Top 8 Water Jet Machine Parts Suppliers (And How to Choose)

Introduction: Navigating the Global Market for water jet machine parts

Navigating the intricate landscape of sourcing water jet machine parts can be daunting for international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. The challenge lies not only in identifying high-quality components but also in ensuring compatibility, performance, and cost-effectiveness. This comprehensive guide is designed to demystify the process, offering insights into various types of water jet machine parts, their applications across industries, and strategies for effective supplier vetting.

From high-pressure pumps to cutting heads and replacement parts, understanding the nuances of each component is crucial for optimizing operational efficiency and maximizing profitability. This guide will delve into critical considerations such as cost analysis, supplier reliability, and the importance of selecting parts that meet or exceed OEM standards. By providing actionable insights and a structured approach to purchasing decisions, this resource empowers B2B buyers to navigate the global market with confidence.

Whether you are based in Saudi Arabia, Vietnam, or any other emerging market, equipping your water jet systems with the right parts can significantly enhance your production capabilities and competitive edge. With the right knowledge at your fingertips, you can make informed choices that drive your business forward in an increasingly competitive landscape.

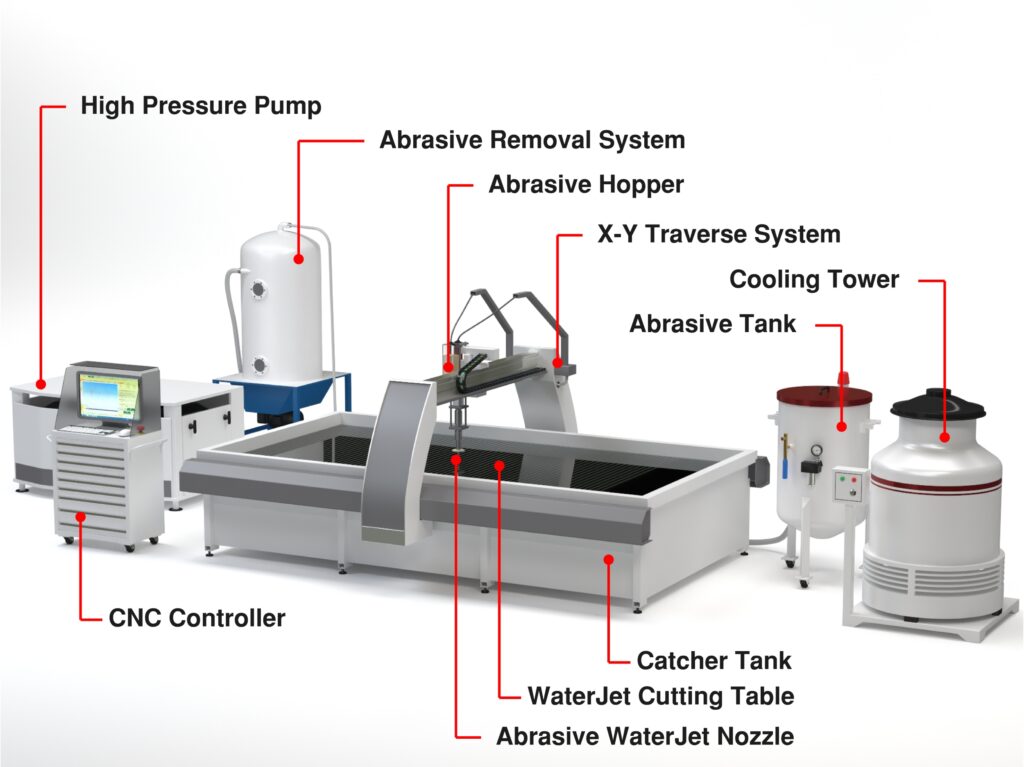

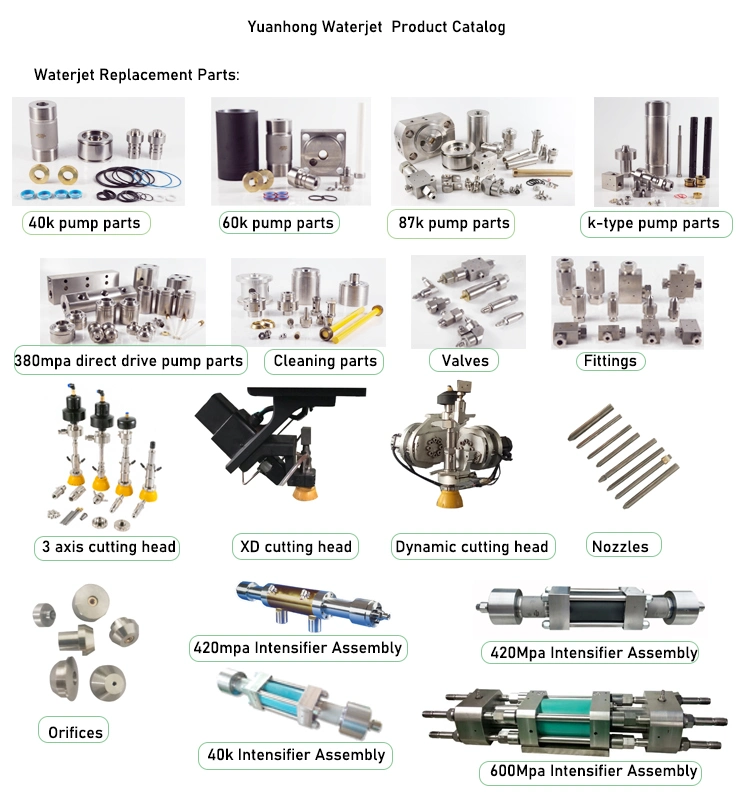

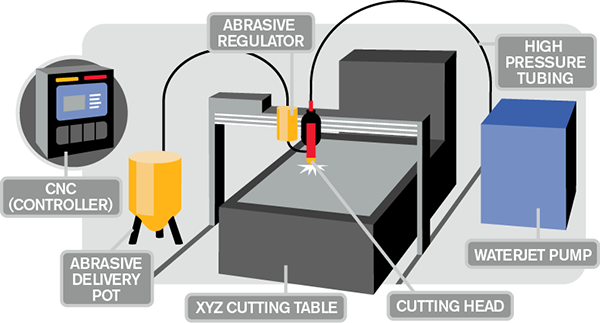

Understanding water jet machine parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Waterjet Pumps | High-pressure capabilities (up to 94,000 psi), customizable designs | Metal fabrication, aerospace, stone cutting | Pros: Enhanced performance, longevity. Cons: Higher upfront costs. |

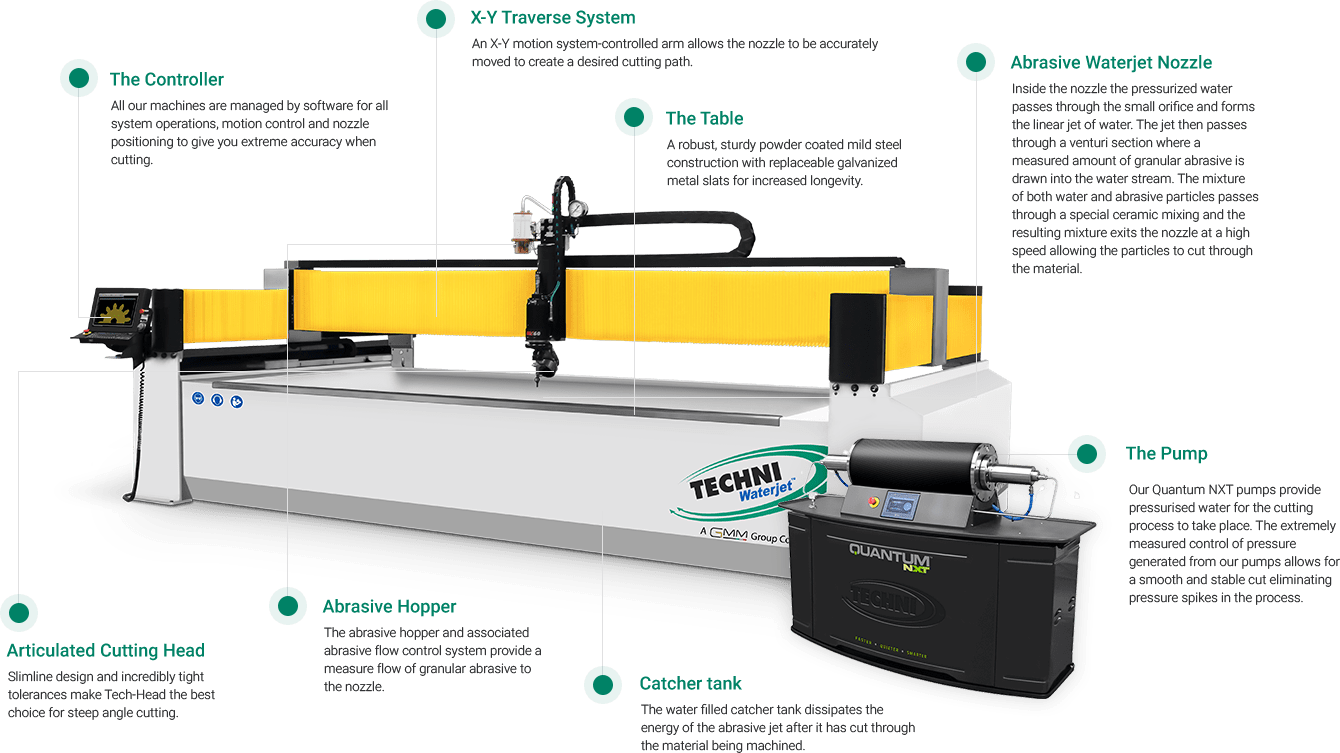

| Cutting Heads | Advanced nozzle designs, integrated mixing chambers, precision cutting | Automotive, manufacturing, art installations | Pros: Superior cutting accuracy, adaptability. Cons: Requires expertise for optimal setup. |

| Abrasive Hoppers | Varying capacities, compatibility with multiple systems | General manufacturing, construction | Pros: Efficient material handling, customizable sizes. Cons: Maintenance can be complex. |

| High-Pressure Fittings | Durable materials, resistance to extreme conditions | All waterjet applications | Pros: Reliability, reduced risk of leaks. Cons: Can be costly if frequently replaced. |

| Replacement Parts | OEM and aftermarket options, extensive compatibility | Maintenance and repair of existing systems | Pros: Cost-effective solutions, wide availability. Cons: Quality can vary among manufacturers. |

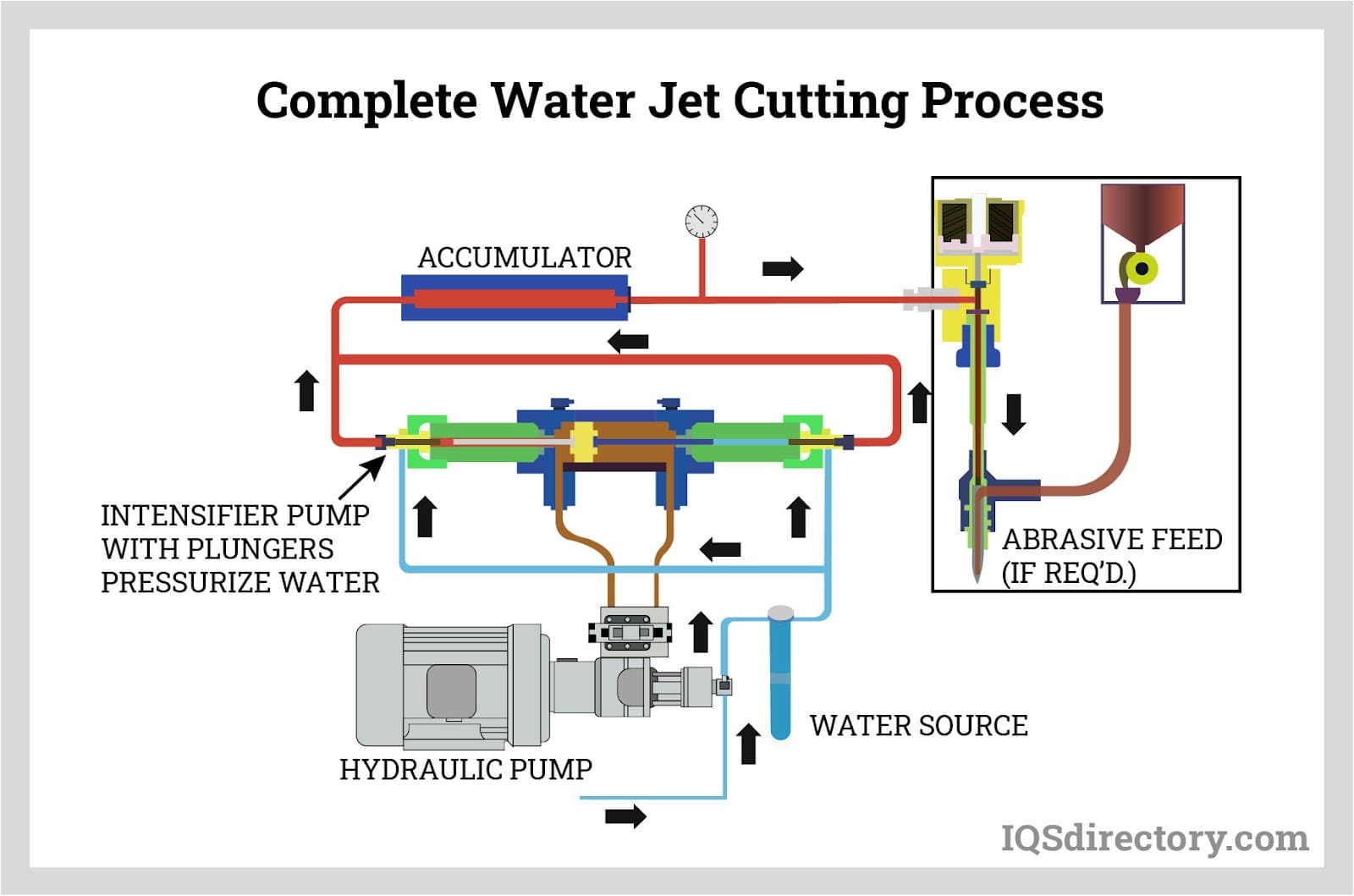

What Are the Key Characteristics of Waterjet Pumps?

Waterjet pumps are vital components that generate the high pressures necessary for effective waterjet cutting. With capabilities reaching up to 94,000 psi, these pumps are engineered for both standard and customized applications. B2B buyers should consider their specific operational requirements, as the right pump can significantly enhance productivity and efficiency. Additionally, while the initial investment may be higher, the longevity and performance of these pumps often justify the cost.

How Do Cutting Heads Impact Waterjet Performance?

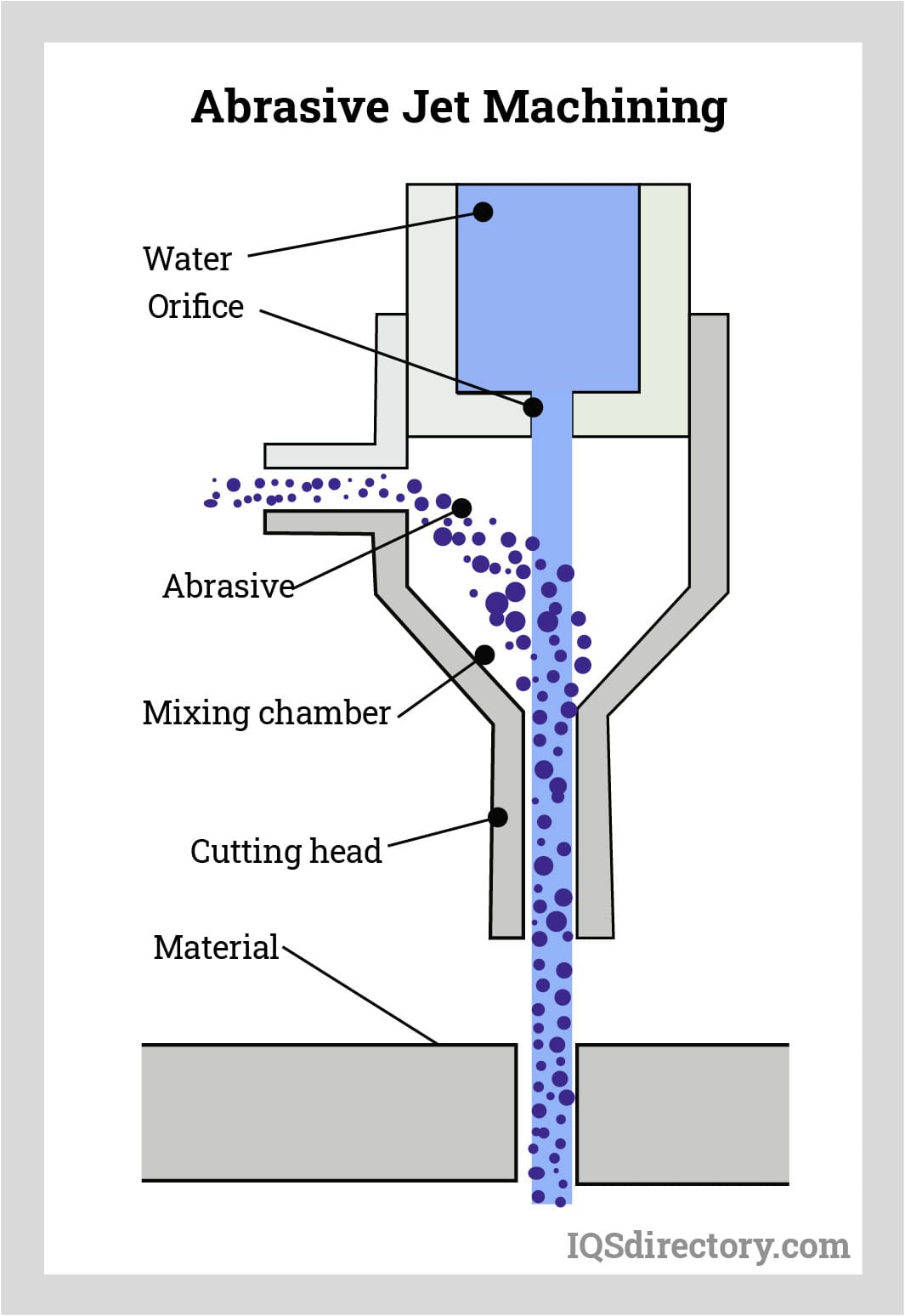

Cutting heads are designed to control the water flow and abrasive material mixture, impacting the precision and quality of the cut. Advanced designs, such as integrated mixing chambers, allow for better performance across various materials. B2B buyers should assess their cutting needs and consider heads that offer adaptability for different applications. While the benefits include improved accuracy and versatility, buyers should be aware that setup may require specialized knowledge.

What Role Do Abrasive Hoppers Play in Waterjet Systems?

Abrasive hoppers are essential for storing and delivering abrasive materials used in the cutting process. They come in various capacities and are compatible with multiple waterjet systems. B2B buyers should evaluate the size and efficiency of hoppers to ensure they meet production demands. Although they improve material handling, maintenance can be complex, necessitating careful consideration during the purchasing process.

Why Are High-Pressure Fittings Crucial for Waterjet Operations?

High-pressure fittings connect various components of the waterjet system, ensuring a secure and leak-proof operation. Made from durable materials, these fittings are designed to withstand extreme conditions. B2B buyers should prioritize quality when selecting fittings, as reliability is crucial to minimize operational downtime. However, the cost of high-quality fittings can be significant, particularly if replacements are frequent.

How Do Replacement Parts Affect Waterjet Machine Longevity?

Replacement parts, including both OEM and aftermarket options, are critical for maintaining waterjet systems. They allow for the repair and upkeep of existing machines, ensuring consistent performance. B2B buyers should consider the compatibility and quality of replacement parts, as they can vary significantly among manufacturers. While they offer cost-effective solutions, the potential for variability in quality means thorough research is essential before purchasing.

Key Industrial Applications of water jet machine parts

| Industry/Sector | Specific Application of water jet machine parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision cutting of composite materials | Enhanced accuracy and reduced waste | Ensure parts meet aerospace standards and certifications. |

| Automotive | Manufacturing of intricate components and prototypes | Faster prototyping and reduced production time | Look for high-performance nozzles and pumps for efficiency. |

| Metal Fabrication | Cutting and shaping of various metals | Versatile applications and high-quality finishes | Source durable, wear-resistant parts for longevity. |

| Construction | Demolition and surface preparation | Minimizes dust and debris, enhancing safety | Consider local suppliers for quick access to parts. |

| Stone and Tile Cutting | Cutting natural stones and tiles | High precision and minimal waste | Assess compatibility with existing waterjet systems. |

How Are Water Jet Machine Parts Used in Aerospace Applications?

In the aerospace industry, water jet machine parts are essential for precision cutting of composite materials used in aircraft manufacturing. These parts enable operators to achieve intricate designs with minimal waste, ensuring that the materials are utilized effectively. International buyers should prioritize sourcing parts that comply with strict aerospace standards and certifications, as reliability and performance are paramount in this sector.

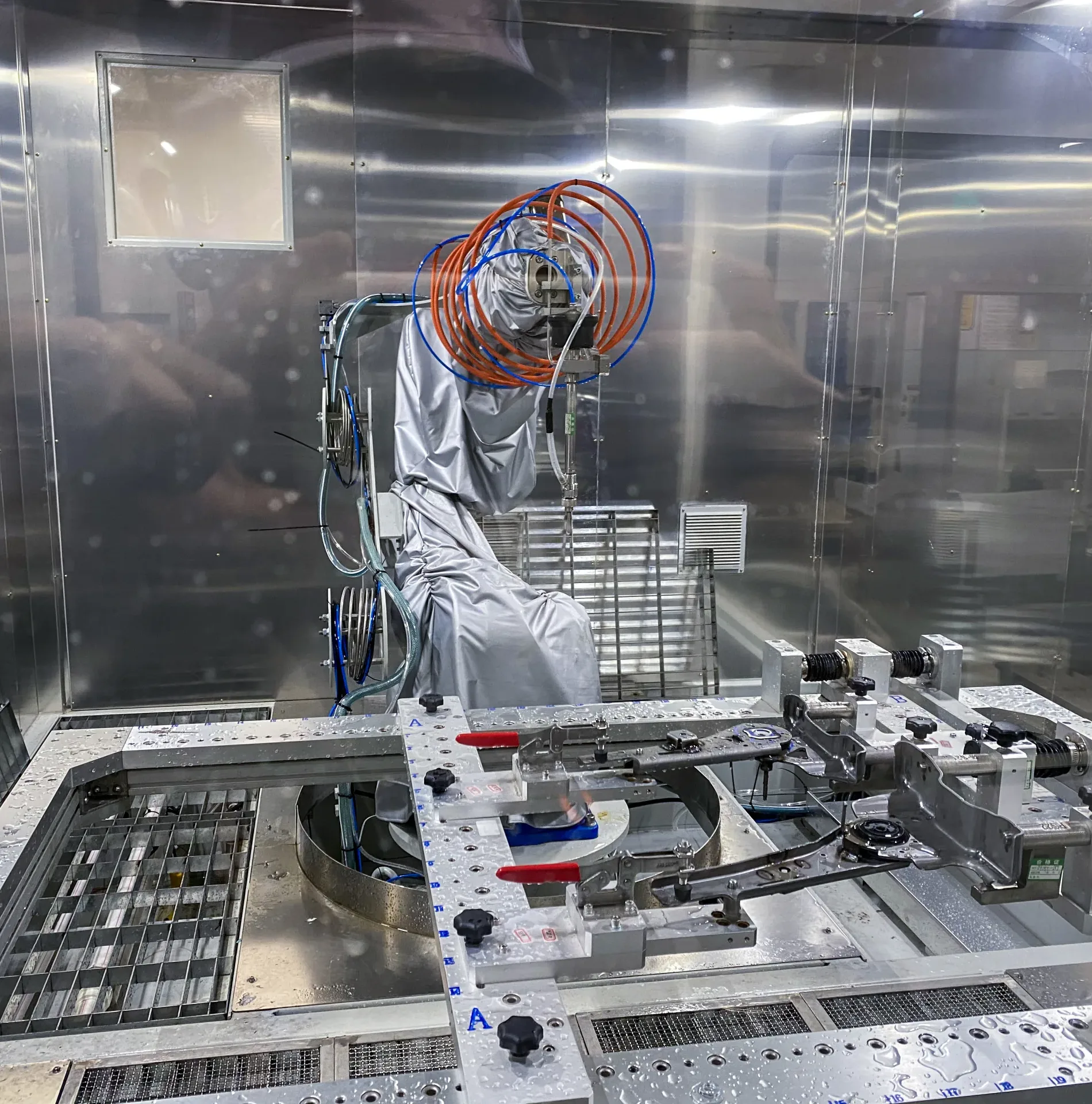

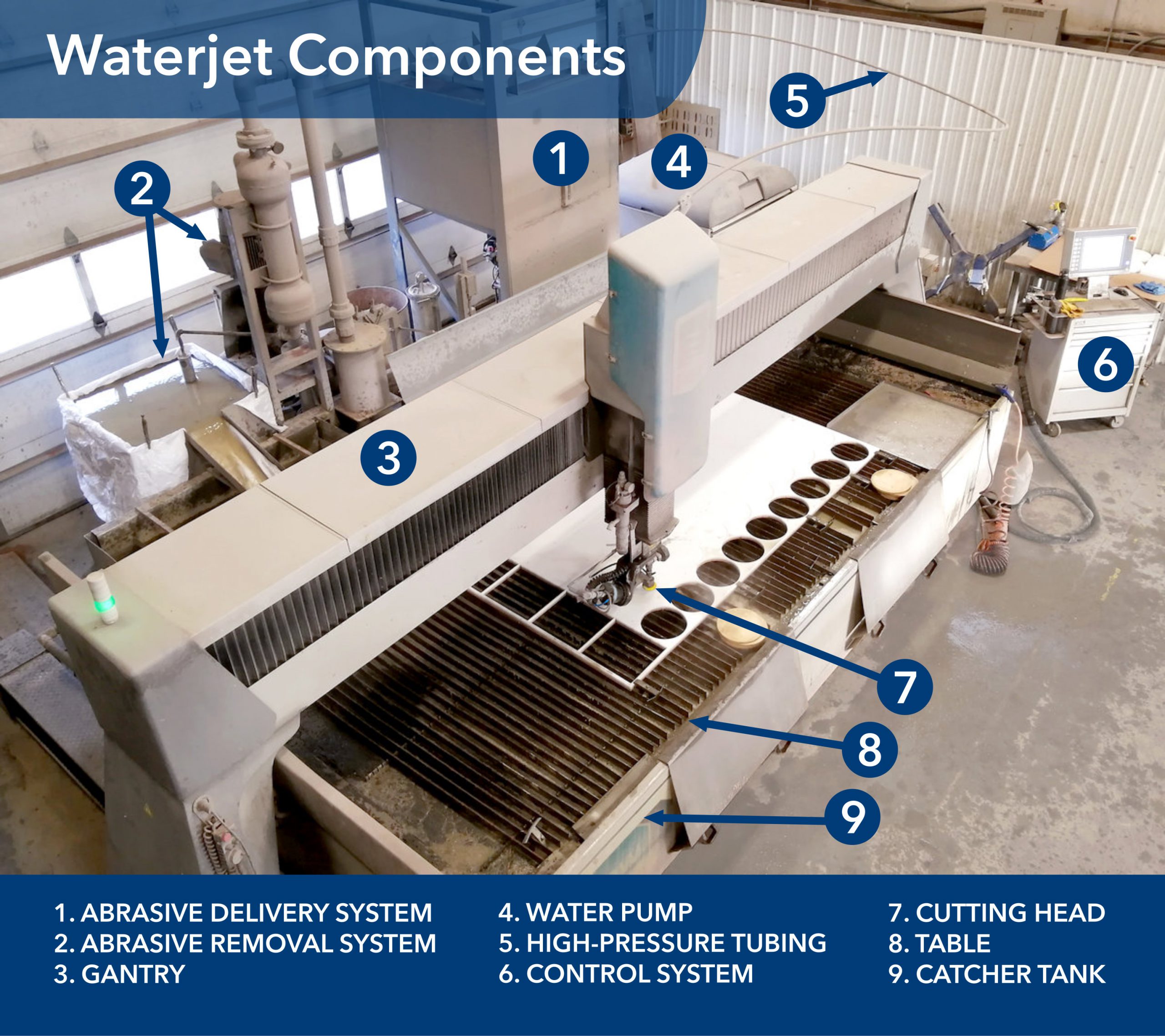

Illustrative image related to water jet machine parts

What Role Do Water Jet Parts Play in Automotive Manufacturing?

Water jet machine parts are widely used in the automotive sector for manufacturing intricate components and prototypes. The ability to cut complex shapes quickly and accurately allows manufacturers to streamline their production processes and reduce lead times. B2B buyers in this industry should focus on acquiring high-performance nozzles and pumps that enhance cutting efficiency and ensure consistent results across various materials.

Why Are Water Jet Parts Important for Metal Fabrication?

In metal fabrication, water jet machine parts facilitate cutting and shaping operations across a range of metals. The versatility of water jet technology allows for high-quality finishes and the ability to work with different thicknesses and types of metal. Buyers should look for durable, wear-resistant components to ensure longevity and minimize downtime, especially in high-demand environments.

How Do Water Jet Parts Enhance Construction Projects?

Water jet machine parts are increasingly utilized in construction for demolition and surface preparation tasks. The use of water jets minimizes dust and debris, creating a safer work environment. For international buyers, sourcing from local suppliers can significantly reduce lead times and shipping costs, ensuring that projects remain on schedule without compromising on quality.

Illustrative image related to water jet machine parts

What Benefits Do Water Jet Parts Offer in Stone and Tile Cutting?

In the stone and tile cutting industry, water jet machine parts provide the precision needed for cutting natural stones and tiles with minimal waste. This capability not only enhances the aesthetic quality of the finished product but also reduces material costs. Buyers should assess the compatibility of parts with their existing waterjet systems to maximize operational efficiency and ensure seamless integration.

3 Common User Pain Points for ‘water jet machine parts’ & Their Solutions

Scenario 1: Inconsistent Cutting Quality Leading to Production Delays

The Problem: Many B2B buyers encounter issues with inconsistent cutting quality when using water jet machines. This can stem from worn-out or substandard parts such as nozzles and mixing tubes. Operators may notice uneven cuts, excessive tapering, or a significant drop in precision, which can lead to rework and production delays. In industries where precision is critical, such as aerospace or automotive, these inconsistencies can severely impact deadlines and customer satisfaction.

The Solution: To mitigate this problem, buyers should prioritize sourcing high-quality, OEM-compatible parts. Regularly replacing worn components like nozzles and mixing tubes with parts that meet or exceed OEM specifications can significantly enhance cutting performance. Buyers can benefit from establishing a relationship with trusted suppliers who offer performance-tested parts. It’s also advisable to implement a preventive maintenance schedule that includes routine checks on critical components to ensure they are functioning optimally, thus reducing downtime and improving overall efficiency.

Scenario 2: Extended Lead Times for Replacement Parts Affecting Operations

The Problem: B2B buyers often face lengthy lead times for replacement parts, which can halt production and lead to financial losses. This issue is exacerbated when parts are sourced from overseas suppliers, resulting in delays due to customs, shipping, or stock availability. In regions with less established logistics, such as parts of Africa and South America, this can be particularly problematic, as even minor delays can cascade into significant operational setbacks.

The Solution: To combat extended lead times, buyers should explore local distributors or regional suppliers who can provide parts more quickly. Building a network of multiple suppliers can also help mitigate risk and ensure a steady flow of parts. Moreover, maintaining an inventory of critical spare parts can act as a buffer against unexpected breakdowns. Engaging in proactive communication with suppliers about lead times and stock levels can further help in planning maintenance schedules effectively, thereby minimizing disruptions.

Illustrative image related to water jet machine parts

Scenario 3: Difficulty in Identifying Compatible Parts for Diverse Water Jet Systems

The Problem: Many buyers struggle with identifying the right parts compatible with various water jet systems, especially when dealing with multiple brands or older machinery. This confusion can lead to incorrect orders, wasted resources, and potential damage to equipment. In industries with tight production timelines, such errors can be particularly costly.

The Solution: To overcome compatibility issues, buyers should invest time in understanding their water jet systems and maintain a detailed parts inventory that includes part numbers and specifications. Utilizing online catalogs from reputable suppliers that offer search functionalities based on machine models can streamline the ordering process. Buyers can also benefit from training sessions or consultation services provided by suppliers to ensure their teams are knowledgeable about part specifications and compatibility. Engaging directly with manufacturers for technical support can also clarify doubts regarding part selection and compatibility, reducing the risk of purchasing errors.

Strategic Material Selection Guide for water jet machine parts

What Are the Key Materials Used in Water Jet Machine Parts?

When selecting materials for water jet machine parts, it is crucial to consider their properties, advantages, and limitations. The right choice can significantly impact the performance, durability, and cost-effectiveness of the water jet cutting system. Below are analyses of four common materials used in water jet machine parts, focusing on their properties, pros and cons, application impacts, and considerations for international B2B buyers.

How Does Stainless Steel Perform in Water Jet Applications?

Key Properties: Stainless steel is known for its excellent corrosion resistance and high strength, making it suitable for high-pressure applications. It can withstand temperatures up to 800°C and pressures exceeding 40,000 psi, depending on the grade.

Pros & Cons: The durability of stainless steel is a significant advantage, as it resists wear and tear, leading to a longer lifespan for parts. However, it is relatively more expensive than carbon steel and can be challenging to machine due to its toughness.

Impact on Application: Stainless steel is compatible with a variety of cutting media, including water and garnet, making it versatile for different applications. Its resistance to corrosion is particularly beneficial in environments with high humidity or exposure to chemicals.

Considerations for International Buyers: Buyers from regions like the Middle East and Africa should ensure compliance with international standards such as ASTM A240 for stainless steel. Additionally, sourcing from local suppliers can reduce shipping costs and lead times.

What Advantages Does Carbide Offer for Water Jet Parts?

Key Properties: Carbide, particularly tungsten carbide, is known for its exceptional hardness and wear resistance. It can handle extreme pressures and temperatures, making it ideal for cutting nozzles and other high-wear components.

Pros & Cons: The primary advantage of carbide is its longevity; parts made from carbide can last significantly longer than those made from softer materials. However, carbide is brittle and can fracture under impact, and its manufacturing process can be complex and costly.

Impact on Application: Carbide is particularly effective in abrasive water jet applications, where it maintains precision and performance over extended use. Its compatibility with various abrasives enhances cutting efficiency.

Considerations for International Buyers: Buyers should consider the availability of carbide parts in their region, as well as compliance with standards like DIN 50119 for hardness. Local suppliers may offer better support for maintenance and replacement.

Why Is Aluminum a Popular Choice for Water Jet Machine Parts?

Key Properties: Aluminum is lightweight and has good corrosion resistance, with a melting point around 660°C. It is often used in parts that require lower pressure ratings, typically under 30,000 psi.

Pros & Cons: The lightweight nature of aluminum makes it easier to handle and install, which can reduce labor costs. However, it is less durable than steel or carbide, making it unsuitable for high-wear applications.

Impact on Application: Aluminum is ideal for components that do not experience extreme wear or pressure, such as machine frames and covers. Its corrosion resistance is beneficial in humid environments.

Illustrative image related to water jet machine parts

Considerations for International Buyers: Compliance with standards such as ASTM B221 for aluminum extrusions is essential. Buyers should also consider local market preferences for aluminum grades, as some regions may favor specific alloys.

How Does Plastic Fit into the Water Jet Parts Landscape?

Key Properties: Engineering plastics, such as polycarbonate and nylon, offer good chemical resistance and can withstand moderate temperatures and pressures.

Pros & Cons: The main advantage of plastic is its low cost and ease of manufacturing, allowing for quick prototyping and production. However, plastics generally have lower strength and wear resistance compared to metals, limiting their use in high-pressure applications.

Illustrative image related to water jet machine parts

Impact on Application: Plastic parts can be used in non-structural applications, such as protective covers and seals. Their chemical resistance makes them suitable for applications involving corrosive materials.

Considerations for International Buyers: Buyers should ensure that the selected plastics comply with international standards like ISO 9001 for quality management. Additionally, sourcing from local manufacturers can enhance supply chain efficiency.

Summary Table of Material Selection for Water Jet Machine Parts

| Material | Typical Use Case for water jet machine parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | High-pressure pump components | Excellent corrosion resistance | Higher cost and machining difficulty | High |

| Carbide | Cutting nozzles and wear parts | Exceptional hardness and longevity | Brittle and complex to manufacture | High |

| Aluminum | Machine frames and non-wear components | Lightweight and easy to handle | Less durable than metals | Medium |

| Plastic | Protective covers and seals | Low cost and easy to manufacture | Lower strength and wear resistance | Low |

This strategic material selection guide serves as a valuable resource for B2B buyers looking to optimize their water jet machine parts, ensuring they make informed decisions that align with their operational needs and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for water jet machine parts

What Are the Key Stages in the Manufacturing Process of Water Jet Machine Parts?

The manufacturing process for water jet machine parts involves several crucial stages that ensure the production of high-quality components capable of withstanding extreme operational conditions. Understanding these stages can help B2B buyers assess the reliability and performance of the parts they purchase.

Material Preparation: What Are the Best Practices?

Material preparation is the first step in manufacturing water jet parts. It begins with selecting high-grade raw materials, such as stainless steel, carbide, or specialized alloys, known for their strength and resistance to wear. The materials are then subjected to rigorous quality checks to ensure they meet specifications. Techniques such as metallurgical analysis and hardness testing are often employed to verify material integrity.

Illustrative image related to water jet machine parts

Once the materials are approved, they are cut into manageable sizes using precision cutting techniques like laser cutting or water jet cutting itself. This step is critical to minimize waste and ensure that the parts can be formed accurately in subsequent processes.

How Are Water Jet Parts Formed?

The forming stage involves shaping the prepared materials into specific part geometries. This can include processes like machining, which may utilize CNC (Computer Numerical Control) technology for precision. CNC machining allows for tight tolerances, essential for parts like cutting heads and nozzles that must maintain exact specifications to function effectively.

Another technique used is forging, particularly for high-stress components. Forging aligns the material’s grain structure, enhancing strength and durability. After forming, parts may undergo heat treatment processes to further improve their mechanical properties.

What Does the Assembly Process Entail?

After individual components are formed, they are assembled into final products. This stage may involve multiple parts coming together, such as pumps and cutting heads. Assembly requires precision to ensure that all components fit together seamlessly, which is vital for operational efficiency.

During assembly, manufacturers often employ jigs and fixtures to maintain alignment and accuracy. Additionally, automated assembly lines can enhance efficiency while minimizing human error. This stage may also include applying lubricants and other protective coatings to prevent wear during operation.

How Is Finishing Done for Optimal Performance?

The finishing stage enhances the aesthetic appeal and functional performance of water jet parts. Techniques such as polishing, anodizing, or coating are commonly used to improve surface properties. For instance, anodizing can increase corrosion resistance, while polishing can reduce friction and enhance the performance of moving parts.

Quality checks during this stage often include visual inspections and surface roughness measurements to ensure that the parts meet the required specifications.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance is paramount in manufacturing water jet machine parts, particularly for international B2B buyers. Compliance with recognized international standards like ISO 9001 ensures that manufacturers maintain a robust quality management system (QMS). This certification indicates that the manufacturer adheres to strict quality control processes throughout the production lifecycle.

Which Industry-Specific Certifications Are Relevant?

In addition to ISO standards, industry-specific certifications such as CE marking (indicating compliance with EU safety, health, and environmental protection standards) and API (American Petroleum Institute) certification for parts used in oil and gas applications are essential. These certifications provide additional assurance of the quality and safety of the products.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to ensure that all parts meet rigorous standards. These checkpoints typically include:

-

Incoming Quality Control (IQC): This initial checkpoint verifies the quality of raw materials before production begins. Tests may include material composition analysis and dimensional checks.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are performed to identify defects early. This may involve monitoring machining tolerances and checking for material consistency.

-

Final Quality Control (FQC): Once the parts are assembled and finished, a comprehensive evaluation is conducted. This may involve performance testing, dimensional inspections, and functional assessments to ensure that the finished products meet all required specifications.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers should actively verify the quality control processes of their suppliers to ensure reliability. Here are some effective methods:

-

Supplier Audits: Conducting on-site audits can provide insight into the supplier’s manufacturing processes and QC practices. This allows buyers to assess the capabilities and compliance of potential suppliers firsthand.

-

Requesting Quality Reports: Suppliers should be able to provide documentation of their QC processes, including inspection reports and certifications. This transparency can help buyers gauge the reliability of the parts they are purchasing.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality management practices. This can be particularly valuable for buyers in regions where local verification may be challenging.

What Are the QC and Certification Nuances for International B2B Buyers?

International buyers, especially those from regions like Africa, South America, the Middle East, and Europe, must be aware of specific nuances in QC and certification. Understanding local regulations and compliance requirements is crucial, as these can vary significantly by region.

For instance, while CE marking is essential for parts sold in Europe, buyers in the Middle East may need to consider local certification bodies. Additionally, language barriers and differing quality expectations may complicate negotiations. Buyers should prioritize suppliers who demonstrate familiarity with international standards and can provide documentation in the required languages.

Illustrative image related to water jet machine parts

Conclusion: How Can Buyers Ensure They Source the Best Water Jet Machine Parts?

In conclusion, understanding the manufacturing processes and quality assurance standards for water jet machine parts is critical for B2B buyers. By being informed about the various stages of production, the importance of certifications, and effective QC practices, buyers can make educated decisions that enhance operational efficiency and product reliability. Engaging with reputable suppliers who prioritize quality can lead to long-term partnerships and improved performance in water jet cutting applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘water jet machine parts’

The following guide provides a structured approach for B2B buyers to effectively source water jet machine parts. This checklist is designed to ensure that your procurement process is efficient, reliable, and tailored to your specific operational needs.

Step 1: Define Your Technical Specifications

Understanding the specific requirements of your water jet machine is crucial. This includes the type of materials you will be cutting, the required pressure levels, and the machine’s compatibility with various parts. Clearly defined specifications help streamline the sourcing process and ensure that you receive parts that will function optimally within your system.

- Identify Material Types: Determine the materials you will be cutting (e.g., metal, glass, stone) as this affects the choice of cutting heads and nozzles.

- Pressure Requirements: Specify the pressure range your machine operates within to ensure compatibility with pumps and fittings.

Step 2: Research Reputable Suppliers

Not all suppliers are created equal. Conduct thorough research to identify reputable suppliers known for quality and reliability. Look for suppliers that specialize in water jet parts and have a proven track record in the industry.

- Check Online Reviews: Utilize platforms like industry forums and review sites to gauge customer satisfaction.

- Evaluate Supplier Experience: Prioritize suppliers with extensive experience and a robust catalog of parts compatible with your machine brand.

Step 3: Verify Supplier Certifications

Before making any commitments, it’s essential to verify the certifications and quality standards of potential suppliers. This step ensures that the parts you procure meet necessary industry standards and regulations.

- Look for ISO Certifications: ISO 9001 certification indicates a commitment to quality management practices.

- Check for OEM Standards: Ensure that the parts are manufactured according to Original Equipment Manufacturer (OEM) specifications for optimal performance.

Step 4: Request Samples and Technical Data

Before placing a bulk order, request samples of critical parts to evaluate quality. Additionally, ask for technical data sheets that provide detailed information about the parts’ specifications and performance metrics.

- Assess Quality through Samples: Evaluate the durability and compatibility of the sample parts with your existing machinery.

- Understand Performance Metrics: Technical data sheets can reveal essential information regarding wear resistance and expected lifespan, helping you make informed decisions.

Step 5: Compare Pricing and Terms

Once you’ve narrowed down your list of suppliers, compare pricing and payment terms. Ensure you understand what is included in the price, such as shipping costs and warranties.

- Evaluate Total Cost of Ownership: Consider not just the initial purchase price but also long-term costs, including maintenance and replacement.

- Negotiate Terms: Don’t hesitate to negotiate pricing or inquire about bulk purchase discounts to maximize your budget.

Step 6: Assess Customer Support and After-Sales Service

Reliable customer support and after-sales service can significantly impact your operations. Ensure that the supplier offers comprehensive support to assist with installation, maintenance, and troubleshooting.

- Inquire about Support Availability: Check if the supplier provides dedicated support channels, such as phone or chat support.

- Evaluate Warranty Options: A solid warranty can protect your investment and provide peace of mind regarding the longevity of the parts.

Step 7: Finalize Your Purchase and Monitor Performance

After selecting a supplier and finalizing your order, monitor the performance of the parts once they are installed. Keep track of any issues that arise and communicate with the supplier for support.

- Document Performance Metrics: Regularly assess the performance of the parts against your initial specifications to ensure they meet your operational needs.

- Provide Feedback: Share your experiences with the supplier to help them improve their products and services, which can be beneficial for future purchases.

By following this checklist, B2B buyers can streamline their sourcing process for water jet machine parts, ensuring they select the right components to enhance operational efficiency and productivity.

Comprehensive Cost and Pricing Analysis for water jet machine parts Sourcing

What Are the Key Cost Components in Water Jet Machine Parts Sourcing?

When sourcing water jet machine parts, understanding the cost structure is crucial for effective budgeting and negotiation. The primary cost components include:

-

Materials: The choice of materials significantly influences the cost. High-performance parts typically require advanced materials such as high-grade tungsten carbide or specially treated alloys, which can increase the price but enhance durability and efficiency.

-

Labor: Labor costs vary depending on the region and the complexity of the manufacturing process. Skilled labor, particularly in advanced machining and assembly, can command higher wages, impacting overall costs.

-

Manufacturing Overhead: This includes costs associated with facility maintenance, utilities, and equipment depreciation. Companies that invest in modern, efficient manufacturing technologies may have lower overhead in the long run, enabling competitive pricing.

-

Tooling: The investment in specialized tools and molds for producing specific parts is a critical cost factor. Custom tooling can lead to higher initial costs but may result in lower per-unit costs for larger production runs.

-

Quality Control (QC): Ensuring that parts meet stringent quality standards incurs additional costs. However, robust QC processes can reduce returns and rework, ultimately contributing to better customer satisfaction and lower total costs.

-

Logistics: Shipping and handling costs can vary widely based on distance, shipping methods, and packaging requirements. For international buyers, understanding Incoterms is vital to determine who bears these costs.

-

Margin: Suppliers will add a margin to cover their costs and ensure profitability. This margin can vary significantly based on the supplier’s market position and the competitiveness of the industry.

How Do Price Influencers Affect Water Jet Machine Parts Costs?

Several factors can influence pricing when sourcing water jet machine parts:

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically result in lower per-unit costs due to economies of scale. Negotiating for higher volumes can lead to substantial savings.

-

Specifications and Customization: Custom parts designed to specific requirements may incur higher costs due to increased complexity in manufacturing. Buyers should weigh the benefits of customization against potential cost increases.

-

Materials and Quality Certifications: The choice of materials and certifications (such as ISO standards) can affect prices. Parts that meet higher quality standards often come at a premium but can offer better performance and longevity.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers with a track record of quality may charge more, but their reliability can reduce risks associated with sourcing.

-

Incoterms: Understanding the terms of delivery can impact total costs. For example, FOB (Free on Board) means the buyer assumes responsibility once the goods are on board the vessel, which can influence logistics costs and responsibilities.

What Are Effective Buyer Tips for Negotiating Water Jet Machine Parts Pricing?

-

Leverage Volume Discounts: Always consider negotiating for volume discounts. If your business anticipates regular orders, committing to larger quantities can yield better pricing.

-

Evaluate Total Cost of Ownership (TCO): Look beyond initial purchase prices. Assess the TCO, including maintenance, operational efficiency, and longevity of the parts, to make informed decisions.

-

Research Supplier Backgrounds: Investigate potential suppliers’ histories and customer reviews. Reliable suppliers may justify higher prices through better quality and service.

-

Be Aware of Pricing Nuances for International Sourcing: International buyers, particularly from regions like Africa and South America, should account for potential tariffs, import duties, and currency fluctuations that can affect pricing.

-

Negotiate Terms and Conditions: Don’t hesitate to discuss payment terms, warranties, and return policies. Favorable terms can enhance value and reduce risks associated with sourcing.

Disclaimer on Indicative Prices

Prices for water jet machine parts can fluctuate based on various factors, including market conditions, material availability, and specific supplier pricing strategies. It is advisable to obtain quotes from multiple suppliers to ensure competitive pricing and to account for any additional costs associated with international transactions.

Alternatives Analysis: Comparing water jet machine parts With Other Solutions

Understanding Alternatives in Waterjet Technology

When considering solutions for cutting and material processing, waterjet machine parts stand out due to their precision and versatility. However, various alternative technologies may also fulfill similar functions, often presenting unique advantages or challenges. This section evaluates waterjet machine parts against other cutting solutions, such as laser cutting and plasma cutting technologies, to help B2B buyers make informed decisions tailored to their operational needs.

Illustrative image related to water jet machine parts

| Comparison Aspect | Water Jet Machine Parts | Laser Cutting | Plasma Cutting |

|---|---|---|---|

| Performance | High precision; ideal for hard materials | Excellent for thin metals; high speed | Good for thick materials; faster than waterjet |

| Cost | Moderate to high initial investment; lower operating costs | Lower initial cost; high energy consumption | Generally lower cost; consumable parts can add up |

| Ease of Implementation | Requires specialized setup and training | Easier setup with widespread availability | Relatively simple setup; training needed |

| Maintenance | Regular maintenance needed; parts are durable | Low maintenance; laser optics need periodic cleaning | Frequent maintenance; consumable tips must be replaced |

| Best Use Case | Cutting hard materials (stone, glass, metals) | Thin metals and complex shapes | Thick metals and fast production runs |

What Are the Pros and Cons of Laser Cutting?

Laser cutting technology uses focused light to melt or vaporize materials. Its primary advantage lies in speed and precision, making it particularly effective for thin metals and intricate designs. However, it may struggle with thicker materials and can be limited by the types of materials it can effectively cut. Additionally, while the initial investment may be lower than that of waterjet systems, the energy consumption can lead to higher operational costs over time.

How Does Plasma Cutting Compare?

Plasma cutting employs a high-velocity jet of ionized gas to cut through electrically conductive materials. This method is favored for its speed, especially when dealing with thicker metals. The advantages of plasma cutting include lower equipment costs and a quicker setup process. However, it can produce rougher edges and may require additional finishing work. Moreover, the consumables, such as tips and electrodes, can lead to ongoing expenses that might offset initial savings.

Conclusion: How Should B2B Buyers Choose the Right Solution?

Selecting the right cutting technology requires a thorough assessment of specific operational needs, material types, and budget constraints. Waterjet machine parts excel in precision and versatility, particularly for hard materials, while laser and plasma cutting offer their unique advantages in speed and cost. By evaluating the performance, cost implications, ease of implementation, and maintenance requirements of each solution, B2B buyers can make informed choices that align with their production goals and enhance overall efficiency. The right technology not only improves cutting capabilities but can also significantly impact profitability in competitive markets across Africa, South America, the Middle East, and Europe.

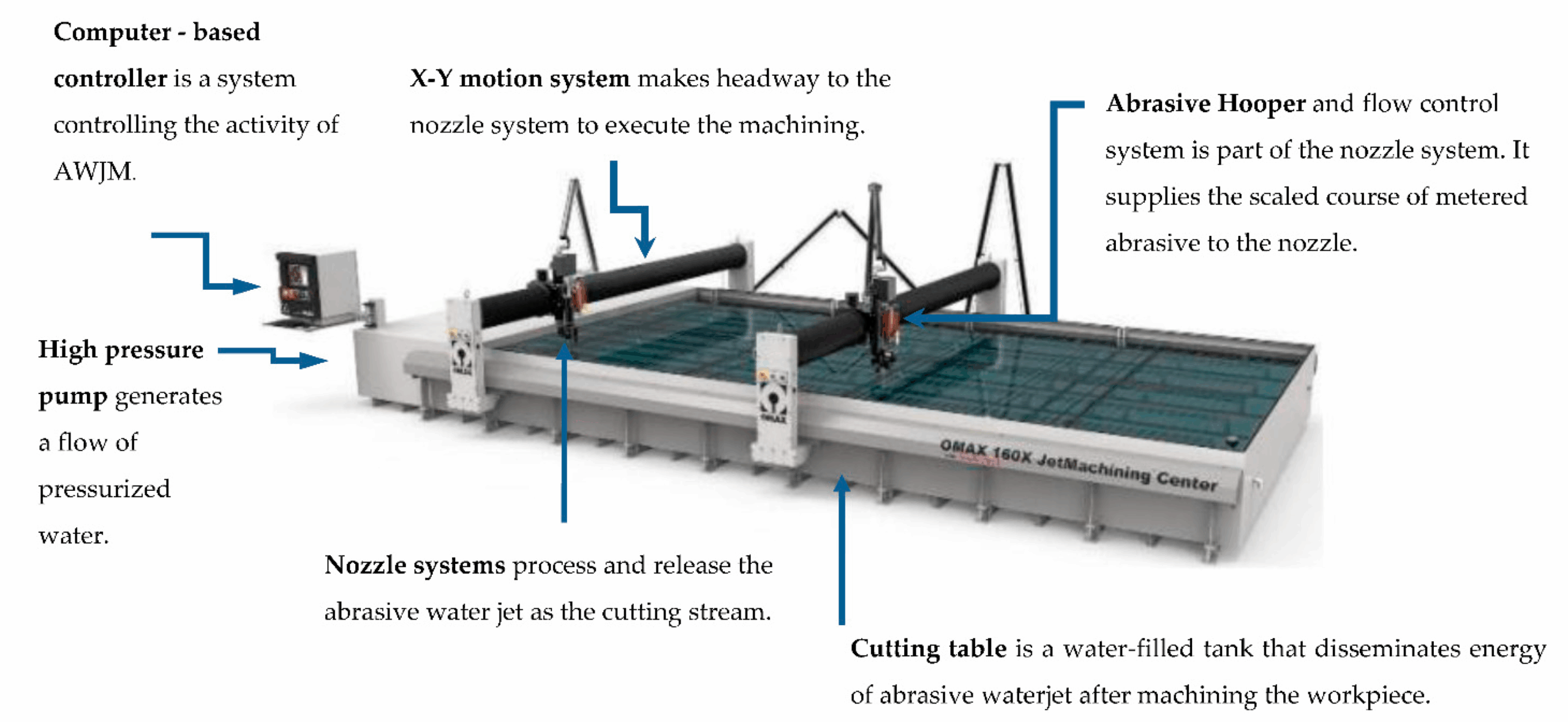

Essential Technical Properties and Trade Terminology for water jet machine parts

What Are the Essential Technical Properties of Water Jet Machine Parts?

Understanding the technical specifications of water jet machine parts is crucial for B2B buyers to ensure optimal performance and longevity of their systems. Below are key properties that define the quality and suitability of these components:

Illustrative image related to water jet machine parts

1. Material Grade

Water jet machine parts are typically made from high-grade materials such as stainless steel, carbide, or specialized alloys. The material grade affects the part’s durability, resistance to wear, and ability to withstand high pressures. For instance, carbide nozzles are preferred for their exceptional hardness and longevity, making them suitable for abrasive cutting applications. Choosing the right material can significantly reduce maintenance costs and downtime.

2. Tolerance

Tolerance refers to the permissible limit of variation in a part’s dimensions. In water jet cutting, precise tolerances are critical for achieving accurate cuts and maintaining operational efficiency. Parts that do not meet specified tolerances can lead to poor cutting quality and increased material waste. B2B buyers should prioritize suppliers who can guarantee the required tolerances for their applications, as this directly impacts the performance of the entire cutting system.

3. Pressure Rating

The pressure rating indicates the maximum pressure a component can handle during operation. Water jet pumps and fittings are rated in psi (pounds per square inch), with common ratings ranging from 40,000 psi to over 90,000 psi. Understanding the pressure requirements is essential for selecting compatible parts and ensuring safety during operation. Parts that exceed the required pressure ratings may lead to catastrophic failures, while those that fall short can hinder cutting performance.

Illustrative image related to water jet machine parts

4. Flow Rate

Flow rate measures the volume of water passing through a nozzle or pump over a specific period, usually expressed in gallons per minute (GPM). A higher flow rate generally leads to faster cutting speeds and improved efficiency. However, it is essential to balance flow rate with pressure for optimal performance. B2B buyers must evaluate their cutting needs and ensure that the selected components can deliver the necessary flow rates for their applications.

5. Abrasive Compatibility

In abrasive water jet cutting, the compatibility of parts with different abrasive materials is vital. Not all nozzles and mixing tubes are designed to handle specific abrasives, such as garnet or aluminum oxide. Selecting parts that can withstand the wear from these materials is critical for maintaining cutting precision and extending the lifespan of the equipment.

What Are Common Trade Terms in Water Jet Machine Parts Procurement?

Navigating the procurement landscape for water jet machine parts involves familiarizing oneself with industry-specific terminology. Here are several key terms that buyers should understand:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts that are identical to those originally manufactured for a specific machine. When sourcing parts, B2B buyers often look for OEM components to ensure compatibility and reliability. However, there are also aftermarket options available that may offer similar or superior performance at a lower cost.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for managing inventory and ensuring cost-effectiveness. B2B buyers should negotiate MOQs that align with their operational needs to avoid excess inventory or supply shortages.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing information for specific parts. This process helps buyers compare costs, lead times, and terms from different suppliers, ensuring they make informed purchasing decisions. A well-structured RFQ can streamline the procurement process and foster better supplier relationships.

4. Incoterms

Incoterms (International Commercial Terms) are a set of predefined rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms helps B2B buyers clarify shipping costs, insurance, and delivery responsibilities, thereby minimizing disputes and ensuring smooth transactions.

5. Lead Time

Lead time is the amount of time it takes from placing an order to receiving the goods. This is a critical factor for B2B buyers, especially in industries where time-sensitive projects are common. Knowing the lead times for various suppliers can help buyers plan their operations more effectively and avoid potential delays.

By understanding these essential properties and trade terms, B2B buyers can make more informed decisions when sourcing water jet machine parts, ultimately leading to improved operational efficiency and profitability.

Navigating Market Dynamics and Sourcing Trends in the water jet machine parts Sector

What Are the Current Market Dynamics and Key Trends in the Water Jet Machine Parts Sector?

The water jet machine parts sector is witnessing a transformative phase, driven by advancements in technology, increasing demand for precision cutting, and the globalization of supply chains. Key drivers include the growing industrialization in regions such as Africa and South America, where manufacturing is rapidly expanding. This rise is complemented by the need for efficient and versatile cutting solutions in industries such as aerospace, automotive, and metal fabrication, leading to a surge in the adoption of water jet technology.

Emerging trends are reshaping the B2B landscape. Digital transformation is at the forefront, with companies increasingly leveraging e-commerce platforms for streamlined procurement processes. This trend is particularly evident in regions like the Middle East and Europe, where international buyers are seeking quick access to a wide range of water jet parts online. Additionally, the integration of IoT (Internet of Things) technology is enhancing the functionality of water jet machines, allowing for real-time monitoring and predictive maintenance, which can significantly reduce downtime and operational costs.

Another notable trend is the shift towards customization and tailored solutions. B2B buyers are prioritizing suppliers that offer bespoke parts and systems, ensuring compatibility with existing machinery and meeting specific operational needs. As competition intensifies, suppliers that can provide rapid prototyping and agile manufacturing capabilities will have a distinct advantage in capturing market share.

How Is Sustainability and Ethical Sourcing Influencing the Water Jet Machine Parts Market?

Sustainability and ethical sourcing are becoming critical considerations for B2B buyers in the water jet machine parts sector. The environmental impact of manufacturing processes, including resource consumption and waste generation, is under increasing scrutiny. Buyers are now prioritizing suppliers that implement sustainable practices, such as utilizing recycled materials and minimizing energy consumption in their production processes.

Illustrative image related to water jet machine parts

The importance of ethical supply chains cannot be overstated. Buyers are increasingly aware of the socio-economic implications of their sourcing decisions. As a result, there is a growing demand for transparency in the supply chain, with an emphasis on ensuring fair labor practices and responsible sourcing of raw materials. Suppliers that can demonstrate compliance with international standards and certifications related to sustainability, such as ISO 14001, are more likely to gain the trust and preference of discerning buyers.

Furthermore, the adoption of ‘green’ materials in the production of water jet machine parts is gaining traction. Companies are exploring biodegradable lubricants and environmentally friendly coatings that not only reduce the ecological footprint but also enhance the performance of their products. This focus on sustainability not only meets regulatory requirements but also aligns with the values of a growing segment of environmentally conscious consumers and businesses.

What Is the Evolution of the Water Jet Machine Parts Sector and Its Relevance Today?

The evolution of the water jet machine parts sector dates back to the late 20th century when water jet technology first emerged as a viable alternative to traditional cutting methods. Initially limited to niche applications, advancements in pump technology and nozzle design have expanded its use across various industries. The introduction of high-pressure water jets capable of cutting through complex materials has revolutionized manufacturing processes.

Today, the sector is characterized by continuous innovation, driven by the need for higher efficiency, precision, and cost-effectiveness. The transition from purely mechanical systems to digitally integrated solutions has further enhanced the capabilities of water jet machines. As international B2B buyers seek advanced solutions that offer both performance and reliability, understanding this evolution is vital for making informed sourcing decisions.

In conclusion, navigating the complexities of the water jet machine parts market requires a keen awareness of current trends, sustainability initiatives, and the historical context of the industry. B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, must leverage this knowledge to identify suppliers that align with their operational needs and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of water jet machine parts

-

How do I ensure the quality of water jet machine parts before purchasing?

To guarantee the quality of water jet machine parts, request certifications and test reports from the supplier. Verify if the parts are OEM (Original Equipment Manufacturer) or equivalent and inquire about warranties. It’s beneficial to check customer reviews and case studies to gauge performance in real-world applications. Establishing a relationship with suppliers who have a reputation for rigorous quality control processes will further assure you of the parts’ reliability. -

What is the best type of water jet cutting head for my application?

The optimal cutting head depends on your specific needs, such as the material thickness and type you’re working with. Advanced cutting heads, like those with patented nozzle designs, provide superior performance and efficiency. Consider the compatibility of the cutting head with your existing water jet system and the type of abrasives you plan to use. Engaging with suppliers for personalized recommendations based on your operational parameters can lead to better outcomes. -

How can I customize water jet machine parts for my specific needs?

Most suppliers offer customization options for water jet machine parts to suit unique operational requirements. You should communicate your specific needs, such as pressure ratings, dimensions, and materials, to the supplier. Many manufacturers can design parts tailored to your specifications, enhancing performance and efficiency. Requesting prototypes or samples before full-scale orders can help ensure the customized parts meet your expectations. -

What are the common minimum order quantities (MOQs) for water jet machine parts?

Minimum order quantities can vary significantly between suppliers and part types. Generally, OEM parts may have higher MOQs due to manufacturing processes, while aftermarket suppliers might offer lower quantities. When sourcing parts, inquire directly with suppliers about their MOQs and see if they can accommodate smaller orders, especially if you’re testing new components or managing a limited budget. -

What payment terms should I expect when purchasing water jet machine parts?

Payment terms can differ widely among suppliers, often influenced by order size and buyer-supplier relationships. Standard terms include upfront payments, net 30, or net 60 days, especially for larger orders. It’s advisable to clarify payment methods accepted (e.g., bank transfer, credit card) and inquire about any discounts for early payments or bulk orders. Understanding these terms upfront can help manage cash flow effectively. -

How do I vet suppliers for water jet machine parts in international markets?

Vetting suppliers involves several steps: researching their reputation in the industry, checking customer testimonials, and confirming their compliance with international quality standards. Requesting references and samples can help assess their product quality. Additionally, consider their logistics capabilities and after-sales support. Utilizing platforms that specialize in B2B connections can also assist in finding reliable suppliers. -

What logistics considerations should I keep in mind when sourcing water jet parts internationally?

When sourcing internationally, consider shipping methods, lead times, and customs regulations that might affect delivery. It’s essential to understand the total landed cost, including tariffs and taxes. Engage with suppliers who have experience in international shipping to ensure timely delivery. Establishing a clear communication channel regarding logistics will help prevent delays and ensure that all documentation is in order. -

How can I obtain technical support for water jet machine parts after purchase?

Technical support is critical for maintaining optimal performance. Most reputable suppliers offer customer service or technical support teams to assist with installation, troubleshooting, and maintenance. Before purchasing, inquire about the availability of support services, including manuals, online resources, and response times for inquiries. Establishing a relationship with a supplier that prioritizes customer support can significantly enhance your operational efficiency.

Top 8 Water Jet Machine Parts Manufacturers & Suppliers List

1. H2O Jet – Waterjet Pumps

Domain: waterjetparts.com

Registered: 1999 (26 years)

Introduction: H2O Jet manufactures high-pressure pumps and parts for waterjet cutting systems, designed for performance and reliability. Key products include: 1. Waterjet Pumps: Available in standard or custom options, with pressure ratings from 40,000 psi to 94,000 psi, compatible with nearly any brand waterjet system. 2. Cutting Head Technology: Features advanced designs including the Integrated Diamond Educt…

2. Waterjet Depot – Advanced Carbide Nozzles

Domain: waterjetdepot.com

Registered: 2014 (11 years)

Introduction: Waterjet Depot specializes in advanced, hard-wearing carbide for abrasive waterjet cutting nozzles. Key features include:

– Patented processes for enhanced wear resistance.

– NANO tungsten particles for superior durability and longer lifespan compared to standard tungsten carbide nozzles.

– Reduced binder content and increased material density for improved wear resistance.

– Advanced manufactu…

3. AccuStream – Replacement Parts for Cutting Heads and Pumps

Domain: accustream.com

Registered: 2001 (24 years)

Introduction: Replacement Parts for Flow Cutting Head, Filters, Nozzles, On/Off Valve, Orifices, 60k & 90k Pump Parts, Swivels, Misc. Parts for KMT, Pump Parts for BFT, AccuStream, Bleed Down Valve Parts, DiaLine Cutting Head, A2 Cutting Head, Water Only On/Off Valve, Misc. Products for Jet Edge, Pump Parts for WSI, Pump Parts for OMAX, High Pressure Tubing & Fittings (60K Tubing, 100k Tubing & Fittings), Adapt…

4. IWP Waterjet – MaxDrive™ High Performance Parts

Domain: iwpwaterjet.com

Registered: 1999 (26 years)

Introduction: MaxDrive™ high performance Omax replacement parts; OEM pumps running for 6000+ hours; MaxDrive parts exceed OEM performance specifications by 28%; Wide variety of waterjet brand parts including cutting heads, mixing tubes, orifices, cylinders, check valves, seals, fittings, tubing, filters, consumables; OMAX Style Parts: F300-D0096-0000 HP CYLINDER, DD, E-MAX; F300-D0071-0000 CYLINDER HIGH PRESSUR…

5. Flow – Genuine Waterjet Parts

Domain: flowwaterjet.com

Registered: 2003 (22 years)

Introduction: Genuine Flow Waterjet Parts are OEM parts designed to maintain peak performance throughout the lifecycle of waterjet systems. They ensure the machine remains in optimal condition, with a one-year warranty on nearly all non-consumable spare parts. Flow emphasizes safety, manufacturing parts to high standards suitable for operating pressures up to 94,000 psi. The company continuously innovates to en…

6. OMAX – Waterjet Parts

Domain: marketplace.omax.com

Registered: 1996 (29 years)

Introduction: OMAX Waterjet parts, OEM parts ensure peak performance, longer machine life, certified quality, and unmatched compatibility for waterjet systems. Categories include: Maintenance Kits, Filtration & Lubrication, Abrasive Handling, Cutting Head Components, Pump Components, Tubing & Fittings, Table Components. Genuine parts maximize system performance, reduce downtime, and guarantee quality and precis…

7. CNCShop – Waterjet Parts & Services

Domain: cncshop.com

Registered: 2005 (20 years)

Introduction: CNCShop offers a variety of Waterjet parts and services, including: Intensifier Pumps, Cutting Heads, WARDJet Parts & Spares, High Pressure components, Maintenance Kits, and Accessories. Specific products include Rebuild Kits, Hydraulic & Water Filters, Bleed Down Valves, Orifices, Nozzles, Thimble Filters, Splash Guards, and various Cutting Head Body Parts. Additionally, they provide training ser…

8. AccuStream – BFT Valve Seat

Domain: abrasiveblastsupply.com

Registered: 2008 (17 years)

Introduction: AccuStream™ water-jet parts, manufactured by AccuStream™, a Hypertherm brand. They offer replacement parts for major brands including Flow, Jet Edge, KMT, OMAX, WSI, and HP Components. Key products include:

– AccuStream BFT Valve Seat – MSRP: $55.50

– AccuStream DiaLine4 Nozzle Nut – MSRP: $135.00

– AccuStream DiaLine4 Abrasive Body – MSRP: $379.00

– AccuStream DiaLine4 Nozzle Splash Guard – M…

Strategic Sourcing Conclusion and Outlook for water jet machine parts

In today’s competitive landscape, strategic sourcing of water jet machine parts is not just advantageous; it is essential for operational efficiency and profitability. By prioritizing high-quality components, such as pumps, nozzles, and cutting heads, businesses can enhance their machine performance, reduce downtime, and ultimately lower operational costs. Engaging with reputable suppliers, who offer both OEM and custom solutions, ensures that buyers can tailor their systems to meet specific production needs, maximizing output and minimizing waste.

As markets in Africa, South America, the Middle East, and Europe continue to evolve, the demand for reliable and innovative water jet cutting technologies will only increase. Buyers are encouraged to leverage local distributors to reduce shipping costs and lead times, thereby optimizing their supply chains. By investing in quality parts and establishing strong supplier relationships, companies can secure a competitive edge in their respective industries.

Looking ahead, the future of water jet machining is bright, with advancements in technology promising even greater efficiencies. Now is the time for international buyers to act—explore your options, assess your sourcing strategies, and partner with leading suppliers to elevate your operations. The right parts can make all the difference in achieving exceptional cutting performance and driving sustainable growth.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to water jet machine parts

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.