Top 8 Tyo Bevel Gears Suppliers (And How to Choose)

Introduction: Navigating the Global Market for tyo bevel gears

In today’s dynamic industrial landscape, sourcing tyo bevel gears can present significant challenges for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. The complexity of selecting the right bevel gears—ranging from straight to spiral types—along with the need for precise specifications and dependable suppliers can make the purchasing process daunting. This guide is designed to equip you with the knowledge and insights necessary to navigate these challenges effectively.

Throughout this comprehensive resource, we will delve into the various types of bevel gears available, their applications across different industries, and the critical factors to consider when vetting suppliers. We will also address cost considerations, ensuring that you can make informed decisions that align with your operational budgets and project requirements. By understanding the nuances of bevel gear selection and procurement, you will be empowered to enhance your supply chain efficiency and reduce downtime in your operations.

Whether you’re based in Brazil, Nigeria, or elsewhere, this guide serves as your essential tool for making strategic purchasing decisions in the global market for tyo bevel gears. With actionable insights and expert advice, you can streamline your sourcing process, mitigate risks, and ultimately drive greater value for your business.

Understanding tyo bevel gears Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Straight Bevel Gears | Teeth are straight and point toward the apex of the cone. | Machine tools, printing machines | Pros: Simpler manufacturing, no inward thrust. Cons: Limited precision, not suitable for high forces. |

| Spiral Bevel Gears | Curved teeth that allow smooth engagement and high precision. | Automotive differentials, aerospace | Pros: High precision, can be ground after heat treatment. Cons: More complex to manufacture, higher cost. |

| Hypoid Gears | Offset axes with curved teeth, enabling higher speed ratios. | Heavy machinery, automotive | Pros: High torque capacity, smooth operation. Cons: More expensive, requires precise installation. |

| Miter Gears | Special type of bevel gear with equal angles, typically 45°. | Robotics, conveyors | Pros: Simple design, efficient for right-angle turns. Cons: Limited speed and load capacity. |

| Crown Gears | Large pitch angle, resembling a rack. | Marine applications, heavy machinery | Pros: Effective for low-speed applications, easy to manufacture. Cons: Less efficient at high speeds. |

What are the Characteristics of Straight Bevel Gears?

Straight bevel gears are characterized by their straight teeth, which align directly toward the apex of the cone. This design makes them simpler to manufacture, and they do not produce inward thrust, which can simplify bearing design. However, their inability to undergo grinding after heat treatment limits their precision, making them suitable primarily for low-speed applications such as machine tools and printing machinery. When purchasing, buyers should consider the operational speed and load requirements to ensure compatibility.

How Do Spiral Bevel Gears Differ from Other Types?

Spiral bevel gears feature curved teeth that provide a gradual engagement, enhancing smoothness and reducing noise during operation. They are widely used in applications requiring high precision, such as automotive differentials and aerospace systems. While they can be ground after heat treatment for better accuracy, this complexity increases manufacturing costs. Buyers should weigh the benefits of precision against budget constraints and application requirements when selecting spiral bevel gears.

What Makes Hypoid Gears Unique?

Hypoid gears are distinguished by their offset axes and curved teeth, allowing for higher speed ratios and improved torque handling. They are commonly found in heavy machinery and automotive applications due to their ability to transmit power efficiently. However, their installation requires precision, and they tend to be more expensive than other bevel gear types. Buyers should assess the specific torque and speed requirements of their applications to determine if hypoid gears are the right fit.

What are the Applications of Miter Gears?

Miter gears, with their equal pitch angles—often set at 45°—are designed for efficient right-angle power transmission. They are particularly useful in robotics and conveyor systems where space constraints and directional changes are prevalent. Their straightforward design allows for easy installation, but their capacity for speed and load is limited compared to other bevel gear types. Buyers should consider the operational requirements to ensure that miter gears meet their application needs.

Why Choose Crown Gears for Specific Applications?

Crown gears, known for their large pitch angles, are particularly effective in low-speed applications and are often used in marine and heavy machinery. Their design resembles a rack, which makes them easier to manufacture. However, they are less efficient at higher speeds and may not be suitable for applications requiring high torque. Buyers should evaluate the speed and load conditions of their specific use cases to determine the appropriateness of crown gears.

Key Industrial Applications of tyo bevel gears

| Industry/Sector | Specific Application of tyo bevel gears | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | CNC Machinery Drive Systems | Enhanced precision and efficiency in machining processes | Material quality, precision specifications, and lead times |

| Automotive | Differential Gear Systems | Improved torque distribution and vehicle performance | Load capacity, noise reduction, and compatibility |

| Renewable Energy | Wind Turbine Gearboxes | Increased reliability and energy conversion efficiency | Corrosion resistance, weight considerations, and durability |

| Mining and Construction | Heavy Equipment Gear Drives | Enhanced durability under extreme conditions | Load ratings, maintenance requirements, and sourcing locally |

| Food and Beverage Processing | Conveyor Systems | Smooth operation and reduced wear in food handling | Hygiene compliance, material certifications, and cost |

How are tyo bevel gears utilized in manufacturing, particularly in CNC machinery?

In the manufacturing sector, tyo bevel gears are integral to CNC machinery drive systems. These gears enable the precise transmission of power between intersecting shafts, essential for maintaining the accuracy of machining operations. By facilitating smoother motion, bevel gears minimize vibrations and wear, extending the lifespan of machinery. Buyers in this sector should prioritize sourcing gears made from high-quality materials, ensuring they meet specific precision standards to maintain operational efficiency.

What role do tyo bevel gears play in automotive applications, especially in differential systems?

In the automotive industry, tyo bevel gears are crucial for differential gear systems, which distribute torque to the wheels while allowing for differences in wheel speed during turns. This functionality enhances vehicle performance and stability, particularly in high-torque applications. For international buyers, it is vital to consider factors like load capacity, noise reduction, and compatibility with existing systems, ensuring the selected gears can withstand the rigors of diverse driving conditions.

How do tyo bevel gears contribute to the efficiency of renewable energy systems like wind turbines?

Within the renewable energy sector, tyo bevel gears are used in wind turbine gearboxes to effectively convert and transmit mechanical energy generated by wind. The reliability and efficiency of these gears directly impact energy conversion rates, making them vital for maximizing output. Buyers should focus on sourcing gears that offer corrosion resistance and durability, as these components face harsh environmental conditions. Additionally, weight considerations can influence the overall design and efficiency of the turbine.

What benefits do tyo bevel gears provide in mining and construction equipment?

In mining and construction, tyo bevel gears are employed in heavy equipment gear drives, where they must endure extreme loads and harsh operating conditions. The durability and strength of these gears are critical for ensuring the reliability of equipment such as excavators and loaders. Buyers should assess load ratings, maintenance requirements, and the feasibility of sourcing locally to mitigate supply chain risks while ensuring gear longevity.

How are tyo bevel gears essential in food and beverage processing applications?

In the food and beverage processing industry, tyo bevel gears are utilized in conveyor systems, where they facilitate smooth operation and reduce wear during food handling. The hygiene compliance of these gears is paramount to ensure food safety. Buyers should prioritize materials that meet health standards and certifications while also considering cost-effectiveness to maintain competitive pricing in a demanding market.

3 Common User Pain Points for ‘tyo bevel gears’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Bevel Gear Type

The Problem: B2B buyers often struggle to choose the appropriate bevel gear type due to the diverse range of applications and specifications available. With options like straight bevel gears and spiral bevel gears, understanding which type best meets operational needs can be overwhelming. This confusion can lead to costly errors, including purchasing incompatible gears that affect machinery performance and increase maintenance costs.

The Solution: To effectively navigate gear selection, buyers should first assess their specific application requirements, such as load capacity, speed, and installation constraints. Utilizing a systematic approach, buyers can create a checklist that includes operational parameters, the environment in which the gears will be used, and any specific regulatory standards that must be met. Engaging with a reputable supplier that offers a comprehensive catalog of bevel gears can also provide valuable insights. Suppliers often have selection tools or knowledgeable staff who can assist in identifying the most suitable gear type based on the gathered criteria. Additionally, consulting technical datasheets and leveraging CAD models can ensure that the selected bevel gear aligns with the intended application.

Scenario 2: Challenges in Ensuring Gear Durability and Performance

The Problem: Many B2B buyers face issues related to the durability and performance of bevel gears in demanding environments. Factors such as high loads, extreme temperatures, or exposure to corrosive substances can lead to premature gear failure, resulting in costly downtimes and repairs. Buyers may find it difficult to determine which materials and treatments will yield the best performance under their specific conditions.

The Solution: To ensure longevity and reliability, buyers should prioritize sourcing bevel gears made from high-quality materials suited for their operational environment. For instance, gears made from SCM415 alloy steel are known for their strength and resistance to wear, making them ideal for heavy-duty applications. It is also advisable to consider gears that undergo advanced manufacturing processes, such as carburizing or surface hardening, to enhance their performance. Buyers should actively communicate their operating conditions to suppliers, who can recommend the best material and treatment options based on real-world use cases. Furthermore, implementing regular maintenance checks and monitoring gear performance can preemptively identify wear and tear, allowing for timely replacements before total failure occurs.

Scenario 3: Complications with Gear Alignment and Installation

The Problem: Misalignment during the installation of bevel gears is a common challenge that can lead to inefficiencies, excessive wear, and noise. B2B buyers may find it challenging to achieve precise alignment, especially in complex machinery setups where space constraints are present. This issue can not only affect performance but can also diminish the lifespan of the gears and related components.

The Solution: To mitigate alignment issues, buyers should invest in alignment tools such as laser alignment systems or dial indicators that ensure precise positioning during installation. Prior to installation, it’s crucial to review the manufacturer’s guidelines regarding mounting surfaces and tolerance specifications. Engaging experienced technicians or engineers who specialize in gear installation can also significantly reduce the risk of misalignment. Additionally, it may be beneficial to conduct training sessions for maintenance staff on best practices for gear installation and alignment techniques. By emphasizing the importance of precise installation, companies can enhance the operational efficiency of their gear systems and prolong the lifespan of their bevel gears.

Strategic Material Selection Guide for tyo bevel gears

What Are the Key Properties of Common Materials Used for tyo Bevel Gears?

When selecting materials for tyo bevel gears, it’s crucial to consider their mechanical properties, durability, and suitability for specific applications. Below, we analyze four common materials: carbon steel, alloy steel, stainless steel, and engineering plastics.

Carbon Steel (e.g., S45C)

Key Properties:

Carbon steel, particularly S45C, is known for its good tensile strength and hardness after heat treatment. It has a moderate temperature rating and can withstand pressures typical in mechanical applications.

Pros & Cons:

The advantages of carbon steel include its cost-effectiveness and ease of manufacturing, making it suitable for mass production. However, it has lower corrosion resistance compared to stainless steel, which can limit its use in humid or corrosive environments.

Impact on Application:

Carbon steel bevel gears are commonly used in machinery that operates in dry conditions. However, their susceptibility to rust means they may not be ideal for applications involving exposure to moisture or chemicals.

Illustrative image related to tyo bevel gears

Considerations for International Buyers:

Buyers from regions like Africa and South America should ensure compliance with local standards, such as ASTM or JIS, when sourcing carbon steel gears. Understanding the local climate and its impact on material performance is also essential.

Alloy Steel (e.g., SCM415)

Key Properties:

Alloy steel, particularly SCM415, offers enhanced strength, toughness, and wear resistance. It can maintain performance under higher temperatures and pressures than standard carbon steels.

Pros & Cons:

The key advantage of alloy steel is its durability and ability to withstand heavy loads, making it suitable for demanding applications. The downside is its higher cost and more complex manufacturing processes, which can lead to increased lead times.

Impact on Application:

Alloy steel bevel gears are preferred in high-stress environments, such as automotive and aerospace applications. They provide reliable performance under extreme conditions but require careful consideration of lubrication and maintenance.

Considerations for International Buyers:

Buyers should verify that the alloy steel meets international standards, such as DIN or ASTM, particularly when exporting to Europe or the Middle East. Additionally, understanding the local supply chain for alloy materials can impact delivery times.

Illustrative image related to tyo bevel gears

Stainless Steel (e.g., SUS303)

Key Properties:

Stainless steel, like SUS303, is renowned for its excellent corrosion resistance, making it suitable for applications exposed to moisture or chemicals. It also offers good strength and machinability.

Pros & Cons:

The primary advantage of stainless steel is its longevity and resistance to rust, which reduces maintenance costs over time. However, it is generally more expensive than carbon and alloy steels, which may impact budget considerations.

Impact on Application:

These bevel gears are ideal for food processing, marine, and chemical industries where hygiene and corrosion resistance are critical. While they perform well in wet environments, their higher cost may not be justified in low-stress applications.

Considerations for International Buyers:

International buyers should ensure compliance with food safety and environmental standards, particularly in the food and beverage industry. Understanding local regulations regarding stainless steel grades is also vital.

Engineering Plastics (e.g., MC901)

Key Properties:

Engineering plastics, such as MC901, are lightweight and offer good chemical resistance. They can operate effectively at lower temperatures and pressures compared to metals.

Pros & Cons:

The advantages of using engineering plastics include their low weight and noise-dampening properties, making them suitable for applications where sound reduction is crucial. However, they generally have lower strength and wear resistance compared to metals, which limits their use in high-load applications.

Impact on Application:

Plastic bevel gears are often used in consumer electronics and light machinery where weight and noise are significant factors. However, they may not be suitable for heavy-duty applications.

Considerations for International Buyers:

Buyers should check for compliance with local material standards and ensure that the selected plastic can withstand the operational conditions of their specific applications.

Summary Table of Material Selection for tyo Bevel Gears

| Material | Typical Use Case for tyo bevel gears | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | General machinery in dry environments | Cost-effective and easy to manufacture | Lower corrosion resistance | Low |

| Alloy Steel | High-stress applications (automotive, aerospace) | Enhanced strength and durability | Higher cost and complex manufacturing | Medium |

| Stainless Steel | Food processing, marine, and chemical industries | Excellent corrosion resistance | Higher cost than carbon/alloy steels | High |

| Engineering Plastics | Consumer electronics, light machinery | Lightweight and noise-dampening | Lower strength and wear resistance | Medium |

This material selection guide provides essential insights for international B2B buyers, helping them make informed decisions based on application requirements, cost considerations, and compliance with local standards.

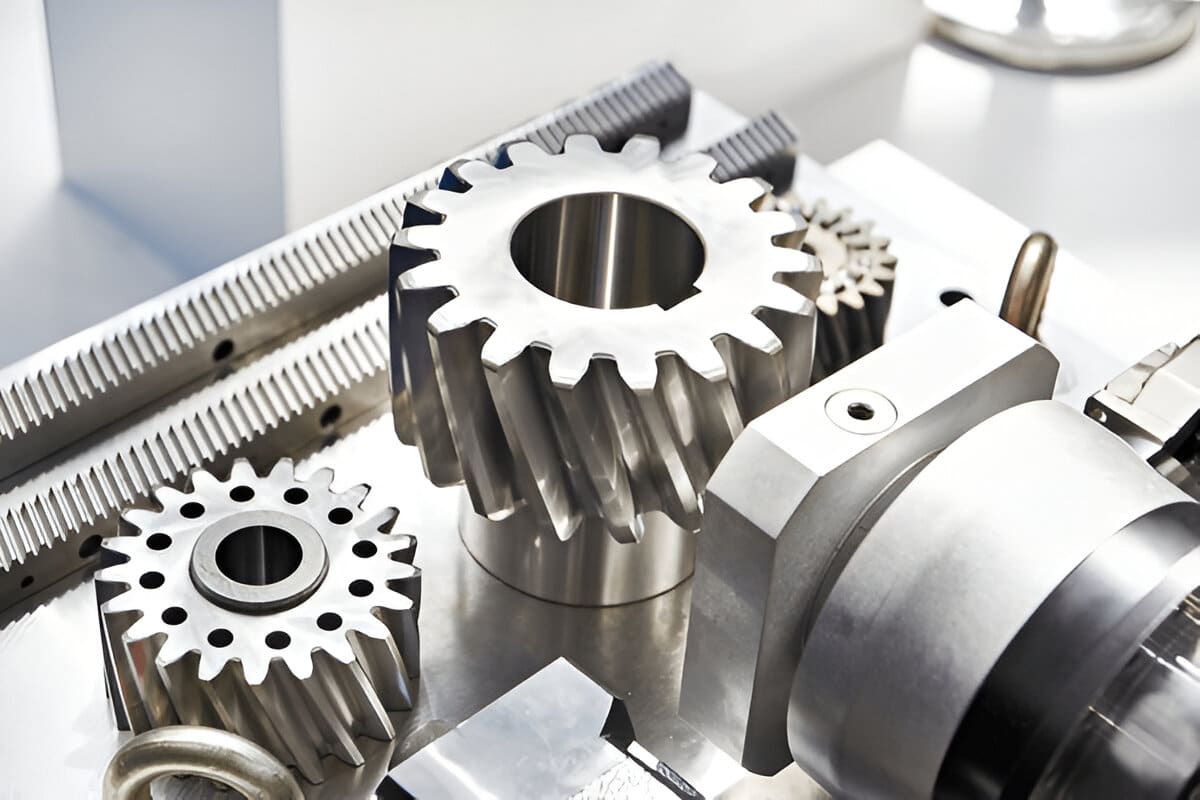

In-depth Look: Manufacturing Processes and Quality Assurance for tyo bevel gears

What Are the Key Stages in the Manufacturing Process of Tyo Bevel Gears?

The manufacturing of tyo bevel gears involves several critical stages that ensure precision and quality. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Tyo Bevel Gears?

The first step in manufacturing tyo bevel gears is material preparation. Common materials used include carbon steel, alloy steel, and engineering plastics. For steel gears, S45C and SCM415 are popular choices due to their strength and machinability. The selected material is cut into appropriate sizes and shapes, which may involve processes like shearing or sawing.

Material quality is paramount; therefore, incoming materials undergo inspection to ensure they meet specified standards. This initial quality control (IQC) step is crucial for preventing defects in the final product.

What Forming Techniques Are Used in Tyo Bevel Gear Production?

After preparing the materials, the next stage is forming, which involves shaping the gear teeth. This process can be accomplished using various techniques, including:

-

Gleason Method: This is the most widely used technique for producing bevel gears. It allows for precise tooth profiles and is particularly advantageous for spiral bevel gears due to its ability to accommodate complex geometries.

-

Klingelnberg Method: Although less common, this method is also used, especially in Europe. It offers unique tooth designs that can optimize performance in specific applications.

-

Hobbing and Shaping: For straight bevel gears, hobbing or shaping can be employed to cut the teeth. These processes are generally faster but may not achieve the same level of precision as the Gleason method.

-

Grinding: After initial forming, gears may undergo grinding to enhance tooth accuracy and surface finish, particularly for high-precision applications.

What Is Involved in the Assembly and Finishing Stages?

The assembly stage involves aligning and securing the gear components, including shafts and housings. This step is vital for ensuring the proper functioning of the gear system.

Finishing processes may include heat treatment, which enhances the hardness and wear resistance of the gears. Techniques like carburizing and induction hardening are common. Finally, polishing or coating may be applied to improve surface properties, reduce friction, and enhance corrosion resistance.

Illustrative image related to tyo bevel gears

How Is Quality Assurance Implemented in Tyo Bevel Gear Manufacturing?

Quality assurance is a critical aspect of manufacturing tyo bevel gears. Manufacturers typically adhere to international standards, such as ISO 9001, to ensure consistent quality and customer satisfaction.

What Are the International Standards Relevant to Tyo Bevel Gear Manufacturing?

ISO 9001 establishes a framework for quality management systems that manufacturers must follow. Compliance with this standard involves regular audits, documentation of processes, and continuous improvement initiatives. In addition to ISO standards, industry-specific certifications like CE and API may also be relevant, depending on the application of the gears.

What Quality Control Checkpoints Are Common in the Manufacturing Process?

Quality control (QC) is integrated at various checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet the required specifications.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to monitor the production process and catch any deviations from quality standards.

-

Final Quality Control (FQC): Once the bevel gears are completed, final inspections are performed to verify the dimensions, surface finish, and overall quality of the product.

Which Testing Methods Are Commonly Used for Tyo Bevel Gears?

Various testing methods are employed to ensure the performance and reliability of tyo bevel gears:

-

Dimensional Inspection: Using precision measuring tools like calipers and micrometers, manufacturers check the gear dimensions against design specifications.

-

Hardness Testing: Techniques such as Rockwell or Brinell hardness tests assess the material properties of the gears.

-

Load Testing: This method evaluates how gears perform under operational loads, ensuring they can withstand the stresses of real-world applications.

-

Noise and Vibration Analysis: For applications where noise reduction is critical, testing for operational noise and vibrations helps ensure that the gears function smoothly.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers must take proactive measures to verify the quality control processes of their suppliers. Here are some strategies to consider:

What Steps Can Buyers Take to Conduct Supplier Audits?

Conducting supplier audits is an effective way to assess a manufacturer’s quality control systems. Buyers should establish a checklist that includes:

Illustrative image related to tyo bevel gears

- Compliance with ISO and industry-specific standards.

- The presence of documented quality management processes.

- Evidence of regular training for staff involved in production and quality assurance.

How Can Buyers Request Quality Reports and Third-Party Inspections?

Buyers should request quality reports that document the results of various tests performed on the bevel gears. Additionally, engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control processes. This can be particularly beneficial for international transactions where direct oversight may be challenging.

What Are the Quality Control Nuances for International B2B Buyers?

For international B2B buyers, understanding the nuances of quality control is essential. Different regions may have varying standards and expectations, which can impact the procurement process. Buyers from Africa, South America, the Middle East, and Europe should consider:

-

Regulatory Compliance: Ensure that suppliers comply with local regulations and international standards relevant to their market.

-

Cultural Considerations: Be aware of cultural differences that may affect communication and expectations regarding quality and delivery timelines.

-

Supply Chain Transparency: Seek suppliers that provide transparent information about their sourcing and manufacturing processes, as this can significantly affect the quality of the final product.

By understanding the manufacturing processes and quality assurance measures for tyo bevel gears, B2B buyers can make informed decisions, ensuring they procure high-quality components that meet their operational requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘tyo bevel gears’

Introduction

This sourcing guide aims to equip B2B buyers with actionable steps for procuring high-quality ‘tyo bevel gears’. Given the critical role these components play in various mechanical applications, it’s essential to approach the sourcing process methodically to ensure compatibility, reliability, and cost-effectiveness.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the bevel gears you need. This includes specifications such as gear type (straight or spiral), material (steel, stainless steel, or plastic), and specific dimensions (module size and pitch angle). Understanding your exact needs will streamline the sourcing process and help avoid compatibility issues later.

- Consider application requirements: Identify the load capacity, speed ratios, and environmental conditions (e.g., humidity, temperature) your bevel gears will face.

- Document tolerances and finishes: Specify acceptable tolerances and any surface finish requirements that may impact performance or longevity.

Step 2: Research Potential Suppliers

Start by identifying suppliers who specialize in bevel gears. Conduct thorough research to compile a list of candidates, focusing on those with a solid reputation in the industry.

- Utilize trade directories and online marketplaces: Platforms like Alibaba or ThomasNet can provide insights into various suppliers and their offerings.

- Seek recommendations: Leverage industry contacts or forums to find suppliers with proven track records in your region, especially if you are operating in Africa, South America, or the Middle East.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold relevant certifications that demonstrate quality and compliance with international standards. This step is crucial in ensuring that the bevel gears you procure will meet safety and performance expectations.

- Check ISO certifications: Look for ISO 9001 or similar quality management certifications, which indicate a commitment to quality control.

- Review industry-specific standards: Depending on your sector, certifications like AS9100 (aerospace) or API (oil and gas) may also be relevant.

Step 4: Request Samples and Technical Data

Before making a large order, request samples of the bevel gears along with detailed technical data sheets. This allows you to assess the quality and compatibility of the components with your machinery.

Illustrative image related to tyo bevel gears

- Test for fit and performance: Conduct trials to ensure that the samples meet your operational requirements and perform under expected conditions.

- Review material specifications: Ensure that the materials used align with your initial specifications, especially for critical applications where failure could have severe consequences.

Step 5: Analyze Pricing and Payment Terms

Once you have shortlisted suppliers, compare pricing and payment terms. This analysis should go beyond just looking for the lowest price; consider the overall value offered.

- Inquire about volume discounts: Many suppliers provide better rates for bulk purchases, which can significantly reduce your costs.

- Understand payment terms: Clarify payment schedules, methods, and any available financing options to ensure they align with your cash flow needs.

Step 6: Negotiate and Finalize Contracts

Engage in negotiations with your chosen supplier to finalize pricing, delivery timelines, and warranty terms. This step is vital to ensure both parties are aligned on expectations and responsibilities.

- Include quality assurance clauses: Ensure that the contract includes provisions for quality checks and potential penalties for non-compliance.

- Discuss after-sales support: Confirm that the supplier offers adequate support post-purchase, including maintenance advice and parts replacement.

Step 7: Establish a Strong Communication Channel

Maintain open lines of communication with your supplier throughout the procurement process. This is essential for addressing any issues that may arise and for fostering a long-term partnership.

- Schedule regular updates: Arrange periodic check-ins to discuss order status, potential delays, and any changes in requirements.

- Encourage feedback: Provide feedback on the quality of products and service to help the supplier improve their offerings and strengthen your business relationship.

Comprehensive Cost and Pricing Analysis for tyo bevel gears Sourcing

Understanding the cost structure and pricing dynamics of tyo bevel gears is crucial for international B2B buyers. The sourcing of these essential components involves several cost components and price influencers that can significantly affect the total expenditure.

What Are the Key Cost Components in Tyo Bevel Gears Sourcing?

-

Materials: The choice of materials directly impacts the cost of bevel gears. Common materials include machine structural carbon steel (S45C), alloy steel (SCM415), and engineering plastics (e.g., MC901). Higher-grade materials typically yield better performance but increase costs.

-

Labor: Labor costs are influenced by the manufacturing location. Countries with lower labor costs can offer competitive pricing, but it’s essential to consider the trade-off between cost and quality. Skilled labor is often required for precision machining, particularly in producing high-quality spiral bevel gears.

-

Manufacturing Overhead: This includes costs related to utilities, equipment maintenance, and facility management. Efficient manufacturing processes can help minimize overheads, which in turn can lower the price for buyers.

-

Tooling: The cost of tooling is significant, especially for custom or specialized bevel gears. Investments in high-quality tooling can enhance production efficiency and gear precision but may require higher initial costs.

-

Quality Control (QC): Ensuring that bevel gears meet industry standards necessitates rigorous quality control processes. This can add to the overall cost but is essential for maintaining product reliability and performance.

-

Logistics: Shipping costs can vary based on the supplier’s location and the buyer’s destination. Factors such as Incoterms, shipping methods, and freight charges all play a role in the final cost.

-

Margin: Suppliers will typically include a profit margin in their pricing. This margin can fluctuate based on the supplier’s market position, competition, and the perceived value of their products.

What Factors Influence the Pricing of Tyo Bevel Gears?

-

Volume and Minimum Order Quantity (MOQ): Bulk orders often lead to significant cost savings. Suppliers may offer discounts for larger volumes, making it beneficial for buyers to consolidate orders.

-

Specifications and Customization: Custom gears designed to specific requirements generally cost more than standard options. Buyers should evaluate whether customization is necessary and if the added cost aligns with their operational needs.

-

Material Quality and Certifications: Higher quality materials and certifications (e.g., ISO standards) can drive up costs. Buyers should assess the importance of these factors in relation to their application.

-

Supplier Factors: The reputation, reliability, and production capabilities of the supplier can influence pricing. Established suppliers may charge a premium for their experience and track record.

-

Incoterms: Understanding the agreed Incoterms is crucial as they define the responsibilities for shipping, insurance, and tariffs. This can significantly affect the total landed cost of the bevel gears.

What Are the Best Practices for Buyers in Tyo Bevel Gears Sourcing?

-

Negotiation: Engage suppliers in discussions about pricing, especially for large orders. Leverage volume commitments to negotiate better terms and conditions.

-

Focus on Cost-Efficiency: Evaluate the total cost of ownership (TCO), which includes not just the purchase price but also maintenance, operational efficiency, and lifespan of the gears.

-

Understand Pricing Nuances: Different regions may have varying pricing structures due to labor costs, tariffs, and local demand. Buyers from Africa, South America, the Middle East, and Europe should be aware of these differences when sourcing.

-

Conduct Market Research: Stay informed about market trends and benchmark pricing against multiple suppliers. This enables informed decision-making and helps avoid overpaying.

-

Request Indicative Prices with Caution: While suppliers may provide indicative prices, these can fluctuate based on market conditions and specific order details. Always confirm pricing before finalizing any purchase.

In summary, the sourcing of tyo bevel gears is a multifaceted process that requires careful consideration of various cost components and pricing factors. By understanding these elements, international B2B buyers can make informed decisions that optimize their procurement strategies.

Illustrative image related to tyo bevel gears

Alternatives Analysis: Comparing tyo bevel gears With Other Solutions

Exploring Alternatives to Tyo Bevel Gears

In the realm of mechanical power transmission, tyo bevel gears are widely recognized for their ability to efficiently transfer torque between intersecting shafts. However, depending on specific applications, there may be alternative solutions that offer comparable or enhanced benefits. Understanding these alternatives can empower B2B buyers to make informed decisions that align with their operational needs and budget constraints.

Comparison Table

| Comparison Aspect | Tyo Bevel Gears | Worm Gears | Planetary Gear Systems |

|---|---|---|---|

| Performance | High efficiency (98-99%), suitable for moderate speeds | Moderate efficiency, suitable for high torque applications | Very high efficiency, suitable for compact designs |

| Cost | Moderate to high, depending on design and materials | Generally low to moderate | Higher due to complexity and precision engineering |

| Ease of Implementation | Requires precise alignment and mounting | Easier to implement with fewer alignment issues | Complex installation requiring specialized knowledge |

| Maintenance | Moderate, depends on load and lubrication | Low, but may require periodic lubrication | Moderate to high, depending on design and load |

| Best Use Case | Machine tools, automotive differentials | Heavy machinery, conveyor systems | Robotics, automotive applications |

Detailed Breakdown of Alternatives

Worm Gears

Worm gears consist of a worm (screw) that meshes with a worm wheel (gear), allowing for high torque transmission in a compact design. One of the primary advantages of worm gears is their ability to provide significant gear reduction in a single stage, making them ideal for applications where space is limited. They also tend to be quieter during operation. However, their efficiency is lower compared to bevel gears, typically ranging from 50% to 90%, which may not be suitable for all applications. Additionally, while they require less maintenance, they can generate more heat due to friction.

Planetary Gear Systems

Planetary gear systems consist of a central sun gear, planet gears, and a ring gear, allowing for multiple gear ratios in a compact form. Their design enables high torque output with minimal size, making them ideal for applications in robotics and automotive engineering. The efficiency of planetary systems is often higher than that of bevel gears, reaching up to 97%. However, they are generally more expensive and complex to manufacture, which may be a consideration for budget-conscious buyers. Installation can also be complicated, requiring specialized skills and tools.

Conclusion: How to Choose the Right Solution for Your Needs

When deciding between tyo bevel gears and alternative solutions such as worm gears or planetary gear systems, B2B buyers should carefully evaluate their specific application requirements. Consider factors such as performance needs, budget constraints, ease of installation, and maintenance capabilities. For instance, if space is a premium and high torque is required, worm gears or planetary systems may be more advantageous. Conversely, if high efficiency and moderate complexity are key, tyo bevel gears might be the optimal choice. Ultimately, aligning the gear selection with operational goals will ensure long-term satisfaction and efficiency in mechanical systems.

Illustrative image related to tyo bevel gears

Essential Technical Properties and Trade Terminology for tyo bevel gears

What Are the Key Technical Properties of tyo Bevel Gears?

When assessing tyo bevel gears, understanding their essential technical properties is crucial for making informed purchasing decisions. Here are some critical specifications:

1. Material Grade

The choice of material is fundamental in determining the strength, durability, and suitability of bevel gears for specific applications. Common materials include S45C carbon steel, SCM415 alloy steel, and various engineering plastics like MC901. For instance, S45C is often used for its balance between cost and mechanical properties, while SCM415 offers enhanced strength due to alloying elements. Selecting the right material grade ensures that the gear can withstand operational stresses and environmental factors, leading to longer service life and lower maintenance costs.

2. Tooth Finish

The tooth finish of bevel gears, whether ground, cut, or injection molded, significantly impacts performance. Ground teeth provide higher accuracy and smoother operation, which is essential for high-speed applications. In contrast, cut teeth may offer cost advantages but could result in higher noise and wear. Understanding tooth finish helps buyers align gear specifications with their operational requirements and noise tolerance levels.

3. Module

The module indicates the size of the gear teeth and is crucial for compatibility with other gears in a system. It is defined as the ratio of the pitch diameter to the number of teeth and influences the gear’s load capacity and performance. Selecting the correct module is vital for ensuring proper meshing with mating gears, which directly affects the efficiency and effectiveness of power transmission.

4. Speed Ratio

The speed ratio describes the relationship between the input and output speeds of the gear system. It is essential for calculating the desired torque and understanding how the gears will perform under load. For example, a speed ratio of 1:2 means that for every rotation of the input gear, the output gear rotates half as much. This property is critical for applications requiring specific speed adjustments, such as in automotive differentials or conveyor systems.

5. Hardening Process

The hardening process, such as carburizing or induction hardening, enhances the wear resistance and overall strength of bevel gears. This treatment is particularly important for gears subjected to high loads or abrasive conditions. Buyers should evaluate the hardening specifications to ensure they meet the operational demands of their machinery and applications.

6. Tolerance

Tolerance refers to the allowable deviation in the dimensions of the gear components. High precision in tolerances is necessary for ensuring proper fit and function in mechanical assemblies. Poor tolerance can lead to increased wear, noise, and potential failure of the gear system. Selecting gears with appropriate tolerances is critical for maintaining efficiency and reliability in operations.

What Are Common Trade Terms in the Bevel Gear Industry?

Navigating the purchase of tyo bevel gears requires familiarity with industry terminology. Here are some common terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that manufactures products or components that are sold to another company for resale under that company’s brand. Understanding OEM relationships is important for buyers seeking quality assurance and compatibility with existing machinery.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. This term is crucial for budget planning and inventory management, especially for international buyers who may face higher shipping costs for smaller orders.

3. RFQ (Request for Quotation)

An RFQ is a document that solicits price proposals from suppliers. It’s a formal way for buyers to communicate their needs and specifications, allowing for accurate comparisons of pricing and services from multiple vendors.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, covering aspects like shipping, insurance, and tariffs. Familiarity with these terms helps mitigate risks and clarifies obligations in global trade, ensuring a smoother procurement process.

5. Lead Time

Lead time refers to the period between placing an order and receiving the goods. Understanding lead times is essential for inventory management and planning, particularly in industries with tight production schedules.

6. Tolerance Levels

Tolerance levels specify the acceptable limits of variation in gear dimensions. They are critical for ensuring compatibility and functionality in mechanical systems. Buyers should ensure that the tolerance levels specified by suppliers meet their operational requirements to avoid issues related to performance and reliability.

By comprehensively understanding these technical properties and trade terminology, B2B buyers can make informed decisions that enhance operational efficiency and ensure compatibility in their applications.

Navigating Market Dynamics and Sourcing Trends in the tyo bevel gears Sector

What Are the Key Market Dynamics Influencing the tyo Bevel Gears Sector?

The global market for tyo bevel gears is shaped by several key drivers, including the increasing demand for precision machinery in diverse industries such as automotive, aerospace, and manufacturing. As companies in Africa, South America, the Middle East, and Europe seek to enhance operational efficiency, there is a rising inclination towards advanced gear systems that promise high reliability and performance. Emerging technologies like additive manufacturing and automation are revolutionizing gear production, enabling manufacturers to create custom solutions that meet specific operational needs. Furthermore, the shift towards digitalization in supply chain management is facilitating more transparent sourcing processes, allowing B2B buyers to make informed decisions.

In terms of sourcing trends, there is a noticeable movement towards local suppliers, especially in regions like Brazil and Nigeria, where reducing lead times and shipping costs is critical. Additionally, the trend towards modularity in design is gaining traction, enabling buyers to customize bevel gear systems more easily. This adaptability is crucial for sectors that require rapid prototyping and short production cycles, reflecting a broader industry shift towards agile manufacturing practices.

How Can Sustainability and Ethical Sourcing Impact the tyo Bevel Gears Supply Chain?

Sustainability has emerged as a fundamental consideration in the sourcing of tyo bevel gears. The environmental impact of gear production, particularly in terms of resource extraction and waste generation, has prompted B2B buyers to prioritize suppliers who adhere to sustainable practices. This includes the use of recycled materials and energy-efficient manufacturing processes. Buyers should look for manufacturers that possess green certifications, which signal compliance with international environmental standards.

Moreover, ethical sourcing is gaining importance as companies increasingly recognize the need for responsible supply chains. This encompasses labor practices, sourcing of materials, and overall corporate responsibility. B2B buyers should conduct thorough due diligence to ensure that their suppliers not only meet quality and performance standards but also adhere to ethical labor practices and sustainable sourcing. In this context, suppliers that utilize eco-friendly materials, such as biodegradable plastics or low-impact metals, can provide a competitive edge in the marketplace.

How Has the tyo Bevel Gears Sector Evolved Over Time?

The evolution of tyo bevel gears can be traced back to the early days of mechanical engineering, where the need for efficient power transmission between intersecting shafts was paramount. Initially, the designs were rudimentary, with straight bevel gears being the standard. However, advancements in manufacturing techniques, particularly the adoption of the Gleason method for producing spiral bevel gears, revolutionized the sector by enabling higher precision and reduced noise levels.

As industries expanded and technology progressed, the demand for more sophisticated gear systems grew, leading to innovations in materials and design. The introduction of computer-aided design (CAD) and manufacturing (CAM) has further propelled the industry forward, allowing for customized solutions that meet the specific needs of various applications. Today, the tyo bevel gears sector continues to innovate, focusing on high-efficiency solutions that align with the demands of modern machinery and sustainable practices.

Frequently Asked Questions (FAQs) for B2B Buyers of tyo bevel gears

-

How do I select the right bevel gear for my application?

Selecting the right bevel gear involves understanding the specific requirements of your application, including the power transmission needs, shaft angles, and load conditions. Start by determining the type of bevel gear you need—straight or spiral—based on efficiency and noise considerations. Additionally, consider the material, tooth pitch, and manufacturing method, as these factors affect durability and performance. Consulting with manufacturers about your application can help narrow down options and ensure optimal performance. -

What are the advantages of using spiral bevel gears over straight bevel gears?

Spiral bevel gears offer several advantages, including smoother operation due to gradual tooth engagement, which reduces noise and vibration. They can also be ground after heat treatment, allowing for higher precision and improved wear resistance. This makes them suitable for high-speed applications or where accuracy is critical. However, they are typically more complex and costly to manufacture than straight bevel gears, which may be a consideration depending on your budget and application needs. -

What are the typical minimum order quantities (MOQs) for bevel gears?

Minimum order quantities for bevel gears can vary widely among suppliers, often depending on the manufacturing process and material used. Generally, MOQs can range from 10 to 100 units for standard gears. Custom gears may have higher MOQs due to the specialized production processes involved. It is advisable to discuss your specific requirements with suppliers to negotiate the best terms that suit your business needs. -

How can I ensure the quality of bevel gears from international suppliers?

To ensure quality when sourcing bevel gears internationally, conduct thorough supplier vetting. Look for manufacturers with certifications such as ISO 9001, which indicate adherence to quality management standards. Request samples to evaluate craftsmanship, and consider visiting the manufacturing facility if feasible. Additionally, inquire about their quality assurance processes, including testing methods and warranty policies, to confirm that they meet your quality expectations. -

What payment terms are commonly offered by bevel gear suppliers?

Payment terms can vary, but many suppliers offer options such as 30% upfront payment with the balance due upon shipment or delivery. Some may accept letters of credit for larger orders, which can provide added security. It’s essential to clarify payment terms before finalizing your order to avoid misunderstandings and ensure a smooth transaction. Discussing terms directly with suppliers can also help you negotiate favorable conditions based on your relationship and order size. -

What customization options are available for bevel gears?

Many manufacturers offer customization options for bevel gears, including variations in size, material, tooth design, and finishing processes. Custom gears can be tailored to meet specific performance requirements, such as load capacity or environmental resistance. When requesting customization, provide detailed specifications and application requirements to facilitate the design process. Collaborating closely with your supplier can ensure that the final product meets your precise needs. -

What logistics considerations should I keep in mind when sourcing bevel gears internationally?

When sourcing bevel gears internationally, consider logistics factors such as shipping methods, lead times, and customs regulations. Choose a reliable freight forwarder familiar with the specific requirements of your destination country. Additionally, factor in the potential for delays due to customs clearance and plan accordingly to maintain your production schedule. Establishing clear communication with suppliers regarding shipment tracking and delivery timelines can also help mitigate logistical challenges. -

How can I address potential issues with bevel gear performance after purchase?

To address performance issues with bevel gears, begin by conducting a thorough inspection to identify any visible defects or misalignments. Consult the supplier’s documentation for installation guidelines and operational parameters to ensure proper usage. If problems persist, reach out to the supplier for support or warranty claims. Many manufacturers offer technical assistance and may provide solutions or replacements if the issues stem from manufacturing defects or non-compliance with specifications.

Top 8 Tyo Bevel Gears Manufacturers & Suppliers List

1. KHK – Bevel Gears

Domain: khkgears.net

Registered: 2015 (10 years)

Introduction: Bevel Gears are cone-shaped gears that transmit power between two intersecting axes. They can be classified into straight bevel gears (no helix angles) and spiral bevel gears (with helix angles). KHK manufactures bevel gears using the Gleason method. Key specifications include:

1. **MHP High-Ratio Hypoid Gears**:

– Module: 1 – 1.5

– Speed ratio: 15 – 60

– Material: SCM415

– Harden…

2. Gobilda – Bevel Gears

Domain: gobilda.com

Registered: 2015 (10 years)

Introduction: Bevel gears are designed to drive a shaft at a 90° angle, available in ratios of 1:1 (miter gears) and 2:1 for speed and torque tuning. Key products include:

– MOD 1.5 Bevel Gears (2:1 Ratio): Requires specific tooth profile, compatible only with pinion gear.

– MOD 1 Miter Gears (1:1 Ratio): Two-piece steel construction with pinch bolts for secure locking, titanium nitride finish.

– MOD 1.25 Mi…

3. MISUMI – Bevel Gears

Domain: us.misumi-ec.com

Registered: 2007 (18 years)

Introduction: Bevel gears are mechanical components used to transmit power between shafts oriented at an angle, typically 90 degrees. They include types such as straight, spiral, and hypoid bevel gears, each designed for specific performance characteristics. Bevel gears are ideal for applications with limited space and require proper alignment for effective power transmission. They feature a robust design for d…

4. Huco – Bevel Gears

Domain: huco.com

Registered: 1996 (29 years)

Introduction: Bevel Gears, Helical Bevel Gears, Straight, Metric, Imperial, Material options include Steel 11SMnPb30, Steel, Polyketone, Polyacetal Resin (die-cast), Brass Ms58 (milled teeth), Stainless Steel 1.4305, Zinc Die-Cast ZnAl4Cu1, Polyacetal. Total products available: 387.

5. Maedler – Bevel Gears

Domain: maedlernorthamerica.com

Registered: 2020 (5 years)

Introduction: Bevel Gears, Steel, Straight Tooth System, ratio 1.5:1; Material: Steel; Module options: 0.5, 1, 1.5, 2, 2.5, 3; Teeth options: 16, 20, 24, 30; Milled; Part Numbers: 36054800, 36054900, 36074800, 36074900, 36075200, 36075300, 36104800, 36104900, 36105200, 36105300, 36114800, 36114900, 36115200, 36115300, 36144800, 36144900, 36145200, 36145300; Prices range from $26.39 to $87.44.

6. Kelston Actuation – Bevel Gear Sets

Domain: kelstonactuation.com

Registered: 2016 (9 years)

Introduction: Bevel gear sets are used to change the direction of a shaft’s rotation, commonly found in applications like car differentials and actuation mechanisms. They aim to transmit torque efficiently while minimizing noise, vibration, and space. Types of bevel gears include: 1. Straight Cut Bevel Gears: Suitable for low-speed applications with gear ratios of 1:1 to 5:1; relatively noisy due to tooth engag…

7. BSC Industries – Bevel Gears

Domain: bsc-ind.com

Registered: 2015 (10 years)

Introduction: Bevel gears are used to change the direction of a shaft’s rotation, typically mounted on shafts that are 90 degrees apart, but can be designed for other angles. They feature a cone as their pitch surface with teeth cut along the cone. The product selection includes Spiral Bevel Gears & Pinions and Straight Bevel Gears & Pinions from various brands such as Browning® and Regal Rexnord. Specific prod…

8. ScienceDirect – Bevel Gears

Domain: sciencedirect.com

Registered: 1997 (28 years)

Introduction: Bevel gears are conical-shaped gears used to transmit rotational power between shafts typically oriented at an angle of 90 degrees. They are commonly used in applications such as cordless hand-tools and automotive transmissions. Bevel gears can be designed for various angles, although they are most frequently used for 90° drives. Key types of bevel gears include straight bevel gears, spiral bevel …

Strategic Sourcing Conclusion and Outlook for tyo bevel gears

In today’s competitive landscape, strategic sourcing of tyo bevel gears is essential for businesses aiming to optimize performance and reduce operational costs. Understanding the nuances of gear types—such as straight versus spiral bevel gears—and their manufacturing methods, like the Gleason and Klingelnberg techniques, empowers B2B buyers to make informed decisions. Buyers should prioritize suppliers who offer a diverse range of materials and finishes, ensuring that they meet specific application requirements, from noise reduction to load capacity.

Investing in high-quality bevel gears not only enhances machinery reliability but also improves overall system efficiency, with typical efficiencies ranging from 98% to 99%. As global industries continue to evolve, the demand for precision-engineered gears will grow, particularly in emerging markets across Africa, South America, the Middle East, and Europe.

Looking ahead, international buyers should seize opportunities to collaborate with reputable manufacturers who can provide tailored solutions to meet their unique needs. By embracing strategic sourcing practices, businesses can strengthen their supply chains and position themselves for success in a rapidly changing market. Reach out today to explore how the right bevel gear solutions can drive your business forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.