Types Of Gate Locks: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for types of gate locks

In today’s global market, sourcing the right types of gate locks is critical for businesses aiming to enhance security and streamline access control. As international B2B buyers face the dual challenge of safeguarding assets while navigating diverse regulatory landscapes, understanding the vast array of available gate lock options becomes essential. This guide delves into various types of gate locks, their specific applications, and the nuances of choosing the right solution for different environments—from commercial properties in bustling urban centers to residential gates in rural locales.

Buyers will find a comprehensive overview of the various lock mechanisms, including traditional latches, electronic locks, and innovative self-closing models. We also explore critical factors such as supplier vetting, cost considerations, and compliance with international security standards. By equipping businesses with the necessary knowledge to make informed decisions, this guide empowers buyers from regions like Africa, South America, the Middle East, and Europe—including key markets like Vietnam and Germany—to select high-quality gate locks that meet their unique security needs.

Navigating the complexities of the gate lock market can be daunting, but with the right insights, businesses can confidently enhance their perimeter security while ensuring a smooth purchasing process.

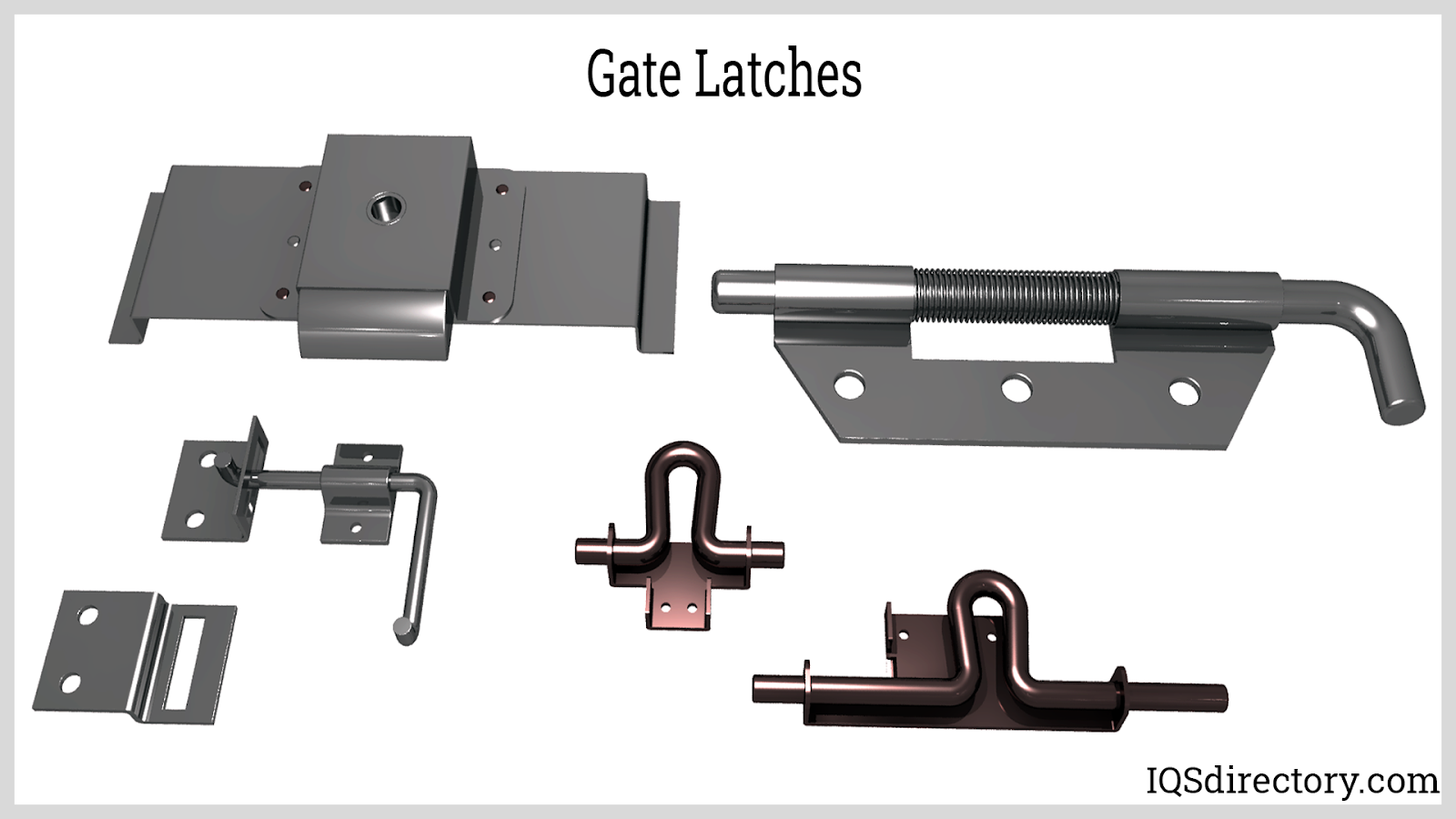

Understanding types of gate locks Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Mortise Gate Locks | Installed within the gate frame, offers higher security. | High-security commercial properties, gates. | Pros: Robust security; Cons: Higher installation complexity. |

| Padlocks | Portable and versatile, available in various sizes. | Temporary or mobile gates, storage units. | Pros: Easy to use; Cons: Less secure than fixed locks. |

| Electric Gate Locks | Operated electronically, often with remote access features. | Commercial access control systems, residential. | Pros: Enhanced security; Cons: Requires power source. |

| Chain Link Locks | Specifically designed for chain link gates, often simple latch. | Fencing for parks, schools, and industrial sites. | Pros: Cost-effective; Cons: Limited security features. |

| Slide Bolt Locks | Simple locking mechanism that slides into a catch. | Residential gates, garden entrances. | Pros: Easy installation; Cons: Vulnerable to tampering. |

What are Mortise Gate Locks and Their Applications?

Mortise gate locks are embedded within the gate frame, providing a high level of security that is ideal for commercial applications. They are typically used in environments where unauthorized access must be strictly controlled, such as office complexes, warehouses, and high-value storage areas. When considering a mortise lock, B2B buyers should assess the security needs, installation requirements, and compatibility with existing gate structures. While installation may require professional assistance, the long-term benefits of enhanced security make it a worthwhile investment.

Illustrative image related to types of gate locks

How Do Padlocks Serve B2B Needs?

Padlocks offer a portable and versatile solution suitable for various applications, including temporary gates and storage units. Their ease of use and availability in multiple sizes make them a popular choice for businesses needing flexible security options. However, buyers should consider the level of security required, as padlocks may not provide the same deterrent effect as more permanent locking systems. For companies looking for a quick and cost-effective security solution, padlocks can be an excellent choice, albeit with some limitations.

What Advantages Do Electric Gate Locks Offer?

Electric gate locks operate electronically and can integrate with access control systems, allowing for remote access and monitoring. They are particularly beneficial for commercial properties that require secure entry points while facilitating easy access for authorized personnel. B2B buyers should evaluate the power requirements and installation complexity of electric locks, as these systems can be more expensive upfront. However, their advanced security features and convenience often justify the investment, especially in high-traffic areas.

Why Choose Chain Link Locks for Your Business?

Chain link locks are specifically designed for use with chain link gates, making them a practical choice for fencing in parks, schools, and industrial sites. They are typically simple latch mechanisms that provide basic security at a low cost. While chain link locks are cost-effective, buyers should be aware that they may lack advanced security features and can be more easily compromised. For businesses on a budget or those requiring temporary solutions, chain link locks can serve as a viable option.

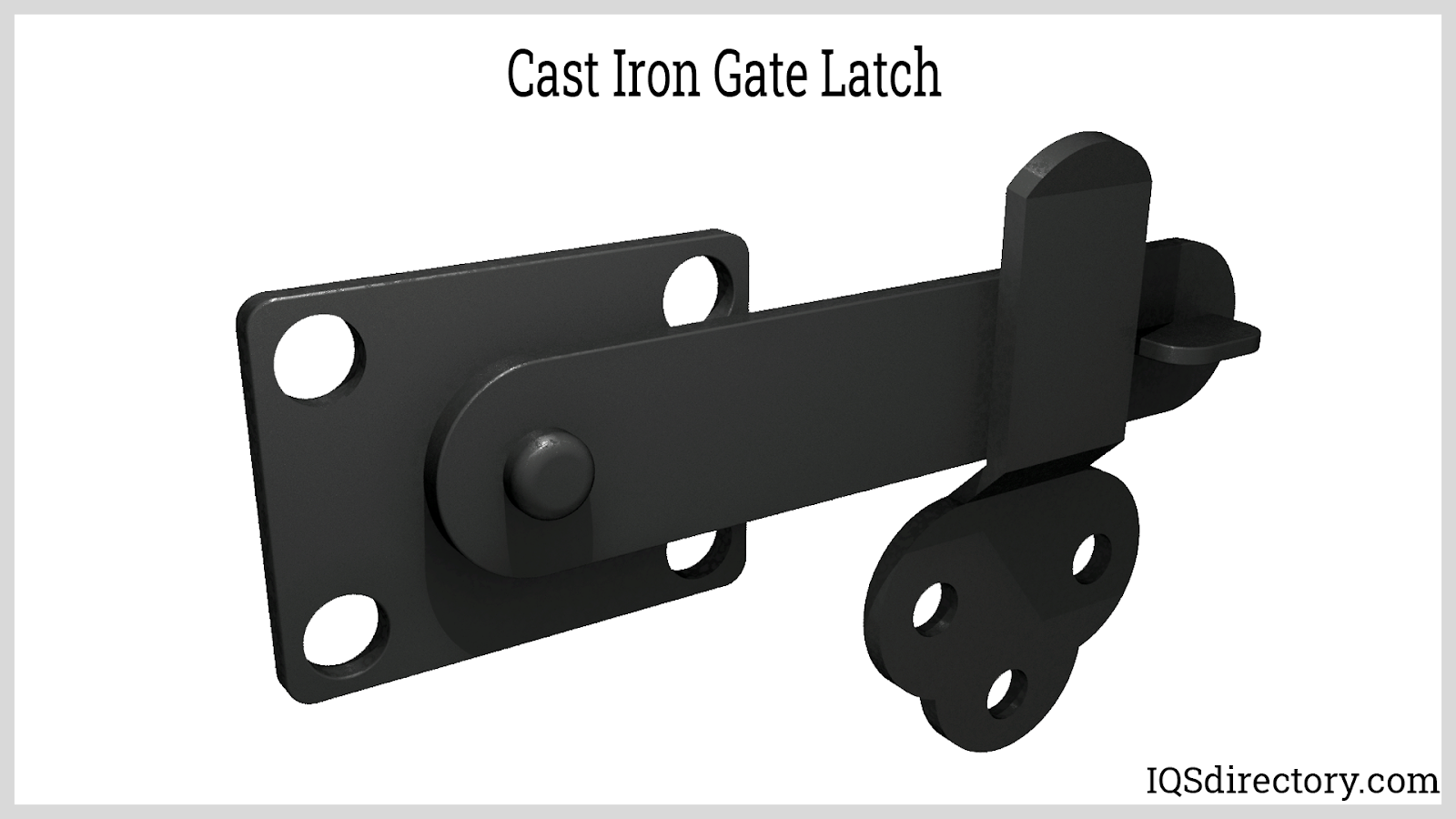

What are the Benefits and Drawbacks of Slide Bolt Locks?

Slide bolt locks are a straightforward locking mechanism that slides into a catch, making them easy to install and use for residential gates and garden entrances. They are often favored for their simplicity and low cost. However, B2B buyers should consider the potential vulnerabilities, as slide bolts can be susceptible to tampering or forced entry. For businesses looking for a quick and affordable locking solution, slide bolt locks can be effective, but additional security measures may be necessary to enhance protection.

Key Industrial Applications of types of gate locks

| Industry/Sector | Specific Application of types of gate locks | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Secure site access control for construction sites | Prevents unauthorized access, reducing theft and vandalism | Durability, weather resistance, and compliance with local regulations |

| Agriculture | Locking gates for livestock and crop protection | Protects valuable assets and ensures safety of animals | Types of locks compatible with gate materials and ease of operation |

| Commercial Real Estate | Access control for gated communities and office parks | Enhances security and privacy for residents and businesses | Aesthetic design, electronic access options, and maintenance requirements |

| Logistics & Warehousing | Security for loading docks and storage areas | Protects inventory and sensitive materials from theft | Heavy-duty options, lock integration with existing security systems |

| Public Sector | Securing parks and recreational facilities | Ensures public safety and deters vandalism | Compliance with safety standards and ease of installation |

How Are Types of Gate Locks Applied in the Construction Industry?

In the construction sector, gate locks are vital for controlling access to job sites. By securing entry points, businesses can significantly reduce the risk of theft and vandalism, which are common challenges in this industry. Buyers in this field should prioritize locks that are durable and weather-resistant to withstand harsh conditions. Additionally, compliance with local regulations regarding site security is essential, making it crucial for international buyers to understand regional standards.

What Is the Role of Gate Locks in Agriculture?

Gate locks are extensively used in agriculture to secure gates that protect livestock and crops. These locks prevent unauthorized access, safeguarding valuable assets and ensuring the safety of animals. Buyers should focus on lock types that are easy to operate and compatible with various gate materials, as this can enhance usability. Additionally, considerations for weather resistance and durability are critical, especially in regions prone to harsh environmental conditions.

How Do Gate Locks Enhance Security in Commercial Real Estate?

In commercial real estate, types of gate locks are integral for access control in gated communities and office parks. They enhance security and privacy, providing peace of mind to residents and businesses alike. When sourcing these locks, buyers should consider aesthetic designs that complement the property while also evaluating electronic access options for convenience. Maintenance requirements and the ability to integrate with existing security systems are also important factors for buyers to consider.

Why Are Heavy-Duty Gate Locks Essential in Logistics and Warehousing?

In logistics and warehousing, securing loading docks and storage areas with gate locks is crucial for protecting inventory and sensitive materials from theft. Heavy-duty locks are often necessary due to the high-value items stored in these facilities. Buyers should seek locks that can integrate seamlessly with existing security systems to enhance overall safety. Additionally, the ability to withstand heavy use and environmental factors should be a top priority when sourcing these products.

How Are Gate Locks Used in the Public Sector?

In the public sector, gate locks are essential for securing parks and recreational facilities, ensuring public safety and deterring vandalism. Sourcing considerations should include compliance with safety standards, as well as the ease of installation to facilitate quick deployment. Buyers must also consider the lock’s ability to withstand frequent use and potential tampering, ensuring long-term reliability in securing public spaces.

3 Common User Pain Points for ‘types of gate locks’ & Their Solutions

Scenario 1: Inadequate Security for High-Value Assets

The Problem: B2B buyers often face the challenge of securing high-value assets, particularly in industries such as construction, manufacturing, or retail. Many traditional gate locks may not provide adequate protection against sophisticated theft techniques, leading to potential losses. Buyers may struggle to find locks that not only deter unauthorized access but also withstand tampering and harsh environmental conditions, especially in regions with varying climates like Africa or South America.

Illustrative image related to types of gate locks

The Solution: To address this issue, buyers should invest in high-security gate locks that meet industry standards for durability and resistance to tampering. Look for locks that feature hardened steel construction, anti-drill plates, and pick-resistant designs. Additionally, consider incorporating electronic access control systems that provide real-time monitoring and logging of access events. When sourcing these locks, it’s crucial to partner with reputable suppliers who specialize in high-security hardware and can offer installation guidance tailored to your specific security needs. Regular maintenance and inspection of the locking mechanisms can further ensure their longevity and effectiveness.

Scenario 2: Compliance with Local Safety Regulations

The Problem: Many businesses are required to comply with local safety regulations that dictate specific locking mechanisms for gates, particularly in settings like schools, hospitals, or public facilities. Failing to adhere to these regulations can result in legal penalties and increased liability. B2B buyers may find it challenging to navigate the diverse safety standards across different regions, leading to confusion about which types of gate locks to install.

The Solution: To ensure compliance, B2B buyers should conduct thorough research on local regulations regarding gate locks. Engaging with local regulatory bodies or industry associations can provide clarity on the required standards. Additionally, consider locks that are specifically designed for compliance, such as self-closing mechanisms for pool gates or locks that meet child safety standards. It’s advisable to work with suppliers who are knowledgeable about these regulations and can provide documentation confirming that their products meet local safety requirements. Regular training for staff on compliance issues and periodic audits can also help maintain adherence to safety standards.

Illustrative image related to types of gate locks

Scenario 3: Difficulty in Selecting the Right Lock for Various Gate Materials

The Problem: B2B buyers often manage multiple gate installations across different materials—wood, metal, vinyl, or chain link. Each material may require a specific type of lock for optimal performance and security. This can lead to confusion when trying to source compatible locks, potentially resulting in improper installations that compromise security and durability.

The Solution: To overcome this challenge, buyers should develop a comprehensive understanding of the various gate materials and their corresponding locking needs. Create a specification guide that outlines which types of locks are best suited for each material type. For example, wood gates may require latch locks that accommodate the natural expansion and contraction of wood, while chain link gates often benefit from padlocks or sliding gate locks. Working closely with manufacturers who offer a wide range of locks designed for specific materials can streamline the selection process. Additionally, consider investing in modular locking systems that can adapt to various gate types, ensuring flexibility and ease of installation across your properties. Regular training sessions for the installation team on best practices for different materials can also enhance overall security and operational efficiency.

Strategic Material Selection Guide for types of gate locks

What Are the Key Properties of Common Materials Used in Gate Locks?

When selecting gate locks for various applications, the choice of material plays a crucial role in determining performance, durability, and suitability for specific environments. Here, we analyze four common materials used in gate locks: stainless steel, brass, aluminum, and plastic.

How Does Stainless Steel Perform in Gate Locks?

Stainless steel is renowned for its excellent corrosion resistance, strength, and durability, making it a preferred choice for gate locks in harsh environments. It can withstand high temperatures and pressures, which is particularly beneficial for locks exposed to extreme weather conditions. The primary advantage of stainless steel is its longevity and resistance to rust, which minimizes maintenance costs over time.

However, stainless steel can be more expensive than other materials, which may be a consideration for budget-conscious buyers. Manufacturing complexity can also be higher due to the need for specialized equipment to work with this tough material. For international B2B buyers, compliance with standards such as ASTM A240 for stainless steel can ensure quality and performance.

Illustrative image related to types of gate locks

What Are the Advantages of Brass in Gate Locks?

Brass is another popular material for gate locks, known for its aesthetic appeal and moderate corrosion resistance. It offers good durability and is less prone to wear compared to softer metals. Brass locks are often used in residential applications where appearance matters, as they can be polished to a bright finish.

On the downside, brass may not perform well in highly corrosive environments, such as coastal areas, where saltwater can lead to rapid deterioration. Additionally, while brass is generally more affordable than stainless steel, its cost can vary based on alloy composition. International buyers should consider compliance with standards like ASTM B453 for brass products to ensure they meet quality expectations.

How Does Aluminum Compare in Gate Lock Applications?

Aluminum is lightweight and resistant to corrosion, making it an excellent choice for gate locks that require easy handling and installation. Its natural resistance to oxidation allows it to perform well in various climates, particularly in humid or coastal environments. Aluminum is also cost-effective, which can be a significant advantage for bulk purchases.

However, aluminum is less durable than stainless steel or brass, making it more suitable for low-security applications. It can also be more susceptible to dents and scratches. Buyers in regions with specific security requirements should evaluate whether aluminum meets their needs and consider local standards for gate hardware.

Is Plastic a Viable Option for Gate Locks?

Plastic, particularly high-density polyethylene (HDPE) or polycarbonate, is increasingly used in gate locks due to its lightweight and non-corrosive properties. Plastic locks are often employed in residential settings, pool areas, or temporary installations where security requirements are lower. They are also cost-effective and easy to manufacture.

The main limitation of plastic is its reduced strength compared to metal options, which may not deter determined intruders. Additionally, plastic may not perform well under extreme temperatures, leading to potential brittleness in cold weather. Buyers should consider local climate conditions and security needs when opting for plastic locks.

Summary of Material Selection for Gate Locks

| Material | Typical Use Case for types of gate locks | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Commercial and residential gates | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Brass | Residential gates | Aesthetic appeal and moderate durability | Poor performance in corrosive environments | Medium |

| Aluminum | Lightweight gates, low-security areas | Lightweight and cost-effective | Less durable and susceptible to dents | Low |

| Plastic | Pool gates, temporary installations | Lightweight and non-corrosive | Reduced strength and temperature sensitivity | Low |

This guide provides a comprehensive overview of material options for gate locks, helping international B2B buyers make informed decisions based on their specific needs and regional requirements.

Illustrative image related to types of gate locks

In-depth Look: Manufacturing Processes and Quality Assurance for types of gate locks

What Are the Main Stages in the Manufacturing Process of Gate Locks?

The manufacturing of gate locks involves several critical stages, each designed to ensure the final product meets the highest standards of durability and security. The primary stages include:

-

Material Preparation: The first step in manufacturing gate locks is selecting the appropriate materials. Commonly used materials include stainless steel, brass, and high-grade plastic. The selected materials undergo rigorous testing for quality and durability. Suppliers typically provide material certificates that indicate compliance with international standards, which is crucial for B2B buyers looking for reliable products.

-

Forming: This stage involves shaping the raw materials into the desired components of the gate lock. Techniques such as stamping, forging, and machining are commonly employed. Precision engineering is vital at this stage to ensure that parts fit together seamlessly. Advanced technologies like CNC (Computer Numerical Control) machining are often used to enhance accuracy, which is particularly important for locking mechanisms that require tight tolerances.

-

Assembly: After forming, the various components of the gate lock are assembled. This process can be manual or automated, depending on the scale of production. Quality assurance is integrated into the assembly line, where trained technicians ensure that each lock functions correctly and meets design specifications. This step is crucial for the reliability of the locking mechanism, which must operate smoothly under various conditions.

-

Finishing: The final stage involves applying protective coatings, such as powder coating or electroplating, to enhance corrosion resistance and improve aesthetics. Finishing processes also include polishing and surface treatment, which not only enhance the appearance but also contribute to the longevity of the lock. Quality checks are performed at this stage to ensure that the finishing meets the required standards.

How Is Quality Assurance Implemented in Gate Lock Manufacturing?

Quality assurance (QA) in gate lock manufacturing is critical for ensuring that products meet both industry standards and customer expectations. Here are the key aspects of QA relevant to B2B buyers:

-

International Standards Compliance: Manufacturers often adhere to international quality management standards such as ISO 9001. This standard outlines requirements for a quality management system (QMS) that can enhance customer satisfaction through effective processes. Compliance with ISO 9001 can be a significant factor for B2B buyers, as it indicates a commitment to quality.

-

Industry-Specific Certifications: Depending on the application, additional certifications may be relevant. For example, CE marking indicates compliance with European safety standards, while API certification is essential for locks used in the oil and gas industry. B2B buyers should inquire about these certifications to ensure that the products meet specific regulatory requirements for their markets.

-

Quality Control Checkpoints: Quality control (QC) is integrated at multiple checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): Inspects raw materials for compliance with specifications before they are used in production.

– In-Process Quality Control (IPQC): Monitors the production process to identify and address any issues in real-time.

– Final Quality Control (FQC): Conducts thorough testing of the finished products, ensuring that they meet performance, durability, and safety standards. -

Common Testing Methods: Testing methods for gate locks can include mechanical testing (to assess strength and durability), corrosion resistance testing (to evaluate performance in various environmental conditions), and functionality testing (to ensure proper operation of the locking mechanism). Non-destructive testing (NDT) methods are also employed to evaluate material integrity without damaging the product.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must take proactive steps to verify the quality control measures of their suppliers. Here are effective strategies to ensure that suppliers maintain high-quality standards:

-

Conducting Audits: Regular audits of suppliers can provide insights into their manufacturing processes and quality control systems. These audits can be conducted internally or by third-party organizations specializing in quality assurance.

-

Requesting Quality Reports: Suppliers should provide detailed quality reports that outline their QC processes, testing results, and compliance with relevant standards. These documents can serve as evidence of the supplier’s commitment to maintaining quality.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s manufacturing processes. These services can assess everything from raw material quality to the final product, ensuring that it meets specified standards before shipment.

-

Understanding Certification Nuances: B2B buyers should be aware of the nuances of certifications, especially when sourcing from different regions. For example, a CE mark is essential for selling in Europe, while UL certification may be necessary for the U.S. market. Understanding these differences can help buyers ensure compliance and avoid potential legal issues.

What Should International B2B Buyers Consider Regarding Quality Control?

International B2B buyers, particularly from diverse regions like Africa, South America, the Middle East, and Europe, must consider several factors when evaluating the quality control measures of gate lock suppliers:

-

Regional Standards and Compliance: Different regions may have unique standards and regulations for gate locks. Buyers should familiarize themselves with these requirements to ensure that the products they import meet local regulations.

-

Supplier Reputation and Experience: Partnering with established suppliers who have a proven track record of quality can mitigate risks. Researching supplier history and customer reviews can provide valuable insights into their reliability and quality assurance practices.

-

Cultural and Language Barriers: Communication can be challenging when dealing with suppliers from different regions. Ensuring that there are clear channels for communication regarding quality expectations can help prevent misunderstandings.

-

Supply Chain Transparency: Buyers should seek suppliers that provide transparency regarding their sourcing and manufacturing processes. This transparency can enhance trust and facilitate easier quality control assessments.

By understanding the manufacturing processes and quality assurance practices specific to gate locks, B2B buyers can make informed decisions that safeguard their investments and ensure the security of their properties.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘types of gate locks’

In today’s global market, selecting the right gate locks is crucial for ensuring security and functionality across various applications. This practical sourcing guide aims to provide B2B buyers with a structured checklist to facilitate informed decision-making when procuring gate locks.

Step 1: Identify Your Security Needs

Understanding your security requirements is the first step in selecting the appropriate gate locks. Consider factors such as the level of access control needed, potential threats, and whether the locks will be used for residential or commercial purposes. Assessing these aspects will help narrow down your options effectively.

- Access Control: Determine if you require key-based locks, electronic access controls, or a combination of both.

- Environmental Factors: Consider if the locks will be exposed to harsh weather conditions, which may necessitate weather-resistant materials.

Step 2: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline the technical specifications needed for your gate locks. This includes the type of lock (e.g., deadbolt, latch, or coded), material (e.g., steel, brass, or plastic), and compatibility with existing gate structures.

Illustrative image related to types of gate locks

- Gate Type: Specify whether the locks are for wooden, metal, or vinyl gates.

- Size and Dimensions: Ensure that the locks fit the dimensions of your gates, as improper sizing can compromise security.

Step 3: Research Potential Suppliers

Conduct thorough research on potential suppliers to assess their credibility and reliability. Look for suppliers with a proven track record in providing gate locks that meet your specifications.

- Supplier Reviews: Check online reviews and testimonials from other businesses in your industry.

- Industry Experience: Prefer suppliers who have experience serving clients in your geographical region, as they may better understand local security needs.

Step 4: Evaluate Supplier Certifications

Verifying supplier certifications ensures that the products meet industry standards for quality and safety. Look for ISO certifications or other relevant industry accreditations.

- Quality Assurance: Certifications can indicate a commitment to quality control processes.

- Regulatory Compliance: Ensure that the locks comply with local security regulations and standards.

Step 5: Request Samples or Demonstrations

Before finalizing your order, request samples or demonstrations of the gate locks. This step allows you to evaluate the product’s functionality and quality firsthand.

- Functionality Testing: Assess how the locks operate and whether they meet your usability requirements.

- Material Quality: Inspect the material used in the locks to ensure durability and resistance to tampering.

Step 6: Negotiate Terms and Conditions

Once you’ve selected a supplier, negotiate the terms of purchase, including pricing, delivery timelines, and warranty conditions. Clear communication at this stage can prevent misunderstandings later on.

- Pricing Structure: Discuss bulk pricing options if you plan to make a large order.

- Warranties and Support: Ensure that warranties are in place for defects and inquire about post-purchase support.

Step 7: Finalize Your Purchase and Plan Installation

After agreeing on terms, finalize your purchase and plan for installation. Determine whether you will handle installation in-house or require professional assistance.

- Installation Guidelines: Request installation instructions from the supplier if you plan to install the locks yourself.

- Professional Services: If hiring professionals, ensure they have experience with the specific types of locks you are installing.

Following this checklist will help B2B buyers make informed decisions when sourcing gate locks, ensuring security and functionality for their properties.

Comprehensive Cost and Pricing Analysis for types of gate locks Sourcing

What Are the Key Cost Components in Sourcing Gate Locks?

When sourcing gate locks, understanding the cost structure is crucial for effective budgeting and procurement. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margin.

-

Materials: The choice of materials significantly impacts cost. Stainless steel and marine-grade materials, often used for their durability, can be more expensive than standard steel or plastic options. Additionally, specialized finishes (e.g., powder coating) to enhance aesthetics and corrosion resistance can add to the material costs.

-

Labor: Labor costs vary based on the complexity of the lock design and the manufacturing location. Regions with lower labor costs, such as certain parts of Asia or South America, can offer competitive pricing, but may also affect lead times and quality assurance.

-

Manufacturing Overhead: This encompasses indirect costs such as utilities, rent, and equipment depreciation. Efficient manufacturing processes can help reduce these overheads, impacting the overall pricing.

-

Tooling: Custom tooling for unique lock designs or specifications can require significant upfront investment. For standard products, tooling costs are amortized over larger production runs, making unit costs lower.

-

Quality Control (QC): High-quality locks often undergo rigorous testing and certification processes, which add to costs but are essential for ensuring product reliability and compliance with safety standards.

-

Logistics: Shipping costs can vary dramatically based on the destination, size of the order, and chosen Incoterms. For international buyers, understanding these logistics costs is vital for accurate pricing.

-

Margin: Suppliers typically add a margin based on their costs, market conditions, and competitive landscape. Negotiating this margin can yield significant savings, particularly for bulk orders.

How Do Price Influencers Affect Gate Lock Sourcing?

Several factors influence the pricing of gate locks, which international B2B buyers must consider:

-

Volume and Minimum Order Quantities (MOQ): Larger orders can significantly reduce per-unit costs due to economies of scale. Suppliers often provide better pricing for bulk purchases, making it advantageous for companies to consolidate their orders.

-

Specifications and Customization: Custom designs or specific certifications can increase costs. Buyers should weigh the benefits of customization against the potential price increases.

-

Material Selection: The choice of materials not only affects durability and aesthetic appeal but also influences pricing. Buyers should assess whether premium materials justify the costs based on their application needs.

-

Quality and Certifications: Locks that meet international standards or specific certifications (e.g., ISO) may command higher prices but provide assurance of quality and reliability, which is crucial for security applications.

-

Supplier Factors: The supplier’s reputation, reliability, and location can impact pricing. Established suppliers may offer higher prices due to their quality assurance processes but can also provide better service and support.

-

Incoterms: The choice of shipping terms can affect total landed costs. Understanding Incoterms is vital for international transactions to avoid unexpected costs related to shipping, insurance, and tariffs.

What Are Effective Buyer Tips for Negotiating Gate Lock Prices?

To maximize value when sourcing gate locks, buyers should consider the following strategies:

-

Negotiation: Engaging suppliers in negotiation can lead to better pricing, especially for larger orders. Buyers should be prepared to discuss their needs clearly and leverage competitive quotes from multiple suppliers.

-

Cost-Efficiency: Evaluate the total cost of ownership (TCO) rather than just the initial purchase price. This includes considering the longevity, maintenance costs, and potential replacement frequency of the locks.

-

Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should be aware of local market conditions and currency fluctuations that can influence pricing. Establishing long-term relationships with suppliers can also provide negotiation leverage and more favorable terms.

-

Market Research: Conduct thorough market research to understand prevailing prices and trends. This information can empower buyers during negotiations and help them identify the best sourcing opportunities.

-

Request Samples: Before placing large orders, requesting samples can help assess quality and suitability, ensuring that the product meets the intended security requirements.

By understanding these cost components, price influencers, and negotiation strategies, international B2B buyers can make informed decisions in sourcing gate locks, optimizing their procurement processes while ensuring security and reliability.

Illustrative image related to types of gate locks

Alternatives Analysis: Comparing types of gate locks With Other Solutions

Exploring Alternative Security Solutions for Gates

When considering security for gates, various options are available beyond traditional gate locks. Each solution has its unique advantages and disadvantages, making it essential for B2B buyers to evaluate which method best aligns with their security needs and operational requirements. This analysis compares types of gate locks with two alternative security solutions: electronic access control systems and physical barriers.

| Comparison Aspect | Types of Gate Locks | Electronic Access Control Systems | Physical Barriers |

|---|---|---|---|

| Performance | High security, reliable physical deterrent | Enhanced security with access logs and remote access | Very effective at preventing unauthorized entry |

| Cost | Moderate initial investment; ongoing costs for maintenance | Higher initial investment; potential recurring subscription fees | Low initial cost; minimal ongoing expenses |

| Ease of Implementation | Simple installation; no technical expertise required | Requires professional installation and setup | Easy to deploy; can be temporary or permanent |

| Maintenance | Moderate; occasional lubrication and adjustments | High; requires regular software updates and battery replacements | Low; typically requires occasional inspections |

| Best Use Case | Residential and commercial properties needing controlled access | High-security areas needing detailed access tracking | Locations needing a strong physical deterrent, like construction sites |

In-Depth Analysis of Alternative Solutions

Electronic Access Control Systems

Electronic access control systems provide a modern approach to security by utilizing keycards, biometrics, or mobile applications to grant access. The primary advantage is the ability to monitor and control entry remotely, offering real-time tracking and reporting of access events. However, the initial investment can be substantial, and ongoing maintenance is necessary to keep the system updated and functional. These systems are best suited for high-security environments where detailed access records are crucial.

Physical Barriers

Physical barriers, such as fences, walls, or bollards, serve as an effective means of deterring unauthorized access. They are particularly useful in environments where a strong physical presence is necessary, such as construction sites or outdoor storage areas. The cost of implementing physical barriers is generally low, and they require minimal ongoing maintenance. However, they may not provide the same level of access control or tracking capabilities as electronic systems or traditional locks.

Illustrative image related to types of gate locks

Making the Right Choice for Your Security Needs

When choosing the right security solution for gates, B2B buyers should consider several factors, including the specific security requirements of their premises, budget constraints, and the level of convenience they desire. Types of gate locks offer a reliable and cost-effective solution for many applications, while electronic access control systems provide advanced features ideal for high-security environments. Physical barriers can serve as a robust deterrent but may lack the sophistication of electronic solutions. Ultimately, the best choice will depend on balancing security needs with budget and operational considerations.

Essential Technical Properties and Trade Terminology for types of gate locks

What Are the Key Technical Properties of Gate Locks?

When selecting gate locks for security applications, understanding essential technical properties is crucial for ensuring durability and reliability. Below are several critical specifications that B2B buyers should consider:

-

Material Grade

The material used in manufacturing gate locks significantly affects their strength and resistance to corrosion. Common materials include stainless steel, brass, and zinc alloy. Stainless steel is often preferred for its durability and resistance to rust, making it suitable for outdoor environments. Knowing the material grade helps buyers assess the lock’s lifespan and maintenance needs. -

Locking Mechanism Type

Gate locks can feature various mechanisms, such as deadbolts, padlocks, or electronic locks. Each mechanism offers different levels of security and ease of use. For instance, deadbolts provide enhanced security against forced entry, while electronic locks offer convenience with keyless entry options. Understanding the locking mechanism aids in selecting the right product for specific security requirements. -

Security Rating

Many gate locks come with a security rating, often designated by organizations like Underwriters Laboratories (UL) or the American National Standards Institute (ANSI). These ratings evaluate the lock’s resistance to unauthorized access, with higher ratings indicating better security. Buyers should consider security ratings to ensure the locks meet their safety standards. -

Tolerance and Fit

Tolerance refers to the allowable variation in dimensions, which is critical for ensuring a proper fit between the lock and the gate. A lock that does not fit correctly may compromise security and functionality. Ensuring compatibility with the gate’s design and materials is essential for effective installation and long-term performance. -

Weather Resistance

For outdoor applications, gate locks should be weather-resistant to withstand environmental conditions such as rain, snow, and temperature fluctuations. Features such as weather seals and coatings can enhance resistance to moisture and temperature extremes. This property is particularly important for buyers in regions with harsh climates. -

Size and Weight

The size and weight of a gate lock can affect its installation and usability. Heavier locks may provide better security but can also require more robust mounting solutions. It’s important for buyers to consider the gate’s design and the intended use when selecting the appropriate size and weight for a lock.

What Are Common Trade Terms in the Gate Lock Industry?

Understanding industry jargon is vital for effective communication and decision-making in the B2B space. Here are some commonly used terms:

Illustrative image related to types of gate locks

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand. In the gate lock industry, an OEM may produce locks for a brand that markets them under its name. This term is crucial for buyers looking for specific product quality and reliability. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers plan their purchases and avoid overstock or understock situations. This is particularly important for bulk purchases in commercial settings. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing information for specific products. It’s a standard practice in B2B transactions, allowing buyers to compare offers and negotiate better terms. Understanding how to formulate an RFQ can lead to more favorable purchasing conditions. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. They clarify aspects such as shipping costs, insurance, and delivery responsibilities. Familiarity with these terms is essential for buyers engaged in international procurement of gate locks. -

Lead Time

Lead time refers to the time taken from placing an order to the delivery of goods. It is crucial for planning inventory and project timelines. Buyers must consider lead times when placing orders to ensure timely project execution. -

Certification

Certification indicates that a product meets specific standards set by regulatory bodies or industry organizations. For gate locks, certifications related to safety and security can provide assurance to buyers regarding the product’s quality. Understanding certification requirements is essential for compliance and risk management.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing gate locks, ensuring they meet their specific security and operational needs.

Navigating Market Dynamics and Sourcing Trends in the types of gate locks Sector

What Are the Current Market Dynamics and Key Trends Impacting the Types of Gate Locks Sector?

The global gate locks market is experiencing significant growth, driven by increasing security concerns and the rising demand for residential and commercial safety solutions. Key trends include the integration of advanced technologies such as smart locks and biometric systems, which enhance security and offer convenience. International B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, are increasingly looking for products that combine reliability with technological innovation. For instance, smart locks that can be controlled via smartphones are gaining traction among businesses focused on modernizing their security systems.

Moreover, the market is witnessing a shift towards customizable solutions to cater to various gate types and materials, such as wood, vinyl, and metal. This adaptability is crucial for buyers who require specific functionalities such as child safety latches, pool gate locks, or heavy-duty options for commercial applications. B2B buyers are also increasingly influenced by product certifications and compliance with international safety standards, which can serve as a competitive differentiator in tendering processes.

Illustrative image related to types of gate locks

With the rise of e-commerce, many suppliers are enhancing their online presence to streamline the sourcing process, allowing international buyers to easily compare products and prices. This trend is particularly relevant in developing regions where traditional retail channels may be less accessible.

How Are Sustainability and Ethical Sourcing Shaping the Types of Gate Locks Industry?

As global awareness of environmental issues grows, sustainability is becoming a central theme in the gate locks industry. B2B buyers are increasingly seeking products made from environmentally friendly materials, such as recycled metals and sustainably sourced wood. This shift not only helps reduce the environmental impact but also aligns with the values of consumers who prioritize eco-friendly practices.

Ethical sourcing is another crucial factor influencing purchasing decisions. Buyers are now more inclined to partner with suppliers who maintain transparent supply chains and adhere to fair labor practices. Certifications such as ISO 14001 for environmental management and FSC (Forest Stewardship Council) for wood products are becoming increasingly important in the selection process. These certifications not only enhance the credibility of suppliers but also assure buyers that they are investing in products that support ethical practices.

Furthermore, the demand for products that can contribute to green building certifications, such as LEED (Leadership in Energy and Environmental Design), is on the rise. This trend presents an opportunity for manufacturers to innovate and develop gate locks that not only meet security needs but also contribute positively to the environment.

Illustrative image related to types of gate locks

What Is the Historical Context of Gate Locks and Its Relevance to Today’s B2B Buyers?

The evolution of gate locks dates back centuries, with early designs focused primarily on basic security features. Ancient civilizations utilized simple mechanisms to secure their gates, primarily made from wood and metal. As societies advanced, so did the complexity and functionality of locking mechanisms. The Industrial Revolution introduced mass production techniques, leading to the availability of standardized locks that could be easily installed across various gate types.

In the contemporary B2B landscape, this historical context underscores the importance of reliability and innovation. Modern gate locks now incorporate advanced technologies such as electronic access controls and smart integration, reflecting an ongoing commitment to security and user convenience. For today’s buyers, understanding the evolution of gate locks not only provides insight into the reliability of products but also highlights the importance of choosing suppliers that embrace both tradition and innovation. This knowledge is essential for making informed purchasing decisions that align with current market trends and future needs.

Frequently Asked Questions (FAQs) for B2B Buyers of types of gate locks

-

1. How do I choose the right gate lock for my business needs?

Selecting the appropriate gate lock involves assessing your specific security requirements, gate type, and usage frequency. Consider factors such as the material of the gate (wood, metal, vinyl), the level of security needed (commercial vs. residential), and whether you require features like self-closing mechanisms or keyless entry. Additionally, evaluate the environment; for instance, coastal areas may require locks made from corrosion-resistant materials. Consulting with a security specialist can help you identify the best options tailored to your unique situation. -

2. What types of gate locks are available for international buyers?

International buyers can access a wide range of gate locks, including mechanical, electronic, and smart locks. Mechanical locks include traditional padlocks and deadbolts, while electronic options may feature keypads or biometric entry systems. Smart locks often integrate with mobile applications for remote access control. It’s crucial to verify that the selected lock meets international safety standards and is compatible with local infrastructure and regulations in your target market. -

3. What factors should I consider when vetting suppliers of gate locks?

When vetting suppliers, assess their reputation, experience, and product quality. Request samples to evaluate the durability and functionality of their locks. Check for certifications and compliance with international standards, which can indicate reliability. Additionally, consider their ability to provide customization options and their responsiveness to inquiries. Reviewing customer testimonials and seeking references from other businesses can also provide insight into their reliability and service quality. -

4. What are the typical minimum order quantities (MOQs) for gate locks?

Minimum order quantities (MOQs) for gate locks can vary significantly by supplier and product type. Generally, MOQs can range from a few dozen units for standard locks to several hundred for custom-designed products. It’s advisable to discuss your specific needs with potential suppliers to negotiate favorable terms. Be sure to consider your inventory management capabilities and whether bulk purchasing aligns with your business strategy to avoid overstocking. -

5. What payment terms should I expect when purchasing gate locks internationally?

Payment terms for international purchases of gate locks typically include options such as upfront payment, partial payment upon order confirmation, and the balance upon delivery. Common methods include wire transfers, letters of credit, or payment through platforms like PayPal. It’s crucial to clarify these terms before finalizing the order to ensure smooth transactions and avoid potential disputes. Always ensure that you have documentation to protect your financial interests. -

6. How can I ensure the quality of gate locks before shipment?

To ensure quality, request a quality assurance (QA) inspection before shipment. This may include checking the locks for functionality, durability, and adherence to specifications. Many suppliers offer third-party QA services that can provide unbiased assessments. Additionally, consider implementing a pre-shipment inspection process where you can evaluate a sample batch of the locks. Establishing clear quality standards and expectations in your contract with the supplier can also help mitigate risks. -

7. What are the logistics considerations when importing gate locks?

When importing gate locks, consider shipping methods, customs regulations, and potential tariffs that may apply. Sea freight is often the most economical option for large orders, while air freight is faster but more expensive. Ensure that the supplier provides all necessary documentation, including invoices, packing lists, and certifications, to facilitate smooth customs clearance. Additionally, partner with a reliable logistics provider who understands the nuances of international shipping to avoid delays. -

8. Are there customization options available for gate locks?

Many manufacturers offer customization options for gate locks, including variations in size, finish, and locking mechanisms. You can also request branding or logo engraving for promotional purposes. Discuss your specific requirements with potential suppliers to explore available customization options and any associated costs. Custom locks can enhance security and align with your brand identity, making them a valuable investment for your business.

Top 5 Types Of Gate Locks Manufacturers & Suppliers List

1. D&D – Gate Latches and Locks

Domain: gatehardwarecenter.com

Registered: 2017 (8 years)

Introduction: Gate Latches and Locks provide safe and reliable perimeter security. D&D Latches and Locks are top-of-the-line, exceeding industry standards. Available styles include privacy and security latches, child safety latches, pool gate locks, and models for commercial and residential gates. They cater to different gate material types, with options for self-closing and non-self-closing models, keyable loc…

2. HingeOutlet – BadAss Coded Gate Locks

Domain: hingeoutlet.com

Registered: 2004 (21 years)

Introduction: Gate Locks – HingeOutlet offers a variety of gate locks and hardware for both residential and commercial applications. Key products include BadAss Coded Gate Locks, Locinox Gate Locks and Latches for security and privacy, and various types of heavy-duty gate hinges such as Bolt On, Weld On, and Double Action Spring Hinges. Additional items include drop bolts, gate access controls, gate closers, an…

3. Abbey Hardware – Gate Latches

Domain: abbeyhardware.com

Registered: 2019 (6 years)

Introduction: Gate latches can be divided into four main categories: bolt, lever, ring, and thumb latches. Key features include:

1. **Bolts**: Also known as padbolts, slide bolts, or barrel bolts; they secure gates with a sliding metal bar and can be padlocked. Available in light-duty to heavy-duty designs.

2. **Levers**: Simple mechanism with a backplate and a metal bar that lifts with a lever; typically dec…

4. Jackson’s Fencing – Garden Gate Locks & Latches

Domain: jacksons-fencing.co.uk

Registered: 1997 (28 years)

Introduction: This company, Jackson’s Fencing – Garden Gate Locks & Latches, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Hoover Fence Co. – Gate Latches

Domain: hooverfence.com

Registered: 1996 (29 years)

Introduction: Gate Latches available at Hoover Fence Co. include various types such as single gate latches, double gate latches, pool gate latches, and wooden gate latches. They are made from materials like aluminum, steel, polymer, and stainless steel. Key features include key locking options, padlock compatibility, and suitability for both swinging and sliding gates. The product range includes brands like D&D…

Strategic Sourcing Conclusion and Outlook for types of gate locks

How Can Strategic Sourcing Enhance Your Gate Lock Procurement?

In conclusion, the diverse landscape of gate locks offers international B2B buyers a wealth of options tailored to various security needs and operational requirements. From residential to commercial applications, the selection of gate locks—including coded, surface-mounted, and heavy-duty options—ensures that businesses can effectively safeguard their assets while enhancing convenience and accessibility.

Illustrative image related to types of gate locks

Strategic sourcing plays a pivotal role in this process, enabling buyers to leverage supplier relationships, negotiate competitive pricing, and ensure product quality. By focusing on long-term partnerships with manufacturers and distributors, businesses can streamline their procurement processes and reduce total cost of ownership.

As global markets continue to evolve, it is crucial for buyers in Africa, South America, the Middle East, and Europe to stay informed about emerging trends and technological advancements in gate lock solutions. Investing in robust security measures not only protects assets but also fosters trust and reliability in your operations.

We encourage you to explore innovative gate lock solutions that align with your strategic goals and to engage with reputable suppliers who can support your unique needs. Take proactive steps today to secure your perimeter and enhance the safety of your operations for tomorrow.

Illustrative image related to types of gate locks

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.