Tuning Fork Level Switch: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for tuning fork level switch

In today’s fast-paced industrial landscape, sourcing reliable tuning fork level switches is a critical challenge for businesses aiming to ensure precision and efficiency in level measurement applications. These devices, known for their high accuracy and low maintenance requirements, play a pivotal role in various sectors, including chemical processing, food and beverage, and water treatment. This guide serves as a comprehensive resource for international B2B buyers, especially those operating in Africa, South America, the Middle East, and Europe, such as Vietnam and Germany.

Within these pages, you will find detailed insights into the diverse types of tuning fork level switches available in the market, their specific applications, and essential criteria for supplier vetting. We delve into factors influencing pricing, helping you make informed purchasing decisions that align with your operational needs and budget constraints. By equipping you with the knowledge to navigate this global market, this guide empowers you to select the most suitable tuning fork level switches for your business, ensuring optimal performance and compliance with industry standards. Whether you are looking for advanced features like wireless capabilities or specific certifications for hazardous environments, our insights will streamline your decision-making process and enhance your procurement strategy.

Understanding tuning fork level switch Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Mini Tuning Fork Level Switch | Compact design, ideal for tight spaces | Powder monitoring, small tanks | Pros: Space-saving, versatile; Cons: Limited range. |

| Standard Tuning Fork Level Switch | Fixed length, suitable for various liquids | Chemical processing, water treatment | Pros: Reliable for liquids; Cons: May require calibration. |

| Dual Tuning Fork Level Switch | Two forks for enhanced sensitivity and reliability | High-precision applications | Pros: High accuracy, suitable for challenging environments; Cons: More complex installation. |

| Wireless Tuning Fork Level Switch | Wireless communication, easy installation | Remote monitoring in inaccessible locations | Pros: Reduced installation costs; Cons: Battery dependency. |

| Hygienic Tuning Fork Level Switch | Compliance with hygiene standards (3-A, EHEDG) | Food and beverage, pharmaceutical sectors | Pros: Ensures safety and compliance; Cons: Higher upfront costs. |

What are the characteristics of a Mini Tuning Fork Level Switch?

The Mini Tuning Fork Level Switch is designed for compact applications where space is at a premium. Its small footprint makes it ideal for monitoring powder levels in small tanks or containers. This type is particularly suitable for B2B buyers in industries such as food processing or pharmaceuticals, where precise level detection is crucial. When purchasing, consider the switch’s compatibility with the specific media and the operating environment, as its limited range may not suit all applications.

How does a Standard Tuning Fork Level Switch perform in various applications?

Standard Tuning Fork Level Switches are versatile devices used for detecting liquid levels in a wide range of industries, including chemical processing and water treatment. They operate on a fixed length principle, providing reliable performance for various liquid types. Buyers should evaluate the switch’s calibration requirements and ensure it meets the operational needs of their processes. The reliability and accuracy of these switches make them a popular choice for businesses requiring consistent level monitoring.

What advantages does a Dual Tuning Fork Level Switch offer?

The Dual Tuning Fork Level Switch features two vibrating forks that enhance sensitivity and reliability, making it suitable for high-precision applications. This type is ideal for industries where accurate level detection is critical, such as in the chemical and petrochemical sectors. When considering this option, buyers should assess the installation complexity and ensure that the additional sensitivity aligns with their operational requirements. While it offers high accuracy, the complexity may necessitate specialized installation and maintenance.

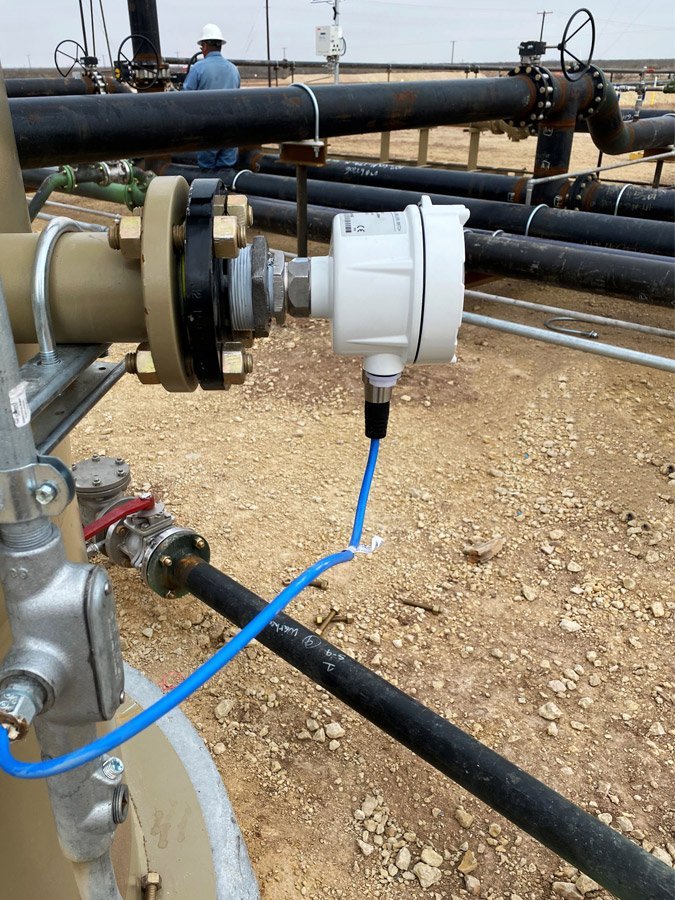

Illustrative image related to tuning fork level switch

Why choose a Wireless Tuning Fork Level Switch for remote monitoring?

Wireless Tuning Fork Level Switches eliminate the need for extensive wiring, making them perfect for remote monitoring in locations that are difficult to access. This feature reduces installation costs and time, appealing to industries such as oil and gas or any sector with extensive infrastructure. Buyers should consider the battery life and maintenance implications, as reliance on batteries can affect long-term operational costs. The convenience of wireless technology can significantly enhance operational efficiency.

What makes a Hygienic Tuning Fork Level Switch essential for certain industries?

Hygienic Tuning Fork Level Switches are specifically designed to meet stringent hygiene standards, making them essential in the food and beverage or pharmaceutical sectors. Compliance with certifications like 3-A and EHEDG ensures that these switches maintain product safety and integrity. Buyers should weigh the benefits of enhanced safety and compliance against the higher upfront costs associated with these specialized devices. Investing in hygienic switches can prevent costly recalls and ensure adherence to regulatory requirements.

Key Industrial Applications of tuning fork level switch

| Industry/Sector | Specific Application of Tuning Fork Level Switch | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Monitoring liquid levels in fermentation tanks | Ensures optimal fermentation processes, preventing overflow | Compliance with hygiene standards (FDA, EHEDG), material selection for sanitary applications |

| Chemical Processing | Level detection of viscous liquids in reactors | Enhances safety by preventing overflows and ensuring accurate dosing | Compatibility with aggressive chemicals, temperature ratings, and certification for hazardous environments |

| Oil and Gas | Overfill prevention in storage tanks | Reduces spill risks and environmental impact, ensuring compliance with regulations | Robustness against harsh conditions, including temperature and pressure ratings |

| Water and Wastewater | Monitoring sludge levels in treatment plants | Improves efficiency in waste management, reducing downtime | Resistance to corrosion, reliability in harsh environments, and ease of maintenance |

| Pharmaceuticals | Liquid level monitoring in sterile environments | Maintains process integrity and compliance with strict regulations | Material certifications, reliability in critical processes, and low maintenance needs |

How Are Tuning Fork Level Switches Used in the Food and Beverage Industry?

In the food and beverage sector, tuning fork level switches are crucial for monitoring liquid levels in fermentation tanks. These devices provide precise level detection, ensuring that fermentation processes occur without overflow, which can lead to product loss and contamination. Buyers from this industry must prioritize switches that comply with hygiene standards such as FDA and EHEDG, ensuring that materials are suitable for sanitary applications.

Illustrative image related to tuning fork level switch

What Role Do Tuning Fork Level Switches Play in Chemical Processing?

Within chemical processing, tuning fork level switches are employed to detect levels of viscous liquids in reactors. Their reliable performance helps prevent overflows, thereby enhancing safety and ensuring accurate dosing of materials. Buyers in this sector should focus on the compatibility of these switches with aggressive chemicals and their certification for hazardous environments, as well as their temperature ratings to withstand demanding conditions.

How Are Tuning Fork Level Switches Essential for Oil and Gas Operations?

In the oil and gas industry, tuning fork level switches serve a vital role in overfill prevention for storage tanks. By accurately monitoring liquid levels, these devices help mitigate spill risks, thereby ensuring compliance with environmental regulations. When sourcing these switches, businesses need to consider their robustness against harsh conditions, including temperature and pressure ratings, to guarantee reliable operation in challenging environments.

Why Are Tuning Fork Level Switches Important in Water and Wastewater Management?

In water and wastewater treatment plants, tuning fork level switches are used to monitor sludge levels effectively. Their ability to provide consistent level detection improves efficiency in waste management processes, minimizing downtime associated with overflow incidents. Buyers should ensure that the switches are resistant to corrosion and reliable under harsh environmental conditions, as well as easy to maintain for long-term use.

How Do Tuning Fork Level Switches Support Pharmaceutical Manufacturing?

Tuning fork level switches find critical application in pharmaceutical manufacturing, particularly for monitoring liquid levels in sterile environments. These devices help maintain process integrity and compliance with stringent industry regulations. When sourcing for this application, buyers should look for switches with relevant material certifications, high reliability in critical processes, and low maintenance requirements to ensure continuous operation.

3 Common User Pain Points for ‘tuning fork level switch’ & Their Solutions

Scenario 1: Difficulty in Ensuring Accurate Level Detection in Challenging Environments

The Problem: B2B buyers in industries such as chemicals or food processing often face the challenge of ensuring accurate level detection in extreme conditions. High temperatures, pressure fluctuations, and the presence of vapor can interfere with the performance of standard level sensors, leading to false readings and operational disruptions. For instance, a chemical plant may require a reliable level switch to prevent overflows in tanks that handle corrosive liquids, yet existing solutions may fail under such demanding conditions, risking both safety and product quality.

The Solution: To address these challenges, buyers should consider investing in robust tuning fork level switches specifically designed for high-stress environments. These devices often feature materials like 316 stainless steel or specialized coatings to withstand corrosive substances and extreme temperatures. When sourcing these devices, ensure that they are certified for the specific conditions of your application, such as compliance with FDA or 3-A standards for hygienic applications. Additionally, utilizing tuning fork switches with adjustable sensitivity can help fine-tune performance based on the medium being measured, enhancing accuracy and reliability. Regular maintenance checks and calibration, although minimal with these devices, should also be scheduled to ensure sustained performance and reliability.

Scenario 2: Challenges in Integrating Level Switches into Existing Systems

The Problem: Many businesses experience frustration when trying to integrate new level detection technologies into their existing operational systems. Compatibility issues can arise, leading to unexpected downtime and extra costs. For example, a manufacturing facility may have an outdated control system that is not easily compatible with modern tuning fork switches, causing delays in installation and operational inefficiencies.

The Solution: To mitigate these integration challenges, buyers should prioritize choosing tuning fork level switches with versatile connectivity options. Look for devices that offer multiple output types, such as relay, analog, or digital signals, allowing for seamless integration into diverse control systems. Additionally, selecting products that support communication protocols like HART or Modbus can simplify connectivity and provide greater flexibility in data management. Before finalizing a purchase, engage with suppliers to discuss your specific system requirements and seek recommendations for compatible models. This proactive approach can streamline the integration process, reduce downtime, and enhance overall operational efficiency.

Scenario 3: Overlooked Maintenance and Safety Protocols

The Problem: Buyers often underestimate the importance of regular maintenance and safety checks for level detection systems, leading to potential failures and safety hazards. For instance, a company may neglect routine testing of their tuning fork level switches, resulting in undetected overfills or dry runs that could lead to equipment damage or environmental spills.

Illustrative image related to tuning fork level switch

The Solution: To combat this oversight, it is crucial for organizations to implement a structured maintenance schedule that includes regular functional tests of tuning fork level switches. Buyers should seek devices that come equipped with built-in diagnostic features, allowing for easy verification of operational integrity. Investing in models that facilitate remote monitoring and testing can also enhance safety measures, enabling operators to conduct checks without physical presence in hazardous areas. Training staff on proper maintenance practices and the significance of adhering to safety protocols will further ensure that the level detection systems operate reliably, thus safeguarding both personnel and the environment. Establishing a culture of proactive maintenance can lead to reduced risks and prolonged equipment lifespan.

Strategic Material Selection Guide for tuning fork level switch

What Are the Key Materials Used in Tuning Fork Level Switches?

When selecting materials for tuning fork level switches, it is crucial to consider the specific requirements of the application, including environmental conditions, media compatibility, and regulatory standards. Here, we analyze four common materials used in the construction of these devices: stainless steel, plastic, Hastelloy, and titanium. Each material has distinct properties, advantages, and limitations that can significantly impact performance and suitability for various applications.

How Does Stainless Steel Perform in Tuning Fork Level Switches?

Key Properties: Stainless steel, particularly grades 316 and 304, is renowned for its excellent corrosion resistance and high-temperature tolerance, typically rated up to 1000°F (537°C). It also possesses good mechanical strength and durability.

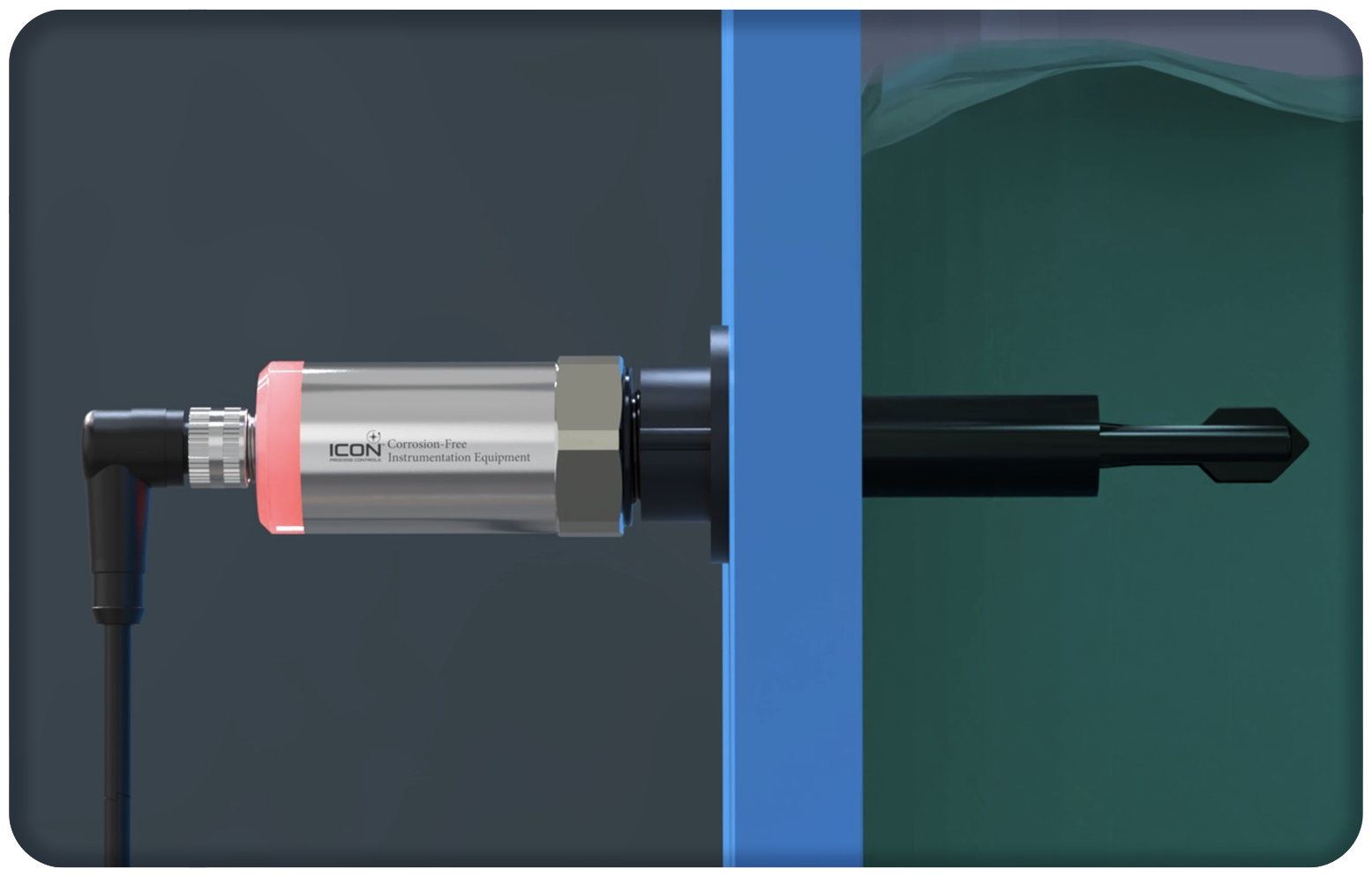

Illustrative image related to tuning fork level switch

Pros & Cons: The primary advantage of stainless steel is its robustness and resistance to corrosion, making it ideal for harsh environments, such as chemical processing and food production. However, it can be more expensive than other materials and may require specialized manufacturing processes, which can increase lead times.

Impact on Application: Stainless steel is compatible with a wide range of media, including liquids and slurries, making it versatile for various industries. Its hygienic properties also make it suitable for food and pharmaceutical applications.

International Considerations: Buyers from regions like Europe and the Middle East should ensure compliance with standards such as ASTM A240 for stainless steel. In Africa and South America, local certifications may be required, emphasizing the importance of understanding regional regulations.

What Role Does Plastic Play in Tuning Fork Level Switches?

Key Properties: Common plastics used include polyphenylene sulfide (PPS) and polyvinyl chloride (PVC), which offer good chemical resistance and can operate at moderate temperatures (typically up to 200°F or 93°C).

Pros & Cons: The main advantage of plastic is its lower cost and lightweight nature, which simplifies installation. However, plastics may not be suitable for high-pressure applications and can degrade over time when exposed to UV light or extreme temperatures.

Impact on Application: Plastic tuning fork level switches are ideal for less aggressive media, such as water or certain chemicals. However, they may not be appropriate for high-temperature or high-pressure environments.

International Considerations: Buyers should verify compliance with relevant standards such as ISO 9001 for quality management and ensure that the selected plastic meets local environmental regulations, particularly in Europe.

How Does Hastelloy Enhance Tuning Fork Level Switch Performance?

Key Properties: Hastelloy is a nickel-based alloy known for its exceptional corrosion resistance and ability to withstand extreme temperatures and pressures. It maintains integrity in highly corrosive environments, making it suitable for chemical processing applications.

Pros & Cons: The key advantage of Hastelloy is its durability and reliability in harsh conditions. However, it is significantly more expensive than stainless steel and may require specialized machining, which can complicate manufacturing.

Illustrative image related to tuning fork level switch

Impact on Application: Hastelloy is particularly effective in applications involving aggressive chemicals, such as acids and chlorides. Its robustness ensures long-term reliability, reducing maintenance costs.

International Considerations: Compliance with ASTM B575 for Hastelloy is essential for buyers in North America, while European buyers may refer to EN standards. Understanding the specific material certifications required in different regions is crucial for successful procurement.

What Advantages Does Titanium Offer for Tuning Fork Level Switches?

Key Properties: Titanium is lightweight and possesses excellent corrosion resistance, particularly in seawater and acidic environments. It can withstand temperatures up to 800°F (427°C) and is known for its strength-to-weight ratio.

Pros & Cons: The primary advantage of titanium is its superior resistance to corrosion and its lightweight nature, making it ideal for specialized applications. However, it is one of the most expensive materials, and its machining can be complex, leading to higher production costs.

Impact on Application: Titanium tuning fork level switches are well-suited for marine applications or industries dealing with highly corrosive substances. Their longevity can lead to lower lifecycle costs despite the initial investment.

International Considerations: Buyers should ensure compliance with ASTM B348 for titanium and be aware of specific regional regulations regarding its use, particularly in the marine and aerospace sectors.

Summary of Material Selection for Tuning Fork Level Switches

| Material | Typical Use Case for tuning fork level switch | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Chemical processing, food industry | Excellent corrosion resistance and durability | Higher cost and manufacturing complexity | High |

| Plastic | Water and less aggressive chemicals | Lightweight and cost-effective | Limited temperature and pressure tolerance | Low |

| Hastelloy | Chemical processing, harsh environments | Exceptional corrosion resistance | High cost and complex machining | High |

| Titanium | Marine and highly corrosive applications | Superior corrosion resistance and lightweight | Very high cost and manufacturing complexity | High |

Selecting the appropriate material for tuning fork level switches is essential for ensuring optimal performance and compliance with industry standards. By understanding the properties, advantages, and limitations of each material, B2B buyers can make informed decisions that align with their specific application needs.

Illustrative image related to tuning fork level switch

In-depth Look: Manufacturing Processes and Quality Assurance for tuning fork level switch

What Are the Key Stages in the Manufacturing Process of Tuning Fork Level Switches?

The manufacturing process for tuning fork level switches involves several critical stages, ensuring that each unit meets performance specifications and quality standards. Understanding these stages can help B2B buyers from various regions, including Africa, South America, the Middle East, and Europe, make informed procurement decisions.

Material Preparation: What Materials Are Used and How Are They Processed?

The initial step in manufacturing tuning fork level switches is selecting high-quality materials. Typically, stainless steel (such as 316 SS) is used for the tuning forks due to its corrosion resistance and durability, particularly in harsh environments. Other materials, like polyphenylene sulfide (PPS), are also employed for specific applications where chemical compatibility is crucial.

Once the materials are selected, they undergo preparation processes such as cutting, machining, and surface treatment. Machining involves precise milling and turning to form the forks’ dimensions accurately. Surface treatments may include polishing or electro-polishing to enhance corrosion resistance and improve hygiene, particularly important for industries like food and pharmaceuticals.

How Are Tuning Forks Formed and Assembled?

After material preparation, the forming stage begins. This involves creating the tuning fork structure, which is typically done through a process called precision stamping or laser cutting. The tuning fork’s design is crucial, as it must vibrate at a specific frequency when immersed in a medium.

Following the forming process, assembly takes place. During this stage, the individual components, including the tuning fork, electronic housing, and sensors, are meticulously assembled. The use of automated assembly lines is common, ensuring consistency and reducing human error. Each unit is integrated with electronic components that monitor frequency changes, enabling the switch to function accurately in detecting liquid levels.

What Finishing Techniques Are Utilized to Ensure Quality?

Finishing processes are essential for enhancing the performance and aesthetic appeal of tuning fork level switches. Techniques such as coating, anodizing, or additional polishing are often employed to improve durability and resistance to environmental factors.

In addition, the finishing stage often includes rigorous cleaning processes to remove any contaminants that may interfere with the switch’s operation. This is especially critical in applications where hygiene is paramount, such as in food processing or pharmaceuticals.

Illustrative image related to tuning fork level switch

How Is Quality Assurance Implemented in Tuning Fork Level Switch Manufacturing?

Quality assurance (QA) is a fundamental aspect of the manufacturing process for tuning fork level switches. International standards, such as ISO 9001, guide manufacturers in establishing effective quality management systems. Compliance with these standards ensures that products meet customer and regulatory requirements consistently.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is integrated at various checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials and components before they are used in production. Materials must meet specified standards to prevent defects in the final product.

-

In-Process Quality Control (IPQC): During manufacturing, IPQC involves monitoring processes and components at various stages. This helps identify issues early, allowing for corrective actions to be implemented immediately.

-

Final Quality Control (FQC): At this stage, finished products undergo rigorous testing and inspection to ensure they meet design specifications and performance standards. This may include vibration tests, frequency response evaluations, and environmental simulations.

What Testing Methods Are Commonly Used for Tuning Fork Level Switches?

Several testing methods are employed to verify the functionality and reliability of tuning fork level switches:

-

Vibration Testing: This assesses the switch’s performance under conditions simulating its operational environment, ensuring that it can function accurately without false readings due to external vibrations.

-

Frequency Response Testing: This critical test evaluates how well the tuning fork responds to changes in the medium it is immersed in. It is essential for ensuring that the switch will activate at the correct levels.

-

Environmental Testing: This includes exposure to extreme temperatures, pressures, and corrosive environments to confirm that the switch can withstand the conditions it will encounter in real-world applications.

How Can B2B Buyers Verify Supplier Quality Control Standards?

B2B buyers should take proactive steps to verify the quality control measures implemented by suppliers. Here are some strategies:

-

Conduct Supplier Audits: Regular audits of suppliers can provide insights into their manufacturing processes, quality control systems, and compliance with international standards.

-

Request Quality Assurance Reports: Suppliers should be willing to provide documentation detailing their quality management practices, testing results, and certifications.

-

Engage Third-Party Inspection Services: Independent inspection agencies can assess the supplier’s facilities and processes, ensuring compliance with industry standards and identifying any potential risks.

What Are the Compliance and Certification Nuances for International B2B Buyers?

For international buyers, understanding compliance and certification nuances is critical. Different regions may have varying requirements, such as CE marking in Europe, API certification in the oil and gas sector, or specific safety standards in Africa and South America.

Buyers should ensure that suppliers not only meet local regulations but also adhere to international standards that facilitate trade across borders. This includes verification of certifications and compliance with safety and environmental regulations, which can significantly impact procurement decisions.

Conclusion: Why Understanding Manufacturing and Quality Assurance Is Vital for B2B Buyers

An in-depth understanding of the manufacturing processes and quality assurance measures for tuning fork level switches equips B2B buyers with the knowledge needed to make informed purchasing decisions. By focusing on material quality, manufacturing techniques, and stringent quality control measures, businesses can ensure they procure reliable and high-performing level switches suitable for their specific applications across diverse industries.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘tuning fork level switch’

Introduction

Navigating the procurement process for a tuning fork level switch can be challenging, especially for B2B buyers operating across diverse international markets. This checklist serves as a practical guide to ensure that you make informed decisions, optimize your purchasing strategy, and ultimately select the right product for your operational needs.

Step 1: Define Your Technical Specifications

Before you begin sourcing, it’s essential to outline your specific technical requirements. Consider factors such as the type of media (liquid or powder), temperature ranges, pressure conditions, and compatibility with existing systems. This step ensures that you target products that meet your operational demands, minimizing the risk of purchasing a device that cannot perform effectively in your environment.

- Media Compatibility: Ensure the switch materials are suitable for the substances it will monitor.

- Temperature and Pressure Ratings: Specify the maximum and minimum operational limits to avoid equipment failure.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers with a strong reputation in the industry. Look for companies that specialize in level detection technologies and have a proven track record of delivering high-quality products. Supplier reliability is crucial for ongoing support and service.

- Industry Experience: Assess how long the supplier has been in business and their expertise in level switch technologies.

- Customer Reviews: Explore testimonials and case studies to gauge customer satisfaction and product performance.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold relevant certifications that demonstrate compliance with international standards. Certifications such as ISO 9001, IEC61508, and others indicate a commitment to quality and safety, particularly in critical applications.

- Safety Standards: Ensure that the products are certified for the specific applications you intend to use them for, especially in industries with stringent regulations.

- Material Certifications: Check for certifications regarding the materials used in the switch, especially for food and pharmaceutical applications.

Step 4: Request Detailed Product Information

Once you have shortlisted suppliers, request detailed product specifications and datasheets for the tuning fork level switches. Understanding the technical capabilities and limitations of each model will help you make an informed decision.

- Performance Metrics: Look for information on accuracy, response time, and maintenance requirements.

- Installation Guidelines: Ensure that the product can be easily integrated into your existing systems with minimal disruption.

Step 5: Assess After-Sales Support and Warranty Options

Evaluate the after-sales support offered by suppliers, as this can significantly affect the longevity and performance of your equipment. A robust warranty and responsive customer service can save you time and money in the long run.

- Technical Support: Ensure the supplier provides comprehensive technical support and troubleshooting assistance.

- Warranty Length: A longer warranty period often reflects confidence in product reliability.

Step 6: Compare Pricing and Payment Terms

After gathering all necessary information, compare pricing among the shortlisted suppliers. Consider not just the upfront cost but also any additional fees, shipping costs, and payment terms.

- Total Cost of Ownership: Factor in long-term costs, including maintenance and potential downtime.

- Flexible Payment Options: Look for suppliers that offer favorable payment terms to ease cash flow management.

Step 7: Finalize Your Decision and Place Your Order

Once you have completed the above steps, it’s time to make your final decision. Ensure that all your questions are answered and that you are confident in your choice before placing an order.

- Order Confirmation: Double-check that the order details align with your specifications and requirements.

- Documentation: Keep copies of all agreements and product specifications for future reference.

This checklist will help streamline your procurement process, ensuring that you select a tuning fork level switch that meets your needs while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for tuning fork level switch Sourcing

What Are the Key Cost Components for Tuning Fork Level Switches?

When sourcing tuning fork level switches, it is crucial to understand the underlying cost structure, which includes several components:

-

Materials: The primary materials used in manufacturing tuning fork level switches include stainless steel, polyphenylene sulfide, and various electronic components. The choice of materials can significantly influence the durability and performance of the switch, especially in harsh environments.

-

Labor: Labor costs encompass the expenses related to skilled workers who assemble and calibrate the switches. Skilled labor is essential for ensuring the precise tuning of the fork, which directly impacts the accuracy and reliability of the device.

-

Manufacturing Overhead: This includes costs associated with factory utilities, maintenance, and administrative expenses that support production processes. Efficient manufacturing practices can help in minimizing these costs.

-

Tooling: Tooling costs refer to the investment in molds and specialized equipment required for production. Custom tooling may be necessary for unique specifications, which can increase initial investment but may lower per-unit costs in larger production runs.

-

Quality Control (QC): Quality assurance processes are essential in the production of tuning fork level switches. The costs associated with testing and certification ensure that the devices meet industry standards and regulatory requirements.

-

Logistics: This includes shipping, handling, and storage costs. International buyers should consider logistics expenses as they can vary significantly based on the distance and mode of transport.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on market demand, competition, and value-added services offered.

What Influences the Pricing of Tuning Fork Level Switches?

Several factors can influence the pricing of tuning fork level switches in the international market:

-

Volume/MOQ (Minimum Order Quantity): Bulk purchases often lead to lower per-unit costs. Suppliers may offer discounts for larger orders, which can be a significant advantage for companies with high-volume needs.

-

Specifications and Customization: Custom features, such as specific materials or electronic configurations, can increase costs. Buyers should assess whether the added functionality justifies the higher price.

-

Materials and Quality Certifications: The quality of materials used, along with certifications (like SIL or FDA compliance), can affect the price. Devices designed for specific applications, such as those requiring high hygiene standards, often come at a premium.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their track record of quality and customer service.

-

Incoterms: The chosen Incoterms (International Commercial Terms) can impact the final cost. For example, DDP (Delivered Duty Paid) may include higher shipping costs but simplifies the purchasing process for the buyer.

What Tips Can Help Buyers Negotiate Better Prices?

For B2B buyers, especially those in Africa, South America, the Middle East, and Europe, effective negotiation and cost management can lead to significant savings:

-

Leverage Volume Discounts: If your company can commit to larger orders, negotiate for better pricing. Establishing a long-term relationship with the supplier can also yield favorable terms.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, operational costs, and potential downtime. A higher-quality switch may have a lower TCO due to reduced failure rates and maintenance needs.

-

Understand Pricing Nuances: Be aware that prices can fluctuate based on global supply chain dynamics and raw material costs. Building flexibility into your procurement strategy can help mitigate the impact of price changes.

-

Seek Multiple Quotes: Obtaining quotes from various suppliers can provide leverage in negotiations. It also helps in benchmarking the market price for similar products.

-

Focus on Quality and Compliance: Prioritize suppliers who offer quality products that meet necessary certifications. This can save costs related to compliance and potential product failures in the future.

Disclaimer on Indicative Prices

Pricing for tuning fork level switches can vary widely based on specific requirements, market conditions, and supplier capabilities. It’s advisable to request detailed quotes tailored to your unique needs for accurate budgeting.

Alternatives Analysis: Comparing tuning fork level switch With Other Solutions

Exploring Alternatives to Tuning Fork Level Switches

In the realm of industrial automation and process control, selecting the appropriate level sensing technology is crucial for ensuring efficiency and safety. Tuning fork level switches are known for their reliability and precision, but various alternative solutions exist that may be better suited to specific applications or environments. This section explores these alternatives, providing a comprehensive comparison to guide B2B buyers in their decision-making process.

| Comparison Aspect | Tuning Fork Level Switch | Ultrasonic Level Sensor | Capacitive Level Sensor |

|---|---|---|---|

| Performance | High accuracy in various liquids; immune to vibration interference. | Good for non-contact measurement but affected by environmental factors (e.g., temperature, humidity). | Effective for solid and liquid detection; performance varies with dielectric properties. |

| Cost | Moderate initial investment with low operational costs. | Generally lower initial cost but may require calibration and maintenance. | Low initial cost; however, may involve additional costs for installation and calibration. |

| Ease of Implementation | Simple installation; requires minimal setup and configuration. | Installation can be complex due to the need for line-of-sight and environmental considerations. | Installation is straightforward but may need adjustments based on material properties. |

| Maintenance | Low maintenance needs; robust design minimizes wear and tear. | Moderate maintenance; requires periodic calibration and cleaning. | Low maintenance; however, can be affected by buildup on sensor surfaces. |

| Best Use Case | Ideal for liquids and slurries in challenging environments (e.g., chemical processing). | Best for applications where contact with the medium is not desirable, such as in open tanks. | Suited for applications with solids or liquids with stable dielectric properties. |

Ultrasonic Level Sensors: Pros and Cons

Ultrasonic level sensors operate by emitting sound waves that reflect off the surface of the measured medium. They are particularly beneficial in applications where contact with the material is not possible, such as in open tanks or when dealing with hazardous substances. However, their performance can be influenced by environmental factors like temperature, humidity, and pressure, which may lead to inaccuracies. While they often come with a lower initial cost, ongoing calibration and maintenance can add to the total cost of ownership.

Capacitive Level Sensors: Pros and Cons

Capacitive level sensors detect changes in capacitance caused by the presence or absence of a material. They are versatile and can be used for both liquids and solids, making them suitable for various applications. Their low initial cost is appealing; however, they may require careful calibration and adjustment based on the dielectric properties of the materials being measured. Additionally, capacitive sensors can experience issues with buildup on their surfaces, which may necessitate periodic cleaning to maintain accuracy.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting a level sensing solution, B2B buyers should consider various factors, including the specific application requirements, environmental conditions, and budget constraints. Tuning fork level switches offer high accuracy and low maintenance, making them an excellent choice for challenging environments. However, alternatives like ultrasonic and capacitive sensors may provide advantages in specific scenarios, such as non-contact measurement or cost-effectiveness. By carefully evaluating these aspects, buyers can make informed decisions that align with their operational needs and strategic goals.

Essential Technical Properties and Trade Terminology for tuning fork level switch

What Are the Key Technical Properties of Tuning Fork Level Switches?

When selecting a tuning fork level switch, understanding its technical properties is crucial for ensuring compatibility with your application and achieving optimal performance. Here are some essential specifications:

-

Material Grade

– Tuning fork level switches are commonly made from materials like 316 stainless steel or polyphenylene sulfide (PPS). The material grade affects corrosion resistance, durability, and compatibility with various media. For industries like food processing or chemicals, selecting the right material is vital to avoid contamination and ensure compliance with safety standards. -

Operating Temperature Range

– This specification indicates the minimum and maximum temperatures the switch can endure while maintaining functionality. A broad operating temperature range allows for versatility in applications across different environments, from refrigeration systems to high-temperature processing plants. Understanding this range helps businesses select switches that can withstand their operational conditions. -

Process Connection Type

– The connection type, such as threaded or flanged, dictates how the switch integrates into existing systems. Choosing the correct process connection is essential for ensuring a secure fit and preventing leaks. B2B buyers should match this specification with their piping systems to avoid costly modifications or installation issues. -

Supply Voltage

– Tuning fork level switches operate on different supply voltages (e.g., 24V DC, 120V AC). Knowing the required voltage is critical for compatibility with existing electrical systems. This specification also impacts energy consumption and operational costs, making it a key consideration for long-term budgeting. -

Switch Type (NO/NC)

– Switches can be normally open (NO) or normally closed (NC), indicating their state when not activated. This affects how the switch interacts with alarms or control systems. Understanding which type is necessary for your application can enhance system safety and reliability. -

Compliance Standards

– Many tuning fork level switches are certified according to industry standards such as IEC61508 for safety integrity levels (SIL). Compliance ensures that the device meets rigorous performance and safety criteria, which is particularly important in regulated industries. Buyers should verify certifications to ensure compliance with local regulations.

What Are Common Trade Terms Related to Tuning Fork Level Switches?

Navigating the purchasing process can be simplified by understanding common trade terminology. Here are several key terms that B2B buyers should be familiar with:

-

OEM (Original Equipment Manufacturer)

– An OEM produces components that are used in another company’s end products. Understanding OEM relationships can help buyers source reliable components and ensure compatibility with their existing systems. -

MOQ (Minimum Order Quantity)

– This term refers to the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for budgeting and inventory planning, especially for businesses looking to minimize costs while ensuring a sufficient supply. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting pricing and availability for specific products. Issuing an RFQ allows buyers to compare options and negotiate terms effectively, ensuring they secure the best deal for their needs. -

Incoterms (International Commercial Terms)

– These are standardized trade terms that define the responsibilities of buyers and sellers regarding shipping, risk, and delivery. Understanding Incoterms helps businesses clarify shipping costs and responsibilities, minimizing potential disputes during transactions. -

Lead Time

– Lead time refers to the time taken from placing an order to delivery. Awareness of lead times is crucial for project planning and inventory management, allowing businesses to align their operations with supply chain capabilities. -

Calibration

– Calibration is the process of adjusting the switch to ensure accurate measurements. Some tuning fork level switches come pre-calibrated or require periodic recalibration. Knowing the calibration requirements helps buyers maintain accuracy and reliability in their applications.

By familiarizing themselves with these technical properties and trade terminologies, B2B buyers can make informed decisions regarding tuning fork level switches, ultimately enhancing operational efficiency and safety in their applications.

Navigating Market Dynamics and Sourcing Trends in the tuning fork level switch Sector

What Are the Current Market Dynamics and Key Trends Affecting Tuning Fork Level Switches?

The tuning fork level switch market is experiencing significant growth driven by advancements in automation and the need for precise level measurement across various industries. Key sectors such as food and beverage, pharmaceuticals, and oil and gas are increasingly adopting these devices due to their reliability and low maintenance requirements. Emerging trends include the integration of smart technologies, such as IoT connectivity, enabling remote monitoring and predictive maintenance. This shift not only enhances operational efficiency but also provides real-time data analytics that help businesses optimize processes and reduce downtime.

Illustrative image related to tuning fork level switch

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly looking for suppliers that offer customizable solutions tailored to specific operational needs. The growing demand for compact, lightweight, and versatile tuning fork switches reflects a broader trend toward streamlined operations and space-efficient designs. Furthermore, as industries face stringent regulatory requirements, the need for certified and compliant devices has never been more critical. Buyers are advised to seek out manufacturers who can provide documentation for compliance with international standards, ensuring that their systems meet safety and quality benchmarks.

How Is Sustainability and Ethical Sourcing Impacting the Tuning Fork Level Switch Market?

Sustainability is becoming a crucial consideration in the procurement of tuning fork level switches. Environmental impacts associated with manufacturing and disposal processes have prompted businesses to prioritize ethical sourcing and sustainability in their supply chains. Buyers should look for suppliers who utilize eco-friendly materials and processes, such as recyclable metals and non-toxic coatings, which contribute to reducing the overall carbon footprint.

Moreover, obtaining green certifications, such as ISO 14001, can enhance a supplier’s credibility and demonstrate their commitment to sustainable practices. The demand for products that meet stringent environmental standards is rising, particularly in regions with strong regulatory frameworks. Buyers are increasingly seeking manufacturers that offer products designed for longevity, which not only minimizes waste but also reduces the frequency of replacements, further supporting sustainability initiatives.

Illustrative image related to tuning fork level switch

What Is the Historical Context of Tuning Fork Level Switches in B2B Applications?

The tuning fork level switch technology has evolved significantly since its inception in the late 20th century. Initially developed for simple liquid level detection, advancements in materials science and electronics have transformed these devices into versatile tools capable of operating in a wide range of industrial environments. The introduction of piezoelectric technology allowed for more accurate and responsive measurements, which has been pivotal in sectors requiring stringent level monitoring.

As industries have grown more complex, the demand for reliable and precise level measurement has surged. Today, tuning fork level switches are integral to process control systems, serving not only as alarms for high and low levels but also as essential components in automation systems. Their evolution reflects the broader trends in industrial automation, where the need for efficiency, safety, and regulatory compliance continues to shape market dynamics.

Frequently Asked Questions (FAQs) for B2B Buyers of tuning fork level switch

-

How do I choose the right tuning fork level switch for my application?

Choosing the right tuning fork level switch depends on several factors including the type of media (liquid or powder), the operating environment (temperature and pressure), and the required accuracy. Assess the compatibility of materials with your media, as some switches are made from stainless steel, while others may use plastic. Additionally, consider features like vibration immunity, maintenance requirements, and certifications relevant to your industry standards. Collaborating with suppliers to understand their product specifications can help you make an informed decision. -

What are the key features to look for in a tuning fork level switch?

Key features to consider include media compatibility, switching type (normally open or closed), and the range of operating temperatures and pressures. Look for switches that offer vibration immunity, low power consumption, and easy installation. Additionally, certifications such as IEC61508 for safety applications can be critical for industries like oil and gas or food processing. Customization options for length and electrical connections can also enhance compatibility with existing systems. -

What is the minimum order quantity (MOQ) for tuning fork level switches?

The minimum order quantity (MOQ) for tuning fork level switches varies by manufacturer and can range from a single unit to several hundred. Smaller suppliers may accommodate low MOQs, making them suitable for startups or projects with limited budgets. In contrast, larger manufacturers may require higher MOQs, especially for customized solutions. It’s important to discuss your needs with suppliers upfront to find a mutually beneficial arrangement. -

What payment terms should I expect when sourcing tuning fork level switches?

Payment terms for tuning fork level switches can vary widely among suppliers. Common terms include net 30, net 60, or even payment upon delivery. Many international suppliers may require a deposit upfront, especially for custom orders. It’s advisable to clarify payment terms during initial negotiations and consider using secure payment methods to protect against fraud. Always ensure that the terms align with your cash flow capabilities to avoid disruptions. -

How can I ensure the quality of tuning fork level switches from international suppliers?

To ensure quality, request detailed product specifications and certifications from potential suppliers. Conducting factory audits or quality inspections can provide insights into their manufacturing processes. Additionally, ask for product samples to test in your specific application. Establishing a solid relationship and clear communication with suppliers will facilitate transparency regarding quality control measures and adherence to industry standards. -

What logistics considerations should I keep in mind when importing tuning fork level switches?

When importing tuning fork level switches, consider shipping methods, lead times, and customs regulations in your country. Air freight is faster but more expensive, while sea freight is cost-effective for larger orders. Ensure that your supplier provides all necessary documentation for customs clearance, including invoices and certifications. Familiarize yourself with import duties and taxes applicable to your products to avoid unexpected costs. -

Are there customization options available for tuning fork level switches?

Yes, many manufacturers offer customization options for tuning fork level switches. Customizations can include variations in length, materials, electrical connections, and sensitivity settings. Discuss your specific application needs with suppliers to explore available options. Custom solutions can enhance performance and compatibility with your existing systems, ensuring optimal functionality in your operational environment. -

What are the common applications for tuning fork level switches in different industries?

Tuning fork level switches are widely used in various industries, including food and beverage, chemical processing, oil and gas, and water treatment. They are particularly effective for point-level detection in liquids and powders, ensuring safety and efficiency in processes such as overfill prevention and pump protection. Their reliability in harsh environments makes them suitable for monitoring levels in tanks, silos, and other storage systems. Understanding industry-specific requirements can guide your selection of the most appropriate switch for your application.

Top 7 Tuning Fork Level Switch Manufacturers & Suppliers List

1. Emerson – Tuning Fork Level Detector

Domain: emerson.com

Registered: 1995 (30 years)

Introduction: This company, Emerson – Tuning Fork Level Detector, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Dwyer – Tuning Fork Level Switches

Domain: dwyeromega.com

Registered: 2022 (3 years)

Introduction: {“product_name”: “Tuning Fork Level Switches”, “brand”: [“Dwyer”, “Omega”], “price_range”: “$200-$499.99, $500-$999.99, $1,000-$9,999.99”, “sku_availability”: “In Stock”, “media_compatibility”: [“Air”, “Alkaline solutions”, “Argon”, “Carbon dioxide”, “Dry Bulk Materials”, “Dry Powders”, “Dilute Acids”, “Gases”, “Helium”, “Hydraulic Oil”, “Hydrogen”, “Light Oil”, “Liquids”, “Nitrogen”, “Non-corrosi…

3. Kobold – NWS Vibrating Fork Level Switches

Domain: koboldusa.com

Registered: 1996 (29 years)

Introduction: Product Name: NWS Vibrating Fork Level Switches

Key Features:

– Compact Size

– No Wear Components

– Works with Many Liquids

– User Selectable Switch Logic

– Suitable for Sterile or Hygienic Applications

– CIP Cycles to 300 °F

Sample Application Media: Oils, Foamed Oils, Water, Paints, Transparent Inks, Sauces, Milk, Liquids with Carbon Dioxide

Operating Principle: Vibrating fork principle using a …

4. VEGA – VEGAPULS 6X

Domain: vega.com

Registered: 1994 (31 years)

Introduction: Product Name: VEGAPULS 6X

Key Features:

– Point level measurement with vibrating level switches

– Utilizes a vibrating rod or fork to detect medium contact

– Outputs a switching command upon vibration change

– Used for overfill protection and low-level indicators in liquids and bulk solids

Advantages:

– Easy installation

– Reliable measurement independent of installation position, pressure, temp…

5. ABB – RS85 Vibrating Fork Level Switch

Domain: new.abb.com

Registered: 1990 (35 years)

Introduction: RS85 Vibrating Fork Level Switch utilizes a piezoelectric driven tuning fork that changes resonant frequency when immersed in liquid. Features include: direct replacement for ultrasonic gap switches, RF capacitance switches, float switches; immune to coating or build-up; robust sensing element; process connections of ¾” and 1” (NPT, BSPT); choice of international flanges and tri-clamp fittings; op…

6. Wika – Vibrating Level Switches

Domain: wika.com

Registered: 1996 (29 years)

Introduction: Vibrating level switches provide high accuracy in detecting limit levels in various mounting positions. The functionality is based on a tuning fork that vibrates at its resonance frequency. Changes in the fill level of the tank, which cover or uncover the tuning fork, alter the oscillation frequency. This change is precisely analyzed for reliable limit level detection, unaffected by mounting posit…

7. Burkert – Vibrating Filling Level Switch

Domain: burkert.com

Registered: 1995 (30 years)

Introduction: This company, Burkert – Vibrating Filling Level Switch, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for tuning fork level switch

In conclusion, the strategic sourcing of tuning fork level switches presents a valuable opportunity for international B2B buyers across diverse regions, including Africa, South America, the Middle East, and Europe. These devices offer significant advantages such as reliability, low maintenance, and precise measurement capabilities, making them ideal for various applications in industries ranging from food processing to chemical manufacturing.

By carefully evaluating suppliers based on their technological advancements, compliance with international standards, and customer support, businesses can ensure they select the best products for their operational needs. Moreover, embracing innovations such as wireless technology and enhanced diagnostics can further optimize process efficiency and safety.

As the demand for reliable level detection continues to grow, organizations should proactively seek partnerships with reputable manufacturers to stay ahead of the competition. Investing in high-quality tuning fork level switches not only streamlines operations but also reinforces a commitment to safety and regulatory compliance. Take the next step in enhancing your operations—explore your sourcing options today and position your business for long-term success in a rapidly evolving market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.