product compliance and marketability.

In regions such as the Middle East and Europe, ensuring compliance with local regulations is vital. Buyers should familiarize themselves with regional standards and any specific requirements that may apply to shelving products. This knowledge can help prevent costly mistakes and ensure that purchased products meet all necessary legal requirements.

In summary, a thorough understanding of the manufacturing processes and quality assurance practices for shelving systems is essential for B2B buyers. By focusing on material selection, manufacturing techniques, and robust quality control measures, businesses can make informed decisions that will ultimately enhance their operational efficiency and product offerings.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘types of shelving’

When sourcing shelving solutions for your business, it’s essential to approach the process methodically to ensure you find the right fit for your needs. This guide provides a step-by-step checklist to help B2B buyers navigate the complexities of selecting the appropriate shelving types, materials, and suppliers.

Step 1: Assess Your Storage Needs

Understanding your specific storage requirements is the first step in selecting the right shelving. Consider factors such as the weight and dimensions of items to be stored, the available space, and whether you need adjustable or fixed shelving. This assessment will guide your decisions, ensuring that the shelving you choose is not only functional but also maximizes your available space.

Step 2: Define Your Technical Specifications

Once you’ve assessed your needs, it’s crucial to define the technical specifications for your shelving. This includes selecting the material (e.g., wood, metal, plastic), load capacity, and design (e.g., freestanding, wall-mounted, or modular). By clarifying these specifications upfront, you can streamline your search and avoid wasting time on products that do not meet your criteria.

Step 3: Identify Potential Suppliers

Research and identify suppliers that specialize in the types of shelving you require. Look for companies with a solid reputation in the market and experience in your industry. Consider attending trade shows or utilizing online platforms to discover potential suppliers that can meet your specifications.

Step 4: Evaluate Supplier Certifications and Compliance

Before proceeding with a supplier, it’s vital to verify their certifications and compliance with relevant standards. Look for ISO certifications or local regulatory compliance that indicates quality and safety. This step is crucial, especially in regions with stringent safety regulations, as it ensures the products you receive will meet legal and safety requirements.

Step 5: Request Samples and Conduct Quality Checks

Request samples of the shelving to evaluate their quality and suitability for your needs. Inspect the materials, construction, and finish of the samples. This hands-on approach allows you to assess whether the shelving will perform as expected in your operational environment.

Step 6: Review Pricing and Terms of Purchase

Pricing can vary significantly between suppliers, so it’s important to review and compare quotes. Look for transparency in pricing structures, including shipping, installation, and potential bulk discounts. Additionally, pay attention to the terms of purchase, including warranties and return policies, to safeguard your investment.

Illustrative image related to types of shelving

Step 7: Seek References and Case Studies

Before finalizing a supplier, request references and case studies from their existing clients. This feedback can provide valuable insights into the supplier’s reliability, customer service, and the performance of their shelving solutions in real-world applications. Engaging with other businesses that have similar needs can help you make an informed decision.

By following this checklist, B2B buyers can confidently navigate the sourcing process for shelving solutions, ensuring that their final choice aligns with their operational needs and business goals.

Comprehensive Cost and Pricing Analysis for types of shelving Sourcing

What are the Key Cost Components in Shelving Manufacturing?

When sourcing shelving for business needs, understanding the cost structure is crucial. The primary cost components include:

-

Materials: The choice of materials—such as metal, wood, plastic, or a combination—significantly impacts pricing. Metal shelving tends to be more durable and thus more expensive, while plastic options are often more cost-effective but may lack strength.

-

Labor: Labor costs vary based on the location of manufacturing and the complexity of production. Regions with lower labor costs can offer competitive pricing, but this might also affect quality.

-

Manufacturing Overhead: This encompasses all indirect costs related to production, including utilities, rent, and administrative expenses. A higher overhead can lead to increased prices for buyers.

-

Tooling: The initial investment in tools and molds for production can be substantial, particularly for custom designs. This cost is typically amortized over the production volume.

-

Quality Control (QC): Ensuring product quality through rigorous testing and inspections incurs additional costs. High-quality shelving often comes with a price premium due to these QC measures.

-

Logistics: Shipping costs, including freight, customs duties, and insurance, are essential to factor in, especially for international buyers. The distance and mode of transport can significantly affect the final cost.

-

Margin: Supplier profit margins vary widely based on market conditions, brand reputation, and competition. Understanding these margins can help buyers negotiate better deals.

How Do Volume and Customization Affect Shelving Prices?

Volume and minimum order quantities (MOQ) play a crucial role in pricing. Suppliers often offer discounts for larger orders, making it more economical for businesses with significant storage needs. Additionally, customization requests—such as specific dimensions, colors, or additional features—can lead to higher costs due to the need for specialized production processes.

Quality certifications, such as ISO or safety standards, can also influence pricing. Shelving that meets higher standards may command a premium but offers assurances of durability and safety, which are crucial for businesses in sectors like healthcare or manufacturing.

Illustrative image related to types of shelving

What Buyer Tips Can Enhance Cost-Efficiency in Shelving Sourcing?

For B2B buyers, especially those in Africa, South America, the Middle East, and Europe, several strategies can enhance cost efficiency:

-

Negotiation: Always negotiate prices, especially when ordering in bulk. Suppliers may have room for flexibility, particularly if they value your business.

-

Total Cost of Ownership (TCO): Consider the total cost over the product’s lifespan, not just the initial purchase price. This includes installation, maintenance, and potential replacement costs.

-

Understand Pricing Nuances: International buyers should be aware of currency fluctuations, tariffs, and taxes that can affect overall costs. Familiarity with Incoterms can also help clarify responsibilities related to shipping and logistics.

-

Supplier Relationships: Building strong relationships with suppliers can lead to better pricing and priority service. Regular communication can also help in understanding market trends that may affect pricing.

What Should International Buyers Keep in Mind Regarding Pricing?

International buyers should be cautious of indicative prices due to fluctuating market conditions. Prices can vary significantly based on local economic factors, material availability, and shipping costs. It’s essential to obtain multiple quotes and assess the overall value rather than just the price tag.

By understanding these components and strategies, B2B buyers can make informed decisions when sourcing shelving solutions tailored to their specific needs, ensuring both quality and cost-effectiveness in their purchasing process.

Alternatives Analysis: Comparing types of shelving With Other Solutions

Introduction to Alternatives in Storage Solutions

When considering storage solutions, businesses often evaluate various options beyond traditional shelving. While different types of shelving provide effective organization and display capabilities, alternatives such as modular storage systems and automated storage solutions can also meet diverse needs. This comparison will explore how these alternatives stack up against conventional shelving in terms of performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | Types Of Shelving | Modular Storage Systems | Automated Storage Solutions |

|---|---|---|---|

| Performance | High; suitable for various loads and uses | High; flexible configurations for changing needs | Very high; maximizes space efficiency and speed |

| Cost | Moderate; varies by material and design | Moderate to high; initial investment but cost-effective in the long run | High; significant upfront costs but can reduce labor expenses |

| Ease of Implementation | Easy; typically requires assembly | Moderate; may require planning and assembly | Complex; often requires professional installation |

| Maintenance | Low; regular cleaning required | Low; durable materials with minimal upkeep | Moderate; system checks and software updates needed |

| Best Use Case | General storage in diverse settings | Dynamic environments needing flexibility (e.g., warehouses) | High-volume environments needing fast retrieval (e.g., distribution centers) |

Detailed Breakdown of Alternatives

Modular Storage Systems

Modular storage systems offer flexibility and scalability, making them ideal for businesses that anticipate changes in inventory or storage needs. These systems can be easily reconfigured as requirements evolve, allowing for optimal use of space. However, while they provide a high-performance solution, the initial setup can be more complex and may require significant planning. The cost can also be variable, depending on the materials and design chosen, which might be a consideration for budget-conscious buyers.

Automated Storage Solutions

Automated storage solutions, such as vertical lift modules and robotic storage systems, provide the highest performance in terms of speed and efficiency. These systems are designed to maximize storage space while minimizing retrieval times, making them ideal for high-volume operations. However, they come with a higher price tag and require a level of technical expertise for installation and maintenance. While they significantly reduce labor costs over time, the initial investment can be a barrier for smaller businesses.

Conclusion: Choosing the Right Storage Solution for Your Business

For B2B buyers evaluating storage options, the choice between types of shelving and alternatives like modular systems or automated solutions hinges on specific operational needs and budget constraints. Traditional shelving is often the best choice for straightforward storage needs where cost and ease of implementation are priorities. In contrast, modular systems are suited for businesses expecting growth or changes in inventory, while automated solutions are best for high-demand environments where efficiency is critical. Assessing the unique requirements of your business will guide you in selecting the most appropriate storage solution to enhance productivity and organization.

Essential Technical Properties and Trade Terminology for types of shelving

What Are the Key Technical Properties of Shelving Systems?

Understanding the technical properties of shelving is crucial for B2B buyers to ensure that the selected systems meet their operational needs. Here are several critical specifications that should be considered:

1. Material Grade

The grade of materials used in shelving—such as steel, wood, or plastic—directly influences durability and load-bearing capacity. For instance, industrial-grade steel shelving can support heavier weights and withstand harsher environments compared to standard residential options. Selecting the appropriate material grade is essential for ensuring longevity and safety in storage solutions.

2. Load Capacity

Load capacity refers to the maximum weight a shelving unit can support. This specification is vital for businesses that store heavy items or inventory. Knowing the load capacity helps prevent structural failures and accidents, ensuring compliance with safety regulations. It’s advisable to choose shelving with a load capacity that exceeds the expected weight of stored items to allow for safe operational margins.

3. Tolerance

Tolerance defines the allowable deviation from specified dimensions in shelving units. This property is crucial for ensuring that shelves fit perfectly within designated spaces and can accommodate various items without wobbling or collapsing. Proper tolerance levels are particularly important in modular shelving systems, where components must align accurately for functionality.

4. Dimensions and Configurations

The dimensions of shelving units, including height, width, and depth, determine how they fit within a space. Different configurations, such as freestanding, wall-mounted, or modular systems, offer flexibility for various storage needs. Understanding these dimensions and configurations enables buyers to optimize their storage solutions based on available space and specific requirements.

5. Surface Finish

The surface finish of shelving materials can affect aesthetics, maintenance, and resistance to corrosion or damage. Options may include powder coating, laminate, or untreated wood. A suitable finish enhances not only the appearance but also the durability of the shelves in different environments, such as warehouses or retail spaces.

6. Assembly Requirements

Assembly requirements detail how easy or complex it is to install shelving units. Some systems may come pre-assembled, while others require significant assembly time and skills. For businesses looking to minimize downtime, understanding assembly requirements can aid in selecting products that are efficient to install.

What Are Common Trade Terms in the Shelving Industry?

Familiarity with industry terminology can streamline communication and negotiations between buyers and suppliers. Here are several common trade terms relevant to shelving:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are used as components in another company’s product. In shelving, this may involve manufacturers that produce custom shelves or components for larger retail or industrial applications. Understanding OEM relationships can help buyers source high-quality components tailored to their needs.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is important for buyers to know, as it can impact purchasing decisions and inventory management. Companies should evaluate their needs against MOQ requirements to avoid overstocking or understocking.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers. This process is crucial for comparing options and ensuring competitive pricing. A well-structured RFQ can lead to more accurate quotes and better supplier relationships.

Illustrative image related to types of shelving

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs in international transactions. Understanding these terms helps buyers clarify shipping costs and risks associated with their orders, ensuring smoother logistics.

5. Customization

Customization refers to the ability to modify shelving solutions according to specific requirements, such as dimensions, materials, or features. This term is significant for businesses that need tailored solutions to fit unique operational spaces or aesthetic preferences.

6. Lead Time

Lead time is the period between placing an order and receiving the products. Knowing the lead time is critical for inventory planning and operational efficiency, as it affects stock availability and overall project timelines.

Navigating Market Dynamics and Sourcing Trends in the types of shelving Sector

What Are the Current Market Dynamics and Key Trends in the Types of Shelving Sector?

The global shelving market is experiencing significant growth, driven by increasing urbanization, changing consumer behaviors, and a surge in e-commerce. In regions like Africa, South America, the Middle East, and Europe, there is a rising demand for versatile and adaptable shelving solutions that cater to both residential and commercial needs. Key trends include the growing popularity of modular shelving systems, which allow businesses to customize their storage solutions according to specific space requirements. Additionally, the integration of technology into shelving products, such as smart shelving systems with inventory management capabilities, is gaining traction among B2B buyers.

Emerging technologies in manufacturing, such as automation and advanced materials, are reshaping sourcing strategies. Suppliers are increasingly adopting digital platforms for inventory management and order processing, enhancing efficiency and reducing lead times. Moreover, the rise of e-commerce has led to an increased focus on warehouse shelving solutions that optimize space and improve logistics. For international buyers, particularly from developing markets, it is crucial to stay informed about regional variations in shelving preferences and regulatory compliance to ensure successful sourcing.

How Is Sustainability Impacting the Shelving Industry and What Are the Ethical Sourcing Considerations?

Sustainability has become a pivotal concern in the shelving sector, with businesses increasingly prioritizing environmentally friendly practices. The sourcing of materials plays a crucial role in minimizing the environmental impact of shelving products. Buyers are now looking for options made from sustainable materials, such as recycled metals and sustainably sourced wood, which not only reduce carbon footprints but also appeal to eco-conscious consumers.

Ethical supply chains are also gaining importance, as businesses seek to ensure fair labor practices and responsible sourcing. Certifications such as Forest Stewardship Council (FSC) for wood products and Global Recycled Standard (GRS) for recycled materials are becoming essential for B2B buyers to validate their sustainability claims. Emphasizing these credentials can enhance brand reputation and foster customer loyalty. As the demand for transparency in sourcing increases, suppliers that align with these values will be better positioned to attract international buyers from diverse markets.

What Is the Brief Evolution and History of Shelving Solutions in a B2B Context?

The evolution of shelving solutions can be traced back to ancient civilizations, where basic wooden shelves were used for storage. Over the years, advancements in materials and manufacturing processes have transformed the shelving landscape. The Industrial Revolution marked a significant turning point, introducing metal and wire shelving that offered greater durability and weight capacity.

In the late 20th century, the advent of modular and adjustable shelving systems allowed businesses to optimize space usage in warehouses and retail environments. Today, the focus has shifted towards multifunctional designs that cater to both aesthetic and practical needs, reflecting the diverse requirements of modern B2B buyers. As the market continues to evolve, the emphasis on technology integration and sustainability will shape the future of shelving solutions, ensuring they meet the demands of a dynamic global marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of types of shelving

-

How do I choose the right type of shelving for my business needs?

Choosing the right type of shelving involves assessing your specific storage requirements, the nature of the items to be stored, and the available space. Consider the weight capacity, dimensions, and material of the shelving. For heavy-duty storage, metal or industrial shelving is ideal, while lighter items can be accommodated with plastic or wood options. Additionally, think about whether you need adjustable shelves for flexibility or fixed shelves for a more permanent solution. Consulting with a shelving expert can also provide tailored recommendations based on your industry. -

What are the advantages of custom shelving solutions for my business?

Custom shelving solutions offer several benefits, including optimized space utilization, tailored dimensions to fit your specific layout, and the ability to select materials that match your branding or operational needs. Custom designs can also incorporate features like adjustable heights, specialized compartments, or integrated technology for enhanced functionality. This personalized approach can improve efficiency in operations, enhance organization, and ultimately contribute to better workflow within your facility. -

What are the minimum order quantities (MOQs) for shelving products?

Minimum order quantities (MOQs) for shelving products can vary significantly based on the supplier and the type of shelving being ordered. Generally, standard shelving units may have lower MOQs, while custom or specialized shelving could require higher quantities. It’s essential to discuss your specific needs with suppliers to negotiate MOQs that align with your purchasing capabilities, especially if you are a smaller business or a startup. Some suppliers may offer flexibility based on your order frequency or potential for future orders. -

What payment terms should I expect when sourcing shelving internationally?

Payment terms for international shelving orders can vary widely depending on the supplier and your negotiation. Common terms include upfront payments, net 30 or net 60 days after delivery, or payment upon shipment. It’s advisable to establish clear payment terms early in negotiations to avoid misunderstandings. Additionally, consider using secure payment methods such as letters of credit or escrow services to protect your investment, especially when dealing with new suppliers or large orders. -

How can I ensure quality assurance (QA) for my shelving products?

To ensure quality assurance for shelving products, start by vetting suppliers through reviews, certifications, and quality management systems. Request samples or visit the manufacturing facility if possible. Establish clear quality standards in your contract, including specifications for materials, load capacity, and finish. Implementing a third-party inspection before shipment can also provide added assurance that the products meet your quality requirements. Regular communication with your supplier throughout the production process can help address any issues early on. -

What are the key factors to consider for logistics when importing shelving?

When importing shelving, key logistics factors include shipping methods, lead times, and import regulations. Choose a reliable freight forwarder familiar with your target markets in Africa, South America, the Middle East, or Europe. Understand the tariffs and customs duties applicable to your shelving products, as these can impact overall costs. Additionally, consider the packaging to ensure protection during transit, as well as the handling requirements upon arrival to avoid delays or damages. -

How do I vet suppliers for international shelving purchases?

Vetting suppliers for international shelving purchases involves several steps. Start by researching potential suppliers through online directories, trade shows, and industry referrals. Check their credentials, such as business licenses, industry certifications, and customer testimonials. Request references from previous clients to gauge their reliability and quality. It’s also beneficial to conduct site visits or virtual tours to assess their manufacturing capabilities and quality control processes. Establishing clear communication and building a relationship can further ensure a reliable partnership. -

What are the most common materials used in commercial shelving, and how do they compare?

Common materials for commercial shelving include metal, wood, plastic, and wire. Metal shelving is known for its durability and strength, making it suitable for heavy-duty applications. Wood offers aesthetic appeal and is often used in retail environments but may require more maintenance. Plastic shelving is lightweight and resistant to moisture, ideal for warehouses or cold storage. Wire shelving provides excellent air circulation, making it suitable for food storage or environments where humidity is a concern. Each material has distinct advantages, so consider your specific application when making a choice.

Top 2 Types Of Shelving Manufacturers & Suppliers List

1. IKEA – BILLY Bookcase

Domain: ikea.com

Registered: 1995 (30 years)

Introduction: IKEA offers a wide range of shelving furniture including bookshelves, bookcases, and storage shelves. Key products include the BILLY Bookcase available in various sizes and colors (white, black oak effect, brown walnut effect) with prices ranging from $49.00 to $398.00. The KALLAX Shelf unit is also popular, available in multiple finishes and sizes, priced from $44.99 to $109.99. Other notable pro…

2. Lowe’s – Shelving Solutions

Domain: lowes.com

Registered: 1995 (30 years)

Introduction: Shelves & Shelving options include Freestanding Shelving Units, Wall Mounted Shelves, Floating Shelves, Shelving Brackets & Hardware, Cube Storage Organizers, and Bookshelves. Freestanding shelves come in various materials, styles, and colors (black, white) with different weight capacities. Wall mounted shelves utilize vertical space, with options like floating shelves (no visible hardware) and br…

Strategic Sourcing Conclusion and Outlook for types of shelving

As the global market for shelving continues to expand, understanding the diverse types of shelving available is crucial for international B2B buyers. From freestanding and wall-mounted options to innovative solutions like ceiling-mounted and adjustable slotted shelves, each type serves specific needs across various industries. The strategic sourcing of shelving is not only about selecting the right type but also about aligning with suppliers who understand the local market dynamics and can provide tailored solutions that enhance efficiency and productivity.

Leveraging strategic sourcing enables businesses to optimize their storage solutions, reduce costs, and improve operational workflows. By investing in high-quality shelving that meets both aesthetic and functional requirements, companies can create organized spaces that enhance customer experiences and drive sales.

Looking ahead, international buyers from regions such as Africa, South America, the Middle East, and Europe should prioritize partnerships with suppliers who offer innovative shelving solutions and understand the unique challenges of their markets. Embrace the opportunity to elevate your storage strategies—partner with trusted suppliers to explore the most effective shelving solutions that can drive your business forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.