Types Of Fork Lifts: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for types of fork lifts

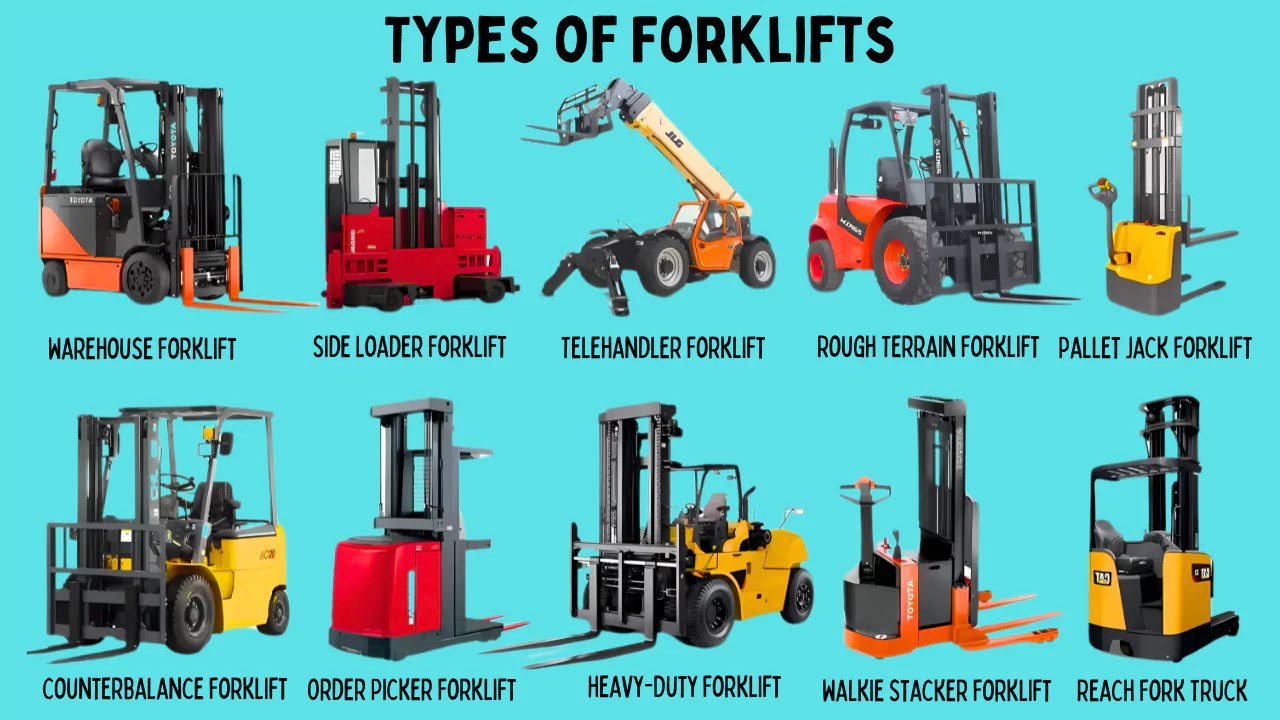

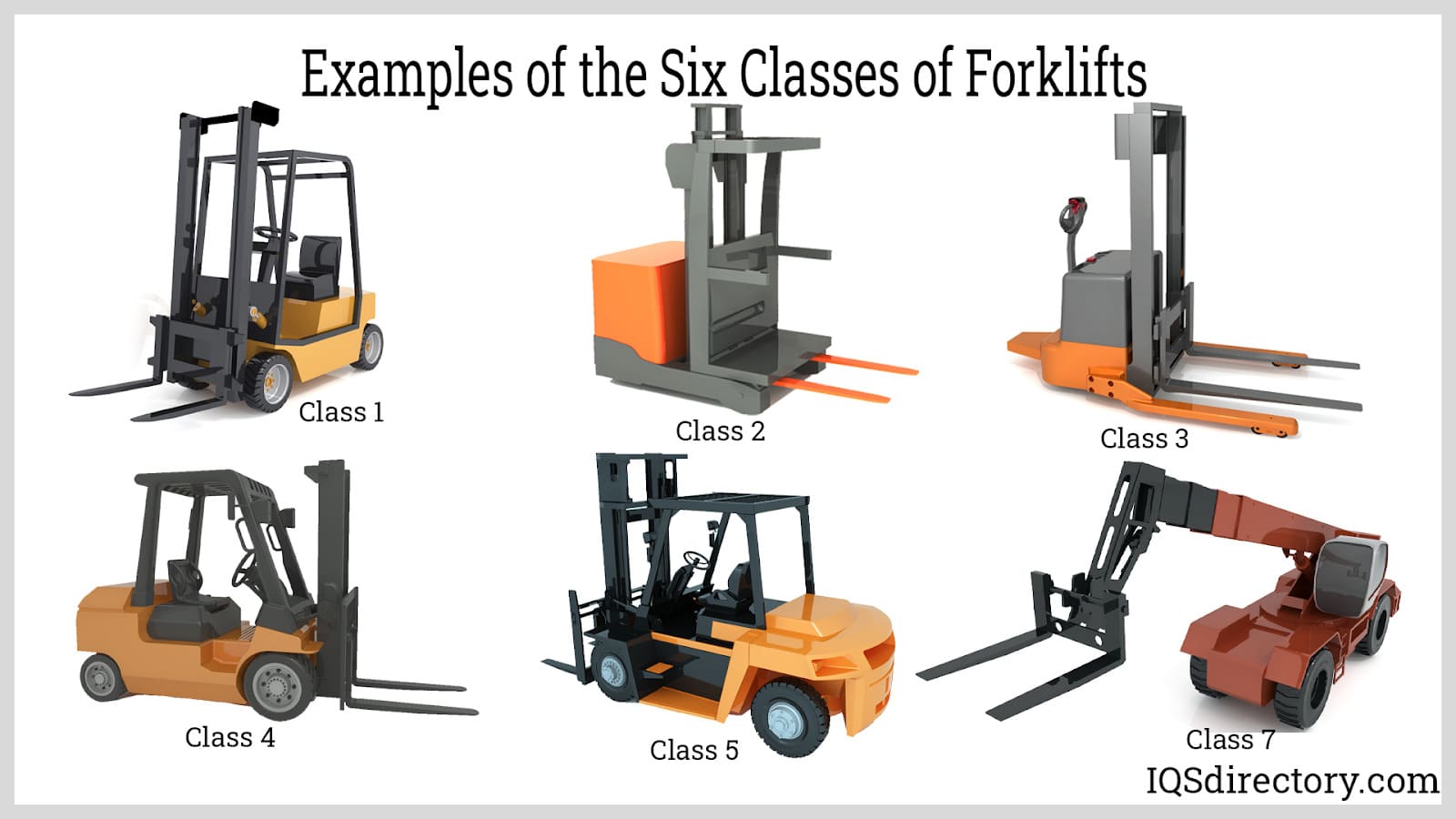

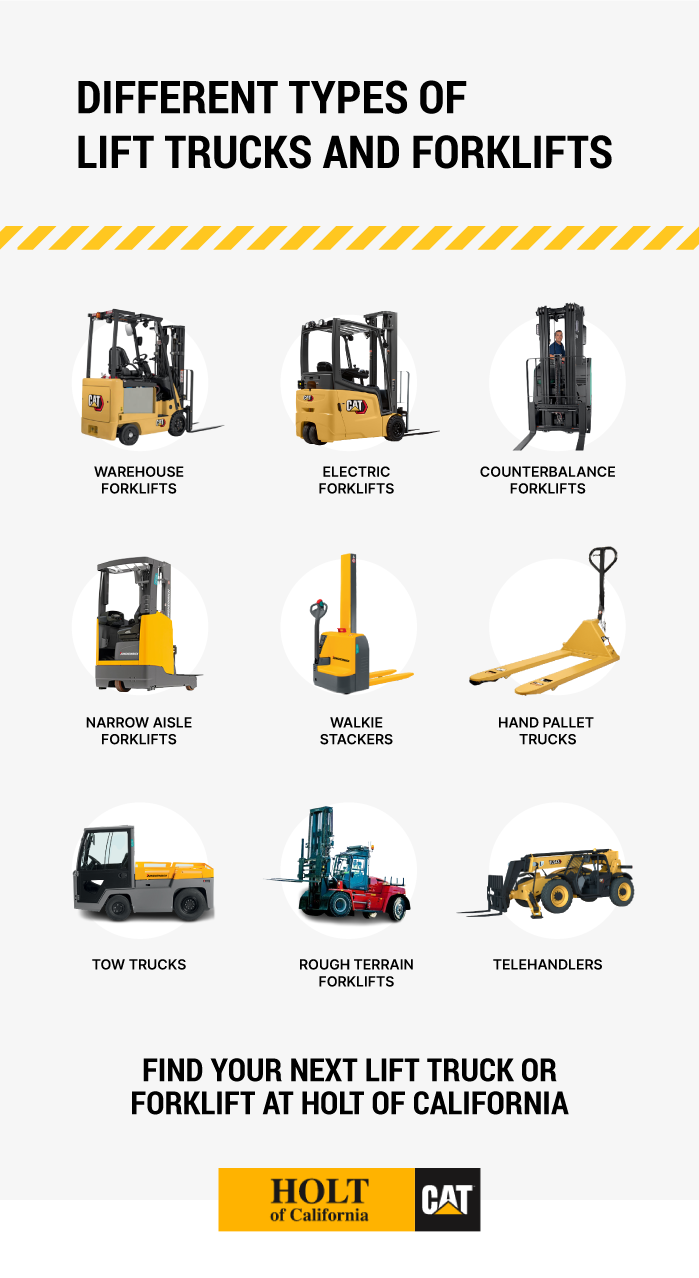

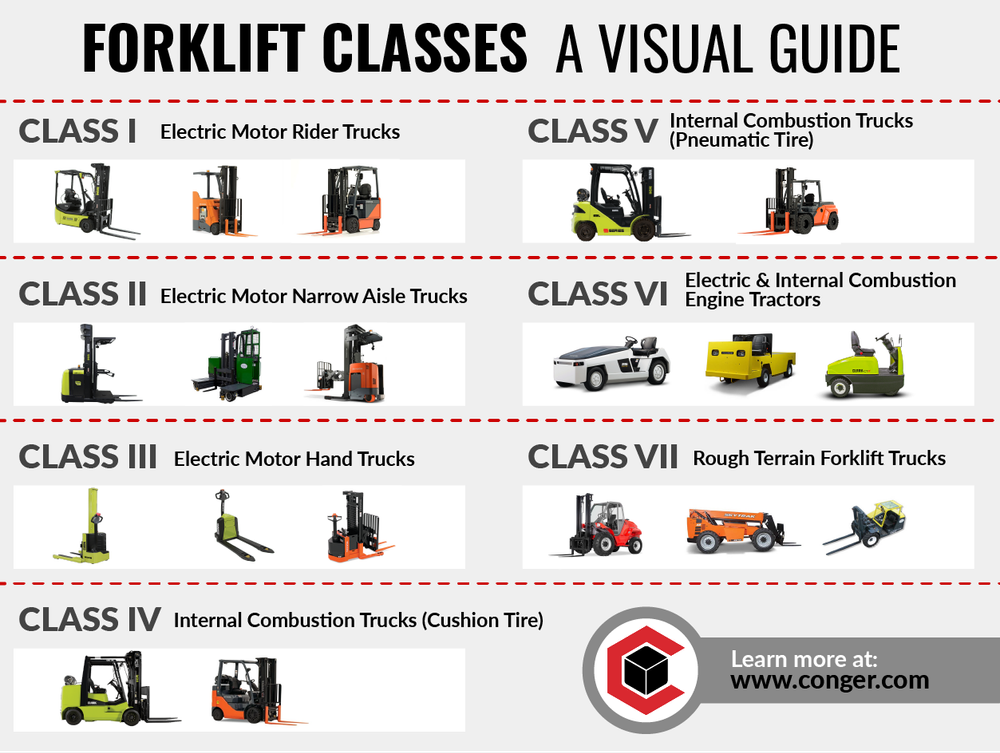

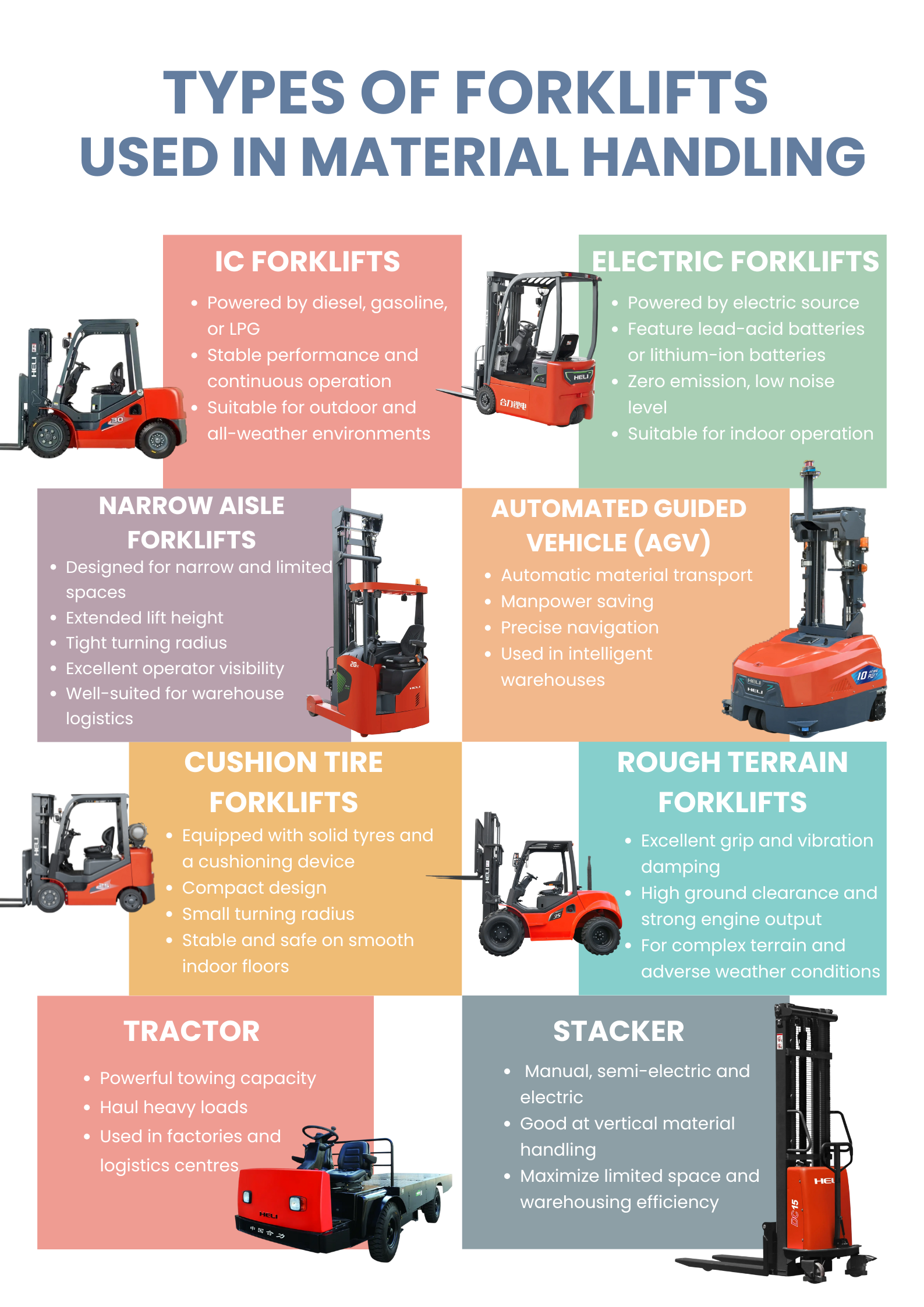

In today’s competitive global landscape, sourcing the right types of forklifts can be a daunting challenge for B2B buyers, especially when considering the diverse operational needs across regions like Africa, South America, the Middle East, and Europe. With various models available—including warehouse forklifts, telehandlers, and rough terrain options—making an informed decision requires a thorough understanding of each type’s unique applications and specifications. This comprehensive guide delves into the ten primary forklift types, their classifications, and the critical factors to consider when evaluating suppliers.

As you navigate this intricate market, our guide equips international buyers with actionable insights on cost implications, supplier vetting processes, and operational efficiencies. Whether you’re in Saudi Arabia looking for heavy-duty forklifts for construction sites, or in Germany sourcing electric models for indoor warehousing, we provide the essential knowledge to make confident purchasing decisions. With clear comparisons and expert recommendations, this resource empowers you to optimize your logistics operations while ensuring safety and reliability in your material handling solutions.

Understanding types of fork lifts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Warehouse Forklift | Compact design, typically battery or gas-powered | Loading/unloading pallets in warehouses | Pros: Versatile, good for tight spaces. Cons: Limited outdoor use. |

| Telehandler | Extendable arm and boom for reaching higher loads | Construction sites, agricultural applications | Pros: High lift capacity, versatile. Cons: Larger footprint, may require more training. |

| Counterbalance Forklift | Front forks with a rear counterweight | General material handling in tight spaces | Pros: Excellent maneuverability. Cons: Not suitable for uneven terrain. |

| Rough Terrain Forklift | Sturdy design with oversized tires for stability | Outdoor construction, landscaping | Pros: Handles rough surfaces well. Cons: Limited speed and precision. |

| Order Picker | Elevated platform for picking items from shelves | Warehousing, e-commerce fulfillment | Pros: Efficient for picking individual items. Cons: Limited load capacity. |

What Are the Key Characteristics of a Warehouse Forklift?

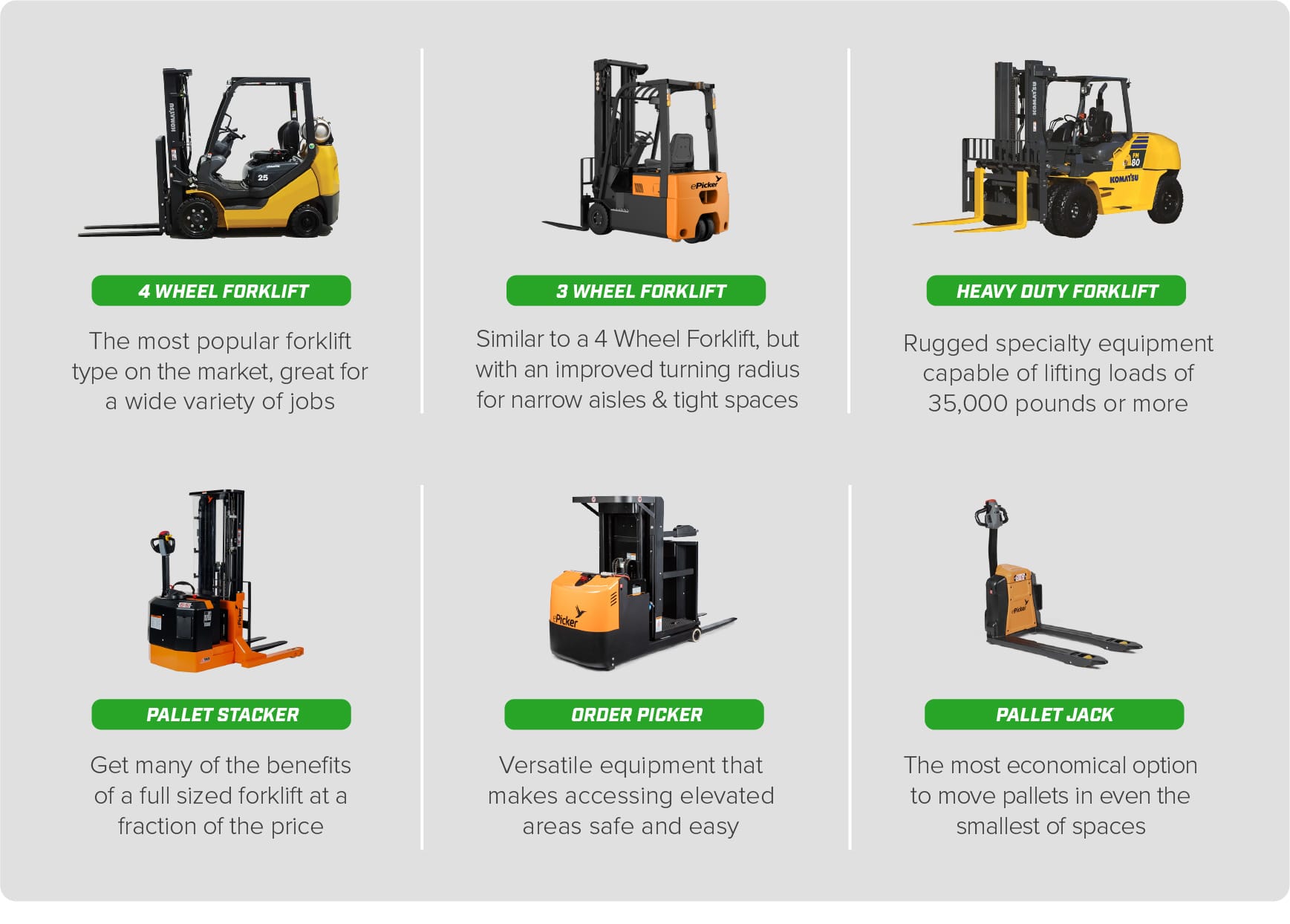

Warehouse forklifts are the workhorses of indoor material handling. They typically feature a compact design, allowing for easy navigation in tight spaces. Ideal for loading and unloading pallets, these forklifts can lift weights ranging from 5,000 to 25,000 pounds, depending on the model. When considering a warehouse forklift, B2B buyers should assess their specific space constraints and weight requirements to ensure optimal performance.

How Does a Telehandler Differ from Other Forklifts?

Telehandlers, or telescopic forklifts, combine the functionalities of a crane and a forklift. With an extendable arm and boom, they can reach loads up to 55 feet high, making them particularly useful in construction and agricultural settings. However, their larger footprint may require more space for operation, and operators may need specialized training. Buyers should evaluate their lifting height needs and operational space when considering telehandlers.

Why Choose a Counterbalance Forklift?

Counterbalance forklifts are characterized by their front forks and rear counterweight, providing excellent stability and maneuverability. They are particularly effective in environments where space is limited, allowing operators to navigate tight aisles easily. While they excel in indoor applications, buyers should be cautious as they are not designed for rough or uneven terrains. Understanding the operational environment is crucial for making an informed purchasing decision.

What Makes Rough Terrain Forklifts Essential for Outdoor Use?

Rough terrain forklifts are specifically engineered for outdoor applications on uneven surfaces. Their oversized tires and robust design provide stability, allowing them to handle loads typically ranging from 6,000 to 8,000 pounds. While they are invaluable for construction and landscaping projects, their speed and precision may be lower compared to standard forklifts. B2B buyers should consider the terrain and load requirements of their projects when investing in rough terrain models.

Illustrative image related to types of fork lifts

How Do Order Pickers Enhance Warehouse Efficiency?

Order pickers are specialized forklifts designed for picking items directly from warehouse racks. They feature an elevated platform that allows operators to reach items at various heights, making them ideal for e-commerce and inventory management. While they improve picking efficiency, their load capacity is generally lower than that of traditional forklifts. Buyers should analyze their picking processes to determine if an order picker aligns with their operational needs.

Key Industrial Applications of types of fork lifts

| Industry/Sector | Specific Application of types of fork lifts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Heavy-duty forklifts for assembly lines | Increased efficiency in handling heavy materials | Assess load capacity and durability for continuous use |

| Warehousing | Order pickers for inventory management | Improved accuracy and speed in order fulfillment | Evaluate reach height and maneuverability in tight spaces |

| Construction | Rough terrain forklifts on job sites | Enhanced mobility on uneven surfaces | Consider tire type and lift height for outdoor conditions |

| Retail | Pallet jacks for stock replenishment | Cost-effective solution for moving goods | Determine weight capacity and ease of use in confined areas |

| Agriculture | Telehandlers for material handling | Versatile lifting capabilities for various loads | Look for models with extended reach and stability on soft ground |

How Are Forklifts Used in Manufacturing Processes?

In the manufacturing sector, heavy-duty forklifts are essential for moving large components and materials along assembly lines. These forklifts are designed to handle significant weights and can operate efficiently in industrial environments. By investing in the right heavy-duty forklift, manufacturers can streamline their operations, reduce manual labor costs, and minimize the risk of injuries associated with lifting heavy items. Buyers should focus on load capacity, durability, and maintenance support when sourcing these forklifts, especially in regions like Africa and South America where rugged usage is common.

What Role Do Forklifts Play in Warehousing?

Order pickers are pivotal in warehousing operations, specifically for picking items from shelves to fulfill customer orders. They allow operators to reach high storage racks, thus maximizing vertical space and improving inventory management efficiency. This leads to faster order processing and reduced errors, providing a competitive edge in the market. B2B buyers should consider the height of the reach, ease of operation, and compatibility with existing warehouse layouts to ensure optimal performance in their logistics operations across Europe and the Middle East.

How Are Forklifts Utilized in Construction Environments?

Rough terrain forklifts are uniquely suited for construction sites where uneven ground is prevalent. These forklifts feature robust designs and oversized tires that provide stability and traction on challenging surfaces, allowing for the transport of materials such as bricks, lumber, and equipment. For construction companies, this means improved safety and efficiency in material handling. When sourcing rough terrain forklifts, buyers should prioritize specifications like lift height and load capacity, particularly in regions with diverse terrain conditions.

Illustrative image related to types of fork lifts

Why Are Pallet Jacks Important in Retail Settings?

In retail environments, pallet jacks are commonly used for stock replenishment and moving goods within warehouses or backrooms. Their compact size allows them to navigate tight spaces, making them ideal for busy retail settings. This cost-effective solution enhances operational efficiency and ensures that products are readily available for customers. Retailers should consider the weight capacity and the ease of maneuvering in confined areas when selecting pallet jacks, especially in urban locations where space is limited.

What Advantages Do Telehandlers Offer in Agriculture?

Telehandlers are increasingly used in agriculture for various tasks, including lifting and transporting feed, tools, and harvested crops. Their extendable arms provide versatility, allowing operators to reach high or difficult areas, which is crucial in farm settings. By utilizing telehandlers, agricultural businesses can improve productivity and reduce the time spent on manual material handling. Buyers should assess the reach capabilities, stability features, and overall durability of telehandlers to ensure they meet the specific demands of agricultural operations, especially in regions with varying soil conditions.

3 Common User Pain Points for ‘types of fork lifts’ & Their Solutions

Scenario 1: Choosing the Right Forklift for Diverse Environments

The Problem: B2B buyers often face the daunting task of selecting the appropriate type of forklift for their specific operational environment. For instance, a logistics manager in a South American warehouse might find themselves needing equipment that can handle both indoor operations and the occasional outdoor delivery. This dual requirement can lead to confusion, as many forklifts are designed for either environment but not both. Additionally, the costs associated with incorrect purchases can escalate quickly, leading to wasted budgets and operational inefficiencies.

The Solution: To mitigate this challenge, buyers should conduct a thorough needs assessment that includes understanding the operational environment, load capacities, and the specific tasks the forklift will perform. For a versatile solution, consider investing in a telehandler or a rough terrain forklift that offers flexibility across different surfaces. When engaging with suppliers, request detailed specifications, including the forklift’s performance metrics in various settings. Additionally, consider renting different types of forklifts for trial runs to evaluate their effectiveness in real-world conditions before making a significant investment. This approach not only ensures the right fit for diverse environments but also helps prevent costly mistakes.

Illustrative image related to types of fork lifts

Scenario 2: Managing Maintenance and Downtime Risks

The Problem: Maintenance and unexpected downtime are critical pain points for businesses relying on forklifts for their operations. A manufacturing plant in Germany may experience significant disruptions if their heavy-duty forklifts suffer mechanical failures, resulting in halted production lines and potential losses. The challenge lies in identifying the right maintenance schedule and ensuring that parts are readily available, especially when dealing with specialized equipment.

The Solution: Buyers should establish a proactive maintenance program tailored to the specific types of forklifts in use. Collaborating with manufacturers or authorized dealers can provide insights into optimal maintenance schedules based on usage patterns and environmental factors. Additionally, consider investing in a comprehensive parts inventory management system to ensure critical components are available for repairs. Leveraging technology, such as IoT sensors, can also help monitor forklift performance in real-time, alerting operators to potential issues before they lead to significant downtime. This preventative approach not only reduces operational disruptions but also enhances the longevity of the forklifts.

Scenario 3: Ensuring Operator Safety and Compliance

The Problem: Ensuring the safety of forklift operators is a paramount concern for B2B buyers, especially in regions with stringent safety regulations, such as Europe. A warehouse manager in the Middle East might struggle to keep up with compliance requirements related to operator training, equipment safety features, and workplace safety standards. Non-compliance can lead to severe penalties and a hazardous work environment, impacting employee morale and productivity.

The Solution: To address these concerns, companies should prioritize comprehensive training programs for all forklift operators, ensuring they are certified according to local regulations. This training should cover safe operational practices, emergency procedures, and equipment-specific guidelines. Moreover, buyers should source forklifts equipped with the latest safety features, such as automatic shut-off systems, improved visibility designs, and stability controls. Regular safety audits and feedback sessions can also help reinforce a culture of safety within the organization. By investing in both training and safety technology, companies can not only meet compliance requirements but also create a safer working environment that enhances overall productivity.

Illustrative image related to types of fork lifts

Strategic Material Selection Guide for types of fork lifts

When selecting materials for the construction of forklifts, various factors such as performance, durability, and cost-effectiveness come into play. Understanding these materials can significantly influence the decision-making process for international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. Here, we analyze four common materials used in forklift manufacturing: steel, aluminum, composite materials, and rubber.

What Are the Key Properties of Steel in Forklift Construction?

Steel is the most widely used material in forklift construction due to its strength and durability. It typically has excellent tensile strength, can withstand high temperatures, and is resistant to deformation under pressure. Steel’s corrosion resistance can be enhanced through galvanization or coating, making it suitable for various environments, including humid or corrosive conditions.

Pros and Cons: The primary advantage of steel is its high strength-to-weight ratio, which allows for the construction of robust structures capable of lifting heavy loads. However, steel can be heavy, increasing the overall weight of the forklift, which may affect maneuverability. Additionally, manufacturing complexity can be high due to the need for specialized welding techniques.

Impact on Application: Steel forklifts are ideal for heavy-duty applications in warehouses and construction sites, where strength and reliability are paramount. However, they may not be the best choice for operations in extremely corrosive environments unless treated.

Illustrative image related to types of fork lifts

Considerations for International Buyers: Buyers must ensure compliance with local standards such as ASTM in the U.S. or DIN in Germany. In regions like Saudi Arabia, where environmental conditions can be harsh, selecting a corrosion-resistant steel variant is crucial.

How Does Aluminum Compare as a Material for Forklifts?

Aluminum is increasingly being used in forklift construction due to its lightweight properties and resistance to corrosion. It has a lower density than steel, which can enhance fuel efficiency and reduce operational costs. Aluminum also has good thermal conductivity, making it suitable for applications requiring heat dissipation.

Pros and Cons: The key advantage of aluminum is its lightweight nature, which allows for easier handling and transportation. However, aluminum is generally less strong than steel, which may limit its use in heavy-duty applications. The manufacturing process can also be more complex and costly due to the need for specialized welding techniques.

Impact on Application: Aluminum forklifts are ideal for environments where weight is a critical factor, such as in aviation or food processing industries. Their corrosion resistance makes them suitable for outdoor applications, particularly in coastal areas.

Considerations for International Buyers: Buyers should be aware of the specific aluminum grades and their compliance with international standards. In Europe, for example, EN standards govern aluminum use, while in the Middle East, buyers may prefer materials that withstand high temperatures.

What Role Do Composite Materials Play in Forklift Design?

Composite materials, including fiberglass and carbon fiber, are becoming popular in forklift design due to their high strength-to-weight ratio and resistance to corrosion. These materials can be engineered to provide specific performance characteristics, such as flexibility and impact resistance.

Pros and Cons: The main advantage of composites is their lightweight nature, which can significantly enhance the forklift’s efficiency. However, they are often more expensive than traditional materials and can require specialized manufacturing processes, which can complicate production.

Impact on Application: Composite materials are particularly beneficial in specialized applications where weight savings are critical, such as in aerospace or automotive industries. They also perform well in corrosive environments, making them suitable for chemical handling.

Illustrative image related to types of fork lifts

Considerations for International Buyers: Buyers should consider the availability of composite materials in their region and ensure that suppliers meet necessary quality standards. In regions like South America, where the market for advanced materials is still developing, sourcing can be a challenge.

How Important Is Rubber in Forklift Operations?

Rubber is primarily used in forklift tires and grips, providing essential traction and shock absorption. The properties of rubber can vary significantly based on its formulation, affecting its durability and performance under different conditions.

Pros and Cons: The key advantage of rubber is its ability to provide excellent grip and stability, essential for safe operations. However, rubber can wear down quickly in harsh conditions, requiring frequent replacement, which can increase operational costs.

Impact on Application: Rubber tires are crucial for both indoor and outdoor forklifts. They are particularly important in environments with uneven surfaces, such as construction sites, where stability is vital.

Illustrative image related to types of fork lifts

Considerations for International Buyers: Buyers should ensure that the rubber used in tires meets local safety and performance standards. In Europe, for instance, compliance with EN standards is essential for safety and performance.

Summary Table

| Material | Typical Use Case for types of fork lifts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty lifting in warehouses | High strength-to-weight ratio | Heavy, affecting maneuverability | Medium |

| Aluminum | Lightweight applications in food processing | Lightweight, corrosion-resistant | Less strong than steel | High |

| Composite Materials | Specialized applications in aerospace | High strength-to-weight ratio | Expensive, complex manufacturing | High |

| Rubber | Tires and grips for stability | Excellent grip and shock absorption | Wears down quickly | Medium |

This strategic material selection guide provides essential insights for B2B buyers looking to optimize their forklift choices based on material properties, performance requirements, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for types of fork lifts

What Are the Main Stages of Forklift Manufacturing Processes?

The manufacturing process of forklifts is a complex operation that involves several stages, each critical to ensuring the final product meets industry standards for safety, reliability, and performance.

Material Preparation: What Materials Are Used in Forklift Manufacturing?

The first step in the manufacturing process is material preparation, where raw materials are sourced and prepared for production. Forklifts typically use high-strength steel and aluminum for their frames and components due to their durability and lightweight properties. Additionally, components such as hydraulic systems, electrical systems, and tires must also be procured, often from specialized suppliers.

Quality assurance begins at this stage, as suppliers must meet specific material standards to ensure strength and longevity. Manufacturers may require certifications from suppliers to validate the quality of materials used.

How Are Forklifts Formed and Assembled?

After material preparation, the next phase is forming, which involves cutting, welding, and shaping the raw materials into components. Advanced techniques such as CNC machining and robotic welding are employed to ensure precision and consistency. For instance, the frame of the forklift is welded together using automated systems that ensure uniformity and strength.

Once the components are formed, the assembly process begins. This stage involves integrating various parts such as the engine, transmission, hydraulic systems, and electrical wiring. Manufacturers often use lean manufacturing principles to optimize efficiency during assembly, reducing waste and ensuring that each forklift is built to specification.

Illustrative image related to types of fork lifts

What Finishing Techniques Are Applied to Forklifts?

Finishing is the final stage of manufacturing, where forklifts undergo painting, coating, and final inspections. A durable coating is applied to protect against corrosion and wear, which is particularly important for forklifts operating in harsh environments.

Quality control checkpoints are established during this phase to ensure that each forklift meets the desired aesthetic and functional standards. This includes visual inspections for paint quality and adherence to design specifications.

What Quality Assurance Standards Are Relevant for Forklift Manufacturing?

Quality assurance is paramount in forklift manufacturing, especially for B2B buyers who rely on these machines for safety and efficiency in their operations. Several international and industry-specific standards govern forklift manufacturing.

Which International Standards Should Buyers Be Aware Of?

ISO 9001 is a widely recognized quality management standard that provides a framework for manufacturers to ensure consistent quality and customer satisfaction. Compliance with ISO 9001 indicates that a manufacturer has implemented effective quality management systems.

In addition to ISO standards, forklift manufacturers may also adhere to CE marking requirements for products sold in Europe, which ensures compliance with health, safety, and environmental protection standards. For heavy-duty applications, compliance with the American Petroleum Institute (API) standards may also be necessary, particularly for forklifts used in oil and gas industries.

Illustrative image related to types of fork lifts

What Are the Key Quality Control Checkpoints in Forklift Manufacturing?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to ensure that each forklift meets established standards. These checkpoints typically include:

Incoming Quality Control (IQC)

At the IQC stage, incoming materials and components are inspected for compliance with specifications. This includes testing the strength of metals and ensuring that electrical components meet performance standards.

In-Process Quality Control (IPQC)

During the manufacturing process, IPQC ensures that assembly operations meet quality standards. This can involve regular inspections of welds, assembly alignment, and the functionality of hydraulic systems.

Final Quality Control (FQC)

The FQC stage involves a comprehensive inspection of the finished forklift. This includes testing operational capabilities, safety features, and load-bearing capacities. Forklifts may undergo performance testing, where they are loaded to their maximum capacity to ensure they operate safely and effectively.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are several actionable steps:

What Steps Should Buyers Take for Supplier Audits?

Conducting regular supplier audits is an effective way to assess a manufacturer’s quality assurance practices. Buyers should request access to the manufacturer’s quality management system documentation, including records of past audits, certifications, and compliance with industry standards.

Illustrative image related to types of fork lifts

How Important Are Quality Reports and Certifications?

Requesting quality reports and certifications from manufacturers can also provide insight into their commitment to quality. These documents should detail compliance with ISO 9001, CE marking, and any relevant industry-specific standards.

What Role Do Third-Party Inspections Play?

Engaging third-party inspection services can provide an unbiased assessment of the manufacturer’s quality control processes. These inspections can be particularly beneficial before finalizing contracts, as they ensure that the forklifts meet the buyer’s specifications and industry standards.

What Are the QC and Certification Nuances for International Buyers?

International buyers must be aware of specific nuances when dealing with suppliers from different regions. For instance, while European standards like CE marking are stringent, other regions may have different requirements.

How Do Regional Standards Impact Forklift Quality?

Buyers in the Middle East and Africa may encounter varying standards and regulations. It is essential to understand local compliance requirements and ensure that the supplier’s products adhere to both international and regional standards.

Why Is Supplier Communication Essential?

Effective communication with suppliers regarding quality expectations is crucial. B2B buyers should engage in discussions about the manufacturer’s quality assurance processes, asking specific questions about their methodologies and certifications to ensure alignment with their operational needs.

Illustrative image related to types of fork lifts

By understanding the manufacturing processes and quality assurance standards, B2B buyers can make informed decisions when selecting forklift suppliers, ensuring that they invest in reliable and safe equipment that meets their operational demands.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘types of fork lifts’

Introduction

This practical sourcing guide serves as a comprehensive checklist for B2B buyers looking to procure various types of forklifts. Understanding the specific requirements and nuances of forklift selection is vital for optimizing operational efficiency and ensuring safety in material handling. This checklist will guide you through the essential steps to make an informed purchasing decision.

Step 1: Identify Your Operational Needs

Begin by assessing the specific material handling tasks your business requires. Different types of forklifts serve various purposes, such as warehouse operations, outdoor construction, or handling heavy loads.

- Consider load capacity: Determine the maximum weight you need to lift.

- Assess environment: Identify whether operations will be indoors or outdoors, which influences the type of forklift suitable for your needs.

Step 2: Define Your Technical Specifications

Establish clear technical specifications to ensure compatibility with your operational environment. This step is crucial for selecting a forklift that meets both your current and future needs.

- Forklift type: Decide between electric, diesel, or propane options based on your operational setting.

- Maneuverability requirements: Consider dimensions, turning radius, and lift height to ensure the forklift can navigate your workspace effectively.

Step 3: Evaluate Potential Suppliers

Thoroughly vet suppliers to ensure they can provide quality equipment and reliable service. This assessment is critical to avoid potential pitfalls in your procurement process.

- Request documentation: Ask for company profiles, case studies, and references from similar industries.

- Check certifications: Ensure suppliers comply with relevant safety and quality standards, such as ISO certifications.

Step 4: Compare Forklift Brands and Models

Research various forklift brands and models that align with your defined specifications. Understanding the strengths and weaknesses of each brand can help you make an informed choice.

- Read reviews: Look for customer feedback and industry expert reviews to gauge performance and reliability.

- Evaluate warranty options: A solid warranty can provide peace of mind and protect your investment.

Step 5: Assess Total Cost of Ownership (TCO)

Beyond the initial purchase price, consider the total cost of ownership, which includes maintenance, fuel, and insurance costs. This analysis is essential for budgeting and long-term planning.

- Maintenance costs: Research typical service intervals and costs associated with each forklift type.

- Operational efficiency: Evaluate the fuel efficiency and potential downtime to understand the overall impact on your bottom line.

Step 6: Conduct a Trial or Demonstration

If possible, arrange for a trial or demonstration of the forklift models you are considering. This hands-on experience can provide valuable insights into the forklift’s operation and suitability for your needs.

- Test performance: Evaluate lifting capabilities, maneuverability, and operator comfort during the demonstration.

- Engage operators: Involve your team in the trial to gather feedback from those who will be using the equipment.

Step 7: Finalize Purchase and Negotiate Terms

Once you’ve selected the appropriate forklift, finalize the purchase and negotiate favorable terms. This step ensures you secure the best deal while maintaining flexibility for future needs.

- Review financing options: Explore leasing versus purchasing to determine the best financial strategy for your business.

- Negotiate service agreements: Ensure that maintenance and service support are included in the purchase agreement for long-term reliability.

By following this checklist, B2B buyers can navigate the complexities of forklift procurement with confidence, ensuring they select the most suitable equipment for their operational needs.

Comprehensive Cost and Pricing Analysis for types of fork lifts Sourcing

When sourcing forklifts, understanding the comprehensive cost structure is vital for making informed purchasing decisions. The costs associated with forklifts can be broken down into several key components, each influencing the overall price.

What Are the Main Cost Components in Forklift Sourcing?

-

Materials: The primary materials in forklift manufacturing include steel for the frame, rubber for tires, and various electrical components for electric models. The quality of these materials significantly affects the cost. Higher-grade materials may lead to better performance and longevity, impacting the Total Cost of Ownership (TCO).

-

Labor: Labor costs encompass the wages paid to skilled workers involved in the assembly and production of forklifts. Regions with higher labor costs will see increased pricing, while countries with lower labor costs may offer more competitive pricing.

-

Manufacturing Overhead: This includes costs associated with factory operations, such as utilities, equipment maintenance, and facility management. Efficient production processes can help lower these costs, which can be a negotiating point for buyers.

-

Tooling: Specialized tools and equipment used in the manufacturing process can add to the initial costs. Custom tooling for unique forklift designs or specifications may also influence the final price.

-

Quality Control (QC): Rigorous QC processes ensure that forklifts meet safety and performance standards. Investing in quality control can increase upfront costs but may reduce long-term expenses associated with repairs and maintenance.

-

Logistics: Transportation costs for delivering forklifts to the buyer’s location vary based on distance, shipping method, and any import tariffs. International buyers should consider logistics when evaluating total costs.

-

Margin: Suppliers typically add a profit margin to their costs, which can vary significantly based on market demand, brand reputation, and competition. Established brands may command higher margins due to perceived reliability and support.

What Influences Forklift Pricing in B2B Transactions?

Several factors can influence the pricing of forklifts, particularly in international markets:

-

Volume/MOQ: Bulk purchases often lead to lower per-unit costs. Suppliers are more inclined to offer discounts for larger orders, making it essential for buyers to assess their needs accurately.

-

Specifications and Customization: Custom features or specifications can increase costs. Buyers should weigh the benefits of customization against budget constraints.

-

Quality and Certifications: Forklifts that comply with international safety and environmental standards may carry a premium price. Buyers in regions with strict regulations should prioritize certified models to avoid future compliance costs.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may offer warranties and post-sale support, which can justify a higher price point.

-

Incoterms: Understanding the terms of shipping and delivery (Incoterms) is crucial for international buyers. Costs can vary significantly based on the agreed terms, affecting overall pricing.

What Are Effective Buyer Tips for Forklift Sourcing?

-

Negotiate: Leverage your purchasing volume and long-term business potential to negotiate better pricing. Suppliers are often open to discussions, especially for bulk orders.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also maintenance, fuel efficiency, and potential downtime costs. A more expensive forklift may offer lower operational costs in the long run.

-

Research Local Regulations: Buyers from regions like Africa, South America, the Middle East, and Europe should familiarize themselves with local regulations and standards, as these can influence the types of forklifts available and their pricing.

-

Seek Multiple Quotes: Obtaining quotes from various suppliers can help identify competitive pricing and reveal market trends. This information can provide leverage during negotiations.

Disclaimer on Indicative Prices

It is important to note that forklift prices can fluctuate based on market conditions, currency exchange rates, and supplier capabilities. Always seek updated quotes and conduct thorough research to ensure you are making an informed decision.

Alternatives Analysis: Comparing types of fork lifts With Other Solutions

Exploring Alternatives to Forklifts for Material Handling Solutions

When it comes to material handling, businesses often consider various solutions that can effectively meet their operational needs. Forklifts are a well-known option, but there are alternative technologies and methods that can achieve similar goals. Understanding these alternatives is crucial for B2B buyers aiming to optimize their logistics and operations.

| Comparison Aspect | Types of Fork Lifts | Automated Guided Vehicles (AGVs) | Hand Trucks & Pallet Jacks |

|---|---|---|---|

| Performance | High load capacity, versatile for various tasks | Efficient for repetitive tasks, limited load capacity | Best for small loads, manual handling |

| Cost | Higher initial investment and maintenance costs | Moderate initial investment, low operating costs | Low cost, minimal maintenance required |

| Ease of Implementation | Requires operator training and safety protocols | Requires setup and programming, but less operator training | Easy to use with no formal training required |

| Maintenance | Regular maintenance needed for longevity | Minimal maintenance, mostly software updates | Low maintenance; occasional wheel checks |

| Best Use Case | Ideal for warehouses and construction sites | Best for automated environments like manufacturing | Effective for small deliveries and tight spaces |

What Are the Advantages and Disadvantages of Automated Guided Vehicles (AGVs)?

Automated Guided Vehicles (AGVs) are a modern alternative to traditional forklifts, especially in environments where automation is feasible. These vehicles navigate autonomously along predefined paths, making them excellent for repetitive tasks such as transporting materials within a facility.

Pros: AGVs can operate continuously without fatigue, reducing labor costs and increasing efficiency. They are particularly advantageous in high-volume operations where consistency is key.

Cons: However, AGVs come with a moderate initial investment and may require a more complex setup, including infrastructure modifications. They are not suitable for all environments, particularly those with unpredictable layouts or where human interaction is necessary.

How Do Hand Trucks and Pallet Jacks Compare to Forklifts?

Hand trucks and pallet jacks represent a more manual approach to material handling. These tools are simple yet effective for transporting smaller loads over short distances, making them ideal for retail or small warehouse environments.

Pros: Their low cost and minimal maintenance requirements make them accessible for small businesses or operations that do not require heavy lifting. They are easy to maneuver in tight spaces, allowing for flexibility in various applications.

Illustrative image related to types of fork lifts

Cons: On the downside, hand trucks and pallet jacks are limited in load capacity and require physical effort from operators, which can lead to fatigue and potential injuries over time. They also lack the advanced capabilities of forklifts in terms of lifting height and weight.

How Can B2B Buyers Choose the Right Material Handling Solution?

Selecting the right material handling solution depends on several factors, including load requirements, operational environment, budget, and employee capabilities. Forklifts are optimal for heavy-duty tasks and large-scale operations, while AGVs may offer improved efficiency in automated settings. For smaller businesses or those with limited lifting needs, hand trucks and pallet jacks provide a cost-effective alternative.

Ultimately, B2B buyers should evaluate their specific operational needs and consider the long-term implications of each solution. Conducting a thorough cost-benefit analysis and consulting with industry experts can help ensure the chosen solution aligns with business goals while enhancing productivity and safety in the workplace.

Essential Technical Properties and Trade Terminology for types of fork lifts

What Are the Key Technical Properties of Forklifts?

When selecting a forklift, understanding its technical specifications is crucial for B2B buyers, especially when considering the demands of various operational environments. Here are some essential properties to keep in mind:

-

Load Capacity

This specification indicates the maximum weight a forklift can safely lift. Typical capacities range from 3,000 lbs for smaller models to over 100,000 lbs for heavy-duty forklifts. Knowing the appropriate load capacity ensures safe operations and prevents equipment failure, which can lead to costly downtime and accidents. -

Lift Height

The lift height is the maximum vertical distance a forklift can raise its load. Forklifts are designed for various applications, from warehouse stacking (which may require heights of up to 30 feet) to outdoor construction (which might need only a few feet). Selecting the right lift height is vital for efficiency in storage and material handling tasks. -

Turning Radius

This measurement defines the smallest circular turn a forklift can make. Smaller turning radii are beneficial in tight spaces, such as warehouses with narrow aisles. Understanding this property helps B2B buyers select forklifts that can maneuver effectively in their specific work environments. -

Power Source

Forklifts can be powered by different sources: electric, diesel, or propane. Electric forklifts are ideal for indoor use due to their low emissions, while diesel models are suited for outdoor applications requiring high power. Choosing the right power source aligns with operational needs and environmental considerations. -

Mast Type

The mast is the vertical assembly that raises and lowers the load. There are various types, including standard, duplex, and triplex masts. Each type has different capabilities regarding lift height and visibility. Understanding mast types helps in selecting a forklift that meets specific operational needs. -

Tire Type

Forklift tires can be solid, pneumatic, or cushion, each suited for different environments. Solid tires are durable and ideal for indoor use, while pneumatic tires offer better shock absorption for outdoor terrains. Selecting the right tire type is crucial for performance, safety, and longevity.

What Are Common Trade Terms Related to Forklifts?

Familiarity with industry terminology can streamline the purchasing process and enhance communication with suppliers. Here are several key terms relevant to forklift procurement:

Illustrative image related to types of fork lifts

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM products is essential for buyers seeking reliable replacement parts or equipment that meets original specifications. -

MOQ (Minimum Order Quantity)

MOQ represents the minimum number of units a supplier is willing to sell. This term is vital for B2B buyers to know, as it affects inventory management and pricing negotiations. -

RFQ (Request for Quotation)

An RFQ is a formal document requesting pricing and terms from suppliers for specific products. This process helps buyers compare options and negotiate better deals, ensuring they receive the best value for their investment. -

Incoterms (International Commercial Terms)

These are standardized terms used in international trade to clarify the responsibilities of buyers and sellers. Understanding Incoterms helps B2B buyers navigate shipping logistics, costs, and risks associated with transporting forklifts across borders. -

Service Agreement

This is a contract outlining the maintenance and service terms for equipment. Buyers should ensure that service agreements are in place to avoid unexpected downtime and ensure the longevity of their forklifts. -

Warranty

A warranty is a promise from the manufacturer regarding the repair or replacement of faulty products within a specific time frame. Understanding warranty terms is essential for buyers to ensure they are covered against defects and can plan for long-term operational costs.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when selecting the right forklifts for their operations.

Navigating Market Dynamics and Sourcing Trends in the types of fork lifts Sector

What are the Current Market Dynamics and Key Trends in the Forklift Sector?

The global forklift market is experiencing significant transformation driven by technological advancements, evolving consumer needs, and economic fluctuations. Key trends include the increasing demand for electric forklifts, propelled by their lower operational costs and environmental benefits. In regions like Europe, particularly Germany, regulatory frameworks are pushing for greener technologies, fostering an accelerated shift toward battery-operated models. Additionally, automation in material handling is gaining traction, with the integration of robotics and AI enhancing operational efficiency and safety. This trend is particularly relevant for international B2B buyers in Africa and South America, where logistics and supply chain efficiency are paramount for competitive advantage.

Emerging technologies such as telematics and IoT are also becoming integral in forklift operations, allowing businesses to monitor fleet performance and optimize maintenance schedules. This data-driven approach is essential for buyers looking to maximize ROI on their equipment investments. Moreover, as the demand for e-commerce grows, the need for versatile forklifts that can operate in confined spaces—such as warehouse and order picker models—is becoming increasingly critical.

Illustrative image related to types of fork lifts

How is Sustainability and Ethical Sourcing Impacting Forklift Procurement?

Sustainability is at the forefront of procurement strategies for many B2B buyers in the forklift sector. The environmental impact of traditional fuel-powered forklifts has prompted a shift toward more sustainable options, such as electric and hybrid models. These alternatives not only reduce greenhouse gas emissions but also align with the global push for corporate responsibility and sustainable practices.

Ethical sourcing is becoming essential, especially for buyers in regions with stringent environmental regulations. Companies are increasingly seeking suppliers who prioritize ethical supply chains, ensuring that materials used in forklift manufacturing are sourced responsibly. Certifications such as ISO 14001 for environmental management systems and the use of recycled materials are becoming critical factors in the decision-making process.

Furthermore, businesses are encouraged to evaluate their suppliers based on their commitment to sustainability, which can enhance brand reputation and customer loyalty. As the market evolves, buyers who prioritize sustainability will likely gain a competitive edge in their respective industries.

Illustrative image related to types of fork lifts

What is the Brief Evolution of Forklift Technology and Its Relevance Today?

The forklift has undergone significant evolution since its inception in the early 20th century. Originally designed for manual material handling, the introduction of electric power in the 1950s revolutionized operations, allowing for greater efficiency and reduced labor costs. Over the decades, advancements in hydraulic systems and the introduction of safety features have further enhanced the functionality and safety of forklifts.

In recent years, the development of smart technologies, such as AI and IoT, has transformed forklifts into intelligent machines capable of real-time data analysis. This evolution is particularly relevant for B2B buyers who are looking to invest in equipment that not only meets current operational demands but also aligns with future technological trends. Understanding the historical context of forklifts can inform strategic purchasing decisions, ensuring that businesses are well-equipped to adapt to the ever-changing landscape of material handling.

Frequently Asked Questions (FAQs) for B2B Buyers of types of fork lifts

-

How do I determine the right type of forklift for my business needs?

Selecting the right forklift involves assessing your specific operational requirements. Consider factors such as the types of loads you’ll be handling, the environment (indoor vs. outdoor), and the space constraints of your facility. For example, if you need to navigate narrow aisles, a reach truck or walkie stacker may be ideal. Additionally, evaluate the lifting capacity required for your operations and whether you need a specialized forklift, such as a telehandler for high-reach applications. -

What is the best forklift for warehouse operations?

For warehouse operations, counterbalance forklifts and reach trucks are typically the best choices. Counterbalance forklifts offer versatility in lifting and maneuvering loads, making them suitable for various tasks. Reach trucks, on the other hand, excel in high-density storage environments where maximizing vertical space is critical. Both options should be evaluated based on load capacity, aisle width, and the specific tasks you need to perform. -

What are the key factors to consider when vetting forklift suppliers?

When vetting forklift suppliers, prioritize their industry reputation, experience, and customer service history. Check for certifications and compliance with international safety standards. Additionally, inquire about their warranty policies, parts availability, and after-sales support. Request references from previous clients, especially those in similar industries or regions, to gain insights into their reliability and service quality. -

What customization options are available for forklifts?

Forklift customization options can vary widely among manufacturers. Common customizations include modifications for specific load types, safety features like enhanced visibility or guards, and ergonomic adjustments for operator comfort. Additionally, you can choose different attachments, such as forks, clamps, or lifting platforms. Discuss your specific needs with potential suppliers to determine what customization options they offer and how they can accommodate your operational requirements. -

What is the typical minimum order quantity (MOQ) for forklifts?

The minimum order quantity for forklifts can vary significantly depending on the manufacturer and your location. Some suppliers may offer single units, while others might have MOQs ranging from 2 to 5 units or more to ensure cost-effectiveness in production and shipping. It’s crucial to communicate your needs with suppliers and explore potential flexibility in their MOQ policies, especially if you are a smaller business or a new buyer. -

What payment terms should I expect when purchasing forklifts internationally?

Payment terms for international forklift purchases typically include options such as advance payment, letters of credit, or staggered payments based on delivery milestones. It’s essential to negotiate terms that protect both parties, ensuring you receive the equipment as agreed upon. Be aware of currency exchange risks and factor in shipping costs, customs duties, and any additional fees when calculating your total investment. -

How can I ensure quality assurance (QA) when sourcing forklifts?

To ensure quality assurance when sourcing forklifts, establish clear criteria for inspection and testing before purchase. Request detailed specifications and certifications from the manufacturer, and consider third-party inspections if necessary. It’s also advisable to visit the supplier’s facility, if feasible, to observe their production processes. Additionally, check for warranties and service agreements that outline the supplier’s commitment to quality and support. -

What logistics considerations should I keep in mind when importing forklifts?

When importing forklifts, consider logistics factors such as shipping methods, lead times, and customs clearance processes. Choose a reliable freight forwarder familiar with heavy equipment transport to navigate the complexities of international shipping. Additionally, factor in any import regulations specific to your country, including safety certifications and documentation requirements. Proper planning will help ensure timely delivery and minimize potential delays in your supply chain.

Top 3 Types Of Fork Lifts Manufacturers & Suppliers List

1. Concentric USA – Forklift Types Explained

Domain: blog.concentricusa.com

Registered: 2019 (6 years)

Introduction: Forklift Types: 1. Counterbalanced Lift (Type 1) – Uses counterweights for balance, suitable for various loads. 2. Stand-Up Lift (Type 2) – Designed for speed and maneuverability, ideal for narrow aisles and quick tasks. 3. Trolley Lift – Operated by pushing, features a ‘T’ handle, suitable for tight spaces and heavy loads. Forklift Sizes: 1. 20 Ton Forklifts – Load Capacity: 2,000 – 15,000 lbs, e…

2. United Rentals – Warehouse Forklift Rentals

Domain: unitedrentals.com

Registered: 1997 (28 years)

Introduction: Warehouse Forklift Rentals – Electric, Gas/LP & Diesel Forklifts. United Rentals offers a large fleet of warehouse forklift rentals including lift trucks, pallet stackers, and narrow aisle forklifts with various lift capacities, tire types, and fuel types for most indoor applications. Exclusive online rates available through the website or app. Cat Class Code: 231-0500. Example: 1,000-4,000 lb. El…

3. Crown – Electric Counterbalance Forklifts

Domain: crown.com

Registered: 1998 (27 years)

Introduction: New Forklifts and Lift Trucks For Sale | Crown Equipment. Key products include: 1. Electric Counterbalance Forklifts: RC 5700 (Capacity: Up to 4,000 lb, Lift Height: 276 in), SC 5700/6200 (Capacity: Up to 4,000 lb, Lift Height: 295 in), FC 5700 (Capacity: Up to 6,500 lb, Lift Height: 312 in), CB 25/35 (Capacity: Up to 7,000 lb, Lift Height: 276 in), CB 40/50 (Capacity: Up to 10,000 lb, Lift Height…

Strategic Sourcing Conclusion and Outlook for types of fork lifts

In the evolving landscape of material handling, the strategic sourcing of forklifts is essential for international B2B buyers seeking efficiency and reliability. With a diverse range of types—from counterbalance and telehandlers to rough terrain forklifts—each model serves specific operational needs, ensuring that businesses can optimize their logistics and warehousing processes. Understanding the unique capabilities and applications of each forklift type allows buyers to make informed decisions that align with their operational requirements and budget constraints.

Moreover, the importance of considering local market conditions and regulatory standards cannot be overstated, especially for buyers in regions like Africa, South America, the Middle East, and Europe. Leveraging strategic sourcing practices can facilitate better supplier relationships and ensure access to the latest technology and equipment that enhance productivity.

As we look to the future, the demand for advanced material handling solutions will likely increase, making it imperative for companies to stay ahead of industry trends and innovations. By prioritizing strategic sourcing, businesses can not only elevate their operational efficiency but also position themselves competitively in the global market. Take the next step in optimizing your supply chain—evaluate your forklift options today and empower your operations for tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to types of fork lifts