Top 7 Two Pin Plug Suppliers (And How to Choose)

Introduction: Navigating the Global Market for two pin plug

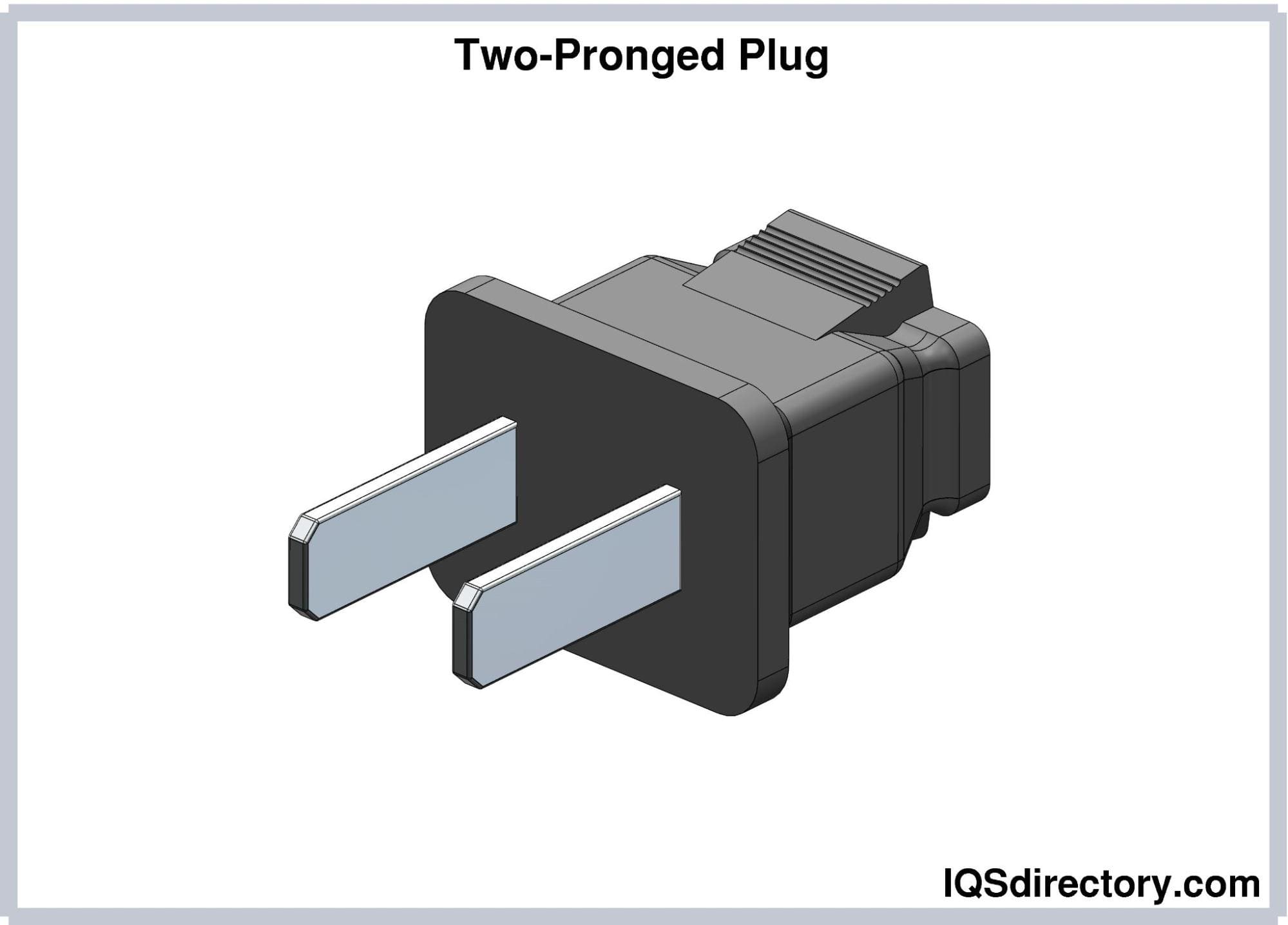

In the ever-evolving landscape of global commerce, sourcing reliable two pin plugs is a critical challenge for international B2B buyers. As businesses expand their reach across diverse markets in Africa, South America, the Middle East, and Europe, understanding the intricacies of two pin plug specifications, safety standards, and applications becomes paramount. This guide serves as a comprehensive resource, exploring various types of two pin plugs, their wide-ranging applications—from household appliances to specialized medical devices—and the nuances of supplier vetting processes.

By delving into the cost considerations, quality certifications, and the importance of compliance with regional standards, this guide empowers B2B buyers to make informed purchasing decisions. The ability to navigate the complexities of the two pin plug market will not only enhance product reliability but also improve supply chain efficiency. Whether you are a manufacturer seeking to optimize your product offerings or a distributor looking to meet customer demands, this guide provides the insights needed to connect with reputable suppliers and secure high-quality components. With actionable strategies tailored to the unique challenges faced in markets like Brazil and Nigeria, you will be equipped to make choices that drive value and innovation in your business.

Understanding two pin plug Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Type A | Flat parallel pins, typically 15A rated | Consumer electronics, chargers, small appliances | Pros: Compact design, globally accepted; Cons: No grounding, lower safety for high-power devices |

| Type C | Round pins, universal compatibility, 2.5A rated | Household appliances, portable electronics | Pros: Versatile, widely used in multiple regions; Cons: Limited to lower power applications |

| Type I | Flat pins with a grounding pin, 10A rated | Industrial equipment, appliances needing grounding | Pros: Enhanced safety, suitable for high power; Cons: Bulkier design, may require adapters in some regions |

| Type E/F | Round pins with grounding, 16A rated | Heavy-duty appliances, medical devices | Pros: High power capacity, strong grounding; Cons: Less portable due to size |

| Type N | Unique pin configuration, 20A rated | Specialized equipment, industrial applications | Pros: High capacity, reliable in demanding environments; Cons: Limited global availability |

What Are the Key Characteristics of Type A Two Pin Plugs?

Type A plugs are characterized by their flat parallel pins and are commonly used in North America and Japan. They are rated for 15A and are most frequently found in consumer electronics, such as phone chargers and small appliances. For B2B buyers, the compact design and universal acceptance make Type A plugs a practical choice for products intended for international markets. However, it’s essential to note that Type A plugs lack grounding, which can pose safety risks for high-power devices.

How Does Type C Compare to Other Two Pin Plugs?

Type C plugs feature round pins and are often referred to as the “Europlug.” They are rated at 2.5A and are compatible with various household appliances and portable electronics. Their versatility and widespread use across Europe and other regions make them an attractive option for manufacturers looking to cater to diverse markets. However, Type C plugs are limited to lower power applications, which may restrict their use in industrial settings.

What Advantages Does Type I Offer for B2B Applications?

Type I plugs, found primarily in Australia and New Zealand, have flat pins with an additional grounding pin, providing enhanced safety for high-power applications. Rated at 10A, these plugs are commonly used in industrial equipment and appliances that require grounding. B2B buyers should consider Type I plugs for products that demand higher safety standards, although their bulkier design may necessitate the use of adapters in certain regions.

Why Are Type E/F Plugs Essential for Heavy-Duty Applications?

Type E/F plugs, known for their round pins and grounding capabilities, are rated for 16A and commonly used in heavy-duty appliances and medical devices. Their robust design ensures safety and reliability in high-power applications, making them a preferred choice for B2B buyers in sectors requiring stringent safety measures. However, their larger size can limit portability, which is a consideration for manufacturers targeting both industrial and consumer markets.

What Makes Type N an Emerging Choice in the Market?

Type N plugs feature a unique pin configuration and are rated for 20A, making them suitable for specialized equipment and demanding industrial applications. Their high capacity and reliable performance in challenging environments make them an attractive option for B2B buyers. However, the limited global availability of Type N plugs can pose challenges for manufacturers aiming for widespread distribution.

Key Industrial Applications of two pin plug

| Industry/Sector | Specific Application of two pin plug | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Consumer Electronics | Power supply for portable chargers and small appliances | Compact design enhances portability and ease of use | Compliance with international safety standards; voltage ratings |

| Automotive | Connection for sensors and lighting systems in vehicles | Simplifies wiring without the need for grounding | Durability and resistance to environmental factors; certifications |

| Healthcare | Power for medical devices like patient monitors | Ensures safe and reliable operation in critical applications | Compliance with medical safety regulations; reliability standards |

| Lighting | Connection for LED lighting systems | Energy-efficient solutions reduce operating costs | Compatibility with local power standards; environmental impact |

| Personal Care Devices | Power supply for grooming tools like hairdryers | Lightweight and portable design enhances user convenience | Quality assurance for safety; insulation standards |

How is the Two Pin Plug Used in Consumer Electronics?

In the consumer electronics sector, two pin plugs are commonly utilized for charging portable devices and powering small appliances such as fans, lamps, and chargers. Their compact design allows for easy integration into various products, making them ideal for travel and everyday use. For international B2B buyers, it’s essential to ensure that these plugs comply with regional safety standards, especially in markets like Africa and South America where electrical regulations may vary significantly. Buyers should also consider the voltage ratings and durability of the plugs to ensure compatibility with local power supply systems.

What Role Does the Two Pin Plug Play in the Automotive Industry?

In the automotive industry, two pin plugs are frequently employed to connect sensors, lighting systems, and other non-grounded components. Their simple design facilitates quick and reliable connections, reducing installation time and complexity. International buyers, especially in regions like the Middle East and Europe, should prioritize sourcing plugs that meet automotive safety standards and can withstand harsh environmental conditions. Additionally, compatibility with existing vehicle systems and components is crucial for seamless integration.

How is the Two Pin Plug Essential in Healthcare Applications?

Two pin plugs are vital in healthcare applications, powering essential medical devices such as patient monitors and diagnostic tools. Their lightweight and non-grounding design make them suitable for portable medical equipment, ensuring ease of use in various settings. B2B buyers in this sector must ensure that the plugs comply with stringent medical safety regulations and reliability standards to mitigate risks associated with patient care. Sourcing plugs with high-quality insulation and durability is also critical to maintaining device performance.

Illustrative image related to two pin plug

Why are Two Pin Plugs Used in LED Lighting Systems?

In the lighting industry, two pin plugs are widely used for low-voltage LED lighting systems, offering energy-efficient solutions that minimize operational costs. Their straightforward installation and reliable connection make them a popular choice for both residential and commercial applications. Buyers should focus on sourcing plugs that align with local power standards and consider the environmental impact of materials used in their production. Ensuring compatibility with various lighting fixtures is also essential for effective implementation.

How Do Two Pin Plugs Benefit Personal Care Devices?

Two pin plugs are commonly found in personal care devices, such as hairdryers and electric shavers, where portability and lightweight design are paramount. These plugs allow for easy and safe operation without the need for grounding, catering to consumer preferences for convenience. International B2B buyers should prioritize sourcing plugs that meet safety certifications and quality assurance standards to prevent electrical hazards. Additionally, ensuring that the plugs are designed for frequent use will enhance the longevity of personal care devices.

3 Common User Pain Points for ‘two pin plug’ & Their Solutions

Scenario 1: Ensuring Compatibility Across International Markets

The Problem: B2B buyers often face challenges related to the compatibility of two pin plugs with different electrical standards and socket types across various countries. For instance, a manufacturer in Brazil may need to source two pin plugs that can be used seamlessly in the European market. Without proper understanding of the local electrical standards, there is a risk of product returns, safety hazards, and ultimately, damage to brand reputation.

The Solution: To mitigate this issue, buyers should conduct thorough research on the electrical standards of the target markets, including voltage, current, and plug types. When sourcing two pin plugs, it’s crucial to select products that are certified to meet international safety standards, such as IEC or local equivalents. Collaborating with suppliers who have a comprehensive range of plugs that comply with various international standards can ensure compatibility. Buyers should also consider sourcing plugs with multiple prong configurations (e.g., flat, round) or those that offer interchangeable heads to adapt to different socket types. This proactive approach will not only enhance product reliability but also streamline distribution channels across regions.

Scenario 2: Managing Supply Chain Disruptions

The Problem: In today’s volatile market conditions, supply chain disruptions can significantly impact the availability of two pin plugs, leading to project delays and increased costs. For example, a company in Nigeria may experience challenges in sourcing reliable two pin plugs for their electronic devices due to geopolitical issues or logistical bottlenecks. Such interruptions can halt production lines and delay product launches, affecting revenue and market positioning.

The Solution: To address supply chain vulnerabilities, buyers should diversify their supplier base by engaging with multiple manufacturers across different regions. Establishing relationships with suppliers who have flexible manufacturing capabilities can help mitigate risks associated with single-source dependency. Implementing a robust inventory management system that incorporates demand forecasting and safety stock levels can also alleviate pressure during supply shortages. Furthermore, buyers should consider partnerships with suppliers who have strong logistics and distribution networks, ensuring timely delivery even in challenging circumstances. This strategic approach not only enhances supply chain resilience but also promotes long-term sustainability.

Scenario 3: Safety and Regulatory Compliance Concerns

The Problem: B2B buyers often grapple with ensuring that the two pin plugs they source comply with safety and regulatory standards specific to their industry. For instance, in the healthcare sector, medical devices that utilize two pin plugs must adhere to stringent safety regulations to prevent electrical hazards. Non-compliance can lead to serious consequences, including legal liabilities and damage to customer trust.

The Solution: To ensure compliance, it is essential for buyers to work closely with suppliers who have a proven track record of meeting industry-specific safety standards. Buyers should request documentation demonstrating compliance with relevant regulations, such as UL, CE, or specific medical device safety standards. Additionally, integrating quality assurance processes, including regular audits and product testing, can help verify the reliability and safety of sourced two pin plugs. Investing in training for procurement teams on the latest safety regulations and compliance requirements will further bolster the organization’s ability to navigate these complexities. This proactive stance not only enhances product safety but also builds trust with end users, ultimately leading to stronger market positioning.

Strategic Material Selection Guide for two pin plug

What Are the Key Materials Used in Two Pin Plugs?

When selecting materials for two pin plugs, it is crucial to consider their properties, advantages, and limitations. The choice of material can significantly impact the performance, durability, and compliance of the plugs in various applications. Below, we analyze four common materials used in the manufacturing of two pin plugs.

How Does Polyvinyl Chloride (PVC) Perform in Two Pin Plugs?

Key Properties: PVC is known for its excellent electrical insulation properties, temperature resistance up to 70°C, and good mechanical strength. It is also resistant to moisture and many chemicals.

Pros & Cons: PVC is cost-effective and easy to mold, making it a popular choice for mass production. However, it can become brittle over time when exposed to UV light and extreme temperatures, which may lead to durability issues in outdoor applications.

Impact on Application: PVC is suitable for household appliances and low-voltage applications. However, its limitations in high-temperature environments can restrict its use in industrial settings.

Considerations for International Buyers: Compliance with safety standards such as IEC 60884-1 is essential, especially in regions like Europe and South America, where strict regulations govern electrical products. Buyers should also ensure that the PVC used is free from harmful additives.

What Are the Advantages of Using Thermoplastic Elastomers (TPE)?

Key Properties: TPE combines the properties of rubber and plastic, offering flexibility and resilience. It can withstand temperatures ranging from -40°C to 120°C and is resistant to UV light and ozone.

Illustrative image related to two pin plug

Pros & Cons: The flexibility of TPE allows for easy handling and installation, making it suitable for applications requiring frequent plugging and unplugging. However, TPE can be more expensive than PVC and may complicate the manufacturing process.

Impact on Application: TPE is ideal for portable electronics and consumer appliances, where durability and flexibility are paramount. Its excellent insulation properties make it suitable for medical devices as well.

Considerations for International Buyers: Buyers should verify compliance with ASTM D624 and other relevant standards, particularly in the healthcare sector, where safety is critical. The higher cost of TPE may be a consideration for budget-sensitive projects.

Why Is Nylon a Preferred Material for Two Pin Plugs?

Key Properties: Nylon is a strong, lightweight material that offers excellent thermal stability and resistance to abrasion and chemicals. It can perform well in temperatures up to 120°C.

Illustrative image related to two pin plug

Pros & Cons: Nylon’s durability makes it suitable for heavy-duty applications, but it can be more challenging to process than other materials, leading to increased manufacturing costs. Its rigidity may also limit its use in flexible applications.

Impact on Application: Nylon is often used in industrial and automotive applications where robustness is essential. Its resistance to chemicals makes it suitable for environments exposed to harsh conditions.

Considerations for International Buyers: Compliance with international standards such as ISO 9001 is crucial for buyers in Europe and the Middle East. The material’s higher cost may be justified in applications requiring superior durability.

What Role Does Metal Play in Two Pin Plug Design?

Key Properties: Metals, particularly copper and brass, are commonly used for the prongs of two pin plugs due to their excellent electrical conductivity and durability. They can withstand high temperatures and mechanical stress.

Pros & Cons: Metal connectors provide reliable connections and can handle higher currents, making them suitable for a wide range of applications. However, they are susceptible to corrosion if not properly treated, which can affect performance over time.

Impact on Application: Metal is ideal for high-power applications, including industrial equipment and appliances. However, the risk of corrosion in humid environments may necessitate protective coatings.

Considerations for International Buyers: Buyers must ensure that metal components comply with standards such as RoHS and REACH, especially in regions like Europe where environmental regulations are stringent. The initial cost may be higher, but the long-term reliability can justify the investment.

Summary of Material Selection for Two Pin Plugs

| Material | Typical Use Case for two pin plug | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyvinyl Chloride (PVC) | Household appliances, low-voltage devices | Cost-effective and easy to mold | Brittle over time, UV sensitivity | Low |

| Thermoplastic Elastomers (TPE) | Portable electronics, medical devices | Flexible and resilient | Higher cost, complex manufacturing | Medium |

| Nylon | Industrial equipment, automotive applications | Strong and durable | More challenging to process | High |

| Metal (Copper/Brass) | High-power applications, industrial use | Excellent conductivity and durability | Susceptible to corrosion | Medium |

This strategic material selection guide provides B2B buyers with essential insights into the materials used in two pin plugs, enabling informed decisions tailored to specific applications and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for two pin plug

What Are the Key Stages in the Manufacturing Process of Two Pin Plugs?

The manufacturing process of two pin plugs involves several critical stages that ensure the final product meets industry standards and customer expectations. Understanding these stages can help B2B buyers assess suppliers more effectively.

Material Preparation: What Materials Are Used for Two Pin Plugs?

The initial stage of manufacturing begins with the selection of high-quality materials. Two pin plugs typically use materials such as virgin copper for the conductive pins, which ensures excellent conductivity and durability. The casing is often made from PVC or halogen-free thermoplastics, which not only provide insulation but also contribute to the product’s environmental compliance.

The materials are subjected to rigorous quality checks upon arrival at the manufacturing facility. This initial quality check, known as Incoming Quality Control (IQC), verifies that the materials meet the specified standards before they proceed to the next stage.

How Are Two Pin Plugs Formed and Assembled?

After material preparation, the next stage is forming the components. This involves several techniques such as stamping and injection molding. The copper pins are stamped into shape, while the plastic casing is formed through injection molding. These processes are crucial for achieving precise dimensions and ensuring that the components fit together seamlessly.

Once the individual components are formed, they are assembled. This stage may involve automated machinery or manual labor, depending on the complexity of the plug design. Automated assembly lines are increasingly favored for their efficiency and consistency, reducing the risk of human error.

What Finishing Processes Are Applied to Two Pin Plugs?

Finishing processes include surface treatment and quality checks to ensure that the plugs are not only functional but also aesthetically pleasing. Surface treatments may involve applying coatings to enhance corrosion resistance or to improve insulation properties.

After the finishing processes, the plugs undergo further inspections, including In-Process Quality Control (IPQC). This ensures that each stage of the manufacturing process meets quality standards, allowing for immediate rectification of any identified issues.

What International Standards Govern Quality Assurance for Two Pin Plugs?

Quality assurance in the manufacturing of two pin plugs is governed by various international standards, ensuring that products are safe, reliable, and compliant with regulatory requirements.

Which ISO Standards Are Relevant for Two Pin Plugs?

ISO 9001 is one of the most widely recognized quality management standards globally. It emphasizes a process-based approach to quality management, encouraging continuous improvement and customer satisfaction. Manufacturers that comply with ISO 9001 demonstrate their commitment to quality, which is a crucial factor for B2B buyers.

In addition to ISO standards, many plugs must meet specific regional and international safety standards, such as CE marking for products sold in Europe, and UL certification in the United States. These certifications indicate that the plugs have been tested for safety and performance, providing an added layer of assurance to buyers.

What Are the Common Quality Control Checkpoints During Manufacturing?

Quality control checkpoints are critical to maintaining the integrity of the manufacturing process. For two pin plugs, the following checkpoints are common:

Illustrative image related to two pin plug

-

Incoming Quality Control (IQC): This stage verifies that raw materials meet specified standards before they are used in production.

-

In-Process Quality Control (IPQC): Conducted during the manufacturing process, this checkpoint ensures that the production is in line with quality standards and allows for immediate corrections if needed.

-

Final Quality Control (FQC): After assembly, FQC involves comprehensive testing of the finished plugs. This may include electrical testing, mechanical stress testing, and safety checks to confirm that the plugs are ready for market.

What Testing Methods Are Used to Ensure Quality in Two Pin Plugs?

Various testing methods are employed to ensure that two pin plugs meet quality and safety standards:

-

Electrical Testing: This includes continuity testing to ensure proper electrical flow and insulation resistance testing to prevent electrical shocks.

-

Mechanical Testing: Tests for mechanical strength and durability are conducted to ensure that the plugs can withstand everyday use without failure.

-

Environmental Testing: Assessments for temperature and humidity resistance are performed, especially for plugs intended for specific markets or applications.

How Can B2B Buyers Verify Supplier Quality Control Practices?

When sourcing two pin plugs, B2B buyers should take proactive steps to verify the quality control practices of potential suppliers:

-

Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes, quality control measures, and compliance with international standards.

-

Requesting Quality Reports: Buyers should ask for documentation of quality tests, certifications, and inspection results to ensure that the supplier meets the required standards.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control practices, ensuring that they adhere to agreed-upon standards.

What Quality Control Nuances Should International B2B Buyers Be Aware Of?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of the following nuances:

-

Regulatory Differences: Different regions may have varying regulations for electrical products. It’s essential to ensure that the plugs comply with local regulations to avoid issues during importation.

-

Cultural Considerations: Understanding cultural differences in business practices and expectations can enhance communication and negotiation with suppliers.

-

Supply Chain Reliability: Consider the supplier’s capacity to deliver consistently, including their logistics capabilities and the potential impact of geopolitical factors on supply chains.

By understanding the manufacturing processes and quality assurance measures for two pin plugs, B2B buyers can make informed decisions, ensuring they source reliable and compliant products for their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘two pin plug’

When sourcing two pin plugs for your business needs, a structured approach can help ensure you select the right products and suppliers. This checklist serves as a practical guide for B2B buyers, focusing on essential steps to procure reliable two pin plugs that meet your specifications.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical specifications required for the two pin plugs. Consider factors such as voltage, current ratings, and specific application needs. This clarity will guide your supplier search and ensure compatibility with your products.

Step 2: Research Compliance and Standards

Ensure that the two pin plugs you intend to purchase comply with international safety and quality standards relevant to your market. Look for certifications such as CE, UL, or ISO that verify the product’s safety and reliability. Compliance not only reduces legal risks but also enhances the credibility of your brand.

Step 3: Evaluate Potential Suppliers

Thoroughly vet suppliers to ensure they can meet your quality and delivery requirements. Request detailed company profiles, including their manufacturing capabilities and quality assurance processes. Additionally, seek references or case studies from other businesses in your industry to gauge their reliability and service quality.

Step 4: Request Samples

Before placing a bulk order, request samples of the two pin plugs to assess their quality firsthand. Evaluate the materials used, design features, and overall durability. Testing samples in real-world applications can provide valuable insights into their performance and suitability for your needs.

Step 5: Compare Pricing and Terms

Collect quotes from multiple suppliers to compare pricing and payment terms. While cost is a crucial factor, also consider the overall value, including warranty options and after-sales support. A slightly higher price may be justified by superior quality or better customer service.

Step 6: Check for Customization Options

If your application requires specific design features, inquire about customization capabilities. Some suppliers may offer tailored solutions to meet unique requirements, such as different pin shapes or materials. Customization can enhance product integration and performance in your specific context.

Step 7: Finalize Logistics and Delivery Plans

Once you’ve selected a supplier, discuss logistics, including shipping methods and delivery timelines. Ensure that the supplier can meet your deadlines and discuss any potential tariffs or customs considerations for international shipments. Effective logistics planning is crucial to maintaining your supply chain efficiency.

Following this checklist can streamline the procurement process for two pin plugs, ensuring that you make informed decisions that align with your business needs. By focusing on technical specifications, supplier evaluation, and compliance, you can secure reliable products that enhance your operations and meet market demands.

Comprehensive Cost and Pricing Analysis for two pin plug Sourcing

What Are the Key Cost Components of Two Pin Plug Sourcing?

When sourcing two pin plugs, understanding the cost structure is essential for B2B buyers to make informed purchasing decisions. The primary cost components include:

-

Materials: The quality of materials used significantly impacts the overall cost. Common materials include copper for the pins, PVC or halogen-free plastics for the casing, and rubber or silicone for insulation. Higher-quality materials can enhance durability and safety but may increase costs.

-

Labor: Labor costs vary by region and can be influenced by local wage rates and the complexity of the manufacturing processes. Automation in production can mitigate some labor costs, but skilled labor is often required for quality assurance and assembly.

-

Manufacturing Overhead: This encompasses utilities, facility maintenance, and equipment depreciation. Overhead costs can vary based on the manufacturer’s location and operational efficiency.

-

Tooling: The cost of molds and tools necessary for producing two pin plugs can be substantial, particularly for custom designs. This upfront investment is amortized over production runs, influencing unit costs.

-

Quality Control (QC): Ensuring that products meet safety and performance standards involves rigorous testing and inspection processes. Investment in QC can elevate costs but is critical for compliance with international safety standards.

-

Logistics: Transportation costs, including shipping and customs duties, are vital considerations, particularly for international buyers. The choice of Incoterms can significantly affect the final price due to variations in responsibility for shipping costs and risks.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on market demand, competition, and the perceived value of the product.

How Do Price Influencers Affect Two Pin Plug Sourcing?

Several factors influence the pricing of two pin plugs, and understanding these can help buyers negotiate better deals:

-

Volume/MOQ: Pricing often decreases with larger order volumes due to economies of scale. Suppliers may offer significant discounts for bulk purchases, making it advantageous for buyers to assess their needs accurately.

-

Specifications and Customization: Customized designs or unique specifications can lead to higher costs. Buyers should balance their requirements with budget constraints and explore whether standard options suffice.

-

Materials and Quality Certifications: The choice of materials directly correlates with cost. Additionally, products with certifications (e.g., CE, UL) may incur higher production expenses but are essential for compliance and safety in certain markets.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established manufacturers may charge more due to their experience and assurance of quality, while newer entrants may offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms is crucial for international transactions. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) can shift costs and responsibilities between the buyer and seller, impacting the total landed cost.

What Are the Best Buyer Tips for Cost Efficiency in Two Pin Plug Sourcing?

For B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, here are actionable tips for optimizing sourcing:

-

Negotiate Wisely: Engage in open discussions with suppliers about pricing and terms. Leverage your purchasing power by discussing potential volume commitments to secure better pricing.

-

Consider Total Cost of Ownership (TCO): Beyond the initial purchase price, evaluate the long-term costs associated with sourcing two pin plugs. This includes maintenance, potential failures, and compliance costs, which can add up over time.

-

Understand Pricing Nuances: Be aware that international buyers may face additional costs such as tariffs, taxes, and shipping fees. Factor these into your overall budget to avoid surprises.

-

Explore Multiple Suppliers: Diversifying your supplier base can provide better price comparisons and reduce dependency on a single source. This can also foster competition, potentially leading to more favorable pricing.

-

Leverage Technology: Utilize digital platforms for sourcing to streamline the procurement process and gain access to a broader range of suppliers. These platforms often provide tools for price comparisons and supplier ratings.

Disclaimer on Indicative Prices

While the insights provided here aim to inform and guide B2B buyers in their sourcing decisions for two pin plugs, actual prices may vary based on market conditions, specific supplier offerings, and the unique requirements of each buyer. Always conduct thorough market research and supplier evaluations to obtain accurate pricing tailored to your needs.

Alternatives Analysis: Comparing two pin plug With Other Solutions

Exploring Alternatives to Two Pin Plugs: A Comparative Analysis

In the realm of electrical connectors, the two pin plug is a widely recognized solution due to its simplicity and versatility. However, as industries evolve and technology advances, alternative solutions have emerged that offer distinct advantages depending on the specific application. This analysis aims to compare the two pin plug with other viable alternatives to help B2B buyers make informed decisions.

Comparison Table

| Comparison Aspect | Two Pin Plug | Alternative 1: Three Pin Plug | Alternative 2: USB-C Connector |

|---|---|---|---|

| Performance | Good for low-power devices | Better safety with grounded connection | High-speed data and power transfer |

| Cost | Generally low cost | Moderate cost due to complexity | Variable cost, can be higher due to technology |

| Ease of Implementation | Simple to integrate | Slightly more complex installation | Requires compatible ports |

| Maintenance | Low maintenance | Low, but may require more parts | Low, but dependent on cable quality |

| Best Use Case | Household appliances, portable electronics | Domestic and industrial appliances | Modern electronics, laptops, and fast chargers |

Understanding the Alternatives

What Advantages Does a Three Pin Plug Offer?

The three pin plug is an effective alternative that provides enhanced safety through its grounding feature. This makes it a preferred choice for high-power appliances such as refrigerators and air conditioners. While the three pin plug is generally more complex and costly than the two pin option, its ability to prevent electrical shocks makes it an essential component in many applications. However, its bulkier design can be a drawback in portable devices, where space and weight are crucial.

Why Consider USB-C Connectors?

USB-C connectors have revolutionized how devices are powered and connected. They support high-speed data transfer and can deliver power up to 100 watts, making them ideal for modern electronics like laptops and smartphones. Their versatility allows them to replace multiple types of connectors, simplifying the user experience. However, the cost can be higher compared to traditional plugs, and compatibility issues may arise with older devices. Despite these challenges, USB-C is rapidly becoming the standard for new technology.

Making the Right Choice for Your Business Needs

When selecting the right electrical connector for your business, consider the specific requirements of your applications. The two pin plug remains an excellent choice for low-power devices due to its cost-effectiveness and simplicity. Conversely, if your products require enhanced safety and are high-power, the three pin plug would be more suitable. For cutting-edge technology that demands fast charging and data transfer, USB-C connectors are the best option.

Ultimately, understanding the performance, cost, and application of each alternative will enable you to choose a solution that aligns with your operational goals and customer needs. As the market evolves, staying informed about these options will ensure you remain competitive and responsive to industry demands.

Essential Technical Properties and Trade Terminology for two pin plug

What Are the Key Technical Properties of a Two Pin Plug?

Understanding the technical properties of two pin plugs is essential for B2B buyers looking to ensure compatibility, safety, and performance in their applications. Here are several critical specifications:

Illustrative image related to two pin plug

1. Material Grade

The material used in the construction of a two pin plug significantly affects its durability and electrical conductivity. Common materials include polycarbonate or thermoplastic for the housing and copper for the pins. Higher-grade materials offer improved resistance to heat and wear, making them crucial for applications that require longevity and reliability, especially in high-demand environments.

2. Voltage and Current Ratings

Two pin plugs are rated for specific voltage and current levels, which dictate their suitable applications. For example, a plug rated for 250V and 10A is designed for higher-power devices, while lower ratings are suitable for smaller electronics. Understanding these ratings helps businesses select plugs that match the electrical requirements of their devices, preventing potential failures or hazards.

3. Pin Dimensions and Configuration

The dimensions and configuration of the pins (flat or round) determine compatibility with various sockets and electrical systems worldwide. Additionally, the spacing between pins must adhere to international standards to ensure safe and effective connections. Buyers should be aware of these specifications to avoid compatibility issues, especially in diverse markets like Africa and South America.

4. Insulation Type

Insulation materials, such as PVC or halogen-free options, are vital for safety and environmental compliance. Halogen-free insulation reduces toxic emissions during fires, making it a preferred choice in many markets. Selecting the right insulation type not only ensures safety but also aligns with sustainability goals, which is increasingly important to consumers and regulatory bodies.

5. Fusing Options

Some two pin plugs come with built-in fuses that protect devices from overcurrent situations. Fused plugs are particularly important in high-risk environments where equipment could be damaged or pose safety hazards. Understanding whether a plug has fusing options is crucial for B2B buyers in industries where equipment protection is paramount.

Illustrative image related to two pin plug

What Are Common Trade Terms Related to Two Pin Plugs?

Navigating the world of B2B transactions involves understanding specific trade terminology. Here are key terms related to two pin plugs:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components or products that are used in another company’s end products. For B2B buyers, collaborating with OEMs can ensure that the components meet specific quality and compatibility standards, essential for maintaining product integrity.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for businesses to manage inventory effectively while ensuring they meet supplier requirements. Lower MOQs can benefit smaller companies or startups by reducing upfront costs.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other relevant information for a specific product or service. For buyers, issuing an RFQ for two pin plugs allows them to compare pricing, terms, and capabilities from multiple suppliers, facilitating better purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, particularly concerning shipping, insurance, and tariffs. Familiarity with these terms helps B2B buyers understand their liabilities and responsibilities, ensuring smoother cross-border transactions.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving it. For B2B buyers, understanding lead times is essential for planning production schedules and inventory management. Shorter lead times can enhance flexibility and responsiveness to market demands.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing two pin plugs, ensuring they meet the necessary specifications and operational requirements.

Navigating Market Dynamics and Sourcing Trends in the two pin plug Sector

What Are the Current Market Dynamics and Key Trends Affecting the Two Pin Plug Sector?

The two pin plug sector is experiencing significant growth driven by various global factors. The increasing demand for portable electronic devices, coupled with the rise of smart home technologies, is propelling the market forward. Regions such as Africa, South America, the Middle East, and Europe are witnessing a surge in electronic consumption, leading to heightened requirements for reliable and cost-effective power solutions. In particular, countries like Brazil and Nigeria are expanding their electrical infrastructure, which creates substantial opportunities for international suppliers of two pin plugs.

Emerging B2B tech trends indicate a shift towards customization and innovation in product design. Manufacturers are increasingly focusing on providing tailored solutions to meet specific customer needs, such as miniaturized components for portable devices or enhanced safety features for healthcare applications. Additionally, the adoption of automation in production processes is improving efficiency and reducing lead times, which is crucial for meeting the demands of fast-paced markets.

Market dynamics are also influenced by evolving safety standards and regulatory requirements. International buyers must stay informed about the compliance landscape to ensure that their products meet the necessary certifications in different regions. The trend towards e-commerce is reshaping procurement strategies, making it essential for B2B buyers to leverage digital platforms for sourcing and supplier engagement.

How Is Sustainability and Ethical Sourcing Impacting the Two Pin Plug Market?

Sustainability is becoming a crucial consideration in the two pin plug sector, as businesses increasingly recognize the environmental impact of their operations. The production of electrical connectors often involves materials and processes that can be harmful to the environment. Therefore, adopting sustainable practices is essential not only for compliance but also for enhancing brand reputation among eco-conscious consumers and businesses.

Ethical sourcing is gaining traction as companies strive to build transparent supply chains. Buyers should seek suppliers who prioritize ethical labor practices and adhere to environmental regulations. Certifications such as ISO 14001 for environmental management and RoHS (Restriction of Hazardous Substances) compliance are indicators of a supplier’s commitment to sustainability.

Moreover, manufacturers are exploring the use of eco-friendly materials, such as halogen-free plastics and recycled components, to reduce their carbon footprint. This shift not only aligns with global sustainability goals but also appeals to B2B buyers looking to enhance their own sustainability credentials. By prioritizing suppliers who integrate sustainability into their product development and supply chain management, businesses can contribute to a more responsible and ethical marketplace.

Illustrative image related to two pin plug

What Is the Brief Evolution and History of the Two Pin Plug Sector?

The two pin plug has evolved significantly since its inception, adapting to the changing needs of consumers and industries. Initially designed for basic household applications, it gained popularity due to its simplicity and cost-effectiveness. Over the decades, advancements in technology and materials have led to the development of safer and more efficient plug designs.

In the late 20th century, the rise of portable electronics catalyzed the need for more versatile and compact connectors. Manufacturers began to innovate, introducing features such as insulated pins and anti-tracking designs to enhance safety and reliability. Today, the two pin plug is not only a staple in residential settings but also plays a critical role in various industries, including healthcare, automotive, and consumer electronics.

As the market continues to grow and evolve, international B2B buyers must remain vigilant in their sourcing strategies, ensuring they align with current trends and regulatory requirements. This historical perspective highlights the adaptability of the two pin plug and its ongoing relevance in a rapidly changing technological landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of two pin plug

-

How do I choose the right two pin plug for my product?

When selecting a two pin plug, consider the specific electrical requirements of your product, including voltage and current ratings. Ensure that the plug complies with local safety standards and regulations in your target market. Additionally, evaluate the plug’s design features, such as the type of pins (flat or round), material (PVC or halogen-free), and insulation options. If customization is needed, work with suppliers who offer tailored solutions to meet your unique product specifications. -

What are the common applications for two pin plugs in various industries?

Two pin plugs are widely used across multiple sectors, including consumer electronics, healthcare, automotive, and household appliances. Common applications include powering devices like laptops, chargers, medical equipment, and small appliances like fans and lamps. Their versatility and compact design make them ideal for low-power devices that do not require grounding, ensuring they remain a popular choice among manufacturers. -

What should I look for when vetting suppliers for two pin plugs?

When vetting suppliers, assess their manufacturing capabilities, certifications, and compliance with international safety standards. Request product samples to evaluate quality and performance. Investigate their track record for delivery times, customer service, and responsiveness to inquiries. It’s also beneficial to gather references from other clients to understand their experiences and satisfaction with the supplier’s products and services. -

What are the minimum order quantities (MOQ) for two pin plugs?

MOQs for two pin plugs can vary significantly depending on the supplier and the specific product specifications. Many manufacturers set MOQs ranging from 500 to 10,000 units, especially for custom designs. Always clarify the MOQ before placing an order, as this can impact your inventory management and cash flow. Some suppliers may offer flexibility for first-time buyers or smaller businesses, so it’s worth negotiating. -

What payment terms should I expect when sourcing two pin plugs internationally?

Payment terms can differ based on the supplier and your negotiation. Common options include advance payment, net 30, or letter of credit. Ensure that payment terms are clearly outlined in your contract to avoid misunderstandings. Additionally, consider using secure payment methods that offer buyer protection, especially for larger transactions or new suppliers. Discussing payment terms upfront can help establish trust and streamline the purchasing process. -

How can I ensure quality assurance for two pin plugs?

To ensure quality assurance, partner with suppliers who adhere to recognized quality management systems, such as ISO 9001. Request detailed documentation of their quality control processes, including testing standards and certifications. Consider conducting on-site inspections or third-party audits to verify manufacturing practices. Finally, establish a clear return policy for defective products to mitigate risks associated with quality issues. -

What logistics considerations should I keep in mind when importing two pin plugs?

When importing two pin plugs, consider shipping methods, lead times, and customs regulations in your destination country. Evaluate the total landed cost, including shipping, duties, and taxes, to accurately assess pricing. Choose suppliers with experience in international shipping to ensure compliance with export and import regulations. Additionally, explore options for tracking shipments to monitor delivery progress and mitigate potential delays. -

Are there any environmental considerations when sourcing two pin plugs?

Yes, environmental considerations are increasingly important. Look for suppliers who offer eco-friendly options, such as halogen-free materials and reduced PVC usage. Compliance with international environmental regulations, like RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment), is crucial. Partnering with manufacturers committed to sustainable practices can enhance your brand’s reputation and appeal to environmentally conscious consumers.

Top 7 Two Pin Plug Manufacturers & Suppliers List

1. Custom Connector Kits – 2 Pin Automotive Connectors

Domain: customconnectorkits.com

Registered: 2016 (9 years)

Introduction: This company, Custom Connector Kits – 2 Pin Automotive Connectors, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Elmousa – 2 Pin Plug

Domain: elmousa.com

Registered: 1999 (26 years)

Introduction: {“product_name”: “2 Pin Plug”, “item_number”: “5ZA0000232”, “product_code”: “# 5ZA0000232”, “description”: “Replacement 2 Pin Plug for various models including P10, P10S, P30, P30S, P100, P100N, P30HD, MO-1, P100HD, TT-X1, TT-L1, PX-10, PX-30, TT-12F, PX-10E, PX-30E.”, “compatibility”: [“US plug (MX-P, MX-P2, MX-P3)”, “US Plug (TT-12W, MA-1, MO-2)”, “AC Adapter (MX-P, MX-P2, MX-P3)”, “AC Adapter (…

3. Volex – 2-Pin and 3-Pin Plugs

Domain: volex.com

Registered: 1993 (32 years)

Introduction: Volex is a leading manufacturer and supplier of 2-Pin and 3-Pin Plugs, offering a portfolio that includes: a worldwide range of safety approvals (types A, B, C, D, E/F, G, H, I, J, K, L, M & N), straight and angled versions, plugs with flat and/or round pins, PVC or halogen-free overmould, standard or housing/anti-tracking types, insulated or non-insulated pins, fused or non-fused options, and fil…

4. BatterySpace – One Pair Two Pins Lockable Connector with 8′ Coil Cord

Domain: batteryspace.com

Registered: 2002 (23 years)

Introduction: Category: 2 Pin Connectors

Total Products: 27

Key Products:

1. One Pair Two Pins Lockable Connector with 8′ Coil Cord – Price: $6.95, Product ID: 2898

2. Two Pins Lockable Female with 4 Feet Coil Cord – Price: $4.95, Product ID: 3491

3. 4 Feet Coil Cord – Price: $2.95, Product ID: 3111

4. From 2 Pins Female to Waterproof & Lockable Male – Price: $5.95, Product ID: 2671

5. From Tamiya Female Adapt…

5. McMaster – Two-Prong Connectors

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Two-Prong Connectors, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Shutterstock – 2-Pin Plug Icon

Domain: shutterstock.com

Registered: 2003 (22 years)

Introduction: This company, Shutterstock – 2-Pin Plug Icon, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. WeighTronix – 2-Pin Power Plug

Domain: store.agexpress.com

Registered: 1997 (28 years)

Introduction: {‘name’: ‘2-Pin Power Plug’, ‘sku’: ‘AE8062K’, ‘price’: ‘$35.00’, ‘description’: ‘Use this 2-pin power plug as a convenient 12 volt supply on implement harnessing. Includes connector and strain relief. Connector mates with AE8112K.’, ‘compatible_with’: ‘WeighTronix’, ‘type_of_equipment’: [‘Grain Carts’, ‘Seed Tenders’], ‘current_stock’: ‘Available’}

Strategic Sourcing Conclusion and Outlook for two pin plug

In the ever-evolving landscape of global trade, the strategic sourcing of two pin plugs presents a wealth of opportunities for international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe. The reliability, simplicity, and cost-effectiveness of two pin connectors make them an essential component across various sectors, including consumer electronics, automotive, and healthcare. By prioritizing high-quality suppliers who adhere to stringent safety standards, businesses can ensure they are not only meeting regulatory requirements but also enhancing their product offerings.

Investing in strategic sourcing of two pin plugs fosters stronger supplier relationships and ensures a consistent supply chain, which is vital in today’s competitive market. Furthermore, as demand for portable and energy-efficient solutions rises, the versatility of two pin connectors positions them as a key player in future innovations.

As you navigate your sourcing strategy, consider leveraging the insights shared in this guide to enhance your procurement processes. Embrace the potential of two pin plugs to drive efficiency and reliability in your operations. Connect with trusted manufacturers today to stay ahead in a rapidly changing marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.