Top 7 What Is A Vacuum Chamber Made Of Suppliers (And How to Choose)

Introduction: Navigating the Global Market for what is a vacuum chamber made of

In today’s competitive landscape, international B2B buyers face the challenge of sourcing vacuum chambers that align with specific operational needs and budget constraints. Understanding what a vacuum chamber is made of—whether aluminum, stainless steel, or other materials—is crucial for selecting the right equipment for diverse applications, from leak testing to atmospheric simulation. This guide provides an in-depth exploration of vacuum chamber materials, examining their performance characteristics, cost implications, and suitability for various industrial applications.

As businesses expand globally, particularly in regions such as Africa, South America, the Middle East, and Europe, making informed purchasing decisions becomes increasingly vital. This comprehensive resource not only outlines the types of vacuum chambers available but also delves into supplier vetting processes and long-term cost considerations, ensuring that buyers can confidently navigate the complexities of sourcing. By equipping decision-makers with essential insights into material properties, outgassing rates, and thermal considerations, this guide empowers companies to optimize their investments in vacuum technology, ultimately enhancing operational efficiency and product quality.

Understanding what is a vacuum chamber made of Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Stainless Steel Vacuum Chamber | Low outgassing rates, high durability, corrosion resistance | UHV applications, chemical processing, aerospace | Pros: Long lifespan, minimal maintenance. Cons: Higher initial cost. |

| Aluminum Vacuum Chamber | Lightweight, high thermal conductivity, easier to machine | Laboratory use, material testing, vacuum drying | Pros: Cost-effective, easier customization. Cons: Higher outgassing rates than stainless steel. |

| Glass Vacuum Chamber | Transparent, allows for visual monitoring | Research labs, educational settings, material studies | Pros: Easy observation, non-reactive. Cons: Fragile, limited pressure tolerance. |

| Plastic Vacuum Chamber | Lightweight, cost-effective, suitable for low vacuum levels | Food packaging, low-pressure applications | Pros: Affordable, easy to handle. Cons: Limited durability and chemical resistance. |

| Ceramic Vacuum Chamber | High thermal stability, low outgassing | High-temperature applications, semiconductor fabrication | Pros: Excellent thermal resistance. Cons: Generally more expensive and less common. |

What Are the Characteristics of Stainless Steel Vacuum Chambers?

Stainless steel vacuum chambers are renowned for their low outgassing rates, making them ideal for ultra-high vacuum (UHV) applications. Their high durability and resistance to corrosion ensure they perform well in harsh environments, such as chemical processing and aerospace industries. When considering a stainless steel vacuum chamber, B2B buyers should evaluate their long-term costs, as these chambers typically require a higher upfront investment but offer minimal maintenance and a longer lifespan, making them cost-effective over time.

Why Choose Aluminum Vacuum Chambers for Your Applications?

Aluminum vacuum chambers are favored for their lightweight nature and high thermal conductivity, which allows for efficient heat dissipation during processes that involve temperature cycling. They are easier to machine than stainless steel, facilitating customization for specific applications such as laboratory testing and vacuum drying. However, buyers should be aware that aluminum has higher outgassing rates compared to stainless steel, which may impact performance in sensitive applications. The cost-effectiveness of aluminum makes it an attractive option for businesses focused on budget-friendly solutions.

What Are the Benefits of Glass Vacuum Chambers?

Glass vacuum chambers provide a unique advantage with their transparent design, allowing for easy visual monitoring of processes. They are commonly used in research labs and educational settings, where observation of the vacuum environment is crucial. While glass chambers are non-reactive, making them suitable for a variety of materials, they are fragile and have limited pressure tolerance. B2B buyers must weigh the benefits of visibility against the potential risks of breakage and the need for careful handling.

How Do Plastic Vacuum Chambers Fit into the Market?

Plastic vacuum chambers are lightweight and cost-effective, making them suitable for low-pressure applications such as food packaging. Their affordability and ease of handling make them appealing for businesses looking to minimize costs. However, they have limited durability and chemical resistance compared to metal or glass options. B2B buyers should consider the specific requirements of their applications, particularly in terms of pressure and chemical exposure, before opting for plastic chambers.

What Are the Advantages of Ceramic Vacuum Chambers?

Ceramic vacuum chambers are recognized for their high thermal stability and low outgassing rates, making them suitable for high-temperature applications and semiconductor fabrication. While they are less common and generally more expensive than other materials, their excellent thermal resistance can justify the investment for specialized industries. Buyers should assess the operational conditions and expected performance requirements when considering ceramic chambers, as their unique properties can provide significant advantages in the right applications.

Key Industrial Applications of what is a vacuum chamber made of

| Industry/Sector | Specific Application of what is a vacuum chamber made of | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Semiconductor Manufacturing | Used for thin film deposition and etching processes | Ensures high purity and low contamination levels | Require low outgassing materials like stainless steel; evaluate thermal stability. |

| Food Packaging | Vacuum sealing for preservation and shelf-life extension | Reduces spoilage, enhances product longevity | Consider food-grade materials; ensure compliance with safety regulations. |

| Pharmaceutical Industry | Sterilization and lyophilization of drugs | Maintains efficacy and stability of sensitive compounds | Look for chambers with low outgassing rates; assess chemical compatibility. |

| Aerospace | Testing components under vacuum conditions | Validates performance and durability of parts | Need for robust materials that withstand extreme conditions; focus on weight-to-strength ratio. |

| Research Laboratories | Atmospheric simulation for experiments | Provides accurate environmental conditions for testing | Evaluate customization options for access and configuration; ensure precision in vacuum control. |

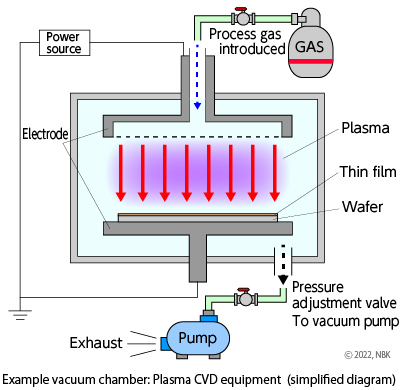

How is a Vacuum Chamber Used in Semiconductor Manufacturing?

In semiconductor manufacturing, vacuum chambers are critical for processes like thin film deposition and etching. These chambers are typically made from stainless steel or aluminum to minimize contamination and ensure high purity environments. The low outgassing rates of stainless steel are essential for maintaining the integrity of the vacuum, which is crucial for the precision required in semiconductor fabrication. International buyers must consider the thermal stability of the materials used to ensure consistent performance, especially in regions with varying climate conditions.

What Role Does a Vacuum Chamber Play in Food Packaging?

In the food packaging sector, vacuum chambers are employed for sealing products to extend shelf life and reduce spoilage. The use of vacuum technology helps to eliminate oxygen, thereby slowing down the oxidation process that leads to food deterioration. For B2B buyers in Africa and South America, it is vital to source vacuum chambers made from food-grade materials that comply with local safety regulations. Ensuring that the chambers are capable of maintaining a consistent vacuum level is essential for effective packaging.

How is a Vacuum Chamber Essential in the Pharmaceutical Industry?

The pharmaceutical industry utilizes vacuum chambers for processes such as sterilization and lyophilization, which are critical for preserving the efficacy of drugs. These chambers must be constructed from materials that exhibit low outgassing rates to avoid contamination of sensitive compounds. Buyers from the Middle East and Europe should focus on sourcing chambers that meet stringent regulatory requirements and possess chemical compatibility with various pharmaceutical agents to ensure safe processing.

Why are Vacuum Chambers Important in Aerospace Applications?

In aerospace, vacuum chambers are used for testing components under simulated vacuum conditions to validate their performance and durability. The materials selected for these chambers must be robust enough to withstand extreme conditions while maintaining a lightweight profile. B2B buyers in this sector need to prioritize sourcing chambers that balance strength with weight, particularly for high-stakes applications where performance is critical.

How Do Research Laboratories Utilize Vacuum Chambers?

Research laboratories frequently employ vacuum chambers for atmospheric simulation, which allows for controlled testing environments. These chambers can be customized to meet specific research needs, such as accommodating various access points or configurations. Buyers should evaluate the precision of vacuum control systems and the overall design of the chambers to ensure they can replicate accurate environmental conditions for their experiments. This is particularly important for international buyers looking to align with global research standards.

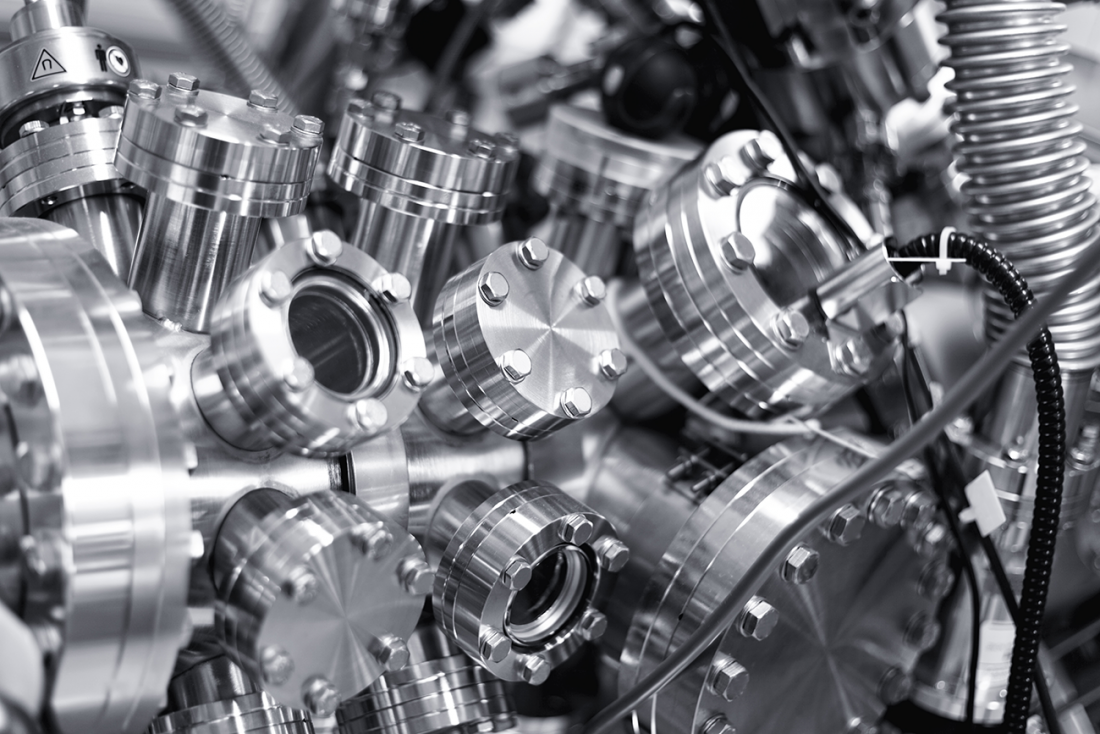

Illustrative image related to what is a vacuum chamber made of

3 Common User Pain Points for ‘what is a vacuum chamber made of’ & Their Solutions

Scenario 1: Selecting the Right Material for Your Vacuum Chamber Needs

The Problem: A B2B buyer in the pharmaceutical industry is tasked with procuring a vacuum chamber for a sensitive drug formulation process. They are aware that both aluminum and stainless steel are commonly used materials, but they struggle to understand the specific properties of each and how these materials will impact their vacuum processes. The buyer is concerned about contamination risks, outgassing rates, and the potential for material degradation, especially when dealing with corrosive substances. This uncertainty can lead to costly delays and complications in their production schedule.

The Solution: To effectively choose between aluminum and stainless steel, buyers should conduct a thorough analysis of their application requirements. Stainless steel is generally the better choice for environments involving corrosive materials due to its chemical resistance and lower outgassing rates. Buyers should request detailed specifications from suppliers, including outgassing rates and chemical compatibility data, to ensure that the selected material aligns with their operational needs. Additionally, investing in surface treatments for aluminum, such as anodizing, can mitigate some outgassing concerns. Collaborating with manufacturers who specialize in vacuum technology can provide insights into custom solutions that enhance durability and performance.

Scenario 2: Understanding the Impact of Vacuum Chamber Geometry on Performance

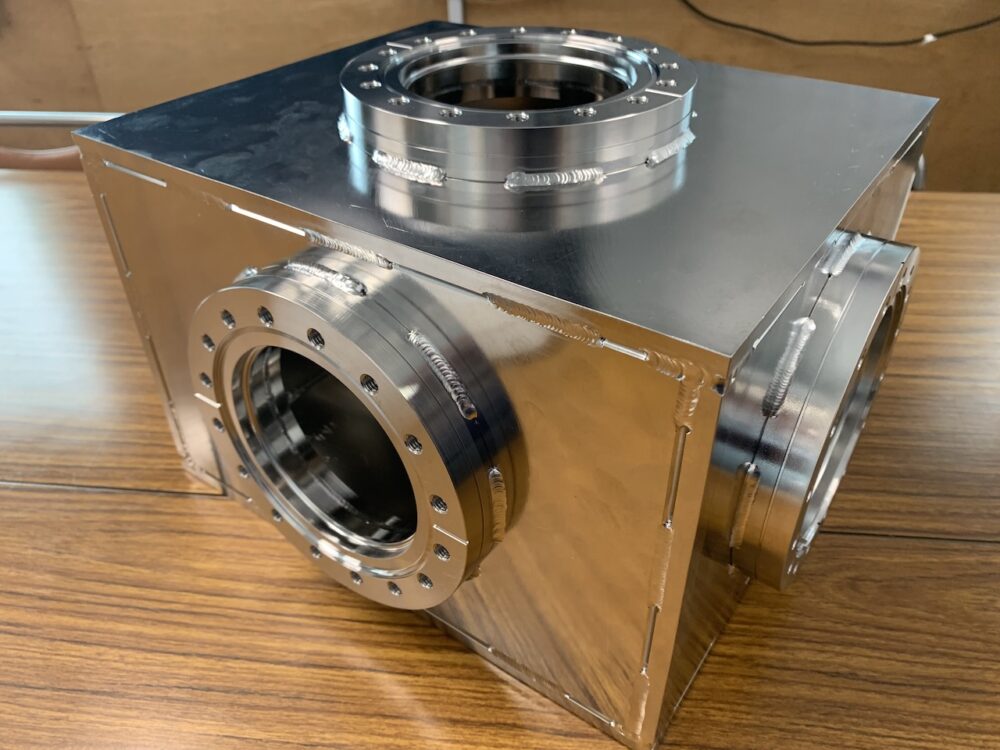

The Problem: A research laboratory is looking to purchase a vacuum chamber but is confused about how the geometry of the chamber affects its performance and utility. They need a chamber that can handle various sample sizes and types, but they are unsure whether to opt for a cylindrical, spherical, or rectangular design. The wrong choice could result in inefficient vacuum conditions, leading to inaccurate test results and wasted resources.

The Solution: Buyers should start by evaluating the specific applications for which the vacuum chamber will be used. Cylindrical chambers are ideal for general-purpose applications due to their strength and uniform pressure distribution, while rectangular chambers offer flexibility and ease of access for frequent sample handling. Consulting with engineers who understand the nuances of vacuum chamber design can help buyers select the most effective geometry for their needs. Additionally, manufacturers often provide customization options, allowing buyers to tailor the chamber’s design to accommodate unique requirements, such as integrating multiple access ports or custom mounting points for instruments.

Scenario 3: Navigating Cost vs. Durability in Vacuum Chamber Purchases

The Problem: An industrial manufacturer is evaluating options for purchasing vacuum chambers but is caught in a dilemma between choosing aluminum for its lower initial cost or stainless steel for its long-term durability. They are concerned that opting for the cheaper option may result in higher maintenance costs and shorter lifespan, leading to greater expenditures over time. This decision is critical as it directly impacts their operational budget and production reliability.

The Solution: To make an informed decision, buyers should conduct a total cost of ownership analysis that includes not just the initial purchase price but also maintenance, repair, and replacement costs over time. Stainless steel chambers may have a higher upfront cost, but their durability and lower maintenance needs often result in cost savings in the long run. Buyers should also inquire about warranty options and service agreements that manufacturers offer, which can provide added assurance of durability and support. Furthermore, engaging with suppliers to understand the long-term performance of both materials in similar applications can provide valuable insights that lead to more strategic purchasing decisions.

Strategic Material Selection Guide for what is a vacuum chamber made of

What Materials Are Commonly Used for Vacuum Chambers?

When selecting materials for vacuum chambers, it’s essential to consider various factors such as performance, durability, and cost. Below, we analyze four common materials used in vacuum chamber construction: stainless steel, aluminum, glass, and high-density ceramic. Each material presents unique properties and implications for specific applications, particularly for international B2B buyers.

How Does Stainless Steel Perform in Vacuum Chambers?

Stainless steel is a popular choice for vacuum chambers due to its excellent strength and low outgassing rates. It can withstand high temperatures and pressures, making it suitable for a wide range of applications, including those involving corrosive environments. The material’s corrosion resistance ensures longevity, reducing the frequency of maintenance and replacement.

Pros: Stainless steel chambers are highly durable and resistant to chemical damage, which is critical for applications involving harsh substances. They also maintain structural integrity under varying temperature conditions.

Cons: The primary drawback is the higher initial cost and manufacturing complexity compared to other materials like aluminum. Additionally, stainless steel is heavier, which can increase shipping costs and installation complexity.

Impact on Application: Stainless steel is ideal for applications requiring high vacuum levels, such as spectroscopic analyses and thin film deposition. Its chemical compatibility makes it suitable for industries ranging from pharmaceuticals to semiconductor manufacturing.

Considerations for International Buyers: Buyers in regions such as Africa, South America, and the Middle East should consider compliance with international standards like ASTM or DIN for material specifications. The availability of stainless steel can vary, so suppliers should be vetted for quality assurance.

What Advantages Does Aluminum Offer for Vacuum Chambers?

Aluminum is known for its lightweight and high thermal conductivity, making it an excellent choice for applications that require rapid temperature changes. It is easier to machine than stainless steel, allowing for more flexible designs and customization.

Pros: The low weight of aluminum reduces shipping costs, and its machinability allows for quicker production times. Additionally, aluminum chambers can be anodized to enhance their corrosion resistance.

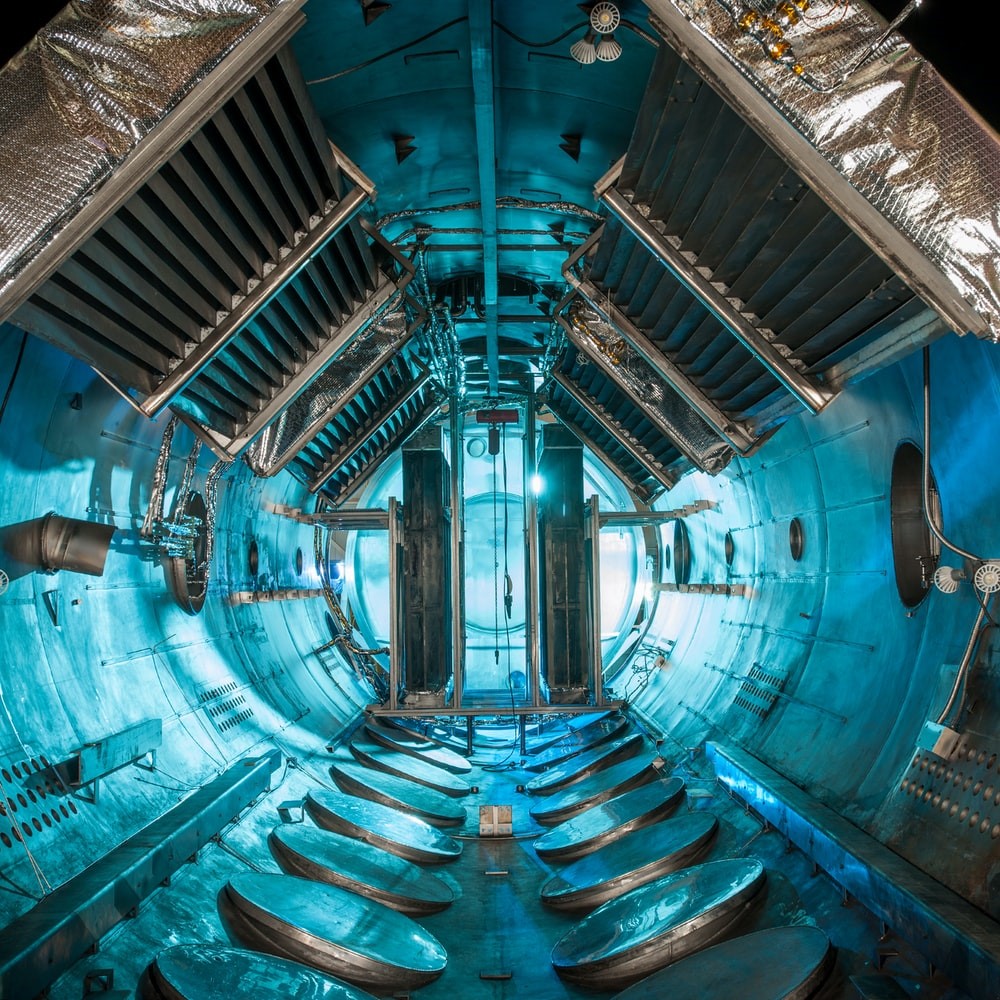

Illustrative image related to what is a vacuum chamber made of

Cons: While aluminum is generally less expensive, it has higher outgassing rates than stainless steel, which may limit its use in ultra-high vacuum applications. It is also less chemically resistant, making it unsuitable for environments with corrosive gases.

Impact on Application: Aluminum vacuum chambers are often used in laboratory settings and for applications involving less aggressive media, such as food packaging or material testing.

Considerations for International Buyers: Buyers should ensure that aluminum chambers meet regional standards for safety and performance. Anodizing processes may vary by region, affecting the material’s suitability for specific applications.

How Does Glass Compare as a Vacuum Chamber Material?

Glass vacuum chambers are primarily used in laboratory settings where visibility is essential. They offer excellent resistance to chemical corrosion and are generally easy to clean.

Pros: Glass provides a clear view of the internal processes, making it ideal for experiments requiring observation. It is also chemically inert, which minimizes contamination risks.

Cons: The fragility of glass makes it less durable than metal options. It is also heavier and can be more challenging to manufacture into complex shapes.

Impact on Application: Glass chambers are suitable for applications like vacuum drying and degassing, where monitoring the process is crucial.

Considerations for International Buyers: Compliance with safety standards is vital, especially in regions where glass breakage could pose risks. Buyers should verify that suppliers adhere to relevant quality certifications.

What Role Does High-Density Ceramic Play in Vacuum Chambers?

High-density ceramic materials are increasingly being used in vacuum chambers for their excellent thermal stability and low outgassing rates. They are particularly useful in high-temperature applications.

Pros: Ceramics can withstand extreme temperatures and provide excellent insulation, making them suitable for high-performance applications.

Cons: The brittleness of ceramics can lead to challenges in manufacturing and handling, and they are typically more expensive than metal options.

Impact on Application: High-density ceramics are ideal for specialized applications, such as aerospace and semiconductor industries, where high temperatures and low outgassing are critical.

Considerations for International Buyers: Buyers should ensure that ceramic materials meet international standards for thermal and mechanical properties, particularly in high-tech industries.

Summary Table of Vacuum Chamber Materials

| Material | Typical Use Case for what is a vacuum chamber made of | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | High vacuum applications, chemical processing | Excellent durability and corrosion resistance | Higher initial cost and weight | High |

| Aluminum | Laboratory experiments, food packaging | Lightweight and easy to machine | Higher outgassing rates | Medium |

| Glass | Laboratory settings, vacuum drying | Excellent visibility and chemical inertness | Fragile and heavier | Medium |

| High-Density Ceramic | Aerospace, semiconductor applications | High thermal stability | Brittle and expensive | High |

This strategic material selection guide provides B2B buyers with actionable insights into the materials used in vacuum chamber construction, enabling informed purchasing decisions tailored to specific applications and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for what is a vacuum chamber made of

What Are the Main Stages of Manufacturing a Vacuum Chamber?

The manufacturing of vacuum chambers involves several critical stages, each designed to ensure the structural integrity and functionality required for specialized applications. The main stages include material preparation, forming, assembly, and finishing.

Illustrative image related to what is a vacuum chamber made of

How Is Material Prepared for Vacuum Chamber Production?

Material preparation is the initial step, focusing on selecting the right materials, typically high-quality aluminum or stainless steel. The choice of material is crucial, as it affects the chamber’s performance, including its outgassing rates and chemical compatibility. Materials are sourced from certified suppliers, and specifications are verified according to international standards like ISO 9001.

Once selected, the materials undergo processes such as cutting and machining to meet the required dimensions. This stage may also include surface treatments, such as anodizing for aluminum, to enhance durability and reduce outgassing. Each batch of material is inspected for defects, ensuring that only high-quality inputs proceed to the forming stage.

What Forming Techniques Are Used in Vacuum Chamber Manufacturing?

The forming stage involves shaping the prepared materials into the desired chamber configuration. Common techniques include:

- CNC Machining: This precision method is often employed to achieve intricate designs and exact dimensions, particularly for components that require high tolerances.

- Hydroforming: This technique uses high-pressure fluid to mold metal into complex shapes without sacrificing material strength. It is especially useful for creating seamless chamber bodies.

- Welding: For assembling the chamber components, welding methods such as TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) are used. Stainless steel is favored due to its superior weldability, allowing for leak-tight joints that are essential in vacuum applications.

The choice of forming technique can significantly impact the chamber’s performance, longevity, and maintenance needs.

Illustrative image related to what is a vacuum chamber made of

How Are Vacuum Chambers Assembled?

Assembly is a critical phase where all components, including the main body, ports, and valves, are brought together. This stage requires meticulous attention to detail to ensure that all parts fit correctly and function as intended.

Key assembly considerations include:

- Sealing Mechanisms: Proper sealing is vital for maintaining vacuum integrity. Gaskets and seals are often used, with materials selected based on the intended application environment.

- Integration of Components: Components like vacuum gauges and control modules are integrated during assembly. These elements are essential for monitoring and maintaining vacuum levels.

- Quality Checks: During assembly, in-process quality control (IPQC) checkpoints are established to catch any defects early, ensuring that components meet specifications before moving to the next phase.

What Finishing Processes Are Involved in Vacuum Chamber Production?

Finishing processes enhance the final product’s aesthetics and functional characteristics. They may include:

- Surface Treatments: Additional surface treatments, such as passivation for stainless steel, are applied to improve corrosion resistance. This is particularly important in industries where exposure to harsh chemicals is common.

- Final Machining: Any necessary adjustments are made to ensure precise fit and finish. This may involve additional machining of edges or surfaces to meet the required tolerances.

- Inspection and Testing: Before the vacuum chamber is deemed complete, it undergoes final quality checks, including dimensional inspections and functional testing to verify performance under vacuum conditions.

What Quality Assurance Measures Are Implemented in Vacuum Chamber Production?

Quality assurance (QA) is integral to the manufacturing of vacuum chambers, ensuring that products meet international and industry-specific standards.

Which International Standards Govern Vacuum Chamber Quality?

Many international standards apply, with ISO 9001 being the foundational quality management standard. Compliance with this standard indicates that a manufacturer has a structured approach to quality management that enhances customer satisfaction.

Industry-specific certifications, such as CE marking for compliance with European health and safety standards, or API standards for equipment used in the petroleum and natural gas industries, may also be relevant. These certifications assure B2B buyers of the quality and safety of the vacuum chambers.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This initial inspection verifies that incoming materials meet specified requirements.

- In-Process Quality Control (IPQC): Conducted during manufacturing, this ensures that processes are followed correctly and that any deviations are addressed immediately.

- Final Quality Control (FQC): At the end of the manufacturing process, the complete vacuum chamber undergoes rigorous testing, including leak tests and performance evaluations to ensure it meets all design specifications.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is essential. Here are several methods:

- Supplier Audits: Conducting on-site audits allows buyers to assess manufacturing practices, cleanliness, and adherence to quality standards.

- Quality Reports: Requesting detailed quality reports can provide insights into the supplier’s QC processes, including testing results and compliance with standards.

- Third-Party Inspections: Engaging third-party inspectors to evaluate the manufacturing facility can provide an unbiased assessment of the supplier’s quality control measures.

What Are the Quality Control Nuances for International Buyers?

Buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of several nuances in quality control:

- Regulatory Differences: Different regions may have varying regulations and standards that affect product certification and acceptance. Understanding these can aid in selecting suppliers that meet local compliance requirements.

- Cultural Considerations: Establishing clear communication with suppliers about quality expectations is critical, as cultural differences can impact interpretations of quality standards.

- Logistics and Supply Chain: Buyers should consider how supply chain logistics may affect the quality of materials and components, particularly if they are sourced from multiple locations.

By understanding the manufacturing processes and quality assurance measures involved in vacuum chamber production, B2B buyers can make informed decisions that align with their operational needs and industry standards. This comprehensive approach ensures that the vacuum chambers they procure will perform reliably and effectively in their intended applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘what is a vacuum chamber made of’

In this guide, we provide a practical checklist for B2B buyers focused on sourcing vacuum chambers. Understanding the materials and specifications that comprise a vacuum chamber is essential for ensuring optimal performance and cost-effectiveness. Follow these steps to make informed decisions when procuring vacuum chambers for your business needs.

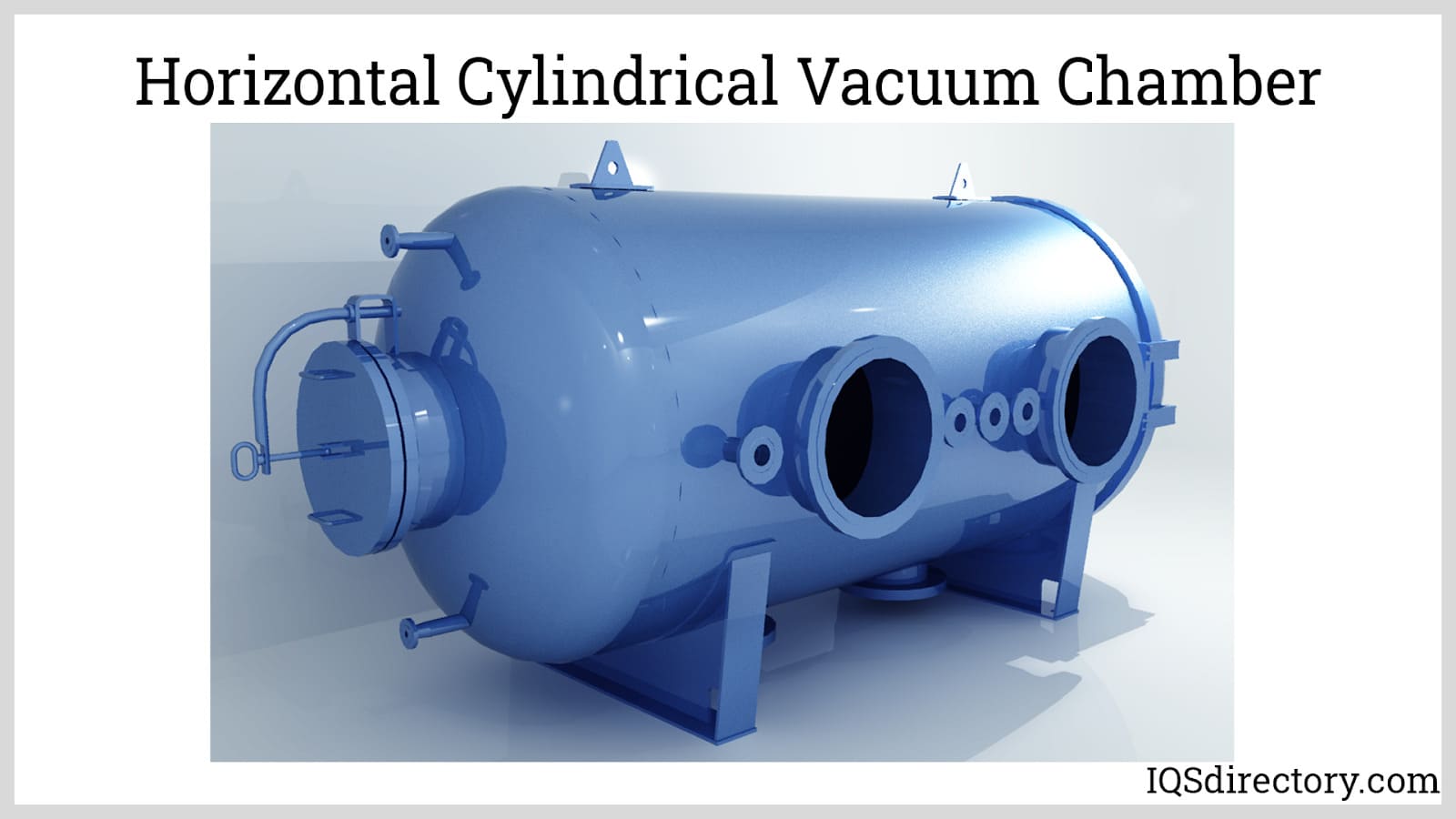

Illustrative image related to what is a vacuum chamber made of

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for identifying the right vacuum chamber for your application. Consider factors such as the desired vacuum level, operating temperature ranges, and the types of materials you plan to process. A well-defined specification will help you communicate effectively with suppliers and ensure they understand your unique requirements.

Step 2: Evaluate Material Options

The primary materials for vacuum chambers are aluminum and stainless steel, each with its advantages. Aluminum is lightweight and offers good thermal conductivity, making it suitable for applications requiring rapid temperature changes. In contrast, stainless steel provides superior durability and lower outgassing rates, making it ideal for high and ultra-high vacuum applications. Assess your application needs to choose the right material.

- Outgassing Rates: Low outgassing rates are essential for maintaining vacuum integrity. Stainless steel generally performs better than aluminum in this regard.

Step 3: Assess Supplier Experience and Reputation

Before making a purchase, it’s essential to evaluate potential suppliers’ experience in manufacturing vacuum chambers. Look for suppliers with a proven track record in your industry or application area. Request case studies and references to gauge their expertise and customer satisfaction levels. A reputable supplier will provide insights into their manufacturing processes and material sourcing.

Step 4: Examine Customization Capabilities

Vacuum chambers often require customization to meet specific operational needs. Inquire about the supplier’s ability to customize dimensions, ports, and other features. A flexible supplier can adapt designs to accommodate unique requirements, such as integrating specialized feedthroughs or vacuum control modules, which can enhance the functionality of your chamber.

Step 5: Verify Quality Assurance Processes

Quality assurance is vital in the procurement process to ensure that the vacuum chamber meets your specifications and industry standards. Ask about the supplier’s quality control measures, including material testing, weld integrity checks, and compliance with relevant certifications. This verification helps prevent costly errors and ensures the reliability of your vacuum chamber.

Step 6: Review Cost and Total Ownership

While upfront costs are important, consider the total cost of ownership over the chamber’s lifespan. Stainless steel chambers may have a higher initial price but often result in lower maintenance costs due to their durability. Evaluate the long-term benefits of each material type and factor in potential maintenance, repair, and operational costs when making your decision.

Step 7: Finalize Logistics and Delivery Terms

Once you’ve selected a supplier, clarify logistics, including delivery timelines, shipping costs, and installation support. Understanding these factors upfront can help avoid delays and ensure that the vacuum chamber is operational when needed. Confirm that the supplier can provide necessary documentation and support during the installation phase to facilitate a smooth transition.

By following this checklist, you can systematically evaluate and procure the right vacuum chamber that aligns with your operational needs and strategic goals.

Comprehensive Cost and Pricing Analysis for what is a vacuum chamber made of Sourcing

What Are the Key Cost Components in Vacuum Chamber Manufacturing?

When sourcing vacuum chambers, it’s essential to understand the various cost components that contribute to the final price. The primary cost elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Materials are the most significant factor, with options typically ranging from aluminum to stainless steel. Stainless steel, while more expensive upfront, offers lower maintenance costs and longer lifespan, which can be beneficial for long-term projects. Labor costs can vary significantly based on region; skilled labor in Europe may command higher wages than in emerging markets like Africa or South America. Manufacturing overhead includes utilities, equipment maintenance, and facility costs, which should not be overlooked as they can substantially affect the overall pricing.

Tooling costs involve the specialized equipment needed for fabrication. This can include molds, dies, and CNC machines tailored for vacuum chamber production. Quality control is critical in ensuring that the chambers meet specific performance standards, particularly in high-stakes applications like aerospace or pharmaceuticals. This process can add to the cost but is vital for minimizing defects and ensuring reliability.

Logistics encompass transportation and shipping, which can be influenced by distance, mode of transport, and any import duties or tariffs applicable in the buyer’s country. Finally, the margin that suppliers add to their costs will depend on market conditions and competition.

How Do Price Influencers Affect Vacuum Chamber Costs?

Several factors influence the pricing of vacuum chambers, which B2B buyers must consider. Volume and minimum order quantities (MOQs) play a significant role; larger orders typically yield better pricing per unit due to economies of scale. Customization also impacts cost, as tailored designs may require additional engineering time and materials.

The choice of materials directly affects pricing, with stainless steel generally being more costly than aluminum but offering superior durability and lower outgassing rates. Additionally, quality certifications can drive up prices; chambers that meet international standards such as ISO or ASTM will often command a premium due to the assurance of quality and performance.

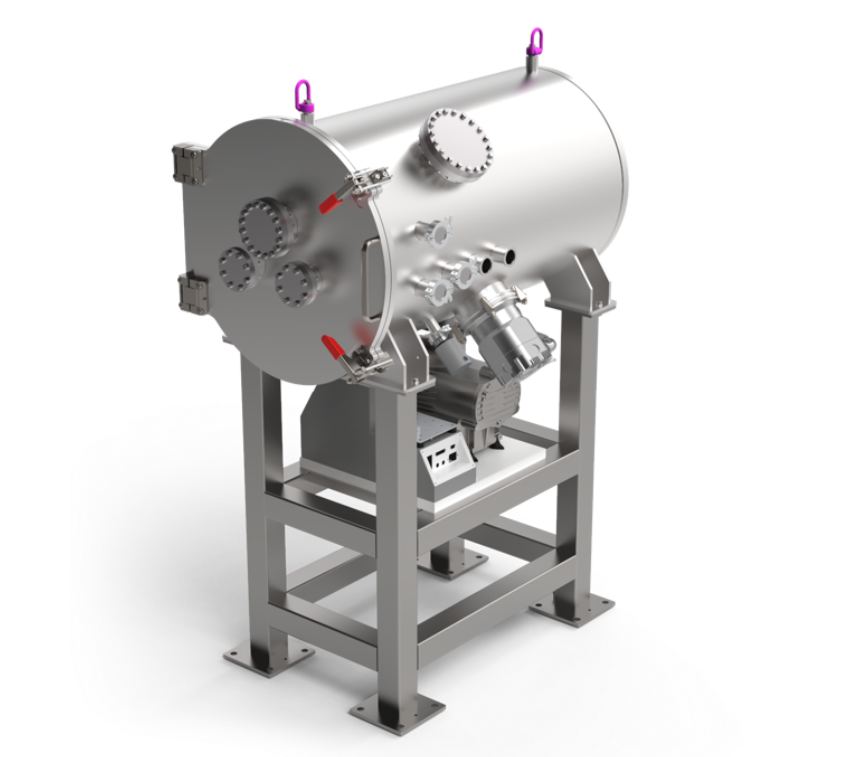

Illustrative image related to what is a vacuum chamber made of

Supplier factors are equally important; established suppliers with a strong reputation may charge higher prices due to their reliability and service offerings. Finally, understanding Incoterms is crucial for international transactions, as these terms dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, ultimately influencing total costs.

What Are Effective Buyer Tips for Sourcing Vacuum Chambers?

When negotiating prices for vacuum chambers, buyers should focus on total cost of ownership (TCO) rather than just upfront costs. This includes considering maintenance, operational efficiency, and potential downtime. For instance, while a stainless steel chamber may have a higher initial cost, its longevity and lower maintenance needs can result in cost savings over time.

Buyers should also leverage their purchasing power; engaging in negotiations for bulk orders can lead to significant discounts. It’s advisable to seek multiple quotes from different suppliers to compare pricing and quality. Additionally, understanding the supplier’s production capabilities can aid in negotiations, particularly if the buyer is looking for customization.

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, it’s crucial to be aware of local market conditions and currency fluctuations that can affect pricing. It’s also beneficial to establish clear communication with suppliers to mitigate misunderstandings that can lead to unexpected costs.

Disclaimer on Indicative Prices

Prices for vacuum chambers can vary widely based on the factors discussed, and this analysis provides a general framework. For specific pricing, it is recommended to engage directly with manufacturers or suppliers to obtain tailored quotes based on precise requirements and specifications.

Alternatives Analysis: Comparing what is a vacuum chamber made of With Other Solutions

Exploring Alternatives to Vacuum Chambers: What Are the Options?

In the realm of industrial applications requiring vacuum environments, vacuum chambers are widely utilized due to their effectiveness in maintaining low-pressure conditions. However, there are alternative solutions that can achieve similar objectives. Understanding these alternatives allows B2B buyers to make informed decisions based on performance, cost, and application needs.

| Comparison Aspect | What Is A Vacuum Chamber Made Of | Alternative 1: Vacuum Sealed Bags | Alternative 2: Controlled Atmosphere Chambers |

|---|---|---|---|

| Performance | High performance with low outgassing rates; ideal for high and ultra-high vacuum applications. | Suitable for short-term applications; limited vacuum levels. | Maintains specific atmospheric conditions but does not achieve vacuum. |

| Cost | Higher initial investment, but lower long-term costs due to durability. | Lower initial cost, but less durable and reusable. | Moderate to high cost depending on technology and features. |

| Ease of Implementation | Requires specialized installation and setup. | Simple setup; easy to use for various applications. | Can be complex to implement; requires calibration for gas mixtures. |

| Maintenance | Low maintenance due to durable materials; periodic checks needed. | Minimal maintenance; single-use may lead to waste. | Regular calibration and maintenance required for sensors and controls. |

| Best Use Case | Ideal for scientific research, industrial manufacturing, and processes requiring precise vacuum control. | Best for food preservation, shipping sensitive materials, and short-term storage. | Suited for controlled experiments in labs, agriculture, and certain manufacturing processes. |

What Are the Pros and Cons of Vacuum Sealed Bags?

Vacuum sealed bags are an alternative to vacuum chambers that provide a cost-effective solution for applications such as food preservation and shipping. These bags remove air to create a semi-vacuum environment, which can extend the shelf life of products. The primary advantage is their low cost and ease of use, making them accessible for businesses with limited budgets. However, they are not suitable for high-performance applications that require sustained vacuum levels, as they can only achieve moderate vacuum conditions and are typically designed for single-use, leading to waste.

How Do Controlled Atmosphere Chambers Compare?

Controlled atmosphere chambers maintain specific gas compositions rather than achieving a vacuum. These chambers are invaluable in agricultural settings for preserving perishables or in laboratory environments for experiments requiring controlled conditions. The advantage of controlled atmosphere chambers lies in their versatility, allowing for the precise manipulation of gases and humidity levels. However, they come with a moderate to high cost and require regular maintenance and calibration to ensure accurate gas levels, which can be a drawback for some businesses.

Making the Right Choice: How Should B2B Buyers Decide?

When evaluating whether to invest in a vacuum chamber or explore alternative solutions, B2B buyers should consider their specific needs, including the required performance level, budget constraints, and the intended application of the technology. For businesses focused on high-precision applications, the durability and low maintenance of vacuum chambers make them a worthwhile investment despite the higher upfront costs. Conversely, if the primary need is short-term preservation or low-cost solutions, vacuum sealed bags may suffice. Controlled atmosphere chambers can be ideal for specialized applications, but buyers should weigh their complexity and maintenance demands against their operational needs. Ultimately, understanding the nuances of each option will empower buyers to select the most effective solution for their unique challenges.

Essential Technical Properties and Trade Terminology for what is a vacuum chamber made of

What Are the Key Technical Properties of a Vacuum Chamber?

When selecting a vacuum chamber, understanding the essential technical properties is crucial for ensuring optimal performance and longevity. Here are the critical specifications to consider:

1. Material Grade

The material grade of a vacuum chamber significantly influences its performance. Common materials include aluminum and stainless steel, each with distinct characteristics. Stainless steel, particularly 304 or 316 grades, offers superior durability and lower outgassing rates, making it ideal for ultra-high vacuum applications. Aluminum, while lighter and easier to machine, can have higher outgassing rates, impacting vacuum stability. For B2B buyers, choosing the right material grade is essential for balancing cost, performance, and application requirements.

2. Outgassing Rate

Outgassing refers to the release of gas trapped within materials when exposed to a vacuum. This property is measured in torr liters per second per linear centimeter. Stainless steel typically exhibits lower outgassing rates (around 6 x 10^-9) compared to aluminum (7 x 10^-9), making it more suitable for applications requiring high purity and stability. Understanding outgassing rates helps businesses select chambers that maintain the integrity of the vacuum environment, especially in sensitive processes like spectroscopic analyses.

3. Tolerance

Tolerance defines the permissible limit of variation in a chamber’s dimensions. High tolerances are critical for ensuring that the chamber can maintain vacuum pressure without deformation or leaks. For example, tighter tolerances in the construction of ports and seals prevent unwanted air ingress, which can compromise vacuum integrity. B2B buyers should prioritize manufacturers that can meet specific tolerance requirements to enhance the reliability of their vacuum systems.

Illustrative image related to what is a vacuum chamber made of

4. Thermal Conductivity

Thermal conductivity impacts how effectively a vacuum chamber can manage temperature fluctuations. Aluminum has higher thermal conductivity, making it suitable for applications requiring quick heat dissipation. Conversely, stainless steel, while slower to dissipate heat, can withstand higher temperatures over extended periods. Buyers should consider the thermal demands of their processes when selecting a chamber material to ensure optimal performance.

5. Permeability

Permeability refers to a material’s ability to allow gases to pass through it. Aluminum is more permeable than stainless steel, which can lead to increased outgassing and compromised vacuum conditions. This property is particularly vital in applications involving corrosive gases or where vacuum stability is paramount. Understanding permeability helps buyers select appropriate materials based on their operational environments.

What Are Common Trade Terms Related to Vacuum Chambers?

Familiarity with industry jargon can facilitate smoother transactions and negotiations. Here are several common terms relevant to vacuum chambers:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of vacuum chambers, buyers often work directly with OEMs to ensure they receive high-quality, customized solutions that meet their specific needs. Understanding this term is crucial for B2B buyers looking for reliable suppliers.

Illustrative image related to what is a vacuum chamber made of

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. For vacuum chambers, MOQs can vary significantly based on the complexity and customization level required. Recognizing MOQ is essential for buyers to manage inventory costs and negotiate favorable terms.

3. RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers for specific products or services. In the vacuum chamber industry, an RFQ typically includes detailed specifications, quantities, and delivery timelines. Understanding how to craft an effective RFQ can lead to better pricing and terms.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized terms that define the responsibilities of buyers and sellers in international trade. For vacuum chamber transactions, Incoterms clarify who is responsible for shipping, insurance, and tariffs. Familiarity with these terms helps B2B buyers avoid misunderstandings and ensures smoother logistics.

5. UHV (Ultra-High Vacuum)

UHV refers to vacuum conditions below 10^-9 torr. This term is critical for applications requiring extremely low pressures, such as semiconductor manufacturing and surface analysis. Understanding UHV specifications helps buyers ensure that their equipment can meet stringent operational requirements.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and enhance their procurement strategies.

Navigating Market Dynamics and Sourcing Trends in the what is a vacuum chamber made of Sector

What are the Key Market Dynamics and Trends in the Vacuum Chamber Sector?

The vacuum chamber market is witnessing significant growth driven by advancements in various industries such as pharmaceuticals, electronics, and aerospace. A key trend is the increasing demand for high-performance materials like stainless steel and aluminum, which offer superior durability and lower outgassing rates compared to plastic alternatives. This shift is particularly relevant for international B2B buyers in regions such as Africa, South America, the Middle East, and Europe, where stringent quality standards and regulatory compliance are becoming more prevalent.

Emerging technologies, such as 3D printing and advanced welding techniques, are also reshaping the sourcing landscape. Manufacturers are increasingly adopting these technologies to enhance customization capabilities and reduce lead times. Additionally, the rise of automation in production processes is driving efficiency, allowing suppliers to better meet the specific needs of their clients. For buyers in countries like Brazil and Vietnam, understanding these technological trends can lead to more informed purchasing decisions and stronger supplier partnerships.

Furthermore, the market is moving towards more versatile vacuum chamber designs, including cylindrical and box-shaped chambers that cater to various applications. As industries evolve, the need for specialized chambers that accommodate unique requirements is becoming a priority. Buyers must stay informed about these market dynamics to effectively navigate the procurement process and secure the best solutions for their specific applications.

How Can B2B Buyers Ensure Sustainability and Ethical Sourcing in Vacuum Chamber Procurement?

Sustainability has become a critical consideration in the vacuum chamber sector, with a growing emphasis on reducing environmental impact. The production of vacuum chambers, particularly those made from metals like aluminum and stainless steel, involves energy-intensive processes that can contribute to carbon emissions. B2B buyers are increasingly seeking suppliers who prioritize sustainable manufacturing practices and offer products that align with green certification standards.

Ethical sourcing is equally important, especially as global supply chains become more complex. Buyers should ensure that their suppliers adhere to ethical labor practices and environmental regulations throughout the supply chain. This not only enhances brand reputation but also fosters customer loyalty in markets where consumers are becoming more environmentally conscious.

Moreover, the use of recyclable materials and the implementation of circular economy principles are gaining traction in the industry. Suppliers who integrate these practices into their operations can provide buyers with vacuum chambers that not only meet performance standards but also contribute to a more sustainable future. By prioritizing suppliers committed to sustainability and ethical sourcing, B2B buyers can play a pivotal role in promoting responsible practices within the vacuum chamber sector.

What is the Historical Evolution of Vacuum Chambers Relevant to B2B Buyers?

The evolution of vacuum chambers dates back to the late 19th century when the first rudimentary models were developed for scientific experiments. Initially, these chambers were primarily made from glass, which provided limited durability and performance. As industries advanced, particularly in the mid-20th century, the introduction of metals like stainless steel and aluminum revolutionized the design and functionality of vacuum chambers.

This transition allowed for improved resistance to chemical exposure, lower outgassing rates, and enhanced structural integrity, making them suitable for a broader range of applications. Over the decades, innovations in manufacturing techniques, such as precision machining and advanced welding, have further refined vacuum chamber designs, allowing for greater customization and efficiency.

Today, the ongoing evolution of materials and technologies continues to shape the vacuum chamber market, presenting B2B buyers with an array of options tailored to their specific needs. Understanding this historical context can empower buyers to make informed decisions as they navigate the complexities of sourcing vacuum chambers in a competitive global marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of what is a vacuum chamber made of

-

How do I choose the right material for a vacuum chamber?

Choosing the right material for a vacuum chamber largely depends on your specific application requirements. For low and ultra-high vacuum applications, stainless steel is generally preferred due to its lower outgassing rates and superior durability. However, if weight and cost are significant factors, aluminum may be suitable for less demanding applications. Consider factors like chemical compatibility, thermal conductivity, and the expected operating environment when making your decision. -

What are the advantages of stainless steel versus aluminum for vacuum chambers?

Stainless steel offers superior durability, lower outgassing rates, and better chemical resistance compared to aluminum, making it ideal for high-performance applications. Although it comes with a higher initial cost, its long-term maintenance and replacement savings can offset this. Aluminum, on the other hand, is lighter and easier to machine, making it suitable for applications where weight is a critical factor, but it may not perform as well in extreme conditions. -

What customization options are available for vacuum chambers?

Many manufacturers offer customization options for vacuum chambers, including specific dimensions, shapes (cylindrical, square, or spherical), and additional ports or feedthroughs. You can also request modifications to accommodate specialized equipment or access points, depending on your operational needs. Be sure to communicate your requirements clearly to your supplier to ensure that the final product meets your specifications. -

What is the minimum order quantity (MOQ) for vacuum chambers?

The minimum order quantity (MOQ) for vacuum chambers varies by supplier and can depend on the complexity and customization of the chambers. Some manufacturers may accept orders for single units, especially for standard models, while custom orders may require a higher MOQ. It’s best to discuss your needs directly with potential suppliers to understand their policies and negotiate terms that suit your business. -

How do I vet suppliers when sourcing vacuum chambers internationally?

When sourcing vacuum chambers, especially from international suppliers, it’s essential to conduct thorough due diligence. Look for suppliers with established reputations, positive reviews, and relevant certifications (e.g., ISO standards). Request samples or references from previous clients to evaluate the quality of their products. Additionally, consider their manufacturing capabilities, lead times, and customer support to ensure they can meet your requirements. -

What payment terms should I expect when ordering vacuum chambers?

Payment terms can vary significantly among suppliers, so it’s crucial to clarify these before finalizing an order. Common terms include upfront deposits (often 30% to 50%) with the balance due upon delivery or after inspection. Some suppliers may offer financing options or extended payment plans for larger orders. Be sure to negotiate terms that align with your cash flow and budget constraints. -

How can I ensure quality assurance (QA) for vacuum chambers?

To ensure quality assurance for vacuum chambers, inquire about the supplier’s QA processes, including inspections and testing protocols. Look for manufacturers that adhere to international quality standards and can provide documentation or certifications for their products. Establishing a clear QA agreement before production can also help ensure that the final product meets your specifications and performance requirements. -

What logistics considerations should I keep in mind when importing vacuum chambers?

When importing vacuum chambers, consider factors such as shipping costs, customs duties, and lead times. It’s important to work with suppliers who have experience in international shipping and can provide accurate shipping estimates. Additionally, ensure that your logistics partner is familiar with regulations and documentation required for customs clearance in your country. This will help avoid delays and ensure a smooth delivery process.

Top 7 What Is A Vacuum Chamber Made Of Manufacturers & Suppliers List

1. Kurt J. Lesker Company – Vacuum Chambers

Domain: lesker.com

Registered: 1995 (30 years)

Introduction: Kurt J. Lesker Company offers a variety of vacuum chambers including box, spherical, cylindrical, D-shape, and bell jar designs. Key features include:

– Box Chambers: Available in UHV and high vacuum versions, designed for easy access and suitable for batch processes and research applications.

– Spherical Chambers: Equipped with CF flanges, ideal for radial component placement and can reach UHV …

2. Reddit – Vacuum Chamber Construction Advice

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: User is attempting to create a vacuum chamber using acrylic for the sides of the box. They are seeking advice on whether this is a smart choice and how to determine the strength of the box.

3. Instructables – Cooking Pot and Polycarbonate Sheet

Domain: instructables.com

Registered: 2005 (20 years)

Introduction: Cooking Pot: Tall pot with a diameter not larger than 8 inches, used for steaming asparagus.

Polycarbonate or Acrylic Sheet: 9″ x 9″ x 1/2″ polycarbonate sheet, chosen for strength and resistance to cracking.

Silicone RTV Gasket Maker: Used to create a seal for the lid, available in different colors.

Permatex Multipurpose RTV Silicone Gasket Maker: Specific brand used for sealing.

Fittings:

-…

4. Atlas UHV – Superior Aluminum Chambers

Domain: atlasuhv.com

Registered: 2003 (22 years)

Introduction: This company, Atlas UHV – Superior Aluminum Chambers, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Practical Machinist – High Vacuum Chamber Solutions

Domain: practicalmachinist.com

Registered: 2000 (25 years)

Introduction: Clear vacuum chamber, ideal vacuum level of 10^-6 torr, preferred materials: acrylic, polycarbonate, glass. Recommended O-ring: Buna-N or Buna 70 Silicon. Chamber dimensions: 3″ OD with two flat end caps. Suggested use of high vacuum grease for sealing. Alternative options include glass bell jars or mason jars with fittings.

6. Plasma – Vacuum Chamber Solutions

Domain: plasma.com

Registered: 1998 (27 years)

Introduction: The vacuum chamber is designed to hold process gas at low pressure and acts as a pressure reservoir. It is typically made from materials resistant to etching from process gases, commonly stainless steel, although some processes may require high-purity silica glass. An example includes the recipient of the Diener electronic Plasma system Bell Jar, which is made from high-purity quartz glass.

7. Smooth-On – 5 Gallon Vacuum Chamber

Domain: smooth-on.com

Registered: 1996 (29 years)

Introduction: 5 Gallon Vacuum Chamber for vacuuming liquid rubbers and plastics. Designed to remove air from high viscosity materials like silicone rubber before pouring and ideal for vacuum degassing liquid plastics (e.g., Crystal Clear™) for bubble-free castings. Constructed from tough aluminum with a shatter-resistant acrylic lid and rubber gasket for an airtight seal. Inside dimensions: 14″ (35.56 cm) diame…

Strategic Sourcing Conclusion and Outlook for what is a vacuum chamber made of

How Can Strategic Sourcing Enhance Your Vacuum Chamber Procurement?

In conclusion, understanding the materials and design characteristics of vacuum chambers is essential for making informed procurement decisions. The choice between aluminum and stainless steel impacts performance, durability, and long-term cost-effectiveness. Stainless steel, while initially more expensive, offers lower outgassing rates, superior chemical resistance, and enhanced durability, making it a preferred choice for critical applications. Conversely, aluminum’s lighter weight and higher thermal conductivity can be advantageous for specific uses, particularly where cost is a primary concern.

Strategic sourcing plays a pivotal role in optimizing your procurement process, allowing you to identify suppliers that provide high-quality materials tailored to your operational needs. By leveraging insights into material performance and long-term value, businesses can enhance their operational efficiency and reduce costs associated with maintenance and replacement.

As you navigate the global market, particularly in regions such as Africa, South America, the Middle East, and Europe, consider the long-term implications of your vacuum chamber choices. Engage with reputable suppliers who understand your unique requirements, and invest in materials that will support your operations for years to come. Take action today to ensure your vacuum processes are built on a foundation of quality and reliability.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.