Types Of Mixing: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for types of mixing

In the ever-evolving landscape of global commerce, sourcing the right types of mixing equipment can pose a significant challenge for B2B buyers, particularly in diverse markets across Africa, South America, the Middle East, and Europe. Companies in industries ranging from pharmaceuticals to food production require precise and effective mixing solutions to ensure product quality and operational efficiency. This comprehensive guide delves into the various types of mixing processes, including blending miscible liquids, emulsifying immiscible substances, and dispersing solids into liquids, among others.

By offering detailed insights into the applications and benefits of each mixing type, this guide empowers international buyers to make informed purchasing decisions. Additionally, we address crucial factors such as supplier vetting, cost considerations, and technological advancements that can influence equipment selection. Whether you are in Germany seeking high-shear mixers or in Brazil exploring industrial blenders, this guide serves as a valuable resource to navigate the complexities of the mixing equipment market. With the right knowledge, B2B buyers can not only optimize their production processes but also enhance their competitive edge in the global marketplace.

Understanding types of mixing Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Blending Miscible Liquids | Involves mixing liquids that completely dissolve in each other. | Food and beverage, pharmaceuticals, cosmetics | Pros: Simple process, low energy consumption. Cons: Limited to compatible liquids. |

| Emulsifying Immiscible Liquids | Combines liquids that do not naturally mix using emulsifiers. | Food production, cosmetics, pharmaceuticals | Pros: Enables creation of stable mixtures. Cons: Requires precise emulsifier selection. |

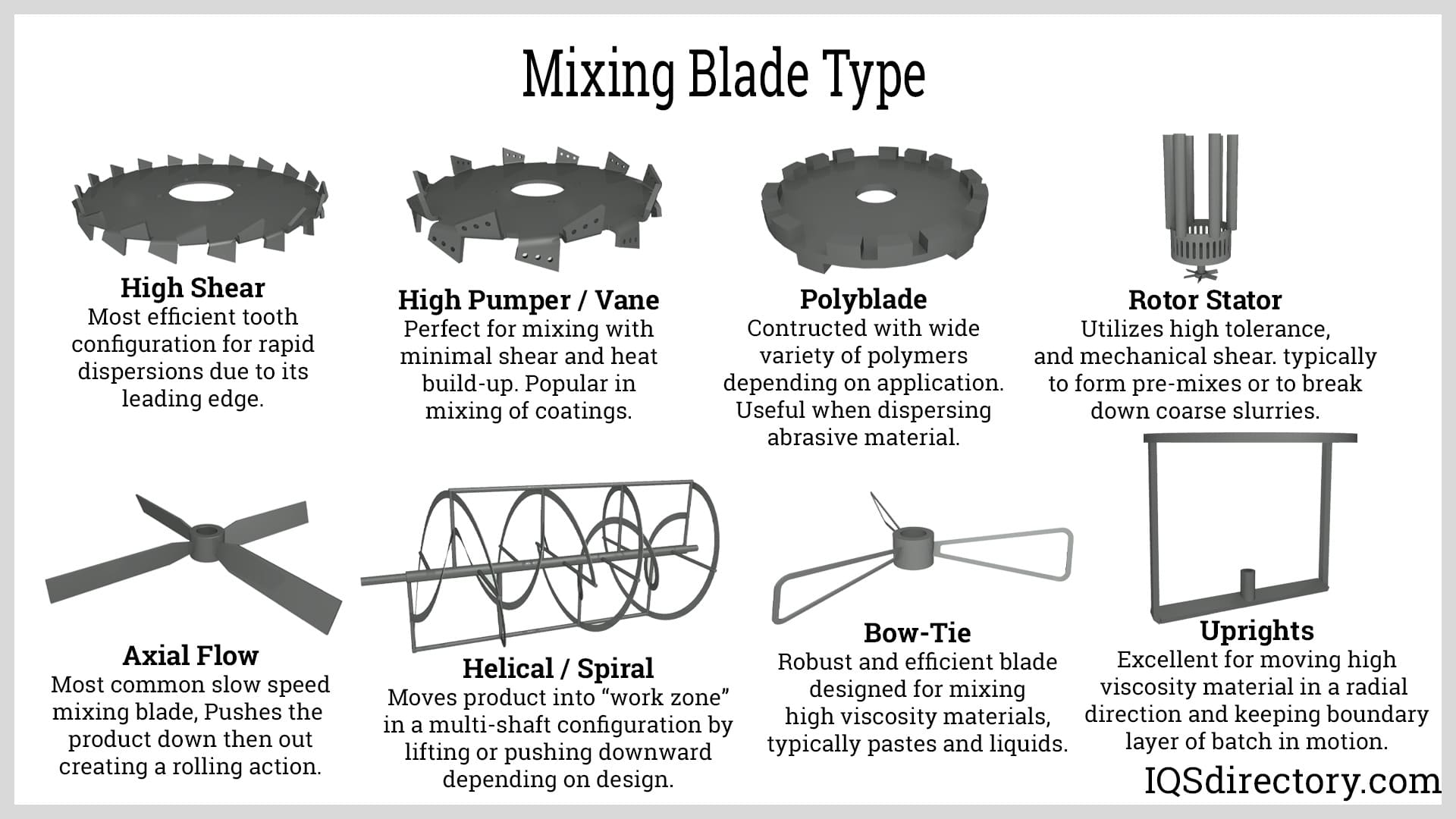

| High Shear Mixing | Utilizes high shear forces to break down and blend materials. | Chemical processing, food, and pharmaceuticals | Pros: Effective for tough mixtures. Cons: Higher operational costs and energy use. |

| Suspension Mixing | Maintains insoluble materials suspended in a liquid medium. | Paints, pharmaceuticals, nutraceuticals | Pros: Good for creating stable mixtures. Cons: Requires ongoing agitation to prevent settling. |

| Chemical Reaction Facilitation | Enhances mixing to support chemical reactions between components. | Specialty chemicals, pharmaceuticals | Pros: Optimizes reaction efficiency. Cons: Complex setup and monitoring needed. |

What are the Characteristics and Suitability of Blending Miscible Liquids?

Blending miscible liquids is a straightforward process that involves mixing two or more liquids that completely dissolve in one another. This method is commonly used in industries like food and beverage production, pharmaceuticals, and cosmetics. The key consideration for B2B buyers is the compatibility of the liquids being mixed; since this process does not require high energy input, it is cost-effective. However, the limitation lies in its applicability only to miscible substances, making it unsuitable for products requiring a combination of immiscible liquids.

How Does Emulsifying Immiscible Liquids Work in Industrial Applications?

Emulsifying immiscible liquids involves using emulsifiers to create stable mixtures of liquids that ordinarily do not mix, such as oil and water. This technique is vital in sectors like food production (e.g., mayonnaise), cosmetics (e.g., lotions), and pharmaceuticals (e.g., creams). For B2B buyers, the choice of emulsifier is crucial, as it directly affects the stability and quality of the final product. While this method is effective in creating uniform products, it requires precise formulation and control, which can increase costs.

What Benefits Do High Shear Mixing Techniques Offer?

High shear mixing employs powerful agitators to create intense shear forces that break down materials and blend them effectively. This technique is particularly advantageous in industries such as chemical processing, food production, and pharmaceuticals, where the materials may be viscous or require thorough dispersion. Buyers should consider the operational costs associated with high shear mixers, as they generally consume more energy and may involve higher maintenance. However, their ability to handle challenging formulations makes them invaluable in many applications.

Why is Suspension Mixing Important for Certain Industries?

Suspension mixing is essential for maintaining insoluble materials within a liquid medium, ensuring that products like paints, pharmaceuticals, and nutraceuticals remain homogeneous. This process requires continuous agitation to prevent settling, which can complicate production timelines. For B2B buyers, understanding the specific requirements for maintaining suspension stability is key. While this method is effective for certain applications, it necessitates ongoing monitoring and may incur additional costs for equipment and energy.

Illustrative image related to types of mixing

How Does Chemical Reaction Facilitation Enhance Mixing Processes?

Chemical reaction facilitation involves creating optimal mixing conditions to support chemical reactions, often requiring specific agitation levels and environmental controls (like temperature and pressure). This method is crucial for specialty chemicals and pharmaceuticals, where precise reactions are vital for product efficacy. B2B buyers should weigh the complexity of setup and monitoring against the efficiency gains in reaction performance. While this technique can enhance product quality and consistency, it demands a more intricate operational approach.

Key Industrial Applications of types of mixing

| Industry/Sector | Specific Application of types of mixing | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Pharmaceutical | Blending miscible liquids for injectables | Ensures precise dosing and product consistency | Regulatory compliance, precision mixing technology |

| Food and Beverage | Emulsifying ingredients for sauces and dressings | Enhances texture and shelf stability | Food safety standards, quality of emulsifiers |

| Cosmetics and Personal Care | Dispersing solids in lotions and creams | Improves product performance and consumer satisfaction | Ingredient compatibility, mixing speed and shear |

| Chemicals and Plastics | Chemical reaction facilitation in polymer production | Increases efficiency and product yield | Reactor design, mixing intensity and temperature control |

| Agriculture | Mixing fertilizers and pesticides for uniform application | Ensures effective crop treatment and maximizes yield | Environmental regulations, compatibility of ingredients |

How is Mixing Used in the Pharmaceutical Industry?

In the pharmaceutical sector, blending miscible liquids is essential for creating injectables and ophthalmic solutions. This process requires precise mixing to ensure uniformity and consistency, which are critical for patient safety and efficacy. Buyers in this industry must consider equipment that meets stringent regulatory standards and offers high precision to prevent dosing errors. Additionally, the capability for light to moderate agitation is necessary to maintain the integrity of sensitive compounds.

What Role Does Mixing Play in Food and Beverage Production?

Emulsification is a key process in the food and beverage industry, particularly for products like sauces and dressings. The ability to combine immiscible liquids enhances texture and extends shelf life, making emulsifiers crucial. For B2B buyers, sourcing high-quality emulsifiers and mixers that comply with food safety regulations is vital. Understanding the specific requirements for agitation and mixing speed can significantly impact the final product’s quality and consumer appeal.

How is Mixing Essential in Cosmetics and Personal Care?

In the cosmetics and personal care industry, the dispersion of solids into lotions and creams is critical for product effectiveness and consumer satisfaction. This mixing process ensures that active ingredients are evenly distributed, enhancing the product’s performance. Buyers should focus on sourcing mixers that can handle varying viscosities and maintain ingredient compatibility. Additionally, the speed and shear levels of the mixing process must be carefully managed to prevent degradation of sensitive components.

Why is Mixing Important in Chemical and Plastics Manufacturing?

Chemical reaction facilitation through effective mixing is vital in the production of polymers and other chemical products. Proper mixing ensures that reactants are evenly distributed, which can significantly increase efficiency and yield. For international buyers, considerations should include reactor design, mixing intensity, and the ability to control temperature and pressure, all of which are essential for optimizing production processes and achieving desired chemical properties.

Illustrative image related to types of mixing

How Does Mixing Benefit Agricultural Applications?

In agriculture, mixing fertilizers and pesticides is crucial for ensuring uniform application and maximizing crop yield. This process requires specialized mixers that can handle various formulations while adhering to environmental regulations. Buyers must consider the compatibility of ingredients and the efficiency of the mixing equipment to achieve optimal results. Effective mixing can lead to improved crop health and productivity, making it a key focus for agricultural businesses.

3 Common User Pain Points for ‘types of mixing’ & Their Solutions

Scenario 1: Inconsistent Product Quality in Pharmaceutical Manufacturing

The Problem: A pharmaceutical manufacturer faces frequent complaints about the quality of its products, stemming from inconsistent mixing processes. With varying particle sizes and densities in the formulation, improper mixing leads to uneven distribution of active ingredients, resulting in ineffective or even unsafe products. This not only jeopardizes patient safety but also puts the company at risk of regulatory scrutiny and damage to its reputation.

The Solution: To address this issue, the manufacturer should invest in high-shear mixers specifically designed for pharmaceutical applications. These mixers provide the necessary shear force to achieve uniform particle dispersion and effective emulsification of immiscible liquids. When selecting the mixer, it is crucial to consider factors such as the viscosity of the formulation, the desired mixing speed, and the batch size. Conducting a pilot test with the new equipment can help identify optimal parameters before full-scale implementation. Additionally, regular training for operators on best practices in mixing techniques will ensure consistent quality and adherence to industry standards.

Scenario 2: High Production Costs Due to Inefficient Mixing Processes

The Problem: A cosmetics company is struggling with high production costs attributed to lengthy mixing times and excessive energy consumption. The current mixing equipment is outdated and inefficient, leading to increased overheads and a longer time to market for new products. This inefficiency not only affects the company’s bottom line but also hinders its ability to respond swiftly to market trends.

Illustrative image related to types of mixing

The Solution: To improve efficiency and reduce costs, the company should evaluate its existing mixing processes and consider upgrading to a modern tank mixer or an inline mixer. These advanced mixers are designed to optimize flow dynamics and provide faster, more uniform mixing, which can significantly decrease production time. Conducting a thorough analysis of the mixing process can reveal bottlenecks, allowing the company to implement specific solutions such as variable speed drives or automated mixing controls. Investing in energy-efficient mixers may also reduce power consumption, further lowering production costs over time.

Scenario 3: Difficulty in Achieving Stable Emulsions for Food Products

The Problem: A food processing company is facing challenges in creating stable emulsions, leading to product separation and quality issues. This is particularly problematic for products like sauces and dressings, where consistent texture and appearance are crucial for consumer acceptance. The current emulsification process is inadequate, causing customer dissatisfaction and increased returns.

The Solution: To solve this problem, the company should invest in high-quality emulsifiers and high-shear mixing technology. High-shear mixers effectively break down the droplets of immiscible liquids, promoting better emulsification and stability. When selecting emulsifiers, it is important to choose those compatible with the specific ingredients used, as well as those that meet regulatory requirements. Additionally, implementing a standardized mixing protocol can help maintain consistency in the emulsification process. Regular quality control checks and adjustments to mixing parameters based on product feedback will ensure that the emulsions remain stable and meet consumer expectations.

Strategic Material Selection Guide for types of mixing

What Are the Key Properties of Common Materials Used in Mixing Applications?

In the realm of industrial mixing, the selection of materials significantly influences the performance and longevity of mixing equipment. Below are analyses of four common materials used in mixing applications, highlighting their properties, advantages, disadvantages, and considerations for international buyers.

1. Stainless Steel

Key Properties:

Stainless steel is renowned for its excellent corrosion resistance, high strength, and ability to withstand high temperatures and pressures. It typically has a temperature rating of up to 800°F (427°C) and can handle pressures exceeding 150 psi, making it suitable for a variety of mixing applications.

Pros & Cons:

The durability of stainless steel ensures a long service life, which is crucial for high-volume production environments. However, it can be more expensive than other materials, leading to higher initial costs. Manufacturing complexity can also increase due to the need for specialized welding techniques.

Impact on Application:

Stainless steel is compatible with a wide range of media, including corrosive chemicals, making it ideal for pharmaceutical and food processing applications. Its non-reactive nature ensures that it does not contaminate the product.

Considerations for International Buyers:

Buyers from regions like Europe (e.g., Germany) should ensure compliance with standards such as DIN EN 10088 for stainless steel grades. Understanding local regulations regarding food-grade materials is also essential.

Illustrative image related to types of mixing

2. Carbon Steel

Key Properties:

Carbon steel offers good strength and is typically rated for temperatures up to 400°F (204°C). While it is less resistant to corrosion than stainless steel, it can be treated with coatings to enhance its durability.

Pros & Cons:

Carbon steel is cost-effective and easier to fabricate, making it an attractive option for budget-conscious projects. However, its susceptibility to rust and corrosion limits its use in applications involving moisture or corrosive substances.

Impact on Application:

This material is often used in mixing applications involving non-corrosive materials, such as certain paints and adhesives. However, it may require additional maintenance to prevent rust.

Considerations for International Buyers:

Buyers in Africa and South America should consider the environmental conditions, such as humidity, which can accelerate corrosion. Compliance with local standards for industrial materials is also crucial.

3. Polypropylene

Key Properties:

Polypropylene is a lightweight, chemical-resistant thermoplastic with a temperature rating of up to 200°F (93°C). It is particularly effective in applications involving acidic or alkaline substances.

Pros & Cons:

The low cost and ease of manufacturing make polypropylene a popular choice for many industries. However, its lower temperature and pressure ratings compared to metals can limit its use in high-performance applications.

Illustrative image related to types of mixing

Impact on Application:

Polypropylene is suitable for mixing applications involving corrosive liquids, such as certain chemicals and cleaning agents. Its flexibility can also accommodate various shapes and designs in mixing equipment.

Considerations for International Buyers:

For buyers in the Middle East, understanding the specific chemical compatibility of polypropylene with local substances is vital. Compliance with ASTM standards for plastics is also a consideration.

4. Glass

Key Properties:

Glass is chemically inert, making it an excellent choice for applications requiring purity. It can withstand temperatures up to 300°F (149°C) but is more fragile than metals or plastics.

Illustrative image related to types of mixing

Pros & Cons:

The primary advantage of glass is its non-reactive nature, ensuring that it does not alter the properties of the mixed materials. However, its fragility can lead to higher breakage rates, requiring careful handling and maintenance.

Impact on Application:

Glass is often used in laboratory settings and small-scale production where purity is paramount. Its transparency allows for easy monitoring of the mixing process.

Considerations for International Buyers:

Buyers in Europe should ensure compliance with safety regulations regarding glass equipment. Understanding local shipping and handling regulations is also important to minimize breakage during transit.

Summary Table of Material Selection for Types of Mixing

| Material | Typical Use Case for types of mixing | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Pharmaceutical and food processing | Excellent corrosion resistance | Higher initial cost | High |

| Carbon Steel | Paints and adhesives | Cost-effective and easy to fabricate | Susceptible to rust | Medium |

| Polypropylene | Chemical mixing | Lightweight and chemical-resistant | Limited temperature and pressure ratings | Low |

| Glass | Laboratory and small-scale production | Non-reactive and allows for visibility | Fragile and higher breakage risk | Medium |

This strategic material selection guide provides valuable insights for B2B buyers in diverse regions, enabling them to make informed decisions based on their specific mixing needs and operational contexts.

In-depth Look: Manufacturing Processes and Quality Assurance for types of mixing

What Are the Main Stages in Manufacturing Mixing Equipment?

The manufacturing process for mixing equipment involves several critical stages, each designed to ensure the equipment meets specific industry standards and customer requirements. These stages typically include material preparation, forming, assembly, and finishing.

How is Material Prepared for Mixing Equipment Manufacturing?

Material preparation begins with sourcing high-quality raw materials, such as stainless steel or specialized plastics, depending on the type of mixer being produced. Suppliers should be vetted for quality and reliability, and materials often undergo initial inspections to check for defects. For example, stainless steel should meet relevant standards for corrosion resistance, especially for food and pharmaceutical applications.

Additionally, manufacturers may employ techniques like cutting and machining to prepare these materials for the next stage. Advanced technologies, such as laser cutting or CNC machining, are often used to ensure precision and minimize waste.

Illustrative image related to types of mixing

What Techniques Are Used in Forming Mixing Equipment?

The forming stage involves shaping the prepared materials into the required mixer components. This may include processes like stamping, casting, or injection molding, depending on the complexity and design of the mixer. High shear mixers, for example, require precise rotor and stator designs to achieve the desired shear rates.

In this phase, quality control is crucial. Manufacturers often utilize in-process inspections to ensure that dimensions and tolerances are met. Techniques like ultrasonic testing can be employed to detect internal flaws in components, ensuring long-term reliability.

How is Assembly Conducted in Mixing Equipment Manufacturing?

The assembly stage brings together all the components to create the final product. This process can be manual or automated, depending on the scale of production. For high-volume production, robotic assembly can enhance efficiency and consistency.

During assembly, manufacturers often conduct checks for alignment and functionality. For instance, ensuring that the impeller is correctly positioned within the mixer is vital for optimal performance.

What Finishing Techniques Are Applied to Mixing Equipment?

Finishing involves applying coatings, treatments, or surface modifications to enhance the durability and functionality of the mixers. Common techniques include polishing, anodizing, or applying protective coatings to prevent corrosion.

Illustrative image related to types of mixing

Final inspections, including visual checks and performance testing, are essential at this stage. Manufacturers may conduct operational tests under simulated conditions to validate the mixer’s performance before it is shipped to customers.

How is Quality Assurance Implemented in Mixing Equipment Manufacturing?

Quality assurance (QA) in mixing equipment manufacturing is vital to ensure that products meet international standards and customer expectations. Various quality control checkpoints are established throughout the manufacturing process.

What International Standards Should B2B Buyers Be Aware Of?

International standards, such as ISO 9001, provide a framework for quality management systems that manufacturers should adhere to. This standard emphasizes customer satisfaction, continuous improvement, and process efficiency.

In addition to ISO standards, industry-specific certifications can also play a significant role in quality assurance. For example, equipment used in pharmaceuticals may require compliance with the API (Active Pharmaceutical Ingredient) standards, while food-grade mixers must meet CE (Conformité Européenne) marking requirements for safety and performance.

What Are the Key Quality Control Checkpoints in Mixing Equipment Manufacturing?

Quality control checkpoints typically include:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): Ongoing inspections during manufacturing help catch defects early, reducing waste and rework.

-

Final Quality Control (FQC): After assembly, final inspections ensure the product meets all specifications and performance criteria before shipment.

Which Testing Methods Are Commonly Used for Mixing Equipment Quality Assurance?

Common testing methods for mixing equipment include:

-

Performance Testing: Simulating operational conditions to assess the mixer’s efficiency and effectiveness.

-

Durability Testing: Subjecting the mixer to stress tests to evaluate its resistance to wear and tear over time.

-

Material Testing: Analyzing material properties, such as tensile strength and corrosion resistance, to ensure compliance with industry standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, verifying a supplier’s quality control practices is essential to ensure product reliability. Here are several methods to achieve this:

What Steps Can Buyers Take to Conduct Supplier Audits?

Conducting supplier audits provides firsthand insight into the manufacturer’s quality processes. Buyers can develop a checklist based on industry standards and specific requirements to assess the supplier’s compliance. Key areas to evaluate include:

- Manufacturing processes and techniques

- Quality control procedures and documentation

- Employee training and qualifications

How Can Buyers Utilize Quality Control Reports and Certifications?

Buyers should request quality control reports and certifications from suppliers. These documents provide evidence of adherence to international standards and can reveal the results of recent inspections and tests.

Certification from recognized bodies can serve as a testament to the supplier’s commitment to quality. For example, a supplier with ISO 9001 certification demonstrates a structured approach to quality management.

What Role Do Third-Party Inspections Play in Quality Assurance?

Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s quality control practices. These services can provide detailed reports on the manufacturer’s capabilities and compliance with relevant standards.

Third-party inspections are particularly beneficial for international buyers, as they can bridge the gap between different regulatory environments and provide assurance that products meet local requirements.

What Unique Quality Control Considerations Exist for International B2B Buyers?

International B2B buyers, especially those from Africa, South America, the Middle East, and Europe, may face unique quality control challenges. Different regions may have varying standards and regulations, necessitating careful navigation of compliance requirements.

How Can Buyers Address Regulatory Nuances in Different Regions?

Buyers should familiarize themselves with the specific regulations governing their industry in each region. For instance, the European Union has stringent regulations for food and pharmaceutical products, while other regions may prioritize cost over compliance.

Engaging local consultants or legal experts can help navigate these complexities and ensure that all aspects of quality assurance are addressed.

Illustrative image related to types of mixing

By understanding the manufacturing processes and quality assurance practices for mixing equipment, B2B buyers can make informed decisions, ensuring they partner with reliable suppliers who prioritize quality and compliance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘types of mixing’

In the rapidly evolving landscape of industrial mixing, selecting the right type of mixing equipment is crucial for operational efficiency and product quality. This practical sourcing guide aims to help B2B buyers navigate the complexities of procuring mixing solutions that align with their unique needs.

Step 1: Define Your Technical Specifications

Start by clearly outlining the technical requirements for your mixing application. Consider factors such as the types of materials to be mixed (liquids, solids, or a combination), the desired consistency, and the scale of production.

– Material Compatibility: Ensure that the materials can coexist without adverse reactions.

– Mixing Objectives: Determine if your focus is on blending, emulsifying, or suspending materials, as each process has distinct requirements.

Step 2: Assess the Required Mixing Process

Identify which mixing process best suits your application from the various types available, such as blending miscible liquids, dissolving solids, or emulsifying immiscible liquids. Each process demands different techniques and equipment.

– Blend Types: For example, high-shear mixers are ideal for emulsifying, while agitators work well for homogeneous blending.

– Production Scale: Consider whether you need batch, semi-batch, or continuous mixing processes, as this will affect equipment choice.

Step 3: Evaluate Potential Suppliers

Before making a commitment, thoroughly vet potential suppliers to ensure they meet your operational needs. Request company profiles, case studies, and references from buyers in similar industries.

– Supplier Reputation: Look for suppliers with a proven track record in your specific market.

– Technical Support: Assess the level of post-purchase support and maintenance services offered.

Step 4: Verify Compliance and Certifications

Ensure that suppliers adhere to relevant industry standards and certifications, which can vary by region and application. Compliance with safety and quality regulations is critical for operational integrity.

– Certification Types: Check for ISO certifications, CE marking, or any local regulatory compliance that applies to your industry.

– Quality Assurance Processes: Inquire about the quality control measures employed during manufacturing.

Step 5: Request Demonstrations or Samples

Whenever possible, request demonstrations or samples of the mixing equipment. This hands-on approach allows you to assess the equipment’s performance and suitability for your specific application.

– Performance Metrics: Pay attention to factors like mixing speed, uniformity, and ease of use.

– Scalability: Ensure that the equipment can scale with your production needs.

Step 6: Compare Total Cost of Ownership

Evaluate the total cost of ownership (TCO), not just the initial purchase price. Consider factors like energy consumption, maintenance costs, and potential downtime.

– Energy Efficiency: Look for energy-efficient models that can reduce operational costs over time.

– Maintenance Requirements: Understand the maintenance schedule and costs associated with the equipment.

Step 7: Finalize Your Purchase Agreement

Once you’ve selected a supplier and equipment, ensure that all terms are clearly outlined in a purchase agreement. This should include delivery timelines, warranties, and after-sales support.

– Clear Terms: Be explicit about payment terms, shipping arrangements, and installation services.

– Warranties and Support: Confirm the warranty period and the scope of after-sales service.

By following this checklist, B2B buyers can make informed decisions when sourcing mixing equipment, ultimately leading to enhanced operational efficiency and product quality.

Comprehensive Cost and Pricing Analysis for types of mixing Sourcing

Understanding the cost structure and pricing dynamics of mixing equipment is essential for international B2B buyers, particularly in diverse markets like Africa, South America, the Middle East, and Europe. This analysis breaks down the various cost components, identifies key price influencers, and offers practical tips for buyers to optimize their sourcing strategy.

What Are the Key Cost Components in Mixing Equipment?

-

Materials: The type of materials used in manufacturing mixing equipment significantly impacts costs. High-quality stainless steel or specialized alloys for sanitary applications will incur higher material costs. In contrast, standard carbon steel may reduce initial expenses but could compromise longevity and performance.

-

Labor: Labor costs vary by region and the complexity of the manufacturing process. Skilled labor for precision engineering in Europe may command higher wages compared to emerging markets. Understanding the labor market dynamics in the supplier’s location can provide insights into overall pricing.

-

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and administrative expenses. Suppliers with advanced manufacturing technologies may have lower overhead costs, which can translate to more competitive pricing.

-

Tooling: Custom tooling for specific mixing applications can add significant upfront costs. Buyers should consider whether a standard mixer will suffice or if custom tooling is necessary, impacting the overall investment.

-

Quality Control (QC): Rigorous QC processes ensure product reliability and compliance with industry standards. While these processes may increase the price, they are crucial for maintaining quality, especially in regulated industries like pharmaceuticals and food production.

-

Logistics: Shipping costs can vary dramatically based on the supplier’s location and the buyer’s delivery requirements. International shipping, customs duties, and local transportation should all be factored into the total cost.

-

Margin: Supplier margins can vary significantly based on market competition, brand reputation, and the value-added services they provide, such as installation and after-sales support.

What Influences the Pricing of Mixing Equipment?

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically reduce per-unit costs, making it essential for buyers to negotiate volume discounts. Understanding MOQ can also help in assessing the feasibility of a purchase.

-

Specifications and Customization: Customization of mixing equipment to meet specific application needs can lead to increased costs. Buyers should balance the necessity of tailored solutions against budget constraints.

-

Materials and Quality Certifications: The choice of materials affects both durability and regulatory compliance. Certifications (e.g., ISO, FDA) may also impact price but are crucial for maintaining product integrity in sensitive industries.

-

Supplier Factors: The reputation, experience, and reliability of suppliers can influence pricing. Established suppliers may charge a premium for their track record, while newer entrants might offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms is vital for international transactions. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) can shift cost responsibilities, affecting the total landed cost.

How Can Buyers Negotiate for Better Prices?

-

Conduct Market Research: Understanding the market landscape and average pricing for specific types of mixers can empower buyers during negotiations.

-

Leverage Total Cost of Ownership (TCO): Focus on the long-term value rather than just the initial purchase price. An equipment that is slightly more expensive but offers lower maintenance costs and greater efficiency may represent a better overall investment.

-

Build Relationships with Suppliers: Establishing strong relationships can lead to better pricing and preferential treatment during negotiations. Regular communication fosters trust and may result in more favorable terms.

-

Explore Financing Options: Some suppliers offer financing arrangements that can ease the burden of upfront costs, making higher-quality equipment more accessible.

-

Consider Regional Differences: Understanding the economic conditions and currency fluctuations in the supplier’s country can provide leverage in negotiations.

Disclaimer on Indicative Prices

Prices for mixing equipment can vary widely based on the aforementioned factors. Buyers should obtain multiple quotes and conduct thorough due diligence to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing types of mixing With Other Solutions

Exploring Alternative Solutions to Types of Mixing

In the realm of industrial mixing, various methods and technologies exist to achieve similar objectives, such as blending, emulsifying, or dispersing materials. Each method has its unique advantages and limitations, making it essential for B2B buyers to consider alternatives that best suit their specific operational needs. This section compares traditional mixing techniques with other viable solutions, providing insights into their performance, costs, and best use cases.

| Comparison Aspect | Types Of Mixing | Alternative 1 Name: High Shear Mixers | Alternative 2 Name: Agitators |

|---|---|---|---|

| Performance | Versatile across multiple applications; effective for blending miscible and immiscible liquids. | Highly effective for emulsification and dispersion; provides consistent results in high-viscosity applications. | Good for basic mixing tasks; less effective for emulsification or high-shear applications. |

| Cost | Varies widely depending on equipment and scale; generally moderate to high. | Higher initial investment but offers rapid ROI due to efficiency in production. | Lower upfront costs; operational costs may increase with frequent maintenance. |

| Ease of Implementation | Requires careful setup and calibration; training may be necessary for operators. | Moderate complexity; some training required for optimal operation. | Generally easy to implement; minimal training for operators. |

| Maintenance | Regular maintenance needed; parts may require replacement based on usage. | Maintenance-intensive due to complex parts; needs specialized service. | Low maintenance; straightforward design reduces downtime. |

| Best Use Case | Ideal for diverse applications including food, pharmaceuticals, and chemicals. | Best for high-shear applications, such as cosmetics and food emulsions. | Suitable for simple mixing tasks in various industries, including water treatment and agriculture. |

What Are the Pros and Cons of High Shear Mixers?

High shear mixers are designed to achieve superior emulsification and dispersion, making them ideal for applications requiring a fine particle size and uniform consistency. Their performance in high-viscosity materials is unmatched, leading to efficient production cycles. However, the initial investment can be substantial, and these mixers often require specialized maintenance, which may not be feasible for all companies.

How Do Agitators Compare in Industrial Mixing Applications?

Agitators are commonly used in various industries for basic mixing needs. They work well for suspending solids or blending liquids but may not be as effective for applications that require high shear or emulsification. Their cost-effectiveness and ease of use make them appealing for businesses with simpler mixing requirements. However, their limitations in achieving a homogeneous mixture in complex applications could lead to inconsistent product quality.

Conclusion: How Can B2B Buyers Choose the Right Mixing Solution?

When selecting a mixing solution, B2B buyers should assess their specific production needs, including the types of materials being processed, desired outcomes, and budget constraints. While traditional types of mixing offer versatility, alternatives like high shear mixers and agitators can provide targeted benefits that enhance efficiency and product quality. A thorough understanding of each option’s strengths and weaknesses will empower buyers to make informed decisions that align with their operational goals and market demands.

Essential Technical Properties and Trade Terminology for types of mixing

What Are the Essential Technical Properties for Types of Mixing?

Understanding the technical properties of mixing equipment is crucial for B2B buyers, particularly when ensuring the right mixer for specific applications. Here are some key specifications that should be considered:

-

Material Grade

The material used in constructing mixing equipment can significantly affect durability and compatibility with various substances. Common materials include stainless steel for corrosion resistance and plastic for lightweight applications. Selecting the appropriate material grade ensures longevity and minimizes contamination risks in sensitive processes, such as pharmaceuticals or food production. -

Agitation Speed (RPM)

The revolutions per minute (RPM) indicates the mixing speed of the equipment. Different applications require varying agitation speeds; for example, emulsification often demands high RPMs to ensure proper dispersion of immiscible liquids. Understanding the required RPM is essential for achieving consistent product quality and optimizing process efficiency. -

Shear Rate

Shear rate is a measure of the intensity of mixing, reflecting how forces are applied to the material during mixing. High-shear mixers are essential for applications requiring fine emulsions or dispersions. Knowing the shear rate needed for specific products helps in selecting the right mixer type, ensuring effective blending and reducing processing times. -

Tank Capacity

The capacity of the mixing tank dictates the volume of material that can be processed in one batch. It is vital to match the tank size with production needs to prevent bottlenecks or excessive downtime. Understanding tank capacity assists buyers in scaling operations effectively and optimizing production workflows. -

Power Consumption

The power requirements of mixing equipment can influence operational costs. Energy-efficient mixers not only reduce electricity bills but also contribute to sustainability goals. Evaluating power consumption helps businesses to balance performance with cost-effectiveness, especially in large-scale operations. -

Temperature Control Range

Certain mixing processes require specific temperature ranges to ensure product integrity and quality. Equipment with built-in temperature control features allows for precise thermal management during mixing, which is critical in chemical reactions and sensitive formulations. Understanding temperature control capabilities can prevent product degradation and ensure compliance with industry standards.

What Are the Common Trade Terms in the Mixing Industry?

Familiarity with industry terminology is essential for effective communication and negotiation in B2B transactions. Here are several common terms that buyers should understand:

-

OEM (Original Equipment Manufacturer)

An OEM produces parts and equipment that may be marketed by another manufacturer. For mixing equipment, working with an OEM can ensure that buyers receive high-quality, compatible parts that meet specific operational requirements. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units that a supplier is willing to sell. This is crucial for buyers to understand when planning their inventory and budget. Knowing the MOQ helps in negotiating bulk purchases and managing supply chain efficiency. -

RFQ (Request for Quotation)

An RFQ is a document issued by buyers to solicit price quotes from suppliers. It outlines the specifications and quantities of the required products. Submitting an RFQ is a standard practice in B2B transactions that enables buyers to compare prices and terms from different suppliers. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce, which define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for managing shipping logistics and costs, particularly for international buyers. -

Lead Time

Lead time refers to the time taken from placing an order to the delivery of goods. For mixing equipment, understanding lead times can help businesses plan their production schedules effectively, ensuring that they meet customer demands without delays. -

Batch vs. Continuous Mixing

This terminology distinguishes between two types of mixing processes. Batch mixing refers to mixing a set quantity of materials at once, while continuous mixing involves a constant flow of materials. Recognizing the differences helps buyers choose the appropriate mixing solution based on their production requirements.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance operational efficiency and product quality in their mixing processes.

Navigating Market Dynamics and Sourcing Trends in the types of mixing Sector

What Are the Current Market Dynamics and Key Trends Affecting the Types of Mixing Sector?

The global mixing equipment market is experiencing significant growth, driven by industrial expansion, technological advancements, and the increasing demand for efficient production processes. Key sectors such as food and beverage, pharmaceuticals, and chemicals are at the forefront of this growth, with a notable rise in demand for high-shear mixers and emulsifiers. Notably, international B2B buyers from regions like Africa, South America, the Middle East, and Europe are increasingly focusing on sourcing advanced mixing technologies that enhance product quality and consistency.

Emerging trends include the integration of Industry 4.0 principles, where automation and data analytics are reshaping how mixing processes are monitored and optimized. For example, the adoption of smart sensors in mixing equipment allows real-time data collection, enabling manufacturers to fine-tune their processes and reduce waste. Additionally, the shift toward sustainable manufacturing practices is prompting buyers to seek mixing solutions that minimize energy consumption and raw material usage.

The competitive landscape is further influenced by globalization, with suppliers from different regions vying for market share. B2B buyers are advised to consider not only the cost but also the technological capabilities and after-sales support offered by suppliers. Establishing partnerships with manufacturers who can provide tailored solutions and demonstrate a commitment to innovation will be crucial in navigating these market dynamics effectively.

Illustrative image related to types of mixing

How Is Sustainability and Ethical Sourcing Shaping the Mixing Equipment Industry?

Sustainability has become a paramount concern for B2B buyers in the types of mixing sector. As industries face increased scrutiny over their environmental impact, there is a growing emphasis on sourcing equipment that adheres to eco-friendly practices. This includes the use of materials that are recyclable or biodegradable and technologies that reduce energy consumption during production.

Ethical sourcing is equally important, as consumers and regulatory bodies demand transparency in supply chains. Buyers are increasingly looking for suppliers that can provide certifications indicating their commitment to sustainability, such as ISO 14001 or Green Seal certifications. These certifications not only enhance a company’s reputation but also align with the values of environmentally-conscious consumers.

Moreover, the trend towards the use of ‘green’ materials in mixing processes is on the rise. For instance, bio-based emulsifiers and solvents are gaining traction in the food and personal care industries, offering a more sustainable alternative to traditional chemical agents. By prioritizing suppliers who embrace these practices, international buyers can ensure that their sourcing strategies are aligned with global sustainability goals while also meeting regulatory compliance.

What Is the Historical Evolution of Mixing Technologies?

The evolution of mixing technologies has transformed significantly over the past century, driven by industrial demands and innovations. Initially, mixing was a rudimentary process involving manual labor and simple tools. However, the advent of mechanization in the late 19th and early 20th centuries marked a turning point, with the introduction of basic agitators and mixers designed to enhance efficiency.

As industries progressed, particularly in food processing and pharmaceuticals, the need for precision and consistency led to the development of specialized mixing equipment. The introduction of high-shear mixers and emulsifiers in the mid-20th century enabled manufacturers to create complex formulations with improved texture and stability. Today, the focus is on smart technology and automation, reflecting a continuous journey towards enhancing operational efficiency and product quality in the mixing sector. This historical context is essential for B2B buyers to understand the capabilities and advancements in mixing technologies available today.

Illustrative image related to types of mixing

Frequently Asked Questions (FAQs) for B2B Buyers of types of mixing

-

How do I choose the right mixing technology for my application?

Selecting the appropriate mixing technology depends on several factors, including the physical and chemical properties of the materials, the desired end product, and production scale. For example, high shear mixers are ideal for emulsifying and homogenizing immiscible liquids, while agitators are better suited for blending miscible liquids. Consider conducting a pilot test with different mixing processes to evaluate performance before making a significant investment. Consulting with manufacturers and technical experts can also provide insights tailored to your specific application. -

What is the best mixer type for producing emulsions?

High shear mixers are typically the best choice for producing emulsions, as they effectively disperse immiscible liquids and create stable mixtures. These mixers utilize high-speed rotors to generate intense shear forces, breaking down droplets to achieve a uniform consistency. In applications like food processing or cosmetics, where product stability is crucial, selecting a high shear mixer can ensure quality outcomes. Be sure to assess the mixer’s capacity, energy consumption, and maintenance requirements to align with your operational goals. -

What should I consider when vetting suppliers for mixing equipment?

When vetting suppliers for mixing equipment, prioritize their industry experience, reputation, and compliance with international quality standards. Evaluate their product range and whether they offer customization options to meet your specific needs. Request references or case studies from previous clients, and inquire about their after-sales support, warranty terms, and spare parts availability. It’s also beneficial to assess their logistics capabilities, especially if you’re sourcing from different continents, to ensure timely delivery and installation. -

What are typical minimum order quantities (MOQs) for industrial mixers?

Minimum order quantities (MOQs) for industrial mixers can vary significantly based on the supplier and the type of equipment. Generally, MOQs may range from one unit for specialized or custom machines to several units for standardized models. Suppliers often set MOQs to cover production costs and ensure profitability. When negotiating, discuss your specific needs and explore options for reduced MOQs, especially if you are a new buyer or require unique configurations. -

How can I ensure quality assurance (QA) for my mixing equipment?

To ensure quality assurance for mixing equipment, request certifications such as ISO 9001, which indicates adherence to international quality management standards. Conduct thorough inspections upon delivery, including functionality tests and verification of compliance with your specifications. Establish a preventive maintenance schedule and develop a partnership with the supplier for ongoing support. Regularly train your staff on best practices for equipment operation and maintenance to uphold quality standards in production. -

What payment terms are commonly offered by suppliers in the mixing industry?

Payment terms can vary widely among suppliers in the mixing industry, but common arrangements include upfront deposits (typically 30-50%) with the balance due upon delivery or installation. Some suppliers may offer financing options or extended payment plans for larger purchases. When negotiating payment terms, consider factors like your cash flow, the supplier’s reputation, and the overall project timeline. It’s essential to have a clear agreement documented in the purchase contract to avoid misunderstandings. -

What logistics challenges should I anticipate when importing mixing equipment?

Importing mixing equipment can present several logistics challenges, such as customs clearance, shipping delays, and compliance with local regulations. It’s crucial to understand the import duties and taxes applicable in your country, as these can significantly impact total costs. Partnering with a reliable freight forwarder can help streamline the process, ensuring proper documentation and adherence to shipping timelines. Additionally, consider the equipment’s size and weight, as these factors can influence shipping costs and transport methods. -

How can I customize mixing equipment to suit my specific processes?

Customization of mixing equipment often involves modifications to size, mixing speed, and the type of agitator or impeller used. When discussing customization with suppliers, clearly outline your process requirements, including material properties, batch sizes, and end-product specifications. Many manufacturers offer tailored solutions, including specialized coatings or materials for corrosive substances. Engaging in collaborative design sessions can also lead to innovative solutions that enhance efficiency and product quality in your operations.

Top 7 Types Of Mixing Manufacturers & Suppliers List

1. IQS Directory – Types of Mixers

Domain: iqsdirectory.com

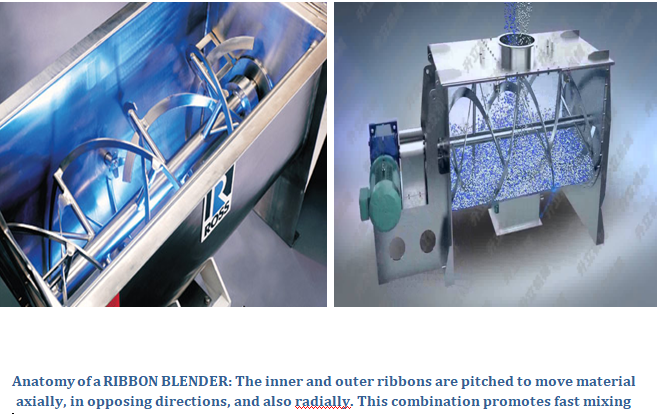

Registered: 2004 (21 years)

Introduction: Types of Mixers: Paddle Mixer (for viscous semi-solid substances), Horizontal Ribbon Mixer (for food, chemicals, powders), Tumbler Mixer (for bakery ingredients), Drum Mixer (for low and medium viscosity materials like slurry or cement), Emulsifier (for immiscible liquids like oils), Static Mixer (for gasses and liquids). Capacity: Drum mixers typically have a capacity of 50 to 100 gallons (190 to…

2. KitchenAid – Baking Techniques

Domain: kitchenaid.com

Registered: 1998 (27 years)

Introduction: Baking Techniques: Mix, Fold, Whisk & Cream. Mixing is a common baking technique that involves combining ingredients to create a unified product. It helps hydrate flour, distribute ingredients evenly, and incorporate air for optimal volume and texture in baked goods. Tools for mixing include wooden spoons, spatulas, electric handheld or stand mixers. KitchenAid hand mixers are available in 5-, 7-,…

3. PowderProcess – Mixing Mechanisms Explained

Domain: powderprocess.net

Registered: 2016 (9 years)

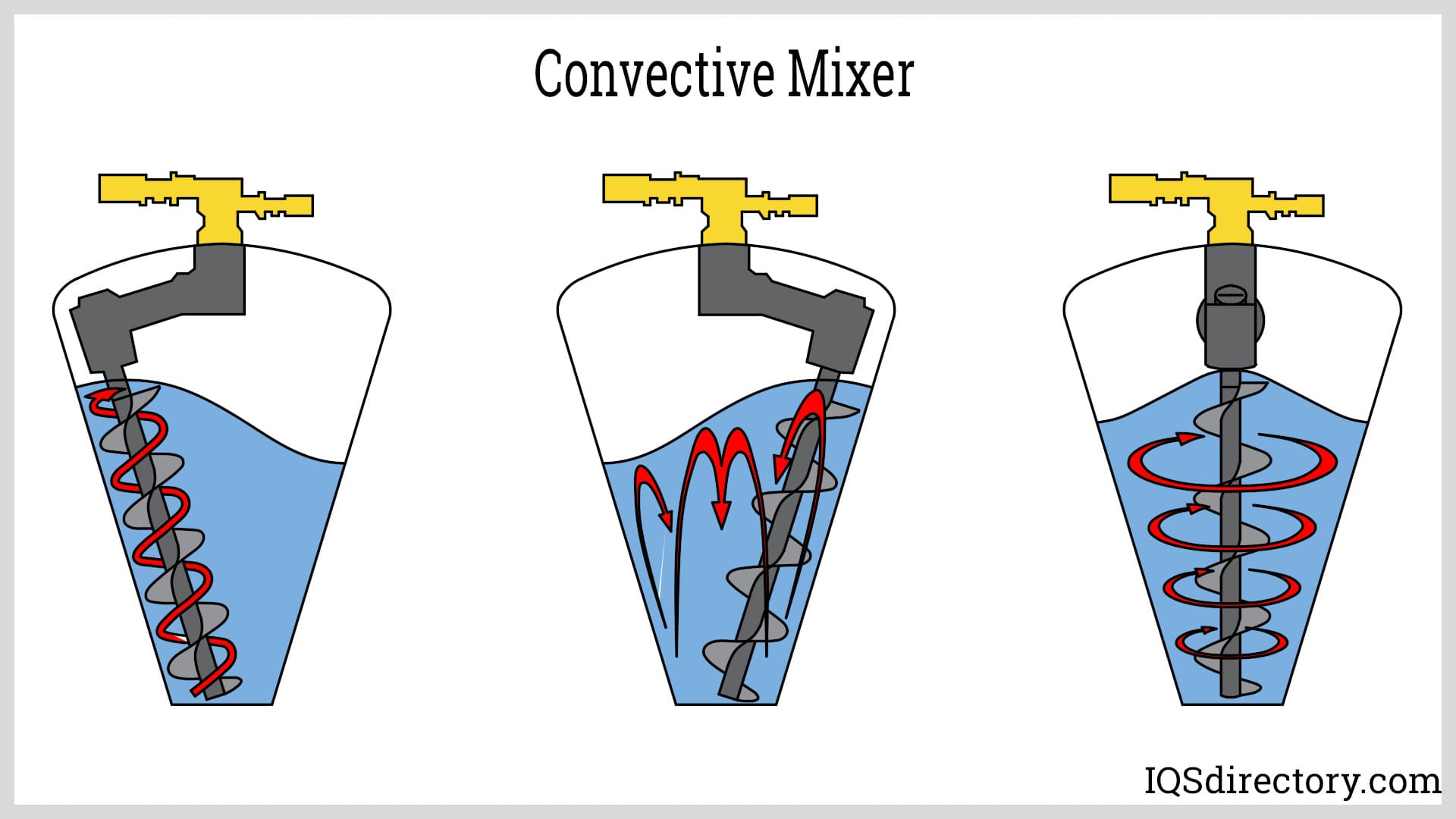

Introduction: The text discusses three main types of mixing mechanisms for bulk solids: diffusive mixing, convective mixing, and shear mixing.

1. **Diffusive Mixing**: Involves random movement of particles, typically in tumbler mixers, drum blenders, and IBC blenders. It is characterized by long mixing times and sensitivity to segregation.

2. **Convective Mixing**: Utilizes a mixing tool (agitator) to force…

4. Stuart Equipment – Bulk Mixers

Domain: azom.com

Registered: 1999 (26 years)

Introduction: Bulk mixers come in varying sizes, from small scale magnetic stirrer hot plates to pilot scale food mixers and industrial scale chemical mixers. Common types include Stirrer hotplates, magnetic stirrer plates, and vortex mixers. Manufacturers mentioned include Stuart Equipment, Thermo Fischer Scientific, Camlab, Corning, IKA, Kevin Process Technologies, Silverson, Ross, Morton Mixers, and Hosokawa…

5. Zero Instrument – Paddle and Anchor Mixers

Domain: zeroinstrument.com

Registered: 2017 (8 years)

Introduction: 1. Paddle (Flat-Blade) Mixers: Simple design with flat blades for gentle agitation of low-viscosity liquids; used in blending fluids and heat transfer in chemicals and food processing. 2. Anchor Mixers: Designed for high-viscosity materials with wall-hugging blades and scrapers; used in adhesives, polymers, and coatings. 3. Ribbon (Helical) Mixers: Dual-layer helical design for blending high-visco…

6. Slideshare – Mixing Techniques in Pharmacy

Domain: slideshare.net

Registered: 2006 (19 years)

Introduction: The document outlines various mixing techniques and equipment used in pharmacy, emphasizing the importance of proper mixing in producing homogeneous products. It discusses factors affecting mixing and mixing mechanisms for solids, liquids, and semi-solids. Key types of mixing equipment mentioned include double cone blenders, v cone blenders, ribbon blenders, and sigma blade mixers. The document al…

7. Pharma Guideline – Mixing Mechanisms

Domain: pharmaguideline.com

Registered: 2011 (14 years)

Introduction: Mechanism of Solid Mixing, Liquids Mixing and Semisolids Mixing. A mixer is classified based on dosage form. For solids, mixing is affected by particle shape, stickiness, material density, wettability, and particle size. Common mixers include tumble action and fixed shell mixers. Liquid mixing includes turbulent mixing, laminar mixing, and molecular diffusion. Semisolid mixing involves sigma blade…

Strategic Sourcing Conclusion and Outlook for types of mixing

Why is Strategic Sourcing Essential for Mixing Technologies?

In today’s competitive landscape, understanding the various types of mixing processes is crucial for international B2B buyers seeking to optimize production efficiency and product quality. From blending miscible liquids to emulsifying immiscible ones, each mixing method presents unique advantages tailored to specific applications. Strategic sourcing allows businesses to identify the right equipment, ensuring that they meet both operational needs and regulatory requirements effectively.

How Can Buyers Leverage Mixing Equipment for Competitive Advantage?

Investing in advanced mixing technologies not only enhances product consistency but also reduces operational costs in the long run. As markets in Africa, South America, the Middle East, and Europe continue to evolve, buyers must prioritize suppliers that offer innovative solutions and reliable support. By forging partnerships with industry leaders, companies can access the latest equipment and techniques that drive efficiency and sustainability.

What’s Next for Global Buyers in the Mixing Industry?

As you navigate your sourcing strategies, consider the growing demand for sustainable practices and innovative mixing solutions. Engage with suppliers who are committed to research and development, ensuring your operations remain agile and competitive. Now is the time to take action—explore the diverse mixing technologies available and secure your position in the market by making informed, strategic sourcing decisions.

Illustrative image related to types of mixing

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.