Toroidal Amp: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for toroidal amp

In an increasingly interconnected world, sourcing high-quality toroidal amplifiers presents a significant challenge for B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. The unique advantages of toroidal amplifiers, including their compact design, superior sound quality, and enhanced efficiency, make them an attractive option for various applications, from audio systems in commercial venues to advanced industrial uses. However, navigating the global market to find reliable suppliers who meet specific technical requirements and regulatory standards can be daunting.

This comprehensive guide delves into the essential aspects of toroidal amplifiers, covering various types, applications, and the intricacies of supplier vetting. By addressing key considerations such as performance metrics, cost factors, and compliance with industry standards, this resource empowers international B2B buyers to make informed purchasing decisions. Whether you’re based in Nigeria, Brazil, or anywhere else, understanding the nuances of the toroidal amp market will enable you to identify the right products that meet your operational needs while maximizing value.

With actionable insights and expert recommendations, this guide aims to streamline your sourcing process, helping you connect with reputable manufacturers and suppliers. Equip yourself with the knowledge necessary to capitalize on the benefits of toroidal amplifiers and enhance your business’s audio performance and efficiency.

Understanding toroidal amp Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Audio Toroidal Amplifier | High power output, low distortion, compact design | Professional audio systems, home theaters | Pros: Superior sound quality, space-efficient. Cons: Higher initial cost. |

| Medical Grade Toroidal Amp | Meets strict safety standards, high reliability | Medical equipment, healthcare applications | Pros: Compliance with medical standards, durable. Cons: Specialized design may limit options. |

| Industrial Toroidal Amplifier | Enhanced efficiency, robust construction | Manufacturing, industrial automation | Pros: High efficiency, less heat generation. Cons: May require specialized installation. |

| Custom Toroidal Amplifiers | Tailored specifications, unique voltage and size options | Specialized audio setups, unique industrial needs | Pros: Fully customizable to specific needs. Cons: Longer lead times and higher costs. |

| Home Theater Toroidal Amp | Multi-channel capabilities, aesthetic designs | Residential entertainment systems | Pros: Improved audio dynamics, stylish. Cons: May require additional components for full functionality. |

What Are the Characteristics of Audio Toroidal Amplifiers?

Audio toroidal amplifiers are designed to deliver high power output while minimizing distortion. Their compact design allows for efficient integration into various audio setups, making them ideal for professional audio systems and home theaters. B2B buyers should consider the amplifier’s power rating and distortion levels when selecting a product to ensure it meets their specific audio requirements.

Why Choose Medical Grade Toroidal Amplifiers?

Medical-grade toroidal amplifiers are engineered to meet stringent safety and reliability standards, making them essential for healthcare applications. These amplifiers ensure consistent performance, crucial for medical devices and systems. When purchasing, B2B buyers should verify compliance with relevant medical regulations and consider the long-term reliability of the amplifier in critical environments.

How Do Industrial Toroidal Amplifiers Enhance Efficiency?

Industrial toroidal amplifiers are known for their enhanced efficiency and robust construction, making them suitable for manufacturing and industrial automation. Their design reduces heat generation, which is a significant advantage in high-demand environments. Buyers should evaluate the efficiency ratings and durability of these amplifiers to ensure they can withstand the rigors of industrial applications.

What Are the Benefits of Custom Toroidal Amplifiers?

Custom toroidal amplifiers offer tailored specifications to meet unique voltage and size requirements, making them ideal for specialized audio setups or industrial applications. While these amplifiers provide flexibility, B2B buyers should be prepared for longer lead times and potentially higher costs associated with custom manufacturing. Understanding specific needs upfront can streamline the purchasing process.

How Do Home Theater Toroidal Amplifiers Improve Audio Dynamics?

Home theater toroidal amplifiers are designed with multi-channel capabilities and aesthetic considerations, enhancing both audio performance and visual appeal in residential entertainment systems. They provide improved audio dynamics, allowing users to experience a more immersive sound environment. Buyers should consider compatibility with existing systems and the overall design when selecting a home theater amplifier.

Key Industrial Applications of toroidal amp

| Industry/Sector | Specific Application of toroidal amp | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Audio & Entertainment | High-fidelity audio amplifiers | Enhanced sound quality with reduced distortion | Compatibility with existing audio systems and local regulations |

| Renewable Energy | Power conversion in solar inverters | Improved efficiency and reduced energy losses | Compliance with international energy standards and certifications |

| Medical Equipment | Medical-grade audio amplifiers | High reliability and safety for critical applications | Meeting stringent medical safety standards and certifications |

| Industrial Automation | Amplification for control systems | Increased operational efficiency and reduced noise levels | Customization options for specific industrial environments |

| Home Automation & IoT | Smart home audio systems | Compact design that fits into modern aesthetics | Versatile connectivity options for integration with smart devices |

How Are Toroidal Amplifiers Used in the Audio & Entertainment Industry?

In the audio and entertainment sector, toroidal amplifiers are integral to high-fidelity audio systems. Their design minimizes distortion and enhances sound quality, making them ideal for professional sound systems in concert venues and studios. For international buyers, particularly in regions like Africa and South America, sourcing amplifiers that comply with local electrical standards is crucial to ensure performance and safety.

What Role Do Toroidal Amplifiers Play in Renewable Energy Applications?

In renewable energy, toroidal amplifiers are utilized in solar inverters for their efficiency and compact design. They help convert DC to AC power with minimal energy loss, which is vital for maximizing output in solar installations. Buyers in the Middle East, where solar energy is booming, should consider the efficiency ratings and certifications of these amplifiers to align with renewable energy regulations.

How Are Toroidal Amplifiers Essential for Medical Equipment?

Medical-grade toroidal amplifiers are designed to meet stringent safety and reliability standards, making them essential for medical devices that require high performance without interference. Their low noise levels are particularly beneficial in sensitive environments such as hospitals. B2B buyers in Europe must ensure that these amplifiers are compliant with medical certifications, such as IEC 60601, to guarantee safety in critical applications.

What Advantages Do Toroidal Amplifiers Provide in Industrial Automation?

In industrial automation, toroidal amplifiers enhance the performance of control systems by providing reliable amplification with reduced noise levels. Their compact design allows for easy integration into existing machinery, which is crucial for maintaining operational efficiency. Businesses in sectors like manufacturing should prioritize sourcing amplifiers that can be customized to fit specific industrial requirements, ensuring seamless integration.

How Do Toroidal Amplifiers Enhance Home Automation Systems?

In the realm of home automation and IoT, toroidal amplifiers are favored for their compact size and aesthetic appeal, fitting seamlessly into modern home designs. They are used in smart home audio systems to deliver high-quality sound without compromising space. Buyers, especially in Europe and South America, should look for amplifiers that offer versatile connectivity to ensure compatibility with various smart home devices.

3 Common User Pain Points for ‘toroidal amp’ & Their Solutions

Scenario 1: Managing Noise Interference in Audio Applications

The Problem: One of the most significant challenges faced by B2B buyers in the audio equipment sector is dealing with noise interference, especially in environments where sound quality is critical, such as recording studios or public venues. Traditional transformers can introduce hum or buzz, which compromises audio clarity and can lead to dissatisfaction from clients or end-users. This issue is particularly pressing in regions where power quality is inconsistent, causing further complications in audio reproduction.

The Solution: To overcome noise interference, B2B buyers should consider investing in toroidal amplifiers that utilize toroidal transformers. These transformers are designed to minimize electromagnetic interference and mechanical vibrations, significantly reducing unwanted noise. When sourcing these amplifiers, it is crucial to evaluate suppliers who provide detailed specifications on their noise ratings and efficiency. Engaging with manufacturers who offer custom solutions can also ensure that the transformer is tailored to specific audio needs, such as voltage requirements and shielding options. Additionally, integrating these transformers into well-isolated installations can further enhance audio performance, ensuring that the final output meets the highest standards of clarity and fidelity.

Scenario 2: Space Constraints in Installation Settings

The Problem: Many businesses face the challenge of limited physical space for audio equipment installations. In settings like small venues, corporate offices, or mobile setups, traditional transformers can be bulky and difficult to integrate seamlessly into the environment. This can lead to increased installation costs and aesthetic concerns, as larger equipment may detract from the overall design of the space.

The Solution: The compact design of toroidal amplifiers presents a practical solution for B2B buyers working in constrained environments. When selecting a toroidal amplifier, it’s essential to look for models that offer a high power-to-size ratio. Buyers should also consult with suppliers about mounting options that facilitate easier integration into their existing setups. For instance, some toroidal amplifiers are designed to be mounted in a single rack unit, allowing them to fit into tight spaces without sacrificing performance. Additionally, engaging with suppliers who provide customizable features can help buyers ensure that the amplifier meets specific dimensional requirements, effectively maximizing the available space while maintaining high audio quality.

Scenario 3: Ensuring Compliance with Industry Standards

The Problem: For companies involved in sectors like healthcare, telecommunications, or any regulated industry, ensuring that audio equipment meets specific compliance standards can be a daunting task. Many amplifiers do not meet the stringent safety and performance criteria required for medical or industrial applications, leading to potential legal liabilities and operational delays.

Illustrative image related to toroidal amp

The Solution: To navigate compliance challenges, B2B buyers should prioritize sourcing toroidal amplifiers that are explicitly designed for regulated industries. This includes seeking out products that come with certifications such as IEC 60601-1 for medical applications, which ensures that the equipment adheres to essential safety standards. When engaging with suppliers, buyers should ask for documentation demonstrating compliance with relevant standards and inquire about their testing procedures. Additionally, leveraging manufacturers who specialize in custom solutions can help tailor the amplifier to meet specific regulatory requirements, ensuring that the equipment not only performs optimally but also aligns with industry mandates. Regular communication with compliance experts during the procurement process can further safeguard against potential pitfalls.

Strategic Material Selection Guide for toroidal amp

What Are the Common Materials Used in Toroidal Amplifiers?

When selecting materials for toroidal amplifiers, it’s essential to consider how they influence the performance, durability, and cost-effectiveness of the final product. Here, we analyze four common materials used in the construction of toroidal amplifiers, focusing on their properties, advantages, disadvantages, and relevant considerations for international B2B buyers.

1. Silicon Steel

Key Properties:

Silicon steel is known for its high magnetic permeability and low core losses, making it ideal for toroidal transformers. It typically operates effectively at temperatures up to 150°C and can handle moderate pressure levels.

Pros & Cons:

The primary advantage of silicon steel is its excellent magnetic properties, which enhance efficiency and reduce energy loss. However, it can be more expensive than other materials and may require complex manufacturing processes, such as lamination, to optimize performance.

Impact on Application:

Silicon steel is particularly suitable for audio applications where low noise and high fidelity are critical. Its magnetic properties ensure that the amplifier delivers clear sound without distortion.

Considerations for International Buyers:

Compliance with international standards such as ASTM A677 for electrical steel is crucial. Buyers from regions like Africa and South America should also consider local sourcing options to mitigate costs.

2. Ferrite

Key Properties:

Ferrite materials exhibit high electrical resistivity and are effective at high frequencies. They can operate at temperatures up to 200°C and are resistant to corrosion.

Pros & Cons:

Ferrite’s high resistivity minimizes eddy current losses, making it suitable for compact designs. However, its brittleness can lead to manufacturing challenges, and it may not perform as well at lower frequencies compared to silicon steel.

Impact on Application:

Ferrite is ideal for applications requiring compactness and efficiency, such as portable audio devices. Its properties are particularly beneficial in environments where space is limited.

Considerations for International Buyers:

Buyers should ensure that ferrite materials meet relevant standards, such as IEC 60424, to guarantee quality and performance. Additionally, understanding local regulations regarding material sourcing is essential.

3. Copper Wire

Key Properties:

Copper wire is known for its excellent electrical conductivity and thermal properties. It can withstand high temperatures (up to 200°C) and has good corrosion resistance when properly insulated.

Pros & Cons:

The primary advantage of copper is its superior conductivity, which enhances the efficiency of the amplifier. However, it can be relatively expensive compared to aluminum alternatives, and its weight may be a consideration in portable applications.

Impact on Application:

Copper wire is critical for winding the transformer coils in toroidal amplifiers, directly affecting the amplifier’s performance and sound quality.

Considerations for International Buyers:

International buyers should be aware of the fluctuating copper prices and the importance of sourcing from reputable suppliers to ensure compliance with standards such as ASTM B3 for copper wire.

4. Aluminum

Key Properties:

Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity. It operates efficiently at temperatures up to 150°C.

Pros & Cons:

The lightweight nature of aluminum makes it an attractive option for portable applications. However, its electrical conductivity is lower than that of copper, which may impact overall performance.

Impact on Application:

Aluminum is often used in the casing of toroidal amplifiers, providing structural integrity while minimizing weight. It is suitable for applications where portability is a priority.

Considerations for International Buyers:

Buyers should ensure that aluminum components meet standards such as ASTM B221 for structural aluminum. Additionally, understanding local market preferences for material types can influence purchasing decisions.

Summary Table of Material Selection for Toroidal Amplifiers

| Material | Typical Use Case for toroidal amp | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Steel | Audio transformers | High efficiency and low core losses | Higher cost and complex manufacturing | High |

| Ferrite | Compact audio devices | High resistivity and low losses | Brittle and less effective at low frequencies | Medium |

| Copper Wire | Transformer coils | Superior electrical conductivity | Higher cost and weight | High |

| Aluminum | Casing for portable amplifiers | Lightweight and corrosion-resistant | Lower conductivity than copper | Medium |

This guide provides a comprehensive overview of material selection for toroidal amplifiers, helping international B2B buyers make informed decisions based on performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for toroidal amp

What Are the Key Stages in the Manufacturing Process of Toroidal Amplifiers?

The manufacturing of toroidal amplifiers involves several critical stages, ensuring that the final product meets high standards of performance and quality. Below are the main phases involved in the production process:

1. Material Preparation: What Materials Are Used in Toroidal Amplifier Manufacturing?

The first stage involves selecting and preparing high-quality materials essential for the construction of toroidal amplifiers. Key components include:

- Copper Wire: Used for winding the toroidal transformer, copper wire must be of high purity to ensure efficient conductivity and minimal energy loss.

- Core Materials: Ferrite or laminated silicon steel is often used for the transformer core, chosen for their magnetic properties that enhance efficiency and reduce noise.

- Insulation Materials: Insulation is critical to prevent electrical shorts and to maintain safety standards. High-temperature resistant materials are often employed.

These materials are sourced from reliable suppliers, ensuring compliance with international quality standards.

2. Forming: How Are Toroidal Transformers Shaped and Assembled?

Once materials are prepared, the next step is forming. This stage includes:

- Winding the Transformer: The copper wire is meticulously wound around the toroidal core. This process requires precision to ensure that the windings are uniform, which is crucial for minimizing electromagnetic interference and ensuring sound quality.

- Core Assembly: After winding, the core is assembled, and any necessary insulation is applied. This step often involves advanced machinery to ensure accuracy and consistency.

Techniques such as CNC machining may be employed to enhance precision in forming the components.

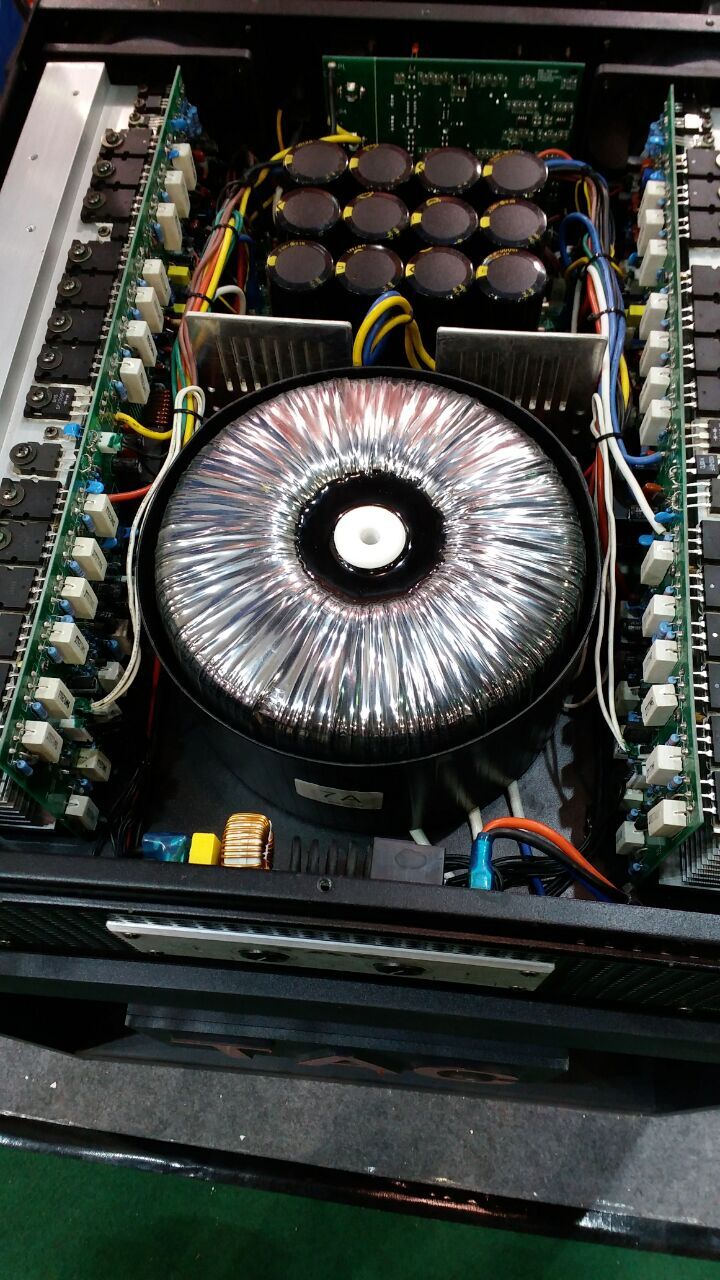

3. Assembly: What Is Involved in the Assembly of Toroidal Amplifiers?

The assembly of toroidal amplifiers combines several components into a cohesive unit. Key activities include:

- Integration of Circuitry: The toroidal transformer is integrated with other electronic components, including capacitors, resistors, and amplifying circuits. This step is critical for achieving desired audio performance.

- Mechanical Assembly: The assembled circuit is housed in a robust chassis, often constructed from aluminum for lightweight durability. Care is taken to ensure that all components are securely mounted to minimize vibrations.

This stage may also involve testing the assembly for initial functionality before proceeding to quality control checks.

4. Finishing: What Quality Assurance Measures Are Taken During Finishing?

Finishing processes ensure that the toroidal amplifiers are aesthetically pleasing and functionally robust. This includes:

Illustrative image related to toroidal amp

- Surface Treatment: The chassis may undergo anodizing or painting to enhance corrosion resistance and improve appearance.

- Final Assembly Checks: Before packaging, the amplifier is subjected to final checks to ensure that all components are correctly assembled and functioning as intended.

What Quality Control Measures Are Implemented in Toroidal Amplifier Manufacturing?

Quality control (QC) is essential in the manufacturing of toroidal amplifiers to ensure they meet both industry standards and customer expectations. Below are the key QC components:

International Standards: Which Standards Are Relevant for Toroidal Amplifiers?

Manufacturers often adhere to several international standards, including:

- ISO 9001: This standard outlines the criteria for a quality management system, ensuring that manufacturers maintain consistent quality in their products and services.

- CE Marking: For products sold in Europe, CE marking indicates compliance with safety, health, and environmental protection standards.

- API Standards: For applications in the industrial sector, adherence to API standards ensures that the products are suitable for specific operational environments.

These certifications not only enhance product credibility but also facilitate smoother international trade.

QC Checkpoints: What Are the Key QC Checkpoints During Production?

Quality control is typically structured around several checkpoints:

- Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials and components upon arrival. Only materials meeting specified standards are accepted for production.

- In-Process Quality Control (IPQC): During manufacturing, ongoing checks ensure that processes are followed correctly and that components meet quality specifications. This may involve measuring dimensions and conducting electrical tests.

- Final Quality Control (FQC): After assembly, a comprehensive inspection is conducted. This includes functional testing of the amplifier, ensuring it meets performance specifications, and checking for aesthetic flaws.

Common Testing Methods: How Are Toroidal Amplifiers Tested for Quality?

Various testing methods are employed to ensure the amplifiers function as intended:

- Electrical Testing: This includes measuring output power, distortion levels, and frequency response to verify that the amplifier meets performance standards.

- Thermal Testing: Assessing how the amplifier performs under different temperature conditions ensures reliability during operation.

- Durability Testing: Amplifiers are subjected to stress tests to simulate long-term use, helping to identify potential failures before products reach the market.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is crucial. Here are several strategies to ensure product quality:

Supplier Audits: What Should Buyers Look for in Supplier Audits?

Conducting supplier audits allows buyers to assess the manufacturing processes firsthand. During audits, buyers should look for:

- Documentation of Quality Procedures: Suppliers should maintain thorough records of their quality control measures, including compliance with international standards.

- Facility Conditions: Observing the cleanliness and organization of the manufacturing environment can provide insights into overall quality.

- Employee Training Programs: Ensuring that employees are trained in quality management practices is vital for maintaining high standards.

Reports and Certifications: How Can Buyers Use Documentation to Ensure Quality?

Buyers should request documentation regarding quality control practices, including:

- Quality Management System Certificates: These documents demonstrate adherence to standards like ISO 9001.

- Test Reports: Requesting samples of test results for previous batches can provide assurance of product quality.

- Third-Party Inspection Reports: Engaging third-party inspectors can provide an unbiased assessment of the manufacturing process and product quality.

What Are the Nuances of Quality Control for International B2B Buyers?

Understanding the nuances of quality control can be particularly beneficial for international buyers. Some considerations include:

- Regulatory Compliance: Buyers should familiarize themselves with the regulatory requirements specific to their region, as these can vary significantly.

- Cultural Differences in Quality Standards: Different regions may have varying expectations regarding quality and performance. Open communication with suppliers can help bridge these gaps.

- Supply Chain Transparency: Building a transparent supply chain can enhance trust and facilitate better quality assurance practices.

By understanding the manufacturing processes and quality assurance protocols for toroidal amplifiers, B2B buyers can make informed decisions and establish strong partnerships with reliable suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘toroidal amp’

In the competitive world of audio equipment, sourcing a toroidal amplifier requires a strategic approach to ensure you select the right product that meets your needs. This guide provides a step-by-step checklist designed for B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, to facilitate a successful procurement process.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for your toroidal amplifier based on the application. Consider factors such as power output (measured in watts), channel configuration (mono, stereo, multi-channel), and impedance compatibility. Knowing these specifications helps narrow down your options and ensures compatibility with your existing audio systems.

Step 2: Research Supplier Backgrounds

Conduct thorough research on potential suppliers to assess their credibility and reliability. Look for established manufacturers with a history of producing quality toroidal amplifiers. Verify their industry certifications, such as ISO standards, which indicate compliance with international quality and safety regulations.

- Check Reviews and Testimonials: Seek feedback from previous customers to gauge satisfaction and reliability.

- Evaluate Case Studies: Request examples of similar projects they have completed successfully.

Step 3: Evaluate Product Features and Benefits

Examine the specific features of the toroidal amplifiers offered by potential suppliers. Look for attributes that enhance audio quality, such as low distortion rates, high efficiency (above 90%), and compact design. These features can significantly impact performance, especially in environments where sound clarity is paramount.

- Consider Advanced Circuitry: Ensure the amplifier includes features like differential amplifier circuits for improved signal-to-noise ratios.

Step 4: Assess Customization Options

Determine if the supplier offers customization options for their toroidal amplifiers. Customization can be vital for meeting unique requirements, such as specific voltage needs, connector types, or mounting configurations. This flexibility can lead to enhanced performance tailored to your specific application.

- Inquire About Compliance: Ensure that any custom solutions adhere to relevant industry standards and regulations.

Step 5: Request Samples and Perform Testing

Before finalizing your order, request samples of the toroidal amplifiers to conduct performance testing. Testing allows you to evaluate audio quality, compatibility with your systems, and overall functionality. This step is crucial to avoid costly mistakes and ensure the product meets your expectations.

- Conduct Listening Tests: Assess the sound quality in real-world scenarios to verify performance claims.

Step 6: Negotiate Pricing and Terms

Once you have identified a suitable supplier and product, engage in negotiations regarding pricing, payment terms, and delivery schedules. Be clear about your budget constraints and seek competitive pricing without compromising on quality.

Illustrative image related to toroidal amp

- Consider Long-Term Partnerships: Discuss potential for bulk purchasing discounts or ongoing support agreements.

Step 7: Finalize the Purchase Agreement

Carefully review and finalize the purchase agreement, ensuring all terms discussed are included. Pay close attention to warranty conditions, return policies, and after-sales support. A well-drafted agreement protects your interests and establishes a clear understanding between you and the supplier.

By following this checklist, B2B buyers can effectively navigate the sourcing process for toroidal amplifiers, ensuring they make informed decisions that align with their technical and business needs.

Comprehensive Cost and Pricing Analysis for toroidal amp Sourcing

What Are the Key Cost Components in Toroidal Amplifier Production?

When sourcing toroidal amplifiers, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: High-quality materials such as copper wire for windings, laminated silicon steel for cores, and durable casings are essential. The choice of materials directly impacts the efficiency and performance of the amplifier. For instance, using premium-grade copper can enhance conductivity but may increase costs.

-

Labor: Skilled labor is required for the assembly and testing of toroidal amplifiers. The complexity of the assembly process, which includes winding the toroidal core and integrating electronic components, necessitates expertise, thereby influencing labor costs.

-

Manufacturing Overhead: This includes utilities, equipment depreciation, and facility costs. Manufacturers with advanced technology and automated processes may have lower overhead costs, which can be passed on to buyers.

-

Tooling: Initial tooling costs for specialized equipment can be significant, particularly for custom designs. These costs are typically amortized over production runs, impacting pricing based on the volume ordered.

-

Quality Control (QC): Rigorous testing to ensure compliance with industry standards (e.g., IEC 60601-1 for medical applications) adds to costs. However, effective QC processes can prevent costly returns and enhance brand reputation.

-

Logistics: Shipping costs vary based on the distance, mode of transport, and weight of the products. International buyers should consider these factors, especially when sourcing from regions with high shipping rates.

-

Margin: Suppliers typically apply a markup to cover their costs and generate profit. Understanding the expected margin can help buyers negotiate better prices.

How Do Price Influencers Impact Toroidal Amplifier Sourcing?

Several factors can influence the pricing of toroidal amplifiers:

-

Volume/MOQ: Higher order volumes often lead to discounted pricing due to economies of scale. Buyers should evaluate their needs to leverage bulk pricing effectively.

-

Specifications and Customization: Customized amplifiers that meet specific requirements can significantly increase costs. Buyers should weigh the benefits of customization against the additional expenses involved.

-

Materials and Quality Certifications: The use of premium materials and certifications can raise prices. For instance, medical-grade transformers typically cost more due to stringent compliance requirements.

-

Supplier Factors: Supplier reputation, reliability, and production capacity can influence pricing. Established suppliers may charge more due to their proven track record, while new entrants may offer lower prices to gain market share.

-

Incoterms: The choice of Incoterms (e.g., FOB, CIF) affects logistics costs and responsibilities. Buyers should clearly understand these terms to avoid unexpected expenses.

What Negotiation Strategies Can Help Optimize Costs?

To achieve cost efficiency in toroidal amplifier sourcing, buyers should consider the following strategies:

-

Volume Negotiation: Leverage bulk orders to negotiate lower prices. Suppliers are often willing to offer discounts for larger commitments.

-

Comparison Shopping: Engage multiple suppliers to compare quotes. This not only helps in identifying the best price but also provides insights into market rates.

-

Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider factors such as energy efficiency, maintenance costs, and potential warranties. A slightly higher upfront cost may lead to lower long-term expenses.

-

Cultural Sensitivity: For buyers in regions like Africa and South America, understanding local business practices can enhance negotiation outcomes. Building relationships and trust can lead to more favorable terms.

-

Flexibility in Specifications: If possible, be open to standard models instead of custom designs. This can significantly reduce costs and lead times.

Are There Pricing Nuances for International B2B Buyers?

International buyers, especially from regions like Africa, Brazil, and the Middle East, should be aware of specific pricing nuances:

-

Currency Fluctuations: Exchange rates can affect pricing. Consider negotiating in a stable currency to mitigate this risk.

-

Import Duties and Taxes: Be aware of any tariffs or taxes that may apply when importing toroidal amplifiers, as these can add to the total cost.

-

Shipping and Handling: Factor in the logistics costs, as these can vary significantly based on the shipping route and method chosen.

In conclusion, while the pricing of toroidal amplifiers can vary based on numerous factors, understanding the cost structure and employing strategic sourcing methods can lead to significant savings and optimal purchasing decisions.

Alternatives Analysis: Comparing toroidal amp With Other Solutions

Understanding Alternatives to Toroidal Amplifiers

When considering audio amplification solutions, businesses must evaluate various technologies to determine the best fit for their specific needs. Toroidal amplifiers, known for their compact design and efficiency, are popular in various applications. However, several alternatives exist, each offering distinct advantages and disadvantages. This section provides a comparative analysis of toroidal amplifiers against two viable alternatives: traditional linear amplifiers and Class D amplifiers.

Comparison Table

| Comparison Aspect | Toroidal Amp | Traditional Linear Amplifier | Class D Amplifier |

|---|---|---|---|

| Performance | High efficiency (90-97%); low noise | Excellent sound quality; high power | Good efficiency (80-90%); lower sound quality than linear |

| Cost | Moderate to high upfront investment | Generally lower upfront cost | Lower upfront cost, but may require additional components |

| Ease of Implementation | Requires specific mounting; compact | Standard installation; bulkier size | Simple installation; minimal space required |

| Maintenance | Low maintenance; durable design | Moderate maintenance; larger components | Low maintenance; fewer parts to service |

| Best Use Case | High-fidelity audio systems; compact setups | High-end audio applications; professional sound | Home theaters; portable audio solutions |

In-Depth Analysis of Alternatives

What Are the Advantages and Disadvantages of Traditional Linear Amplifiers?

Traditional linear amplifiers are well-regarded for their sound quality, particularly in high-end audio setups. They provide clear, distortion-free audio and are often favored for professional applications. However, they tend to be larger and less efficient, consuming more power and generating more heat. This can lead to higher operational costs over time. Additionally, their bulkiness may pose installation challenges in space-constrained environments.

How Do Class D Amplifiers Compare to Toroidal Amps?

Class D amplifiers, also known as switching amplifiers, are recognized for their efficiency and compactness. They operate by rapidly switching the output devices on and off, allowing for lower power consumption and heat generation. While they are typically less expensive and easier to install, the sound quality may not match that of toroidal or linear amplifiers, particularly in high-fidelity applications. Class D amplifiers are best suited for home theaters and portable systems where space and power efficiency are crucial.

Conclusion: Which Amplification Solution Should B2B Buyers Choose?

Choosing the right amplification solution depends on the specific requirements of your application. For businesses looking for high fidelity in compact spaces, toroidal amplifiers offer an excellent balance of performance and efficiency. Traditional linear amplifiers may be the best choice for applications where sound quality is paramount, despite their size and power consumption. On the other hand, Class D amplifiers can serve well in cost-sensitive and space-constrained environments, providing good performance for general audio needs. Assessing your priorities—whether they are performance, cost, ease of installation, or maintenance—will guide you in selecting the most suitable amplifier for your business.

Essential Technical Properties and Trade Terminology for toroidal amp

What Are the Key Technical Properties of a Toroidal Amplifier?

Understanding the technical specifications of toroidal amplifiers is crucial for B2B buyers aiming to make informed purchasing decisions. Here are several critical specifications that define the performance and reliability of these devices:

1. Efficiency Rating

Efficiency ratings for toroidal amplifiers typically range from 90% to 97%. This metric indicates how effectively the amplifier converts input power into output power without excessive energy loss. High efficiency is particularly important for businesses focused on sustainability, as it leads to reduced energy costs and minimal heat generation.

2. Total Harmonic Distortion (THD)

THD measures the distortion of an audio signal as it passes through the amplifier. A lower THD percentage (ideally below 0.1%) ensures that the sound quality remains pristine and true to the original recording. For businesses in the audio industry, this specification is critical for maintaining high-quality standards and satisfying customer expectations.

3. Power Output

Power output, measured in Watts RMS, indicates the amplifier’s ability to drive speakers effectively. Specifications often include various power outputs at different impedance levels (e.g., 100 Watts RMS at 8 Ohms). This property is vital for buyers to ensure compatibility with their audio systems, allowing for optimal performance in both commercial and residential settings.

4. Signal-to-Noise Ratio (SNR)

SNR is a measure of the desired signal compared to background noise, typically expressed in decibels (dB). A higher SNR indicates clearer sound reproduction with minimal interference, which is essential for professional audio applications. Buyers should prioritize amplifiers with high SNR ratings to ensure superior audio clarity.

Illustrative image related to toroidal amp

5. Mounting Configuration

The mounting configuration of a toroidal amplifier can significantly impact installation flexibility. Toroidal amplifiers are designed to be compact and often require fewer mounting points than traditional transformers. Understanding these requirements can facilitate easier installation in diverse environments, which is especially beneficial for integrators and installers.

6. Thermal Management Features

Effective thermal management is essential for the longevity and reliability of amplifiers. Features such as temperature compensation and overload protection help prevent overheating and ensure stable operation. Businesses should seek amplifiers equipped with robust thermal management systems to mitigate risks of failure and enhance durability.

What Are Common Trade Terms in the Toroidal Amplifier Industry?

Navigating the procurement process requires familiarity with industry-specific terminology. Here are several essential terms that B2B buyers should understand:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces components or products that are used in another company’s end product. For toroidal amplifiers, OEM partnerships can be beneficial for businesses looking to integrate high-quality components into their audio systems without investing in manufacturing processes.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ is critical for buyers to assess their purchasing strategies and budget allocations. For instance, if a supplier has a high MOQ for toroidal amplifiers, it may necessitate a larger upfront investment, impacting cash flow.

3. RFQ (Request for Quote)

An RFQ is a formal request sent to suppliers to obtain pricing and terms for specific products. B2B buyers should use RFQs to compare prices and negotiate terms with multiple suppliers, ensuring they receive the best value for toroidal amplifiers.

4. Incoterms

Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping costs, risks, and delivery responsibilities, which is essential for smooth cross-border procurement of toroidal amplifiers.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the product. Understanding lead times is crucial for inventory management and project planning. Buyers should inquire about lead times to ensure timely delivery of toroidal amplifiers, especially for urgent projects.

6. Certification Standards

Certification standards (e.g., IEC, UL) indicate that a product meets specific safety and performance criteria. For buyers, ensuring that toroidal amplifiers comply with relevant certification standards is vital for regulatory compliance and quality assurance in their applications.

Illustrative image related to toroidal amp

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing toroidal amplifiers, ensuring they meet their operational needs and quality expectations.

Navigating Market Dynamics and Sourcing Trends in the toroidal amp Sector

What Are the Current Market Dynamics and Key Trends in the Toroidal Amplifier Sector?

The global market for toroidal amplifiers is witnessing significant growth driven by advancements in audio technology, increasing demand for high-quality sound systems, and the rise of home entertainment setups. Key trends include the integration of digital technologies into traditional analog systems, enabling enhanced audio performance and user experience. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe seek reliable audio solutions, they are increasingly gravitating toward toroidal amplifiers due to their compact design and superior sound quality.

Emerging sourcing trends highlight a shift toward customized solutions. Manufacturers are responding to the diverse needs of buyers by offering tailor-made toroidal transformers that meet specific voltage, size, and aesthetic requirements. This customization is particularly appealing in markets where space and design are paramount, such as in high-end residential and commercial audio installations. Furthermore, the growing awareness of energy efficiency is steering buyers towards toroidal amplifiers, which typically boast higher efficiency ratings (90-97%) compared to traditional laminated transformers, thus lowering operational costs in the long term.

Illustrative image related to toroidal amp

International buyers must also be aware of the increasing competition in the sector, which is resulting in price variations. Thus, strategic sourcing decisions, focusing on quality and performance, are essential for ensuring that investments yield the desired audio excellence.

How Do Sustainability and Ethical Sourcing Impact the Toroidal Amplifier Industry?

Sustainability is becoming a critical factor in the purchasing decisions of B2B buyers, particularly in regions that prioritize environmental responsibility. The production of toroidal amplifiers can have a significant environmental impact, primarily through the materials used and the manufacturing processes involved. Buyers are now encouraged to seek suppliers who adhere to sustainable practices, including the use of recycled materials and energy-efficient production methods.

The importance of ethical supply chains cannot be overstated. Buyers should look for suppliers that are transparent about their sourcing practices and demonstrate a commitment to fair labor standards. Certifications such as ISO 14001, which focuses on effective environmental management systems, and RoHS compliance, which restricts hazardous substances, can be indicative of a supplier’s dedication to sustainability. Additionally, the demand for “green” certifications is increasing, as companies strive to enhance their brand reputation and appeal to environmentally conscious consumers.

Investing in toroidal amplifiers from suppliers who prioritize sustainability not only mitigates environmental impact but also aligns with the growing global trend towards corporate social responsibility. This approach can enhance brand loyalty and open doors to new market opportunities.

Illustrative image related to toroidal amp

What Is the Evolution of the Toroidal Amplifier Sector?

The evolution of the toroidal amplifier sector can be traced back to the late 20th century when the need for efficient and compact audio solutions became apparent. Initially developed for use in high-fidelity audio systems, toroidal transformers quickly gained recognition for their superior performance, particularly in minimizing noise and distortion. As technology advanced, the design and manufacturing processes of toroidal amplifiers improved, leading to their widespread adoption in both professional and consumer audio applications.

In recent years, the integration of digital signal processing (DSP) technology has further enhanced the capabilities of toroidal amplifiers, allowing for unprecedented sound quality and flexibility. This evolution has positioned toroidal amplifiers as a staple in modern audio setups, appealing to both audiophiles and commercial enterprises alike. As the market continues to evolve, the focus on customization, sustainability, and technological integration will likely shape the future of the toroidal amplifier sector, providing exciting opportunities for international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of toroidal amp

-

How do I choose the right toroidal amplifier for my business needs?

Selecting the appropriate toroidal amplifier involves assessing the specific audio requirements of your application. Consider factors such as power output, channel configuration, and efficiency ratings. Look for amplifiers that provide low Total Harmonic Distortion (THD) and high signal-to-noise ratios to ensure audio clarity. Additionally, evaluate the physical dimensions and design to ensure compatibility with your existing setup. Engaging with suppliers for detailed specifications and possible customization options can also help in making an informed choice. -

What are the advantages of using toroidal transformers in amplifiers?

Toroidal transformers offer significant benefits over traditional laminated transformers, including higher efficiency, reduced electromagnetic interference, and lower audible noise. Their compact design allows for space-saving installations, making them ideal for various applications, from professional audio to home theater systems. Additionally, toroidal transformers produce minimal vibration, enhancing sound quality. This combination of factors makes them a preferred choice for businesses seeking reliable and high-performance audio solutions. -

What customization options are available when sourcing toroidal amplifiers?

Many manufacturers offer customization options to meet specific business needs. Customization can include variations in voltage ratings, unique connector types, and specific mounting requirements. You may also request features like enhanced shielding or tailored cabinet heights. It’s essential to communicate your precise requirements to suppliers to ensure that the final product aligns with your operational needs. Establishing a collaborative relationship with your supplier can facilitate this process. -

What is the minimum order quantity (MOQ) for toroidal amplifiers?

Minimum order quantities for toroidal amplifiers can vary significantly based on the manufacturer and the specific model requested. Typically, MOQs can range from a few units to several dozen, depending on the complexity of the product and the supplier’s production capabilities. When sourcing, inquire about MOQs upfront to ensure they align with your purchasing strategy. Some suppliers may offer flexibility on MOQs for first-time orders or long-term partnerships. -

What payment terms are common when purchasing toroidal amplifiers?

Payment terms can vary among suppliers, but common practices include upfront payments, deposits with the balance due upon delivery, or net payment terms (e.g., net 30 or net 60 days). It’s crucial to clarify these terms before finalizing any purchase to avoid misunderstandings. Additionally, consider negotiating terms that suit your cash flow needs. International buyers should also be aware of potential currency exchange rates and transaction fees. -

How can I ensure quality assurance (QA) for my toroidal amplifiers?

To guarantee quality assurance, choose suppliers who adhere to recognized industry standards and certifications, such as ISO or UL. Request documentation that verifies compliance with safety and performance regulations. Additionally, inquire about the manufacturer’s testing procedures and quality control measures. Establishing a clear understanding of the QA process can help mitigate risks associated with subpar products. -

What logistics considerations should I keep in mind when sourcing toroidal amplifiers internationally?

When sourcing internationally, consider logistics factors such as shipping costs, delivery times, and customs regulations. Research potential tariffs or import duties that may apply to your shipments. It’s advisable to work with suppliers who offer comprehensive logistics support, including freight forwarding services and tracking capabilities. Ensure that all shipping documentation is complete to facilitate smooth customs clearance upon arrival. -

What are the best practices for vetting suppliers of toroidal amplifiers?

Vetting suppliers involves evaluating their reputation, reliability, and product quality. Start by researching potential manufacturers online, checking customer reviews, and seeking references from other businesses. Request samples to assess the product quality firsthand. It can also be beneficial to visit manufacturing facilities, if possible, to gauge operational standards. Establishing clear communication and setting expectations upfront can help build a strong supplier relationship.

Top 5 Toroidal Amp Manufacturers & Suppliers List

1. Tonewinner – AD-5100PA+ 5-Channel Power Amplifier

Domain: summithifiusa.com

Registered: 2020 (5 years)

Introduction: {‘model’: ‘Tonewinner AD-5100PA+’, ‘type’: ‘5-Channel Power Amplifier’, ‘power_output’: {‘8_Ohms_one_channel’: ‘117 Watts RMS’, ‘4_Ohms_one_channel’: ‘164 Watts RMS’, ‘8_Ohms_two_channels’: ‘100 Watts RMS’, ‘4_Ohms_two_channels’: ‘121 Watts RMS’, ‘8_Ohms_all_channels’: ’71+ Watts RMS’}, ‘total_power_consumption’: {‘240V’: ‘633.6W’, ‘120V’: ‘613.2W’}, ‘frequency_response’: {‘power_bandwidth’: ’10 H…

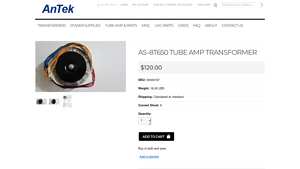

2. AnTek Products Corp – AS-8T650 Tube Amp Transformer

Domain: antekinc.com

Registered: 2004 (21 years)

Introduction: {‘name’: ‘AS-8T650 Tube Amp Transformer’, ‘RRP’: ‘$120.00’, ‘SKU’: ‘00000167’, ‘brand’: ‘AnTek Products Corp’, ‘weight’: ‘16.0lb’, ‘availability’: ‘Current Stock: 6’, ‘bulk_discounts’: {‘6-19’: ‘5% off’, ’20-49′: ‘10% off’, ’50 or above’: ‘15% off’}, ‘description’: ‘The 800VA toroidal transformers are commonly used in high-end tube audio amplifiers and RF transmitters. They feature a static shield…

3. DIY Audio – Transformer Sound Quality Debate

Domain: diyaudio.com

Registered: 1999 (26 years)

Introduction: This company, DIY Audio – Transformer Sound Quality Debate, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Audiogon – Torroid Transformers in Tube Amps

Domain: forum.audiogon.com

Registered: 1998 (27 years)

Introduction: This company, Audiogon – Torroid Transformers in Tube Amps, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Toroid – Tube Amplifier Transformers

Domain: toroid.com

Registered: 1996 (29 years)

Introduction: Product Name: Tube Amplifier Transformers

Key Features:

– Low Temperature Rise

– Excellent Voltage Regulation

– Low Mechanical Noise

– Low Profile

Specifications:

1. Power Transformer P/N 236.5072

– Power: 363 VA

– Current: 3.2 A

– Temperature Rise at Full Load: 55ºC

– Size: O.D. 5.0″, Height 2.6″

– Weight: 6.7 lbs.

2. Pre-Amp Power Transformer P/N 205.5076

– Power: 54 VA

– …

Strategic Sourcing Conclusion and Outlook for toroidal amp

In summary, the strategic sourcing of toroidal amplifiers offers numerous benefits that align with the evolving needs of international B2B buyers. The superior efficiency, compact design, and reduced noise levels of toroidal transformers make them an ideal choice for high-performance audio applications. By selecting toroidal amplifiers, companies can enhance product quality while optimizing operational costs, particularly in markets such as Africa, South America, the Middle East, and Europe, where competitive pricing and performance are crucial.

As we look to the future, the demand for custom solutions tailored to specific audio applications is likely to grow. B2B buyers should prioritize suppliers that offer both standard and bespoke toroidal transformers, ensuring compliance with industry standards and regulations. This strategic approach not only fosters innovation but also ensures that businesses remain competitive in a rapidly changing market landscape.

For international buyers, now is the time to engage with reputable manufacturers and explore the vast potential of toroidal amplifiers. By investing in high-quality audio solutions, you can elevate your offerings and meet the diverse needs of your clientele. Embrace this opportunity to enhance your product portfolio and drive your business forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.