Top 8 V Belt Conveyor Suppliers (And How to Choose)

Introduction: Navigating the Global Market for v belt conveyor

In today’s competitive landscape, sourcing the right v belt conveyor system can pose significant challenges for international B2B buyers. With a variety of applications across industries such as food processing, manufacturing, and logistics, understanding the intricacies of v belt conveyor options is crucial for optimizing operational efficiency. This guide serves as a comprehensive resource, detailing the diverse types of v belt conveyors available, their specific applications, and best practices for supplier vetting. Additionally, we will explore cost considerations and maintenance strategies that can enhance the lifespan and performance of your conveyor systems.

As businesses expand globally, particularly in regions like Africa, South America, the Middle East, and Europe, the need for reliable and efficient material handling solutions becomes increasingly paramount. This guide empowers B2B buyers to make informed purchasing decisions by providing insights into the latest advancements in v belt conveyor technology, as well as practical tips for selecting the right suppliers and negotiating favorable terms. By leveraging this knowledge, organizations can not only streamline their operations but also reduce downtime and improve overall productivity. Whether you are navigating the complexities of procurement for a new facility or upgrading existing systems, this guide is designed to support your journey toward effective and strategic investments in v belt conveyor solutions.

Understanding v belt conveyor Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Solid V-Guide Conveyor | Continuous v-shaped guides for improved tracking | Food processing, manufacturing, packaging | Pros: Excellent tracking, reduces wear. Cons: Limited flexibility in design. |

| Notched V-Guide Conveyor | V-guides with notches for better grip and tracking | Distribution, airport logistics | Pros: Enhanced load stability. Cons: Can be more expensive to produce. |

| Deep Notched V-Guide Conveyor | Deeper notches for heavy-duty applications | Heavy manufacturing, automotive | Pros: Suitable for high-load applications. Cons: Requires precise installation. |

| Urethane Segmented V-Guide Conveyor | Segmented design for flexibility and adaptability | Recycling, waste management | Pros: Customizable lengths, easy to maintain. Cons: May have higher upfront costs. |

| Dual V-Guide Conveyor | Two parallel v-guides for added stability | Bottling, packaging lines | Pros: Exceptional tracking and load distribution. Cons: More complex installation. |

What Are Solid V-Guide Conveyors and When Should You Use Them?

Solid V-guide conveyors feature continuous v-shaped profiles that enhance belt tracking, making them ideal for industries such as food processing and manufacturing. These conveyors help maintain alignment, reducing wear on the belt edges and minimizing downtime. When purchasing, consider the specific application needs, as these guides offer limited design flexibility but excel in environments where consistent tracking is crucial.

How Do Notched V-Guide Conveyors Improve Performance?

Notched V-guide conveyors incorporate strategically placed notches that provide enhanced grip and tracking. This design is particularly beneficial in distribution centers and airport logistics where load stability is vital. Buyers should assess their operational requirements, as the benefits of improved load handling may justify the higher production costs associated with these guides.

What Advantages Do Deep Notched V-Guide Conveyors Offer?

Deep notched V-guide conveyors are designed for heavy-duty applications, making them suitable for sectors like automotive and heavy manufacturing. Their deeper notches allow for better grip under substantial loads, ensuring operational efficiency. However, buyers need to ensure precise installation to maximize performance, which may require specialized expertise.

Why Choose Urethane Segmented V-Guide Conveyors?

Urethane segmented V-guide conveyors feature customizable segments that offer flexibility in length and adaptability to various applications, such as recycling and waste management. Their easy maintenance and ability to be tailored to specific needs make them appealing to buyers. However, the initial investment may be higher, so businesses should evaluate long-term operational savings against upfront costs.

When Is a Dual V-Guide Conveyor the Right Choice?

Dual V-guide conveyors utilize two parallel v-guides to provide exceptional stability and tracking, making them ideal for bottling and packaging lines. This design ensures even load distribution and minimizes the risk of misalignment. While the installation process can be more complex, the benefits of enhanced performance often outweigh the challenges, making it a worthwhile investment for high-volume operations.

Key Industrial Applications of v belt conveyor

| Industry/Sector | Specific Application of v belt conveyor | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Processing | Transporting packaged goods through production lines | Ensures hygienic transport, reduces contamination risk | Compliance with food safety standards (FDA, USDA) |

| Automotive Manufacturing | Moving components between assembly stations | Increases efficiency and reduces manual handling | Durability and resistance to oil and grease |

| Mining and Aggregates | Conveying bulk materials from extraction sites | Enhances material handling efficiency and reduces downtime | Ability to withstand harsh environments and heavy loads |

| Pharmaceutical | Transporting products in cleanroom environments | Supports stringent hygiene requirements and precision | Compliance with industry regulations and certifications |

| E-commerce Logistics | Sorting and transporting parcels in distribution centers | Streamlines operations and improves order fulfillment | Flexibility in design and integration with existing systems |

How is ‘v belt conveyor’ used in food processing, and what are the benefits for businesses?

In the food processing sector, v belt conveyors are utilized to transport packaged goods along production lines, ensuring a seamless flow from one stage to the next. These conveyors are designed to meet stringent hygiene standards, significantly reducing the risk of contamination. For B2B buyers, sourcing v belt conveyors for food applications requires a focus on compliance with food safety regulations such as FDA and USDA. Additionally, the materials must be food-grade and easy to clean, ensuring the integrity of the products being handled.

What role does ‘v belt conveyor’ play in automotive manufacturing?

In automotive manufacturing, v belt conveyors are integral to moving components between assembly stations, facilitating a more efficient workflow. These conveyors minimize manual handling, thereby reducing the risk of workplace injuries and increasing overall productivity. Buyers in this sector should prioritize sourcing durable materials that can withstand exposure to oils and greases commonly found in automotive environments. Ensuring that the conveyor system can accommodate the specific weight and size of automotive parts is also crucial for operational efficiency.

How does ‘v belt conveyor’ enhance efficiency in mining and aggregates?

In the mining and aggregates industry, v belt conveyors are essential for conveying bulk materials from extraction sites to processing areas. These systems enhance material handling efficiency and significantly reduce downtime associated with manual transport. Buyers should consider the conveyor’s ability to withstand harsh environments, including extreme weather conditions and heavy loads. Additionally, sourcing robust components that require minimal maintenance can lead to long-term cost savings and improved operational reliability.

What are the specific requirements for ‘v belt conveyor’ in pharmaceutical applications?

Within the pharmaceutical sector, v belt conveyors are used to transport products in cleanroom environments, where hygiene and precision are paramount. These conveyors help maintain the integrity of sensitive pharmaceutical products while adhering to strict industry regulations. B2B buyers must ensure that the sourced conveyors meet necessary certifications and are constructed from materials that can be easily sanitized. Flexibility in design is also important to accommodate various product sizes and shapes.

How does ‘v belt conveyor’ streamline operations in e-commerce logistics?

In e-commerce logistics, v belt conveyors play a crucial role in sorting and transporting parcels within distribution centers. By automating the movement of goods, these systems streamline operations, significantly improving order fulfillment rates. Buyers should look for flexible conveyor designs that can integrate with existing systems and be easily adjusted to accommodate changing product lines. Additionally, the ability to handle varying package sizes and weights is essential for optimizing logistics efficiency.

3 Common User Pain Points for ‘v belt conveyor’ & Their Solutions

Scenario 1: Frequent Conveyor Belt Misalignment

The Problem:

In many industrial settings, B2B buyers often face the issue of conveyor belt misalignment, which can lead to significant downtime and costly disruptions. This misalignment is especially prevalent in long or narrow conveyor systems, where the load distribution may not be uniform. Inconsistent tracking can cause the belt to drift off its path, leading to increased wear and tear on both the belt and the conveyor structure. For businesses relying on efficient material handling, such interruptions can severely affect productivity and operational efficiency.

The Solution:

To combat belt misalignment, B2B buyers should consider investing in v-guide conveyor belts. These belts incorporate v-shaped profiles that run along the underside or topside of the belt, providing additional tracking support. When specifying a v-guide belt, it’s essential to consult with suppliers to choose the right size and type of v-guide that fits the specific application. Buyers should focus on ensuring the correct placement of the guides—whether on the pulley side or the conveying side—based on their operational needs. Furthermore, regular maintenance checks should be scheduled to adjust and realign the guides as necessary, ensuring consistent performance and extending the life of the conveyor system.

Scenario 2: High Wear and Tear on Conveyor Belts

The Problem:

High levels of wear and tear on conveyor belts can be a significant concern for B2B buyers, particularly in heavy-duty applications such as manufacturing or distribution centers. Factors such as abrasive materials, heavy loads, and environmental conditions can exacerbate this issue, leading to frequent replacements and increased operational costs. For companies looking to optimize their supply chain, minimizing downtime due to belt failures is crucial, yet challenging.

The Solution:

To reduce wear and tear, buyers should choose v-guide conveyor belts made from durable materials specifically designed for their operational conditions. For example, belts constructed from polyurethane (PU) or specially formulated PVC can offer enhanced resistance to wear and improve longevity. Buyers must also ensure that the belt is appropriately matched to the application’s weight and speed requirements to minimize stress on the belt. Additionally, implementing a scheduled maintenance program that includes regular inspections and prompt repairs can help identify wear issues early, preventing more significant problems and extending the lifespan of the conveyor system.

Scenario 3: Inconsistent Load Distribution Leading to Inefficiency

The Problem:

In many industries, B2B buyers encounter challenges related to inconsistent load distribution on conveyor belts, which can lead to operational inefficiencies. When loads are not evenly distributed, the belt may sag or become overloaded on one side, causing jams or delays in the production line. This issue can result in increased labor costs as workers must intervene to fix problems and can also negatively impact overall throughput.

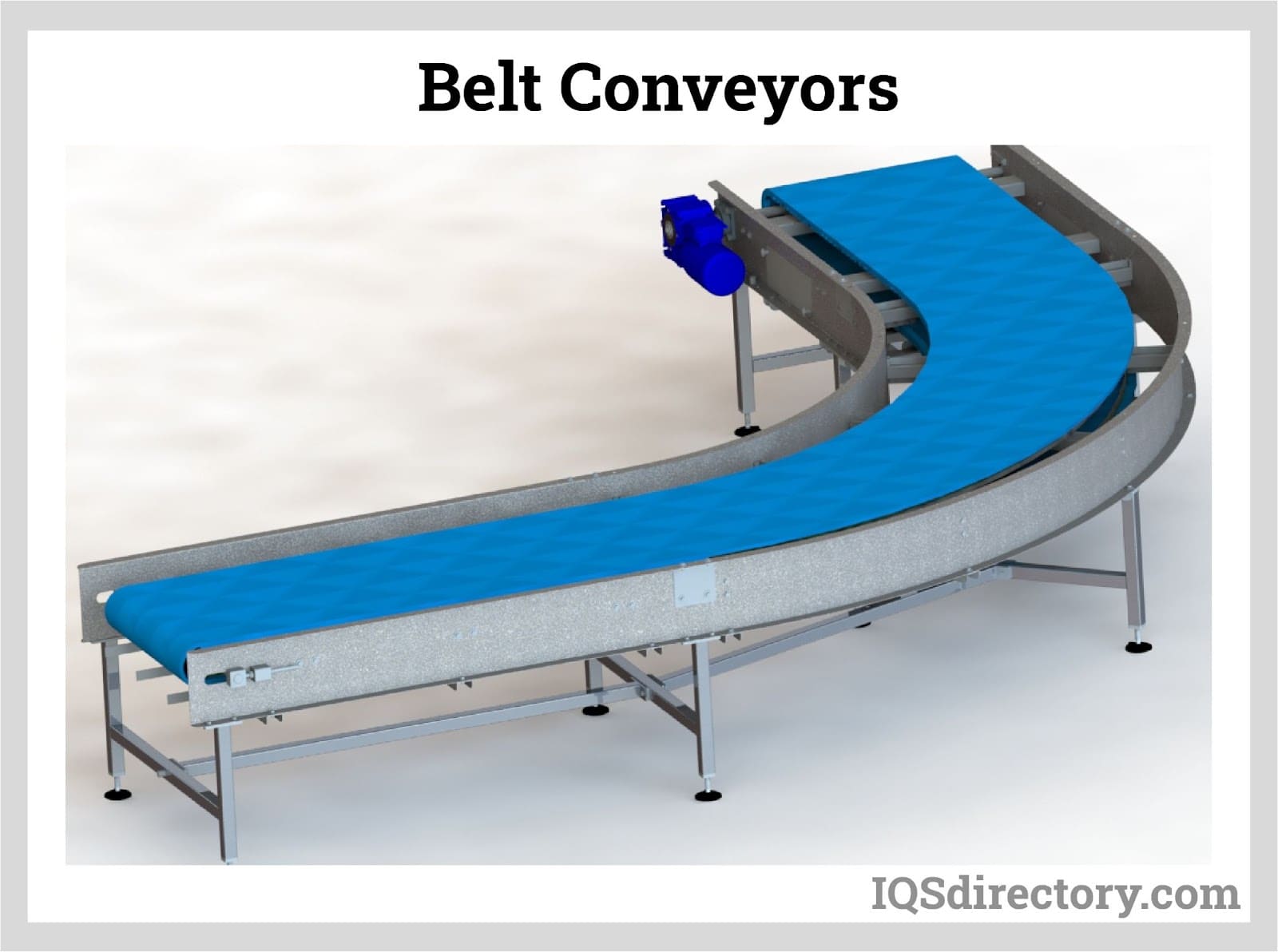

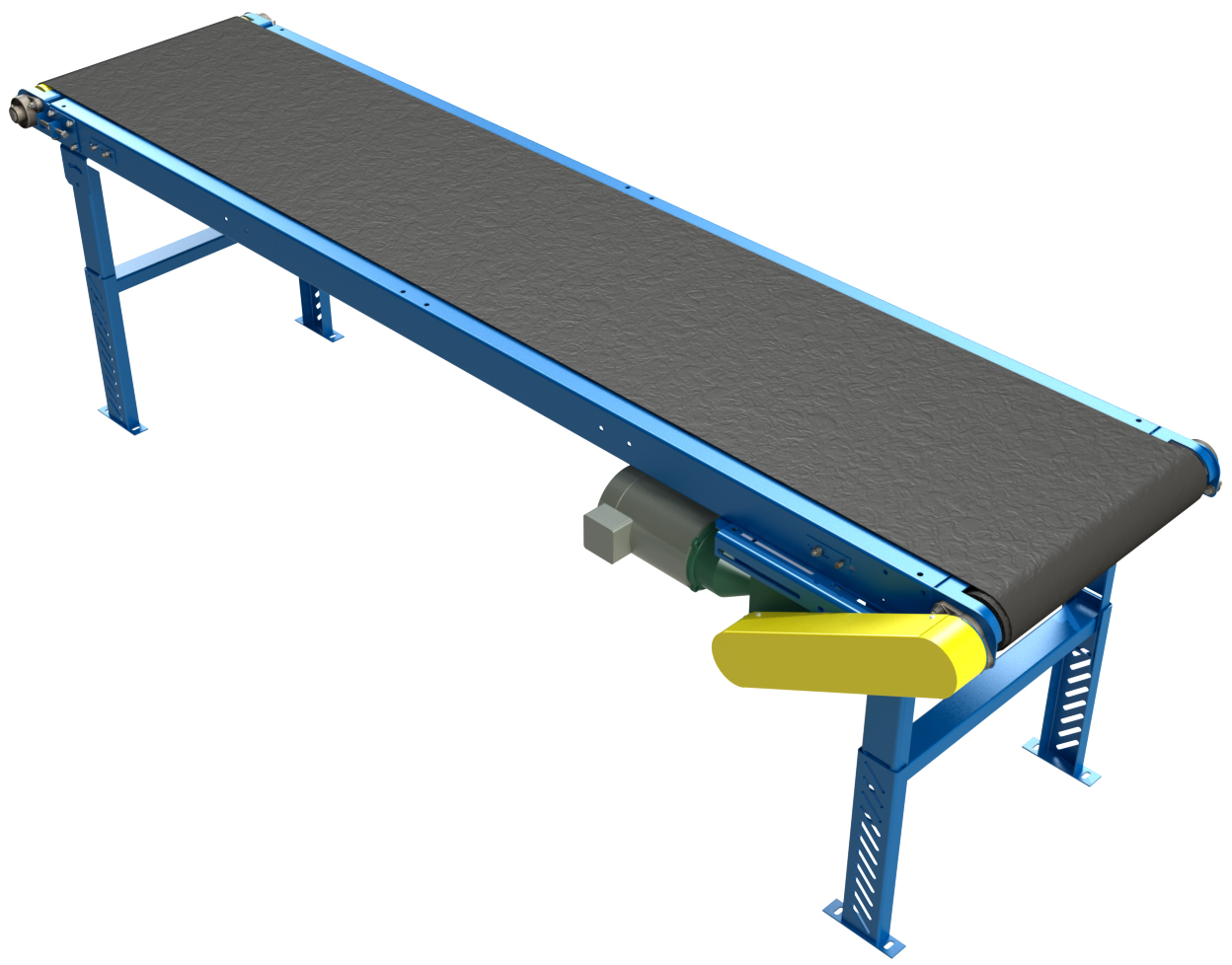

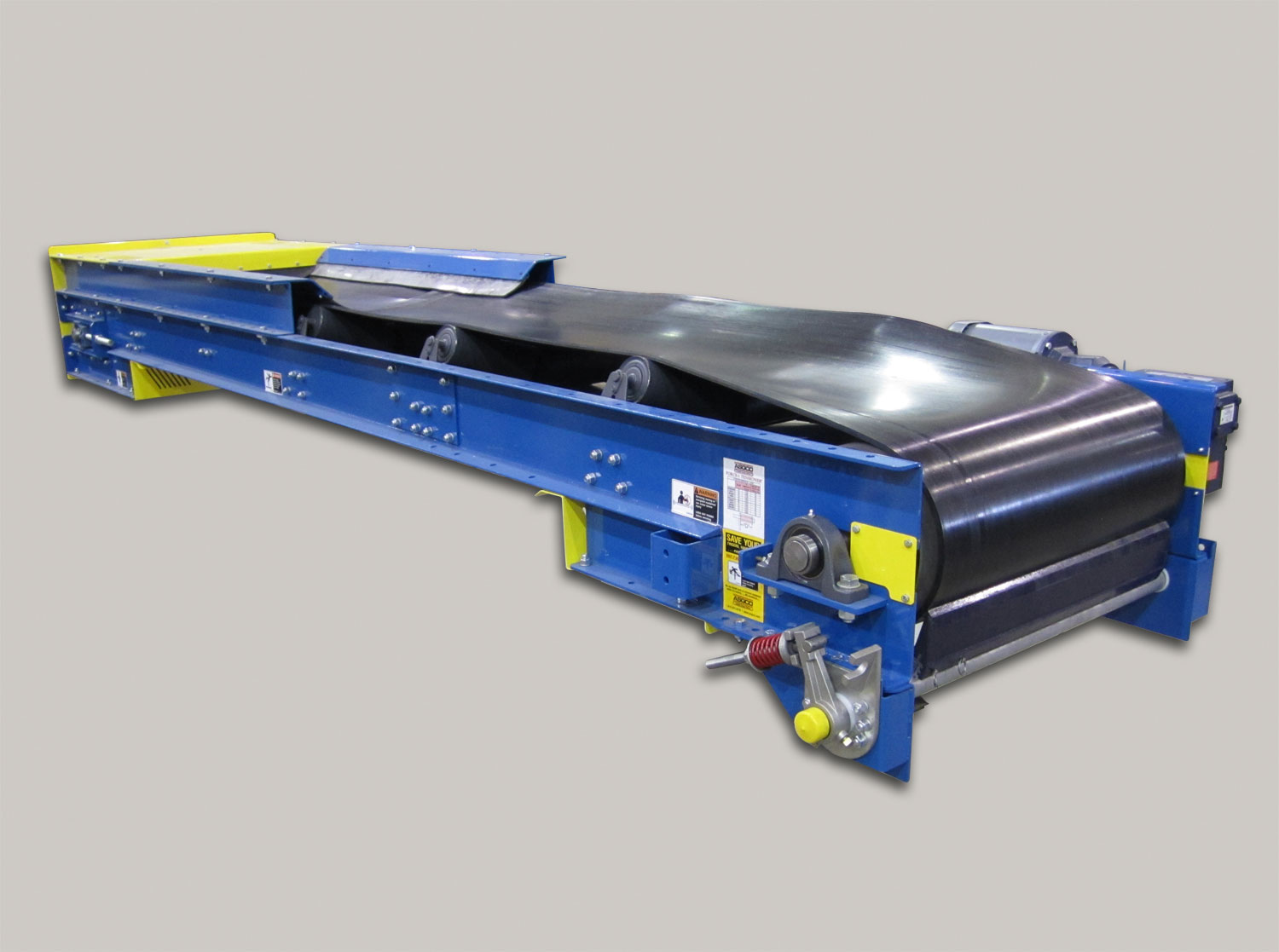

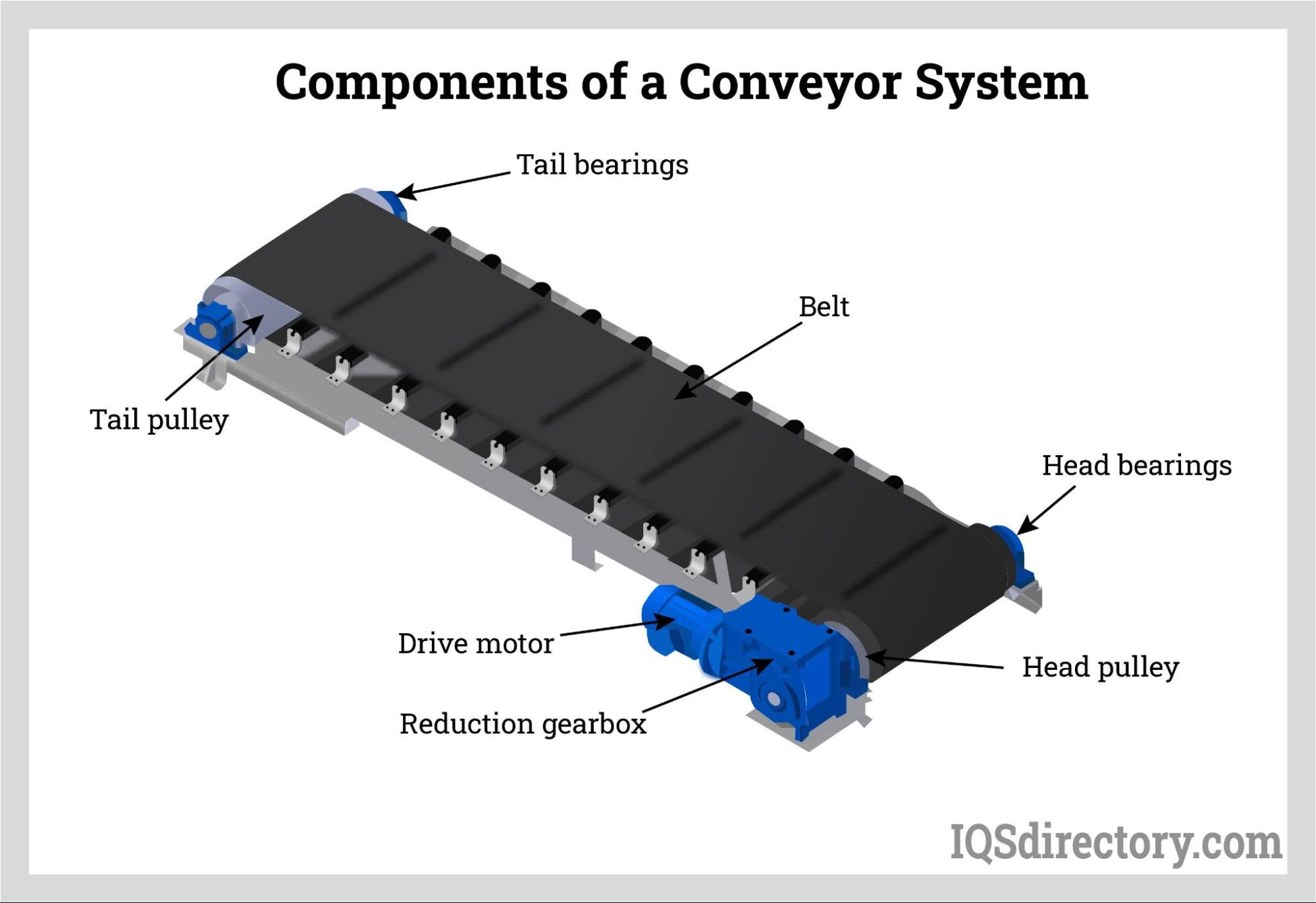

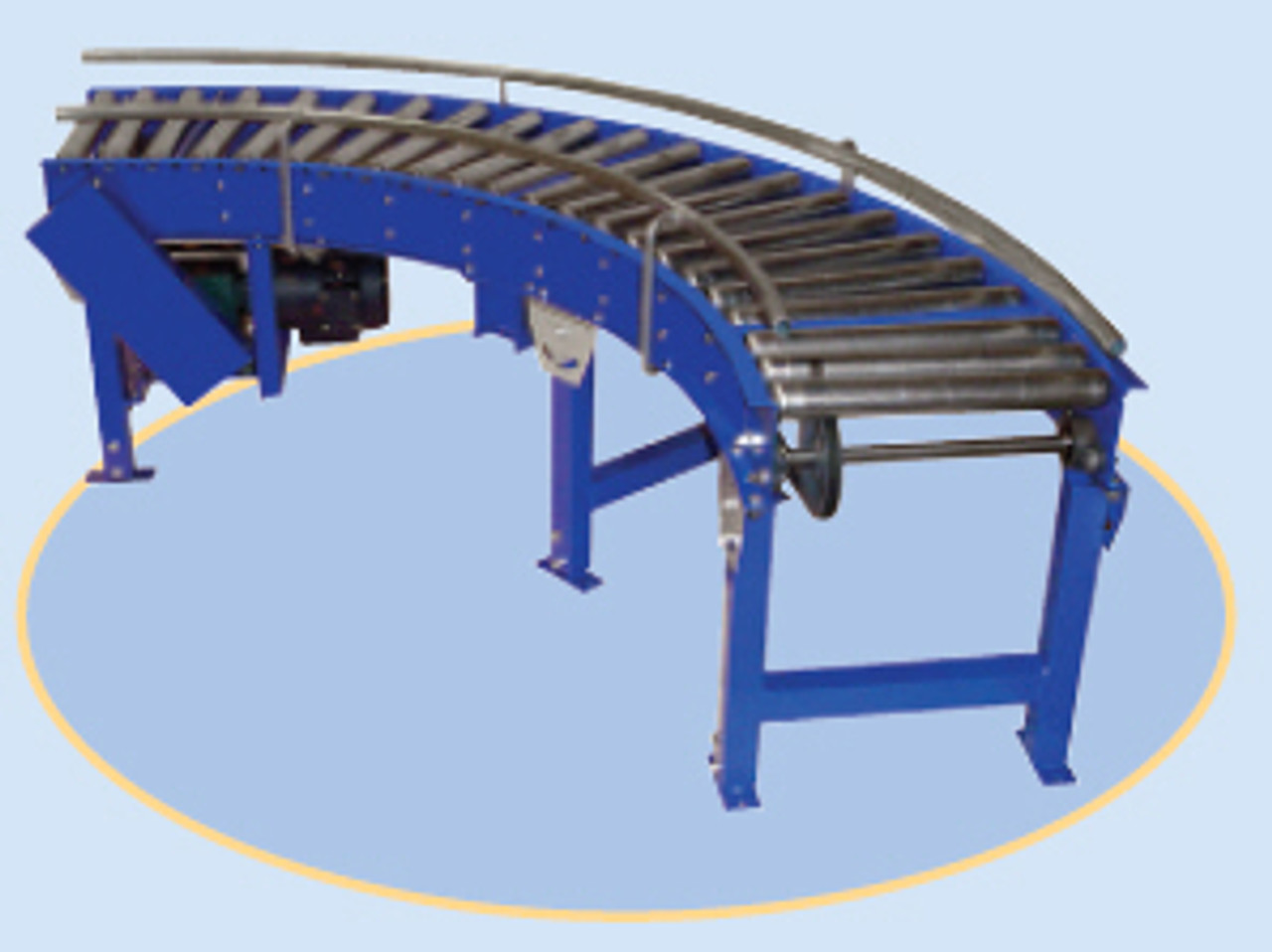

Illustrative image related to v belt conveyor

The Solution:

To address inconsistent load distribution, it is advisable to utilize v-guide conveyor belts, which help maintain alignment and tracking, thereby supporting more uniform load distribution across the belt. Buyers should work closely with suppliers to analyze their specific applications and configure the v-guides to optimize performance. Furthermore, implementing smart sensors or monitoring systems can provide real-time data on load distribution, allowing for quick adjustments and proactive management. Training staff on proper loading techniques can also contribute to balanced weight distribution, enhancing overall conveyor efficiency and productivity.

Strategic Material Selection Guide for v belt conveyor

What Are the Key Properties of Common Materials Used in V-Belt Conveyors?

When selecting materials for V-belt conveyors, it’s essential to consider the specific properties that influence performance. Here, we analyze four common materials: PVC, polyurethane (PU), rubber, and steel-reinforced belts.

PVC (Polyvinyl Chloride)

Key Properties: PVC is known for its excellent chemical resistance and moderate temperature tolerance, typically ranging from -10°C to 60°C. It is lightweight and offers good flexibility, making it suitable for various applications.

Pros & Cons: PVC is cost-effective and easy to manufacture, which makes it a popular choice for general-purpose applications. However, its durability can be a limitation in high-load or extreme temperature environments. While it performs well in many scenarios, it may not be suitable for heavy-duty applications due to its lower tensile strength compared to other materials.

Illustrative image related to v belt conveyor

Impact on Application: PVC is compatible with a wide range of media, including food products, making it ideal for food processing and packaging industries. However, it may not withstand harsh chemicals found in some industrial settings.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards such as ASTM or DIN, especially in food-related applications. The availability of PVC belts can vary, so sourcing from reliable suppliers is crucial.

Polyurethane (PU)

Key Properties: Polyurethane offers superior abrasion resistance and can handle higher temperature ranges, typically from -30°C to 80°C. It also exhibits excellent elasticity and tensile strength.

Pros & Cons: PU belts are highly durable and suitable for heavy-duty applications, making them ideal for industries like automotive and manufacturing. However, they tend to be more expensive than PVC, which may deter cost-sensitive buyers. Manufacturing complexity can also be higher due to the need for specialized equipment.

Illustrative image related to v belt conveyor

Impact on Application: PU belts are particularly effective in applications requiring high load-bearing capacity and resistance to wear and tear. They are also compatible with various media, including oils and chemicals, making them versatile for different industrial uses.

Considerations for International Buyers: Compliance with international standards is essential, especially for industries with stringent regulations. Buyers should verify the manufacturer’s certifications to ensure quality and performance.

Rubber

Key Properties: Rubber belts provide excellent flexibility and high tensile strength, with temperature ratings typically between -20°C and 70°C. They are also resistant to abrasion and impact.

Pros & Cons: The durability of rubber makes it suitable for heavy-duty applications, but it can be more expensive than PVC and PU. The manufacturing process can also be complex, which may lead to longer lead times.

Impact on Application: Rubber is ideal for applications involving heavy loads and rough handling, such as in mining or construction. Its resistance to wear makes it a preferred choice in environments with high friction.

Considerations for International Buyers: Buyers should be aware of the specific rubber grades that comply with local regulations, particularly in the Middle East, where temperature extremes can affect performance. Ensuring that rubber belts meet international quality standards is crucial for reliability.

Illustrative image related to v belt conveyor

Steel-Reinforced Belts

Key Properties: Steel-reinforced belts combine the flexibility of rubber or PU with the strength of steel, providing exceptional tensile strength and durability. They can handle extreme temperatures and heavy loads.

Pros & Cons: These belts are highly durable and suitable for the most demanding applications. However, they are heavier and more expensive, which may limit their use in lighter applications. The complexity of manufacturing can also lead to higher costs.

Impact on Application: Steel-reinforced belts excel in heavy-duty environments, such as mining and heavy manufacturing, where durability is paramount. They can withstand harsh conditions and are ideal for transporting heavy materials.

Considerations for International Buyers: Buyers should consider the specific steel grades used in the reinforcement to ensure compliance with local standards. It’s also important to evaluate the logistics of transporting these heavier belts, especially in regions with limited infrastructure.

Summary Table of Material Selection for V-Belt Conveyors

| Material | Typical Use Case for v belt conveyor | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Food processing and packaging | Cost-effective and flexible | Lower durability in heavy loads | Low |

| Polyurethane (PU) | Automotive and manufacturing | High durability and abrasion resistance | Higher cost and complexity | High |

| Rubber | Mining and construction | Excellent flexibility and strength | More expensive and complex to manufacture | Med |

| Steel-Reinforced Belts | Heavy manufacturing and mining | Exceptional tensile strength | Heavier and more expensive | High |

This guide provides a comprehensive overview of material options for V-belt conveyors, aiding international B2B buyers in making informed decisions tailored to their specific operational needs.

In-depth Look: Manufacturing Processes and Quality Assurance for v belt conveyor

What Are the Main Stages of Manufacturing V-Belt Conveyors?

The manufacturing process for v-belt conveyors is meticulous and involves several key stages that ensure the final product meets the rigorous demands of various industries.

Illustrative image related to v belt conveyor

Material Preparation: What Materials Are Used and How Are They Prepared?

The first stage in the manufacturing process is material preparation. V-belt conveyors typically utilize high-quality materials such as rubber, PVC, polyurethane, and various fabric reinforcements. These materials are chosen for their durability, flexibility, and resistance to wear and tear.

Before the manufacturing begins, materials undergo thorough inspection and testing to verify their quality and compliance with industry standards. Suppliers often conduct tests such as tensile strength assessments and elongation measurements to ensure that the materials will perform under operational stresses.

Forming: How Are V-Belt Components Shaped?

Once the materials are prepared, the next stage is forming. This involves cutting and shaping the materials into the necessary components of the v-belt conveyor, including the belt body, v-guides, and other accessories.

Advanced techniques such as extrusion and molding are commonly employed to achieve precise dimensions. For instance, v-guides are often extruded in continuous lengths and then cut to size based on the conveyor specifications. This process is crucial, as proper dimensions directly affect the tracking and performance of the conveyor.

Assembly: How Are V-Belt Conveyors Assembled?

Following forming, the components are assembled. This stage may involve vulcanizing or welding v-guides onto the belt surface, ensuring they are securely attached and aligned correctly.

Assembly is often performed in a clean environment to prevent contamination, particularly for applications in food processing or pharmaceuticals. Automated systems may be utilized for consistency and efficiency, while skilled technicians oversee critical assembly tasks to guarantee quality.

Finishing: What Final Touches Are Applied?

The final stage is finishing, which includes applying protective coatings, performing final inspections, and preparing the conveyor for shipping. Coatings may enhance resistance to abrasion, chemicals, and UV light, extending the conveyor’s lifespan.

During this stage, quality checks are conducted to ensure the conveyor meets all specifications and performance requirements. This includes visual inspections, dimensional checks, and functional testing to verify that the conveyor operates smoothly and efficiently.

What Quality Assurance Standards Are Relevant for V-Belt Conveyors?

Quality assurance (QA) is a critical aspect of v-belt conveyor manufacturing, ensuring that products meet both international and industry-specific standards.

Illustrative image related to v belt conveyor

Which International Standards Should B2B Buyers Be Aware Of?

ISO 9001 is one of the most recognized international standards for quality management systems. Compliance with ISO 9001 demonstrates a manufacturer’s commitment to quality and continuous improvement, which is essential for B2B buyers seeking reliable suppliers.

In addition to ISO 9001, industry-specific standards such as CE marking (for European markets) and API standards (for the petroleum industry) may also apply. These certifications indicate that products have been tested and meet safety and performance criteria relevant to their intended use.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) is an integral part of the manufacturing process, ensuring that each stage meets predefined standards.

How Are Incoming Materials Inspected (IQC)?

Incoming Quality Control (IQC) is the first checkpoint, where raw materials are inspected upon arrival. This includes verifying certificates of compliance, checking for physical defects, and conducting initial tests. Any materials that do not meet specifications are rejected and returned to the supplier.

What Is In-Process Quality Control (IPQC)?

In-Process Quality Control (IPQC) occurs during the manufacturing process. This includes monitoring dimensions, weights, and other critical parameters at various stages. Technicians may use tools such as calipers and gauges to ensure that components remain within tolerance limits.

How Is Final Quality Control (FQC) Conducted?

Final Quality Control (FQC) is conducted after assembly and finishing. This comprehensive inspection involves testing the overall functionality of the v-belt conveyor, ensuring it meets performance criteria and is free from defects.

Testing methods may include load testing, operational trials, and stress tests to simulate actual working conditions. Documentation of these tests is crucial for buyers who require evidence of compliance with quality standards.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to verify the quality control processes of potential suppliers.

Illustrative image related to v belt conveyor

What Audit Processes Should Buyers Consider?

Conducting supplier audits is an effective way to assess the quality control practices of manufacturers. Audits can include reviewing production processes, checking compliance with standards, and assessing the overall quality management system in place.

Buyers should also request documentation of previous audits and certifications to ensure that the supplier maintains high-quality standards consistently.

How Can Third-Party Inspections Enhance Confidence?

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures. These inspections can be conducted at various stages of the manufacturing process, offering buyers peace of mind regarding the quality and reliability of the products they are purchasing.

What Nuances Should International Buyers Be Aware Of?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, there are specific nuances to consider regarding quality assurance.

How Do Regional Standards Affect Quality Assurance?

Different regions may have varying standards and regulations that affect product quality. Buyers should familiarize themselves with local compliance requirements to ensure that the v-belt conveyors they purchase meet both international and regional standards.

What Role Does Documentation Play?

Documentation is vital for international transactions, serving as proof of compliance with quality standards. Buyers should ensure that suppliers provide detailed quality assurance documentation, including certificates of compliance, test reports, and inspection records.

In summary, understanding the manufacturing processes and quality assurance practices for v-belt conveyors enables B2B buyers to make informed decisions when sourcing products. By focusing on quality standards, inspection protocols, and supplier verification, businesses can secure reliable and high-performance conveyor solutions tailored to their needs.

Illustrative image related to v belt conveyor

Practical Sourcing Guide: A Step-by-Step Checklist for ‘v belt conveyor’

In the competitive landscape of international B2B procurement, sourcing a V-belt conveyor requires careful consideration and a systematic approach. This checklist is designed to guide buyers through the essential steps to ensure they make informed purchasing decisions that align with their operational needs and business goals.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is foundational to sourcing the right V-belt conveyor. Consider the dimensions, load capacity, material type, and specific application requirements. Knowing the operational environment—such as temperature, humidity, and exposure to chemicals—will also influence your choice.

- Key Considerations:

- Conveyor length and width

- Load type and weight

- Required speed and incline

Step 2: Research Potential Suppliers

Identifying reputable suppliers is critical to ensuring quality and reliability. Look for manufacturers with a proven track record in producing V-belt conveyors and check their certifications, such as ISO or industry-specific standards. Engage with suppliers who have experience in your industry sector, as they will better understand your unique needs.

- Key Actions:

- Review supplier websites and product catalogs

- Seek recommendations from industry peers

- Assess online reviews and testimonials

Step 3: Evaluate Supplier Capabilities

Before committing to a supplier, it’s vital to assess their capabilities thoroughly. Request detailed information about their production processes, quality control measures, and lead times. This evaluation will help you gauge whether they can meet your demands consistently.

- What to Look For:

- Manufacturing technology and equipment

- Quality assurance processes

- Flexibility in order fulfillment

Step 4: Request Samples and Prototypes

Sampling is an essential step in the procurement process. Request samples or prototypes of the V-belt conveyor to evaluate their quality and compatibility with your operational requirements. This hands-on experience can provide insights into the product’s performance and durability.

- Considerations for Sampling:

- Test the sample under real-world conditions

- Assess material quality and construction

- Verify the ease of installation and maintenance

Step 5: Verify Supplier Certifications and Compliance

Ensuring that suppliers comply with industry regulations and safety standards is critical for risk management. Request copies of relevant certifications and documentation to confirm that their products meet international quality and safety standards.

- Key Certifications to Check:

- ISO 9001 for quality management

- CE marking for compliance with EU directives

- Industry-specific certifications relevant to your sector

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, engage in negotiations to finalize pricing, payment terms, delivery schedules, and warranty conditions. Clear agreements can prevent misunderstandings and ensure both parties are aligned.

- Important Negotiation Points:

- Volume discounts and pricing tiers

- Payment methods and timelines

- Return policies and warranty coverage

Step 7: Establish a Communication Plan

Effective communication is crucial throughout the procurement process and beyond. Set up regular check-ins with your supplier to discuss updates, address any issues, and ensure that your needs are being met.

Illustrative image related to v belt conveyor

- Best Practices:

- Schedule periodic meetings or calls

- Use project management tools for tracking progress

- Maintain a clear line of communication for feedback

By following this checklist, international B2B buyers can navigate the complexities of sourcing V-belt conveyors, ensuring they choose suppliers that align with their operational needs and contribute to their business success.

Comprehensive Cost and Pricing Analysis for v belt conveyor Sourcing

What Are the Key Cost Components in V-Belt Conveyor Sourcing?

When evaluating the cost structure of v-belt conveyors, it’s crucial to understand the various components that contribute to the final price. The primary cost components include:

-

Materials: The choice of materials significantly impacts costs. High-grade rubber or synthetic materials may be more expensive but can enhance durability and performance. For example, using polyurethane (PU) instead of PVC can increase costs but also extend the conveyor’s lifespan.

-

Labor: Labor costs vary based on the manufacturing location. Countries with higher labor costs, such as those in Europe, may see increased pricing compared to regions in Africa or South America, where labor may be less expensive.

-

Manufacturing Overhead: This includes costs related to facility maintenance, equipment depreciation, and utilities. Efficient manufacturing processes can help minimize these overheads.

-

Tooling: Custom tooling for specific conveyor designs can incur significant upfront costs. However, these can be amortized over large production runs, making them more economical in the long term.

-

Quality Control (QC): Rigorous QC processes ensure that v-belt conveyors meet industry standards. Investments in quality assurance can lead to higher initial costs but reduce long-term expenses related to repairs and replacements.

-

Logistics: Shipping and handling costs can vary widely based on the origin and destination of the product. International shipping can introduce complexities such as tariffs and customs fees, impacting the overall cost.

-

Margin: Suppliers will add a margin to their costs to ensure profitability. This margin can vary based on market demand, competition, and the perceived value of the product.

How Do Price Influencers Impact V-Belt Conveyor Costs?

Several factors can influence the pricing of v-belt conveyors, including:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically result in lower per-unit costs due to economies of scale. Buyers should negotiate MOQs to secure the best pricing.

-

Specifications and Customization: Custom specifications, such as size, material type, and additional features like v-guides, can lead to increased costs. Buyers should clearly communicate their requirements to avoid unexpected pricing.

-

Quality Certifications: Products that meet specific industry certifications (e.g., FDA for food-grade applications) may carry higher costs due to the additional compliance requirements.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their proven track record and quality assurance.

-

Incoterms: Understanding the Incoterms (International Commercial Terms) agreed upon can significantly affect overall costs, as they determine who is responsible for shipping, insurance, and tariffs.

What Are the Best Buyer Tips for Cost-Efficient Sourcing?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, here are strategic tips for effective sourcing:

-

Negotiate Terms: Always negotiate pricing and payment terms with suppliers. Consider bulk purchase discounts or extended payment terms to manage cash flow.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider maintenance, energy consumption, and potential downtime to assess the total cost of ownership.

-

Research Market Trends: Understanding regional market dynamics can provide leverage in negotiations. For instance, knowing peak demand times can help buyers negotiate better prices.

-

Focus on Quality and Reliability: Sometimes, opting for a slightly higher-priced conveyor that offers better quality and reliability can lead to substantial long-term savings.

-

Consider Local Suppliers: Sourcing locally can reduce logistics costs and tariffs. Local suppliers may also offer quicker turnaround times for service and support.

Disclaimer on Indicative Prices

Prices for v-belt conveyors can vary widely based on the factors discussed. It is essential for buyers to obtain quotes from multiple suppliers and conduct thorough market research to ensure competitive pricing. Always factor in the long-term implications of any purchasing decision to optimize your investment in conveyor systems.

Illustrative image related to v belt conveyor

Alternatives Analysis: Comparing v belt conveyor With Other Solutions

Understanding Alternatives to V-Belt Conveyors

In the landscape of material handling solutions, businesses often seek the most effective and efficient systems to meet their operational needs. V-belt conveyors are a popular choice due to their versatility and reliability. However, several alternative technologies can also achieve similar goals, each with its unique advantages and drawbacks. This analysis will explore these alternatives, helping B2B buyers make informed decisions.

Comparison Table

| Comparison Aspect | V Belt Conveyor | Modular Conveyor Systems | Roller Bed Conveyors |

|---|---|---|---|

| Performance | High load capacity; consistent tracking due to v-guides | Flexible configurations; can handle various product types | Efficient for heavy items; gravity-assisted options available |

| Cost | Moderate initial investment; ongoing maintenance costs | Higher upfront cost; lower maintenance due to modularity | Generally lower cost; minimal maintenance required |

| Ease of Implementation | Requires precise installation and alignment | Relatively easy to install; can be customized | Simple installation; often requires less space |

| Maintenance | Regular maintenance needed; potential wear on v-guides | Low maintenance; individual modules can be replaced easily | Low maintenance; durable components |

| Best Use Case | Long, narrow applications with inconsistent loads | Versatile applications; ideal for changing product lines | Heavy, bulk materials; high-speed transport |

In-Depth Analysis of Alternatives

What are Modular Conveyor Systems and Their Benefits?

Modular conveyor systems are designed with interlocking components that can be easily customized and adapted to fit different operational needs. Their flexibility allows for quick changes in layout or product type, making them ideal for environments where production requirements frequently shift. The downside, however, is the higher initial investment compared to V-belt conveyors. Despite this, the reduced maintenance needs and the ability to adapt to varying loads make modular systems a compelling choice for many businesses.

How Do Roller Bed Conveyors Compare?

Roller bed conveyors utilize a series of rollers to move products along a flat surface. They are particularly effective for transporting heavy items, as they can leverage gravity in inclined applications, reducing the need for powered systems. The simplicity of installation and the generally lower costs associated with roller bed conveyors make them an attractive option for many operations. However, they may not provide the same level of tracking precision as V-belt conveyors, which could lead to issues with product misalignment in certain scenarios.

Conclusion: Choosing the Right Conveyor Solution

When selecting a conveyor system, B2B buyers should consider their specific operational requirements, such as load type, space constraints, and maintenance capabilities. While V-belt conveyors excel in tracking and load management, alternatives like modular systems and roller bed conveyors offer unique benefits that might better suit particular applications. Understanding the strengths and weaknesses of each option will empower businesses to make strategic choices that enhance productivity and efficiency in their operations.

Illustrative image related to v belt conveyor

Essential Technical Properties and Trade Terminology for v belt conveyor

What Are the Key Technical Properties of V-Belt Conveyors?

Understanding the technical specifications of v-belt conveyors is crucial for B2B buyers. Here are some essential properties to consider:

1. Material Grade

The material grade of a v-belt conveyor determines its durability and resistance to wear. Common materials include PVC, PU (polyurethane), and rubber. PVC belts are often used for light-duty applications due to their cost-effectiveness, while PU belts offer better abrasion resistance and are suitable for food handling. Choosing the right material can significantly affect the lifespan of the conveyor and the quality of the transported goods.

2. Belt Width and Length

Belt dimensions are critical for ensuring compatibility with existing systems. The width affects load capacity and stability, while length is vital for fitting into the available space. Custom sizing may be necessary for specific applications, particularly in industries with unique material handling needs. Accurate measurements help prevent operational inefficiencies and minimize downtime.

3. Tolerance and Tension Specifications

Tolerance refers to the allowable deviation in the dimensions of the conveyor belt. Precise tolerances are essential for ensuring proper alignment and function, reducing the risk of tracking issues. Additionally, tension specifications help determine the appropriate force required to drive the belt effectively. This is particularly important in high-load applications to maintain efficiency and prevent premature wear.

4. V-Guide Configuration

V-guides are integral to maintaining belt tracking, especially in applications with long and narrow belts. The configuration, including the number and placement of v-guides, can significantly influence the belt’s stability and wear. Buyers should consider their specific application requirements when selecting v-guide options to ensure optimal performance and longevity.

5. Load Capacity

The load capacity of a v-belt conveyor is determined by its design, material, and dimensions. This specification is crucial for ensuring that the conveyor can handle the intended material without risk of failure. Buyers must assess their operational requirements carefully to select a conveyor that meets or exceeds their load demands.

6. Temperature and Chemical Resistance

Different applications may expose v-belt conveyors to varying temperatures and chemicals. For instance, food processing environments require materials that can withstand cleaning agents without degrading. Understanding the chemical and thermal tolerances of the conveyor belt material is essential for maintaining operational efficiency and safety.

What Are Common Trade Terms Associated with V-Belt Conveyors?

Familiarity with industry jargon helps streamline communication and negotiations. Here are some key terms relevant to v-belt conveyors:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of v-belt conveyors, OEMs provide specific components like pulleys or belts tailored to fit particular systems, ensuring compatibility and performance.

Illustrative image related to v belt conveyor

2. MOQ (Minimum Order Quantity)

MOQ represents the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers, as it can impact purchasing decisions, especially for small businesses or those with limited budgets.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and terms for specific products. In the v-belt conveyor market, submitting an RFQ can help buyers gather multiple quotes, enabling informed decision-making based on cost, delivery time, and quality.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Knowing these terms helps B2B buyers understand shipping costs, risk, and insurance requirements, which are crucial for budgeting and logistics planning.

Illustrative image related to v belt conveyor

5. Lead Time

Lead time refers to the amount of time from placing an order until the product is delivered. This metric is vital for B2B buyers to manage their supply chains effectively, particularly in industries where timing is critical for production schedules.

6. Custom Fabrication

Custom fabrication involves modifying standard products to meet specific customer requirements. For v-belt conveyors, this may include altering dimensions, adding features like v-guides, or using specialized materials. Understanding this term allows buyers to explore tailored solutions that enhance operational efficiency.

By grasping these technical properties and industry terms, B2B buyers can make more informed decisions when sourcing v-belt conveyors, ensuring they select solutions that meet their unique operational needs.

Navigating Market Dynamics and Sourcing Trends in the v belt conveyor Sector

What Are the Key Market Dynamics and Trends Affecting the V-Belt Conveyor Sector?

The global v-belt conveyor market is currently experiencing significant shifts driven by technological advancements, growing automation, and an increasing emphasis on efficiency. Key drivers include the rapid adoption of Industry 4.0 practices and smart manufacturing, which prioritize automation and real-time data analytics. For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial. Countries like Saudi Arabia and Vietnam are witnessing a surge in infrastructure development, which, coupled with the demand for reliable material handling solutions, has led to an increased focus on sourcing high-quality v-belt conveyors.

Emerging trends include the integration of IoT-enabled conveyor systems that offer predictive maintenance capabilities. This technology can help businesses reduce downtime and optimize their supply chains, making it essential for international buyers to consider suppliers that offer these advanced features. Additionally, sustainability is becoming a critical factor in sourcing decisions, with companies seeking partners that prioritize eco-friendly materials and manufacturing processes.

Illustrative image related to v belt conveyor

Another notable trend is the customization of v-belt conveyors to meet specific industry needs. For instance, sectors such as food processing and pharmaceuticals require belts that comply with strict hygiene standards. Suppliers that can provide tailored solutions with certifications are likely to stand out in the competitive landscape, making them attractive to discerning B2B buyers.

How Can Sustainability and Ethical Sourcing Impact Your V-Belt Conveyor Purchases?

The environmental impact of manufacturing and sourcing v-belt conveyors cannot be overlooked, especially as global attention shifts toward sustainability. B2B buyers are increasingly demanding suppliers who prioritize ethical sourcing and sustainable practices. This includes using recyclable materials, reducing carbon footprints, and adhering to international environmental standards.

In addition to being environmentally responsible, ethical supply chains enhance brand reputation and foster trust with customers. Buyers should look for suppliers that possess certifications such as ISO 14001, which indicates a commitment to effective environmental management systems. Furthermore, opting for v-belt conveyors made from recycled or eco-friendly materials not only reduces environmental impact but can also lead to cost savings in the long run.

Sustainable sourcing is particularly vital for buyers in regions like Africa and South America, where environmental regulations are becoming more stringent. By choosing suppliers that embrace sustainability, businesses can not only comply with these regulations but also contribute positively to their communities and ecosystems, ultimately driving long-term growth and profitability.

What Is the Historical Context of V-Belt Conveyors in the B2B Sector?

The evolution of v-belt conveyors can be traced back to the early 20th century when they were first introduced as a means to streamline material handling processes in manufacturing settings. Initially, these systems were rudimentary, primarily relying on mechanical components to facilitate the movement of goods. However, as industries grew and technological advancements were made, v-belt conveyors became more sophisticated.

By the latter half of the century, innovations in materials and design led to the development of more durable and efficient belts, capable of handling a diverse range of products. Today, v-belt conveyors are integral to various sectors, including food processing, automotive, and pharmaceuticals, adapting to the specific needs of each industry. This historical context underscores the importance of selecting suppliers who not only understand the legacy of these systems but also remain at the forefront of technological advancements and market trends.

Understanding these facets of the v-belt conveyor market enables international B2B buyers to make informed sourcing decisions that align with their operational needs and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of v belt conveyor

-

How do I solve tracking issues with my v belt conveyor?

Tracking issues often arise due to misalignment or improper belt design. To solve this, first ensure that the conveyor frame is square and that all pulleys are aligned. Incorporating v-guides into your conveyor belt can significantly improve tracking by providing additional lateral support and guiding the belt along the intended path. Regular maintenance and adjustments, including checking for wear and ensuring proper tension, will also help maintain optimal tracking performance. -

What is the best v belt conveyor for heavy-duty applications?

For heavy-duty applications, selecting a v belt conveyor with reinforced construction is crucial. Look for belts made from high-strength materials such as polyurethane or rubber, which offer durability and resistance to wear. Additionally, consider options with v-guides for improved tracking and stability. It’s essential to evaluate load capacity, belt width, and the specific environmental conditions of your application to ensure optimal performance and longevity. -

How can I customize my v belt conveyor to fit specific needs?

Customization options for v belt conveyors are extensive. You can specify the belt material, width, length, and thickness based on your application requirements. Additionally, v-guides can be positioned and sized according to the unique dimensions of your equipment and operational needs. Collaborate with your supplier early in the design process to ensure that all specifications align with your operational goals and to explore any additional features that could enhance performance. -

What are the minimum order quantities (MOQs) for v belt conveyors?

Minimum order quantities (MOQs) for v belt conveyors can vary significantly based on the manufacturer and the complexity of the customization required. Standard products may have lower MOQs, while specialized or customized belts may require larger orders to justify production costs. It’s advisable to discuss your needs with suppliers to determine their specific MOQs and explore options for bulk purchasing or potential discounts based on order size. -

What payment terms are typically offered for international orders?

Payment terms for international orders can range from upfront payments to net 30 or net 60 days, depending on the supplier’s policies and the buyer’s creditworthiness. Common methods include wire transfers, letters of credit, and trade financing options. Always negotiate payment terms that suit your cash flow while ensuring they are favorable enough for the supplier to accept. Be sure to clarify any additional costs, such as tariffs or shipping fees, that could affect the total price. -

How do I vet suppliers for v belt conveyors effectively?

Vetting suppliers involves several key steps. Begin by researching their reputation in the industry through reviews and testimonials from other B2B buyers. Request references and inquire about their experience in your specific sector. Evaluate their manufacturing capabilities, quality assurance processes, and compliance with international standards. Lastly, consider their responsiveness and customer service, as these factors can significantly impact your overall experience and satisfaction. -

What quality assurance measures should I expect from v belt conveyor manufacturers?

Reputable v belt conveyor manufacturers should implement rigorous quality assurance measures, including material testing, dimensional inspections, and performance evaluations. Look for certifications such as ISO 9001, which indicates adherence to quality management standards. Additionally, inquire about their warranty policies and return procedures, as these reflect their commitment to delivering high-quality products. Regular audits and compliance checks can further ensure that the products meet required specifications. -

What logistics considerations should I keep in mind when sourcing v belt conveyors internationally?

When sourcing v belt conveyors internationally, consider logistics aspects such as shipping methods, lead times, and customs regulations. Choose a reliable freight forwarder familiar with the regulations of your destination country to avoid delays. Additionally, account for potential tariffs and duties that may impact overall costs. Effective communication with your supplier regarding shipping schedules and tracking can help ensure timely delivery and mitigate any unexpected challenges during transit.

Top 8 V Belt Conveyor Manufacturers & Suppliers List

1. Belt Power – V-Guide Conveyor Belts

Domain: beltpower.com

Registered: 1998 (27 years)

Introduction: V-Guide Conveyor Belts are designed with v-shaped profiles that can be vulcanized or welded onto the underside or topside of the conveyor belt. They provide additional tracking support, preventing miss-tracks and improving load distribution. Ideal for long and narrow or short and wide belts, v-guides enhance tracking consistency, extend belt life, and reduce wear on edges, leading to fewer failure…

2. Honeywell – Advanced Transportation Conveyor Systems

Domain: automation.honeywell.com

Registered: 1988 (37 years)

Introduction: Honeywell offers advanced transportation conveyor systems designed for high-throughput transportation of various product sizes, shapes, and packaging. Key features include: 1. **Belt Conveyor**: Effective for horizontal, inclined, or declined applications; high speeds; gentle handling; easy maintenance. 2. **Brake Meter Belt**: Low maintenance; controls merge releases; consistent gaps; optimized f…

3. Inpaksystems – V-Belt Bag Closing Conveyors

Domain: inpaksystems.com

Registered: 1999 (26 years)

Introduction: V-Belt Bag Closing Conveyors are designed to keep bags upright while feeding through a heat sealer or bag sewing system. They are positioned between the bag filler and the bag closer and are suitable for inherently unstable bags that may fall over on flat belt conveyors. Typically, these conveyors are 12 inches wide and 10-12 feet long, operating at speeds of 35-55 feet per minute. They have a hea…

4. Hud-Son – 32′ Belt Conveyor

Domain: hud-son.com

Registered: 1998 (27 years)

Introduction: {“name”: “32′ Belt Conveyor”, “type”: “Belt Conveyor”, “length”: “32′”, “width”: “18””, “frame”: “2×4 tube frame”, “motor”: “3.5 HP”, “drive_system”: “V-belt drive system”, “optional_drive_system”: “hydraulic drive system”, “slide_rails”: “hardwood slide rails”, “maximum_height”: “14′”, “recommended_use”: “firewood processor”, “price”: “$10,795.00”}

5. Dura-Belt – Poly-V Conveyor Belts

Domain: russellconveyor.com

Registered: 2015 (10 years)

Introduction: {“Product Name”: “Poly-V Conveyor Belts”, “Brand”: “Dura-Belt”, “SKU”: “RC13”, “Price Range”: “$3.44 – $14.16”, “Load Capacity”: “Up to 1,000 lbs”, “Construction”: “Rubber with nylon reinforcement”, “Design”: “Ribbed Poly-V style for increased grip and torque capacity”, “Temperature Range”: “-22°F to 176°F”, “Chemical Resistance”: “Water, alcohol, alkali (up to pH 10)”, “Not Recommended For”: “Aci…

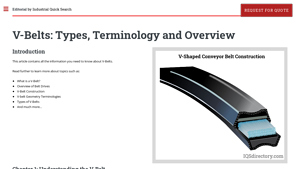

6. IQS Directory – V-Belts

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: V-Belts are crucial components for power transmission between shafts, featuring a trapezoidal shape that ensures a secure fit within sheaves. They are made from synthetic and natural rubber, providing flexibility and resilience. V-belts improve torque transfer and minimize power losses due to slippage, with enhanced load handling capabilities. Some types include additional cogs for increased resis…

7. Norpak – V-Belt Conveyor

Domain: norpak.com

Registered: 1997 (28 years)

Introduction: V-belt conveyor employs a trapezoidal, v-shaped belt that fits easily into the frame or sheaves, increasing traction. It is suitable for operations requiring compactness, minimal slippage, longer lifespan (3 to 5 years), easy installation, and quiet operation.

8. Optibelt – Conveyor Power V-Belts

Domain: optibelt.com

Registered: 1999 (26 years)

Introduction: Optibelt Conveyor Power V-Belts are engineered specifically for powered roller conveyors, suitable for both linear and curved applications. Key features include:

– Profile sizes and length range: B 69-675 inches.

– High Flex Cord: Reduces heat and flex fatigue for increased durability.

– Rubber Compound: Flexes for curved conveyor applications.

– Temperature Range: -22°F to 158°F.

– Available Size…

Strategic Sourcing Conclusion and Outlook for v belt conveyor

In navigating the complexities of v-belt conveyor sourcing, international B2B buyers must prioritize strategic partnerships and quality materials to enhance operational efficiency. As highlighted, v-guide conveyor belts provide significant advantages, including improved tracking and extended lifespan, which are crucial for minimizing downtime and maximizing productivity. Understanding the diverse applications across industries—from food processing to pharmaceuticals—can empower buyers to make informed decisions tailored to their specific needs.

The importance of strategic sourcing cannot be overstated; it enables companies to leverage supplier relationships, negotiate better terms, and ensure compliance with international standards. As markets in Africa, South America, the Middle East, and Europe continue to evolve, staying attuned to innovations in conveyor technology will be vital for maintaining competitive advantage.

Looking ahead, the demand for efficient material handling solutions will only grow. We encourage buyers to explore partnerships with reputable suppliers who can offer customized solutions and support. By investing in high-quality v-belt conveyor systems, businesses can enhance their operational resilience and position themselves for future growth in an increasingly interconnected global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.