Top 7 Shoe Washing Bag Suppliers (And How to Choose)

Introduction: Navigating the Global Market for shoe washing bag

In the competitive landscape of global footwear care, sourcing effective shoe washing bags presents a significant challenge for B2B buyers. These essential accessories not only protect shoes during the cleaning process but also extend their lifespan by preventing damage and wear. As the demand for high-quality shoe care solutions rises, particularly in diverse markets across Africa, South America, the Middle East, and Europe, understanding the nuances of the shoe washing bag market becomes crucial for informed purchasing decisions.

This guide offers a comprehensive overview of shoe washing bags, exploring various types, applications, and materials to help buyers identify the best options for their needs. Key considerations such as supplier vetting processes, cost analysis, and market trends are meticulously detailed, empowering buyers with the knowledge to make strategic choices. By understanding the features and benefits of different shoe washing bags, businesses can enhance their product offerings and meet consumer demands effectively.

With a focus on international markets, particularly regions like Nigeria and Vietnam, this guide serves as a valuable resource for B2B buyers looking to navigate the complexities of sourcing shoe washing bags. By leveraging the insights provided, businesses can not only improve their inventory but also foster customer satisfaction through quality footwear care solutions.

Understanding shoe washing bag Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Mesh Shoe Bag | Lightweight, breathable mesh; typically accommodates one pair of shoes | Retailers, laundries, and households | Pros: Affordable, versatile; Cons: May not protect shoes from heavy scrubbing. |

| Premium Microfiber Bag | Soft microfiber material; provides extra cushioning and protection | High-end retailers, specialty stores | Pros: Gentle on shoes, effective cleaning; Cons: Higher price point. |

| Multi-Function Bag | Designed for various shoe types; includes additional features like removable shoe trees | Sports retailers, shoe care brands | Pros: Versatile, suitable for multiple shoe types; Cons: Bulkier and more expensive. |

| Triangle Mesh Bag | Triangular shape for better storage; compact and easy to use | Small retailers, online marketplaces | Pros: Space-efficient, lightweight; Cons: Limited capacity for larger shoes. |

| Heavy-Duty Shoe Bag | Thick, durable fabric; designed for rugged or heavy-duty shoes | Industrial sectors, outdoor retailers | Pros: Strong and protective; Cons: May not fit in standard washing machines. |

What are the Characteristics of Standard Mesh Shoe Bags?

Standard mesh shoe bags are designed primarily for everyday use, made from lightweight, breathable materials that allow water and detergent to flow freely. Their simple design typically accommodates one pair of shoes, making them ideal for laundries and households. B2B buyers should consider the cost-effectiveness of these bags, as they are generally more affordable than specialized options. However, they may not provide the level of protection needed for delicate or high-end footwear.

How Do Premium Microfiber Bags Differ from Other Types?

Premium microfiber bags stand out due to their soft, cushioned interiors that protect shoes from scuffs and damage during the wash cycle. These bags are particularly suitable for high-end retailers and specialty shoe care brands, where maintaining the integrity of the product is crucial. While they are more expensive, the investment can lead to higher customer satisfaction and repeat business, especially for brands focused on quality and care.

What Makes Multi-Function Bags a Smart Choice for B2B Buyers?

Multi-function bags are versatile, accommodating various shoe types and often including additional features such as removable shoe trees. These bags are particularly beneficial for sports retailers and shoe care brands that cater to diverse customer needs. While they may be bulkier and more costly, their adaptability can reduce the need for multiple bag types, streamlining inventory and enhancing customer experience.

Why Choose Triangle Mesh Bags for Small Retailers?

Triangle mesh bags are compact, making them an excellent choice for small retailers and online marketplaces. Their unique shape allows for better storage and organization, appealing to consumers looking for convenience. Although they may have limited capacity for larger shoes, their lightweight nature and affordability make them attractive for budget-conscious buyers.

In What Scenarios are Heavy-Duty Shoe Bags Essential?

Heavy-duty shoe bags are crafted from thick, durable fabric, making them ideal for industrial sectors and outdoor retailers that cater to rugged footwear. These bags offer superior protection against wear and tear, ensuring the longevity of the shoes they contain. However, B2B buyers should note that these bags may not fit in standard washing machines, which could limit their usability in some settings.

Key Industrial Applications of shoe washing bag

| Industry/Sector | Specific Application of shoe washing bag | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail Footwear | Cleaning and maintaining inventory of shoes | Enhances product presentation and prolongs shoe lifespan | Durability, size compatibility, and material safety certifications |

| Hospitality | Laundry services for staff uniforms and guest footwear | Ensures cleanliness and hygiene, improving guest satisfaction | Bulk purchasing options and customization for branding |

| Sports and Fitness Centers | Regular cleaning of athletic shoes for staff and clients | Promotes a clean environment and maintains equipment longevity | Machine compatibility and ease of use for quick turnaround |

| Construction and Field Work | Maintenance of safety footwear and work boots | Reduces wear and tear, ensuring safety compliance and longevity | Robust design to handle heavy-duty shoes and frequent use |

| Educational Institutions | Washing students’ athletic and casual shoes | Supports hygiene and cleanliness, enhancing student well-being | Cost-effectiveness and ability to handle various shoe types |

How Can Retail Footwear Businesses Benefit from Shoe Washing Bags?

In the retail footwear industry, shoe washing bags are essential for maintaining the cleanliness of inventory. These bags allow retailers to wash display and stock shoes without damaging them, ensuring that products remain visually appealing to customers. This not only enhances the presentation but also prolongs the lifespan of the footwear. When sourcing, retailers should consider the durability of the bags, compatibility with washing machines, and whether the materials used are safe for various shoe types.

Why Are Shoe Washing Bags Important for the Hospitality Sector?

In the hospitality industry, shoe washing bags are crucial for maintaining staff uniforms and guest footwear. These bags facilitate efficient cleaning processes, ensuring that shoes are hygienic and presentable, which is vital for guest satisfaction. The ability to wash multiple pairs at once can significantly improve laundry turnaround times. Businesses should focus on sourcing bags that offer bulk purchasing options and can be customized with branding to enhance their service offerings.

Illustrative image related to shoe washing bag

How Do Sports and Fitness Centers Utilize Shoe Washing Bags?

Sports and fitness centers regularly utilize shoe washing bags to clean athletic shoes used by staff and clients. This practice helps maintain a clean environment, reduces odors, and extends the life of expensive athletic footwear. For these centers, sourcing bags that are machine-compatible and easy to use is crucial, as they need to ensure quick cleaning processes to accommodate high foot traffic.

What Role Do Shoe Washing Bags Play in Construction and Field Work?

In construction and fieldwork environments, shoe washing bags are instrumental in maintaining safety footwear and work boots. Regular cleaning reduces wear and tear, ensuring that footwear remains compliant with safety regulations. When sourcing, businesses should prioritize robust designs capable of handling heavy-duty shoes and frequent use, as well as bags that can withstand tough cleaning cycles without degrading.

How Can Educational Institutions Leverage Shoe Washing Bags?

Educational institutions can significantly benefit from shoe washing bags by providing a means to wash students’ athletic and casual shoes efficiently. This supports hygiene and cleanliness, contributing to the overall well-being of students. Institutions should look for cost-effective solutions that can handle various shoe types, ensuring that the bags are durable enough for regular use while remaining budget-friendly for large-scale procurement.

3 Common User Pain Points for ‘shoe washing bag’ & Their Solutions

Scenario 1: Protecting Shoe Quality During Washing

The Problem: B2B buyers, such as retailers or online platforms, often face the challenge of maintaining the quality and appearance of shoes when cleaning them. Many traditional washing methods can lead to deformation, color fading, and material damage, resulting in unsellable inventory. For businesses that rely on pristine footwear to attract customers, this can significantly impact their reputation and bottom line.

The Solution: To address this issue, sourcing high-quality shoe washing bags specifically designed to protect shoes during the cleaning process is essential. Look for bags made from durable yet gentle materials like soft mesh or microfiber. These materials provide adequate cushioning and prevent scuffs or scratches. When ordering, ensure the bags have features like adjustable straps or compartments that allow for a secure fit of various shoe types, from sneakers to dress shoes. Establishing partnerships with manufacturers who offer customizable solutions can also help tailor the bags to fit specific shoe sizes and styles, ensuring a more effective wash without compromising the shoe’s integrity.

Scenario 2: Streamlining the Cleaning Process for High-Volume Retailers

The Problem: High-volume retailers or e-commerce businesses that handle large quantities of shoes face the dilemma of an inefficient cleaning process. Manual washing is time-consuming and labor-intensive, leading to increased operational costs and slower turnaround times for inventory. This inefficiency can hinder the ability to meet customer demand, especially during peak seasons.

The Solution: Implementing an effective shoe washing bag solution can dramatically streamline the cleaning process. For businesses, investing in bulk orders of industrial-grade washing bags that can accommodate multiple pairs of shoes at once is crucial. These bags should be machine washable and designed for high-capacity loads. Additionally, creating a standardized washing protocol within the operation can enhance efficiency—designate specific washing machines for shoe cleaning and train staff on optimal loading techniques. Utilizing detergent designed for use with these bags will further enhance cleaning effectiveness while protecting shoe materials.

Scenario 3: Ensuring Cost-Effectiveness in Shoe Maintenance

The Problem: B2B buyers often struggle with the high costs associated with shoe maintenance and cleaning, which can eat into profit margins. Regular cleaning is necessary to keep shoes in sellable condition, but using harsh chemicals or methods can lead to damage, resulting in additional replacement costs. This scenario is particularly pressing for businesses in regions with high humidity or dust, where shoes may require frequent washing.

The Solution: To maintain cost-effectiveness, businesses should source shoe washing bags that are not only affordable but also designed to be reusable and durable. Look for products that offer a balance between price and quality, ensuring that they can withstand multiple washes without losing effectiveness. Consider establishing a relationship with a reliable supplier who can provide bulk pricing options or discounts on repeat orders. Additionally, invest in training for staff on how to use the bags properly to maximize their lifespan and effectiveness. This proactive approach minimizes the need for costly replacements while ensuring shoes remain in excellent condition, ultimately supporting better profit margins.

Strategic Material Selection Guide for shoe washing bag

What Are the Key Materials Used in Shoe Washing Bags?

When selecting materials for shoe washing bags, B2B buyers must consider various factors that influence performance, durability, and compliance with international standards. Here, we analyze four common materials used in the manufacturing of shoe washing bags: polyester, nylon, microfiber, and mesh fabric.

How Does Polyester Perform in Shoe Washing Bags?

Polyester is a widely used synthetic material known for its strength and resistance to shrinking and stretching. It can withstand temperatures up to 120°C, making it suitable for regular washing cycles. The durability of polyester contributes to a longer lifespan for the shoe washing bags, reducing the frequency of replacements.

Pros: Polyester is relatively inexpensive, lightweight, and resistant to mildew and abrasion. It is also easy to dye, allowing for a variety of color options that can appeal to different markets.

Illustrative image related to shoe washing bag

Cons: While polyester is durable, it may not be as breathable as other materials, which can lead to moisture retention. Additionally, it is less eco-friendly compared to natural fibers, which may be a consideration for environmentally conscious buyers.

Impact on Application: Polyester is compatible with most detergents and can handle various shoe types, making it versatile for different consumer needs.

Considerations for International Buyers: Buyers from regions like Africa and South America may prefer polyester for its cost-effectiveness. Compliance with standards such as ASTM for textile safety can also influence purchasing decisions.

What Are the Advantages of Nylon in Shoe Washing Bags?

Nylon is another synthetic material known for its exceptional strength and elasticity. It can endure high temperatures and is resistant to wear and tear, making it suitable for rigorous washing cycles.

Pros: Nylon’s high tensile strength allows it to hold heavy shoes without tearing, and its water-resistant properties help prevent moisture damage.

Illustrative image related to shoe washing bag

Cons: Nylon can be more expensive than polyester and may require more complex manufacturing processes. It also has a tendency to absorb odors if not properly cleaned.

Impact on Application: Nylon’s durability makes it ideal for heavy-duty applications, such as washing work boots or athletic footwear.

Considerations for International Buyers: Buyers in the Middle East may appreciate nylon’s heat resistance, while compliance with JIS standards in Japan can be an essential factor for buyers in Asia.

How Does Microfiber Enhance Shoe Washing Bags?

Microfiber is a blend of polyester and polyamide, offering a unique combination of softness and strength. It is highly absorbent and can effectively remove dirt and grime without damaging delicate shoe materials.

Pros: Microfiber is gentle on shoes, preventing scratches and fading. It is also machine washable and dries quickly, making it convenient for consumers.

Cons: The cost of microfiber can be higher than that of traditional materials, and it may require special care to maintain its effectiveness over time.

Impact on Application: Microfiber is particularly suitable for washing delicate shoes, such as dress shoes or sandals, where protection from damage is paramount.

Illustrative image related to shoe washing bag

Considerations for International Buyers: European buyers may be more inclined to invest in microfiber for its performance and eco-friendliness, aligning with the growing trend towards sustainable products.

What Role Does Mesh Fabric Play in Shoe Washing Bags?

Mesh fabric, typically made from polyester or nylon, features a network of interwoven fibers that allow for airflow during washing. This property helps to prevent moisture buildup and promotes quicker drying.

Pros: The breathable nature of mesh fabric enhances the cleaning process by allowing water and detergent to circulate freely around the shoes. It is also lightweight and easy to store.

Cons: Mesh bags may not be as durable as solid fabric options and can be prone to snagging or tearing if subjected to heavy use.

Impact on Application: Mesh is ideal for washing lightweight shoes, such as sneakers or sandals, where breathability and quick drying are essential.

Considerations for International Buyers: Buyers in humid climates, such as parts of Africa and Southeast Asia, may prefer mesh for its moisture-wicking properties, while compliance with local textile regulations can influence purchasing decisions.

Illustrative image related to shoe washing bag

Summary Table of Material Selection for Shoe Washing Bags

| Material | Typical Use Case for Shoe Washing Bag | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | General-purpose shoe washing | Cost-effective and durable | Less breathable, less eco-friendly | Low |

| Nylon | Heavy-duty shoe washing | High tensile strength | More expensive, odor retention | Med |

| Microfiber | Delicate shoe washing | Gentle on shoes, highly absorbent | Higher cost, requires special care | High |

| Mesh | Lightweight shoe washing | Breathable and quick drying | Less durable, prone to snagging | Med |

This analysis provides B2B buyers with essential insights into material selection for shoe washing bags, enabling informed purchasing decisions that align with their operational needs and regional preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for shoe washing bag

What Are the Key Stages in the Manufacturing Process of Shoe Washing Bags?

The manufacturing of shoe washing bags typically involves several critical stages, including material preparation, forming, assembly, and finishing. Each stage plays a vital role in ensuring the final product is durable, effective, and meets customer expectations.

-

Material Preparation: The first step in manufacturing shoe washing bags is selecting appropriate materials. Common choices include high-quality polyester or microfiber, known for their durability and resistance to wear and tear. Suppliers often source these materials in bulk, ensuring they meet specific standards for strength and flexibility. This stage may involve pre-treating materials to enhance their properties, such as water resistance or stain repellency.

-

Forming: Once the materials are prepared, they undergo forming processes. This can involve cutting the fabric into specific dimensions and shapes required for the bag. Techniques such as heat cutting or laser cutting may be employed to ensure clean edges and precise sizing. Additionally, manufacturers may employ sewing techniques that reinforce seams, enhancing the bag’s durability and load-bearing capacity.

-

Assembly: The assembly stage involves bringing together various components of the shoe washing bag. This includes attaching zippers, handles, or any other functional elements. Automated sewing machines are often used for efficiency, allowing for quick assembly while maintaining high quality. Quality checks are often integrated into this stage to ensure all components meet the specified design and functional requirements.

-

Finishing: The final stage of manufacturing involves finishing touches, which can include quality inspections, packaging, and labeling. Manufacturers often ensure that the bags are free from defects and meet aesthetic standards. This stage may also involve applying treatments to enhance the bag’s resistance to dirt and odors. Proper packaging is crucial for protecting the product during shipping and ensuring it reaches the buyer in pristine condition.

How Is Quality Assurance Implemented in the Production of Shoe Washing Bags?

Quality assurance (QA) is a fundamental aspect of the manufacturing process, ensuring that the products meet international standards and customer expectations. Various QA protocols are typically implemented throughout the production process.

-

International Standards Compliance: Many manufacturers adhere to international quality management standards such as ISO 9001. This standard focuses on ensuring consistent quality in production processes and emphasizes customer satisfaction. Compliance with ISO 9001 requires documentation of procedures and regular audits to ensure ongoing adherence to quality standards.

-

Industry-Specific Certifications: Depending on the target market, additional certifications like CE (Conformité Européenne) may be required, especially for products sold in Europe. This certification indicates that the product meets EU safety, health, and environmental protection standards. In some cases, manufacturers may also seek certifications from relevant industry bodies to enhance credibility and marketability.

-

Quality Control Checkpoints: Manufacturers typically implement several quality control (QC) checkpoints throughout the production process. These include:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins.

– In-Process Quality Control (IPQC): During manufacturing, random samples may be taken for inspection to ensure adherence to quality standards at various production stages.

– Final Quality Control (FQC): Before products are packaged and shipped, a final inspection is conducted to ensure that the finished shoe washing bags meet all specifications and are free from defects. -

Common Testing Methods: Various testing methods are employed to assess the durability and effectiveness of shoe washing bags. These include tensile strength tests, wash tests to evaluate colorfastness and material integrity, and usability tests to ensure zippers and seams function correctly. Manufacturers may also conduct performance tests under different conditions to simulate real-world usage.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, especially those from diverse regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is essential to ensure product reliability.

Illustrative image related to shoe washing bag

-

Supplier Audits: Conducting audits is one of the most effective ways to assess a supplier’s manufacturing capabilities and quality control measures. Buyers can perform on-site audits or request third-party audits to evaluate compliance with international standards and internal QA processes. This provides transparency and builds trust in the supplier relationship.

-

Quality Assurance Reports: Suppliers should provide detailed quality assurance reports that outline their manufacturing processes, quality control checkpoints, and testing results. These documents should include information about any certifications obtained, the materials used, and the results of various quality tests performed on the products.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices. These inspections can be scheduled at various stages of production, offering buyers insight into the manufacturing process and the quality of the products being produced.

-

Nuances for International Buyers: B2B buyers from different regions should be aware of specific nuances that may affect quality assurance. For example, compliance with regional regulations may differ significantly, and understanding local market requirements can enhance the procurement process. Buyers should also consider cultural differences in business practices, which may influence communication and negotiation regarding quality standards.

What Challenges and Solutions Exist in Quality Assurance for Shoe Washing Bags?

Despite the robust quality assurance processes in place, manufacturers may face challenges in maintaining consistent quality across production runs. These challenges can include fluctuations in material quality, variations in manufacturing processes, and regional compliance issues.

-

Material Quality Fluctuations: Variability in the quality of raw materials can lead to inconsistencies in the final product. To combat this, manufacturers should establish strong relationships with reliable suppliers and implement stringent IQC procedures to assess incoming materials rigorously.

-

Process Variability: Changes in manufacturing techniques or equipment can impact product quality. Continuous training for staff and regular maintenance of machinery are crucial to ensuring that production processes remain consistent and efficient.

-

Regional Compliance Challenges: Navigating the regulatory landscape can be complex, especially for international buyers. Engaging local experts or consultants who understand the specific compliance requirements in target markets can help manufacturers stay compliant and avoid costly errors.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing shoe washing bags, ensuring they partner with suppliers who prioritize quality and reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘shoe washing bag’

Introduction

This guide serves as a comprehensive checklist for B2B buyers looking to source shoe washing bags. With the increasing demand for efficient and protective cleaning solutions for footwear, it’s essential to navigate the procurement process carefully. This checklist will help you ensure quality, functionality, and supplier reliability, ultimately leading to successful purchases that meet your business needs.

Step 1: Define Your Technical Specifications

Start by outlining the specific requirements for the shoe washing bags you intend to procure. Consider factors such as size, material, and design features. For instance, a bag made from durable mesh or polyester can enhance breathability and prevent damage to shoes during washing.

- Size: Ensure the dimensions accommodate various shoe types, including sneakers, sandals, and children’s shoes.

- Material: Look for bags with soft, durable fabrics that can withstand multiple washes without tearing.

Step 2: Research Market Trends

Understanding market trends can provide insights into the most sought-after features and designs in shoe washing bags. This knowledge can guide your procurement strategy and help you choose products that align with consumer demands.

- Popular Features: Investigate which functionalities (like bristle designs for enhanced cleaning) are gaining traction among consumers.

- Competitive Analysis: Analyze competitors’ offerings to identify gaps in the market that your products can fill.

Step 3: Evaluate Potential Suppliers

Before finalizing a supplier, conduct thorough evaluations to ensure their credibility and capability. Request company profiles, product samples, and references from existing customers, especially those within similar industries or regions.

Illustrative image related to shoe washing bag

- Supplier Background: Verify their experience in manufacturing and supplying shoe washing bags.

- Quality Assurance: Check if they have quality control processes in place, such as certifications for material safety.

Step 4: Request Samples for Testing

Once you have shortlisted potential suppliers, request samples of the shoe washing bags. Testing these samples will allow you to assess their functionality, durability, and overall quality firsthand.

- Performance Testing: Wash various types of shoes using the samples to evaluate how well they perform.

- Material Assessment: Inspect the bags for wear and tear after multiple washes to determine their longevity.

Step 5: Negotiate Pricing and Terms

Engage in negotiations to secure favorable pricing and terms. Understanding your budget and the market rates for shoe washing bags can empower you during this phase.

- Bulk Purchase Discounts: Inquire about discounts for larger orders, which can significantly reduce your costs.

- Payment Terms: Clarify payment options and terms to avoid any future discrepancies.

Step 6: Assess Logistics and Shipping Options

Consider the logistics involved in transporting the shoe washing bags from the supplier to your location. Understanding shipping options can help you manage costs and timelines effectively.

- Shipping Methods: Evaluate different shipping methods based on speed, reliability, and cost.

- Customs and Duties: Be aware of any import duties or taxes that may apply, especially if sourcing internationally.

Step 7: Finalize the Purchase Agreement

After completing all due diligence, finalize the purchase agreement with the selected supplier. Ensure all terms discussed, including pricing, delivery schedules, and warranty information, are documented clearly.

- Contract Review: Have legal counsel review the contract to safeguard against potential issues.

- Follow-Up Procedures: Establish a communication plan for follow-up after the order is placed to ensure timely updates and resolutions.

By following this detailed checklist, B2B buyers can streamline the sourcing process for shoe washing bags and make informed purchasing decisions that align with their business goals.

Illustrative image related to shoe washing bag

Comprehensive Cost and Pricing Analysis for shoe washing bag Sourcing

What Are the Key Cost Components in Sourcing Shoe Washing Bags?

When evaluating the cost structure for sourcing shoe washing bags, several key components need to be considered:

-

Materials: The primary materials used in manufacturing shoe washing bags include durable polyester and mesh fabrics. The quality of these materials can significantly affect the overall cost. High-quality, tear-resistant fabrics may come at a premium but offer better durability and customer satisfaction.

-

Labor: Labor costs will vary depending on the manufacturing location. Regions with lower labor costs, such as parts of Asia and Africa, may provide a more cost-effective solution, while European manufacturers may incur higher wage expenses.

-

Manufacturing Overhead: This includes all indirect costs associated with production, such as utilities, equipment maintenance, and facility rent. Overhead can vary widely based on the efficiency of the manufacturing process and the location.

-

Tooling: Initial setup costs for tooling can be substantial, especially for custom designs. These costs should be amortized over the expected production volume to determine their impact on unit pricing.

-

Quality Control (QC): Implementing robust QC measures ensures that the final product meets specified standards, but it also adds to the overall cost. Businesses should weigh the benefits of stringent QC against potential returns on investment.

-

Logistics: Shipping costs can fluctuate based on the origin of the goods and the destination. Factors such as distance, shipping method, and incoterms (e.g., FOB, CIF) will influence logistics expenses.

-

Margin: Finally, suppliers will add a profit margin to the total cost, which can vary based on the supplier’s pricing strategy, market competition, and perceived value of their products.

How Do Price Influencers Impact the Cost of Shoe Washing Bags?

Understanding the factors that influence pricing is crucial for B2B buyers:

-

Volume/MOQ: Purchasing in bulk can significantly reduce unit costs. Many suppliers offer tiered pricing based on the volume of the order, making it essential to assess your needs and negotiate accordingly.

-

Specifications and Customization: Custom designs, sizes, or branding will often incur additional costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials and Quality Certifications: Higher quality materials and certifications (like ISO standards) often lead to increased costs. However, these can enhance product reliability and customer satisfaction, justifying the investment.

-

Supplier Factors: The reputation and reliability of the supplier can also influence price. Established suppliers may charge a premium for their proven quality and service.

-

Incoterms: The choice of incoterms can affect shipping costs and responsibilities. Understanding who bears the costs at each stage of shipping is vital for budgeting.

What Tips Can Help Buyers Negotiate Better Prices for Shoe Washing Bags?

To optimize costs and improve purchasing decisions, buyers should consider the following strategies:

-

Negotiate Effectively: Engage in discussions with suppliers to explore discounts based on order volume or long-term contracts. Establishing a strong relationship can lead to better pricing.

-

Focus on Cost Efficiency: Evaluate the Total Cost of Ownership (TCO), including purchase price, shipping, storage, and potential returns. Sometimes a higher upfront cost can lead to lower overall expenses.

-

Understand Pricing Nuances in International Markets: Different regions may have varying expectations for quality and pricing. Buyers from Africa, South America, the Middle East, and Europe should be aware of local market conditions and purchasing power when negotiating.

-

Be Informed About Market Trends: Keeping abreast of market trends and competitor pricing can provide leverage during negotiations. Suppliers may be more flexible if they know you have alternatives.

What Should Buyers Keep in Mind Regarding Pricing Disclaimers?

Buyers should be cautious about indicative prices provided by suppliers. Prices can fluctuate based on raw material costs, labor rates, and geopolitical factors. It is advisable to request detailed quotes that include all cost components and terms before making a commitment. This diligence ensures that buyers have a clear understanding of potential costs and can avoid unexpected financial burdens.

Alternatives Analysis: Comparing shoe washing bag With Other Solutions

Exploring Alternatives to Shoe Washing Bags for Effective Shoe Care Solutions

When considering the best methods for maintaining the cleanliness and longevity of footwear, a variety of solutions exist beyond the popular shoe washing bag. In this analysis, we will compare the shoe washing bag with other viable alternatives, helping international B2B buyers understand the nuances of each option.

Illustrative image related to shoe washing bag

| Comparison Aspect | Shoe Washing Bag | Shoe Washing Machine | Manual Hand Washing |

|---|---|---|---|

| Performance | Deep clean, gentle on shoes | Effective but can be harsh | Variable, dependent on technique |

| Cost | $8 – $35 per bag | $500 – $2000 per machine | Minimal (soap and water) |

| Ease of Implementation | Simple, requires no training | Requires machine setup and maintenance | Time-consuming, skill-dependent |

| Maintenance | Low (washable, durable) | Moderate (requires repairs and upkeep) | High (consistent cleaning supplies needed) |

| Best Use Case | Home use, delicate shoes | Commercial settings, bulk cleaning | Quick refresh, emergency cleaning |

What Are the Advantages and Disadvantages of a Shoe Washing Machine?

Shoe washing machines present a sophisticated alternative to shoe washing bags. These machines are designed specifically for cleaning footwear, offering a thorough wash cycle that can handle multiple pairs simultaneously. The main advantages include efficiency and the ability to accommodate larger volumes, making them ideal for commercial applications. However, the initial investment is substantial, ranging from $500 to $2000, and they require regular maintenance, which can add to overall operational costs. Additionally, using a machine can sometimes lead to more wear and tear on delicate footwear compared to the gentle cleaning of a shoe washing bag.

How Does Manual Hand Washing Compare to Shoe Washing Bags?

Manual hand washing is the most traditional method for cleaning shoes and involves using soap, water, and a scrubbing tool. While this method allows for precision in cleaning specific areas, it can be labor-intensive and inconsistent in results. The cost is minimal, as it primarily involves cleaning supplies, but the time required for effective cleaning can be significant, especially for larger quantities. For B2B buyers in regions where labor is inexpensive, manual washing may seem appealing; however, it is often not scalable for larger operations. Furthermore, the risk of damaging shoes through improper technique is higher compared to using a shoe washing bag designed for gentle cleaning.

How Should B2B Buyers Choose the Right Shoe Cleaning Solution?

In choosing the right solution for shoe cleaning, B2B buyers should consider their specific needs, budget, and the scale of their operations. For businesses focused on efficiency and volume, investing in a shoe washing machine may offer the best return on investment despite the upfront costs. Conversely, for companies looking to maintain delicate footwear without risking damage, shoe washing bags present an excellent balance of cost and performance, especially for smaller operations or home use. Lastly, while manual washing can be effective, it may not be the most practical choice for businesses aiming for consistency and efficiency. Evaluating these factors will help buyers make informed decisions that align with their operational goals and customer expectations.

Essential Technical Properties and Trade Terminology for shoe washing bag

What Are the Key Technical Properties of a Shoe Washing Bag?

When sourcing shoe washing bags for B2B purposes, understanding the essential technical properties is crucial for making informed purchasing decisions. Here are some critical specifications to consider:

Illustrative image related to shoe washing bag

-

Material Composition

The primary materials used in shoe washing bags typically include polyester, nylon, or microfiber. These materials are chosen for their durability, resistance to wear, and ability to withstand repeated washing cycles. B2B buyers should prioritize high-quality fabric to ensure longevity and performance, as inferior materials may lead to bag tears or loss of functionality over time. -

Size and Dimensions

Shoe washing bags come in various sizes, typically accommodating standard shoe dimensions. Common dimensions are around 10 x 15 x 9 inches, but larger or smaller options may be available. Understanding the sizing is essential for ensuring compatibility with different shoe types, especially when catering to diverse markets or customer needs. -

Closure Type

Most shoe washing bags feature a zipper closure, which is vital for securely holding shoes during the wash cycle. A robust zipper prevents accidental openings that could lead to damage to both the shoes and the washing machine. Buyers should consider the quality of the zipper, as a sturdy mechanism enhances usability and trust in the product. -

Wash Cycle Compatibility

Shoe washing bags should be compatible with various washing machine settings, including delicate cycles. This property is important as it ensures that the bag can safely clean a wide range of shoe materials, from soft fabrics to sturdier constructions. Buyers should look for bags that clearly state their compatibility with both washing machines and dryers. -

Cleaning Efficiency

Some advanced shoe washing bags incorporate features like internal bristles or multi-layered designs to enhance cleaning performance. These innovations can significantly improve the removal of dirt and stains without damaging the shoe material. B2B buyers should evaluate the effectiveness of these features to provide added value to their customers. -

Durability and Lifespan

The durability of a shoe washing bag is often measured by its resistance to wear and the number of washes it can endure without compromising its structure. A high-quality bag should last through numerous cleaning cycles, making it a cost-effective solution for businesses. Buyers should inquire about the expected lifespan to assess long-term value.

What Are Common Trade Terms Related to Shoe Washing Bags?

Navigating the B2B landscape involves understanding key industry terminology. Here are some common trade terms relevant to sourcing shoe washing bags:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand. For shoe washing bags, buyers may collaborate with OEMs to create customized products tailored to specific market needs. Understanding OEM relationships can lead to more strategic sourcing decisions. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For shoe washing bags, this could vary significantly between manufacturers. B2B buyers should negotiate MOQs that align with their inventory needs to avoid excess stock or missed sales opportunities. -

RFQ (Request for Quotation)

An RFQ is a standard business process where buyers invite suppliers to submit price proposals for specific products. When sourcing shoe washing bags, submitting an RFQ can help buyers compare pricing, quality, and service levels across multiple suppliers, aiding in decision-making. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping, insurance, and customs clearance. Understanding Incoterms is crucial for B2B buyers involved in cross-border transactions, ensuring clarity in delivery terms for shoe washing bags. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the product. For shoe washing bags, shorter lead times can enhance inventory management and responsiveness to market demands. Buyers should always inquire about lead times to ensure they can meet their customers’ needs promptly. -

Quality Assurance (QA)

QA involves systematic processes to ensure products meet specified standards. In the context of shoe washing bags, QA protocols can help ensure that every batch meets the required durability and performance benchmarks. Buyers should prioritize suppliers with strong QA practices to minimize the risk of defects.

Understanding these technical properties and trade terms will empower B2B buyers to make informed decisions, ensuring they select the best shoe washing bags for their business needs.

Navigating Market Dynamics and Sourcing Trends in the shoe washing bag Sector

What Are the Key Trends Influencing the Shoe Washing Bag Market?

The global shoe washing bag market is experiencing significant growth, driven by increasing consumer awareness about shoe maintenance and hygiene. With the rise of athleisure and outdoor activities, consumers are looking for convenient solutions to keep their footwear clean without compromising quality. International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should note that the demand for durable and effective shoe washing bags is on the rise.

Emerging technologies are shaping the sourcing landscape, as manufacturers innovate with materials that enhance cleaning efficacy while protecting shoe integrity. For example, the integration of advanced fabrics like microfiber and mesh has improved wash performance and reduced wear and tear on shoes. Additionally, the trend towards e-commerce has made it easier for B2B buyers to access a wider range of products and suppliers, facilitating competitive pricing and diverse options.

Illustrative image related to shoe washing bag

Furthermore, as sustainability becomes a priority, buyers are increasingly seeking suppliers who offer eco-friendly products. The market is witnessing a shift towards biodegradable materials and processes that minimize environmental impact, aligning with the global push for sustainable practices. For B2B buyers, understanding these dynamics is essential for making informed sourcing decisions that meet market demands.

How Important Is Sustainability and Ethical Sourcing in the Shoe Washing Bag Industry?

Sustainability and ethical sourcing are pivotal considerations for B2B buyers in the shoe washing bag sector. The environmental impact of manufacturing processes is under scrutiny, with a growing emphasis on reducing waste and energy consumption. Buyers are encouraged to seek suppliers who prioritize sustainable practices, such as using recycled materials in their products or adopting energy-efficient production methods.

Moreover, the importance of ethical supply chains cannot be overstated. Brands that demonstrate transparency in their sourcing and manufacturing processes not only enhance their reputation but also build consumer trust. Certifications such as Global Organic Textile Standard (GOTS) and Oeko-Tex Standard 100 can serve as indicators of a supplier’s commitment to environmental and social responsibility.

Investing in sustainable and ethically sourced shoe washing bags is not just a trend; it is a strategic move that can differentiate businesses in competitive markets. B2B buyers who align with suppliers that uphold these values can capitalize on the growing consumer preference for eco-conscious products, which is especially relevant in regions like Europe and North America where sustainability is a significant purchasing factor.

What Is the Brief Evolution of the Shoe Washing Bag Market?

The shoe washing bag market has evolved significantly over the past few decades, transitioning from simple fabric pouches to advanced, specialized products designed to meet consumer needs. Initially, shoe cleaning was a manual and labor-intensive process, often involving harsh chemicals and scrubbing, which led to damage over time.

With the advent of modern washing machines, the demand for protective cleaning solutions surged, giving rise to the concept of shoe washing bags. These bags were designed to facilitate machine washing while safeguarding shoes from deformation and damage. Today, the market is characterized by innovation, with manufacturers incorporating new materials and technologies that enhance cleaning effectiveness and shoe protection.

As consumer lifestyles have shifted towards convenience and sustainability, the shoe washing bag has become an essential accessory for maintaining footwear hygiene. This evolution reflects broader trends in consumer behavior, highlighting the importance of functionality and care in product design. B2B buyers should consider this historical context as they assess potential suppliers and products in an increasingly competitive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of shoe washing bag

-

1. How do I choose the right shoe washing bag for my business?

When selecting a shoe washing bag for your B2B needs, consider factors such as material durability, size compatibility with various shoe types, and cleaning efficiency. Look for bags made from high-quality mesh or polyester that can withstand multiple washes without degrading. Additionally, assess features like protective cushioning and ease of use to ensure they meet your customers’ expectations. Request samples from suppliers to evaluate performance before making a bulk purchase. -

2. What are the common materials used in shoe washing bags?

Shoe washing bags are typically made from durable materials like polyester and mesh fabric. Polyester offers strength and resistance to wear, while mesh allows for better water circulation during the wash cycle. Some premium bags may incorporate specialized materials designed to prevent fading and shape loss. Understanding these materials helps you select a product that aligns with your market’s quality demands. -

3. What is the typical minimum order quantity (MOQ) for shoe washing bags?

MOQs for shoe washing bags can vary significantly depending on the supplier and manufacturing capabilities. Generally, MOQs range from 100 to 1,000 units. It’s advisable to negotiate with suppliers to find a quantity that fits your budget and storage capacity. Additionally, consider suppliers who offer flexibility in MOQs to accommodate smaller businesses or pilot projects. -

4. How can I ensure the quality of shoe washing bags from suppliers?

To ensure product quality, conduct thorough vetting of potential suppliers. Request certifications and production samples to evaluate material quality and craftsmanship. Establish clear quality assurance (QA) standards and procedures for inspection during production and before shipment. If possible, visit the manufacturing facility or work with third-party quality inspectors to verify compliance with your specifications. -

5. What payment terms should I expect when sourcing shoe washing bags internationally?

Payment terms can vary by supplier but typically include options such as a deposit upon order confirmation (often 30-50%) and the balance before shipping. Some suppliers may offer letters of credit or escrow services for added security. It’s crucial to negotiate terms that align with your cash flow and risk management strategies while ensuring both parties are protected. -

6. What logistics considerations should I keep in mind when importing shoe washing bags?

When importing shoe washing bags, consider shipping methods, lead times, and customs regulations in your destination country. Choose between air freight for speed or sea freight for cost-effectiveness, depending on your urgency and budget. Additionally, ensure compliance with local import regulations and tariffs. Collaborating with a reliable logistics provider can streamline this process and reduce potential delays. -

7. Can I customize shoe washing bags for my brand?

Yes, many manufacturers offer customization options for shoe washing bags, including branding with your logo, unique colors, and specific sizes. Customization can enhance brand recognition and appeal to your target market. Discuss your requirements with suppliers early in the negotiation process to understand their capabilities and any associated costs for custom orders. -

8. What types of shoes can be effectively cleaned using shoe washing bags?

Shoe washing bags are versatile and can effectively clean a variety of shoe types, including sneakers, running shoes, casual footwear, and even some delicate dress shoes. However, it’s essential to avoid using them for heavy or rigid shoes, like steel-toe boots, as these may damage the bag. Understanding the limitations of the product can help you provide accurate information to your customers and improve their satisfaction.

Top 7 Shoe Washing Bag Manufacturers & Suppliers List

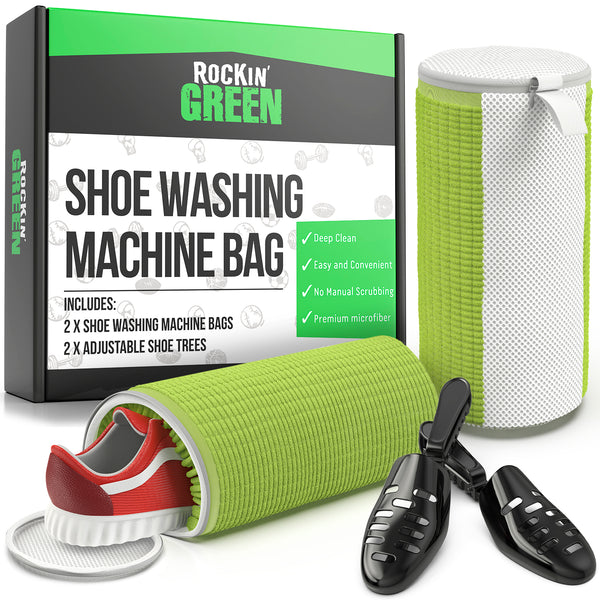

1. Rockin’ Green – Shoe Washing Machine Bag

Domain: rockingreen.com

Registered: 2007 (18 years)

Introduction: {“product_name”: “Shoe Washing Machine Bag”, “price”: “$24.99”, “description”: “Convenient and Easy to Use Laundry Shoe Bag: Simply place your sneakers with the trees in the bag, zip it up, and toss it in the washer for a hassle-free clean. The bags fit easily into most machines, making it quick and simple to freshen up your shoes. Deep Clean, Hassle-Free: Shoe Laundry Bags designed for convenienc…

2. Target – Durable Laundry Shoe Bags

Domain: target.com

Registered: 1997 (28 years)

Introduction: This company, Target – Durable Laundry Shoe Bags, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Laundry Sauce – Shoe Wash Bag

Domain: laundrysauce.com

Registered: 2018 (7 years)

Introduction: Product Name: Shoe Wash Bag

Price: $25.00

Description: Effortlessly clean your shoes with innovative Shoe Wash Bags made from tear-resistant chenille fabric with built-in cleaning fibers. Each bag accommodates a single shoe, ensuring thorough cleaning while maintaining shape and preventing damage.

Quantity: 2 x Shoe Wash Bag

Material: Premium soft chenille microfiber with built-in cleaning propert…

4. Reddit – Shoe Washing Bag

5. Sheec – Triangle Mesh Laundry Bag

Domain: sheecsocks.com

Registered: 2019 (6 years)

Introduction: {“product_name”: “Triangle Mesh Laundry Bag for Washing and Storing Shoes”, “price”: “$8.00 USD”, “dimensions”: “10 x 15 x 9 in”, “materials”: “Polyester”, “care_instructions”: “For use in any laundry cycle. Do not bleach.”, “description”: “Wash your shoes safely and easily. Store your clean shoes so they stay dry and dirt free.”}

6. Koh – Shoe Washing Bag

Domain: koh.com

Registered: 2000 (25 years)

Introduction: Product Name: Shoe Washing Bag

Sale Price: $29.95

Regular Price: N/A

Payment Options: 4 payments of $7.48 (interest-free)

Key Features:

– Designed to safely machine wash sneakers without scrubbing

– Fibre loop interior loosens dirt and distributes detergent

– Reduces wear on shoes and washing machine

– Breathable mesh keeps laces untangled and sneakers protected

– Fits one pair of men’s size 11 sh…

7. Scraping Dog – Instagram Scraping Services

Domain: instagram.com

Registered: 2004 (21 years)

Introduction: Contact us at [email protected] for scraping Instagram. Let us know how many pages you want to scrape per month.

Strategic Sourcing Conclusion and Outlook for shoe washing bag

What Are the Key B2B Insights for Sourcing Shoe Washing Bags?

In conclusion, the strategic sourcing of shoe washing bags presents a promising opportunity for international B2B buyers. The growing consumer demand for convenient, effective, and protective solutions for footwear care underscores the need for high-quality products that enhance the longevity of shoes. Buyers should prioritize sourcing options that not only meet functional requirements but also align with sustainability trends, as eco-friendly materials are increasingly favored in global markets.

Investing in shoe washing bags that feature innovative designs, such as multi-layered protection and gentle cleaning mechanisms, can significantly differentiate your offerings in competitive markets. This not only caters to consumer preferences but also positions your business as a leader in quality and care.

How Can International Buyers Capitalize on This Trend?

As the market continues to evolve, particularly in regions like Africa, South America, the Middle East, and Europe, staying ahead of trends will be crucial. Engaging with reliable suppliers who understand local demands and can deliver scalable solutions will enhance your competitive advantage.

Now is the time to explore partnerships that can provide access to these innovative products. By sourcing strategically, you can meet the rising expectations of consumers and drive growth in your business. Embrace the opportunity to elevate your product line and capture the attention of discerning customers worldwide.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to shoe washing bag

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.