Transparent Plastic Bag: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for transparent plastic bag

In today’s competitive landscape, sourcing transparent plastic bags that meet specific industry needs can be a daunting challenge for B2B buyers across various regions, including Africa, South America, the Middle East, and Europe. These versatile packaging solutions are essential for showcasing products while ensuring their protection from environmental factors. This comprehensive guide serves as a vital resource for international buyers seeking to navigate the complexities of the transparent plastic bag market.

Within these pages, you will discover a wide array of bag types, including gusseted, zipper, and stand-up pouches, each tailored to different applications from food packaging to retail display. We will delve into the nuances of supplier vetting, ensuring you can identify reliable partners who comply with stringent quality and safety standards. Additionally, the guide will provide insights into cost considerations, helping you optimize your purchasing decisions without compromising quality.

By equipping you with actionable insights and expert recommendations, this guide empowers B2B buyers to make informed choices that align with their operational goals. Whether you’re in Saudi Arabia, Vietnam, or beyond, understanding the global market for transparent plastic bags will enhance your ability to procure the right products efficiently and effectively.

Understanding transparent plastic bag Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Crystal Clear Bags | High clarity, archival safe, acid-free, food safe | Retail display, food packaging | Pros: Enhances product visibility; protects contents. Cons: Higher cost compared to non-clear options. |

| Gusseted Bags | Expandable sides for increased capacity, flat base | Bulk packaging, retail, food items | Pros: Maximizes storage; stable when filled. Cons: May require more material, impacting cost. |

| Reclosable Bags | Zip lock or self-seal closure options, easy to open and reseal | Food storage, sample packaging | Pros: Reusable; keeps contents fresh. Cons: Potential for wear over time with repeated use. |

| Poly Tubing | Customizable length, versatile for various shapes | Industrial packaging, custom sizes | Pros: Flexible and adaptable; minimizes waste. Cons: Requires sealing equipment for use. |

| Stand Up Pouches | Upright design, often with a resealable closure, visually appealing | Food products, retail items | Pros: Attractive shelf presence; user-friendly. Cons: May have higher production costs. |

What Are the Key Characteristics of Crystal Clear Bags?

Crystal clear bags are crafted from BOPP material, providing exceptional clarity that allows for easy visibility of contents. They are archival safe and acid-free, making them suitable for food and retail applications. B2B buyers often select these bags for their ability to enhance product presentation while protecting items from dust and moisture. However, their premium quality comes at a higher price point, necessitating careful consideration of budget versus visibility needs.

How Do Gusseted Bags Differ from Other Types?

Gusseted bags feature expandable sides that increase their capacity, making them ideal for bulk packaging. Their flat bottom allows for stability when filled, which is particularly beneficial in retail environments where display is essential. B2B buyers appreciate the versatility of gusseted bags, especially for food items and larger products. However, the additional material used can lead to increased costs, which should be factored into purchasing decisions.

What Benefits Do Reclosable Bags Offer for Businesses?

Reclosable bags come with zip lock or self-seal options, providing convenience for users. They are commonly used in food storage and sample packaging, as they maintain freshness while allowing for easy access. For B2B buyers, the reusable nature of these bags is a significant advantage, promoting sustainability. However, the durability of the closure may diminish with repeated use, which can impact long-term effectiveness.

Why Choose Poly Tubing for Industrial Applications?

Poly tubing is a versatile packaging solution that can be cut to custom lengths, accommodating various product shapes and sizes. This flexibility minimizes waste and is particularly advantageous for businesses with unique packaging needs. B2B buyers in industrial sectors often prefer poly tubing for its adaptability. However, sealing equipment is required to use poly tubing effectively, which could present an additional investment.

What Makes Stand Up Pouches a Popular Choice?

Stand up pouches are designed to stand upright on shelves, offering an attractive display option for food products and retail items. Many come with resealable closures, enhancing user convenience. B2B buyers value these pouches for their eye-catching design and functionality. However, the production costs may be higher compared to traditional bags, which should be weighed against their marketing potential.

Key Industrial Applications of transparent plastic bag

| Industry/Sector | Specific Application of transparent plastic bag | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food & Beverage | Packaging for snacks and perishable items | Enhances product visibility, preserves freshness, and complies with food safety regulations | Ensure bags are food-safe, BPA-free, and compliant with local regulations. |

| Retail & E-commerce | Product display and merchandising | Attracts customers by showcasing products clearly and securely | Look for customizable options and durability to withstand shipping. |

| Pharmaceuticals | Packaging for medical supplies and over-the-counter products | Protects contents from contamination and maintains sterility | Source bags that meet FDA standards and are resistant to punctures. |

| Cosmetics & Personal Care | Packaging for beauty products and samples | Elevates brand image through clear, attractive packaging | Consider eco-friendly materials and options for customization. |

| Electronics | Protective packaging for small electronic components | Prevents dust and moisture damage while allowing visibility | Ensure bags are anti-static and suitable for sensitive electronic items. |

What are the Key Applications of Transparent Plastic Bags in the Food & Beverage Industry?

In the food and beverage sector, transparent plastic bags are widely used for packaging snacks, baked goods, and perishable items. These bags provide excellent visibility, allowing consumers to see the product while ensuring freshness and compliance with food safety regulations. For international B2B buyers, it’s crucial to source bags that are food-safe, BPA-free, and compliant with local health standards, particularly in regions like Africa and the Middle East where regulations may vary.

Illustrative image related to transparent plastic bag

How Do Transparent Plastic Bags Enhance Retail & E-commerce?

In retail and e-commerce, transparent plastic bags serve as an effective merchandising tool. They allow products to be displayed clearly, attracting customers and enhancing the shopping experience. These bags can be customized to include branding, which helps in building brand identity. Buyers should consider the durability of the bags to withstand shipping and handling, especially in markets like South America and Europe where logistics may pose challenges.

Why are Transparent Plastic Bags Essential in the Pharmaceuticals Sector?

The pharmaceutical industry relies on transparent plastic bags for packaging medical supplies and over-the-counter products. These bags offer protection against contamination and are designed to maintain the sterility of their contents. For B2B buyers in this sector, sourcing bags that meet FDA standards and are resistant to punctures is essential to ensure product safety and compliance with stringent regulations.

What Role Do Transparent Plastic Bags Play in Cosmetics & Personal Care?

In the cosmetics and personal care industry, transparent plastic bags are often used for packaging beauty products and samples. They help elevate the brand image by presenting products attractively while allowing consumers to view the contents. When sourcing these bags, businesses should consider eco-friendly materials and customization options to align with consumer preferences and sustainability goals, which are increasingly important in Europe and other markets.

How are Transparent Plastic Bags Used in the Electronics Industry?

Transparent plastic bags are crucial in the electronics sector for packaging small electronic components. These bags protect against dust and moisture while allowing visibility of the items inside. For international buyers, it is important to ensure that the bags are anti-static and suitable for sensitive electronic products, especially in regions where humidity and environmental factors could impact product integrity.

3 Common User Pain Points for ‘transparent plastic bag’ & Their Solutions

Scenario 1: Navigating Regulatory Compliance Challenges in Packaging

The Problem: B2B buyers in industries such as food and cosmetics often face significant challenges in ensuring that their transparent plastic bags comply with local and international regulations. For instance, in regions like the EU and the Middle East, stringent guidelines govern the materials used in packaging, especially for products that come into direct contact with food. Buyers may worry about the implications of using non-compliant bags, which can lead to hefty fines, product recalls, or loss of consumer trust.

The Solution: To mitigate these risks, B2B buyers should prioritize sourcing transparent plastic bags that are explicitly labeled as FDA and USDA compliant. When negotiating with suppliers, it’s crucial to request detailed documentation that verifies compliance with food safety standards. Look for suppliers who provide transparent information regarding the materials used, such as BOPP (Biaxially Oriented Polypropylene), which is known for its clarity and safety. Moreover, establishing relationships with suppliers who specialize in regulatory compliance can provide ongoing support and updates about changing regulations, ensuring that your packaging consistently meets legal requirements.

Scenario 2: Addressing Durability and Protection Concerns

The Problem: Businesses often struggle with the durability of transparent plastic bags, especially when shipping products internationally. Buyers may find that their bags do not withstand the rigors of transport, leading to damaged goods and increased costs. This is particularly concerning for companies shipping fragile items like electronics or delicate food products, where even minor tears or punctures can compromise the integrity of the packaging.

Illustrative image related to transparent plastic bag

The Solution: To enhance durability, it is essential to specify the thickness of the plastic bags when placing orders. Buyers should consider bags made from high-quality virgin polyethylene, which offers greater puncture resistance and load-bearing strength. Additionally, selecting bags with features like gussets or reinforced seams can provide extra support for heavier items. For international shipping, it may be beneficial to use bags designed for specific shipping conditions, such as moisture-resistant or tear-proof variants. Conducting a test run with a small batch of bags can also help evaluate their performance before committing to larger orders.

Scenario 3: Balancing Transparency with Sustainability Goals

The Problem: As global awareness of environmental issues increases, many B2B buyers are under pressure to adopt sustainable practices, including the use of eco-friendly packaging. However, they often face the challenge of finding transparent plastic bags that not only meet their visibility and functionality needs but are also environmentally sustainable. This can create a dilemma, as traditional plastic bags are often perceived as harmful to the environment.

The Solution: To effectively balance transparency with sustainability, buyers should explore options for recyclable or biodegradable transparent plastic bags. Suppliers that offer eco-friendly alternatives, such as bags made from recycled materials or those designed to decompose more rapidly, can help businesses meet their sustainability goals without sacrificing product visibility. When sourcing these bags, inquire about the certifications and processes that ensure the eco-friendliness of the products. Additionally, consider implementing a recycling program for your packaging to further enhance your company’s sustainability profile. This proactive approach not only aligns with consumer expectations but can also improve brand loyalty and market competitiveness.

Strategic Material Selection Guide for transparent plastic bag

What Are the Key Materials Used for Transparent Plastic Bags?

When selecting materials for transparent plastic bags, B2B buyers must consider various properties, advantages, and limitations of each option. The most common materials include Polyethylene (PE), Polypropylene (PP), and Biaxially Oriented Polypropylene (BOPP). Each material has unique characteristics that influence its suitability for specific applications.

How Does Polyethylene (PE) Perform in Transparent Plastic Bags?

Polyethylene is one of the most widely used materials for transparent plastic bags. It is known for its excellent flexibility and impact resistance, making it suitable for various applications, including food packaging and retail use. PE bags can withstand temperatures ranging from -40°F to 120°F, which makes them versatile for different environments.

Pros: PE bags are cost-effective and readily available in various thicknesses and sizes. They are also recyclable, which appeals to eco-conscious buyers.

Cons: However, they may not offer the same clarity as other materials and can be less durable under extreme conditions.

Impact on Application: PE is compatible with a wide range of media, including food products, due to its FDA compliance. This makes it a preferred choice for food packaging in regions with strict food safety regulations.

What Advantages Does Polypropylene (PP) Offer for Transparent Plastic Bags?

Polypropylene is another popular choice for transparent plastic bags, especially in retail and packaging. It boasts higher clarity and a glossy finish compared to PE. PP can withstand temperatures up to 200°F, making it suitable for applications requiring heat resistance.

Pros: Its superior clarity enhances product visibility, which is crucial for retail environments. Additionally, PP bags are resistant to moisture and chemicals, providing excellent protection for the contents.

Cons: The cost of PP is generally higher than PE, and it may require more complex manufacturing processes.

Impact on Application: PP’s resistance to moisture makes it ideal for packaging items that are sensitive to humidity, such as electronics or certain food products. International buyers should ensure compliance with local standards, such as ASTM or DIN, particularly for food-related applications.

Why Choose Biaxially Oriented Polypropylene (BOPP) for Transparent Plastic Bags?

BOPP is a specialized form of polypropylene that has been stretched in both directions, enhancing its strength and clarity. This material is often used for high-end packaging, including gift bags and retail displays.

Pros: BOPP bags offer exceptional clarity and a premium feel, which can enhance brand perception. They are also resistant to UV light, making them suitable for outdoor applications.

Cons: The primary drawback of BOPP is its higher cost compared to PE and PP. Additionally, it may not be as flexible, which can limit its applications.

Impact on Application: BOPP is particularly effective for products that require a strong visual appeal, such as gourmet food items or luxury goods. Buyers in regions like Europe and the Middle East may prefer BOPP for its aesthetic qualities and compliance with stringent packaging regulations.

Summary of Material Considerations for Transparent Plastic Bags

When choosing the right material for transparent plastic bags, international B2B buyers should consider not only the properties of the materials but also their specific application needs and compliance with local standards. Understanding these factors can lead to better decision-making and enhanced product offerings.

| Material | Typical Use Case for transparent plastic bag | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyethylene (PE) | Food packaging, retail bags | Cost-effective and flexible | Lower clarity and durability | Low |

| Polypropylene (PP) | Retail displays, food packaging | High clarity and moisture resistance | Higher cost and manufacturing complexity | Medium |

| Biaxially Oriented Polypropylene (BOPP) | High-end retail and gift packaging | Exceptional clarity and UV resistance | Higher cost and less flexibility | High |

This table encapsulates the essential information for B2B buyers, aiding them in making informed decisions regarding material selection for transparent plastic bags.

In-depth Look: Manufacturing Processes and Quality Assurance for transparent plastic bag

What Are the Key Stages in the Manufacturing Process of Transparent Plastic Bags?

The manufacturing process of transparent plastic bags involves several critical stages, each designed to ensure quality and efficiency. Understanding these stages can help B2B buyers make informed purchasing decisions.

Material Preparation: What Raw Materials Are Used?

The primary material used for manufacturing transparent plastic bags is BOPP (Biaxially Oriented Polypropylene) or virgin polyethylene. These materials are selected for their clarity, durability, and compliance with food safety standards. The preparation phase involves sourcing high-quality resins that meet industry specifications. Buyers should inquire about the resin grades used by suppliers, as this can significantly impact the end product’s performance.

How Are Transparent Plastic Bags Formed?

The forming stage typically involves extrusion and molding techniques. In the extrusion process, the resin is melted and formed into a continuous sheet. This sheet is then cooled and cut to the required dimensions. For bags with specific features, such as gussets or zippers, additional machinery is employed. Suppliers may also utilize blow molding for certain types of bags, allowing for a more flexible design.

What Assembly Techniques Are Commonly Used?

Once the bags are formed, they undergo assembly, which can include sealing and adding closures. Heat sealing is a prevalent method for creating strong seams that are essential for maintaining the integrity of the bag. Custom features, such as printed designs or logos, can also be added during this phase. B2B buyers should consider whether suppliers offer customization options to meet their branding needs.

What Finishing Techniques Enhance Product Quality?

The finishing stage involves quality checks and additional treatments that enhance the bag’s performance. This can include anti-static treatments, UV protection, or surface coatings to improve clarity and durability. Buyers should ask about the finishing techniques employed by their suppliers, as these can affect the product’s suitability for specific applications.

What Quality Control Measures Are Implemented During Production?

Quality assurance is a critical aspect of the manufacturing process for transparent plastic bags. Suppliers typically adhere to various international and industry-specific standards to ensure product quality.

Which International Standards Should B2B Buyers Be Aware Of?

Many manufacturers comply with ISO 9001 standards, which focus on quality management systems. This certification signifies that a supplier has established processes for consistent quality control. Additionally, compliance with FDA and USDA standards is vital for food-safe packaging. B2B buyers should verify that their suppliers can provide documentation of these certifications.

What Are the Key Quality Control Checkpoints?

Quality control is conducted at multiple checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials to ensure they meet specified criteria before production begins.

-

In-Process Quality Control (IPQC): During production, random samples are taken to monitor the manufacturing process and ensure that it adheres to quality standards.

-

Final Quality Control (FQC): Once production is complete, finished products undergo rigorous testing to confirm they meet all specifications. Common tests include tensile strength, puncture resistance, and clarity assessments.

What Testing Methods Are Commonly Used in Quality Assurance?

Several testing methods are employed to ensure that transparent plastic bags meet industry standards:

-

Tensile Testing: Measures the strength of the material and its resistance to stretching.

-

Puncture Resistance Testing: Evaluates how well the bags can withstand sharp objects without tearing.

-

Clarity and Gloss Testing: Assesses the visual appeal of the bags, which is crucial for retail applications.

B2B buyers should request information about the specific tests conducted by their suppliers and review the results to gauge product quality.

How Can B2B Buyers Verify Supplier Quality Control Processes?

To ensure that suppliers maintain high-quality standards, B2B buyers can take several steps:

What Documentation Should Buyers Request?

Buyers should ask for quality assurance documentation, including:

- Certificates of compliance with relevant standards (ISO, FDA, USDA).

- Quality control reports detailing the results of testing conducted on products.

How Do Audits and Third-Party Inspections Work?

Conducting supplier audits can provide insights into their manufacturing processes and quality control measures. Buyers may opt for third-party inspections, which can offer an unbiased assessment of the supplier’s capabilities. Engaging a reputable inspection agency can help identify any potential issues before committing to a purchase.

What Are the Unique Quality Control Considerations for International Buyers?

For B2B buyers from regions such as Africa, South America, the Middle East, and Europe, there are specific nuances to consider when dealing with international suppliers.

How Do Regional Regulations Impact Quality Standards?

Different regions have varying regulations regarding packaging materials, especially for food safety. Buyers should familiarize themselves with local regulations in their markets to ensure compliance. Suppliers should be able to demonstrate their understanding of these regulations and how their products meet them.

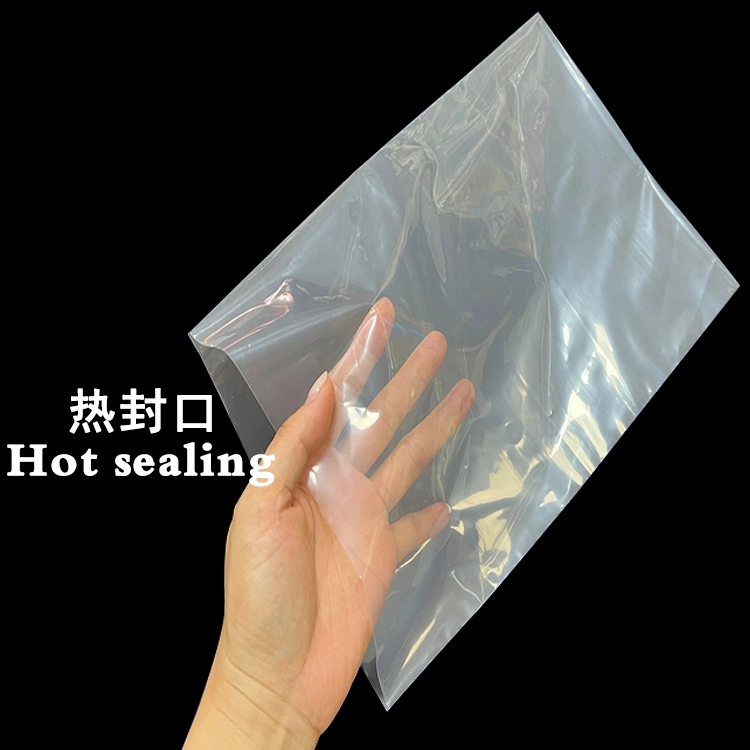

Illustrative image related to transparent plastic bag

What Are the Challenges in Quality Control Across Borders?

Cross-border transactions can introduce challenges in quality assurance due to differences in manufacturing practices and standards. Buyers should establish clear communication with suppliers regarding quality expectations and standards. Additionally, understanding the logistics and potential delays in international shipping can help mitigate risks associated with product quality.

By comprehensively understanding the manufacturing processes and quality assurance measures for transparent plastic bags, B2B buyers can make informed decisions that align with their specific needs and regulatory requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘transparent plastic bag’

In this guide, we will outline a practical checklist for B2B buyers seeking to procure transparent plastic bags. These bags are essential for various applications, including food packaging, retail displays, and more. By following this step-by-step process, buyers can ensure they make informed decisions, selecting the right products and suppliers to meet their needs.

1. Define Your Technical Specifications

Before reaching out to suppliers, clearly outline the technical specifications of the transparent plastic bags you require. Consider factors such as size, thickness, material type (e.g., BOPP, polyethylene), and closure mechanisms (e.g., zip, flap seal). Defining these specifications will help streamline your search and ensure you receive products that meet your operational requirements.

2. Research Potential Suppliers

Conduct thorough research to identify reputable suppliers in the industry. Look for companies that specialize in transparent plastic bags and have a strong market presence. Utilize online directories, trade shows, and industry publications to compile a list of potential vendors. Focus on suppliers with positive reviews and proven track records in quality and service.

3. ✅ Verify Supplier Certifications

Ensuring that your chosen suppliers meet industry standards is critical for maintaining product safety and quality. Verify their compliance with relevant certifications, such as FDA and USDA for food-safe products. Additionally, check for ISO certifications that indicate adherence to quality management systems, which can provide peace of mind regarding the reliability of the products.

4. Request Samples for Evaluation

Before making a bulk purchase, request samples of the transparent plastic bags from your shortlisted suppliers. This allows you to assess the quality, clarity, and durability of the bags firsthand. Pay attention to the material’s thickness, seal integrity, and overall presentation to ensure it aligns with your product packaging needs.

5. Evaluate Pricing and Payment Terms

Once you’ve narrowed down your options, compare pricing across suppliers while considering the value offered. Look for transparent pricing structures without hidden fees, and inquire about bulk order discounts. Additionally, clarify payment terms, including deposits, payment methods, and credit options, to ensure they align with your budget and cash flow requirements.

6. Inquire About Customization Options

If you require branded or customized transparent plastic bags, discuss your options with the suppliers. Many manufacturers offer custom printing and sizes, which can enhance brand visibility and meet specific marketing needs. Ensure that the supplier has the capability to produce high-quality prints and understands your design requirements.

7. Assess Shipping and Lead Times

Finally, inquire about the shipping methods and lead times for your orders. Timely delivery is crucial for maintaining your supply chain, so understand the logistics involved. Ask about shipping options, costs, and how they handle international orders, especially if you are sourcing from suppliers located in different regions.

By following this checklist, B2B buyers can navigate the procurement process for transparent plastic bags efficiently, ensuring they select the right products and suppliers to meet their business needs.

Comprehensive Cost and Pricing Analysis for transparent plastic bag Sourcing

What Are the Key Cost Components of Transparent Plastic Bag Sourcing?

When sourcing transparent plastic bags, understanding the underlying cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The type of plastic used—polyethylene (PE) or polypropylene (BOPP)—affects pricing. Higher-quality, food-safe materials typically command a premium. Prices fluctuate based on global resin market conditions, making it essential to stay updated on material costs.

-

Labor: Labor costs can vary significantly by region. In countries with lower labor costs, such as some parts of South America and Africa, production may be cheaper. Conversely, European manufacturers might have higher labor costs, impacting overall pricing.

-

Manufacturing Overhead: This includes utilities, equipment maintenance, and facility costs. Efficient production processes and modern machinery can reduce these overheads, leading to lower prices for buyers.

-

Tooling: Customization often requires specific tooling, which can be a significant upfront cost. However, once amortized over larger volumes, these costs can be diluted, making customized bags more cost-effective in bulk orders.

-

Quality Control (QC): Implementing rigorous QC standards ensures that products meet specific requirements, particularly for food-safe applications. While this adds to costs, it mitigates the risk of product recalls or customer dissatisfaction.

-

Logistics: Shipping costs can vary based on distance, mode of transport, and packaging volume. International buyers should consider the implications of Incoterms, as they determine who bears the cost and risk at each stage of the shipping process.

-

Margin: Suppliers typically add a margin that reflects their business model and market position. Understanding the competitive landscape helps buyers negotiate better pricing.

How Do Price Influencers Affect Transparent Plastic Bag Sourcing?

Several factors influence the pricing of transparent plastic bags:

-

Volume/MOQ: Manufacturers often provide tiered pricing based on order volume. Higher minimum order quantities (MOQs) can lead to significant savings, making it advantageous for buyers to consolidate purchases.

-

Specifications and Customization: Custom sizes, printing, and specialized features (e.g., zip seals, gussets) can increase costs. Buyers should weigh the benefits of customization against potential price increases.

-

Material Quality and Certifications: Bags that meet specific certifications (e.g., FDA, USDA) are generally more expensive due to stringent manufacturing processes. Investing in certified products ensures compliance and safety.

-

Supplier Factors: The supplier’s reputation, reliability, and production capabilities can impact pricing. Established suppliers may charge higher prices due to their track record and quality assurance.

What Are the Best Buyer Tips for Negotiating Transparent Plastic Bag Prices?

-

Effective Negotiation: Engage suppliers in discussions about pricing, especially when placing large orders. Highlighting long-term partnerships can lead to favorable terms and discounts.

-

Focus on Cost-Efficiency: Evaluate the total cost of ownership (TCO), which includes not just the purchase price but also shipping, storage, and potential wastage. Understanding TCO helps in making informed purchasing decisions.

-

Be Aware of Pricing Nuances in International Markets: Different regions may have varying pricing structures due to local economic conditions. For instance, while labor costs might be lower in some African countries, shipping and logistics can offset these savings.

-

Consider Alternative Suppliers: Diversifying your supplier base can foster competition, leading to better pricing. This is particularly relevant for buyers in regions like the Middle East and Europe, where multiple suppliers may offer similar products.

-

Stay Updated on Market Trends: Global resin prices and geopolitical factors can influence costs. Regularly monitoring these trends allows buyers to time their purchases effectively.

Disclaimer on Indicative Prices

Pricing for transparent plastic bags can vary widely based on the factors discussed. It is advisable for buyers to request quotes from multiple suppliers to obtain the most accurate and competitive pricing for their specific needs.

Alternatives Analysis: Comparing transparent plastic bag With Other Solutions

Exploring Alternatives to Transparent Plastic Bags

In the realm of packaging solutions, transparent plastic bags have established themselves as a popular choice due to their clarity, durability, and versatility. However, businesses often seek alternatives that may offer unique advantages or cater to specific needs. This analysis compares transparent plastic bags with two viable alternatives: paper bags and biodegradable bags. By evaluating performance, cost, ease of implementation, maintenance, and best use cases, international B2B buyers can make informed decisions based on their operational requirements.

| Comparison Aspect | Transparent Plastic Bag | Paper Bag | Biodegradable Bag |

|---|---|---|---|

| Performance | High clarity; durable; moisture-resistant | Moderate strength; can tear; moisture-sensitive | Varies by material; often compostable but less moisture-resistant |

| Cost | Generally low-cost; bulk pricing available | Moderate cost; often more expensive than plastic | Higher cost; varies by supplier and material type |

| Ease of Implementation | Easy to source; widely available | Simple to implement; requires training for recycling | Requires supplier education on disposal; may need special handling |

| Maintenance | Low maintenance; reusable options available | Low maintenance; recyclable but may not be suitable for all waste streams | Requires proper disposal knowledge; composting infrastructure needed |

| Best Use Case | Retail displays, food packaging, and product visibility | Retail, groceries, and gift wrapping | Eco-conscious brands, organic products, and compostable packaging needs |

Understanding the Advantages and Disadvantages of Each Alternative

Paper Bags

Paper bags are a traditional alternative that offers a sustainable image, appealing to eco-conscious consumers. They are widely used in retail and grocery settings, providing a natural aesthetic. However, paper bags can be susceptible to tearing and moisture damage, limiting their use for wet or heavy items. While they are recyclable, the cost is generally higher than transparent plastic bags, which may not be viable for all budgets.

Biodegradable Bags

Biodegradable bags are designed to break down over time, offering an environmentally friendly option for packaging. They cater to businesses looking to enhance their sustainability practices. Despite their benefits, the performance can vary significantly based on the material used, and they are often less durable than plastic bags. Additionally, they require specific disposal methods, such as composting, which may not be available in all regions, complicating their implementation for some businesses.

Conclusion: Choosing the Right Packaging Solution for Your Business

When selecting a packaging solution, B2B buyers must consider the specific needs of their products, target audience, and operational capabilities. Transparent plastic bags offer excellent visibility and protection, making them suitable for various applications. However, if sustainability is a key factor, exploring paper or biodegradable bags may align better with a brand’s values. Ultimately, the choice should reflect the balance between performance, cost, and environmental impact tailored to the unique demands of the business and its customers.

Essential Technical Properties and Trade Terminology for transparent plastic bag

What Are the Key Technical Properties of Transparent Plastic Bags for B2B Buyers?

Transparent plastic bags, commonly used across various industries, possess several critical technical properties that influence their performance and suitability for specific applications. Understanding these specifications is essential for B2B buyers to make informed decisions.

-

Material Grade

The most common materials for transparent plastic bags are polyethylene (PE) and polypropylene (BOPP). PE is known for its flexibility and durability, while BOPP offers superior clarity and stiffness. Selecting the appropriate material grade affects the bag’s strength, transparency, and suitability for food-safe applications. Buyers should ensure the chosen material complies with relevant food safety standards, such as FDA or USDA certifications, particularly when packaging consumables. -

Thickness (Gauge)

The thickness of the bag, often measured in mils (thousandths of an inch), directly impacts its strength and load-bearing capacity. Thicker bags are generally more durable and resistant to punctures or tears, making them ideal for heavier items. For instance, a 2 mil bag may suffice for lightweight products, while a 4 mil or thicker bag is recommended for heavier goods. B2B buyers should consider the nature of the products being packaged to determine the necessary thickness. -

Sealing Options

Various sealing methods are available for transparent plastic bags, including heat seals, zip locks, and adhesive closures. The choice of sealing method affects the bag’s reusability, ease of access, and ability to protect contents from environmental factors such as moisture and dust. Buyers should evaluate their packaging requirements and whether a resealable option is necessary for their products. -

Size and Customization

Transparent plastic bags come in a variety of sizes and can often be customized to meet specific business needs. Customization options may include printing logos or product information, which can enhance brand visibility. Understanding the required dimensions and customization capabilities is crucial for B2B buyers looking to create a unique packaging solution that stands out in the market. -

Environmental Compliance

In today’s eco-conscious market, many buyers are increasingly concerned about the environmental impact of their packaging materials. Transparent plastic bags can be manufactured from recyclable materials or designed to be biodegradable. B2B buyers should inquire about the environmental credentials of their suppliers to align with sustainable business practices and meet regulatory requirements.

What Are the Common Trade Terminology and Jargon Related to Transparent Plastic Bags?

Familiarity with industry-specific terminology is vital for B2B buyers to navigate the purchasing process effectively. Below are several key terms that are frequently encountered.

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces components or products that are used in another company’s end products. In the context of transparent plastic bags, an OEM might manufacture bags that are later branded and sold by another company. Understanding OEM relationships can help buyers identify potential suppliers and their capabilities. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it affects purchasing decisions and inventory management. High MOQs may require businesses to invest more upfront, while lower MOQs can provide flexibility for smaller operations. -

RFQ (Request for Quotation)

An RFQ is a formal process through which a buyer requests pricing and terms from suppliers for a specific product or service. In the transparent plastic bag market, submitting an RFQ can help buyers compare different suppliers, negotiate terms, and secure the best pricing for their needs. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce, which clarify the responsibilities of buyers and sellers in international transactions. Understanding these terms is essential for B2B buyers to manage shipping costs, insurance, and delivery responsibilities when sourcing transparent plastic bags from global suppliers. -

Lead Time

Lead time refers to the time taken from placing an order to the delivery of the product. It is a critical factor for B2B buyers who need to manage inventory levels and production schedules. Clear communication about lead times with suppliers ensures that businesses can plan their operations effectively.

By grasping these essential properties and trade terms, B2B buyers can enhance their purchasing strategies and ensure they select the right transparent plastic bags for their specific applications.

Navigating Market Dynamics and Sourcing Trends in the transparent plastic bag Sector

What Are the Current Market Dynamics and Key Trends in the Transparent Plastic Bag Sector?

The global market for transparent plastic bags is witnessing significant growth, driven by increasing demand across various sectors including food, retail, and e-commerce. One of the key drivers is the emphasis on product visibility, which is crucial for enhancing customer experience. Transparent bags allow consumers to see the contents, thereby influencing purchase decisions. Additionally, the rise in online shopping is creating a surge in demand for efficient packaging solutions that are not only functional but also visually appealing.

Emerging technologies are reshaping the sourcing landscape for transparent plastic bags. Innovations such as automated manufacturing processes and smart packaging solutions are becoming prevalent. These advancements improve production efficiency and reduce costs, making it easier for international B2B buyers to source high-quality bags at competitive prices. Moreover, the integration of e-commerce platforms is facilitating easier access to suppliers across Africa, South America, the Middle East, and Europe, including countries like Saudi Arabia and Vietnam.

Market dynamics are also influenced by regional preferences and regulations. For instance, while Western markets are increasingly leaning towards eco-friendly options, buyers from developing regions may prioritize cost-effectiveness and durability. Understanding these nuances is crucial for B2B buyers to navigate the diverse landscape of suppliers and products effectively.

How Is Sustainability and Ethical Sourcing Impacting the Transparent Plastic Bag Industry?

Sustainability is becoming a critical consideration in the transparent plastic bag sector. The environmental impact of plastic waste has prompted both consumers and businesses to seek alternatives. As a result, many manufacturers are now focusing on producing biodegradable and recyclable transparent bags, which align with global sustainability goals. This shift not only mitigates environmental concerns but also enhances brand reputation among eco-conscious consumers.

Ethical sourcing is another significant factor influencing B2B purchasing decisions. Buyers are increasingly demanding transparency in supply chains, seeking suppliers that adhere to ethical practices. Certifications such as ISO 14001 for environmental management and FSC certification for sustainable sourcing are becoming essential criteria for suppliers. Companies that prioritize these certifications not only appeal to a broader customer base but also mitigate risks associated with unethical practices.

Furthermore, the adoption of recycled materials in the production of transparent plastic bags is gaining traction. B2B buyers are encouraged to inquire about the use of post-consumer recycled content in products, as this contributes to a circular economy. By prioritizing sustainable and ethically sourced options, businesses can not only meet regulatory requirements but also align with consumer expectations for environmentally responsible practices.

What Is the Evolution of the Transparent Plastic Bag Market?

The transparent plastic bag market has evolved significantly since its inception. Initially, these bags were primarily used for basic packaging needs, characterized by simplicity and functionality. However, as consumer preferences shifted towards aesthetics and product visibility, manufacturers began to innovate, introducing various styles such as zip-lock, gusseted, and stand-up pouches.

Over the years, advancements in materials technology have also played a pivotal role in the evolution of transparent plastic bags. The introduction of high-clarity BOPP (Biaxially Oriented Polypropylene) has enhanced the visual appeal and durability of these bags, making them a preferred choice in retail and food packaging. Today, the focus is not only on functionality but also on sustainability, leading to the development of eco-friendly alternatives that cater to the growing demand for responsible packaging solutions.

In summary, the transparent plastic bag sector is experiencing dynamic changes influenced by market demands, technological advancements, and sustainability concerns. For B2B buyers, staying informed about these trends is essential for making strategic sourcing decisions that align with both business goals and consumer expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of transparent plastic bag

-

How do I choose the right transparent plastic bag for my products?

Selecting the appropriate transparent plastic bag involves considering several factors, including size, thickness, and intended use. For food products, ensure the bags are food-safe and compliant with regulations in your country. Assess the weight of the items being packaged, as this will dictate the bag’s thickness. Additionally, consider whether you need features like resealable closures, gussets for bulk items, or custom printing for branding. Always request samples to evaluate clarity and durability before making a bulk purchase. -

What are the benefits of using transparent plastic bags for packaging?

Transparent plastic bags offer numerous advantages, including visibility, which enhances product display and consumer appeal. They protect items from dust, moisture, and damage while allowing customers to see the product inside, promoting transparency and trust. Furthermore, these bags are versatile, suitable for various industries, including food, retail, and e-commerce. They can be customized with branding, which helps businesses stand out in competitive markets, and their lightweight nature can reduce shipping costs. -

What customization options are available for transparent plastic bags?

Customization options for transparent plastic bags are extensive and can include size, thickness, closure type (zipper, flap seal, etc.), and custom printing for branding purposes. Suppliers often offer the ability to print logos, product information, or artwork directly onto the bags. Additionally, you may choose from various materials, such as BOPP for high clarity or LDPE for a softer feel. Discussing your specific needs with suppliers can help you find the best solutions that align with your brand identity. -

What are typical minimum order quantities (MOQs) for transparent plastic bags?

Minimum order quantities for transparent plastic bags vary by supplier and can range from as low as 100 units to several thousand. Factors influencing MOQs include the type of bag, customization options, and production methods. It’s essential to communicate your requirements with potential suppliers to understand their terms and see if they can accommodate smaller orders, particularly for new businesses or trial runs. Some suppliers may offer flexibility for first-time orders or promotional pricing. -

How can I vet suppliers of transparent plastic bags for international trade?

Vetting suppliers is crucial in international trade to ensure product quality and reliability. Start by researching the supplier’s reputation, checking online reviews and testimonials from other B2B buyers. Verify their certifications, such as ISO or FDA compliance for food-safe products. Request samples to assess quality and engage in direct communication to gauge their responsiveness and expertise. Additionally, consider visiting their manufacturing facilities if possible or using third-party inspection services to confirm their capabilities. -

What payment terms should I expect when sourcing transparent plastic bags internationally?

Payment terms can vary significantly between suppliers and regions. Common practices include upfront payments, deposits (typically 30-50%), and net payment terms (e.g., 30 or 60 days after delivery). It’s important to establish clear terms before placing orders and to consider using secure payment methods, such as letters of credit or escrow services, to protect your investment. Negotiating favorable payment terms can help manage cash flow, especially for larger orders or ongoing contracts. -

What quality assurance (QA) processes should I expect from suppliers?

Reputable suppliers of transparent plastic bags should have established quality assurance processes to ensure their products meet industry standards. This can include material inspections, dimensional checks, and testing for durability and clarity. Ask potential suppliers about their QA protocols, including any third-party testing they conduct. Regular audits and compliance with international standards (e.g., ISO 9001) can also indicate a supplier’s commitment to quality, providing peace of mind for your purchases. -

What logistics considerations should I keep in mind when sourcing transparent plastic bags?

When sourcing transparent plastic bags internationally, logistics play a critical role in ensuring timely delivery and cost-effectiveness. Consider shipping methods (air vs. sea), as they will affect transit times and costs. Understand the import regulations in your country to avoid delays at customs. Additionally, inquire about the supplier’s shipping practices, including packaging, handling, and tracking options. Collaborating with a logistics partner can also streamline the process, helping you manage inventory and distribution effectively.

Top 9 Transparent Plastic Bag Manufacturers & Suppliers List

1. ClearBags – Crystal Clear Packaging Solutions

Domain: clearbags.com

Registered: 1999 (26 years)

Introduction: Crystal Clear Bags for Food & Retail – High Clarity Packaging. US Customer Service – Providing Quality Packaging Since 1992. Categories include: ECO Bags, Commercial Compostable Bags, Flap Seal Bags, No Flap Bags, Protective Closure Bags, Rice Paper Pouches, Stand Up Pouches, Zipper Barrier Bags, Side Gusset Bags, Flat Bottom Gusset Bags, Clear Flat Heat Seal Bags, Kraft Flat Heat Seal Bags, and m…

2. ULINE – Plastic and Poly Bags

Domain: uline.com

Registered: 1995 (30 years)

Introduction: Plastic Bags, Poly Bags, Clear Bags in Stock – ULINE offers a variety of bags including Anti-Static Bags, Reclosable Poly Bags, Gusseted Bags, White Block Bags, Food Bags, Bags on a Roll, Retail Bags, Apparel Bags, Pallet Covers, Trash Liners, Burlap and Cloth Bags, Sandbags, and Plastic Sheeting. The site allows searching by size and provides options for bag sealers and shrink film. ULINE also fe…

3. Target – Clear Plastic Bags

Domain: target.com

Registered: 1997 (28 years)

Introduction: This company, Target – Clear Plastic Bags, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Perfection Pack – Clear Plastic Bags

Domain: perfectionpack.com

Registered: 2015 (10 years)

Introduction: {“product_name”:”Clear Plastic Bags (All Sizes)”,”sizes”:[{“size”:”20×30″”,””price”:”$0.00 USD”},{“size”:”5.5×4.75×19″”,””price”:”$0.00 USD”},{“size”:”5×3.5×13″”,””price”:”$0.00 USD”},{“size”:”5×4.5×15″”,””price”:”$0.00 USD”},{“size”:”8×10″”,””price”:”$0.00 USD”},{“size”:”8x4x18″”,””price”:”$0.00 USD”},{“size”:”8x4x21″”,””price”:”$0.00 USD”},{“size”:”8x5x16″”,””price”:”$0.00 USD”},{“size”:”8x5x21″…

5. Upak N Ship – Clear Stretchy PE Bags

Domain: upaknship.com

Registered: 2007 (18 years)

Introduction: Clear Stretchy PE (Polyethylene) Bags

– Material: Clear Virgin Polyethylene

– Features: Soft, pliable, stretchy plastic

– Benefits: Provides added protection while ensuring a neat & professional product arrival

– Compliance: Meets all USDA and FDA standards

– Closure Options: Self Seal Lip & Tape Closure (resealable) or Top Zip Reclosable zip bag

– Recyclability: 100% recyclable

– Available Sizes:…

6. U.S. Poly Pack – Clear Plastic Bags

Domain: uspolypack.com

Registered: 2012 (13 years)

Introduction: Clear Plastic Bags: Poly Bags & Tubing, Resealable & Gusseted Bags. Free Shipping on Orders Over $799. Product Types: Flat Poly Bags, Gusseted Poly Bags, Reclosable Bags, Poly Tubing, Pre Opened Bags On Roll, Polypropylene Clear Bags, Resealable Bags, Wicketed Bags, Zip Reclosable Lock Bags, Reclosable Bags with Hang Holes, Reclosable Bags with White Block, Reclosable Parts Bags, White Block Reclo…

7. United MFRs – Re-Sealable Clear Plastic Bags

Domain: unitedmfrs.com

Registered: 1999 (26 years)

Introduction: Re-Sealable Clear Plastic Bags for Artwork, Prints & More

8. iStock – Transparent Plastic Bags

Domain: istockphoto.com

Registered: 2000 (25 years)

Introduction: This company, iStock – Transparent Plastic Bags, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

9. Opus Art Supplies – Crystal Clear Plastic Bags

Domain: opusartsupplies.com

Registered: 2010 (15 years)

Introduction: Product Name: Crystal Clear Plastic Bags

Brand: Opus Art Supplies

Price: $1.00 USD

Dimensions Available: 2.9 x 3, 4″ x 6″, 5″ x 7″, 6″ x 9″, 8″ x 10″, 8.5″ x 11″, 9″ x 12″, 12″ x 12″, 11″ x 14″, 11″ x 17″, 12″ x 16″, 13″ x 19″, 14″ x 18″, 16″ x 20″, 17″ x 22″, 18″ x 24″, 22″ x 30″, 24″ x 36″

Customer Rating: 4.72 / 5.0 (36 reviews)

Availability: Sold out for most variants

Shipping: Calculated at c…

Strategic Sourcing Conclusion and Outlook for transparent plastic bag

In today’s competitive market, strategic sourcing of transparent plastic bags offers significant advantages for businesses across diverse industries. These bags not only enhance product visibility but also provide essential protection from environmental factors, making them ideal for food and retail applications. The variety of options—from gusseted and reclosable bags to custom-printed solutions—allows buyers to tailor their packaging to meet specific needs, ensuring that products stand out on the shelf.

International B2B buyers, particularly in Africa, South America, the Middle East, and Europe, should leverage the benefits of bulk purchasing and supplier relationships to reduce costs and improve supply chain efficiency. By prioritizing eco-friendly options and ensuring compliance with industry standards, companies can align with global sustainability trends while meeting regulatory requirements.

As we look to the future, the demand for transparent plastic bags is expected to grow, driven by innovations in materials and design. Now is the time for businesses to evaluate their sourcing strategies, embrace quality suppliers, and capitalize on the opportunities presented by this versatile packaging solution. Engage with trusted suppliers today to secure the best options for your product packaging needs and stay ahead in the evolving marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.