Top 8 Fractional Hp Electric Motors Suppliers (And How to Choose)

Introduction: Navigating the Global Market for fractional hp electric motors

Navigating the global market for fractional horsepower (FHP) electric motors presents unique challenges for B2B buyers seeking reliable and efficient solutions. As industries expand across diverse regions, sourcing high-quality FHP motors that cater to specific applications—from industrial automation to consumer electronics—becomes paramount. This guide is designed to equip international buyers, particularly those from Africa, South America, the Middle East, and Europe, with the insights necessary for informed purchasing decisions.

Within this comprehensive resource, we delve into the various types of fractional horsepower motors, their applications across multiple sectors, and critical factors to consider when vetting suppliers. Additionally, we explore cost considerations, market trends, and the evolving technological landscape that influences the performance and efficiency of FHP motors. By understanding these elements, buyers can navigate the complexities of the market with confidence, ensuring they select products that meet their operational needs while optimizing cost-effectiveness.

Whether you are in Brazil, Nigeria, or elsewhere, the information presented in this guide will empower you to make strategic decisions that align with your business goals. With a focus on reliability, efficiency, and innovation, this guide serves as your key to unlocking the full potential of fractional horsepower electric motors in your operations.

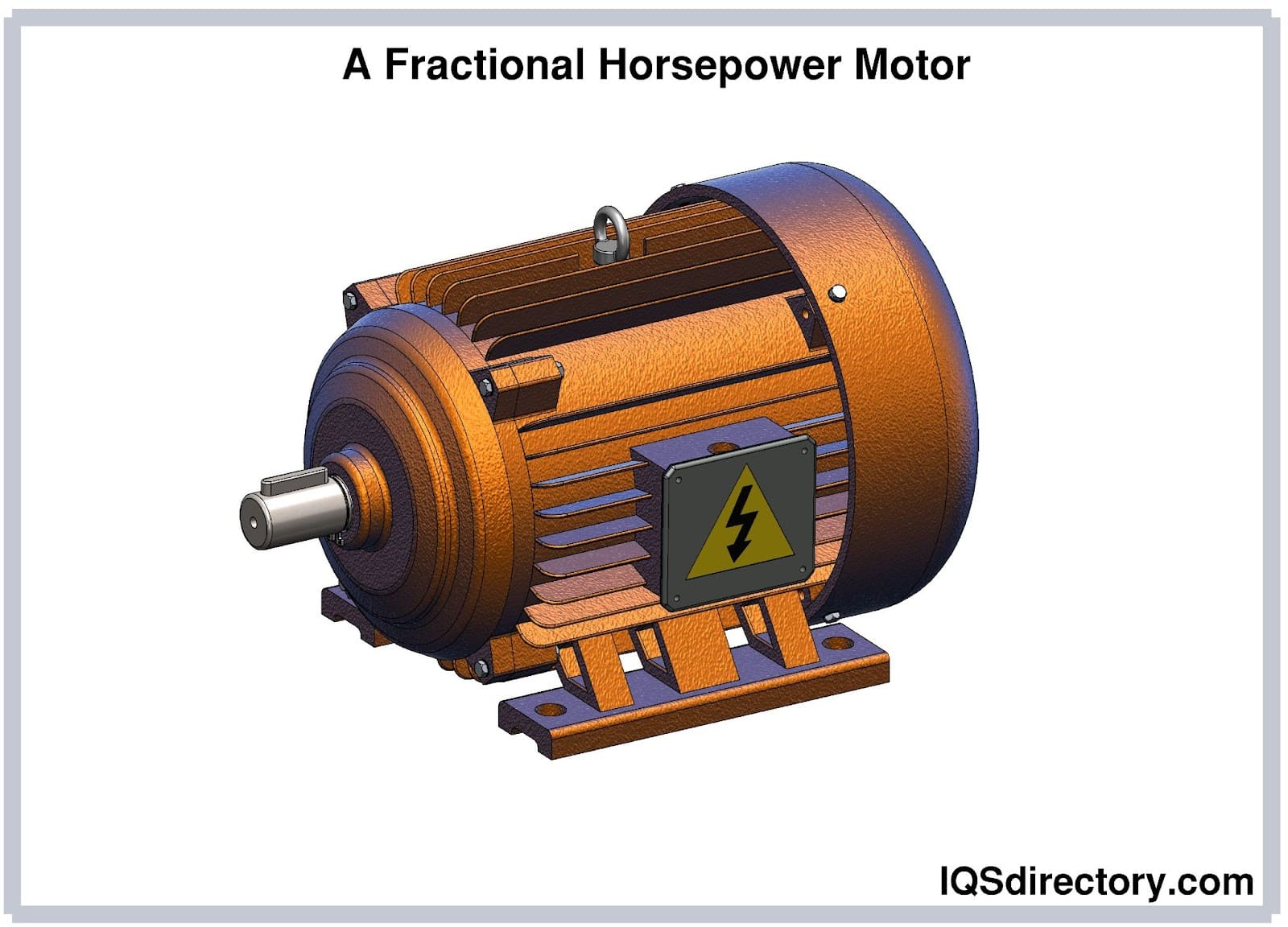

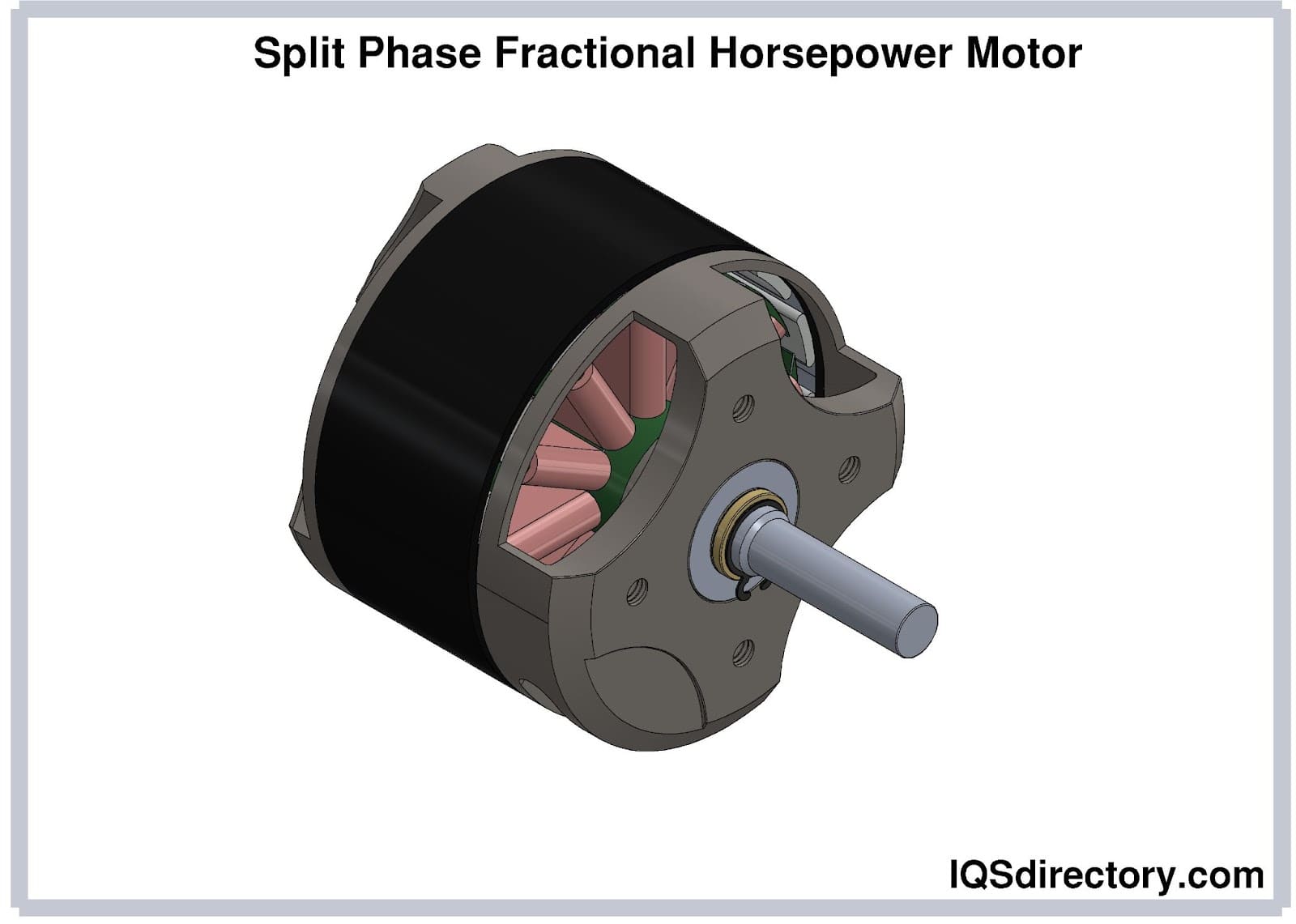

Understanding fractional hp electric motors Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Permanent Magnet Motors | High efficiency, compact size, low maintenance | Robotics, consumer appliances, HVAC systems | Pros: Energy-efficient, quiet operation. Cons: Higher initial cost compared to other types. |

| AC Induction Motors | Simple design, durable, widely available | Industrial machinery, pumps, fans | Pros: Reliable, cost-effective. Cons: Lower efficiency at variable speeds. |

| DC Brushless Motors | High efficiency, low noise, precise control | Automotive applications, medical devices | Pros: Long lifespan, minimal maintenance. Cons: More complex control systems required. |

| Universal Motors | Can operate on AC or DC, compact design | Household appliances, power tools, HVAC | Pros: Versatile use, easy to integrate. Cons: Generally less efficient than other motor types. |

| Gear Motors | Integrated gear reduction, high torque output | Conveyors, robotics, automotive applications | Pros: Increased torque, compact design. Cons: Can be heavier and more expensive. |

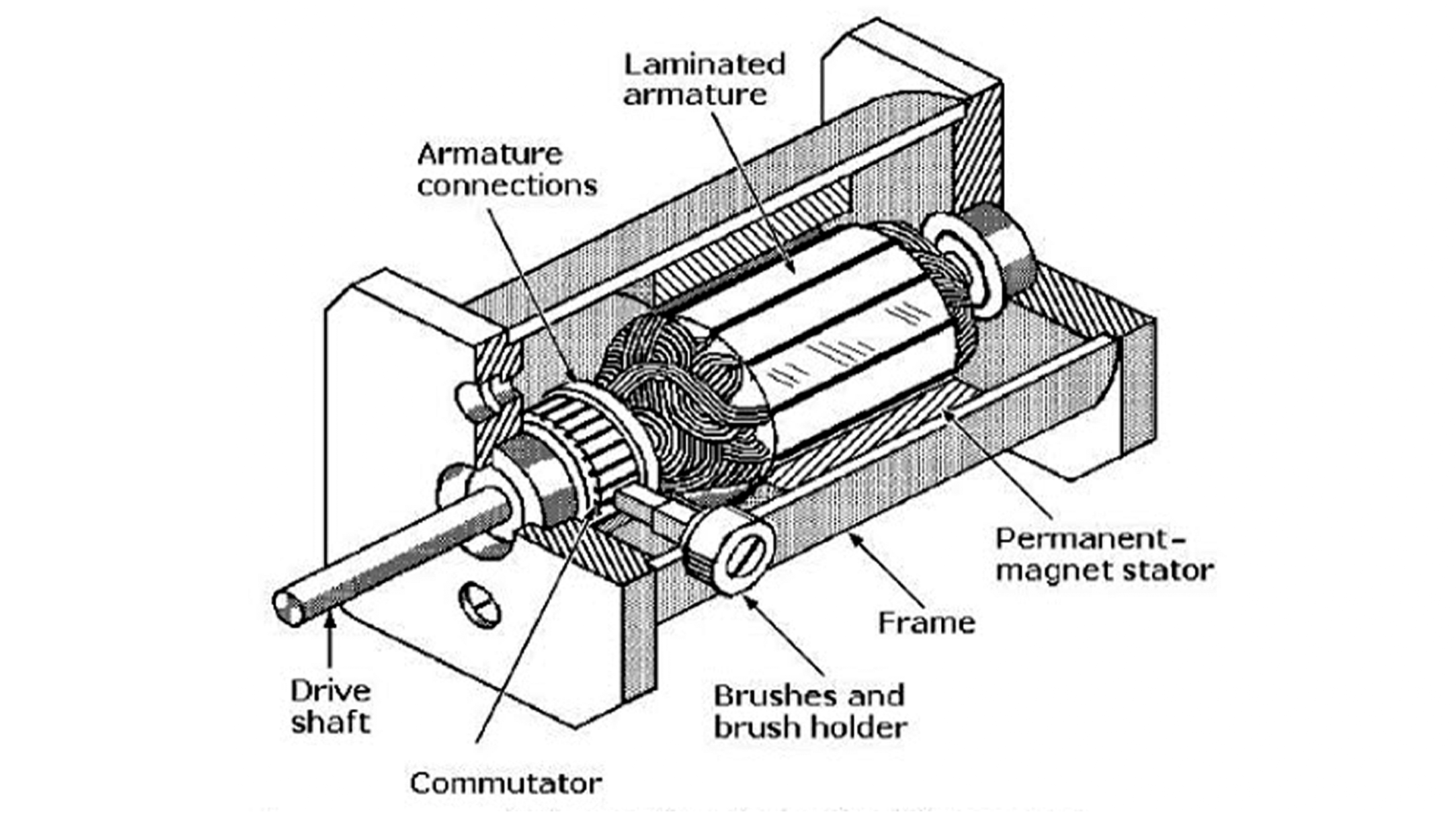

What Are the Characteristics and Suitability of Permanent Magnet Motors?

Permanent magnet motors are characterized by their use of permanent magnets to generate a magnetic field, resulting in high efficiency and compact designs. They are particularly suitable for applications where low noise and energy savings are paramount, such as in robotics and consumer appliances. When purchasing, B2B buyers should consider the initial investment, as these motors tend to have a higher upfront cost compared to others, but they offer long-term savings through reduced energy consumption and maintenance.

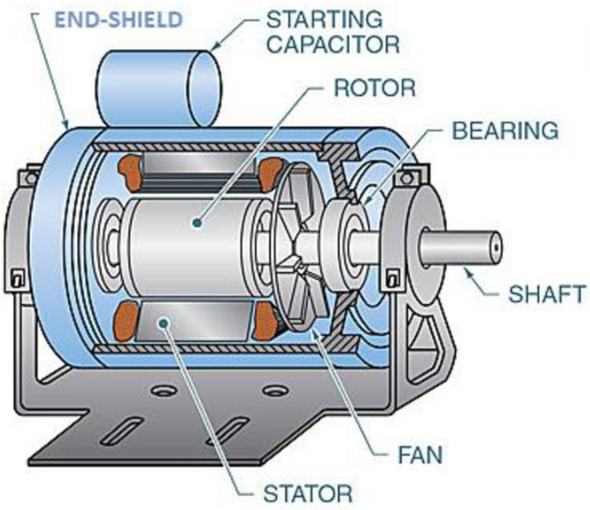

How Do AC Induction Motors Stand Out in Industrial Applications?

AC induction motors are known for their simple design and durability, making them a staple in industrial settings. They are commonly found in pumps, fans, and various machinery due to their reliability and cost-effectiveness. Buyers should focus on the specific power requirements and efficiency ratings when selecting AC induction motors, as these factors can significantly impact operational costs over time. While they are generally less efficient at variable speeds, their robustness makes them ideal for consistent, high-demand applications.

What Makes DC Brushless Motors Ideal for Precision Applications?

DC brushless motors excel in applications requiring high efficiency and precise speed control, such as in automotive and medical devices. Their low noise operation and long lifespan are significant advantages for industries where reliability is critical. Buyers should evaluate the complexity of the control systems needed for these motors, as they can be more intricate than traditional brushed motors. However, the benefits of reduced maintenance and enhanced performance often justify the investment.

Why Choose Universal Motors for Versatile Applications?

Universal motors can operate on both AC and DC power, making them highly versatile for various applications, including household appliances and power tools. Their compact design allows for easy integration into tight spaces. Buyers should consider the specific application requirements, as while universal motors are adaptable, they are generally less efficient than specialized motor types. Their ability to function in diverse settings, however, makes them a valuable option for businesses seeking flexibility.

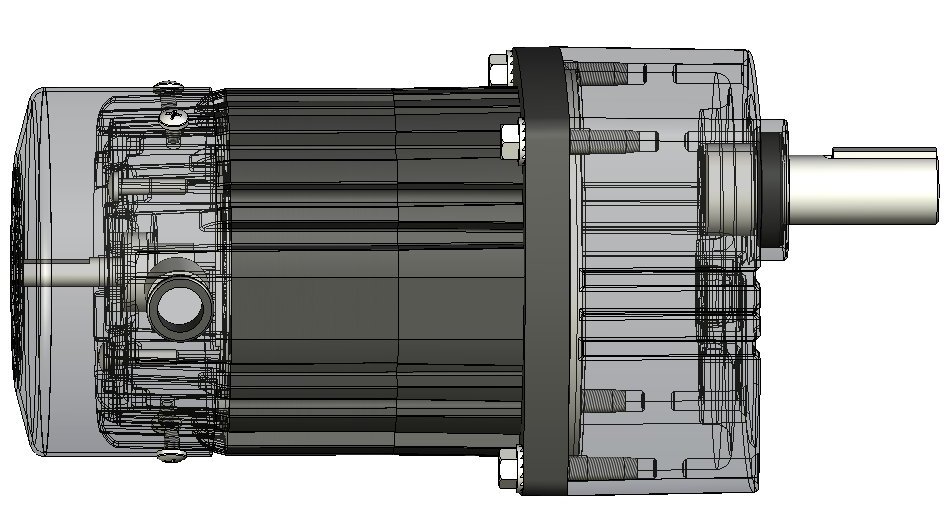

How Do Gear Motors Provide Advantages in Torque Applications?

Gear motors combine a motor with a gear reduction system, providing high torque output in a compact design. They are particularly effective in applications such as conveyors and robotics, where increased torque is essential. Buyers should assess the weight and cost implications of gear motors, as they can be heavier and more expensive than standard motors. However, for applications requiring significant force in limited space, gear motors offer unparalleled advantages in performance.

Key Industrial Applications of fractional hp electric motors

| Industry/Sector | Specific Application of fractional hp electric motors | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Industrial Automation | Powering conveyor systems and packaging machinery | Increases operational efficiency and reduces downtime | Reliability, energy efficiency, and compact design |

| Automotive | Operating power windows and seat adjustments | Enhances vehicle comfort and safety | Durability, precise speed control, and low maintenance |

| Medical Devices | Driving infusion pumps and diagnostic equipment | Ensures precision and reliability in patient care | Compliance with healthcare standards and low noise levels |

| HVAC Systems | Powering fans and compressors in air conditioning | Optimizes energy use and improves indoor air quality | Energy efficiency ratings and adaptability to load changes |

| Consumer Appliances | Functioning in refrigerators and washing machines | Increases product reliability and user satisfaction | Size constraints and noise reduction capabilities |

How are Fractional HP Electric Motors Used in Industrial Automation?

In industrial automation, fractional horsepower electric motors are pivotal in driving conveyor systems, packaging machinery, and light-duty production tools. Their compact design allows for easy integration into existing systems, while their energy efficiency reduces operational costs. These motors solve common challenges such as space limitations and the need for reliable, repeatable motion. Buyers in regions like Africa and South America should prioritize sourcing motors with robust performance and low maintenance requirements to minimize downtime and enhance productivity.

What Role Do Fractional HP Electric Motors Play in Automotive Applications?

In the automotive sector, fractional horsepower motors are essential for operating components such as power windows, seat adjustments, and HVAC systems. Their precise speed control enhances user comfort and safety, meeting the increasing demands for convenience in modern vehicles. For international buyers, especially in Europe and the Middle East, sourcing durable and efficient motors that comply with automotive standards is crucial to ensure long-term performance and reliability in various climatic conditions.

How are Fractional HP Electric Motors Critical in Medical Devices?

Fractional horsepower motors are integral to numerous medical devices, including infusion pumps, blood analyzers, and dental equipment. Their low power consumption and quiet operation are especially valuable in healthcare settings, where precision and reliability are paramount. For B2B buyers in the medical sector, it is essential to consider motors that meet stringent healthcare standards and provide low noise levels to ensure patient comfort and compliance with regulations.

Why are Fractional HP Electric Motors Important for HVAC Systems?

In HVAC systems, fractional horsepower motors power fans, compressors, and blowers, playing a critical role in maintaining effective temperature control and ventilation. Their energy efficiency is vital for reducing operational costs and improving indoor air quality in both commercial and residential applications. Buyers in regions with varying climate conditions, such as Brazil and Nigeria, should focus on sourcing motors that can adapt to fluctuating loads while maintaining optimal performance.

How are Fractional HP Electric Motors Utilized in Consumer Appliances?

Fractional horsepower motors are widely used in consumer appliances like refrigerators, washing machines, and vacuum cleaners. Their compact size and low noise output make them ideal for home environments, where space efficiency and user comfort are paramount. For international buyers, sourcing motors that offer reliable performance and energy efficiency can significantly enhance the quality and marketability of consumer products in competitive markets across Europe and Africa.

3 Common User Pain Points for ‘fractional hp electric motors’ & Their Solutions

Scenario 1: Sourcing Quality Motors for Diverse Applications

The Problem: B2B buyers often face the challenge of sourcing fractional horsepower (FHP) electric motors that meet specific application requirements, especially when dealing with diverse applications across different industries. For instance, a manufacturer producing medical devices needs motors that not only comply with stringent safety standards but also provide reliable performance in critical environments. The difficulty lies in identifying suppliers that offer quality motors with the right specifications, leading to potential delays in production and increased costs.

The Solution: To effectively source quality fractional horsepower motors, B2B buyers should start by conducting thorough market research to identify reputable manufacturers known for their reliability and quality control. Requesting samples or trial units can be invaluable in assessing motor performance in real-world applications. Moreover, buyers should engage with suppliers who are transparent about their manufacturing processes and certifications, ensuring compliance with industry standards. Utilizing a comprehensive checklist that includes performance metrics, certifications, and warranty information can streamline the selection process. Additionally, leveraging industry connections and attending trade shows can provide firsthand insights into supplier reputations and product offerings.

Scenario 2: Ensuring Compatibility with Existing Systems

The Problem: Another common pain point is the compatibility of fractional horsepower motors with existing equipment or systems. Many companies operate with legacy systems that may require specific motor types or configurations. For example, an HVAC company looking to upgrade its air handling units may find that not all available FHP motors are compatible with their older control systems, leading to operational inefficiencies and increased costs for retrofitting.

The Solution: To ensure compatibility, buyers should start by documenting the specifications of their existing systems, including voltage requirements, mounting configurations, and control interfaces. Engaging with motor manufacturers early in the selection process can provide valuable insights into compatibility issues. It’s advisable to work with engineers who can assess the necessary modifications or adaptations required for new motors to integrate seamlessly with existing systems. Additionally, seeking out suppliers who offer customization options can help mitigate compatibility concerns, ensuring that the selected motors will fit without requiring extensive alterations to existing setups.

Scenario 3: Managing Energy Efficiency and Operational Costs

The Problem: B2B buyers are increasingly pressured to reduce operational costs while improving energy efficiency, especially in sectors like manufacturing and HVAC. Many fractional horsepower motors operate at varying efficiencies, and selecting a motor that consumes more energy than necessary can lead to significant long-term costs. This is particularly challenging in regions with fluctuating energy prices, where the total cost of ownership becomes a critical consideration.

The Solution: To address energy efficiency concerns, buyers should prioritize energy-efficient fractional horsepower motors that comply with global efficiency standards such as NEMA Premium or IEC efficiency classifications. Conducting a lifecycle cost analysis can help assess the long-term savings associated with investing in higher-efficiency motors versus cheaper, less efficient options. Additionally, implementing monitoring systems to track energy consumption can provide insights into operational performance, allowing for data-driven decisions regarding motor usage. Collaborating with suppliers who offer energy audits and recommendations can further aid buyers in making informed choices that balance upfront costs with future savings, ultimately enhancing sustainability and profitability.

Strategic Material Selection Guide for fractional hp electric motors

What Materials are Commonly Used in Fractional HP Electric Motors?

When selecting materials for fractional horsepower (FHP) electric motors, it is crucial to understand how different materials can affect performance, durability, and cost. Below, we analyze four common materials used in the construction of these motors, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

What are the Key Properties of Aluminum in FHP Electric Motors?

Aluminum is widely used in the casing and components of fractional hp motors due to its lightweight and excellent thermal conductivity. It typically has a temperature rating up to 150°C and is resistant to corrosion, making it suitable for various environments.

Pros & Cons: The primary advantage of aluminum is its lightweight nature, which reduces the overall weight of the motor, enhancing efficiency in applications where weight is a concern. However, it is less durable than steel and can be more expensive, especially when considering manufacturing complexities such as machining and forming.

Impact on Application: Aluminum is particularly effective in applications requiring heat dissipation, such as HVAC systems and consumer appliances.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards for aluminum quality, such as ASTM or ISO certifications, to avoid issues with material integrity.

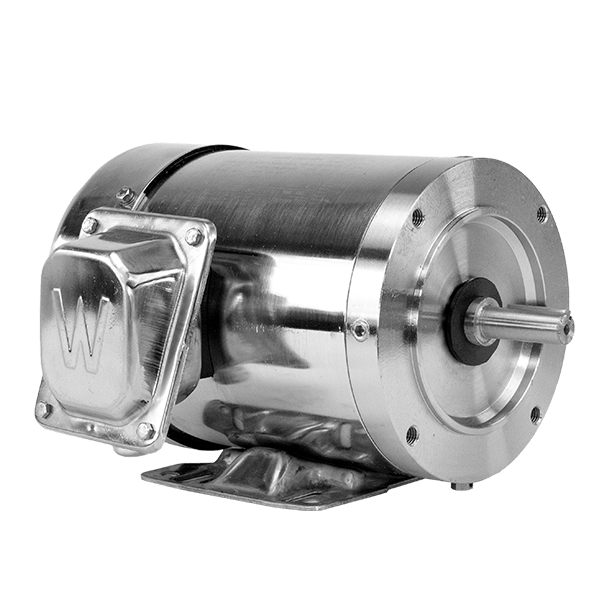

How Does Steel Perform in Fractional HP Electric Motors?

Steel, particularly stainless steel, is often used for components that require high strength and durability, such as shafts and bearings. It can withstand higher temperatures (up to 300°C) and provides excellent wear resistance.

Pros & Cons: The durability of steel makes it ideal for heavy-duty applications, but it is heavier than aluminum and may increase the overall weight of the motor. Additionally, manufacturing steel components can be more complex and costly due to the need for specialized tools.

Impact on Application: Steel is particularly suited for industrial applications where durability and strength are paramount, such as in conveyor systems and robotics.

Considerations for International Buyers: Buyers should be aware of the varying grades of steel and their compliance with international standards like DIN or JIS, especially in regions like Europe and the Middle East.

What Role Does Copper Play in Fractional HP Electric Motors?

Copper is primarily used in windings and electrical connections due to its excellent electrical conductivity and thermal properties. It can operate effectively in temperatures up to 200°C.

Illustrative image related to fractional hp electric motors

Pros & Cons: The high conductivity of copper ensures efficient energy transfer, which is critical for motor performance. However, copper is more expensive than aluminum and can be prone to corrosion if not properly insulated.

Impact on Application: Copper is essential in applications requiring high efficiency and reliability, such as automotive systems and medical devices.

Considerations for International Buyers: Buyers should ensure that the copper used meets international standards for conductivity and purity, particularly in regions with stringent electrical safety regulations.

How is Plastic Used in Fractional HP Electric Motors?

Plastics, particularly engineering-grade thermoplastics, are increasingly used for components like housings and insulation. They can operate effectively at temperatures up to 120°C and offer good chemical resistance.

Pros & Cons: The lightweight nature of plastics and their resistance to corrosion make them ideal for many applications. However, they may not be suitable for high-stress components due to lower mechanical strength compared to metals.

Illustrative image related to fractional hp electric motors

Impact on Application: Plastics are commonly used in consumer electronics and appliances, where weight and corrosion resistance are critical.

Considerations for International Buyers: Buyers should verify that the plastics used comply with relevant safety and environmental standards, especially in regions where regulations are strict.

Summary Table of Material Selection for Fractional HP Electric Motors

| Material | Typical Use Case for fractional hp electric motors | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Casing and components in HVAC systems | Lightweight and good thermal conductivity | Less durable than steel | Medium |

| Steel | Shafts and bearings in industrial applications | High strength and durability | Heavier and more complex to manufacture | High |

| Copper | Windings and electrical connections | Excellent electrical conductivity | More expensive and prone to corrosion | High |

| Plastic | Housings and insulation in consumer electronics | Lightweight and corrosion-resistant | Lower mechanical strength | Low |

This strategic material selection guide provides essential insights into the materials used in fractional hp electric motors, helping international B2B buyers make informed decisions that align with their specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for fractional hp electric motors

What Are the Key Stages in the Manufacturing Process of Fractional Horsepower Electric Motors?

The manufacturing process for fractional horsepower (FHP) electric motors involves several critical stages, each designed to ensure that the final product meets the stringent performance and quality standards required in various applications.

1. Material Preparation: How Are Components Sourced and Prepared?

The first stage in manufacturing FHP motors is material preparation. This involves sourcing high-quality raw materials such as copper for windings, steel for the motor housing, and various insulation materials. Suppliers must adhere to international standards to ensure consistency and reliability.

Illustrative image related to fractional hp electric motors

Materials are often subjected to initial inspections to check for defects or impurities, which could affect the performance of the motor. Proper handling and storage of these materials are essential to prevent damage prior to processing. Additionally, manufacturers may use material certifications to verify that components meet specific industry standards, which is particularly crucial for international buyers.

2. Forming: What Techniques Are Used to Shape Motor Components?

Once materials are prepared, the next stage is forming. This typically includes processes such as stamping, die-casting, and machining, where raw materials are shaped into the required components.

- Stamping is commonly used for creating the laminated steel cores that form the stator and rotor, which are essential for magnetic performance.

- Die-casting may be employed for producing complex shapes in aluminum or other alloys used in the motor casing.

- Machining processes, such as turning and milling, refine component dimensions to meet precise tolerances.

These techniques ensure that parts fit together correctly and function efficiently, which is vital for optimal motor performance.

Illustrative image related to fractional hp electric motors

3. Assembly: How Are Components Integrated into a Complete Motor?

The assembly phase is where the manufactured components come together to form a complete motor. This process often involves:

- Winding the Stator and Rotor: Copper wire is wound into the stator and rotor, which are then insulated to prevent short-circuiting.

- Mounting Components: The assembled stator is fitted into the motor housing, and the rotor is positioned within it. Bearings are then installed to allow smooth rotation.

- Electrical Connections: All electrical connections are made, and the motor is equipped with additional components, such as cooling fans or speed controllers, depending on its intended use.

Quality control checkpoints during assembly are critical, as they allow for immediate corrections of any issues that may arise.

4. Finishing: What Final Steps Ensure Quality and Performance?

The finishing stage includes several processes that prepare the motor for shipment. This often involves:

- Testing: Each motor is subjected to a series of performance tests to ensure it meets operational specifications. This may include testing for electrical efficiency, noise levels, and thermal performance.

- Coating: Motors may receive a protective coating to guard against environmental factors such as moisture and dust.

- Labeling and Packaging: Proper labeling with specifications and certifications is crucial for end-users, and packaging must protect the motor during transportation.

What Quality Assurance Practices Are Essential for FHP Motors?

Quality assurance (QA) in the manufacturing of fractional horsepower motors is vital to ensure reliability and performance.

International Standards: Which Certifications Should Buyers Look For?

Manufacturers often adhere to international standards such as ISO 9001, which outlines requirements for a quality management system (QMS). Compliance with ISO standards assures buyers that the manufacturer consistently meets customer and regulatory requirements.

Illustrative image related to fractional hp electric motors

Additional industry-specific certifications may include:

- CE Marking: Indicates compliance with EU safety, health, and environmental protection standards.

- API Standards: Relevant for motors used in oil and gas applications, ensuring they meet specific performance and safety criteria.

Understanding these certifications can help B2B buyers assess the credibility of potential suppliers.

Quality Control Checkpoints: What Are the Key Stages of QC?

Quality control is integrated throughout the manufacturing process and typically includes several checkpoints:

- Incoming Quality Control (IQC): Raw materials and components are inspected upon arrival at the manufacturing facility to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During manufacturing, operators perform checks at various stages to monitor quality and prevent defects.

- Final Quality Control (FQC): After assembly, finished motors undergo rigorous testing to verify performance metrics, including efficiency, noise levels, and heat generation.

These checkpoints help ensure that any defects are caught early, reducing the risk of poor-quality products reaching the market.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international buyers, especially from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial.

Illustrative image related to fractional hp electric motors

What Verification Methods Are Available?

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturing process and quality control measures firsthand. This can provide insights into the supplier’s adherence to international standards and their overall operational practices.

-

Quality Reports: Requesting detailed quality control reports from suppliers can offer transparency regarding their QC processes and any certifications they hold.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality practices. These inspections can be particularly useful for buyers unfamiliar with local suppliers.

-

References and Case Studies: Asking for references from other clients, especially those in similar industries, can help gauge the supplier’s reliability and quality.

What Nuances Should International Buyers Consider in Quality Assurance?

International buyers must navigate several nuances when it comes to quality assurance in the procurement of fractional horsepower motors:

-

Regulatory Compliance: Different regions may have varying regulatory requirements. Understanding these can help buyers ensure that the motors they procure will be compliant in their respective markets.

-

Cultural Differences: Communication styles and business practices can vary significantly across regions. Establishing clear expectations regarding quality standards and delivery timelines is crucial.

-

Logistics and Supply Chain: The logistics of transporting motors across borders can introduce additional risks. Ensuring that suppliers have robust logistics and quality assurance practices can help mitigate these risks.

In conclusion, the manufacturing processes and quality assurance practices for fractional horsepower electric motors are complex and require careful consideration by B2B buyers. By understanding the manufacturing stages, quality control protocols, and how to verify supplier practices, buyers can make informed decisions that lead to successful procurement and application of FHP motors across various industries.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fractional hp electric motors’

When sourcing fractional horsepower (FHP) electric motors, it’s crucial to follow a structured approach to ensure that you select the right product for your application. This checklist will guide you through the essential steps to effectively procure these motors, considering various technical and supplier-related factors.

Step 1: Define Your Technical Specifications

Begin by clearly outlining the technical requirements for your fractional horsepower motor. This includes determining the power output, voltage, and type (AC or DC) needed for your specific application. Consider the operating environment and any relevant industry standards to ensure compatibility.

- Power Rating: Identify the required horsepower, typically less than one, based on your application’s demands.

- Frame Size: Choose an appropriate frame size that aligns with the physical constraints of your equipment.

Step 2: Research and Identify Potential Suppliers

Conduct thorough market research to identify suppliers specializing in fractional horsepower motors. Look for manufacturers with a solid reputation and extensive experience in your industry.

- Supplier Reputation: Check online reviews, testimonials, and case studies to gauge supplier reliability.

- Global Reach: Ensure the supplier can meet your logistics needs, especially if you are sourcing from different continents.

Step 3: Evaluate Supplier Certifications

Before making a decision, verify that potential suppliers hold relevant certifications. This is crucial for ensuring quality and compliance with industry regulations.

- ISO Certifications: Look for ISO 9001 or similar certifications that indicate adherence to quality management standards.

- Product Certifications: Check for compliance with safety and efficiency standards such as CE, UL, or RoHS.

Step 4: Request Samples and Technical Documentation

Request samples of the motors along with technical documentation to assess their quality and suitability for your application. This step helps you verify the performance claims made by the supplier.

- Performance Testing: Conduct tests to evaluate the motor’s efficiency, noise levels, and durability under load conditions.

- Documentation Review: Examine datasheets and user manuals to understand installation requirements and maintenance needs.

Step 5: Compare Pricing and Terms

Once you have shortlisted potential suppliers, compare their pricing structures, payment terms, and delivery schedules. This will help you find the best overall value for your investment.

- Total Cost of Ownership: Consider not just the purchase price but also the long-term operational costs, including energy consumption and maintenance.

- Negotiation: Don’t hesitate to negotiate terms or seek volume discounts, especially if you’re planning a larger order.

Step 6: Assess After-Sales Support and Warranty

Evaluate the after-sales support offered by the supplier, including warranty terms and availability of replacement parts. Reliable support can significantly reduce downtime and maintenance costs.

- Warranty Duration: Look for warranties that cover defects and performance for a reasonable period.

- Technical Support: Ensure that the supplier provides accessible customer service for troubleshooting and technical inquiries.

Step 7: Finalize Your Order and Establish a Relationship

Once you have completed your evaluations, finalize your order with the chosen supplier. Establishing a strong relationship can lead to better service and future procurement advantages.

Illustrative image related to fractional hp electric motors

- Contract Terms: Clearly define contract terms, including delivery timelines and conditions for returns or exchanges.

- Ongoing Communication: Maintain open lines of communication to facilitate a smooth procurement process and address any issues promptly.

By following this checklist, you can confidently source fractional horsepower electric motors that meet your operational needs while ensuring quality and reliability.

Comprehensive Cost and Pricing Analysis for fractional hp electric motors Sourcing

What Are the Key Cost Components of Fractional HP Electric Motors?

When sourcing fractional horsepower (FHP) electric motors, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. Common materials include copper for windings, steel for frames, and various plastics for housings. High-quality materials can enhance durability and efficiency but may also increase costs.

-

Labor: Labor costs vary widely depending on the manufacturing location. Regions with lower labor costs may offer more competitive pricing, but this can sometimes compromise quality. It’s essential to evaluate the skill level and experience of the workforce involved in production.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can reduce overhead, positively impacting the final price.

-

Tooling: Custom tooling for specific designs can add significant upfront costs. However, this investment may be justified for high-volume orders or specialized applications, where tooling can lead to lower per-unit costs over time.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability and compliance with industry standards, which can influence both cost and price. Higher QC standards may lead to increased costs but also improve customer satisfaction and reduce returns.

-

Logistics: Shipping and handling costs are critical, especially for international buyers. Factors such as distance, shipping methods, and customs duties can add to the total expense, making it vital to assess logistics when evaluating suppliers.

-

Margin: Suppliers typically include a profit margin in their pricing, which varies based on market conditions, competition, and perceived value. Understanding this margin can help buyers negotiate better terms.

How Do Price Influencers Affect Fractional HP Electric Motors?

Several factors can influence the pricing of fractional hp electric motors:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases generally lead to lower prices per unit. Suppliers often provide discounts for larger orders, making it beneficial for buyers with significant needs to negotiate favorable terms.

-

Specifications and Customization: Custom specifications can drive up costs due to additional engineering and production requirements. Buyers should weigh the necessity of custom features against potential price increases.

-

Quality and Certifications: Motors that meet specific industry standards or certifications (like ISO or CE) may command higher prices. However, these certifications can be essential for compliance and safety, influencing the total cost of ownership.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more for their proven quality and service, while newer or less known suppliers may offer lower prices to enter the market.

-

Incoterms: The agreed-upon Incoterms (International Commercial Terms) dictate who is responsible for shipping, insurance, and tariffs. Understanding these terms can help buyers avoid unexpected costs and facilitate smoother transactions.

What Are Effective Buyer Tips for Sourcing Fractional HP Electric Motors?

When sourcing fractional hp electric motors, international B2B buyers should consider the following tips to enhance cost-efficiency:

-

Negotiate with Suppliers: Leverage volume and long-term contracts to negotiate better pricing. Building a strong relationship with suppliers can also lead to additional benefits, such as priority service or better payment terms.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, energy efficiency, and potential downtime costs associated with the motor. A lower upfront cost may not always equate to better value.

-

Understand Pricing Nuances for International Purchases: Be aware of currency fluctuations, import tariffs, and local taxes, as these can significantly affect the total cost. Collaborating with local experts can help navigate these complexities.

-

Research and Compare Suppliers: Conduct thorough research on multiple suppliers, considering both price and quality. Request samples or prototypes to assess performance before committing to larger orders.

-

Stay Informed About Market Trends: Keeping an eye on industry trends and technological advancements can provide insights into pricing dynamics and help buyers make informed decisions.

In summary, understanding the cost components, price influencers, and practical sourcing strategies can empower international B2B buyers to make more informed decisions when sourcing fractional horsepower electric motors. This comprehensive approach will not only optimize costs but also ensure long-term satisfaction and reliability in their applications.

Alternatives Analysis: Comparing fractional hp electric motors With Other Solutions

When considering the best solution for small-scale power applications, businesses often evaluate fractional horsepower (FHP) electric motors against alternative technologies. This analysis provides insights into how these motors compare with other solutions, enabling B2B buyers to make informed decisions.

| Comparison Aspect | Fractional Hp Electric Motors | Stepper Motors | Pneumatic Actuators |

|---|---|---|---|

| Performance | Reliable, efficient for low-power applications | High precision and control, ideal for positioning | High force output, suitable for heavy-duty applications |

| Cost | Generally low-cost, affordable for mass production | Moderate cost, but can increase with complexity | Varies widely; compressor costs can add up |

| Ease of Implementation | Easy to install and integrate into existing systems | Requires careful programming and setup | Requires air supply and additional infrastructure |

| Maintenance | Low maintenance, durable with proper use | Moderate maintenance, depends on usage | High maintenance; potential for leaks and wear |

| Best Use Case | Ideal for small machinery, consumer appliances | Best for precise motion control in robotics | Suitable for heavy lifting and industrial applications |

What Are the Advantages and Disadvantages of Stepper Motors?

Stepper motors are a compelling alternative for applications requiring precise control over movement. Their ability to divide a full rotation into a large number of steps allows for accurate positioning, making them ideal for automation in robotics and CNC machinery. However, they can be more expensive than fractional horsepower motors, particularly when complex control systems are necessary. Additionally, stepper motors often require more maintenance, especially in high-duty cycles, where wear can affect performance.

How Do Pneumatic Actuators Compare to Fractional Hp Electric Motors?

Pneumatic actuators utilize compressed air to produce motion, making them powerful for heavy-duty applications like material handling and industrial machinery. Their high force output is beneficial for lifting and moving heavy loads. However, the requirement for an air compressor and associated infrastructure can lead to higher operational costs and complexity. Maintenance can also be a concern, as pneumatic systems are prone to leaks and require regular checks to ensure optimal performance.

Conclusion: How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting between fractional horsepower electric motors and alternatives like stepper motors or pneumatic actuators, B2B buyers should assess their specific application requirements, including performance needs, budget constraints, and maintenance capabilities. Fractional hp motors excel in applications requiring compact, energy-efficient solutions with low operational costs. In contrast, stepper motors and pneumatic actuators offer unique advantages for precision control and heavy-duty applications, respectively. By understanding the strengths and weaknesses of each option, businesses can make informed decisions that align with their operational goals and financial considerations.

Illustrative image related to fractional hp electric motors

Essential Technical Properties and Trade Terminology for fractional hp electric motors

What Are the Key Technical Properties of Fractional HP Electric Motors?

Understanding the technical specifications of fractional horsepower (FHP) electric motors is essential for B2B buyers aiming to make informed purchasing decisions. Here are some critical specifications to consider:

1. Power Output and Horsepower Rating

Power output, measured in horsepower, indicates the motor’s capacity to perform work over time. For FHP motors, this typically ranges from 1/50 to 1 horsepower (746 watts). Buyers should select motors based on the specific power requirements of their applications, ensuring that the motor can handle the intended load without overheating or underperforming.

2. Frame Size

Frame size defines the physical dimensions of the motor and is crucial for compatibility with existing equipment. Common frame sizes include 42, 48, and 56, which dictate mounting options and fit in designated machinery spaces. Ensuring the correct frame size helps avoid installation challenges and operational inefficiencies.

3. Efficiency Rating

Efficiency ratings, often expressed as a percentage, indicate how much of the input power is converted into useful work. Higher efficiency motors consume less energy, leading to reduced operating costs and enhanced sustainability. B2B buyers should prioritize efficient motors, particularly in applications where long operational hours are expected.

4. Voltage and Frequency

FHP motors operate at specific voltage and frequency levels, typically 120V or 230V for AC motors, and 12V to 48V for DC motors. Understanding these specifications is critical for ensuring compatibility with power supply systems. Incorrect voltage can lead to motor failure or inefficiency, making it essential for buyers to align motor specifications with their power infrastructure.

5. Material Grade and Build Quality

The materials used in motor construction, such as steel for the frame and copper for windings, influence durability and performance. High-grade materials enhance reliability and can withstand harsh operating environments. Buyers should assess material quality to ensure longevity and minimize maintenance costs.

Illustrative image related to fractional hp electric motors

6. Tolerance Levels

Tolerance levels refer to the permissible limits of variation in motor dimensions and performance characteristics. Tight tolerances are crucial for applications requiring precise control and operation. Understanding tolerance specifications helps buyers ensure that the motors will meet the specific demands of their machinery.

What Are Common Trade Terms Related to Fractional HP Electric Motors?

Familiarity with industry terminology can streamline communication and negotiations between buyers and manufacturers. Here are some essential trade terms:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of FHP motors, understanding whether a motor is sourced from an OEM can provide insights into quality and reliability, essential for long-term partnerships.

Illustrative image related to fractional hp electric motors

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For fractional horsepower motors, MOQs can vary based on the manufacturer and the type of motor. Understanding MOQs is vital for budgeting and inventory management, especially for companies entering new markets or launching new products.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to solicit price quotes for specific products or services. When requesting quotes for FHP motors, detailed specifications should be included to ensure accurate pricing and avoid misunderstandings during procurement.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping responsibilities, cost allocations, and risk management, which is especially crucial in cross-border transactions involving FHP motors.

Illustrative image related to fractional hp electric motors

5. Lead Time

Lead time refers to the period from the placement of an order until its delivery. Knowing the lead time for fractional horsepower motors is essential for project planning and inventory control. Longer lead times can impact production schedules, making it important for buyers to clarify this with suppliers.

6. CE Marking

The CE marking indicates that a product meets European safety, health, and environmental protection standards. For buyers in Europe, ensuring that FHP motors carry this certification is crucial for compliance and marketability within the region.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing fractional horsepower electric motors, ensuring they meet both operational needs and compliance requirements.

Illustrative image related to fractional hp electric motors

Navigating Market Dynamics and Sourcing Trends in the fractional hp electric motors Sector

What are the Key Market Trends Impacting Fractional HP Electric Motors?

The fractional horsepower (FHP) electric motors market is experiencing robust growth, driven by a surge in automation across various industries. Global trends such as the increasing demand for energy-efficient solutions, advancements in motor technology, and the rise of smart manufacturing are shaping the landscape. In regions like Africa, South America, the Middle East, and Europe, there is a notable shift towards integrating FHP motors in applications ranging from industrial automation to consumer appliances. For instance, the automotive sector is rapidly adopting FHP motors for applications like power windows and HVAC systems, reflecting a broader trend towards enhancing vehicle efficiency and comfort.

Moreover, the emergence of Industry 4.0 is driving B2B buyers to seek motors that offer advanced features such as IoT compatibility and real-time monitoring capabilities. International buyers are increasingly focused on sourcing suppliers that can provide not only high-quality products but also innovative solutions that cater to their specific operational needs. This trend is particularly pronounced in Brazil and Nigeria, where local manufacturers are exploring partnerships with global suppliers to enhance their technological capabilities and product offerings.

How is Sustainability Influencing the Sourcing of Fractional HP Electric Motors?

Sustainability is becoming a cornerstone of procurement strategies in the fractional horsepower electric motors sector. The environmental impact of production processes and the lifecycle of motors are under scrutiny, prompting buyers to prioritize suppliers committed to ethical sourcing and sustainable practices. This includes using recyclable materials, minimizing waste, and reducing carbon footprints during manufacturing.

B2B buyers are increasingly seeking FHP motors that are certified by recognized environmental standards, such as ISO 14001 or Energy Star. These certifications not only signify a commitment to sustainability but also often translate to lower operational costs due to increased energy efficiency. Additionally, the rise of green technologies has led to the development of motors that utilize eco-friendly materials and manufacturing processes. For international buyers, particularly in Europe and the Middle East, sourcing from suppliers with a strong emphasis on sustainability can enhance brand reputation and meet regulatory requirements while appealing to environmentally conscious consumers.

What is the Historical Context of Fractional HP Electric Motors in B2B?

The history of fractional horsepower motors is intertwined with the evolution of electric power and automation technologies. Nikola Tesla’s invention of the induction motor in 1888 laid the foundation for the development of FHP motors, but it was not until the early 20th century that these motors gained widespread adoption. The growth of electric utilities in urban areas and the introduction of household appliances like washing machines catalyzed the demand for FHP motors, making them an integral part of daily life.

Post-World War II, the market for fractional horsepower motors expanded significantly, fueled by rising consumer demand for electronic goods and industrial automation tools. By 2017, the European FHP market alone was valued at approximately $4.5 billion, showcasing the motors’ critical role across various sectors. As the industry continues to evolve, the ongoing innovations in motor design and applications promise to further enhance the efficiency and versatility of fractional horsepower motors, ensuring their relevance in modern manufacturing and consumer markets.

Frequently Asked Questions (FAQs) for B2B Buyers of fractional hp electric motors

-

How do I choose the right fractional horsepower motor for my application?

Choosing the right fractional horsepower motor involves assessing several factors including power requirements, size constraints, and application specifics. Start by determining the horsepower needed for your equipment, considering both peak and continuous load. Next, evaluate the environment where the motor will operate, as factors like temperature, humidity, and exposure to contaminants can influence performance. Additionally, consider the motor’s efficiency, noise levels, and maintenance needs to ensure it aligns with your operational goals. -

What are the most common applications for fractional horsepower motors?

Fractional horsepower motors are widely used across various industries due to their compact size and efficiency. Common applications include HVAC systems, automotive components, medical devices, and consumer appliances. They power equipment such as fans, pumps, conveyors, and robotics, where reliable performance and energy efficiency are crucial. Understanding the specific needs of your industry will help you identify the most suitable FHP motor for your application. -

What customization options are available for fractional horsepower motors?

Many manufacturers offer customization options for fractional horsepower motors, allowing you to tailor the motor to meet specific requirements. Customizations can include modifications to frame size, voltage ratings, speed settings, and mounting configurations. You can also request specialized features such as variable speed drives or enhanced protection against environmental factors. Engaging with suppliers early in the design process can help ensure that the motor meets your operational needs effectively. -

What are the minimum order quantities (MOQ) for fractional horsepower motors?

Minimum order quantities for fractional horsepower motors can vary significantly between manufacturers. Generally, MOQs may range from a few units to several hundred, depending on the supplier’s production capabilities and the specific motor specifications. It’s advisable to discuss your project needs with potential suppliers to determine if they can accommodate smaller orders, particularly for custom motors or prototypes, which may have different MOQ requirements. -

How can I verify the reliability of a fractional horsepower motor supplier?

To verify a supplier’s reliability, start by researching their reputation within the industry. Look for certifications such as ISO 9001, which indicate adherence to quality management standards. Request references from previous clients and check online reviews or ratings. Additionally, assess their production capabilities, warranty policies, and customer service responsiveness. Engaging in direct communication can also provide insights into their operational practices and commitment to quality. -

What payment terms should I expect when sourcing fractional horsepower motors internationally?

Payment terms for international purchases of fractional horsepower motors typically vary by supplier and region. Common arrangements include advance payment, letters of credit, or payment upon delivery. Discussing payment terms upfront can help establish clear expectations and ensure both parties are aligned. Be aware of additional costs such as tariffs, shipping fees, and currency exchange rates that may impact the overall transaction. -

What quality assurance measures should I consider when sourcing FHP motors?

Quality assurance measures are critical when sourcing fractional horsepower motors to ensure reliability and performance. Look for suppliers that implement rigorous testing protocols, such as performance testing, thermal imaging, and vibration analysis. Inquire about their quality control certifications and processes, including incoming material inspections and end-of-line testing. Additionally, consider requesting a sample motor for evaluation before committing to a larger order. -

How should I approach logistics and shipping for international motor purchases?

When purchasing fractional horsepower motors internationally, it’s essential to plan logistics carefully. Evaluate potential shipping methods, including air freight for expedited delivery or sea freight for cost-effectiveness. Work with suppliers who have experience in international shipping and can assist with customs documentation. Be aware of shipping timelines, as delays can impact project schedules, and ensure that you have adequate insurance coverage for your shipment to protect against loss or damage during transit.

Top 8 Fractional Hp Electric Motors Manufacturers & Suppliers List

1. Fractional Horsepower Motors – FHP Solutions

Domain: fractionalhorsepowermotors.com

Registered: 2000 (25 years)

Introduction: Fractional horsepower motors (FHP motors) are small electric motors with a power rating of less than one horsepower (746 watts). They are categorized by frame size and power output, typically used in industrial automation, automotive systems, medical devices, HVAC equipment, and consumer electronics. Applications include driving pumps, fans, conveyors, automotive components, medical devices, and h…

2. Groschopp – Fractional Horsepower Motors

Domain: groschopp.com

Registered: 1995 (30 years)

Introduction: Fractional horsepower motors are defined as motors with a power output of less than one horsepower (746 Watts). Groschopp specializes in mid- to large-sized fractional horsepower AC motors and small- to mid-sized DC and BLDC motors. Their Universal motors cover a broader range, with horsepower capabilities from 1/20 to 2 ½ hp. Specific horsepower ranges for Groschopp’s motors are as follows: AC mo…

3. IQS Directory – Fractional Horsepower Motors

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Fractional horsepower motors operate using AC or DC and provide less than one horsepower (peak power capacity of 746 watts). They are ideal for compact electronic devices and applications requiring high precision due to minimal vibration. Types include: 1. Brush Series Motors: Simple speed control, used in power tools and household appliances. 2. Brushless Motors: Efficient, low-maintenance, used …

4. Meier Supply – Condenser Fan Motors

Domain: meiersupply.com

Registered: 1997 (28 years)

Introduction: {“products”:[{“SKU”:”EM 5462″,”description”:”Condenser Fan Motor, 1/6-1/3hp 5.6” 208-230v PSC TEAO Rescue”,”power”:”1/6-1/3 hp”,”voltage”:”208-230V”,”enclosure”:”Totally Enclosed Air Over (TEAO)”},{“SKU”:”EM 5465″,”description”:”Condenser Fan Motor, 1/5-1/2hp 5.6” 208-230v PSC TEAO Rescue”,”power”:”1/5-1/2 hp”,”voltage”:”208-230V”,”enclosure”:”Totally Enclosed Air Over (TEAO)”},{“SKU”:”EM 5461″,”d…

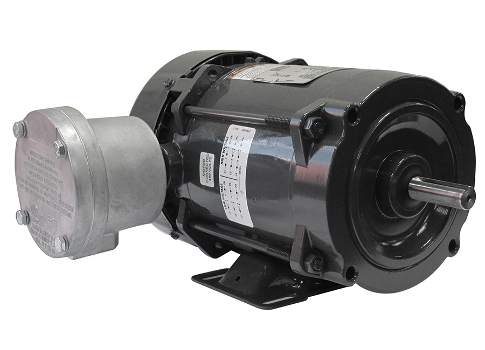

5. WorldWide Electric – Single-phase Fractional TEFC Motors

Domain: worldwideelectric.com

Registered: 1999 (26 years)

Introduction: Single-phase Fractional TEFC Motors from WorldWide Electric Corporation are designed for pumps, compressors, conveyors, and other industrial machinery. Key features include:

– Totally enclosed, fan-cooled design for reliability in harsh environments

– Versatile specifications and mounting options (C-Face with Removable Base)

– Capacitor start/induction run for 1/3 – 1 hp

– Capacitor start/capa…

6. Tecowe Westinghouse – 3-Phase Fractional HP Electric Motor

Domain: tecowestinghouse.com

Registered: 1999 (26 years)

Introduction: 3-Phase Fractional HP Electric Motor

– Type: Totally Enclosed Fan Cooled (TEFC)

– Horsepower: 1/3 HP through 2 HP

– Speed Options: 3600, 1800, 1200 RPM

– Voltage: 230/460V (usable on 200 & 208V)

– Frequency: 60 Hz

– Features:

– Three Phase, 60 Hz

– 1.15 Service Factor (Continuous)

– Class F Insulation

– Class B Temperature Rise

– NEMA Design B Torques

– Rolled Steel Frame and Main Con…

7. RSPSupply – Fractional Horsepower Motors

Domain: rspsupply.com

Registered: 2016 (9 years)

Introduction: Fractional horsepower motors are electric motors that provide less than one horsepower. They are typically used for applications that require less power and for devices that must be compact. These motors are essential for a wide range of residential, commercial, and industrial products. Key characteristics include being compact and lightweight, making them suitable for practical applications where…

8. CNGSE39 – Electric Motors DC & AC Fractional HP

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“title”:”Electric motors DC &AC fractional hp”,”seller”:”cngse39″,”feedback”:”100% positive feedback”,”price”:”$80.00 or Best Offer”,”payment_options”:”4 interest-free payments of $20.00 available with Klarna”,”shipping_cost”:”$84.56 shipping”,”estimated_delivery”:”Tue, Sep 16 – Tue, Sep 23″,”local_pickup”:”free local pickup from Winchester, California, United States 92596″,”condition”:”Used”,”de…

Strategic Sourcing Conclusion and Outlook for fractional hp electric motors

In conclusion, fractional horsepower (FHP) electric motors are pivotal in powering a myriad of applications across diverse industries, from industrial automation to consumer electronics. Their compact design, energy efficiency, and reliability make them indispensable for businesses looking to enhance operational performance and reduce costs. For international B2B buyers in regions like Africa, South America, the Middle East, and Europe, strategic sourcing of FHP motors not only ensures access to high-quality products but also fosters partnerships with manufacturers committed to innovation and sustainability.

As the market evolves, the demand for FHP motors is expected to grow, driven by advancements in technology and increasing applications in renewable energy and automation. Buyers should prioritize suppliers who offer customizable solutions and demonstrate a clear understanding of local market dynamics. Embracing this strategic approach will empower businesses to leverage the full potential of fractional horsepower motors, enhancing productivity and competitiveness.

Looking ahead, now is the time to engage with trusted suppliers and explore the latest offerings in fractional horsepower motors. By investing in these reliable solutions, businesses can position themselves for success in an increasingly dynamic global market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.