Top 7 Small Transformer Suppliers (And How to Choose)

Introduction: Navigating the Global Market for small transformer

In an increasingly interconnected global economy, sourcing the right small transformer can pose significant challenges for B2B buyers across diverse markets, including Africa, South America, the Middle East, and Europe. Whether you’re looking for low-voltage solutions for residential projects or specialized transformers for industrial applications, the stakes are high. Small transformers are essential components that ensure efficient power distribution and voltage regulation, yet navigating the myriad of options can feel overwhelming.

This comprehensive guide serves as a crucial resource, meticulously outlining the various types of small transformers available, their specific applications, and the key factors to consider when selecting a supplier. From understanding technical specifications to evaluating cost implications, this guide empowers international buyers to make informed purchasing decisions. We delve into supplier vetting processes to help you identify reputable manufacturers, ensuring quality and reliability in your procurement strategy.

By equipping you with actionable insights and practical knowledge, this guide aims to streamline your sourcing process, minimize risks, and maximize the value of your investments in small transformers. As you explore the intricacies of this critical component, you will find that making educated choices is not just beneficial—it’s essential for the success of your projects in regions like Nigeria, Saudi Arabia, and beyond.

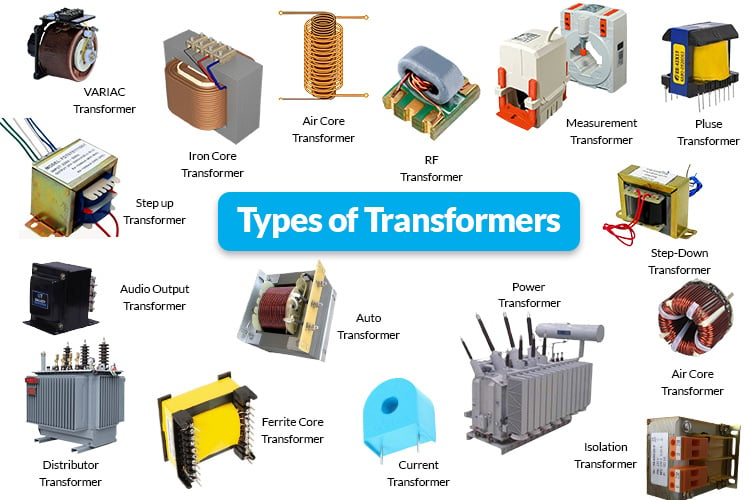

Understanding small transformer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Miniature Surface Mount | Compact size, designed for surface mounting, high isolation voltages | Telecommunications, Gate driver applications | Pros: Space-saving, high efficiency. Cons: Limited power capacity. |

| Low Voltage Transformers | Converts standard line voltage (120V) to low voltage (e.g., 12V) | Landscape lighting, indoor/outdoor lighting solutions | Pros: Cost-effective, easy installation. Cons: Limited to low-voltage applications. |

| Power Transformers | Designed for audio equipment, provides stable voltage supply | Professional audio equipment, musical instruments | Pros: Enhanced sound quality, reliable performance. Cons: Can be bulky and costly. |

| Residential Transformers | Typically pad-mounted or pole-mounted, used in residential areas | Utility companies, residential housing developments | Pros: Essential for grid stability, various voltage options. Cons: Installation and maintenance can be complex. |

| Isolation Transformers | Provides electrical isolation, reduces noise and interference | Industrial machinery, sensitive electronic equipment | Pros: Enhanced safety, minimizes signal distortion. Cons: Higher initial investment. |

What Are Miniature Surface Mount Transformers and Their Applications?

Miniature surface mount transformers are compact devices that are specifically engineered for efficient use in telecommunications and gate driver applications. Their small footprint allows for easy integration into circuit boards, making them ideal for modern electronic devices. When purchasing, businesses should consider the transformer’s isolation voltage and power rating to ensure compatibility with their systems.

Why Choose Low Voltage Transformers for Lighting Solutions?

Low voltage transformers are essential in converting line voltage to a lower voltage suitable for landscape and indoor lighting installations. These transformers are cost-effective and promote energy efficiency, making them a popular choice among contractors and builders. Buyers should assess the wattage capacity and installation requirements, as these factors influence the overall project cost and complexity.

How Do Power Transformers Benefit Audio Equipment?

Power transformers are crucial for audio applications, providing stable voltage supply to enhance sound quality. They are often used in professional audio equipment and musical instruments, ensuring consistent performance under varying load conditions. B2B buyers should evaluate the transformer’s specifications, including power rating and size, to ensure it meets their audio setup requirements.

What Are the Key Features of Residential Transformers?

Residential transformers are typically found in neighborhoods, either pad-mounted or pole-mounted, and are vital for maintaining grid stability. They step down high voltages for safe distribution to homes. When considering these transformers, buyers must account for the voltage ratings and installation logistics, as these factors can significantly impact utility operations and residential safety.

Why Invest in Isolation Transformers for Industrial Applications?

Isolation transformers are designed to provide electrical isolation between circuits, reducing noise and interference in sensitive electronic environments. They are widely used in industrial machinery and other applications where signal integrity is paramount. Buyers should consider the initial investment cost and the long-term benefits of improved safety and performance when selecting isolation transformers for their operations.

Key Industrial Applications of small transformer

| Industry/Sector | Specific Application of small transformer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Audio and Entertainment | Power supply for audio equipment | Ensures reliable sound quality and performance in live settings | Compatibility with audio systems, voltage ratings, and efficiency |

| Telecommunications | Isolation transformers for signal integrity | Protects sensitive data and enhances communication reliability | Isolation voltage levels, compact size, and environmental ratings |

| Lighting and Electrical Systems | Low-voltage transformers for landscape lighting | Enhances safety and aesthetics in outdoor environments | Output wattage, ease of installation, and safety certifications |

| Industrial Automation | Transformers in control panels for machinery | Provides stable voltage for operational efficiency | Load capacity, thermal management, and regulatory compliance |

| Renewable Energy | Transformers in solar power systems | Facilitates efficient energy conversion and distribution | Voltage compatibility, efficiency ratings, and environmental resilience |

How Are Small Transformers Used in the Audio and Entertainment Industry?

In the audio and entertainment sector, small transformers are essential for powering audio equipment, such as mixers and amplifiers. They convert higher voltages to lower, usable levels, ensuring reliable sound quality during performances. Buyers in this field must consider compatibility with existing equipment, as well as the transformer’s efficiency and voltage ratings to avoid distortion or power loss, particularly in regions like Nigeria and Saudi Arabia where power supply can be inconsistent.

What Role Do Small Transformers Play in Telecommunications?

Telecommunications heavily relies on small isolation transformers to maintain signal integrity and prevent data loss. These transformers isolate sensitive components from electrical noise, ensuring clear communication signals. B2B buyers should prioritize transformers with appropriate isolation voltage levels and compact designs, especially in regions with limited space for equipment, such as urban areas in South America and Europe.

How Are Small Transformers Essential for Lighting and Electrical Systems?

In the lighting industry, small transformers are used to convert standard line voltages to low voltages for landscape and architectural lighting. This conversion enhances safety and allows for more flexible installations. When sourcing transformers for lighting applications, businesses should focus on output wattage, ease of installation, and compliance with safety standards, especially in regions with stringent electrical regulations.

How Do Small Transformers Support Industrial Automation?

Small transformers are integral to industrial automation, serving in control panels to provide stable voltage for machinery operations. They help maintain operational efficiency by ensuring that equipment receives the correct voltage levels. Buyers in this sector should consider load capacity and thermal management features, particularly in hot climates found in parts of Africa and the Middle East, where equipment reliability is critical.

What Is the Importance of Small Transformers in Renewable Energy Systems?

In renewable energy applications, such as solar power systems, small transformers facilitate the conversion and distribution of energy generated from solar panels. They ensure that the energy output matches the requirements of the electrical grid or storage systems. When sourcing these transformers, businesses need to evaluate compatibility with different voltage levels and the efficiency ratings to maximize energy usage, particularly in regions investing heavily in renewable energy technologies.

3 Common User Pain Points for ‘small transformer’ & Their Solutions

Scenario 1: Inconsistent Voltage Output Leading to Equipment Malfunction

The Problem: B2B buyers often encounter issues with small transformers that fail to deliver consistent voltage output. This problem is particularly critical in industries where precise voltage levels are essential for the operation of sensitive equipment, such as in telecommunications or medical devices. Fluctuations can lead to equipment malfunction, increased downtime, and potential loss of revenue. Buyers may find themselves in a situation where their equipment is at risk, and the cause of the inconsistent performance is traced back to a faulty transformer.

The Solution: To mitigate this issue, buyers should prioritize sourcing transformers that come with robust voltage regulation features. When selecting a small transformer, it’s crucial to check specifications that indicate voltage stability under varying load conditions. Look for transformers with built-in voltage regulation capabilities or those that comply with industry standards for electrical performance. Additionally, conducting thorough testing in controlled environments before deploying transformers in critical applications can help ensure reliability. Partnering with manufacturers known for their quality assurance processes can also provide peace of mind regarding the transformer’s performance.

Scenario 2: Difficulty in Sizing Transformers for Specific Applications

The Problem: Many B2B buyers struggle with determining the appropriate size and capacity of small transformers for their unique applications. Over-sizing can lead to unnecessary costs and inefficiency, while under-sizing risks equipment failure and safety hazards. For example, in industrial settings where transformers power heavy machinery, incorrectly sizing the transformer can lead to operational inefficiencies or even catastrophic failures.

The Solution: To address sizing issues, buyers should conduct a comprehensive analysis of their power requirements. This includes assessing the total load that the transformer will need to support and considering factors such as peak demand and future expansion. Utilizing tools like load calculators can help in accurately estimating requirements. Additionally, consulting with transformer manufacturers for guidance based on their specifications and application experience can provide insights into optimal sizing. Buyers may also consider modular transformer options that allow for scalability, enabling them to adapt to changing power demands without incurring significant costs.

Scenario 3: Challenges in Installation and Maintenance of Small Transformers

The Problem: Installation and maintenance of small transformers can pose significant challenges for B2B buyers, particularly in remote or challenging environments. Improper installation can lead to operational issues, increased maintenance costs, and even safety hazards. Moreover, a lack of accessible technical support can exacerbate these challenges, leaving buyers unsure about the best practices for installation and ongoing maintenance.

The Solution: To streamline the installation process, buyers should invest in training for their technical staff, ensuring they understand the specific requirements and best practices for handling small transformers. Manufacturers often provide installation guidelines and support; leveraging these resources can significantly reduce installation errors. Furthermore, establishing a maintenance schedule that includes regular inspections and prompt addressing of any performance issues can extend the life of the transformer and improve reliability. Buyers might also consider suppliers who offer comprehensive after-sales support, including troubleshooting assistance and maintenance services, to ensure that they can resolve any issues swiftly and efficiently.

Strategic Material Selection Guide for small transformer

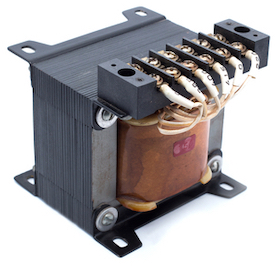

What are the Common Materials Used in Small Transformers?

When selecting materials for small transformers, it is essential to consider the properties, advantages, and limitations of each material. This ensures optimal performance, durability, and cost-effectiveness in various applications. Below, we analyze four common materials used in small transformers: silicon steel, copper, aluminum, and plastic.

How Does Silicon Steel Perform in Small Transformers?

Silicon steel is widely used in transformer cores due to its excellent magnetic properties. It has a high permeability, which enhances the efficiency of the transformer by minimizing energy losses during operation. Silicon steel can withstand high temperatures, making it suitable for various applications.

Pros: Silicon steel is durable and provides high efficiency, which is crucial for energy-saving applications. Its availability in various grades allows manufacturers to choose the most suitable option based on specific performance requirements.

Cons: The primary limitation of silicon steel is its weight, which can increase the overall mass of the transformer. Additionally, it can be more expensive compared to other materials, which may affect the final product’s pricing.

Impact on Application: Silicon steel is particularly effective in applications requiring high magnetic flux, such as audio transformers and power transformers. Its compatibility with high-frequency operations makes it a preferred choice in many sectors.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with international standards such as ASTM or DIN for silicon steel grades. Understanding local market preferences can also influence material selection.

What are the Benefits of Using Copper in Small Transformers?

Copper is a popular choice for windings in small transformers due to its excellent electrical conductivity. It allows for efficient energy transfer and minimizes resistive losses, which is crucial for maintaining performance.

Pros: The high conductivity of copper results in lower energy losses and improved efficiency. It is also highly durable and resistant to corrosion, ensuring a long lifespan for transformers.

Cons: The main drawback of copper is its cost, which is generally higher than aluminum. Additionally, copper is heavier, which can be a consideration in applications where weight is a critical factor.

Impact on Application: Copper’s superior conductivity makes it ideal for high-performance applications, such as audio and power transformers. It is particularly effective in environments where energy efficiency is paramount.

Considerations for International Buyers: Buyers should be aware of the varying copper grades and their compliance with international standards. Regions with stringent electrical safety regulations, such as Europe, may require specific certifications for copper used in transformers.

How Does Aluminum Compare as a Material for Small Transformers?

Aluminum is often used as an alternative to copper for transformer windings due to its lower cost and lighter weight. While it has lower conductivity than copper, it can still be effective in many applications.

Pros: The primary advantage of aluminum is its cost-effectiveness, making it an attractive option for budget-conscious projects. Its lightweight nature also facilitates easier handling and installation.

Cons: Aluminum’s lower conductivity can lead to higher resistive losses compared to copper, which may affect overall efficiency. It is also more susceptible to corrosion, requiring protective coatings in certain environments.

Impact on Application: Aluminum is suitable for applications where weight and cost are more critical than maximum efficiency, such as in certain low-voltage transformers. It is commonly used in residential and commercial lighting applications.

Considerations for International Buyers: Buyers should consider the corrosion resistance of aluminum in their specific environments, particularly in humid or coastal regions. Compliance with local standards for aluminum grades is also essential.

What Role Does Plastic Play in Small Transformers?

Plastic materials are increasingly used in small transformers, particularly for insulation and housing components. They offer excellent electrical insulation properties and can be molded into complex shapes.

Pros: The lightweight nature of plastic reduces overall transformer weight, making it easier to install. Additionally, plastics can be engineered for specific thermal and electrical properties, enhancing performance.

Cons: The primary limitation of plastic is its lower thermal resistance compared to metals, which can restrict its use in high-temperature applications. Plastics may also degrade over time under certain environmental conditions.

Impact on Application: Plastic is commonly used in low-voltage transformers and in applications where insulation is critical. It is especially effective in residential and commercial lighting systems.

Considerations for International Buyers: Buyers should ensure that the plastics used meet relevant safety and environmental standards, such as RoHS compliance. Understanding the local preferences for plastic materials can also influence purchasing decisions.

Summary Table of Material Selection for Small Transformers

| Material | Typical Use Case for small transformer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Steel | Power transformers | High efficiency and durability | Heavier and more expensive | High |

| Copper | High-performance transformers | Excellent conductivity | Higher cost and weight | High |

| Aluminum | Low-voltage transformers | Cost-effective and lightweight | Lower conductivity and corrosion | Medium |

| Plastic | Insulation and housing components | Lightweight and versatile | Lower thermal resistance | Low |

This guide provides a comprehensive overview of material selection for small transformers, enabling international B2B buyers to make informed decisions based on performance, cost, and compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for small transformer

What Are the Key Stages in the Manufacturing Process of Small Transformers?

The manufacturing process of small transformers is a meticulous procedure that involves several critical stages. Each phase ensures that the final product meets the required specifications and performance standards.

Material Preparation

The first step in manufacturing small transformers is material preparation. High-quality raw materials, such as silicon steel for the core and copper or aluminum for the windings, are sourced from reputable suppliers. These materials are subjected to rigorous testing to ensure they meet industry standards. For instance, silicon steel is evaluated for its magnetic properties, while copper is checked for conductivity and resistivity.

Illustrative image related to small transformer

Forming

Once the materials are prepared, the next stage is forming. In this phase, the silicon steel is cut and shaped into the desired core configuration, which is crucial for the transformer’s efficiency. The winding process follows, where copper or aluminum wire is meticulously wound around the core to create primary and secondary coils. Advanced winding techniques, such as computer-controlled winding machines, are often employed to ensure precision and reduce human error.

Assembly

After forming, the components are assembled. This stage involves stacking the laminated core, inserting the windings, and securing them in place. Insulation materials are also applied to prevent electrical short circuits. Depending on the design, additional components, such as tap changers or protective devices, may be integrated into the assembly. Proper alignment and secure fastening are vital to ensure that the transformer operates efficiently and safely.

Finishing

The final stage of manufacturing is finishing. This involves applying protective coatings to prevent corrosion and enhance durability. The transformers are then tested for functionality and performance, ensuring they meet the specified voltage ratings and efficiency levels. Packaging is also an essential part of this stage, as transformers must be protected during transportation to avoid damage.

What Are the Quality Assurance Protocols for Small Transformers?

Quality assurance (QA) is an integral part of the manufacturing process for small transformers, ensuring that each unit meets both international and industry-specific standards.

International Standards and Certifications

To enhance credibility, manufacturers often seek certifications such as ISO 9001, which focuses on quality management systems. Compliance with ISO standards ensures that manufacturers consistently provide products that meet customer and regulatory requirements. Additionally, industry-specific certifications, such as CE for European markets and UL for North American markets, are critical for B2B buyers. These certifications signify that the transformers have passed stringent safety and performance tests.

Quality Control Checkpoints

Quality control (QC) is implemented at various checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial phase involves inspecting raw materials upon receipt to ensure they meet specifications.

-

In-Process Quality Control (IPQC): During the manufacturing process, periodic checks are conducted to monitor the assembly and winding processes, ensuring adherence to quality standards.

-

Final Quality Control (FQC): Once the transformers are assembled, they undergo comprehensive testing, including electrical tests, insulation resistance tests, and load tests to verify performance and safety.

What Common Testing Methods Are Used to Ensure Transformer Quality?

Various testing methods are employed to ensure that small transformers function effectively and safely. Common methods include:

-

Electrical Testing: This involves checking the voltage ratio, insulation resistance, and power factor to confirm the transformer’s electrical integrity.

-

Thermal Testing: Conducting thermal imaging or temperature rise tests helps identify potential overheating issues during operation.

-

Dielectric Testing: This test checks the insulation strength between windings and between windings and the core, ensuring that the transformer can withstand operational voltages.

-

Load Testing: By applying a controlled load, manufacturers can evaluate the performance of the transformer under typical operating conditions.

How Can B2B Buyers Verify Supplier Quality Control Measures?

B2B buyers must exercise due diligence when selecting suppliers for small transformers. Here are some actionable steps to verify supplier QC measures:

Audits and Site Visits

Conducting audits or site visits to manufacturing facilities allows buyers to assess the production processes and quality control measures firsthand. This interaction can provide insights into the supplier’s adherence to quality standards and production capabilities.

Illustrative image related to small transformer

Quality Reports and Documentation

Requesting detailed quality reports, including test results and compliance certifications, can help buyers understand the supplier’s quality assurance practices. Documentation should reflect the QC checkpoints and testing methods utilized during production.

Third-Party Inspections

Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s manufacturing processes and product quality. These inspections can be particularly useful for international buyers who may face challenges in assessing suppliers remotely.

What Are the Unique Quality Control Considerations for International B2B Buyers?

International B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, should be aware of specific QC nuances:

-

Regulatory Compliance: Understanding local regulations and compliance requirements is crucial. Buyers should ensure that suppliers’ products meet the regulatory standards of their respective markets.

-

Cultural and Language Barriers: Communication challenges may arise during negotiations or audits. Engaging local representatives or translators can facilitate smoother interactions.

-

Logistics and Transportation: Quality assurance should extend to packaging and shipping. Buyers must verify that suppliers implement proper packaging methods to prevent damage during transit, especially for sensitive electrical components.

By understanding the manufacturing processes and quality assurance protocols associated with small transformers, B2B buyers can make informed decisions, ensuring they select reliable suppliers that meet their specifications and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘small transformer’

Introduction

Sourcing a small transformer requires a systematic approach to ensure that you choose the right product for your application while minimizing risk. This checklist is designed for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, helping you navigate the complexities of the procurement process.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline the technical requirements for your small transformer. Consider factors such as voltage ratings, power output, and application type (e.g., audio, lighting, or industrial use). This clarity will streamline discussions with suppliers and ensure you receive appropriate options.

- Key Specifications to Define:

- Input and output voltage

- Power rating (in watts)

- Environmental conditions (e.g., temperature range)

Step 2: Research Potential Suppliers

Thoroughly investigate various suppliers to find those that can meet your specifications. Look for manufacturers with a proven track record in producing small transformers and ensure they have experience in your specific application area.

- Where to Look:

- Industry directories

- Trade shows and exhibitions

- Online marketplaces and reviews

Step 3: Verify Supplier Certifications

Ensure that potential suppliers possess the necessary certifications for quality and safety. Certifications such as ISO, UL, or CE indicate compliance with international standards, which is crucial for ensuring reliability and safety in your operations.

- Ask for Documentation:

- Quality assurance certificates

- Product safety certifications

- Compliance with local regulations

Step 4: Request Samples for Evaluation

Before making a bulk purchase, request samples from shortlisted suppliers. Testing samples will help you assess the product’s performance and compatibility with your existing systems, reducing the risk of costly errors post-purchase.

- Evaluation Criteria:

- Build quality and materials used

- Performance under specified conditions

- Electrical efficiency and heat generation

Step 5: Compare Pricing and Terms

Once you have evaluated samples, compare pricing among the suppliers. However, don’t focus solely on the lowest price; consider total cost, including shipping, taxes, and warranty terms. A slightly higher-priced transformer with better service and warranty may offer more value in the long run.

- Considerations for Pricing:

- Volume discounts for bulk orders

- Payment terms and conditions

- Warranty duration and coverage

Step 6: Check Supplier Reputation and References

Before finalizing your decision, investigate the supplier’s reputation in the industry. Reach out to other businesses that have procured from them to gather insights on their experience regarding product quality, customer service, and delivery timelines.

- Questions to Ask References:

- How responsive is the supplier to issues or inquiries?

- Were there any delays in delivery or issues with the product?

- How effectively did they handle any problems?

Step 7: Finalize the Contract and Place Your Order

After thorough evaluation and comparison, finalize the contract with your chosen supplier. Ensure all terms are clearly outlined, including delivery timelines, payment terms, and warranty details, to avoid misunderstandings later.

- Contract Checklist:

- Clearly defined specifications and quantities

- Agreed delivery dates

- Terms for returns and disputes

By following this checklist, B2B buyers can enhance their procurement process for small transformers, ensuring they select the most suitable product for their needs while minimizing risks associated with sourcing.

Comprehensive Cost and Pricing Analysis for small transformer Sourcing

What Are the Key Cost Components in Small Transformer Sourcing?

Understanding the cost structure of small transformers is vital for B2B buyers aiming for effective sourcing. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margin.

-

Materials: The choice of materials significantly affects the cost. High-quality copper for windings, core materials like silicon steel, and insulation materials can vary in price based on market fluctuations and sourcing locations.

-

Labor: Labor costs are influenced by the manufacturing location. Regions with lower wage standards, such as certain parts of Africa and South America, may present cost advantages. However, the expertise required for transformer assembly can also drive costs higher in skilled labor markets.

-

Manufacturing Overhead: This encompasses utilities, rent, and equipment maintenance. Factories in developed regions may incur higher overhead costs, which are typically passed onto buyers.

-

Tooling: Initial tooling costs can be substantial, especially for custom designs. Buyers should consider the amortization of these costs over the expected production volume.

-

Quality Control: Rigorous QC processes ensure product reliability but add to the overall cost. Certifications such as ISO or UL can also elevate prices due to compliance costs.

-

Logistics: Shipping costs can vary widely based on distance, shipping method, and Incoterms used. For international buyers, understanding logistics is crucial for budgeting.

-

Margin: Supplier profit margins will vary based on competition, perceived product value, and market demand.

How Do Price Influencers Impact Small Transformer Costs?

Several factors influence the pricing of small transformers, particularly for international B2B buyers:

-

Volume/MOQ: Higher purchase volumes typically lead to lower per-unit costs due to economies of scale. Buyers should negotiate minimum order quantities (MOQ) to optimize pricing.

-

Specifications and Customization: Custom designs or specifications can increase costs. Standard models are generally more economical, while bespoke solutions may involve additional engineering and production time.

-

Materials and Quality: The quality of components directly affects pricing. Transformers built with premium materials may command higher prices but offer better longevity and efficiency.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more for their assurances of quality and service.

-

Incoterms: Understanding the chosen Incoterms is essential for calculating total landed costs. Terms like FOB (Free On Board) or CIF (Cost Insurance and Freight) can affect logistics expenses and risk.

What Negotiation Strategies Should B2B Buyers Consider?

To ensure cost-efficiency in small transformer sourcing, international buyers should adopt strategic negotiation practices:

-

Leverage Volume Discounts: Communicate your purchasing plans clearly. Suppliers may offer better rates for larger volumes or long-term contracts.

-

Total Cost of Ownership (TCO): Consider the TCO rather than just the initial purchase price. Factors such as energy efficiency, maintenance costs, and lifespan can impact overall expenses significantly.

-

Build Relationships: Cultivating strong relationships with suppliers can lead to better pricing and service. Trust can result in more favorable terms, including flexibility in MOQ and payment terms.

-

Stay Informed on Market Trends: Keeping abreast of material costs and market conditions can provide leverage during negotiations. Seasonal trends or geopolitical factors can influence pricing.

What Pricing Nuances Should International Buyers Be Aware Of?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding pricing nuances is essential:

-

Currency Fluctuations: Be mindful of currency exchange rates, as they can affect pricing agreements and final costs.

-

Tariffs and Duties: Import tariffs can substantially impact the total cost of procurement. Familiarize yourself with the trade regulations in your country.

-

Local Regulations and Standards: Compliance with local electrical standards and certifications may necessitate additional costs for modifications or testing.

-

Shipping and Handling: Costs can vary significantly based on shipping routes and methods. Assessing multiple logistics options can yield cost savings.

Conclusion: Are Indicative Prices Reliable?

While indicative prices can provide a baseline for budgeting, they should not be viewed as fixed. Variability in material costs, supply chain disruptions, and supplier pricing strategies can lead to fluctuations. Engaging in thorough market research and supplier discussions will yield the most accurate pricing insights for small transformers.

Alternatives Analysis: Comparing small transformer With Other Solutions

Exploring Alternatives to Small Transformers in Power Applications

In the realm of electrical engineering, small transformers are essential for voltage regulation and power distribution in various applications. However, alternative solutions exist that can also meet similar needs. This analysis compares small transformers with other viable options, providing B2B buyers with insights to make informed decisions based on their specific requirements.

| Comparison Aspect | Small Transformer | Miniature Surface Mount Transformer | Low Voltage Landscape Lighting Transformer |

|---|---|---|---|

| Performance | High efficiency and reliability for low to medium power applications. | Ideal for low power applications, particularly in data communication. | Designed for outdoor lighting, converting high voltage to low voltage effectively. |

| Cost | Moderate initial investment ($115+). | Generally lower cost, starting around $26.49. | Affordable, typically between $25-$50. |

| Ease of Implementation | Requires proper mounting and electrical connections. | Easy to integrate into existing circuit boards. | Straightforward installation, especially for DIY projects. |

| Maintenance | Low maintenance, but requires occasional inspection. | Minimal maintenance, reliable in stable environments. | Low maintenance; designed for outdoor durability. |

| Best Use Case | Audio equipment and industrial applications. | Gate drivers and data transmission interfaces. | Landscape lighting and low-voltage indoor/outdoor applications. |

Detailed Breakdown of Alternatives

Miniature Surface Mount Transformer

Miniature surface mount transformers are specifically designed for low-power applications, such as data communication interfaces. They offer excellent isolation and reliability, making them ideal for applications that require precise voltage regulation without significant power losses. The compact design allows easy integration onto circuit boards, which can be advantageous in space-constrained environments. However, their limited power capacity makes them unsuitable for high-demand applications where a small transformer might excel.

Illustrative image related to small transformer

Low Voltage Landscape Lighting Transformer

These transformers are tailored for converting line voltage to low voltage for landscape lighting systems. They are user-friendly, often designed for DIY installation, which can reduce labor costs significantly. Their affordability makes them an attractive option for projects where budget constraints are a priority. However, they are primarily designed for lighting applications, and their performance in industrial or audio contexts would be inadequate compared to small transformers.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the appropriate power solution, B2B buyers should consider specific application requirements, including performance, cost, and ease of implementation. Small transformers are well-suited for industrial and audio applications where reliability and efficiency are paramount. In contrast, miniature surface mount transformers excel in low-power data communication tasks, while low voltage landscape lighting transformers are best for outdoor lighting projects. By evaluating these factors, businesses can identify the most effective transformer solution tailored to their operational needs.

Essential Technical Properties and Trade Terminology for small transformer

What Are the Key Technical Properties of Small Transformers?

Understanding the essential technical properties of small transformers is crucial for B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe. Below are several critical specifications that should be evaluated:

-

Power Rating (Wattage)

– Definition: This indicates the maximum output power the transformer can handle, typically measured in watts (W).

– Importance: Selecting a transformer with an appropriate power rating ensures it can adequately support the electrical load of connected devices. Under-specifying can lead to overheating or failure, while over-specifying may increase costs unnecessarily. -

Voltage Rating

– Definition: This refers to the maximum voltage the transformer can safely handle, usually specified as primary (input) and secondary (output) voltages.

– Importance: Ensuring the voltage rating matches your application is critical for safety and functionality. Misalignment can cause equipment damage or operational inefficiencies. -

Efficiency

– Definition: Efficiency measures how effectively a transformer converts input power to output power, typically expressed as a percentage.

– Importance: Higher efficiency translates to lower energy losses, which is particularly relevant in regions with high energy costs. Choosing efficient transformers can significantly reduce operational expenses over time. -

Isolation Voltage

– Definition: This specification indicates the voltage level that separates the primary and secondary windings, enhancing safety and preventing shock.

– Importance: Isolation is vital in applications where safety is paramount, such as in medical or industrial equipment. It protects users and sensitive devices from electrical faults. -

Temperature Rating

– Definition: This indicates the maximum ambient temperature at which the transformer can operate effectively.

– Importance: In hotter climates, understanding the temperature rating helps ensure reliability and longevity. Operating beyond this rating can lead to premature failure. -

Material and Construction

– Definition: The materials used in the core and windings (e.g., copper vs. aluminum) and the construction techniques employed (e.g., encapsulated, open-frame).

– Importance: The choice of materials affects the transformer’s performance, durability, and cost. For instance, copper windings are generally more efficient than aluminum but come at a higher price.

What Are Common Trade Terms Related to Small Transformers?

Familiarity with industry jargon can facilitate smoother transactions and negotiations. Here are several key terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Relevance: Understanding OEM relationships can help buyers identify reliable suppliers and ensure compatibility with existing systems. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Relevance: Knowing the MOQ helps buyers plan their procurement strategies, especially when managing inventory and cash flow. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers to request pricing and other details for specific products or services.

– Relevance: An RFQ is a critical step in the purchasing process, allowing buyers to compare offerings and negotiate terms effectively. -

Incoterms (International Commercial Terms)

– Definition: A series of predefined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international transactions.

– Relevance: Familiarity with Incoterms can prevent misunderstandings regarding shipping costs, risk transfer, and delivery responsibilities. -

Lead Time

– Definition: The time it takes from placing an order to receiving the goods.

– Relevance: Understanding lead times is crucial for project planning and ensures that the supply chain remains uninterrupted. -

Certification Standards

– Definition: Industry standards that products must meet to ensure safety and performance (e.g., UL, CE).

– Relevance: Compliance with certification standards is essential for market acceptance and regulatory approval, particularly in diverse markets like those in Africa and Europe.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions, ensuring that the small transformers they procure meet their operational needs while aligning with industry standards.

Illustrative image related to small transformer

Navigating Market Dynamics and Sourcing Trends in the small transformer Sector

What Are the Key Trends Shaping the Small Transformer Market?

The small transformer market is currently experiencing robust growth driven by several global factors. A significant increase in renewable energy installations across Africa, South America, the Middle East, and Europe is creating a demand for efficient voltage management solutions. As countries prioritize energy security and sustainability, the need for small transformers to integrate renewable sources into existing grids is becoming paramount. Emerging technologies such as smart grids and Internet of Things (IoT) applications are further influencing the market, allowing for real-time monitoring and management of electrical systems, which enhances operational efficiency.

B2B buyers must also consider the evolving landscape of sourcing trends. The rise of digital procurement platforms is facilitating more streamlined supplier relationships, enabling businesses to source components like small transformers from global manufacturers more efficiently. Additionally, the focus on localized manufacturing and supply chains is gaining traction, particularly in regions like Africa and South America, where logistical challenges can impede timely delivery. This shift encourages partnerships with local suppliers who understand regional regulations and market dynamics, which can significantly reduce lead times and costs.

How Can Sustainability and Ethical Sourcing Influence B2B Decisions in the Small Transformer Sector?

Sustainability and ethical sourcing are increasingly critical in the small transformer sector. The environmental impact of manufacturing processes, particularly in the context of energy consumption and waste generation, is under scrutiny. Buyers are now prioritizing suppliers who demonstrate a commitment to sustainability through the use of eco-friendly materials and processes. For instance, transformers that utilize recyclable materials or adhere to energy efficiency standards can enhance a company’s green credentials and appeal to environmentally conscious consumers.

Moreover, ethical supply chains are essential for mitigating risks related to labor practices and sourcing materials. Buyers should seek manufacturers with certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety. These certifications not only signify compliance with international standards but also reflect a supplier’s commitment to corporate social responsibility. By aligning procurement strategies with sustainability goals, businesses can enhance their brand reputation while contributing to a more sustainable future.

What Is the Historical Context Behind the Small Transformer Market’s Development?

The small transformer market has evolved significantly over the decades, driven by advancements in electrical engineering and changing energy demands. Initially, transformers were primarily used in industrial applications; however, the growth of residential and commercial sectors has expanded their use. The introduction of low-voltage and miniature transformers has facilitated applications in landscape lighting, telecommunications, and renewable energy systems, making them more accessible for various end-users.

As energy efficiency regulations became more stringent in the late 20th century, manufacturers began to innovate by developing transformers with higher performance and lower losses. This evolution has continued into the 21st century, with a strong emphasis on smart technologies and renewable energy integration. As a result, today’s B2B buyers can access a diverse range of small transformers designed for specific applications, ensuring they can meet their operational needs while adhering to sustainability standards.

Frequently Asked Questions (FAQs) for B2B Buyers of small transformer

-

How do I choose the right small transformer for my application?

Choosing the right small transformer involves evaluating your specific power requirements, voltage levels, and application type. Determine whether you need a step-up or step-down transformer based on the input and output voltage needed. Additionally, consider factors like efficiency ratings, size constraints, and environmental conditions (e.g., temperature and humidity). Reviewing technical specifications such as power ratings, inductance, and safety certifications will help ensure you select a transformer that meets your operational needs and complies with local regulations. -

What is the best small transformer for low-voltage applications?

For low-voltage applications, such as landscape lighting or small electronic devices, a miniature transformer designed specifically for low-voltage output is ideal. Look for transformers that convert standard line voltage (e.g., 120V) to low voltage (e.g., 12V or 24V) while ensuring they are ETL or UL certified for safety. Transformers with higher efficiency ratings and lower wattage outputs, such as those in the 18W range, are commonly recommended for these applications due to their compact size and reliability. -

What are the common voltage ratings for small transformers?

Small transformers typically come in various voltage ratings, including common outputs like 5V, 12V, 24V, and 48V. The choice depends on the application requirements; for instance, 12V is standard for low-voltage lighting, while 5V is often used for charging devices. Ensure the transformer you choose matches the voltage needs of your equipment to avoid damage or performance issues. -

What factors should I consider when vetting a small transformer supplier?

When vetting a supplier, consider their industry experience, certifications, and customer reviews. Verify their compliance with international quality standards, such as ISO 9001, and check for any relevant product certifications (e.g., CE, RoHS). Additionally, assess their production capacity, lead times, and willingness to provide customization options. A reliable supplier should also offer good after-sales support and warranty terms. -

What are the minimum order quantities (MOQs) for small transformers?

Minimum order quantities for small transformers can vary significantly by supplier and product type. Generally, MOQs may range from as low as 10 units for standard models to several hundred for customized solutions. It is crucial to clarify MOQs during negotiations to ensure they align with your purchasing needs and budget constraints, especially if you are a smaller business or testing a new product line. -

What payment terms are typically offered by international suppliers?

International suppliers may offer various payment terms, including upfront payment, partial payment upon order confirmation, or payment on delivery. Common methods include wire transfers, letters of credit, and secure online payment platforms. Always negotiate terms that suit your cash flow and ensure that they provide sufficient protection against risks such as non-delivery or defective products. -

How can I ensure quality assurance for the small transformers I purchase?

To ensure quality assurance, request detailed product specifications, certificates of compliance, and test reports from your supplier. Inquire about their quality control processes, such as incoming material inspections and final product testing. Additionally, consider conducting factory audits or using third-party inspection services to verify product quality before shipment, particularly for large orders or critical applications. -

What logistics considerations should I be aware of when importing small transformers?

When importing small transformers, consider shipping methods, customs clearance, and potential tariffs. Evaluate the total landed cost, including shipping fees and taxes, to avoid unexpected expenses. Choose a reliable logistics partner familiar with international shipping regulations and who can assist with documentation. Additionally, ensure that the transformers are packaged securely to prevent damage during transit, especially if shipping to regions with challenging logistics infrastructures.

Top 7 Small Transformer Manufacturers & Suppliers List

1. Summit Audio Inc – Power Transformer Small

Domain: summitaudio.com

Registered: 1997 (28 years)

Introduction: {‘name’: ‘Power Transformer Small’, ‘brand’: ‘Summit Audio Inc’, ‘product_code’: ‘Power Transformer Small’, ‘availability’: ‘2’, ‘price’: ‘$115.00’, ‘description’: ‘Power Transformer used in half-rack Summit units’, ‘related_products’: [{‘name’: ‘TD-100 Instrument Preamp/DI’, ‘price’: ‘$899.99’}, {‘name’: ‘2BA-221’, ‘price’: ‘$1,149.99’}, {‘name’: ‘TLA-50 Mono Tube Leveling Amplifier’, ‘price’: ‘$…

2. Hubbell – Low Voltage Distribution Transformer

Domain: store.hubbell.com

Registered: 1995 (30 years)

Introduction: This company, Hubbell – Low Voltage Distribution Transformer, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Reputable Brands – Tiny Transformers 5V/12V

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Looking for tiny transformers, specifically those that output 5V or 12V. The user found a transformer module in a GU10 smart bulb, measuring approximately 2.6cm long, 1.6cm tall, and 2cm wide, which outputs 14V. They are seeking reputable brands and sources to purchase similar modules without disassembling more bulbs.

4. Kichler – Low-Voltage Landscape Lighting Transformers

Domain: kichler.com

Registered: 1995 (30 years)

Introduction: Low-voltage landscape lighting transformers convert line voltage (120V) to low voltage for landscape lighting installations.

5. Electronic Surplus – Small Electronic Transformers

Domain: electronicsurplus.com

Registered: 1996 (29 years)

Introduction: Small Electronic Transformers for Sale | Electronic Surplus

Key Product Details:

1. Types of Transformers Available:

– 3-Phase Transformer

– AC Adaptor Transformer

– Audio Transformer

– Constant Voltage Transformer

– Current Transformer

– Isolation Transformer

– PC Mount Transformer

– Power Transformer

– Pulse Transformer

– RF Transformer

2. Input AC Voltage Options…

6. VOLT® Lighting – Low Voltage Transformers

Domain: voltlighting.com

Registered: 2008 (17 years)

Introduction: Low Voltage Transformers for Landscape Lighting | VOLT® Lighting

– Designed for easy installation, consistent performance, and longevity.

– Backed by a lifetime warranty.

– ETL listed to UL standards.

– Features toroidal cores, weatherproof stainless steel cabinets, timer and photocell receptacles, and magnetic secondary circuit breakers for each 300W common circuit.

– Converts 120 volt current to…

7. Daelim – Residential Transformers

Domain: daelimtransformer.com

Registered: 2019 (6 years)

Introduction: Residential Transformer: 7.2–34.5 kV, 25–3000 kVA; UL Evaluated, Certificate of Compliance Available; In Stock & Ready to Ship from Houston, CA & Florida; Types include Pad Mounted, Pole Mounted, Single Phase, and Three Phase; Meets U.S. DOE 2016 efficiency standards; Designed for safety with tamper-proof structures; Voltage conversion from high voltage (7.2kV, 14.4kV, 12.47kV, 24.94kV) to low vol…

Strategic Sourcing Conclusion and Outlook for small transformer

In today’s competitive landscape, effective strategic sourcing of small transformers is critical for B2B buyers across diverse markets, particularly in regions such as Africa, South America, the Middle East, and Europe. Key takeaways highlight the importance of understanding product specifications, reliability, and compliance with international standards to ensure optimal performance in various applications, from residential to industrial uses. Leveraging relationships with reputable suppliers not only enhances product quality but also streamlines procurement processes, ultimately driving cost efficiencies.

The evolving energy landscape necessitates a forward-thinking approach to sourcing. As technological advancements continue to shape the transformer market, international buyers must stay informed about emerging trends and innovations that can elevate their operational capabilities.

We encourage B2B buyers to actively engage with suppliers, seek out high-quality products, and prioritize sustainability in their sourcing strategies. By doing so, you position your business to capitalize on future opportunities in the small transformer sector. The journey toward enhanced efficiency and reliability starts with informed sourcing decisions—take the next step today to ensure your business remains at the forefront of this dynamic market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.