Trash Compactor Machine: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for trash compactor machine

Navigating the complexities of sourcing a trash compactor machine can present significant challenges for international B2B buyers, especially in diverse markets such as Africa, South America, the Middle East, and Europe. As urban centers grapple with waste management issues, the demand for efficient waste compacting solutions has surged. This comprehensive guide delves into the myriad types of trash compactor machines available, their various applications across industries, and essential factors for supplier vetting.

From understanding the differences between stationary and self-contained compactors to evaluating the cost implications of various models, this guide equips buyers with the insights needed to make informed purchasing decisions. It covers critical aspects such as compaction ratios, operational efficiency, and safety features, ensuring that businesses can select machines that not only meet their waste management needs but also align with their sustainability goals.

By leveraging the information contained within this guide, B2B buyers can navigate the global market with confidence, minimizing risks associated with procurement and maximizing the value derived from their investments in trash compactor machines. Whether you are a distributor in Germany or a facility manager in Nigeria, this resource is designed to empower you with actionable knowledge to enhance your waste management processes effectively.

Understanding trash compactor machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Self-Contained Compactor | Combines compactor and waste container; ideal for wet waste | Restaurants, grocery stores, food processing | Pros: Efficient for liquid waste; compact design. Cons: Higher upfront cost. |

| Stationary Compactor | Compresses dry waste; fixed installation | Warehouses, manufacturing plants, retail stores | Pros: High compaction ratio; reduced disposal frequency. Cons: Requires space; installation time. |

| Apartment Compactor | Smaller units for multi-family housing | Apartment complexes, condominiums | Pros: Space-saving; convenient for residents. Cons: Limited capacity compared to larger models. |

| Pre-Crushers | Designed to crush bulky items before compaction | Distribution centers, thrift stores | Pros: Handles oversized waste effectively; reduces volume significantly. Cons: More complex operation; higher maintenance. |

| Vertical Compactor | Space-efficient design, vertical loading | Industrial sites, construction sites | Pros: Minimal footprint; efficient for high-density waste. Cons: Limited loading capacity; may require specific waste types. |

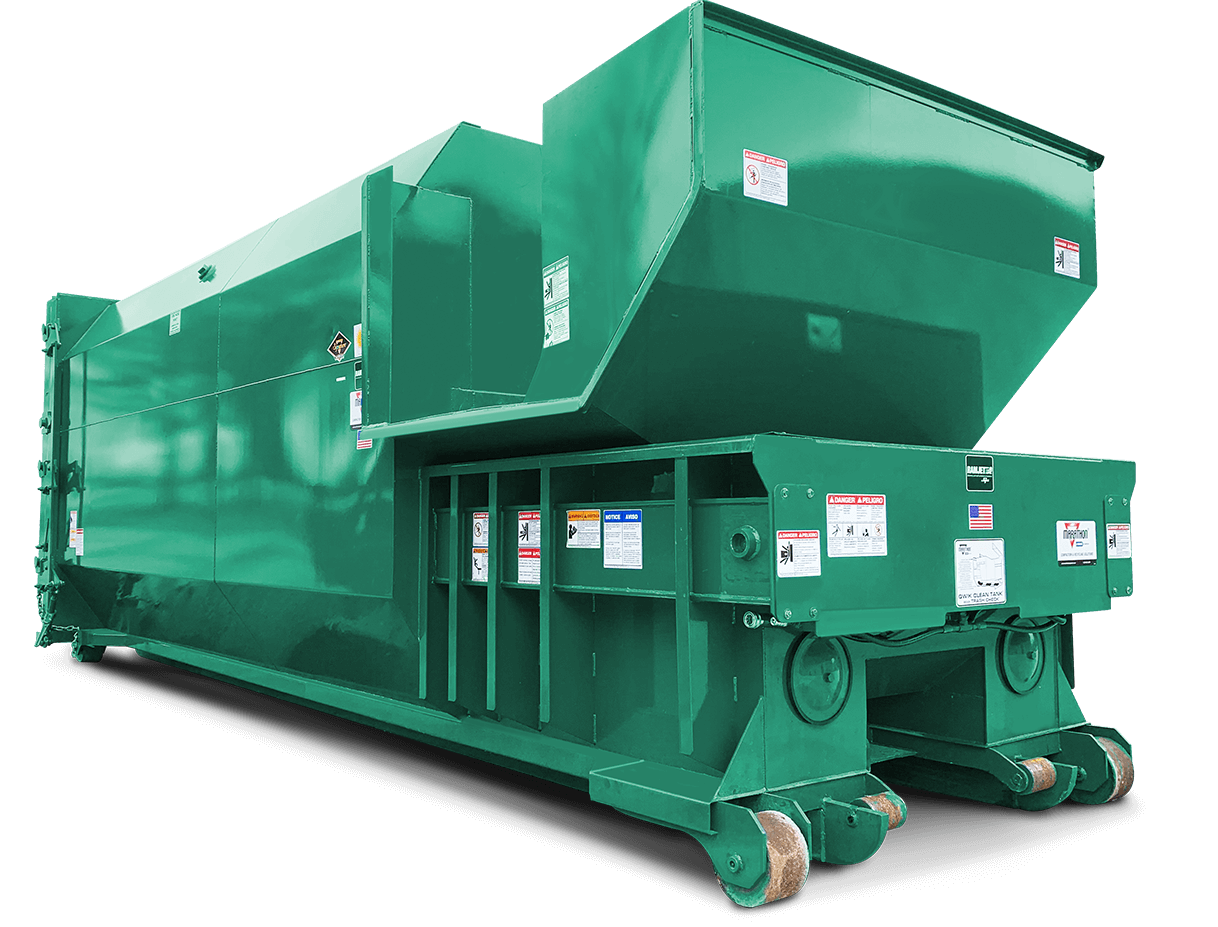

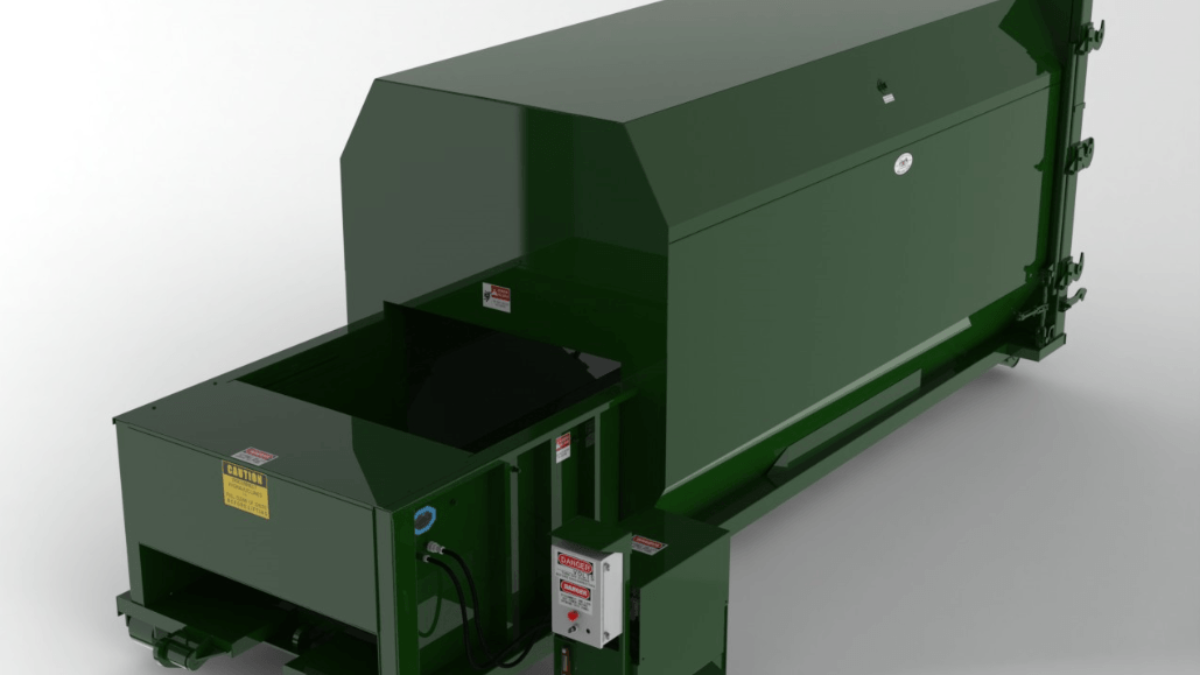

What are the Characteristics of Self-Contained Compactors and Their Suitability for B2B Buyers?

Self-contained compactors are a robust solution for businesses that handle significant volumes of wet waste. They integrate the compaction system with the waste container, making them ideal for environments like restaurants and grocery stores where liquid waste is prevalent. B2B buyers should consider the upfront investment against the potential for reduced waste collection frequency and improved sanitation. Additionally, their compact design allows for efficient space utilization, which is crucial in busy commercial environments.

Illustrative image related to trash compactor machine

How Do Stationary Compactors Benefit Various Industries?

Stationary compactors are designed for heavy-duty waste management, compressing dry materials like cardboard and plastics into manageable bales. They are commonly used in warehouses and manufacturing settings where large quantities of recyclables are processed. Buyers should evaluate their waste volume and type to determine the right model, as these compactors can significantly reduce disposal costs and frequency. Their installation requires more space and time, but the long-term savings often justify the initial commitment.

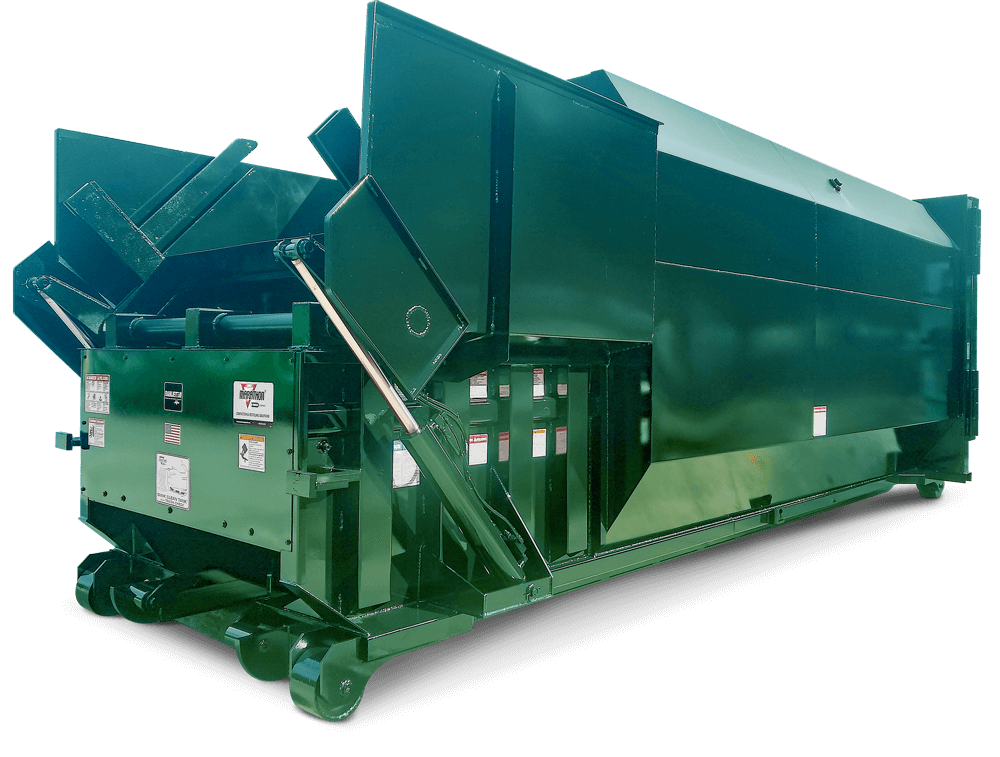

Why Choose Apartment Compactors for Multi-Family Residences?

Apartment compactors cater specifically to multi-family housing, providing a convenient waste disposal solution for residents. Their smaller size allows for easy integration into existing waste management systems, making them an attractive option for property managers. B2B buyers must consider the volume of waste generated in their buildings and the compactors’ capacity to ensure efficient operation. While they are space-saving, the trade-off is a reduced capacity compared to larger models, which may necessitate more frequent emptying.

What Are the Advantages of Using Pre-Crushers in Waste Management?

Pre-crushers are designed to handle bulky waste items before they are compacted, making them essential for industries like distribution centers and thrift stores. They provide substantial crushing power, allowing businesses to manage oversized items such as furniture and pallets efficiently. B2B buyers should assess their waste types and operational complexity, as pre-crushers can require more maintenance and operational training. However, their ability to significantly reduce waste volume can lead to lower disposal costs over time.

How Do Vertical Compactors Optimize Space in Industrial Settings?

Vertical compactors offer a space-efficient solution for businesses needing to manage high-density waste. Their design allows for vertical loading, which minimizes the footprint required compared to traditional compactors. Ideal for industrial and construction sites, these machines can handle a variety of waste types. Buyers should consider their specific waste management needs, as vertical compactors may have limitations in loading capacity. However, for businesses with space constraints, they present a compelling option for effective waste reduction.

Key Industrial Applications of trash compactor machine

| Industry/Sector | Specific Application of trash compactor machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Service | Compacting food waste in restaurants | Reduces waste volume, lowering disposal costs | Ensure compliance with local waste regulations; durability for high usage |

| Retail | Managing cardboard and packaging waste | Streamlines waste management, enhances space efficiency | Size and capacity to match store volume; ease of operation |

| Manufacturing | Compaction of industrial waste and recyclables | Improves safety and reduces landfill costs | Compatibility with existing waste disposal systems; maintenance support |

| Hospitality | Compacting waste in hotels and resorts | Minimizes odor and pest issues; reduces pickup frequency | Energy efficiency and odor management features; service agreements |

| Multi-family Housing | Waste management for apartment complexes | Reduces pickup frequency and enhances tenant satisfaction | Compact size for limited space; ease of use for residents |

How is a Trash Compactor Machine Used in the Food Service Industry?

In the food service sector, trash compactor machines are essential for managing the high volume of food waste generated daily. Restaurants utilize compactors to reduce waste volume by up to 80%, significantly lowering disposal costs and minimizing the frequency of waste collection. Buyers in this sector should consider machines that comply with local health regulations and are robust enough to handle heavy usage, ensuring durability and reliability in busy environments.

What Role Does a Trash Compactor Play in Retail Waste Management?

Retail businesses often face challenges in managing cardboard and packaging waste. Trash compactors streamline waste management by efficiently compressing these materials, thus enhancing space efficiency and reducing disposal costs. Retailers should prioritize compactors that are easy to operate and suited to their specific waste volume, while also considering energy-efficient models to minimize operational costs.

Why is a Trash Compactor Important in the Manufacturing Sector?

Manufacturing facilities generate a variety of industrial waste and recyclables that require effective management. Trash compactors help compress this waste, improving workplace safety and reducing landfill costs. Buyers in this sector need to ensure that the compactor is compatible with their existing waste disposal systems and can handle the specific types of waste generated, while also having access to maintenance support for continued operation.

How Can Trash Compactors Benefit the Hospitality Industry?

In hotels and resorts, trash compactors play a crucial role in managing waste efficiently. These machines minimize odors and pest issues, while also reducing the frequency of waste pickups, which can be particularly beneficial in high-traffic areas. Buyers should look for features such as energy efficiency and odor management systems, as well as service agreements to ensure prompt maintenance and support.

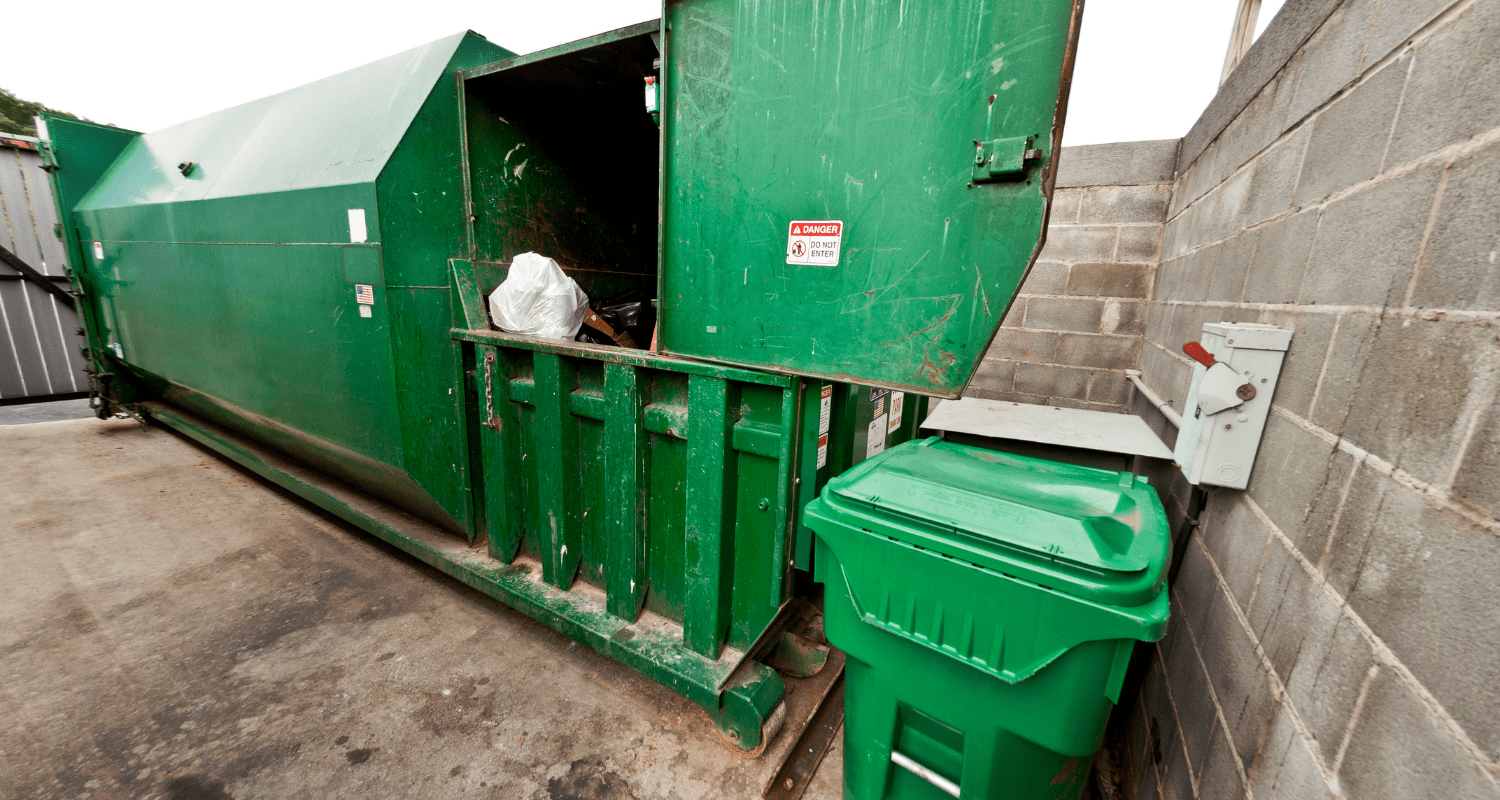

Illustrative image related to trash compactor machine

What Are the Advantages of Trash Compactors for Multi-family Housing?

For apartment complexes, trash compactors offer a practical solution for waste management, allowing tenants to dispose of waste in a compacted form. This not only reduces the frequency of trash pickups but also enhances tenant satisfaction by minimizing overflow and odors. Buyers in this segment should focus on compactors that fit within limited space and are user-friendly to encourage proper usage among residents.

3 Common User Pain Points for ‘trash compactor machine’ & Their Solutions

Scenario 1: Inefficient Waste Management Leading to Increased Costs

The Problem: Many businesses face the challenge of high waste disposal costs, particularly those in industries like hospitality, retail, or manufacturing where waste generation is significant. These organizations often struggle with frequent trash pickups, leading to increased operational costs and a cluttered environment. This inefficiency can result in lost productivity and hinder overall business operations.

The Solution: To address this issue, B2B buyers should consider investing in a high-capacity trash compactor that can significantly reduce waste volume by up to 80%. By properly sizing the compactor according to their specific waste types—whether it be cardboard, food waste, or general refuse—companies can optimize their waste management processes. Conducting a thorough assessment of waste generation patterns will allow buyers to choose a model with the right compaction ratio and features, such as a self-contained compactor for wet waste or a stationary model for dry waste. Additionally, establishing a regular maintenance schedule ensures that the machine operates efficiently, minimizing downtime and maximizing cost savings.

Scenario 2: Odor and Hygiene Issues in Waste Storage

The Problem: In industries such as food processing or hospitality, improper waste management can lead to unpleasant odors and hygiene concerns. This not only creates an uncomfortable environment for employees but can also affect customer satisfaction and overall brand reputation. Odor issues can become particularly pronounced during warmer months or in confined spaces, making it critical to find effective solutions.

The Solution: B2B buyers should look for trash compactors equipped with odor management systems. Many modern compactors feature built-in fans and carbon filters designed to minimize unpleasant smells while compacting waste. When selecting a compactor, it is essential to ensure that the chosen model includes these features, particularly for environments where food waste is prevalent. Additionally, implementing a regular cleaning schedule for both the compactor and the surrounding area can help maintain hygiene standards and further reduce odor issues. Training staff on proper waste disposal techniques can also contribute to improved cleanliness and odor control.

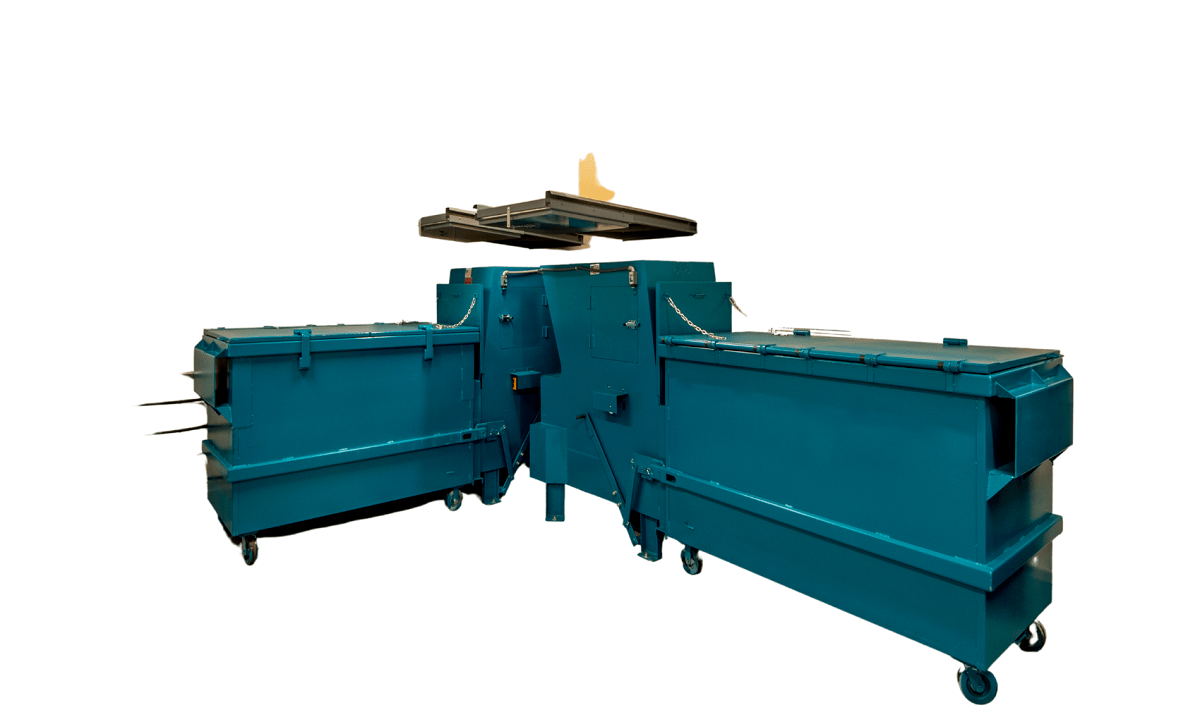

Scenario 3: Limited Space for Waste Management Solutions

The Problem: Many businesses, especially those in urban settings or smaller facilities, face challenges due to limited space for waste management solutions. Traditional waste bins can take up valuable real estate, leading to inefficient use of space and increased clutter. This scenario is common in multi-family housing units, restaurants, and retail outlets where maximizing available space is crucial for operations.

The Solution: B2B buyers should consider compact, vertical trash compactors designed specifically for environments with space constraints. These machines are typically smaller yet capable of handling significant waste volumes, making them ideal for tight locations. Buyers should evaluate their space thoroughly and consult with suppliers to find compactors that fit their specific dimensions and waste types. Furthermore, modular compactors that can be integrated into existing waste management systems can provide a flexible solution. Encouraging staff to utilize the compactor effectively by providing training on how to load waste properly can also enhance space management and overall efficiency.

Strategic Material Selection Guide for trash compactor machine

What Are the Key Materials Used in Trash Compactor Machines?

When selecting materials for trash compactor machines, it is essential to consider their properties, advantages, and limitations. The choice of material directly influences the machine’s performance, durability, and suitability for specific applications. Below, we analyze four common materials used in the construction of trash compactors.

Steel: The Backbone of Trash Compactor Construction

Key Properties: Steel is known for its high strength and durability, with a temperature rating that can withstand significant pressure. It also offers good corrosion resistance when treated with appropriate coatings.

Pros & Cons: Steel is highly durable, making it suitable for heavy-duty applications. However, it can be more expensive than other materials and may require additional coatings to enhance corrosion resistance, particularly in humid or wet environments.

Illustrative image related to trash compactor machine

Impact on Application: Steel compactors are ideal for handling a variety of waste types, including industrial and commercial waste. Its robustness allows for efficient compaction of dense materials.

Considerations for International Buyers: Buyers in regions like Germany and Nigeria should ensure compliance with local standards for steel quality, such as DIN or ASTM specifications. Additionally, the availability of treated steel may vary, affecting procurement strategies.

Aluminum: Lightweight and Corrosion-Resistant

Key Properties: Aluminum is lightweight, with excellent corrosion resistance and a good strength-to-weight ratio. It can handle moderate pressures, making it suitable for less demanding applications.

Illustrative image related to trash compactor machine

Pros & Cons: The primary advantage of aluminum is its lightweight nature, which can reduce shipping costs and ease installation. However, it is generally less durable than steel and may not withstand heavy-duty use as effectively.

Impact on Application: Aluminum compactors are well-suited for residential or light commercial applications where waste volume is lower. They are particularly effective in environments where corrosion is a concern, such as coastal areas.

Considerations for International Buyers: Buyers in Africa and South America should consider local regulations regarding aluminum recycling and disposal. Compliance with international standards for aluminum quality, such as JIS, is also crucial.

Illustrative image related to trash compactor machine

High-Density Polyethylene (HDPE): A Versatile Plastic Option

Key Properties: HDPE is a thermoplastic known for its impact resistance and chemical stability, with a temperature rating that allows it to perform well in various environments.

Pros & Cons: HDPE is cost-effective and resistant to many chemicals, making it suitable for waste that may contain hazardous materials. However, it may not provide the same level of structural integrity as metals, limiting its use in heavy-duty applications.

Impact on Application: HDPE compactors are often used in residential and light commercial settings, especially for organic waste. Their chemical resistance makes them suitable for handling food waste and other biodegradable materials.

Considerations for International Buyers: Compliance with local environmental regulations regarding plastic use and disposal is crucial for buyers in the Middle East and Europe. Understanding the local recycling infrastructure for HDPE can also influence purchasing decisions.

Illustrative image related to trash compactor machine

Stainless Steel: The Premium Choice for Durability

Key Properties: Stainless steel offers exceptional corrosion resistance and durability, with a high-temperature rating suitable for various applications. Its composition includes chromium, which enhances its resistance to rust.

Pros & Cons: The primary advantage of stainless steel is its long lifespan and low maintenance requirements. However, it is typically more expensive than other materials, which may be a consideration for budget-sensitive buyers.

Impact on Application: Stainless steel compactors are ideal for environments requiring hygiene, such as food processing and healthcare facilities. Their resistance to corrosion makes them suitable for wet waste applications.

Considerations for International Buyers: Buyers in Europe and the Middle East should ensure compliance with health and safety standards regarding materials used in food-related applications. Understanding the local market for stainless steel can also influence cost and availability.

Summary Table of Material Selection for Trash Compactor Machines

| Material | Typical Use Case for trash compactor machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty commercial applications | High durability | Higher cost, corrosion risk | High |

| Aluminum | Residential/light commercial applications | Lightweight, corrosion-resistant | Less durable under heavy use | Medium |

| High-Density Polyethylene (HDPE) | Residential and organic waste disposal | Cost-effective, chemical resistance | Limited structural integrity | Low |

| Stainless Steel | Food processing and healthcare facilities | Exceptional durability and hygiene | Higher initial cost | High |

This comprehensive analysis of materials will guide international B2B buyers in making informed decisions that align with their operational needs and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for trash compactor machine

What Are the Main Stages in the Manufacturing Process of Trash Compactor Machines?

The manufacturing process of trash compactor machines involves several key stages that ensure the product meets quality and performance standards. Each stage is crucial for producing a reliable and efficient machine.

Illustrative image related to trash compactor machine

Material Preparation

The first step in the manufacturing process is material preparation, where raw materials such as steel, aluminum, and plastic are sourced and inspected for quality. Suppliers must comply with international material standards to ensure durability and safety. For instance, high-strength steel is often used for the compaction chamber due to its ability to withstand high pressure and stress during operation. Additionally, materials may undergo pre-treatment processes such as galvanization or powder coating to enhance corrosion resistance.

Forming Techniques

Once materials are prepared, they undergo various forming techniques. Common methods include stamping, bending, and welding. Stamping is frequently used to create the compactor’s body and components, allowing for precise shapes and dimensions. Bending processes shape metal sheets into the desired form, while welding joins parts together to create a sturdy structure. Advanced techniques like laser cutting may also be employed for intricate designs and improved precision.

Assembly Process

The assembly stage is where individual components come together to form the complete trash compactor machine. This process involves both manual and automated systems. Workers may assemble critical components such as the motor, hydraulic systems, and control panels, ensuring that each part fits perfectly and operates smoothly. During assembly, manufacturers often conduct in-process quality checks (IPQC) to identify and rectify any issues early in the production line.

Finishing Touches

Finally, the finishing stage includes painting, coating, and additional quality checks. This not only enhances the aesthetic appeal of the machine but also adds protective layers to withstand environmental factors. For instance, a powder coating can provide a durable finish that resists chipping and scratching. Before the machines leave the factory, they undergo final inspections to ensure they meet the specified standards and regulations.

What Quality Assurance Standards Are Relevant for Trash Compactor Machines?

Quality assurance (QA) is vital in the manufacturing of trash compactor machines to ensure safety, reliability, and compliance with international standards. Various certifications and checkpoints are implemented throughout the manufacturing process.

Illustrative image related to trash compactor machine

International Standards and Certifications

Manufacturers often adhere to ISO 9001, a globally recognized quality management system standard. This certification emphasizes a process-based approach to improving quality and customer satisfaction. Additionally, depending on the target market, compliance with CE marking for the European market or API specifications for certain industrial applications may be necessary. These certifications assure buyers that the products meet safety and performance standards.

Key Quality Control Checkpoints

Quality control (QC) involves several checkpoints throughout the manufacturing process. Incoming Quality Control (IQC) checks raw materials upon arrival to ensure they meet specifications. In-Process Quality Control (IPQC) occurs during production, where operators inspect components and assemblies to catch defects early. Finally, Final Quality Control (FQC) is conducted after assembly to verify that the finished product meets all regulatory and performance requirements.

What Common Testing Methods Are Used to Ensure Quality?

To maintain high-quality standards, manufacturers employ various testing methods throughout the production cycle. These methods help verify the functionality, safety, and durability of trash compactor machines.

Illustrative image related to trash compactor machine

Functional Testing

Functional testing ensures that the compactor operates as intended. This includes testing the compaction mechanism, hydraulic systems, and control interfaces. Manufacturers simulate real-world conditions to evaluate performance under different loads.

Durability Testing

Durability testing involves subjecting the machine to extreme conditions to assess its resilience. This may include repetitive compaction cycles, exposure to harsh environments, and stress testing of components. Manufacturers may also perform fatigue testing to determine the lifespan of critical parts.

Safety Testing

Safety is a paramount concern in the design and manufacture of trash compactors. Safety testing verifies that machines comply with industry safety standards, including emergency shut-off features and protective covers. Compliance with safety regulations can significantly influence purchasing decisions for B2B buyers.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying the quality control practices of potential suppliers is essential for making informed purchasing decisions. Here are several methods to ensure suppliers maintain high-quality standards.

Supplier Audits

Conducting supplier audits is one of the most effective ways to assess a manufacturer’s quality control practices. Audits can provide insights into the operational processes, compliance with standards, and adherence to quality management systems. Buyers can request audits to be performed by third-party organizations to ensure impartiality.

Illustrative image related to trash compactor machine

Quality Control Reports

Requesting detailed quality control reports from suppliers can help buyers understand the testing methodologies and results. These reports should outline the QC checkpoints, testing methods, and any corrective actions taken in response to identified issues. Transparency in these reports reflects a supplier’s commitment to quality.

Third-Party Inspections

Engaging third-party inspection services can provide an additional layer of assurance. These organizations can conduct inspections at various stages of the manufacturing process, from material sourcing to final assembly. Third-party inspections offer unbiased evaluations of a supplier’s adherence to quality standards.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific quality control nuances that may affect their purchasing decisions.

Illustrative image related to trash compactor machine

Understanding Regional Regulations

Different regions have varying regulatory requirements that may impact the quality standards of trash compactor machines. For example, European buyers must ensure compliance with CE marking, while buyers in Africa may encounter different safety and environmental regulations. Understanding these regional nuances can help buyers avoid compliance issues.

Language and Cultural Barriers

Language and cultural differences can pose challenges during communication with suppliers. Buyers should seek suppliers who offer multilingual support and are familiar with international trade practices. Clear communication regarding quality expectations is crucial for successful transactions.

Supply Chain Considerations

The complexity of international supply chains can introduce risks related to quality. Buyers should assess the entire supply chain, including material sourcing and logistics, to ensure that quality is maintained at every stage. Building relationships with suppliers who prioritize quality control can mitigate these risks.

In conclusion, understanding the manufacturing processes and quality assurance practices for trash compactor machines is vital for B2B buyers. By focusing on material preparation, forming techniques, assembly, and finishing, alongside rigorous quality control measures, buyers can ensure they select reliable and high-quality products. Proper due diligence and verification of supplier practices will further enhance purchasing decisions, leading to successful outcomes in the international marketplace.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘trash compactor machine’

To assist B2B buyers in procuring a trash compactor machine, this checklist provides a structured approach to ensure a successful sourcing process. Each step is designed to guide you through critical considerations, helping you make informed decisions that align with your operational needs.

Illustrative image related to trash compactor machine

Step 1: Identify Your Waste Management Needs

Understanding your specific waste management requirements is fundamental. Consider the volume and type of waste you typically generate—whether it’s dry recyclables, food waste, or mixed materials. This will inform the capacity and type of compactor you need, such as stationary or self-contained models, and ensure you select a machine that enhances efficiency.

Step 2: Define Your Technical Specifications

Clearly outline the technical specifications that the trash compactor must meet. Key factors include:

– Compaction Ratio: A higher ratio means more waste per load, reducing disposal frequency.

– Horsepower: Ensure the motor’s power is adequate for your waste type.

– Dimensions and Weight: Verify that the machine fits your available space and can be easily maneuvered.

Step 3: Evaluate Potential Suppliers

Before making a purchase, it’s crucial to thoroughly vet potential suppliers. Request:

– Company Profiles: Understand their history and market presence.

– References and Case Studies: Speak with previous clients in similar industries to gauge satisfaction and reliability.

– Certifications: Ensure they comply with industry standards and regulations.

Step 4: Request Quotes and Compare Pricing

Obtain detailed quotes from multiple suppliers to compare costs effectively. Look beyond the initial purchase price; consider:

– Total Cost of Ownership (TCO): Include installation, maintenance, and operational costs over the machine’s lifespan.

– Warranty and Service Agreements: Assess the terms offered for repairs and maintenance.

Illustrative image related to trash compactor machine

Step 5: Inspect Equipment and Conduct Site Visits

If possible, inspect the equipment firsthand or conduct site visits to see the machines in operation. This will help you:

– Assess Build Quality: Check for durable construction and user-friendly features.

– Evaluate Performance: Observe how the compactor handles waste similar to what you generate.

Step 6: Review After-Sales Support and Maintenance Options

Consider the level of after-sales support provided by the supplier. Key aspects include:

– Training: Ensure that your staff receives adequate training for safe and efficient operation.

– Maintenance Services: Confirm the availability of maintenance services and parts supply to minimize downtime.

Step 7: Finalize Contract and Terms

Once you have selected a supplier, carefully review the contract terms. Pay attention to:

– Delivery and Installation Timeline: Ensure it aligns with your operational schedule.

– Payment Terms: Clarify payment schedules and conditions to avoid misunderstandings.

By following this structured checklist, B2B buyers can confidently navigate the sourcing process for trash compactor machines, ensuring their selection meets both operational efficiency and budgetary constraints.

Illustrative image related to trash compactor machine

Comprehensive Cost and Pricing Analysis for trash compactor machine Sourcing

What Are the Key Cost Components in Sourcing Trash Compactor Machines?

When sourcing trash compactor machines, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. For instance, stainless steel is commonly preferred for its durability and resistance to corrosion, but it may come at a higher price compared to standard steel or plastic options.

-

Labor: Labor costs can vary based on the location of manufacturing. Countries with lower labor costs may offer more competitive pricing, but this can affect the quality and reliability of the product.

-

Manufacturing Overhead: This includes costs related to utilities, facilities, and equipment used in production. High-quality manufacturing processes may entail higher overhead, which can reflect in the final pricing.

-

Tooling: Custom tooling may be necessary for specific designs or features, which adds to the initial investment. Buyers should consider whether a one-time tooling cost can be amortized over a large order.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability but also adds to the overall cost. Certifications such as ISO 9001 may be sought by buyers, influencing the pricing structure.

-

Logistics: Transportation costs can vary significantly based on the origin of the product and the destination market. Import tariffs and customs duties should also be accounted for, especially for international buyers.

-

Margin: Suppliers will include their profit margin in the pricing. Understanding the typical margins in the industry can help buyers negotiate better deals.

How Do Price Influencers Affect the Cost of Trash Compactor Machines?

Several factors influence the pricing of trash compactor machines, and understanding these can help buyers negotiate effectively:

-

Volume/MOQ: Suppliers often provide better pricing for larger orders. Minimum Order Quantities (MOQs) can affect per-unit pricing, so consolidating orders can lead to significant savings.

-

Specifications and Customization: Custom features or specific technical requirements can increase costs. Buyers should assess whether these enhancements are necessary for their operations.

-

Materials and Quality Certifications: Higher-quality materials and certifications can lead to increased costs. However, investing in quality often translates to lower maintenance and replacement costs in the long run.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a strong track record may charge a premium but offer better service and product assurance.

-

Incoterms: The choice of Incoterms affects logistics costs and responsibilities. Buyers should be clear on who bears the shipping, insurance, and customs duties to avoid unexpected expenses.

What Are the Best Buyer Tips for Cost-Efficiency in Trash Compactor Sourcing?

To ensure a cost-effective sourcing strategy for trash compactor machines, consider the following tips:

-

Negotiate Pricing and Terms: Don’t hesitate to negotiate with suppliers. Discussing payment terms, delivery schedules, and volume discounts can lead to more favorable conditions.

-

Evaluate Total Cost of Ownership (TCO): Beyond the purchase price, consider the TCO, which includes installation, operation, maintenance, and disposal costs. A cheaper machine may incur higher long-term costs.

-

Pricing Nuances for International Buyers: For buyers from Africa, South America, the Middle East, and Europe, understanding local market conditions, currency fluctuations, and import regulations is vital. Engage local experts or consultants if necessary.

-

Leverage Local Networks: Building relationships with local suppliers can provide better insights into pricing trends and facilitate smoother transactions, especially in emerging markets.

Conclusion

Sourcing trash compactor machines involves careful consideration of various cost components and pricing influencers. By understanding these elements and employing strategic negotiation tactics, international B2B buyers can achieve significant cost savings while ensuring they invest in quality solutions that meet their operational needs. Always remember to request indicative prices and clarify terms to avoid miscommunication and unexpected costs.

Illustrative image related to trash compactor machine

Alternatives Analysis: Comparing trash compactor machine With Other Solutions

Introduction to Alternatives for Trash Compaction

When it comes to managing waste efficiently in a business setting, selecting the right solution is crucial. While trash compactor machines are a popular choice for reducing waste volume, there are alternative methods and technologies that can also achieve similar goals. Understanding the strengths and weaknesses of these alternatives can empower B2B buyers to make informed decisions tailored to their operational needs.

Comparison of Trash Compactor Machine with Alternatives

| Comparison Aspect | Trash Compactor Machine | Vertical Baler | Garbage Disposal Unit |

|---|---|---|---|

| Performance | Reduces waste volume by up to 80% | Compresses recyclables into bales for easy handling | Breaks down food waste for easy disposal |

| Cost | $1,000 – $2,000+ | $3,000 – $10,000+ | $200 – $800 |

| Ease of Implementation | Requires installation and space | Requires significant space and setup | Easy installation under sink |

| Maintenance | Moderate (periodic servicing) | High (requires frequent servicing) | Low (occasional maintenance) |

| Best Use Case | High-volume waste environments | Recycling operations and facilities | Residential and small business food waste management |

In-Depth Analysis of Alternatives

Vertical Baler

Vertical balers are machines designed to compress recyclables like cardboard and plastic into compact bales. They are especially beneficial for businesses that generate large amounts of recyclable waste, such as retail stores and warehouses. Pros include significant space savings and reduced disposal costs due to higher compaction ratios. Cons include a higher initial investment and the need for more space, as well as increased maintenance requirements, which can lead to operational downtime.

Garbage Disposal Unit

Garbage disposal units are installed under kitchen sinks to grind food waste into small particles, allowing for easy disposal through sewage systems. They are particularly useful in restaurants and food service businesses where food waste is generated regularly. Pros of garbage disposals include low cost and ease of installation. They also require minimal maintenance compared to larger systems. However, cons include limitations on the types of waste they can handle and the potential for plumbing issues if not maintained properly.

Conclusion: Choosing the Right Waste Management Solution

When evaluating waste management solutions, B2B buyers should consider their specific operational needs, including the type and volume of waste generated, available space, and budget constraints. Trash compactor machines are ideal for businesses focused on reducing waste volume and managing high volumes of trash, while vertical balers are suited for recycling-heavy operations. Garbage disposal units offer a low-cost, low-maintenance option for food waste but may not meet the needs of larger operations. Assessing these factors will enable businesses to select the most effective waste management solution tailored to their requirements.

Illustrative image related to trash compactor machine

Essential Technical Properties and Trade Terminology for trash compactor machine

What Are the Key Technical Properties of Trash Compactor Machines?

When evaluating trash compactor machines, understanding their technical specifications is crucial for making informed purchasing decisions. Below are some essential properties that B2B buyers should consider:

1. Compaction Ratio

The compaction ratio indicates the volume reduction capability of the compactor. Common ratios range from 3:1 to 5:1, meaning that for every three to five units of waste, only one unit remains after compaction. A higher ratio leads to fewer pickups and optimized waste management, which can significantly lower disposal costs.

2. Horsepower (HP)

Horsepower measures the power of the motor driving the compactor. Typical models range from 1/3 HP to 1.5 HP. A higher horsepower rating often translates to better performance, especially in industrial settings where waste volume and density are greater. This is critical for ensuring the machine can handle varying waste types efficiently.

3. Material Grade

The material used in the construction of the compactor affects its durability and longevity. Heavy-duty steel is commonly used for commercial compactors due to its strength and resistance to corrosion. For B2B buyers, selecting a machine made from high-quality materials can reduce maintenance costs and extend the lifespan of the equipment.

4. Cycle Time

Cycle time refers to the duration required for the compaction process to complete one full cycle. Machines with shorter cycle times can improve operational efficiency, allowing for quicker waste processing and less downtime. This is particularly important in high-volume environments such as restaurants or manufacturing facilities.

Illustrative image related to trash compactor machine

5. Control System

Modern compactors often come with advanced control systems that enhance usability and safety. Features such as touchscreens, remote controls, and automated alerts for maintenance are becoming standard. An effective control system can minimize operator error and streamline the compaction process, making it easier for staff to operate the equipment.

What Are Common Trade Terms Related to Trash Compactor Machines?

Understanding industry jargon is essential for B2B buyers to navigate discussions and negotiations effectively. Here are several common terms:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of trash compactors, working with OEMs ensures that buyers receive high-quality, compatible parts for maintenance and repairs. This is crucial for minimizing downtime and maintaining operational efficiency.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units that a supplier is willing to sell. Understanding MOQ is essential for businesses looking to manage inventory and costs effectively. Buyers should negotiate MOQs to align with their operational needs, especially for large-scale waste management operations.

Illustrative image related to trash compactor machine

3. RFQ (Request for Quotation)

An RFQ is a formal document that buyers send to suppliers to request pricing information for specific products or services. For trash compactors, an RFQ helps buyers gather cost estimates from multiple suppliers, enabling informed decision-making regarding budget and supplier selection.

4. Incoterms (International Commercial Terms)

Incoterms are standardized terms that define the responsibilities of buyers and sellers in international trade. They specify who is responsible for shipping, insurance, and tariffs. Familiarity with Incoterms is vital for B2B buyers engaged in cross-border transactions, ensuring clarity in agreements and minimizing risks.

5. TCO (Total Cost of Ownership)

TCO is a financial estimate that helps buyers assess the direct and indirect costs associated with purchasing and operating a trash compactor. This includes initial purchase price, maintenance, energy costs, and disposal fees. Understanding TCO allows companies to make more strategic investment decisions, ensuring long-term savings and operational efficiency.

By grasping these technical properties and trade terms, B2B buyers can navigate the complexities of acquiring trash compactor machines, optimizing their waste management processes while ensuring cost-effectiveness and efficiency.

Navigating Market Dynamics and Sourcing Trends in the trash compactor machine Sector

What Are the Current Market Dynamics and Key Trends in the Trash Compactor Machine Sector?

The global trash compactor machine market is witnessing significant growth driven by the increasing need for efficient waste management solutions across various industries. This is particularly relevant for international B2B buyers from Africa, South America, the Middle East, and Europe, where urbanization and population growth are intensifying waste generation. Countries like Nigeria and Germany are prioritizing waste reduction and recycling, pushing businesses to adopt compactors that minimize the volume of waste, thereby reducing disposal costs and environmental impact.

Emerging trends include the integration of smart technology into trash compactors, allowing for remote monitoring and optimization of waste management processes. Features such as compactors with built-in sensors can alert operators when the unit is full, facilitating timely waste disposal. Moreover, advancements in materials and designs are leading to more durable and energy-efficient compactors, appealing to environmentally conscious businesses.

In addition, the rise of e-commerce has created a demand for specialized compactors that can handle packaging waste effectively. B2B buyers are increasingly looking for solutions that not only address waste management but also align with their operational efficiencies and cost-saving objectives.

How Is Sustainability and Ethical Sourcing Reshaping the Trash Compactor Machine Sector?

Sustainability is becoming a core focus in the trash compactor machine sector, influencing both product development and sourcing strategies. B2B buyers are increasingly concerned with the environmental impact of their operations, prompting a shift toward ethical sourcing practices. This includes selecting suppliers who prioritize sustainable materials and manufacturing processes, thereby minimizing carbon footprints and promoting circular economies.

Illustrative image related to trash compactor machine

Certification programs such as Energy Star and Green Seal are gaining traction as businesses seek assurance that their equipment meets stringent environmental standards. Buyers are looking for compactors made from recycled materials or those that can be easily recycled at the end of their life cycle. Such practices not only enhance brand reputation but also comply with increasingly stringent regulations on waste management and environmental protection.

Moreover, the importance of ethical supply chains is underscored by consumer demand for transparency. Companies that demonstrate a commitment to sustainability through their sourcing practices are better positioned to attract eco-conscious clients and partners, particularly in regions where environmental regulations are becoming stricter.

What Is the Brief Evolution of Trash Compactor Machines in the B2B Context?

The evolution of trash compactor machines has significantly impacted waste management strategies in the B2B landscape. Initially developed in the mid-20th century, these machines were primarily used in industrial settings to reduce the volume of waste generated by manufacturing processes. Over the years, the technology has advanced, with the introduction of hydraulic systems and automated features that enhance efficiency and safety.

Illustrative image related to trash compactor machine

In recent decades, the emphasis on sustainability has driven innovations in design and functionality. Modern compactors are equipped with smart technology, allowing for real-time monitoring and data analytics, which help businesses optimize their waste management practices. As a result, trash compactors have transitioned from being mere waste reduction tools to integral components of comprehensive waste management systems, enabling businesses to improve operational efficiencies while meeting sustainability goals.

This evolution reflects broader trends in industry towards digitalization and environmental responsibility, making trash compactors a vital investment for B2B buyers looking to streamline their waste management processes and enhance their corporate sustainability initiatives.

Frequently Asked Questions (FAQs) for B2B Buyers of trash compactor machine

-

How do I choose the right trash compactor machine for my business needs?

Selecting the appropriate trash compactor depends on your waste type, volume, and available space. For businesses handling wet waste, self-contained compactors are ideal, while stationary compactors work best for dry waste and recyclables. Evaluate your waste stream and consider factors like compaction ratio, size, and ease of operation. Additionally, assess whether your facility can accommodate built-in or freestanding models, and ensure compliance with local regulations regarding waste management. -

What is the best type of trash compactor for restaurants?

For restaurants, self-contained compactors are often the best choice due to their ability to manage wet waste efficiently. These compactors combine the compactor and container into one unit, preventing leaks and odors. Ensure the model has a robust construction to handle heavy food waste and is equipped with features like odor management systems. Additionally, consider the compaction ratio to minimize the frequency of waste pickups, saving time and costs. -

What are the typical payment terms for purchasing a trash compactor machine internationally?

Payment terms can vary significantly by supplier and region. Common arrangements include upfront payments, letters of credit, or installment plans. Always negotiate terms that suit your cash flow while ensuring supplier reliability. Consider factors like currency exchange rates and transaction fees, especially when dealing with international suppliers. It’s advisable to conduct due diligence on the supplier’s payment history and reputation before finalizing any agreements. -

What should I consider when vetting suppliers for trash compactors?

When vetting suppliers, evaluate their experience in manufacturing trash compactors and their reputation in the industry. Request references and look for customer reviews or case studies to gauge their reliability. Additionally, assess their production capabilities, quality control processes, and certifications, such as ISO or CE compliance. It’s also wise to inquire about after-sales support and warranty terms, as these can significantly impact your long-term satisfaction with the equipment. -

Can I customize the features of a trash compactor machine for my specific needs?

Yes, many manufacturers offer customization options for trash compactors. You can tailor features such as size, compaction ratio, and operational controls to meet your specific requirements. When discussing customization, ensure you communicate your waste management goals and any operational constraints. Additionally, verify how customization might affect lead times, costs, and warranty coverage to avoid unexpected complications. -

What is the minimum order quantity (MOQ) for trash compactor machines?

The MOQ for trash compactors can vary widely depending on the manufacturer and model. Some suppliers may allow single-unit purchases, while others may require a minimum of several units to justify production costs. It’s advisable to discuss your needs with potential suppliers to understand their MOQ policies. This can also be an opportunity to negotiate better pricing or terms based on your projected order volume. -

How does logistics impact the purchase of trash compactor machines?

Logistics plays a crucial role in the procurement of trash compactors, particularly for international buyers. Consider shipping methods, transit times, and associated costs, including customs duties and taxes. Ensure that the supplier can provide reliable shipping options and track the shipment throughout the delivery process. Additionally, confirm that the compactor’s packaging is suitable for international transport to prevent damage during transit. -

What quality assurance measures should I expect from a reputable trash compactor supplier?

Reputable suppliers should have robust quality assurance (QA) measures in place, including regular inspections and testing of their products. Look for suppliers that adhere to international quality standards and provide certifications. Additionally, inquire about their QA processes, such as the materials used, assembly practices, and post-production testing. Understanding these measures will help ensure that the trash compactor you purchase meets your operational requirements and provides long-term reliability.

Top 5 Trash Compactor Machine Manufacturers & Suppliers List

1. KitchenAid – Garbage Disposals and Trash Compactors

Domain: kitchenaid.com

Registered: 1998 (27 years)

Introduction: KitchenAid offers garbage disposals with 1/2-, 3/4-, and 1-horsepower motors suitable for both large families and apartment living. Their trash compactors efficiently reduce trash volume by 80%, minimizing the need for frequent waste removal and eliminating the need for larger trash cans. Some models feature odor management systems that combine a fan and carbon filter to keep kitchens smelling fre…

2. Wastequip – Commercial Trash Compactors

Domain: wastequip.com

Registered: 1997 (28 years)

Introduction: Wastequip offers a range of commercial trash compactors designed for various waste management needs. Key product types include: 1. Self-Contained Compactor: Ideal for high volumes of wet waste, commonly used in restaurants and grocery stores. 2. Stationary Compactor: Compresses dry waste and recyclables, suitable for warehouses and retail stores. 3. Apartment Compactor: Smaller units for multi-fam…

3. US Appliance – Trash Compactors

Domain: us-appliance.com

Registered: 1999 (26 years)

Introduction: Our compactors can help reduce trash to 80% of its original size. A trash compactor can also be used to recycle aluminum cans, plastic bottles or paper products. Less garbage is good for the environment.

4. Compactors Inc – Waste Management Solutions

Domain: compactorsinc.com

Registered: 1999 (26 years)

Introduction: Compactors Inc offers a wide range of waste management solutions including:

1. **Compactors**:

– Vertical Trash Compactors

– Trash Lift Series

– Multi Chamber Compactors

– Marine Offshore Compactors & Balers

– Hazardous Waste Compactor

– Medical Industry Sanitary Compactors

– Chute Fed Compactors

– Large Compactors

– Compactor Bags & Accessories

2. **Crusher…

5. KitchenAid – Stainless Steel Under-counter Trash Compactor

Domain: goodhousekeeping.com

Registered: 1995 (30 years)

Introduction: [{‘name’: ‘KitchenAid Stainless Steel Under-counter Trash Compactor’, ‘type’: ‘Built-in’, ‘compaction_ratio’: ‘5 to 1’, ‘capacity’: ‘1.4 cu. ft.’, ‘width’: ’15 inches’, ‘motor_size’: ‘1/3 horsepower’, ‘pros’: [‘Has charcoal filter and fan for odors’, ‘Hidden controls for integrated design’, ‘Holds more than others’], ‘cons’: [‘Pricey’]}, {‘name’: ‘GE Appliances Built-In Panel Ready Trash Compactor…

Strategic Sourcing Conclusion and Outlook for trash compactor machine

In the rapidly evolving landscape of waste management, strategic sourcing of trash compactor machines stands as a critical lever for operational efficiency and sustainability. By investing in advanced compaction technology, businesses not only reduce their waste volume significantly—up to 80% in some models—but also optimize their waste management processes, leading to lower disposal costs and enhanced safety.

International buyers from regions such as Africa, South America, the Middle East, and Europe must prioritize sourcing from reputable manufacturers who offer reliable, innovative solutions tailored to their unique operational needs. Consideration of factors like compaction ratio, energy efficiency, and user-friendly features can yield substantial long-term savings and improved environmental compliance.

Looking ahead, the demand for trash compactor machines is set to increase, driven by growing environmental regulations and the need for waste reduction strategies. Now is the time for businesses to reassess their waste management strategies and embrace cutting-edge compaction solutions. Engage with suppliers who understand local market dynamics and can provide tailored support to ensure your operations remain competitive and sustainable in an increasingly eco-conscious world.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.