Top 8 Pa66 Gf30 Suppliers (And How to Choose)

Introduction: Navigating the Global Market for pa66 gf30

The global market for PA66 GF30, a glass fiber-reinforced polyamide, presents a unique set of challenges for international B2B buyers seeking reliable sourcing solutions. With its exceptional mechanical properties, including high strength, rigidity, and creep resistance, PA66 GF30 is essential for industries ranging from automotive to power engineering. However, navigating the complexities of material specifications, supplier reliability, and regional availability can be daunting, particularly for buyers in Africa, South America, the Middle East, and Europe, such as Nigeria and Saudi Arabia.

This comprehensive guide aims to demystify the process of sourcing PA66 GF30 by providing an in-depth analysis of its types, applications, and industry standards. We will explore critical factors such as the vetting of suppliers, cost considerations, and best practices for procurement, enabling informed purchasing decisions. By understanding the nuances of PA66 GF30 and its applications, buyers will be better equipped to select the right material for their specific needs, ensuring optimal performance and longevity in demanding environments.

Whether you’re looking to enhance product durability or streamline manufacturing processes, this guide empowers you with the knowledge needed to make strategic decisions in the global market for PA66 GF30. Join us as we navigate through the essential aspects of this high-performance material, providing you with actionable insights tailored to your business requirements.

Understanding pa66 gf30 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| TECAMID 66 GF30 | 30% glass fiber reinforcement, high mechanical strength | Automotive, power engineering, gear mfg. | Pros: Excellent strength and rigidity; Cons: Less suitable for sliding applications due to abrasiveness. |

| Nylatron GF30 | Good machinability, high fatigue resistance | Mechanical engineering, construction | Pros: Easy to machine; Cons: May require additional treatments for specific applications. |

| Ertalon 66 GF30 | Heat-stabilized, good sliding properties | Conveyor technology, automotive components | Pros: Versatile for high-heat applications; Cons: Limited availability in certain regions. |

| NORMAQUICK PS3 | Integrated seal for leak-proof connections | Cooling systems in vehicles | Pros: Time-efficient assembly; Cons: Specific design requirements may limit compatibility. |

| General PA66 GF30 | Standard properties of PA66 with glass fiber reinforcement | Diverse industrial applications | Pros: Good overall performance; Cons: May not excel in specialized applications without modifications. |

What are the Characteristics of TECAMID 66 GF30 and Its B2B Suitability?

TECAMID 66 GF30 is a high-performance material featuring 30% glass fiber reinforcement, making it ideal for applications that require superior mechanical strength and rigidity. This variant is particularly suitable for the automotive and power engineering sectors, where components are subjected to high static loads and elevated temperatures. Buyers should consider its limitations in sliding applications due to the abrasive nature of glass fibers, which can lead to increased wear on mating surfaces.

How Does Nylatron GF30 Stand Out for B2B Purchasers?

Nylatron GF30 is celebrated for its excellent machinability and high fatigue resistance, making it a preferred choice in mechanical engineering and construction applications. Its attributes allow for intricate designs and ease of processing, which can lead to cost savings in manufacturing. However, buyers should be aware that while it performs well in many applications, some may require additional treatments to enhance specific performance characteristics.

Why Choose Ertalon 66 GF30 for High-Heat Applications?

Ertalon 66 GF30 is a heat-stabilized variant that excels in environments where high temperatures are a concern. Its good sliding properties make it suitable for conveyor technology and automotive components. B2B buyers should note that while it offers versatility, its availability can vary by region, which may impact procurement timelines and costs.

What Benefits Does the NORMAQUICK PS3 Provide for Vehicle Cooling Systems?

The NORMAQUICK PS3 connector is designed for secure, leak-proof connections in cooling systems, featuring an integrated seal that enhances its reliability. Its snap assembly design allows for quick installation, which can significantly reduce labor costs. However, potential buyers should ensure compatibility with existing systems, as specific design requirements may limit its use in some applications.

What are the General Considerations for Standard PA66 GF30?

Standard PA66 GF30, while not as specialized as its variants, offers a balanced performance for a wide range of industrial applications. Its glass fiber reinforcement provides improved mechanical properties over unfilled PA66, making it a versatile choice. Buyers should consider the specific requirements of their applications, as the standard variant may not meet the specialized needs of certain projects without additional modifications.

Key Industrial Applications of pa66 gf30

| Industry/Sector | Specific Application of pa66 gf30 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Engine components such as radiator connectors | High thermal stability and strength ensure reliable performance. | Ensure compliance with automotive standards and availability of grades. |

| Power Engineering | Insulation for electrical components | Excellent electrical insulating properties enhance safety and efficiency. | Verify resistance to environmental factors like heat and moisture. |

| Mechanical Engineering | Structural components in machinery | Increased stiffness and fatigue resistance reduce maintenance costs. | Assess dimensional stability under varying loads and temperatures. |

| Construction | Load-bearing structural elements | High creep resistance ensures long-term durability and safety. | Consider regional environmental conditions affecting material performance. |

| Conveyor Technology | Components for conveyor systems | Enhanced wear resistance prolongs service life and reduces downtime. | Evaluate availability of custom shapes and sizes for specific applications. |

In the automotive industry, PA66 GF30 is widely utilized for engine components, particularly radiator connectors. The material’s high thermal stability and mechanical strength ensure that these connectors maintain integrity under extreme temperature fluctuations, preventing leaks and enhancing vehicle reliability. International buyers should prioritize suppliers who comply with automotive industry standards and can provide consistent quality across different grades.

In power engineering, PA66 GF30 serves as an effective insulation material for electrical components. Its excellent electrical insulating properties are crucial for ensuring the safety and efficiency of power systems. Buyers from regions like the Middle East and Africa should consider the material’s resistance to environmental factors such as heat and moisture, which can significantly impact performance in harsh climates.

Within mechanical engineering, PA66 GF30 is favored for structural components in machinery due to its increased stiffness and fatigue resistance. These properties allow manufacturers to produce parts that can withstand high static loads over extended periods, thereby reducing the frequency of maintenance and associated costs. Buyers should assess the material’s dimensional stability when exposed to varying loads and temperatures to ensure long-term reliability.

In the construction sector, PA66 GF30 is employed in load-bearing structural elements, where its high creep resistance is essential for maintaining safety over time. This application is particularly relevant in regions with fluctuating temperatures and humidity, where material degradation can pose serious risks. Buyers must consider the specific environmental conditions of their projects to ensure optimal material performance.

Lastly, in conveyor technology, PA66 GF30 is used for components that require enhanced wear resistance. This characteristic is vital for prolonging the service life of conveyor systems, thus minimizing downtime and maintenance costs. When sourcing, buyers should evaluate the availability of custom shapes and sizes that cater to their specific operational needs, ensuring seamless integration into existing systems.

3 Common User Pain Points for ‘pa66 gf30’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality PA66 GF30 for High-Temperature Applications

The Problem: B2B buyers in industries like automotive or mechanical engineering often face challenges when sourcing PA66 GF30 that meets specific high-temperature requirements. The material’s performance can vary significantly based on the supplier’s quality control processes. Buyers may struggle to find reliable vendors who can consistently provide materials that withstand high service temperatures without compromising mechanical properties, leading to potential production delays and quality issues in their end products.

The Solution: To mitigate sourcing challenges, buyers should develop a clear set of specifications that outline the required mechanical and thermal properties of PA66 GF30. Engage with suppliers who provide detailed datasheets and certifications confirming compliance with industry standards, such as ASTM or ISO. Establish long-term relationships with manufacturers known for their quality control, and consider requesting samples before placing bulk orders. Additionally, leveraging digital platforms and trade shows to connect with multiple suppliers can help in identifying reliable partners who offer the material’s necessary certifications and performance guarantees.

Scenario 2: Managing the Abrasive Nature of Glass Fiber-Reinforced PA66

The Problem: One common pain point for B2B buyers is the abrasive effect that glass fibers in PA66 GF30 can have on mating surfaces. This characteristic can lead to increased wear in applications such as gears or sliding mechanisms, resulting in premature component failure. Buyers may not be fully aware of how to mitigate this issue, leading to unexpected costs and downtime in production.

The Solution: To address the abrasive nature of PA66 GF30, buyers should consider using complementary materials that reduce wear, such as softer metals or specialized coatings on mating surfaces. Implementing design modifications, like increasing the surface area of contact or utilizing lubricants, can also help manage friction and wear. Additionally, opting for alternative glass fiber-reinforced nylon formulations that provide similar strength without the same level of abrasiveness can be beneficial. Collaborating with material engineers during the design phase can yield insights into optimizing component designs to enhance longevity and performance while using PA66 GF30.

Scenario 3: Ensuring Compatibility with Outdoor Applications

The Problem: Many B2B buyers face challenges when using PA66 GF30 in outdoor applications, particularly regarding UV resistance and weatherability. While PA66 GF30 is known for its mechanical strength, buyers may be uncertain about how well it will perform when exposed to sunlight and varying weather conditions. This uncertainty can lead to concerns about long-term durability and product reliability.

The Solution: Buyers can enhance the outdoor performance of PA66 GF30 by selecting formulations with UV stabilizers or additives specifically designed for increased weather resistance. It’s crucial to consult with suppliers about the specific grade of PA66 GF30, ensuring it is treated for outdoor use. Additionally, conducting accelerated weathering tests can provide insights into the material’s longevity under specific environmental conditions. Implementing protective coatings or designs that limit direct exposure to harsh elements can further extend the lifespan of products made from PA66 GF30. For projects requiring long-term outdoor use, it is advisable to work closely with suppliers to tailor the material specifications to meet environmental challenges effectively.

Strategic Material Selection Guide for pa66 gf30

What are the Key Properties of PA66 GF30?

PA66 GF30, or glass fiber reinforced polyamide 66, is known for its superior mechanical properties, making it a preferred choice in various industrial applications. With 30% glass fiber reinforcement, this material exhibits enhanced strength, rigidity, and dimensional stability, particularly under high static loads and elevated temperatures. Its high heat deflection temperature and excellent wear resistance make it suitable for demanding environments, such as automotive and mechanical engineering sectors. However, it is essential to note that the abrasive nature of glass fibers can lead to wear on mating surfaces, limiting its use in sliding applications.

What are the Pros and Cons of Using PA66 GF30?

The advantages of PA66 GF30 include its high mechanical strength and stiffness, which contribute to the durability of components made from this material. It also offers excellent fatigue resistance and is resistant to various solvents, making it versatile across different applications. However, the material is more expensive than unfilled nylon options, which may deter cost-sensitive buyers. Additionally, the manufacturing complexity can increase, as specialized machining may be required to achieve the desired tolerances, particularly in regions with limited access to advanced manufacturing technologies.

How Does PA66 GF30 Impact Specific Applications?

In applications such as power engineering and automotive manufacturing, PA66 GF30 is often used for components that require high strength and thermal stability, such as connectors and housings. Its ability to withstand high temperatures and static loads makes it ideal for parts exposed to harsh conditions. However, international buyers must consider media compatibility, especially when using PA66 GF30 in environments where exposure to aggressive chemicals or high-energy radiation is a concern.

What Should International B2B Buyers Consider When Sourcing PA66 GF30?

For international buyers, particularly from Africa, South America, the Middle East, and Europe, compliance with local and international standards is crucial. Familiarity with standards such as ASTM, DIN, and JIS can help ensure that the materials sourced meet the necessary performance criteria. Additionally, regional preferences may influence material selection, with some markets favoring lower-cost alternatives or specific colors for aesthetic reasons. Buyers should also consider the availability of local suppliers who can provide timely support and service, as well as the potential for logistics challenges when importing materials.

| Material | Typical Use Case for pa66 gf30 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PA66 GF30 | Automotive components, industrial machinery | High strength and thermal stability | Higher cost compared to unfilled nylon | High |

| PA66 GF30 (Black) | Outdoor applications, UV-sensitive parts | Improved UV resistance | Limited sliding applications due to abrasiveness | High |

| Nylatron GF30 | Gear manufacturing, conveyor systems | Excellent wear resistance and machinability | May require specialized machining | Medium |

| Ertalon 66 GF30 | Electrical insulation, high-energy applications | Good electrical insulating properties | Potentially less availability in certain regions | Medium |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling informed decisions when sourcing PA66 GF30 and its variants for various applications. Understanding the properties, advantages, and limitations of these materials can significantly impact product performance and longevity in demanding environments.

In-depth Look: Manufacturing Processes and Quality Assurance for pa66 gf30

What Are the Key Stages in the Manufacturing Process of PA66 GF30?

The manufacturing process for PA66 GF30, a glass fiber-reinforced polyamide, involves several critical stages that ensure the material meets the rigorous demands of various industries. The primary steps include material preparation, forming, assembly, and finishing.

How Is Material Prepared for PA66 GF30 Manufacturing?

The process begins with the preparation of raw materials. PA66 resin and glass fibers are sourced from reputable suppliers, ensuring high quality and consistency. The glass fibers, typically at a 30% weight ratio, are blended with the nylon resin. This mixture is often subjected to a drying process to remove moisture, which can adversely affect the mechanical properties of the final product.

What Forming Techniques Are Used in PA66 GF30 Production?

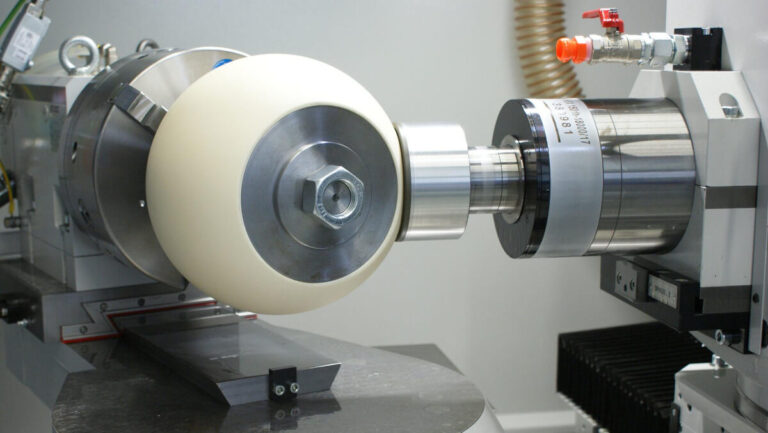

Once the materials are prepared, the next stage is forming. The blended material is typically processed using techniques such as injection molding or extrusion.

-

Injection Molding: This technique is widely used for producing complex shapes and high volumes. The blended resin is heated until it melts and is then injected into molds. The cooling process solidifies the material, ensuring precise dimensions and surface finishes.

-

Extrusion: In cases where continuous shapes are needed, such as rods or sheets, extrusion is preferred. The material is forced through a die, creating long shapes that can be cut to desired lengths.

Both methods ensure that the mechanical properties of PA66 GF30 are optimized, including its strength, stiffness, and dimensional stability.

What Is the Role of Assembly in the Production Process?

While many PA66 GF30 products are manufactured as standalone components, some applications require assembly. For instance, parts may be combined with other materials or components, necessitating careful alignment and fitting. The assembly process must ensure that connections are secure and meet design specifications, particularly in applications such as automotive and mechanical engineering.

What Are the Finishing Techniques for PA66 GF30 Products?

After forming and assembly, finishing processes enhance the material’s performance and aesthetic qualities. Common finishing techniques include:

-

Surface Treatment: To improve wear resistance and aesthetic appeal, surface treatments such as painting or coating may be applied. This is particularly important for applications exposed to UV light and harsh environmental conditions.

-

Machining: For precision components, machining processes such as milling, turning, and drilling are employed to achieve tight tolerances and intricate designs.

These finishing processes not only improve the final product’s performance but also ensure compliance with industry standards.

How Is Quality Assurance Implemented in PA66 GF30 Manufacturing?

Quality assurance (QA) is a critical component of the manufacturing process for PA66 GF30. Manufacturers often implement comprehensive QA systems to ensure that products meet international and industry-specific standards.

What International Standards Govern PA66 GF30 Quality?

International standards such as ISO 9001 provide a framework for quality management systems (QMS). ISO 9001 emphasizes customer satisfaction, continuous improvement, and process efficiency. Compliance with this standard is crucial for suppliers targeting international markets, as it demonstrates a commitment to quality.

In addition to ISO standards, industry-specific certifications such as CE marking for European markets or API standards for the oil and gas sector may also be required. These certifications assure buyers that the products meet stringent safety and performance criteria.

What Are the Key Quality Control Checkpoints in Production?

Quality control (QC) is typically structured around several key checkpoints during the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint assesses raw materials upon delivery. Suppliers must verify that materials conform to specified standards and perform necessary tests to confirm their quality.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections and testing are conducted to monitor production quality. This includes checking parameters such as temperature, pressure, and material consistency.

-

Final Quality Control (FQC): Once the products are completed, a final inspection ensures that they meet all design and quality specifications. This step may involve mechanical testing, dimensional checks, and performance evaluations.

How Can B2B Buyers Verify Supplier Quality Assurance?

B2B buyers must take proactive steps to verify the quality assurance practices of their suppliers. Here are several actionable strategies:

-

Supplier Audits: Conducting audits of potential suppliers helps buyers assess their quality management systems, manufacturing capabilities, and adherence to international standards. Audits can reveal insights into a supplier’s operational processes and commitment to quality.

-

Requesting Quality Reports: Buyers should request documentation that details the supplier’s quality control procedures, test results, and compliance with relevant standards. This documentation can provide reassurance of the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an impartial assessment of a supplier’s quality practices. These agencies can conduct random inspections and tests to ensure that products meet specified standards before shipment.

What Are the Specific Quality Control Nuances for International B2B Buyers?

For international buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, understanding local regulations and market expectations is crucial. Different regions may have varying compliance requirements, which can affect material selection, product testing, and certification processes.

Additionally, language barriers and cultural differences may impact communication with suppliers. Buyers should ensure that all quality specifications are clearly articulated and understood by both parties to avoid misunderstandings.

In conclusion, understanding the manufacturing processes and quality assurance practices for PA66 GF30 is essential for B2B buyers aiming to source high-quality materials. By focusing on the stages of production and implementing thorough quality checks, buyers can ensure that they procure reliable and durable products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pa66 gf30’

Introduction

Navigating the procurement of PA66 GF30 can be complex, particularly for international B2B buyers. This guide provides a practical checklist to streamline your sourcing process, ensuring you secure high-quality materials that meet your specific requirements. By following these steps, you can enhance your purchasing efficiency and mitigate risks associated with sourcing.

Step 1: Define Your Technical Specifications

Clearly outlining your technical specifications is critical before initiating the procurement process. PA66 GF30 is known for its high mechanical strength and thermal stability; therefore, you should specify the required properties for your application, such as tensile strength, impact resistance, and heat deflection temperature.

- Consider application requirements: Identify if your application involves high static loads or exposure to chemicals, as these factors will dictate the material characteristics you need.

Step 2: Research Potential Suppliers

Conduct thorough research to compile a list of potential suppliers. Look for manufacturers with a solid reputation for producing PA66 GF30 and check their previous projects and client testimonials.

- Evaluate their experience: Prioritize suppliers who have a history in your industry, as they will better understand the specific challenges and requirements of your application.

Step 3: Verify Supplier Certifications

Before proceeding with any supplier, it’s essential to verify their certifications and compliance with international standards. Certifications such as ISO 9001 indicate a commitment to quality management practices.

- Check for material safety data sheets (MSDS): Ensure that the supplier can provide MSDS for PA66 GF30 to confirm that the material meets safety and regulatory requirements.

Step 4: Request Samples for Testing

Always request samples of PA66 GF30 before placing a bulk order. Testing the material in your specific application environment will help you assess its performance and suitability.

- Conduct comparative analysis: Use the samples to compare against alternative materials or other grades of PA66 to make informed decisions based on real-world performance.

Step 5: Assess Pricing and Payment Terms

Once you have narrowed down your suppliers, it’s time to assess pricing structures and payment terms. Understanding the total cost of ownership, including shipping and potential tariffs, is vital for accurate budgeting.

- Negotiate terms: Don’t hesitate to negotiate pricing or payment terms, especially if you are considering a long-term partnership or bulk orders.

Step 6: Establish Clear Communication Channels

Effective communication is crucial throughout the procurement process. Ensure that your supplier can provide timely updates and is responsive to inquiries.

- Set expectations upfront: Clearly communicate your expectations regarding delivery timelines, quality checks, and after-sales support to avoid misunderstandings.

Step 7: Finalize Contracts with Clear Terms

Once you’ve selected a supplier, ensure that all agreements are documented in a contract. This should include delivery schedules, payment terms, and quality assurance measures.

- Include dispute resolution procedures: Having clear terms in your contract will help protect both parties and provide a framework for resolving any potential disputes that may arise.

By following this checklist, B2B buyers can streamline their sourcing process for PA66 GF30, ensuring they make informed decisions that align with their operational needs.

Comprehensive Cost and Pricing Analysis for pa66 gf30 Sourcing

When sourcing PA66 GF30, understanding the cost structure and pricing factors is essential for B2B buyers. This material, known for its high mechanical strength and thermal resistance, presents a unique set of cost components and price influencers that can significantly impact purchasing decisions.

What Are the Key Cost Components in PA66 GF30 Sourcing?

-

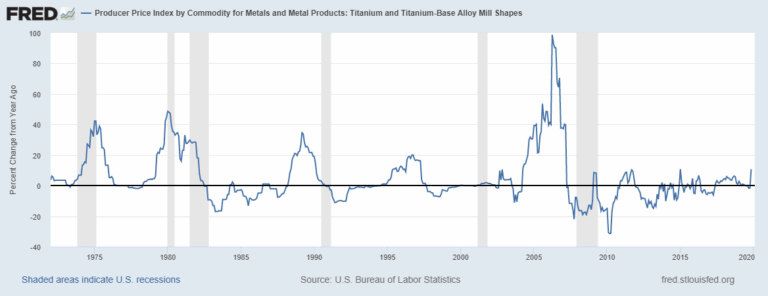

Materials: The primary cost driver for PA66 GF30 is the raw materials used in production. The base polymer, polyamide 66, combined with 30% glass fiber reinforcement, influences the price. Fluctuations in the cost of these raw materials due to market conditions can directly affect the final pricing.

-

Labor: Labor costs vary by region and can impact overall pricing. In regions with higher wage standards, the cost of skilled labor required for manufacturing PA66 GF30 can increase the product price. Understanding local labor markets can help buyers anticipate these costs.

-

Manufacturing Overhead: This includes expenses related to the facility, utilities, and equipment maintenance. Higher overhead costs in developed countries may lead to increased pricing for PA66 GF30. Buyers should consider suppliers’ operational efficiencies when evaluating costs.

-

Tooling: Custom tooling for specific applications can add to the initial costs of sourcing PA66 GF30. While it may be a significant upfront investment, it can lead to cost savings in large-volume orders through reduced per-unit costs.

-

Quality Control (QC): Rigorous QC processes ensure the product meets specifications, which can add to the overall cost. However, this is critical for maintaining the integrity and performance of PA66 GF30 in applications where mechanical reliability is essential.

-

Logistics: Transportation and handling costs also play a crucial role. The shipping method, distance, and Incoterms can influence the final price significantly. Buyers should factor in logistics when assessing total costs.

-

Margin: Suppliers will incorporate their profit margins into the pricing. Understanding typical margins in the industry can aid in negotiations.

What Factors Influence the Pricing of PA66 GF30?

-

Volume and Minimum Order Quantity (MOQ): Larger orders often qualify for discounts, making volume a key negotiating point. Buyers should assess their needs and consider bulk purchasing to achieve cost efficiencies.

-

Specifications and Customization: Custom formulations or specific color requirements can increase costs. Buyers should clarify their needs upfront to avoid unexpected charges later.

-

Quality and Certifications: Products with higher quality standards or certifications (like ISO) typically come at a premium. Buyers should weigh the importance of these certifications against their budget.

-

Supplier Factors: The reputation, reliability, and location of the supplier can influence pricing. Established suppliers with a proven track record may charge more, but they often provide better service and quality assurance.

-

Incoterms: Understanding the terms of sale can impact overall costs. For example, FOB (Free on Board) vs. CIF (Cost, Insurance, and Freight) can lead to different pricing structures, affecting the total landed cost.

How Can Buyers Optimize Costs When Sourcing PA66 GF30?

-

Negotiation Strategies: Engage suppliers in discussions about volume discounts, long-term contracts, and payment terms. Establishing a strong relationship with suppliers can lead to better pricing and terms.

-

Focus on Total Cost of Ownership (TCO): Consider not only the purchase price but also the long-term costs associated with the material, including durability, maintenance, and potential downtime. A slightly higher initial cost may lead to lower overall expenses.

-

Understand Pricing Nuances for International Transactions: For buyers in Africa, South America, the Middle East, and Europe, consider currency fluctuations, import duties, and local taxes. These factors can significantly alter the final cost of PA66 GF30.

Conclusion

In conclusion, a comprehensive understanding of the cost structure and price influencers for PA66 GF30 is crucial for international B2B buyers. By carefully evaluating these elements, buyers can make informed decisions that align with their operational needs and budget constraints. Always keep in mind that prices can vary significantly based on market conditions, so it’s advisable to seek multiple quotes and stay updated on industry trends.

Alternatives Analysis: Comparing pa66 gf30 With Other Solutions

Introduction: Understanding Alternatives to PA66 GF30

In the competitive landscape of engineering materials, businesses often seek alternatives to established solutions like PA66 GF30. This glass fiber-reinforced polyamide offers exceptional mechanical properties suitable for demanding applications. However, various alternatives exist, each with unique advantages and limitations. Understanding these options helps B2B buyers make informed decisions that align with their operational requirements and cost considerations.

Comparison Table

| Comparison Aspect | PA66 GF30 | Nylatron™ GF30/Ertalon™ 66 GF30 | NORMAQUICK® PS3 Connector |

|---|---|---|---|

| Performance | High mechanical strength, rigidity; not ideal for sliding applications due to abrasion | Excellent wear resistance, good sliding properties, high strength | Reliable for coolant systems, strong sealing capabilities |

| Cost | Moderate to high | Moderate | Low to moderate |

| Ease of Implementation | Requires specialized machining and handling | Easy to machine, standard shapes available | Simple snap-fit design, minimal tools needed |

| Maintenance | Low maintenance, but prone to wear in sliding applications | Low maintenance with good durability | Low maintenance; seals require periodic inspection |

| Best Use Case | High-load applications in automotive and mechanical engineering | Precision parts in machinery and equipment | Cooling systems in vehicles and HVAC applications |

Detailed Breakdown of Alternatives

Nylatron™ GF30/Ertalon™ 66 GF30: A Versatile Option

Nylatron™ GF30/Ertalon™ 66 GF30 is an excellent alternative to PA66 GF30, particularly in applications requiring both mechanical strength and good sliding properties. This material maintains high resistance to wear, making it suitable for components that involve motion. Its good machinability allows for efficient fabrication into various shapes, which is a significant advantage for custom applications. However, while it performs well under dynamic loads, its cost may be slightly higher than standard nylon solutions, which could be a concern for budget-sensitive projects.

NORMAQUICK® PS3 Connector: Efficient and Cost-Effective

The NORMAQUICK® PS3 Connector stands out as a practical solution for specific applications, particularly in automotive cooling systems. Its design allows for tool-free installation, significantly reducing assembly time and costs. The connector is reliable, ensuring leak-proof connections in critical systems. However, its application is limited to fluid management, making it unsuitable for structural components that require high mechanical strength. For projects focused on efficient assembly and maintenance in fluid systems, it offers an attractive option at a lower price point.

Conclusion: Choosing the Right Solution for Your Needs

When selecting an engineering material or component, B2B buyers must consider multiple factors, including performance requirements, cost constraints, and ease of implementation. PA66 GF30 excels in high-load scenarios but may not be the best choice for all applications, especially those involving sliding movements. Alternatives like Nylatron™ GF30/Ertalon™ 66 GF30 and the NORMAQUICK® PS3 Connector provide viable options that cater to specific needs. Buyers should evaluate their unique requirements, including the intended application and budget, to make a well-informed decision that enhances operational efficiency and product reliability.

Essential Technical Properties and Trade Terminology for pa66 gf30

What Are the Essential Technical Properties of PA66 GF30?

1. Material Grade: Polyamide 66 (PA66)

PA66 is a type of nylon known for its high strength and rigidity. The GF30 designation indicates that this material is reinforced with 30% glass fibers, which significantly enhances its mechanical properties. For B2B buyers, understanding the material grade is crucial, as it impacts the durability and performance of parts in demanding applications, such as automotive and industrial components.

2. Tensile Strength

The tensile strength of PA66 GF30 is approximately 12,200 psi at 73°F, making it suitable for applications requiring high load-bearing capabilities. This property is essential for manufacturers looking to ensure that components can withstand significant stress without failure. High tensile strength translates to longer service life and reduced maintenance costs.

3. Thermal Stability

PA66 GF30 exhibits a melting temperature of around 499°F and a service temperature of up to 338°F for intermittent use. This thermal stability is vital in applications where materials are exposed to high temperatures, such as in automotive engines or industrial machinery. Understanding thermal properties helps buyers select materials that maintain performance under specific operating conditions.

4. Creep Resistance

Creep resistance is the ability of a material to resist deformation under constant load over time. PA66 GF30’s high creep resistance makes it ideal for components that must maintain their shape and functionality under prolonged stress. This characteristic is particularly relevant for manufacturers in sectors like construction and mechanical engineering, where dimensional stability is critical.

5. Moisture Absorption

With a moisture absorption rate of just 0.25% at 24 hours, PA66 GF30 is less susceptible to environmental effects that can compromise structural integrity. For B2B buyers, low moisture absorption means reduced risks of material degradation and dimensional changes, making it a reliable choice for outdoor applications.

6. Wear Resistance

PA66 GF30 possesses excellent wear resistance, making it suitable for applications that involve friction and contact with other materials. This property is particularly important in industries like automotive and conveyor technology, where components may experience continuous movement against other surfaces.

What Trade Terminology Should B2B Buyers Know About PA66 GF30?

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts that are used in another company’s end products. Understanding OEM relationships is crucial for buyers sourcing PA66 GF30 components, as it ensures compatibility and quality assurance in their applications.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For businesses purchasing PA66 GF30, knowing the MOQ is essential for budgeting and inventory management, especially when considering bulk orders for manufacturing processes.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers solicit price quotes from suppliers for specific quantities and specifications. For PA66 GF30, submitting an RFQ helps buyers obtain competitive pricing and ensures that they understand the terms of supply, including delivery timelines and payment conditions.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms is vital for B2B buyers, as they clarify who bears the risk and cost of shipping PA66 GF30, influencing overall procurement costs.

5. Tolerance

Tolerance refers to the allowable deviation in the dimensions of a part. For PA66 GF30 components, understanding tolerance specifications is critical for ensuring that parts fit and function correctly within larger assemblies, reducing the risk of malfunctions or failures.

6. Lead Time

Lead time is the amount of time it takes from placing an order to receiving the product. Knowing the lead time for PA66 GF30 is important for supply chain planning, especially in industries where timely delivery can impact production schedules.

By familiarizing themselves with these technical properties and trade terms, international B2B buyers can make informed purchasing decisions regarding PA66 GF30, ensuring that they select the right materials for their specific applications.

Navigating Market Dynamics and Sourcing Trends in the pa66 gf30 Sector

What Are the Current Market Dynamics and Key Trends for PA66 GF30?

The PA66 GF30 market is being driven by several global factors, including increasing demand for high-performance materials in various industries such as automotive, construction, and mechanical engineering. As manufacturers seek lightweight yet durable materials, PA66 GF30, known for its high strength, rigidity, and heat resistance, has gained traction. Notably, the automotive sector is evolving rapidly, with a significant push towards lightweight components that can withstand high static loads, especially in regions like Europe and the Middle East where performance standards are stringent.

Emerging B2B technologies are reshaping sourcing strategies. Digital platforms that facilitate direct interactions between suppliers and buyers are on the rise, providing a more streamlined approach to procurement. Additionally, advanced manufacturing techniques, such as 3D printing, are allowing for customized parts made from PA66 GF30, catering to specific industry needs. The trend towards automation and digitalization in supply chains is also notable, enabling faster response times and enhanced inventory management.

For international buyers, particularly from Africa and South America, understanding local regulations and market nuances is crucial. Buyers must navigate varying quality standards and certifications, which can differ significantly between regions. Strategic partnerships with reliable suppliers who can provide consistent quality and compliance with local regulations will be key to successful sourcing.

How Does Sustainability Influence Sourcing Decisions for PA66 GF30?

Sustainability is becoming increasingly important in the sourcing of materials, including PA66 GF30. The environmental impact of production processes and the lifecycle of materials are under scrutiny, compelling manufacturers to adopt more sustainable practices. Buyers are now prioritizing suppliers who demonstrate a commitment to reducing their carbon footprint and implementing eco-friendly manufacturing processes.

Ethical supply chains are also gaining prominence. B2B buyers are more inclined to partner with suppliers who provide transparency regarding their sourcing practices and labor conditions. This demand for ethical sourcing is not only a response to consumer pressure but also a recognition that sustainable practices can lead to long-term cost savings and brand loyalty.

Furthermore, certifications such as ISO 14001 for environmental management and materials that are recyclable or derived from sustainable sources are becoming pivotal in sourcing decisions. Buyers looking for PA66 GF30 should seek suppliers who can offer products with such certifications, aligning with the global shift towards responsible consumption and production.

What Is the Historical Context Behind the Development of PA66 GF30?

The evolution of PA66 GF30 can be traced back to advancements in polymer technology during the mid-20th century. Initially developed for its robust mechanical properties, Polyamide 66 (PA66) quickly found applications in various industries due to its excellent strength-to-weight ratio and thermal stability. The introduction of glass fiber reinforcement in the 1980s further enhanced these properties, resulting in the creation of PA66 GF30.

This modification allowed manufacturers to create components that could withstand extreme conditions, making it particularly valuable in sectors like automotive and construction. Over the years, the material has evolved to meet the growing demands for efficiency and sustainability, leading to innovations in its formulation and processing methods. Today, PA66 GF30 is recognized as a critical material in modern engineering applications, driving both performance and sustainability in product design.

In summary, the PA66 GF30 sector is at a pivotal point, influenced by market dynamics, sustainability trends, and a rich history of development, presenting numerous opportunities for international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of pa66 gf30

-

How do I choose the right supplier for PA66 GF30?

Selecting the right supplier for PA66 GF30 involves assessing several key factors. Start by evaluating the supplier’s reputation and experience in the industry. Look for certifications that demonstrate quality assurance, such as ISO 9001. Check customer reviews and case studies to gauge reliability and service levels. Additionally, consider suppliers that offer technical support and can provide samples for testing. It’s also beneficial to engage in direct communication to discuss your specific needs and ensure they can meet your quality and delivery requirements. -

What are the mechanical properties of PA66 GF30?

PA66 GF30 is renowned for its outstanding mechanical properties, including high tensile strength (up to 12,200 psi) and excellent dimensional stability. The 30% glass fiber reinforcement enhances its stiffness and creep resistance, making it ideal for applications subject to static loads at elevated temperatures. It also offers good fatigue strength and wear resistance, though it may be less suitable for sliding applications due to abrasiveness. Understanding these properties helps in selecting the right material for specific applications in industries like automotive and mechanical engineering. -

What is the typical minimum order quantity (MOQ) for PA66 GF30?

Minimum order quantities (MOQs) for PA66 GF30 can vary significantly by supplier and region. Generally, MOQs can range from 100 kg to several tons, depending on the supplier’s production capabilities and inventory policies. For international buyers, it’s essential to inquire directly with suppliers about their MOQs and whether they can accommodate smaller orders or mixed product shipments. This flexibility can aid in managing inventory and reducing upfront costs, especially for businesses just starting to incorporate PA66 GF30 into their products. -

What payment terms should I expect when sourcing PA66 GF30 internationally?

Payment terms for international sourcing of PA66 GF30 can differ based on the supplier’s policies and your negotiation. Common terms include a 30% deposit upfront with the balance due before shipment, or payment via letters of credit, which provide security for both parties. Always clarify the payment terms in advance and consider options that offer protection against currency fluctuations and potential trade risks. Establishing clear payment terms can streamline the purchasing process and foster a trustworthy relationship with your supplier. -

How can I ensure the quality of PA66 GF30 during shipping?

To ensure quality during shipping, request that suppliers provide a Certificate of Analysis (CoA) along with product samples. This documentation verifies that the material meets specified standards. Use reliable logistics partners experienced in handling industrial materials, and consider employing quality inspections at various stages—pre-shipment and upon arrival. Additionally, ensure that the packaging protects the material from moisture and physical damage, as PA66 GF30 can be sensitive to environmental conditions during transit. -

Can PA66 GF30 be customized for specific applications?

Yes, PA66 GF30 can often be customized to meet specific application requirements. Suppliers may offer variations in color, additives for enhanced properties (like UV resistance), or specific formulations tailored to unique performance needs. When seeking customization, clearly communicate your application details and performance expectations to the supplier. Some manufacturers may also offer prototyping services to test the customized material before full-scale production, allowing for adjustments based on performance feedback. -

What industries commonly use PA66 GF30?

PA66 GF30 is widely utilized across various industries, including automotive, power engineering, mechanical engineering, and construction. Its robust mechanical properties make it suitable for components that experience high static loads and thermal stresses, such as gears, housings, and structural parts. Understanding the primary industries that leverage PA66 GF30 can help buyers identify potential applications within their sectors and explore opportunities for innovation and enhanced product performance. -

What are the logistical considerations when importing PA66 GF30?

When importing PA66 GF30, several logistical factors should be considered. First, verify shipping regulations and customs documentation requirements for your specific region. It’s crucial to understand duties and tariffs that may apply to plastic materials. Additionally, consider lead times for production and shipping, as well as the reliability of your logistics provider. Establishing a clear communication channel with your supplier regarding shipping schedules can help mitigate delays and ensure that your production timelines are met efficiently.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Pa66 Gf30 Manufacturers & Suppliers List

1. PA66-GF30 Car Engine Cooling Radiator

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: PA66-GF30 Car Engine Cooling Radiator, Brand New, Fits Multiple Makes & Models, Price: $99.00 or Best Offer, Delivery: +$15.00, Location: Markleville, IN, Free returns; PA66-GF30 Car Engine Cooling Radiator, Brand New, Price: $143.62 or Best Offer, Delivery: +$4.84, Location: Elgin, IL, Free returns; Normaquick PS3 0702-701-9016 NW16 Coolant Hose Connector PA66-GF30 Nylon, Brand New, Price: $19.50…

2. Ensinger – TECAMID 66 GF30 Black

Domain: ensingerplastics.com

Registered: 2015 (10 years)

Introduction: {“Product Name”: “TECAMID 66 GF30 black”, “Material”: “PA 66 (Polyamide 66)”, “Reinforcement”: “30% glass fibers”, “Color”: “black”, “Density”: “1.36 g/cm3”, “Main Features”: [“very good mechanical strength”, “high heat deflection temperature”, “high stiffness”, “high strength”, “excellent wear properties”, “high fatigue strength”, “resistant to many solvents”, “high creep resistance”], “Target In…

3. JL Wrangler Forums – Radiator Hose T-Connector

Domain: jlwranglerforums.com

Registered: 2016 (9 years)

Introduction: Radiator hose T-connector made of PA66-GF30; compatible with 2018 Jeep Wrangler Unlimited Sport JL; part may not have an individual part number and is likely part of a hose assembly.

4. Mcam – Nylatron™ GF30/Ertalon™ 66 GF30 PA66

Domain: mcam.com

Registered: 1997 (28 years)

Introduction: {‘product_name’: ‘Nylatron™ GF30/Ertalon™ 66 GF30 PA66’, ‘material’: ‘Glass fiber-reinforced nylon 66’, ‘properties’: [‘High mechanical strength’, ‘High stiffness’, ‘High hardness’, ‘High toughness’, ‘Good fatigue resistance’, ‘High mechanical damping ability’, ‘Good sliding properties’, ‘Excellent wear resistance’, ‘Good electrical insulating properties’, ‘Good resistance to high energy radiation…

5. NORMA – NORMAQUICK® PS3 Straight Connector

Domain: shop.normagroup.com

Registered: 2001 (24 years)

Introduction: NORMAQUICK® PS3 Straight Connector designed for secure connection of coolant and heater hoses as well as charged air systems. Highlights include:

– Designed for standard spigot as per VDA guideline

– Resistance to coolant medium with O-ring made of peroxide cured EPDM

– PA66 (GF30 housing and retainer) stabilized against heat and hydrolysis

– Tool-free snap assembly for time and cost reduction…

6. Audi – PA66-GF30 Replacement Part

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Part number: pa66-gf30; Vehicle: 2017 Audi A4; Issue: Coolant leak due to sheared plastic nipples on the part; Temporary fix: Patch from O’Reilly; Need for replacement part.

7. Europlas – PA66 GF30 Glass Fiber-Reinforced Polyamide 66

Domain: europlas.com.vn

Introduction: PA66 GF30 is a 30% glass fiber-reinforced polyamide 66 (PA66) known for its enhanced mechanical properties. Key benefits include: excellent high strength, extremely high stiffness, high dimensional stability, good wear resistance, improved UV protection, good heat deflection temperature, bondable and weldable properties, and resistance to oil, fuel, and grease. Common applications include automoti…

8. ProxyParts – PA66GF30 Car Parts

Domain: proxyparts.com

Registered: 2016 (9 years)

Introduction: Part Number: PA66GF30

Total Stock: 6,163,735 car parts online

Affiliated Suppliers: 177

Customer Rating: 8.0 out of 10 from 23,991 reviews

Car Parts Found: 127

Categories: AC and Heating, Accessories, Brakes, Chassis and Suspension, Computers and Electronics, Dashboard and Switches, Engine and Accessories, Exhaust System, Fuel System, Interior and Upholstery, Lighting, Locks and Hinges, Other Part…

Strategic Sourcing Conclusion and Outlook for pa66 gf30

The increasing demand for high-performance materials like PA66 GF30 across diverse industries underscores the importance of strategic sourcing. This glass fiber-reinforced polyamide offers exceptional mechanical strength, rigidity, and resistance to high temperatures, making it ideal for applications in automotive, power engineering, and construction sectors. For B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, understanding the unique properties and advantages of PA66 GF30 is crucial for making informed procurement decisions.

Investing in PA66 GF30 can enhance product durability and performance, while also optimizing supply chain efficiency. Buyers should consider sourcing from reputable manufacturers who offer consistent quality and technical support, ensuring that they meet their specific application needs. As the global market evolves, leveraging strategic sourcing practices will be key to staying competitive.

Looking ahead, the demand for advanced materials like PA66 GF30 is set to grow, driven by innovations in engineering and manufacturing. International buyers are encouraged to explore partnerships with suppliers who can provide tailored solutions, ensuring they are well-positioned to capitalize on emerging market opportunities. Engage with suppliers today to secure your competitive edge in the marketplace.