Trap Door Hinges: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for trap door hinges

In the dynamic landscape of global commerce, sourcing trap door hinges presents unique challenges for B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. The quest for high-quality, durable, and cost-effective hinges can be daunting, especially when considering the diverse applications—from industrial uses to architectural designs. This comprehensive guide is tailored to help international buyers navigate the complexities of the trap door hinge market, providing essential insights into various types, applications, and the best practices for supplier vetting.

Understanding the intricacies of trap door hinges is vital for making informed purchasing decisions. This guide delves into the key characteristics of different hinge types, such as flush hinges that maintain a discreet profile and heavy-duty hinges designed for high-load applications. Additionally, we will explore the importance of selecting the right materials—like stainless steel for corrosion resistance in harsh environments—and the significance of understanding regional regulations that may impact your sourcing strategies.

By equipping yourself with this knowledge, you will be better positioned to assess suppliers effectively, compare costs, and ultimately secure the best products for your projects. Whether you’re in Saudi Arabia, Nigeria, or beyond, this guide empowers you to make strategic decisions that enhance operational efficiency and meet your unique requirements in the global market for trap door hinges.

Understanding trap door hinges Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Flush Hinges | Completely flat when closed, minimal visible hardware | Residential and commercial trap doors | Pros: Discreet design; smooth surface. Cons: May require precise installation. |

| Lift-Off Hinges | Allows for quick removal of the door, typically heavy-duty | Industrial applications, heavy doors | Pros: Easy maintenance; robust construction. Cons: May not be suitable for high-security areas. |

| Gas Strut Hinges | Assists in lifting and holding doors open, adjustable tension | Commercial and industrial settings | Pros: Reduces effort to open; safe operation. Cons: Requires regular maintenance for gas struts. |

| Spring-Loaded Hinges | Automatically returns the door to a closed position | Safety access doors in commercial spaces | Pros: Enhances safety; convenient. Cons: Potential wear on springs over time. |

| Concealed Hinges | Hidden from view when the door is closed, elegant finish | High-end residential and commercial doors | Pros: Aesthetic appeal; clean lines. Cons: Installation complexity can increase costs. |

What Are Flush Hinges and Their Applications?

Flush hinges are designed to lie completely flat against the surface of a trap door when closed, offering a seamless appearance. This design is particularly suitable for applications where aesthetics are important, such as in residential settings or commercial spaces that prioritize design. When purchasing flush hinges, buyers should consider the thickness and material of the door, as well as the required load capacity. While they provide a discreet look, precise installation is essential to ensure functionality.

Why Choose Lift-Off Hinges for Heavy-Duty Needs?

Lift-off hinges are engineered for durability and allow for the easy removal of doors, making them ideal for industrial applications where maintenance is frequent. These hinges are typically constructed from heavy-duty materials to support the weight of large doors. When selecting lift-off hinges, businesses should assess the door’s weight and frequency of use. While they offer significant convenience, they may not be the best choice for areas requiring high security due to their removable nature.

Illustrative image related to trap door hinges

How Do Gas Strut Hinges Enhance Functionality?

Gas strut hinges are designed to facilitate smooth operation by assisting with the lifting and lowering of trap doors. They are particularly beneficial in commercial environments where heavy doors are common. Buyers should consider the weight of the door and the required tension for optimal performance. Although these hinges reduce the effort needed to operate doors, they require regular maintenance to ensure the gas struts remain functional over time.

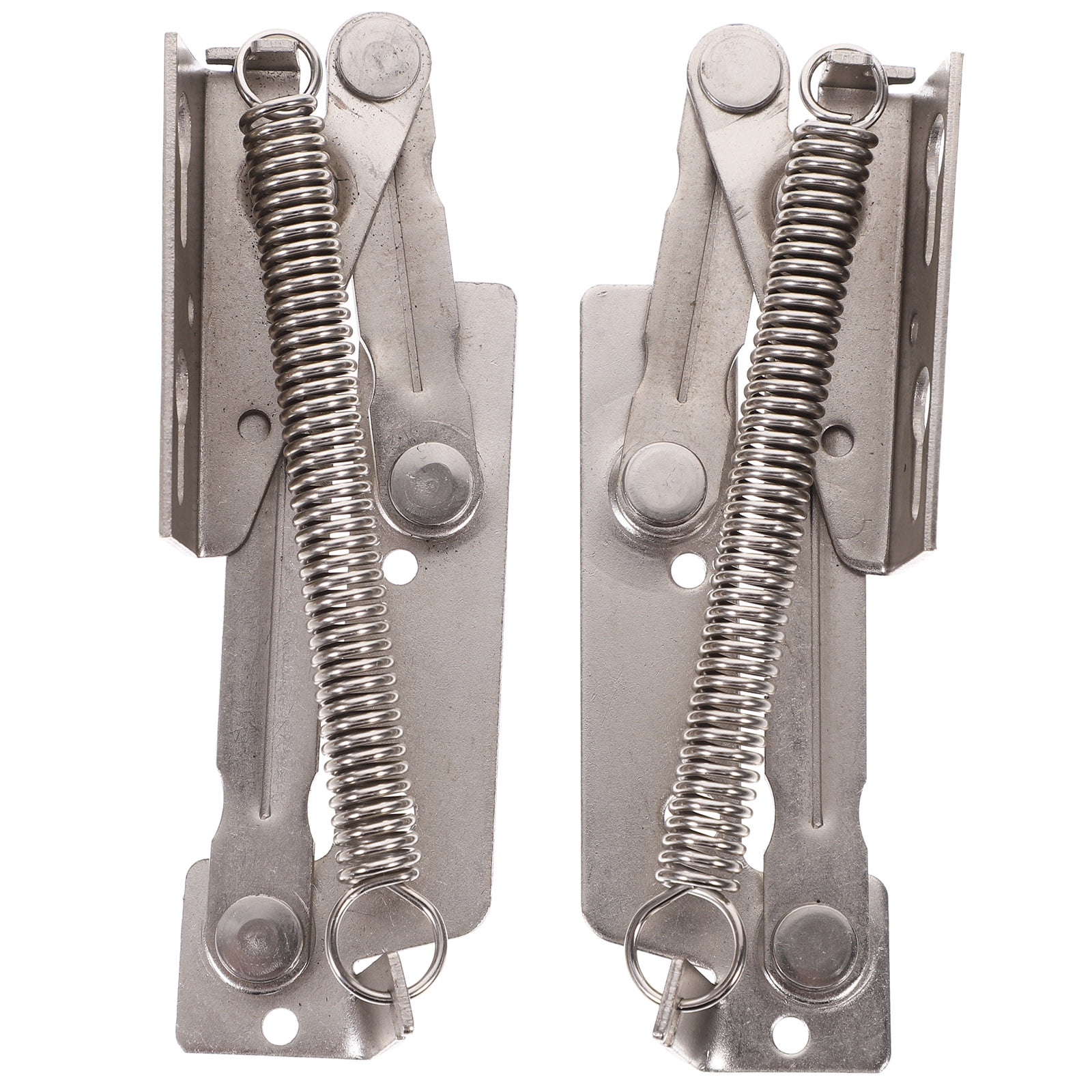

What Are the Benefits of Spring-Loaded Hinges?

Spring-loaded hinges are designed to automatically return the door to a closed position, making them an excellent choice for safety access doors in commercial spaces. These hinges enhance safety by ensuring that doors do not remain ajar unintentionally. When purchasing spring-loaded hinges, businesses should evaluate the spring strength and durability, as wear can occur over time. While they provide convenience and safety, regular checks are necessary to maintain their functionality.

Why Consider Concealed Hinges for Aesthetic Appeal?

Concealed hinges are hidden from view when the door is closed, offering a sleek and modern appearance ideal for high-end residential and commercial doors. They are often used in applications where design integrity is paramount. Buyers should assess the installation complexity and compatibility with the door design, as concealed hinges can increase overall costs. While they enhance the aesthetic appeal of a space, the installation process may require specialized skills.

Key Industrial Applications of trap door hinges

| Industry/Sector | Specific Application of trap door hinges | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Access panels in commercial buildings | Enhances building functionality and accessibility | Durability, weight capacity, and material specifications |

| Maritime | Boat hatches and storage compartments | Provides secure, waterproof access to storage areas | Corrosion resistance and compliance with marine standards |

| Agriculture | Grain storage and equipment access | Facilitates safe and efficient access to stored goods | Load-bearing capacity and weather resistance |

| Hospitality | Hidden access doors in hotels and restaurants | Maintains aesthetics while providing functionality | Design compatibility and ease of use |

| Industrial Warehousing | Trap doors for machinery access | Improves maintenance efficiency and safety | Weight tolerance and integration with existing systems |

How Are Trap Door Hinges Used in Construction Projects?

In the construction industry, trap door hinges are essential for creating access panels in commercial buildings. These hinges allow for easy access to mechanical systems, plumbing, and electrical wiring, ensuring that maintenance can be conducted efficiently without compromising the building’s integrity. Buyers in this sector need to consider the durability and weight capacity of the hinges, as they must support heavy panels while remaining functional over time.

Illustrative image related to trap door hinges

What Role Do Trap Door Hinges Play in Maritime Applications?

In maritime applications, trap door hinges are commonly used for boat hatches and storage compartments. These hinges provide secure, waterproof access to vital storage areas, ensuring that equipment and supplies remain protected from the elements. International buyers must prioritize corrosion resistance and compliance with marine standards to ensure longevity and reliability in harsh environments, particularly in coastal regions.

How Do Trap Door Hinges Improve Agricultural Operations?

In agriculture, trap door hinges are utilized for access to grain storage and equipment. These hinges facilitate safe and efficient access to stored goods, which is crucial for maintaining inventory and ensuring that operations run smoothly. Buyers in this sector should focus on load-bearing capacity and weather resistance to meet the demands of outdoor environments and heavy usage.

Why Are Trap Door Hinges Important in the Hospitality Industry?

In the hospitality sector, trap door hinges are often used for hidden access doors in hotels and restaurants. These hinges maintain the aesthetic appeal of the venue while providing necessary functionality for staff. When sourcing these hinges, businesses should consider design compatibility and ease of use to ensure that staff can operate them quickly and safely without disrupting the guest experience.

How Do Trap Door Hinges Enhance Industrial Warehousing Efficiency?

In industrial warehousing, trap door hinges are critical for enabling access to machinery and storage areas. They improve maintenance efficiency and safety by allowing workers to reach equipment quickly without hindrance. Companies in this sector must ensure that the hinges they select can tolerate substantial weight and integrate seamlessly with existing systems to optimize workflow and safety protocols.

3 Common User Pain Points for ‘trap door hinges’ & Their Solutions

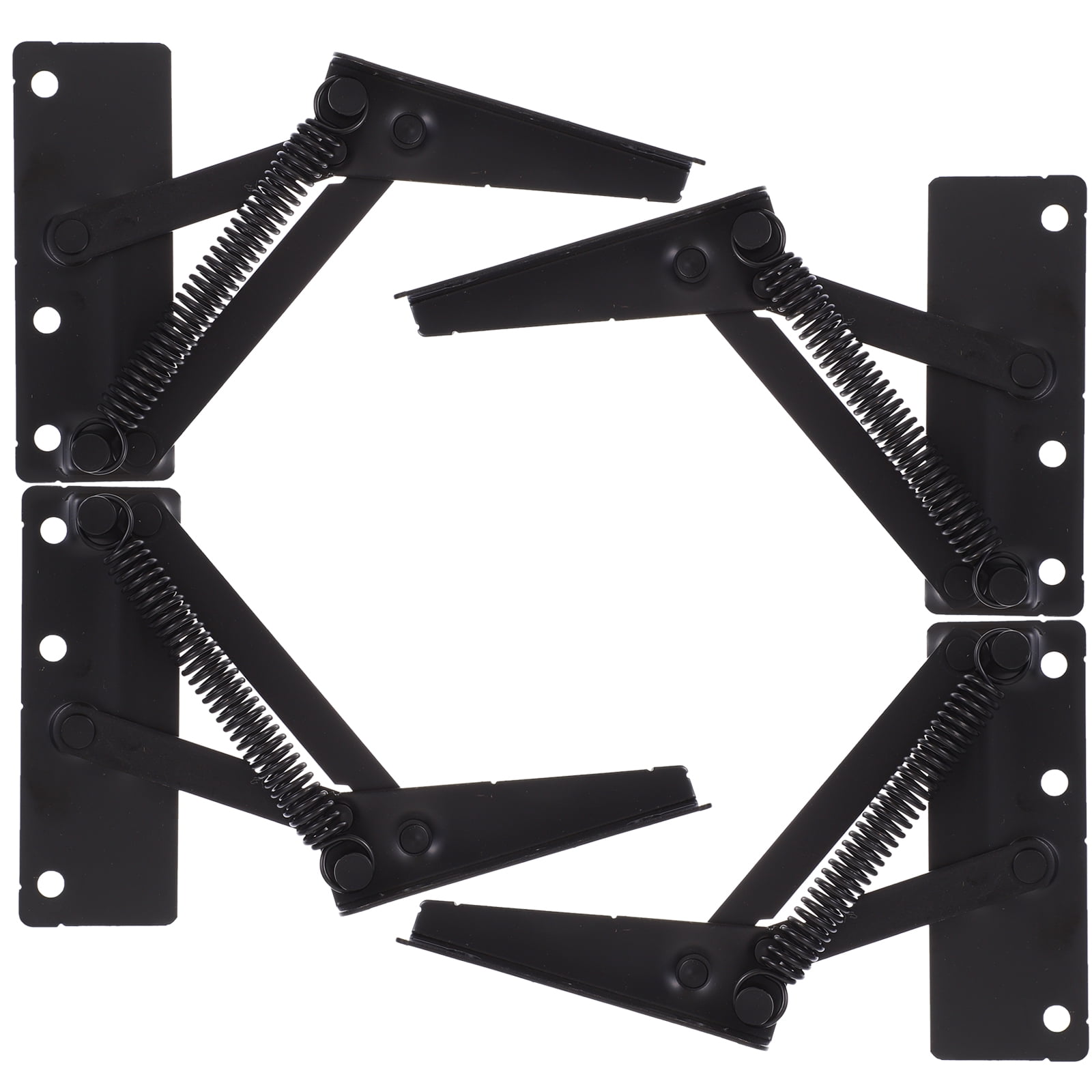

Scenario 1: Sourcing Durable Trap Door Hinges for Harsh Environments

The Problem: B2B buyers operating in coastal or industrial regions often face the challenge of sourcing trap door hinges that can withstand extreme conditions, such as high humidity, saltwater exposure, or heavy loads. Many standard hinges corrode quickly, leading to costly replacements and potential safety hazards. Buyers need reliable hardware that can perform consistently over time without frequent maintenance or replacement, which can disrupt operations and lead to unexpected downtime.

The Solution: To overcome this issue, buyers should focus on selecting trap door hinges made from high-quality materials specifically designed for corrosion resistance, such as 316 stainless steel. This material is ideal for marine environments due to its superior resistance to rust and corrosion. Buyers should also consider the hinge’s load capacity and ensure it meets the specific weight requirements of their application. Engaging with suppliers who specialize in marine-grade hardware can help buyers find the right products. Furthermore, conducting thorough inspections of hinges before installation can prevent future issues. Finally, buyers should establish a regular maintenance schedule to ensure that hinges remain in optimal condition, which includes cleaning and lubricating them periodically.

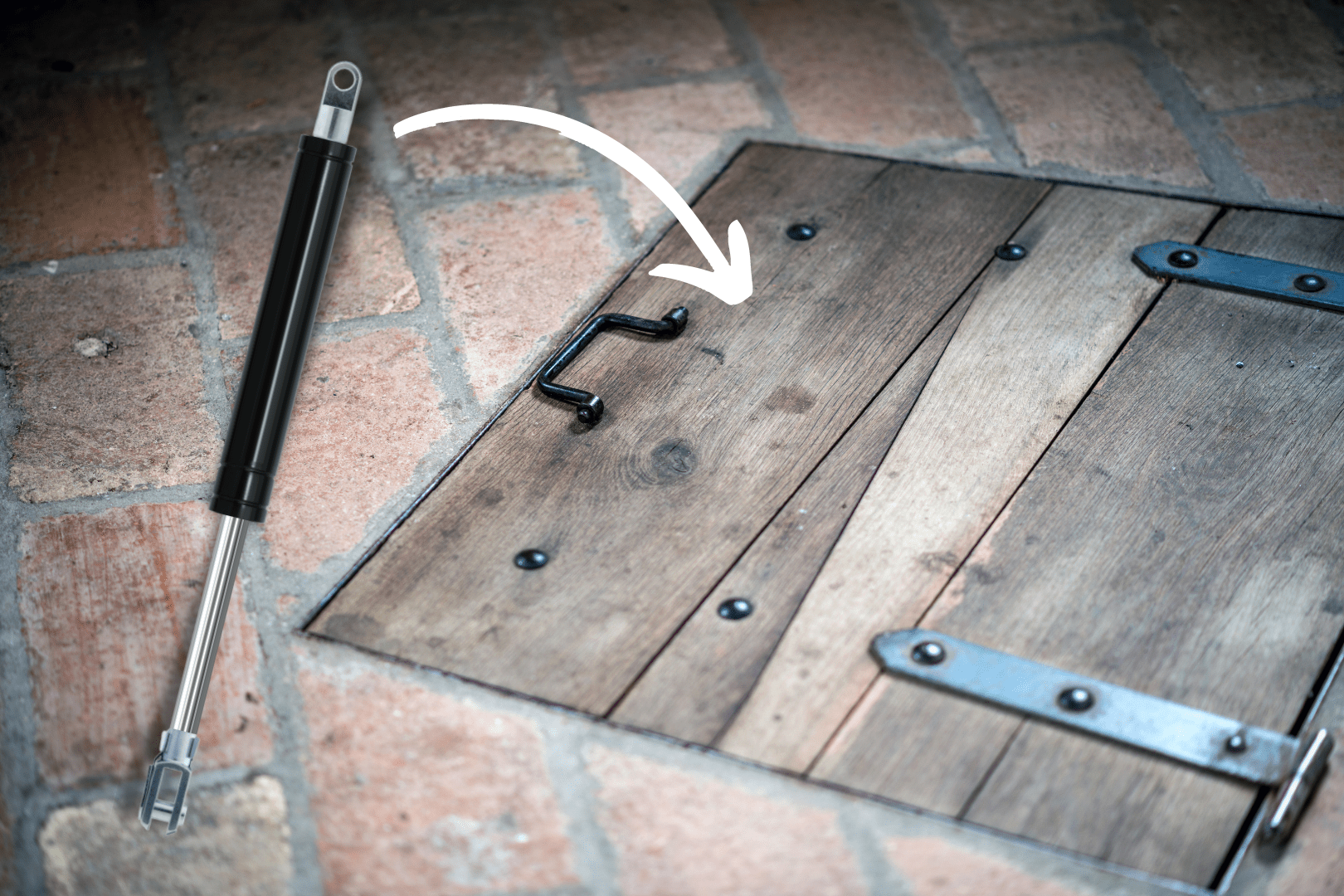

Illustrative image related to trap door hinges

Scenario 2: Ensuring Seamless Operation in High-Traffic Areas

The Problem: In commercial spaces where trap doors are frequently accessed, such as warehouses or retail environments, hinges that do not operate smoothly can lead to operational inefficiencies. Heavy doors that bind or stick can create safety hazards and frustrate staff, ultimately impacting productivity. Buyers need solutions that allow for easy access while maintaining a professional appearance and safety standards.

The Solution: A viable solution for this pain point is to invest in high-performance floor door hinge systems that incorporate gas struts. These systems allow doors to lift smoothly and remain flush with the floor when closed, ensuring both functionality and aesthetics. Buyers should assess the weight and dimensions of their doors to select the appropriate number of hinges and gas struts needed for optimal operation. It is also beneficial to choose systems that feature integrated mounting plates for easy installation. Additionally, implementing a testing phase post-installation can help identify any binding issues early on, allowing for adjustments or replacements before the door goes into full use.

Scenario 3: Finding the Right Aesthetic for Architectural Applications

The Problem: B2B buyers involved in architectural design projects often struggle with sourcing trap door hinges that align with specific aesthetic requirements while still meeting functional needs. A mismatch in design can detract from the overall appearance of a space, especially in high-end residential or commercial projects where visual appeal is paramount. Finding hinges that are both discreet and stylish can be a daunting task.

The Solution: To address this challenge, buyers should explore specialty flush hinges and finishes that complement the design of their project. Options such as polished brass, brushed nickel, or custom finishes can enhance the visual appeal of trap doors. Collaborating with suppliers who offer customizable hinge solutions can provide more options to match specific design aesthetics. Buyers should also consider the installation method—flush hinges that lie flat against the surface of the door can create a seamless look. In addition, consulting with architects or designers during the selection process can ensure that the chosen hinges not only meet functional requirements but also enhance the overall aesthetic of the project. This collaborative approach leads to more satisfying outcomes and helps avoid costly design revisions later on.

Strategic Material Selection Guide for trap door hinges

What are the Key Properties of Common Materials for Trap Door Hinges?

When selecting materials for trap door hinges, it is essential to consider properties such as corrosion resistance, strength, and temperature tolerance. The most common materials used in the production of trap door hinges include stainless steel, brass, aluminum, and carbon steel. Each material has distinct characteristics that make it suitable for specific applications.

How Does Stainless Steel Perform in Trap Door Hinges?

Stainless steel, particularly grades like 316, is renowned for its exceptional corrosion resistance and strength. This material can withstand harsh environments, making it ideal for applications in coastal regions or areas with high humidity. Its high tensile strength ensures durability under heavy loads, which is crucial for trap doors that may experience frequent use.

Pros: Stainless steel hinges are long-lasting, resistant to rust and corrosion, and can handle significant weight without deforming. They are also relatively easy to maintain.

Cons: The primary drawback is cost; stainless steel hinges are generally more expensive than other materials. Additionally, they can be heavier, which may affect installation in certain applications.

For international buyers, compliance with standards such as ASTM and DIN is crucial, especially in regions like Europe and the Middle East, where quality assurance is paramount.

What Advantages Does Brass Offer for Trap Door Hinges?

Brass is another popular choice for trap door hinges, known for its aesthetic appeal and moderate corrosion resistance. It is often used in decorative applications where appearance is a priority, such as in residential settings or high-end commercial projects.

Pros: Brass hinges are visually appealing, lightweight, and resistant to corrosion, making them suitable for indoor applications. They also have good machinability, allowing for intricate designs.

Cons: Brass is not as strong as stainless steel and may not be suitable for heavy-duty applications. It can also tarnish over time, requiring regular maintenance to preserve its appearance.

For buyers in regions like Africa and South America, where humidity can be an issue, it’s essential to consider the specific environment in which brass hinges will be used to avoid premature degradation.

Illustrative image related to trap door hinges

How Does Aluminum Compare for Trap Door Hinges?

Aluminum is lightweight and offers good corrosion resistance, making it an attractive option for applications where weight is a concern. It is often used in portable or temporary structures, such as exhibition stands or mobile units.

Pros: The lightweight nature of aluminum makes it easy to handle and install. It is also cost-effective compared to stainless steel and brass.

Cons: While aluminum is resistant to corrosion, it is not as strong as stainless steel, which may limit its application in heavy-duty scenarios. It can also be prone to bending under significant weight.

For international buyers, particularly in the Middle East, where temperature fluctuations can be extreme, aluminum’s thermal properties should be considered to ensure reliable performance.

What Role Does Carbon Steel Play in Trap Door Hinges?

Carbon steel is known for its strength and affordability. It is often used in heavy-duty applications where high load-bearing capacity is required. However, it is more susceptible to corrosion compared to stainless steel and brass.

Pros: Carbon steel hinges are durable and can support heavy loads, making them suitable for industrial applications. They are also less expensive than stainless steel.

Cons: The primary limitation is their susceptibility to rust and corrosion, necessitating protective coatings or regular maintenance to prolong their lifespan.

For B2B buyers in regions like Nigeria and South America, understanding local environmental conditions is essential to determine whether carbon steel is a viable option.

Summary Table of Material Selection for Trap Door Hinges

| Material | Typical Use Case for trap door hinges | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Coastal applications, heavy-duty use | Exceptional corrosion resistance | Higher cost, heavier weight | High |

| Brass | Decorative indoor applications | Aesthetic appeal, lightweight | Not as strong, tarnishes over time | Medium |

| Aluminum | Portable structures, lightweight needs | Lightweight, cost-effective | Less strength, prone to bending | Low |

| Carbon Steel | Industrial applications, heavy loads | Durable, affordable | Susceptible to rust, requires coating | Medium |

This guide provides a comprehensive overview of material selection for trap door hinges, enabling international B2B buyers to make informed decisions based on their specific needs and environmental conditions.

Illustrative image related to trap door hinges

In-depth Look: Manufacturing Processes and Quality Assurance for trap door hinges

What Are the Key Stages in the Manufacturing Process of Trap Door Hinges?

The manufacturing process for trap door hinges involves several critical stages, each essential for producing high-quality, durable products that meet the demands of various applications.

Material Preparation

The first stage in the manufacturing process is material preparation. Trap door hinges are typically made from robust materials such as stainless steel, brass, or aluminum, which are chosen for their strength and corrosion resistance. During this phase, raw materials are sourced and inspected for quality. This involves checking for defects, ensuring that the materials meet specified standards, and confirming their suitability for further processing.

Forming Techniques Used in Trap Door Hinge Manufacturing

After preparation, the forming stage begins. This involves shaping the raw materials into the desired hinge components. Common techniques include:

Illustrative image related to trap door hinges

- Stamping: This method uses a press to shape flat sheets of metal into hinge parts. It is efficient for high-volume production and ensures uniformity in the final product.

- Casting: In some cases, hinges may be cast from molten metal into molds, allowing for complex designs that would be difficult to achieve through stamping.

- Machining: Precision machining is often employed to achieve tight tolerances, especially for critical areas where the hinge pivots.

These forming techniques ensure that the components are not only functional but also meet aesthetic requirements.

How Are Trap Door Hinges Assembled?

Following the forming process, assembly takes place. This involves bringing together various components such as the hinge plates, pins, and any additional features like springs or gas struts.

- Welding: For stainless steel components, welding is a common method to ensure strong joints.

- Riveting: In some designs, rivets may be used to secure parts together.

- Screws and Fasteners: These are often employed for ease of assembly and maintenance.

During assembly, attention to detail is crucial to ensure that the hinges operate smoothly and meet safety standards.

What Finishing Processes Are Commonly Used for Trap Door Hinges?

The final stage in the manufacturing process is finishing. This not only enhances the appearance of the hinges but also improves their durability against environmental factors.

- Coating: Many trap door hinges undergo processes such as powder coating or plating (e.g., chrome or nickel plating) to enhance corrosion resistance and aesthetic appeal.

- Polishing: For hinges that require a high shine, polishing processes are employed to achieve a smooth, reflective surface.

- Quality Control Checks: Each finished product is subjected to rigorous checks to ensure it meets specified standards.

These finishing techniques contribute significantly to the longevity and performance of trap door hinges, making them suitable for diverse applications.

What Quality Assurance Practices Should B2B Buyers Look For?

Quality assurance (QA) is a vital aspect of the manufacturing process that ensures products meet specified requirements and standards. For B2B buyers, understanding QA practices is essential for making informed purchasing decisions.

What International Standards Should Trap Door Hinges Comply With?

Several international standards govern the quality of hardware products, including trap door hinges. Key standards include:

- ISO 9001: This standard outlines the criteria for a quality management system and is applicable to any organization, regardless of its size or industry. Compliance indicates that a manufacturer has established a systematic approach to managing its processes and enhancing customer satisfaction.

- CE Marking: For products sold within the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: For hinges used in specific applications, such as oil and gas, adherence to American Petroleum Institute (API) standards may be required.

These certifications are critical indicators of a manufacturer’s commitment to quality and safety.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) encompasses various checkpoints throughout the manufacturing process, including:

- Incoming Quality Control (IQC): This initial step involves inspecting raw materials to ensure they meet specified standards before they enter production.

- In-Process Quality Control (IPQC): During manufacturing, regular checks are performed to monitor the production process and detect any deviations from quality standards.

- Final Quality Control (FQC): After production, the finished hinges undergo thorough testing and inspections to verify that they meet all performance and aesthetic criteria.

These checkpoints help identify and rectify issues early, reducing the risk of defective products reaching the market.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is crucial.

What Methods Can Buyers Use to Assess Supplier Quality?

- Audits: Conducting on-site audits of potential suppliers can provide insight into their manufacturing processes and quality control measures. This is an effective way to assess their compliance with international standards.

- Quality Reports: Requesting detailed quality assurance reports can help buyers understand how suppliers monitor and maintain quality throughout the production cycle.

- Third-Party Inspections: Engaging independent inspection services can provide an unbiased evaluation of a supplier’s quality control practices.

Are There Any QC/CERT Nuances for International Buyers?

When sourcing trap door hinges internationally, buyers should be aware of potential nuances in quality certification. Different regions may have varying standards and regulations. Understanding these local requirements is essential to ensure compliance and product acceptance in specific markets.

Conclusion

Manufacturing trap door hinges involves a detailed process that combines material preparation, forming, assembly, and finishing, all supported by robust quality assurance practices. B2B buyers should prioritize suppliers who adhere to international quality standards and demonstrate a commitment to maintaining high-quality products through comprehensive QC measures. By doing so, buyers can ensure they receive reliable and durable hinges that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘trap door hinges’

To assist international B2B buyers in procuring trap door hinges effectively, this practical sourcing guide outlines critical steps to ensure a successful purchase. This checklist will help you navigate the complex landscape of hardware sourcing, ensuring you select the right products and suppliers for your specific needs.

Step 1: Define Your Technical Specifications

Before beginning your search, clearly outline the specifications required for your trap door hinges. Consider factors such as size, weight capacity, material (e.g., stainless steel for corrosion resistance), and the type of hinge mechanism (e.g., flush hinges for discreet installations). Establishing these parameters will help streamline your sourcing process and ensure compatibility with your project requirements.

Step 2: Research Market Trends and Innovations

Stay informed about the latest trends in hinge technology and design. Innovations such as integrated gas struts or advanced locking mechanisms can enhance functionality and safety. Investigate which features are gaining popularity in your target markets, particularly in regions like Africa, South America, and the Middle East, where environmental factors may dictate specific needs.

Step 3: Identify Reliable Suppliers

Choosing the right supplier is crucial for securing quality products. Look for manufacturers or distributors with a proven track record in the industry. Check for certifications or affiliations with recognized industry bodies, as these can be indicators of reliability and quality. Request product samples to evaluate material quality and finish before making a bulk purchase.

Illustrative image related to trap door hinges

Step 4: Evaluate Supplier Certifications and Compliance

Verify that potential suppliers comply with relevant industry standards and regulations. For instance, if sourcing for marine applications, ensure that the hinges meet marine-grade standards for corrosion resistance. This step is vital to prevent future issues related to product failure or legal liabilities, especially in regions with stringent safety regulations.

Step 5: Request Detailed Quotes

Once you have shortlisted potential suppliers, request detailed quotations that include pricing, minimum order quantities, lead times, and shipping costs. Pay attention to the terms of payment and any warranties offered. A comprehensive quote allows for better budget planning and avoids unexpected costs later in the procurement process.

Step 6: Review After-Sales Support and Warranty

Inquire about the after-sales support provided by the supplier, including return policies, warranty terms, and customer service availability. A supplier with robust support can assist you in resolving issues quickly and efficiently. Ensure that you understand the warranty coverage, as this can significantly affect long-term costs and product performance.

Step 7: Finalize Your Order and Maintain Documentation

Once you have selected a supplier, finalize your order by confirming all details in writing. Maintain thorough documentation of the purchase agreement, including specifications, pricing, and delivery timelines. This documentation can be crucial for any future disputes or warranty claims, ensuring you have a clear record of the transaction.

By following this practical checklist, B2B buyers can navigate the procurement process for trap door hinges more effectively, ensuring they make informed decisions that align with their project goals and requirements.

Comprehensive Cost and Pricing Analysis for trap door hinges Sourcing

What Are the Key Cost Components for Trap Door Hinges?

Understanding the cost structure of trap door hinges is essential for B2B buyers looking to make informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly impacts the cost. Stainless steel, particularly marine-grade 316, is a popular option due to its corrosion resistance, especially in coastal areas. Other materials like brass or specialized alloys may be used, depending on specific project requirements.

-

Labor: Labor costs can vary based on the complexity of the hinge design and the manufacturing processes involved. Automated production methods can reduce labor costs, while custom or intricate designs may require skilled labor, driving costs higher.

-

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and administrative expenses. High-volume manufacturers may achieve economies of scale that can lower the overhead costs per unit.

-

Tooling: The initial investment in tooling for custom or specialized hinges can be substantial. This cost is typically amortized over larger production runs, making it crucial for buyers to consider order volumes.

-

Quality Control: Ensuring product quality involves inspection and testing, which adds to the overall cost. Certifications for quality assurance can also affect pricing, especially for international buyers who may require compliance with specific standards.

-

Logistics: Shipping and handling costs are particularly important for international buyers. These can fluctuate based on the destination, shipping method, and current fuel prices.

-

Margin: Suppliers will include a profit margin in their pricing, which can vary based on market demand and competition.

How Do Price Influencers Affect Trap Door Hinge Costs?

Several factors can influence the pricing of trap door hinges, making it essential for buyers to understand these nuances.

-

Volume/MOQ (Minimum Order Quantity): Bulk purchases can lead to significant discounts. Manufacturers often set minimum order quantities that, when met, can lower the cost per unit.

-

Specifications and Customization: Customized hinges tailored to specific applications often come at a premium. Buyers should weigh the benefits of custom features against the additional costs.

-

Quality and Certifications: Hinges that meet international standards or possess certifications for durability and safety may command higher prices. Buyers in regions with stringent regulations, such as Europe, must consider this when sourcing.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their quality assurance processes, while newer or less known suppliers might offer competitive pricing to gain market share.

-

Incoterms: Understanding shipping terms is crucial. Incoterms define who is responsible for shipping, insurance, and tariffs, which can significantly affect the total cost of ownership.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing Trap Door Hinges?

For B2B buyers, especially from Africa, South America, the Middle East, and Europe, several strategies can enhance cost efficiency and ensure a favorable purchase.

-

Negotiation: Always engage in negotiations. Suppliers may have flexibility in pricing, especially for large orders or long-term contracts.

-

Assess Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, installation, and potential replacement costs over time. Selecting high-quality hinges can reduce long-term expenses.

-

Understand Pricing Nuances: Be aware that international shipping can introduce additional costs such as tariffs and customs duties. It’s vital to factor these into the overall budget.

-

Research Local Suppliers: Whenever possible, sourcing from local suppliers can reduce logistics costs and lead times. Additionally, understanding the local market can provide insights into pricing trends.

-

Stay Informed on Market Trends: Regularly monitoring market prices and trends can help buyers make informed decisions and identify the best times to purchase.

Disclaimer

The prices mentioned are indicative and subject to change based on market conditions, supplier pricing strategies, and other factors. Buyers are encouraged to obtain quotes from multiple suppliers to ensure competitive pricing and optimal sourcing decisions.

Alternatives Analysis: Comparing trap door hinges With Other Solutions

Exploring Viable Alternatives to Trap Door Hinges

In various industries, especially in construction and design, choosing the right hardware for trap doors is crucial for functionality and aesthetics. While trap door hinges are a popular choice, several alternative solutions can meet similar needs. Understanding these alternatives can help B2B buyers make informed decisions that align with their specific project requirements.

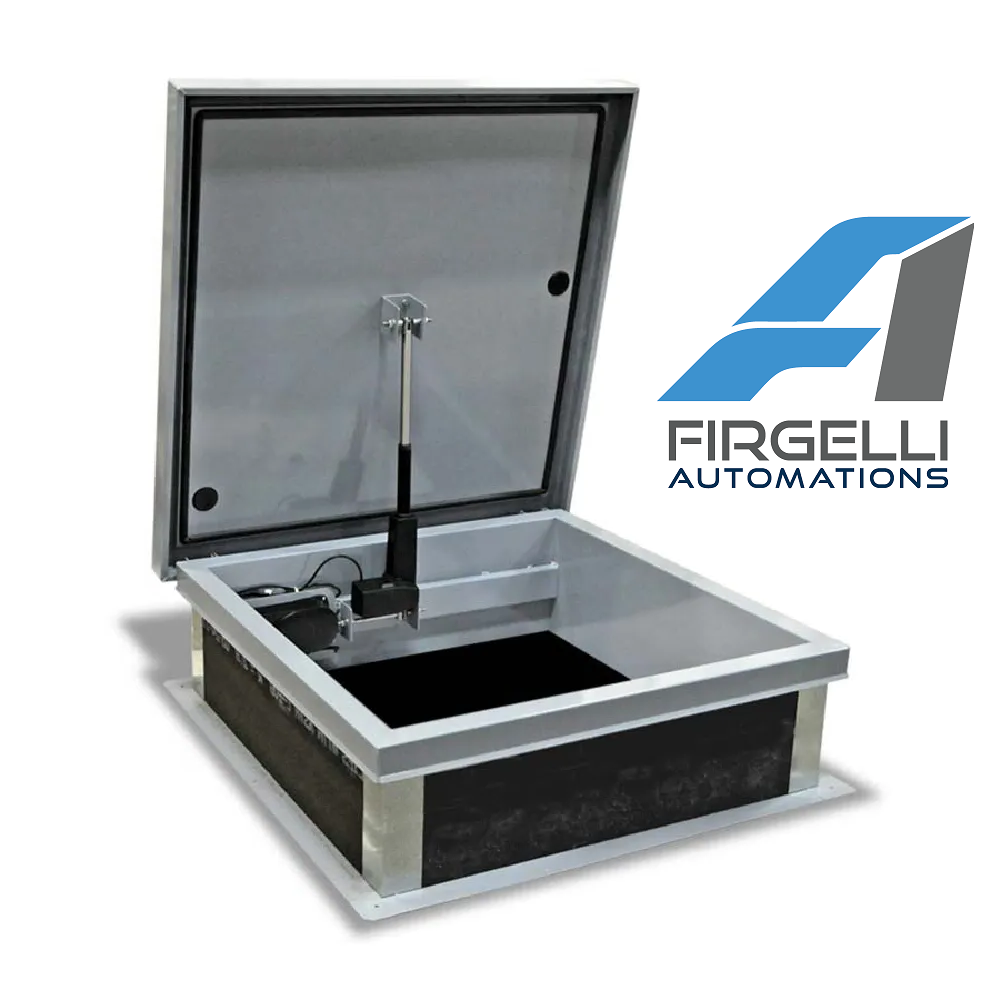

| Comparison Aspect | Trap Door Hinges | Floor Door Hinge System | Concealed Pivot Hinges |

|---|---|---|---|

| Performance | Reliable for lightweight doors | Excellent for heavy doors | Smooth operation, discreet |

| Cost | Moderate ($8 – $50) | High ($1,480+) | Moderate ($30 – $200) |

| Ease of Implementation | Straightforward installation | Complex, requires precise alignment | Easy, but needs careful planning |

| Maintenance | Low maintenance | Moderate maintenance due to gas struts | Low maintenance |

| Best Use Case | Residential and light commercial applications | Commercial settings, high-traffic areas | High-end residential, modern designs |

What Are the Advantages and Disadvantages of the Floor Door Hinge System?

The Floor Door Hinge System offers a unique solution where the door sits flush with the floor, creating a seamless look. This system is ideal for heavy doors, supporting weights of up to 450 lbs. However, its cost can be prohibitive, especially for smaller projects. The installation process is more complex, requiring accurate alignment and potentially professional installation. Additionally, it involves gas struts that may require periodic maintenance.

Illustrative image related to trap door hinges

How Do Concealed Pivot Hinges Compare?

Concealed pivot hinges provide a modern alternative, allowing for a clean aesthetic as they are hidden within the door. They offer smooth operation and are suitable for high-end residential projects or contemporary commercial applications. However, they can be costly and require precise planning during installation to ensure functionality. Maintenance is minimal, but the initial installation can be more complicated compared to traditional trap door hinges.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the appropriate solution for trap doors, B2B buyers should assess their specific project requirements, including weight capacity, design preferences, and budget constraints. Trap door hinges provide a reliable and cost-effective option for lighter applications, while the Floor Door Hinge System is best suited for heavy-duty needs in commercial environments. For high-end residential projects, concealed pivot hinges may offer the desired aesthetic and functionality. By carefully considering these factors, buyers can choose the most effective solution that aligns with their operational and design goals.

Essential Technical Properties and Trade Terminology for trap door hinges

When sourcing trap door hinges, understanding the essential technical properties and terminology is crucial for making informed purchasing decisions. This knowledge ensures compatibility, durability, and compliance with industry standards.

What Are the Key Technical Properties of Trap Door Hinges?

1. Material Grade

Trap door hinges are commonly made from various materials, including stainless steel, brass, and aluminum. Stainless steel, particularly 316 grade, is favored for its corrosion resistance, making it ideal for coastal or humid environments. Understanding material properties helps buyers select hinges that can withstand specific environmental conditions and loads.

Illustrative image related to trap door hinges

2. Load Capacity

The load capacity indicates the maximum weight a hinge can support. This specification is critical for ensuring safety and functionality, particularly in commercial settings where heavy traffic or equipment may be involved. Buyers should match the load capacity of the hinges to the weight of the trap door and any anticipated dynamic loads.

3. Finish and Coating

The finish on trap door hinges—such as polished, brushed, or oil-rubbed—affects aesthetics and functionality. Coatings may provide additional corrosion resistance or improve surface durability. For international buyers, understanding local preferences for finishes can influence product selection.

4. Tolerance

Tolerance refers to the permissible limit of variation in a hinge’s dimensions. High precision is essential for ensuring proper fit and function, especially in applications where alignment is critical. Buyers should consider the tolerances specified by manufacturers to avoid installation issues.

5. Type of Hinge Mechanism

Different hinge mechanisms—such as concealed, pivot, or lift-off—serve various applications. Understanding the type of mechanism needed for a specific installation helps buyers select the most effective solution for their project requirements.

What Are Common Trade Terms Related to Trap Door Hinges?

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of trap door hinges, working with OEMs can ensure that buyers receive high-quality, compliant products tailored to their specifications.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for buyers to ensure they can meet their project needs without overcommitting to excess inventory. This is particularly relevant for businesses operating on tight budgets.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers. This process is important for comparing costs and ensuring budget adherence. A well-prepared RFQ can lead to better pricing and terms from suppliers.

Illustrative image related to trap door hinges

4. Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in the shipping process. Familiarity with these terms is essential for international transactions, as they clarify who is responsible for shipping, insurance, and tariffs.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. Understanding lead times is critical for project planning and inventory management, particularly in regions with longer shipping durations.

By grasping these technical properties and trade terms, B2B buyers can navigate the complexities of sourcing trap door hinges more effectively. This knowledge not only aids in selecting the right product but also ensures compliance with industry standards and enhances overall procurement efficiency.

Navigating Market Dynamics and Sourcing Trends in the trap door hinges Sector

What Are the Current Market Dynamics and Key Trends in the Trap Door Hinges Sector?

The global trap door hinges market is witnessing significant growth, driven by various factors such as urbanization, infrastructure development, and an increasing focus on space optimization. In regions like Africa and South America, rapid urbanization is leading to a surge in construction projects, necessitating efficient access solutions like trap doors. Moreover, in the Middle East and Europe, the demand for high-quality, durable hinges is fueled by stringent building codes and a growing preference for aesthetic appeal in architectural designs.

Illustrative image related to trap door hinges

Emerging B2B technology trends, such as digital procurement platforms and advanced supply chain management systems, are transforming how international buyers source trap door hinges. Companies are increasingly leveraging e-commerce platforms to streamline purchasing processes, ensuring they have access to a wide range of products from various suppliers. Enhanced transparency in pricing and product specifications on these platforms allows buyers to make informed decisions quickly.

Additionally, the market is experiencing a shift towards customized solutions. Manufacturers are responding to the demand for tailored products that meet specific project requirements, such as weight capacity and material type. This trend is particularly relevant for buyers in diverse markets, where local regulations and environmental conditions can vary significantly.

How Is Sustainability and Ethical Sourcing Impacting the Trap Door Hinges Sector?

Sustainability has become a pivotal consideration in the sourcing of trap door hinges. The environmental impact of production processes and materials used is under increasing scrutiny. Buyers are now more inclined to select suppliers that prioritize eco-friendly manufacturing practices and utilize sustainable materials. For instance, the use of recycled metals and environmentally friendly coatings can significantly reduce the carbon footprint associated with hinge production.

Ethical sourcing is equally important, with many B2B buyers actively seeking suppliers who adhere to fair labor practices and responsible sourcing standards. Certifications such as ISO 14001 for environmental management and Fair Trade certifications can enhance a supplier’s credibility and appeal to conscientious buyers.

Furthermore, as the global emphasis on sustainability intensifies, manufacturers are innovating to meet these demands. This includes developing ‘green’ hinges that not only meet functional requirements but also align with environmental standards. Buyers who prioritize sustainability in their sourcing strategies can benefit from enhanced brand reputation and customer loyalty, particularly in markets where consumers are increasingly eco-conscious.

How Has the Trap Door Hinges Market Evolved Over Time?

The evolution of trap door hinges can be traced back to their initial use in residential and commercial buildings as a means of providing access to hidden spaces. Historically, these hinges were simplistic in design and functionality. However, advancements in materials science and engineering have led to the development of more sophisticated hinges that offer enhanced durability, security, and aesthetic appeal.

In recent years, the introduction of innovative materials such as stainless steel and corrosion-resistant finishes has significantly improved the performance of trap door hinges, making them suitable for a variety of applications, including marine and industrial environments. The trend towards customization has also emerged, allowing manufacturers to cater to specific market needs, which has further propelled the growth of the sector.

Overall, the trap door hinges market continues to adapt to changing consumer preferences and technological advancements, positioning itself as a vital component in modern architectural solutions. International B2B buyers can leverage this evolution to source high-quality, innovative products that meet their specific project needs.

Frequently Asked Questions (FAQs) for B2B Buyers of trap door hinges

-

How do I choose the right trap door hinge for my project?

Selecting the appropriate trap door hinge involves considering several factors such as the door’s weight, dimensions, and material. For heavier doors, look for hinges that can support the weight, often specified in the product details. Additionally, consider the hinge design—flush hinges offer a discreet look, while more robust options may be necessary for frequent use. Always consult with suppliers about their recommendations based on your specific application to ensure optimal functionality and durability. -

What materials are best for trap door hinges in harsh environments?

For applications in harsh environments, such as coastal areas or regions with high humidity, stainless steel, particularly marine-grade 316 stainless steel, is the best choice. This material is highly resistant to corrosion and wear, making it ideal for outdoor or industrial settings. If aesthetics are also a concern, consider finishes like brushed nickel or oil-rubbed bronze, which can enhance the hinge’s appearance while maintaining durability. -

What are the typical minimum order quantities (MOQs) for trap door hinges?

Minimum order quantities can vary significantly among suppliers, typically ranging from 50 to 100 units for standard products. However, custom designs or specialized finishes may have higher MOQs. It’s advisable to communicate directly with suppliers to negotiate terms that suit your purchasing needs, especially if you are looking to test a new product line or enter a new market. -

How can I ensure the quality of trap door hinges before purchase?

To ensure quality, request samples from suppliers before placing a bulk order. Evaluate the materials, construction, and finish of the hinges. Additionally, check for certifications or compliance with international standards, as these can indicate a higher quality product. Reading reviews and testimonials from other B2B buyers can also provide insights into the reliability and performance of the hinges. -

What are the payment terms commonly offered by suppliers of trap door hinges?

Payment terms can vary widely, but many suppliers offer options such as net 30 or net 60 days after delivery, requiring full payment upfront for first-time orders. Some suppliers may also accept partial payments or letters of credit, especially for larger transactions. Always clarify payment terms before finalizing an agreement to avoid any misunderstandings that could affect your cash flow. -

How do I vet suppliers of trap door hinges for international trade?

To vet suppliers, start by researching their business credentials, including years in operation, industry certifications, and customer reviews. Use platforms like Alibaba or ThomasNet to find verified suppliers. Additionally, request references from previous clients and assess their responsiveness and communication skills. If possible, conduct a factory visit or audit to ensure they meet your quality and production standards. -

What logistics considerations should I be aware of when importing trap door hinges?

When importing, consider shipping methods, customs duties, and lead times. It’s essential to work with logistics providers experienced in international shipping to navigate customs regulations specific to your country. Also, ensure that the supplier provides accurate documentation, such as invoices and packing lists, to avoid delays at customs. Planning for potential tariffs or taxes can also help in budgeting for the total cost of goods. -

Can trap door hinges be customized to fit specific project requirements?

Yes, many suppliers offer customization options for trap door hinges, including size, finish, and specific design features. If you have unique specifications, communicate these clearly to the supplier. They may require a minimum order quantity for custom products, and lead times may be longer than for standard products. Requesting prototypes or samples before final production can help ensure the final product meets your expectations.

Top 6 Trap Door Hinges Manufacturers & Suppliers List

1. HardwareSource – Hatch and Trap Door Hinges

Domain: hardwaresource.com

Registered: 1996 (29 years)

Introduction: Hatch and Trap Door Hinges | HardwareSource

– 316 Stainless Steel Flush Pull: $16.75 Each

– Flush Ring Pull: From $13.60 Each (Available in Oil Rubbed Bronze, Polished Brass, Brushed Nickel)

– Hatch Hinge, Lift Off, 316 Stainless Steel: $35.95 Each

– Stainless Flush Hatch Door Hinge: $7.95 Each

– Stainless Steel Locker Hinges: From $9.95 Each

– Rounded Butler Tray Table Hinge 3″ Polished Stainles…

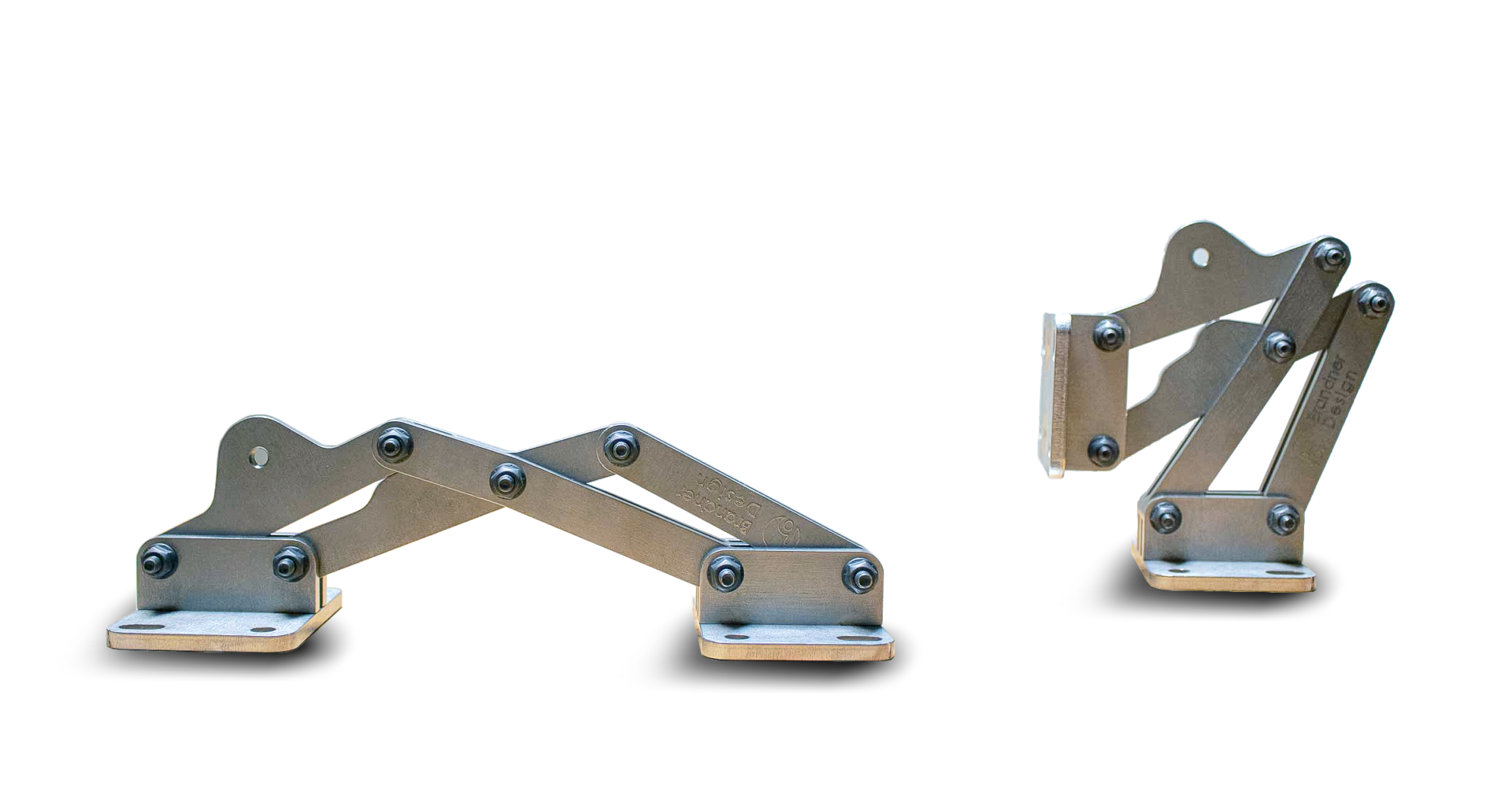

2. Brandner Design – Floor Door Hinge System

Domain: brandnerdesign.com

Registered: 2006 (19 years)

Introduction: Floor Door Hinge System by Brandner Design allows for a smooth operating floor or trap door. Key features include:

– Engineered to sit flush with the floor, hiding hinges below.

– Prevents door binding by lifting the door away from the frame.

– Integrated mounting plates for screw fastening or welding to door and frame.

– Gas struts included for assisted opening and closing.

– One Locking Gas…

3. Brandner Design – Floor Door Hinge System

Domain: brandnerdesignstore.com

Registered: 2018 (7 years)

Introduction: {‘name’: ‘Floor Door Hinge System’, ‘regular_price’: ‘$1,480.00’, ‘options’: [{‘door_length’: ‘up to 72″ L’, ‘hinges’: ‘2’, ‘struts’: ‘2’, ‘max_weight’: ‘180lb’, ‘strut_length_1’: ‘17.13in’, ‘strut_length_2’: ‘N/A’, ‘price’: ‘$1,480.00’}, {‘door_length’: ‘up to 72″ L’, ‘hinges’: ‘2’, ‘struts’: ‘2’, ‘max_weight’: ‘180lb’, ‘strut_length_1’: ‘19.72in’, ‘strut_length_2’: ‘N/A’, ‘price’: ‘$1,480.00’}, …

4. HAHN – Trap Door Hinges

Domain: gasspringsshop.com

Registered: 2014 (11 years)

Introduction: Trap door hinges available in steel and stainless steel variants. Ideal for outdoor and marine applications. Collaborates with HAHN brand, a Stabilus company. Fast shipping within 1 working day. Shipping cost is $4.99, free shipping on orders over $50. Tools available: Calculator Tool for project calculations, Replacement Tool for identifying equivalent replacements, Configurator Tool for customiz…

5. Soss – Concealed Trap Door Hinge

Domain: finehomebuilding.com

Registered: 1997 (28 years)

Introduction: Trap door hinge for a 30″ x 30″ hardwood floor trap door; requires heavy-duty hinge/lid support that mounts under the trap door; no exposed hinge on the surface; Soss fully-concealed hinges recommended; hinges can handle heavy loads (up to 500 pounds); alternative solutions discussed include dowel/steel rod pivot, gas shock lifters, and counterweight systems; door is 1 1/2″ thick and weighs 80-100…

6. Soss – Concealed Hinge for Trap Door

Domain: contractortalk.com

Registered: 2003 (22 years)

Introduction: Concealed hinge for a trap door, suitable for a hatch door to a crawlspace, designed to avoid protrusion on the finished floor. The door is made from 3/4″ CDX plywood and requires a hinge that can be mounted without being visible. Suggestions include Soss or Sugatsune hinges, which can be recessed into the edge of the plywood. Other options discussed include piano hinges and inset euro cabinet hin…

Strategic Sourcing Conclusion and Outlook for trap door hinges

In summary, the strategic sourcing of trap door hinges is pivotal for businesses seeking reliable, durable, and aesthetically pleasing solutions. As highlighted, selecting high-quality materials such as stainless steel ensures longevity and resistance to corrosion, particularly in challenging environments prevalent in regions like Africa and the Middle East. Buyers should prioritize suppliers that offer a diverse range of products, including flush hinges and specialized systems, to accommodate various project requirements.

Moreover, understanding the technical specifications—such as load capacity and installation options—enables companies to make informed purchasing decisions that align with their operational needs. Emphasizing strategic sourcing not only enhances project efficiency but also contributes to long-term cost savings through reduced maintenance and replacement cycles.

As we look ahead, the global market for trap door hinges is poised for growth, driven by increasing construction activities and infrastructural developments. International B2B buyers, particularly from dynamic markets like Nigeria and Saudi Arabia, are encouraged to explore partnerships with trusted suppliers who can provide tailored solutions. Embrace this opportunity to elevate your projects with superior hardware that meets both functional and aesthetic demands.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to trap door hinges

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.