Top 7 Qingdao Aluminum Profile Trading Suppliers (And How to Choose)

Introduction: Navigating the Global Market for qingdao aluminum profile trading

In the dynamic landscape of global trade, sourcing high-quality aluminum profiles from Qingdao can present significant challenges for international B2B buyers. With diverse applications ranging from construction to automotive and industrial uses, understanding the nuances of Qingdao aluminum profile trading is essential for making informed purchasing decisions. This comprehensive guide delves into various types of aluminum profiles, including architectural and industrial options, and explores their specific applications across different sectors.

Navigating the complexities of supplier vetting, pricing structures, and logistical considerations can be daunting, especially for businesses in Africa, South America, the Middle East, and Europe, such as Nigeria and Saudi Arabia. This guide aims to empower you with actionable insights, equipping you to evaluate suppliers effectively, assess quality standards, and negotiate favorable terms. You will find detailed information on critical factors such as certifications, customization options, and the importance of response times in supplier selection.

By leveraging this guide, you will enhance your sourcing strategy, ensuring that your business benefits from the best that Qingdao’s aluminum profile manufacturers have to offer. Ultimately, it is about making confident, informed decisions that align with your operational needs and market demands, paving the way for successful international trade partnerships.

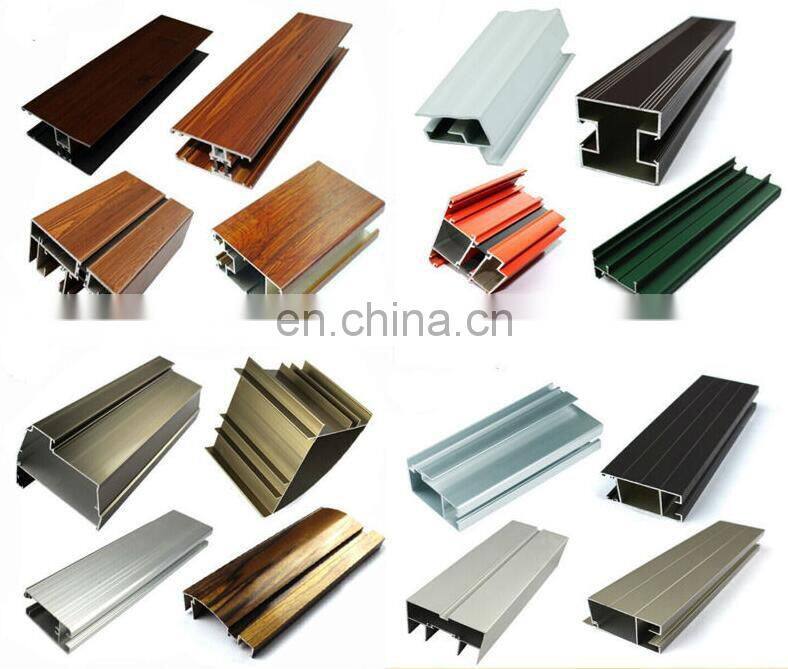

Understanding qingdao aluminum profile trading Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Architectural Profiles | Designed for aesthetic appeal; often anodized or powder-coated. | Windows, doors, facades | Pros: High durability; customizable finishes. Cons: Higher cost than basic profiles. |

| Industrial Profiles | Heavy-duty construction; often features thermal break technology. | Machinery, automotive, structural supports | Pros: Robust and versatile; excellent for load-bearing. Cons: Limited design options. |

| T-slot Profiles | Grooved design for modular assembly; easily adjustable configurations. | Automation, DIY projects | Pros: Flexible; easy to assemble and reconfigure. Cons: Requires additional components for stability. |

| Heat Sink Profiles | Engineered for efficient heat dissipation; typically extruded. | Electronics, LED lighting | Pros: Enhances performance; essential for thermal management. Cons: Specialized; may not suit all applications. |

| Custom Profiles | Tailored designs based on specific client needs; various treatments. | Specialized applications across industries | Pros: Meets unique requirements; full customization. Cons: Longer lead times; potentially higher costs. |

What Are Architectural Profiles and Their B2B Relevance?

Architectural profiles are specifically crafted to enhance the aesthetic quality of buildings while providing structural integrity. They are commonly anodized or powder-coated to resist corrosion and wear. B2B buyers in construction and real estate often opt for these profiles for windows, doors, and facades, as they offer a balance between beauty and durability. Key purchasing considerations include the profile’s finish options, compliance with local building codes, and customization capabilities to match architectural designs.

How Do Industrial Profiles Serve Various Industries?

Industrial profiles are characterized by their heavy-duty construction and often include features like thermal breaks to improve energy efficiency. These profiles are integral to machinery, automotive components, and structural supports. When selecting industrial profiles, B2B buyers should assess their load-bearing capacity, compatibility with existing systems, and potential for customization to meet specific operational requirements. The robustness of these profiles makes them a preferred choice for demanding applications.

What Makes T-slot Profiles Ideal for Modular Assembly?

T-slot profiles are unique for their grooved design, allowing for easy assembly and reconfiguration. They are particularly beneficial in automation and DIY projects where flexibility is paramount. B2B buyers should consider the ease of integration with existing systems, the availability of compatible accessories, and the potential for future expansions when purchasing T-slot profiles. Their adaptability makes them a popular choice for companies looking to create dynamic workspaces.

Why Are Heat Sink Profiles Critical in Electronics?

Heat sink profiles are specifically designed to dissipate heat efficiently, making them crucial in the electronics and LED lighting sectors. Their extruded design allows for maximum surface area exposure, enhancing thermal management. B2B buyers must consider thermal performance metrics, compatibility with electronic components, and the specific heat dissipation requirements of their applications. These profiles are essential for ensuring the longevity and reliability of electronic devices.

What Are the Benefits of Custom Profiles for Specialized Applications?

Custom profiles offer tailored solutions to meet the unique needs of various industries. These profiles can be designed with specific dimensions, surface treatments, and material properties to fit specialized applications. When considering custom profiles, B2B buyers should evaluate the supplier’s ability to deliver on time, the flexibility of design options, and the total cost of ownership. While they provide significant advantages in meeting specific requirements, buyers should be prepared for longer lead times and potentially higher costs.

Key Industrial Applications of qingdao aluminum profile trading

| Industry/Sector | Specific Application of qingdao aluminum profile trading | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Aluminum window and door frames | Enhanced durability and energy efficiency | Certifications (ISO 9001), customization options |

| Automotive | Structural components and heat sinks | Lightweight materials improving fuel efficiency | Compliance with safety standards, quick delivery times |

| Electronics | Heat sinks for electronic devices | Improved thermal management for device longevity | Material properties (6063-T5 alloy), precise tolerances |

| Renewable Energy | Solar panel frames and mounting systems | Increased efficiency and lifespan of installations | Corrosion resistance, customization for local climates |

| Transportation and Logistics | Lightweight cargo containers and structural supports | Reduced shipping costs and increased payload capacity | Robustness under load, customizable dimensions |

How is qingdao aluminum profile trading utilized in the construction industry?

In the construction sector, qingdao aluminum profiles are predominantly used for window and door frames. These profiles provide superior strength while minimizing weight, resulting in energy-efficient designs that enhance thermal insulation. For international buyers, particularly those from regions with extreme climates like Nigeria or Saudi Arabia, sourcing profiles that meet local building regulations and environmental conditions is crucial. Certifications such as ISO 9001 ensure quality and reliability, while customization options allow for tailored solutions to specific architectural needs.

What role does qingdao aluminum profile trading play in the automotive industry?

Within the automotive industry, aluminum profiles are utilized for various structural components, including frames and heat sinks. The lightweight nature of aluminum contributes significantly to fuel efficiency, a critical factor for manufacturers aiming to meet stringent emissions regulations. Buyers from South America and Europe should prioritize suppliers who can provide profiles that comply with international safety standards. Additionally, on-time delivery is essential to maintain production schedules, making responsiveness a key consideration when selecting a supplier.

How do electronics manufacturers benefit from qingdao aluminum profiles?

In the electronics sector, aluminum profiles are primarily used for heat sinks, which help dissipate heat from devices, thereby prolonging their lifespan and enhancing performance. Buyers in this field must ensure that the aluminum meets specific mechanical properties, like the 6063-T5 alloy, known for its excellent thermal conductivity. Precision in dimensions and tolerances is vital, especially for high-performance applications. International buyers should seek suppliers with a proven track record in quality assurance to avoid production delays.

In what ways does qingdao aluminum profile trading support renewable energy initiatives?

Qingdao aluminum profiles are integral to renewable energy applications, such as solar panel frames and mounting systems. The lightweight yet durable nature of aluminum enhances the efficiency and longevity of solar installations, making it an attractive option for energy companies. Buyers from the Middle East, where environmental conditions can be harsh, should prioritize corrosion-resistant profiles. Additionally, customization options allow for designs that cater to specific installation environments, ensuring optimal performance.

How does the transportation sector leverage qingdao aluminum profiles?

In transportation and logistics, aluminum profiles are used to create lightweight cargo containers and structural supports, significantly reducing shipping costs and increasing payload capacities. For international buyers, especially those in Africa, sourcing profiles that can withstand heavy loads while remaining lightweight is essential. Robustness under load and customizable dimensions are key factors that should guide the selection of suppliers. Ensuring timely delivery can also enhance operational efficiency and reduce downtime in logistics operations.

3 Common User Pain Points for ‘qingdao aluminum profile trading’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality Aluminum Profiles

The Problem: International B2B buyers often struggle to find reliable suppliers of aluminum profiles in Qingdao. Many suppliers may present attractive pricing, but the quality of their products can vary significantly. This inconsistency can lead to issues such as product failure, increased costs due to rework, and damage to the buyer’s reputation. For buyers from regions like Africa or South America, the challenge is compounded by geographical barriers and limited access to firsthand product evaluations.

The Solution: To overcome this sourcing challenge, buyers should prioritize suppliers with internationally recognized certifications such as ISO 9001. It’s essential to conduct thorough research on potential partners, including checking for reviews and ratings on platforms like Alibaba or global trade forums. Additionally, buyers should consider requesting samples before placing bulk orders. This allows for an assessment of quality and compliance with specified standards. Engaging a local agent or using third-party quality inspection services can also enhance the sourcing process, ensuring that products meet the required specifications before shipment.

Scenario 2: Managing Customization Requests Efficiently

The Problem: Many B2B buyers require customized aluminum profiles tailored to specific project needs, which can be a complex and time-consuming process. Miscommunication regarding specifications, tolerances, and surface treatments can lead to delays and increased costs. Buyers from regions like the Middle East and Europe may find it particularly challenging to convey their requirements effectively due to language barriers or differing industry standards.

The Solution: To streamline customization processes, buyers should provide detailed drawings and specifications when engaging with suppliers. Utilizing 3D modeling software can help visualize the desired product, making it easier to communicate with manufacturers. Additionally, establishing a clear line of communication through project managers or dedicated liaisons can reduce misunderstandings. It’s also advisable to discuss prototyping capabilities upfront; suppliers that offer quick prototyping services can significantly speed up the development cycle. Ensuring that suppliers have a robust quality control process in place will further minimize errors and ensure that the final products meet expectations.

Scenario 3: Navigating Shipping and Logistics Challenges

The Problem: After sourcing and customizing aluminum profiles, international buyers often face logistical hurdles, such as delays in shipping and unexpected costs. Factors like customs clearance, varying regulations between countries, and the complexities of coordinating shipments from Qingdao can create significant headaches for B2B buyers, especially those operating in Africa or South America where infrastructure may be less developed.

The Solution: To mitigate shipping and logistics issues, buyers should engage with suppliers who have experience exporting to their regions and who can provide comprehensive logistics support. It’s crucial to discuss shipping terms, including Incoterms, upfront to ensure all parties understand responsibilities and costs. Buyers should also consider working with logistics companies that specialize in international freight, as they can navigate customs and provide guidance on import regulations. Additionally, maintaining open communication with the supplier during the shipping process can help address any issues as they arise, ensuring smoother delivery and minimizing potential disruptions to the supply chain.

Strategic Material Selection Guide for qingdao aluminum profile trading

What Are the Key Materials for Qingdao Aluminum Profile Trading?

In the context of Qingdao aluminum profile trading, several aluminum alloys and finishes are commonly utilized. Understanding the properties, advantages, and limitations of these materials is crucial for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. Here, we analyze four prevalent materials used in aluminum profile manufacturing.

6063 Aluminum Alloy: The Versatile Choice

Key Properties:

The 6063 aluminum alloy is known for its excellent extrudability and surface finish. It has a moderate strength level with a tensile strength of around 240 MPa, making it suitable for architectural applications. Its corrosion resistance is also notable, particularly when anodized.

Pros & Cons:

One of the primary advantages of 6063 is its versatility; it can be easily shaped and is lightweight. However, its lower strength compared to other alloys like 6061 may limit its use in heavy-load applications. The manufacturing process is relatively straightforward, but the alloy’s cost can be higher due to its enhanced surface treatment options.

Impact on Application:

6063 is commonly used in window frames, door frames, and architectural applications where aesthetic appeal and corrosion resistance are essential. For international buyers, this alloy complies with ASTM standards, ensuring quality and performance.

6061 Aluminum Alloy: Strength and Durability

Key Properties:

6061 aluminum alloy is known for its high strength-to-weight ratio and excellent mechanical properties. It can withstand temperatures up to 200°C and offers good corrosion resistance, particularly when treated.

Pros & Cons:

The key advantage of 6061 is its strength, making it ideal for structural applications. However, it is more expensive than 6063 and may require more complex manufacturing processes, which can increase lead times. Its higher strength makes it less malleable compared to 6063, potentially limiting design flexibility.

Impact on Application:

This alloy is often used in industrial applications, including automotive and aerospace components. International buyers should ensure compliance with relevant standards like ASTM and ISO for quality assurance.

Anodized Aluminum: Enhanced Surface Protection

Key Properties:

Anodized aluminum undergoes an electrochemical process that enhances its surface properties, providing excellent corrosion resistance and wear resistance. It can withstand harsh environmental conditions, making it suitable for outdoor applications.

Pros & Cons:

The primary advantage of anodized aluminum is its durability and aesthetic appeal, as it can be dyed in various colors. However, the anodizing process can add to the overall cost and may not be suitable for all applications, particularly where heavy mechanical stress is involved.

Impact on Application:

Anodized aluminum is widely used in architectural applications, such as facades and signage. Buyers from regions with high humidity or coastal environments should prioritize this finish for its longevity and compliance with environmental standards.

Powder-Coated Aluminum: Aesthetic and Functional Finish

Key Properties:

Powder-coated aluminum features a dry finishing process that provides a hard, protective layer. This finish is available in various colors and textures and offers good UV resistance.

Pros & Cons:

The major advantage of powder coating is its aesthetic versatility and resistance to chipping, scratching, and fading. However, the process can be more expensive than standard finishes, and if not applied correctly, it may lead to adhesion issues.

Impact on Application:

This finish is ideal for decorative applications, such as furniture and architectural elements. Buyers should verify that the powder coating complies with international standards to ensure durability and performance.

Summary Table

| Material | Typical Use Case for qingdao aluminum profile trading | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| 6063 Aluminum Alloy | Architectural profiles, window frames | Excellent extrudability | Lower strength compared to 6061 | Medium |

| 6061 Aluminum Alloy | Structural components, automotive parts | High strength | Higher cost and complexity | High |

| Anodized Aluminum | Outdoor applications, facades | Superior corrosion resistance | Higher manufacturing cost | Medium |

| Powder-Coated Aluminum | Decorative applications, furniture | Aesthetic versatility | Potential adhesion issues | Medium |

This guide provides a comprehensive overview of material selection for aluminum profiles in Qingdao, enabling international buyers to make informed decisions based on their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for qingdao aluminum profile trading

What Are the Main Stages of Manufacturing Aluminum Profiles in Qingdao?

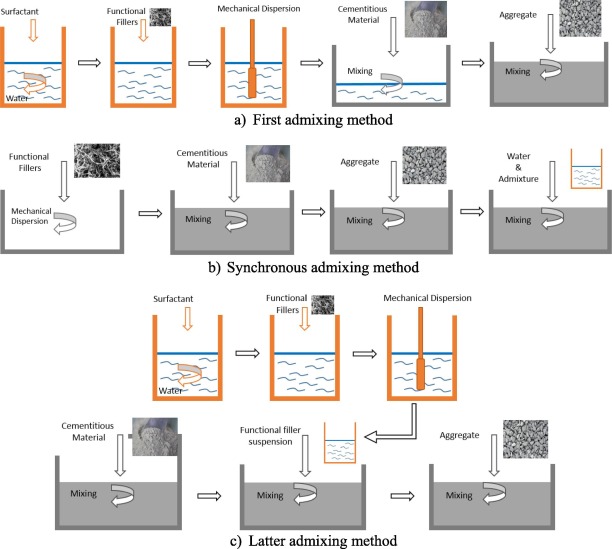

The manufacturing of aluminum profiles in Qingdao involves several critical stages that ensure high-quality output. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with the selection of aluminum alloys, with 6063-T5 being one of the most common due to its excellent extrudability and surface finish. Raw materials are sourced from reputable suppliers, and quality checks are conducted to ensure compliance with industry standards. This stage may include the inspection of the aluminum billets for purity and alloy composition.

-

Forming: The extrusion process is where the aluminum is shaped into profiles. This is achieved using high-pressure extrusion presses that force heated aluminum billets through custom-designed dies. The resulting extrusions are then cooled and cut to specified lengths. This stage is crucial as the design of the die directly impacts the profile’s dimensions and surface quality.

-

Assembly: In cases where profiles need to be integrated with other components—such as fittings or glazing—this stage involves precise assembly. Automated and manual methods may be used, depending on the complexity of the assembly. Ensuring the accuracy of this process is vital for the end-use application, particularly in construction and industrial settings.

-

Finishing: The final stage encompasses surface treatments like anodizing, powder coating, and other protective finishes. These treatments enhance durability and aesthetics. Anodizing, for example, not only provides a protective layer but also allows for color customization. Each method has specific requirements, and adherence to these is crucial for achieving the desired quality.

How Is Quality Assurance Implemented in Qingdao Aluminum Profile Manufacturing?

Quality assurance (QA) in aluminum profile manufacturing is paramount, especially for B2B buyers who rely on consistent quality and compliance with international standards. Several key practices and standards guide these processes.

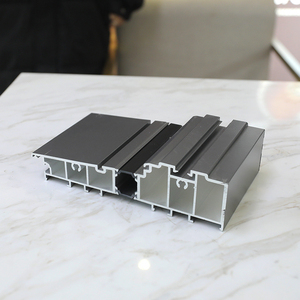

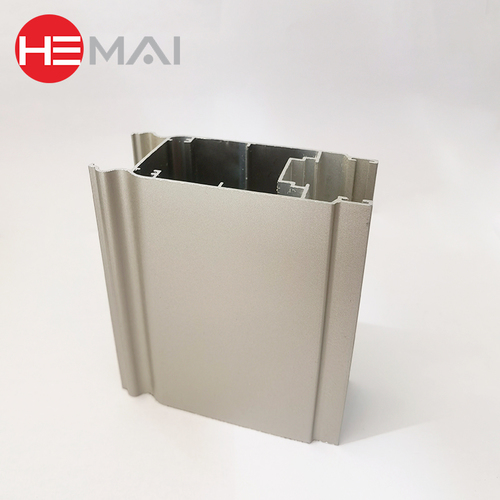

Illustrative image related to qingdao aluminum profile trading

-

International Standards: Compliance with ISO 9001 is essential for manufacturers, as it demonstrates a commitment to quality management practices. This certification requires firms to maintain a systematic approach to managing quality through continuous improvement and customer satisfaction.

-

Industry-Specific Certifications: Depending on the end-use application, manufacturers may also pursue additional certifications such as CE marking for construction products or ASTM standards for material properties. These certifications ensure that products meet specific safety and performance criteria.

-

Quality Control Checkpoints: The QC process typically involves several checkpoints:

– Incoming Quality Control (IQC): This initial inspection occurs when raw materials arrive. Suppliers must provide certificates of compliance for their materials.

– In-Process Quality Control (IPQC): Throughout the manufacturing process, periodic inspections are conducted to monitor critical parameters such as dimensions, tolerances, and surface finishes. This stage aims to catch defects early, minimizing waste and rework.

– Final Quality Control (FQC): Before shipping, a final inspection is performed. This includes functional testing, visual inspections, and packaging checks to ensure that products meet the specified criteria.

What Common Testing Methods Are Used to Ensure Quality in Aluminum Profiles?

To maintain high standards, manufacturers in Qingdao employ various testing methods to validate the quality of aluminum profiles:

-

Mechanical Testing: This includes tensile strength tests, hardness tests, and impact tests to assess the material’s performance under stress. These tests are critical for ensuring that the profiles can withstand the demands of their intended applications.

-

Surface Treatment Testing: Manufacturers often test for adhesion strength and corrosion resistance, particularly for treated surfaces. This ensures that finishes like anodizing or powder coating provide the necessary protection against environmental factors.

-

Dimensional Testing: Precision is vital in aluminum profiles, and various tools—such as calipers and laser measurement systems—are used to verify that dimensions are within specified tolerances.

How Can B2B Buyers Verify Supplier Quality Control Processes?

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should adopt a systematic approach to verify the quality control practices of their suppliers in Qingdao:

-

Factory Audits: Conducting on-site audits allows buyers to assess production capabilities, quality control measures, and compliance with international standards firsthand. If an on-site visit is not feasible, virtual audits can also provide valuable insights.

-

Requesting Documentation: Buyers should ask suppliers for certifications (e.g., ISO 9001, CE, ASTM) and test reports that validate the quality of materials and finished products. This documentation should include mill test certificates for raw materials and reports from any third-party inspections.

-

Engaging Third-Party Inspectors: Hiring independent inspection agencies can provide an unbiased assessment of the manufacturing processes and quality assurance practices. These agencies can perform random checks and provide detailed reports on compliance with agreed specifications.

What Are the Key Quality Control Nuances for International B2B Buyers?

When engaging with suppliers in Qingdao, international buyers must be aware of specific nuances related to quality control:

-

Cultural and Communication Differences: Understanding cultural differences in business practices can enhance collaboration. Clear communication regarding quality expectations and specifications is essential to avoid misunderstandings.

-

Regulatory Compliance: Buyers should familiarize themselves with both local and international regulations that may affect their products. This knowledge helps ensure that suppliers can meet all legal requirements for their target markets.

-

Logistics and Shipping Considerations: The quality of packaging and handling during shipping can impact the final product’s condition. Buyers should discuss packaging standards and ensure that suppliers use suitable materials to protect profiles during transit.

By focusing on these manufacturing processes and quality assurance practices, international B2B buyers can make informed decisions when sourcing aluminum profiles from Qingdao, ultimately leading to successful partnerships and high-quality products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘qingdao aluminum profile trading’

Introduction

This guide serves as a practical checklist for international B2B buyers interested in sourcing aluminum profiles from Qingdao, China. By following these steps, buyers can ensure they make informed decisions, mitigate risks, and establish fruitful partnerships with reliable suppliers.

Illustrative image related to qingdao aluminum profile trading

Step 1: Define Your Technical Specifications

Clearly outline the specific requirements for the aluminum profiles you need. This includes dimensions, alloy types (such as 6063-T5), surface treatments (like anodizing or powder coating), and any custom features.

– Why It Matters: Defining your specifications helps suppliers understand your needs and ensures you receive products that meet your application requirements.

– What to Look For: Create detailed drawings or models to share with potential suppliers, ensuring they can provide accurate quotes and timelines.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable aluminum profile manufacturers in Qingdao. Utilize platforms like Alibaba, industry directories, and trade shows to gather a list of candidates.

– Why It Matters: A comprehensive supplier list increases your chances of finding a partner who meets your quality and pricing standards.

– What to Look For: Focus on suppliers with a proven track record, positive reviews, and relevant certifications, such as ISO 9001, indicating their commitment to quality.

Step 3: Verify Supplier Certifications

Before proceeding, verify that potential suppliers hold necessary certifications. Request copies of quality management certificates and compliance with industry standards.

– Why It Matters: Certifications ensure that the supplier adheres to international quality standards, which is crucial for the reliability of your final products.

– What to Look For: Look for certifications like ISO 9001 and industry-specific standards relevant to your application (e.g., ASTM or GB/T).

Step 4: Evaluate Production Capabilities

Assess the production capabilities of shortlisted suppliers. This includes checking their machinery, production capacity, and quality control processes.

– Why It Matters: Understanding a supplier’s production capabilities helps you gauge whether they can meet your volume and customization requirements.

– What to Look For: Request information about their equipment, production timelines, and any third-party quality inspections they conduct.

Illustrative image related to qingdao aluminum profile trading

Step 5: Request Samples

Before placing a bulk order, request samples of the aluminum profiles you wish to procure. This allows you to evaluate the quality and suitability of the products.

– Why It Matters: Samples provide a tangible way to assess the quality of the materials and craftsmanship, ensuring they meet your specifications.

– What to Look For: Evaluate the samples for dimensional accuracy, surface finish, and overall quality. Ensure they align with your technical specifications.

Step 6: Negotiate Terms and Conditions

Once you’ve selected a supplier, negotiate pricing, payment terms, and delivery schedules. Establish clear communication regarding your expectations.

– Why It Matters: Clear terms help prevent misunderstandings and ensure both parties are aligned on project timelines and costs.

– What to Look For: Aim for favorable terms that reflect the quality and reliability of the supplier, considering factors like minimum order quantities and payment methods.

Step 7: Establish a Communication Plan

Set up a robust communication plan with your chosen supplier. Regular updates and open lines of communication can help address any issues that arise during production or shipping.

– Why It Matters: Proactive communication fosters a strong partnership and can help mitigate potential delays or quality issues.

– What to Look For: Agree on preferred communication channels and frequency of updates to ensure you stay informed throughout the sourcing process.

Comprehensive Cost and Pricing Analysis for qingdao aluminum profile trading Sourcing

What Are the Key Cost Components in Qingdao Aluminum Profile Trading?

In the context of Qingdao aluminum profile trading, understanding the cost structure is essential for B2B buyers. The primary components include:

Illustrative image related to qingdao aluminum profile trading

-

Materials: The choice of aluminum alloy (e.g., 6063-T5, 6061) significantly influences the cost. Higher-grade alloys or specialized materials for specific applications may incur additional costs.

-

Labor: Labor costs in China can vary based on region and the complexity of the manufacturing process. Skilled labor for custom fabrication or specialized surface treatments can elevate overall expenses.

-

Manufacturing Overhead: This encompasses utilities, equipment maintenance, and operational costs associated with running the manufacturing facility. Efficient factories often have lower overhead, which can translate into competitive pricing.

-

Tooling: Custom tooling for unique profiles or specific designs can be a significant upfront cost. Buyers should factor in this expense, especially for low-volume orders that may not justify the tooling investment.

-

Quality Control (QC): Rigorous QC processes ensure that products meet international standards. Investing in quality checks can add to the cost but is crucial for maintaining product integrity and minimizing defects.

-

Logistics: Freight costs from Qingdao Port to various global destinations vary based on shipping terms (Incoterms), weight, and volume. Efficient logistics management can reduce costs.

-

Margin: Suppliers will include a profit margin in their pricing, which can vary based on market demand, competition, and the supplier’s business model.

How Do Pricing Influencers Affect Qingdao Aluminum Profiles?

Several factors can influence the pricing of aluminum profiles sourced from Qingdao:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes often lead to lower per-unit costs. Suppliers may offer discounts for bulk purchases, making it advantageous for buyers to consolidate orders.

-

Specifications and Customization: Customized profiles, unique dimensions, or specific surface treatments (like anodizing or powder coating) can increase costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Quality and Certifications: Products with international certifications (e.g., ISO 9001, ASTM standards) may command higher prices due to the assurance of quality. Buyers should weigh the benefits of certified products against their budget.

-

Supplier Factors: The reputation and experience of the supplier, including their production capabilities and responsiveness, can influence pricing. Established suppliers with a track record of quality and service may charge a premium.

-

Incoterms: The chosen Incoterms (e.g., FOB, CIF) significantly affect the total cost. Understanding these terms helps buyers anticipate additional costs related to shipping, insurance, and customs.

What Tips Can Help Buyers Negotiate Better Prices?

For international B2B buyers from regions like Africa, South America, the Middle East, and Europe, here are actionable tips to enhance cost-efficiency:

-

Conduct Thorough Market Research: Understand the market rates for aluminum profiles, including average pricing and competitor offerings. This knowledge can provide leverage during negotiations.

-

Negotiate Volume Discounts: If possible, consolidate orders to meet or exceed the supplier’s MOQ, allowing for better pricing structures and potentially lower shipping costs.

-

Evaluate Total Cost of Ownership: Consider not just the purchase price but also the long-term costs associated with quality, maintenance, and logistics. A lower upfront cost may lead to higher expenses if quality is compromised.

-

Leverage Supplier Relationships: Building strong relationships with suppliers can lead to better pricing, priority service, and exclusive offers. Frequent communication and feedback can foster loyalty.

-

Stay Informed About Pricing Nuances: Global market fluctuations, changes in raw material costs, and geopolitical factors can impact pricing. Staying updated on these trends can aid in timing purchases effectively.

Disclaimer

The prices mentioned in this analysis are indicative and subject to change based on market conditions, supplier pricing strategies, and specific buyer requirements. Always request updated quotes and conduct due diligence before finalizing any transactions.

Alternatives Analysis: Comparing qingdao aluminum profile trading With Other Solutions

In the competitive landscape of aluminum profiles, international B2B buyers often face the challenge of selecting the right supplier or solution that meets their unique needs. While Qingdao aluminum profile trading is a prominent option, exploring alternatives can provide valuable insights and options for businesses in regions such as Africa, South America, the Middle East, and Europe. This analysis will compare Qingdao aluminum profile trading with two viable alternatives: domestic aluminum profile production and sourcing from other international suppliers.

| Comparison Aspect | Qingdao Aluminum Profile Trading | Domestic Aluminum Profile Production | Sourcing from Other International Suppliers |

|---|---|---|---|

| Performance | High-quality profiles with diverse options and customization. | Varies by manufacturer; may lack variety. | Quality varies widely; often requires thorough vetting. |

| Cost | Competitive pricing due to economies of scale. | Typically higher due to local production costs. | Can be competitive, but often includes high shipping fees. |

| Ease of Implementation | Streamlined logistics via Qingdao Port; efficient supply chain. | Longer lead times; may require additional logistics planning. | Varies; may require complex arrangements for shipping and customs. |

| Maintenance | Low maintenance; high durability of products. | Maintenance depends on the quality of local production. | Varies; depends on the supplier’s standards and materials used. |

| Best Use Case | Ideal for high-volume orders and custom solutions in construction and manufacturing. | Best for projects requiring local sourcing and shorter lead times. | Suitable for specialized needs that cannot be met locally or through Qingdao. |

What Are the Advantages and Disadvantages of Domestic Aluminum Profile Production?

Domestic aluminum profile production allows buyers to source materials locally, which can reduce shipping costs and lead times. This option can be particularly advantageous for projects that require immediate availability. However, the downside is that domestic manufacturers may not offer the same variety of profiles or customization options as suppliers in Qingdao. Additionally, local production costs can be higher, impacting overall project budgets.

How Does Sourcing from Other International Suppliers Compare?

Sourcing from other international suppliers can provide access to unique products or technologies that are not available in Qingdao. This may be beneficial for specialized projects that require specific materials or designs. However, the variability in quality and service can be a significant drawback. Buyers must invest time in vetting suppliers to ensure they meet the necessary quality standards, and shipping costs can add to the overall expense. Additionally, navigating customs regulations can complicate logistics.

Conclusion: How Can B2B Buyers Choose the Right Solution?

When selecting the right aluminum profile solution, B2B buyers should consider their specific project needs, budget constraints, and timelines. Qingdao aluminum profile trading stands out for its competitive pricing, extensive customization options, and efficient logistics, making it an excellent choice for high-volume orders. Conversely, domestic production may be better suited for projects requiring quick turnaround times, while sourcing from other international suppliers could be ideal for specialized requirements. By carefully evaluating these alternatives, buyers can make informed decisions that align with their operational goals and project specifications.

Essential Technical Properties and Trade Terminology for qingdao aluminum profile trading

What Are the Key Technical Properties of Aluminum Profiles in Qingdao Trading?

In the realm of aluminum profile trading, understanding specific technical properties is essential for making informed purchasing decisions. Here are some critical specifications to consider:

1. Material Grade (e.g., 6063-T5)

Material grade refers to the specific alloy composition of the aluminum profile, with 6063-T5 being one of the most common. The numbers indicate the alloy series and temper, where 6063 is known for its excellent extrudability and surface finish. This property is vital for buyers to ensure the profiles meet structural and aesthetic requirements, especially in construction and architectural applications.

2. Tolerance

Tolerance defines the permissible limits of variation in dimensions, typically expressed in millimeters. For example, a tolerance of ±0.1mm ensures precision in fitting and assembly. High tolerance standards are crucial for applications where exact dimensions are necessary, reducing the risk of assembly errors and enhancing product performance.

3. Surface Treatment (Anodized, Powder Coated)

Surface treatments like anodizing and powder coating enhance the durability and appearance of aluminum profiles. Anodizing increases corrosion resistance and allows for various color finishes, while powder coating offers a robust finish that can withstand harsh conditions. Buyers should prioritize surface treatments based on their application needs, especially for outdoor or industrial environments.

Illustrative image related to qingdao aluminum profile trading

4. Extrusion Process

The extrusion process involves shaping aluminum by forcing it through a die, resulting in profiles with desired cross-sectional shapes. This method influences the mechanical properties of the profiles, such as strength and weight. Understanding the extrusion process can help buyers select profiles that align with specific load-bearing requirements in their projects.

5. Customization Options

Many suppliers offer customizable options, including shape, size, and color. This flexibility allows businesses to tailor products to their specific needs, improving compatibility with existing systems or aesthetic requirements. In a competitive market, the ability to customize can be a significant advantage for buyers looking to differentiate their offerings.

What Are Common Trade Terms Used in Qingdao Aluminum Profile Trading?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms you should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In aluminum profile trading, working with an OEM can provide tailored solutions that meet specific design and functionality requirements.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. Understanding MOQ is crucial for buyers as it impacts inventory management and initial investment costs. Suppliers often set MOQs based on production efficiency and cost-effectiveness.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and terms for a specific quantity of products. This process is essential for comparing different suppliers and negotiating favorable terms. A well-prepared RFQ can lead to more competitive pricing and better service levels.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is vital for clarifying shipping costs, risks, and responsibilities, which can significantly affect overall transaction costs.

5. Lead Time

Lead time refers to the amount of time from placing an order to delivery. It is a critical factor in project planning and inventory management. Buyers should discuss lead times with suppliers to ensure that production schedules align with their project timelines.

By grasping these technical properties and trade terms, international B2B buyers can navigate the aluminum profile market in Qingdao more effectively, ensuring they make informed decisions that align with their business needs.

Navigating Market Dynamics and Sourcing Trends in the qingdao aluminum profile trading Sector

What Are the Key Trends Influencing the Qingdao Aluminum Profile Trading Market?

The global aluminum profile trading market is currently experiencing significant growth, driven by various factors including urbanization, technological advancements, and a rising demand for lightweight, durable materials across multiple sectors. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly sourcing aluminum profiles from Qingdao due to its strategic location and established supply chains. The region is renowned for its competitive pricing, diverse product offerings, and robust manufacturing capabilities, which allow for customized solutions tailored to specific industry needs.

Emerging trends in B2B technology are shaping the sourcing landscape. E-commerce platforms and digital marketplaces are streamlining the procurement process, enabling buyers to easily compare suppliers, request quotes, and place orders online. Additionally, advancements in automation and smart manufacturing are enhancing production efficiency, reducing lead times, and improving product quality. Buyers should also be aware of the rising importance of data analytics in forecasting demand and optimizing inventory management.

Furthermore, as global markets evolve, there’s an increasing push towards sustainable practices. Buyers are now more inclined to partner with suppliers who demonstrate a commitment to environmental responsibility and ethical sourcing. This shift is not only about compliance but also about brand reputation and customer loyalty in an increasingly eco-conscious marketplace.

How Are Sustainability and Ethical Sourcing Impacting the Qingdao Aluminum Profile Sector?

Sustainability and ethical sourcing have become paramount in the Qingdao aluminum profile trading sector, reflecting a broader global trend. The environmental impact of aluminum production is significant, often involving high energy consumption and greenhouse gas emissions. Therefore, international buyers are seeking suppliers that prioritize sustainable practices, such as utilizing renewable energy sources in manufacturing processes and implementing efficient recycling programs.

The importance of ethical supply chains cannot be overstated. Companies are increasingly held accountable for their sourcing practices, and buyers are now looking for suppliers with transparent operations and certifications that verify their commitment to sustainability. Certifications such as ISO 14001 for environmental management and aluminum industry-specific standards can serve as indicators of a supplier’s dedication to reducing their ecological footprint.

Moreover, the demand for “green” materials is rising. Buyers should prioritize suppliers that offer aluminum profiles with environmentally friendly surface treatments, such as powder coating and anodizing, which have lower environmental impacts compared to traditional methods. Engaging with suppliers who adhere to these sustainable practices not only helps in meeting regulatory requirements but also enhances brand value and consumer trust.

What Is the Historical Context of the Qingdao Aluminum Profile Trading Industry?

The aluminum profile trading industry in Qingdao has evolved significantly over the past few decades. Initially, the region focused on basic manufacturing capabilities, but as global demand for aluminum products surged, Qingdao began to specialize in high-quality aluminum profiles to serve various applications, including construction, automotive, and industrial sectors.

By leveraging its strategic location near one of China’s busiest ports, Qingdao has transformed into a pivotal hub for aluminum exports, facilitating international trade. The establishment of industrial parks and a focus on technological innovation have further enhanced the region’s manufacturing capabilities, allowing it to compete on a global scale. Today, Qingdao is not just a manufacturing center but also a vital player in the global aluminum profile supply chain, catering to an increasingly diverse international clientele.

This historical context underscores the importance of Qingdao as a reliable source for international B2B buyers, positioning itself as a leader in both quality and innovation in the aluminum profile trading market.

Frequently Asked Questions (FAQs) for B2B Buyers of qingdao aluminum profile trading

-

How do I verify the credibility of a Qingdao aluminum profile supplier?

To verify a supplier’s credibility, start by checking their certifications, such as ISO 9001, which indicate adherence to quality management standards. Request references from previous clients and look for third-party testing reports that validate the quality of their products. Conduct factory audits, either onsite or virtually, focusing on their production capabilities and quality control processes. Additionally, assess their on-time delivery rates and reorder statistics to gauge client satisfaction. -

What is the best way to customize aluminum profiles for my specific needs?

The best way to customize aluminum profiles is to work closely with your chosen supplier from the outset. Discuss your specific requirements regarding dimensions, surface treatments, and finishes. Many suppliers offer drawing-based and sample-based customization options, allowing you to create profiles tailored to your needs. Ensure that the supplier can meet your tolerances, typically ±0.1mm, and inquire about their prototyping capabilities to expedite the process. -

What are common minimum order quantities (MOQs) for aluminum profiles?

Minimum order quantities (MOQs) for aluminum profiles can vary significantly based on the supplier and product specifications. Generally, MOQs can range from as low as 100 kg to several tons for customized profiles. For standard profiles, some suppliers may offer lower MOQs, while larger manufacturers often require higher volumes to ensure cost-effectiveness. Always confirm MOQs with your supplier before placing an order to avoid unexpected costs. -

What payment terms should I expect when sourcing from Qingdao suppliers?

Payment terms can vary by supplier, but common practices include a 30% deposit before production and the remaining 70% upon delivery or before shipment. Some suppliers may also offer letters of credit or payment through platforms like Alibaba for additional security. It’s essential to negotiate terms that align with your cash flow needs while ensuring adequate protection against potential risks. -

How can I ensure quality assurance (QA) for my aluminum profiles?

To ensure quality assurance, select suppliers who implement rigorous QA processes, including raw material inspection, in-process testing, and final product assessments. Request mill test certificates for the aluminum used and ask for third-party inspection reports. Establish clear quality standards and communicate them with your supplier. Regular audits and quality checks during production can further safeguard against defects. -

What logistics considerations should I keep in mind when importing aluminum profiles?

When importing aluminum profiles, consider shipping methods, customs regulations, and lead times. Ensure your supplier can provide necessary documentation for customs clearance, such as bills of lading and certificates of origin. Evaluate shipping options—air freight may be faster but more expensive, while sea freight is cost-effective for larger volumes. Plan for potential delays and ensure your logistics partner is experienced in handling international shipments. -

What are the advantages of sourcing aluminum profiles from Qingdao?

Qingdao offers several advantages for sourcing aluminum profiles, including its strategic location near one of China’s busiest ports, facilitating efficient international shipping. The region is home to numerous manufacturers specializing in various profiles, which fosters competitive pricing and diverse production capabilities. Additionally, suppliers in Qingdao are often equipped with advanced technology, ensuring high-quality products that meet international standards. -

How do I handle disputes with my aluminum profile supplier?

In the event of a dispute, start by communicating directly with your supplier to discuss the issue. Document all communications and agreements made. If a resolution cannot be reached, refer to the contract terms, which should outline the dispute resolution process. Consider mediation or arbitration as alternatives to legal action, as they can be less time-consuming and costly. Maintaining a professional relationship throughout the process can facilitate a more amicable resolution.

Top 7 Qingdao Aluminum Profile Trading Manufacturers & Suppliers List

1. Accio – Key Product Details

Domain: accio.com

Registered: 1997 (28 years)

Introduction: Key Product Details:

– Alloy: 6063-T5

– Finishes: Anodized, Powder Coated, Mill Finish

– Types: Thermal Break, Extruded Profile, T-slot Profile, Heat Sink, Architectural Profile, Industrial Profile

– Customization Options: Thickness, Surface Treatment, Shape, Length, Color, Tolerance, Model Number, Dimension, Package

– Minimum Order Quantity (MOQ): < 5

– Supplier Ratings: 4.5+

– Average Res…

2. QDD Metal Group – Custom Aluminum Extrusions

Domain: qddmetalgroup.com

Registered: 2025 (0 years)

Introduction: Custom 6061 6063 T5 Aluminum Extrusion Profile with Black Anodizing Finishing. In-house tooling and mold design for precision and reduced development time. Integrated production planning to minimize delays. Dedicated project manager for each project. Real-time quality control with CMM, calipers, and gauges. Quality inspection reports and material certificates available upon request.

3. DM Metal Solution – Aluminum Extrusion & Custom Fabrication Services

Domain: dmetalsolution.com

Registered: 2023 (2 years)

Introduction: Aluminum Extrusion Service, Deep-Processed Aluminum Profile, Aluminum Extrusion Heatsink, Extruded Aluminum Profile, Casting Service, CNC Machining Service, Die Casting Service, Forging Service, Plastic Injection Service, Sheet Metal Fabrication, Customized Part Service.

4. Qingdao Idea Aluminium Co. Ltd. – Industrial Aluminium Profile

Domain: alcirclebiz.com

Registered: 2019 (6 years)

Introduction: {“Product Name”: “Industrial Aluminium Profile”, “Manufacturer”: “Qingdao Idea Aluminium Co. Ltd.”, “Price”: “Available on request”, “Category”: “Industrial Extrusion”, “Min Order Quantity”: “100.00 Unit”, “Delivery Lead Time”: “60 Days”, “Place of Origin”: “Shandong, China”, “Supply Ability”: “Customization on Requirement”, “Packaging Details”: “As per customer’s specification”, “Transportation D…

5. Qingdao Xinyi Mengshan Aluminium – Aluminum Profiles

Domain: tradeboss.com

Registered: 2002 (23 years)

Introduction: Qingdao Xinyi Mengshan Aluminium Co., Ltd. specializes in aluminum profiles, decorative profiles, and various industrial aluminum profiles. They offer products such as aluminum profiles for doors, windows, aluminum profile alloys, and aluminum profile accessories. The company has an annual production capacity of 70,000 tons and utilizes advanced production techniques including aluminum casting, el…

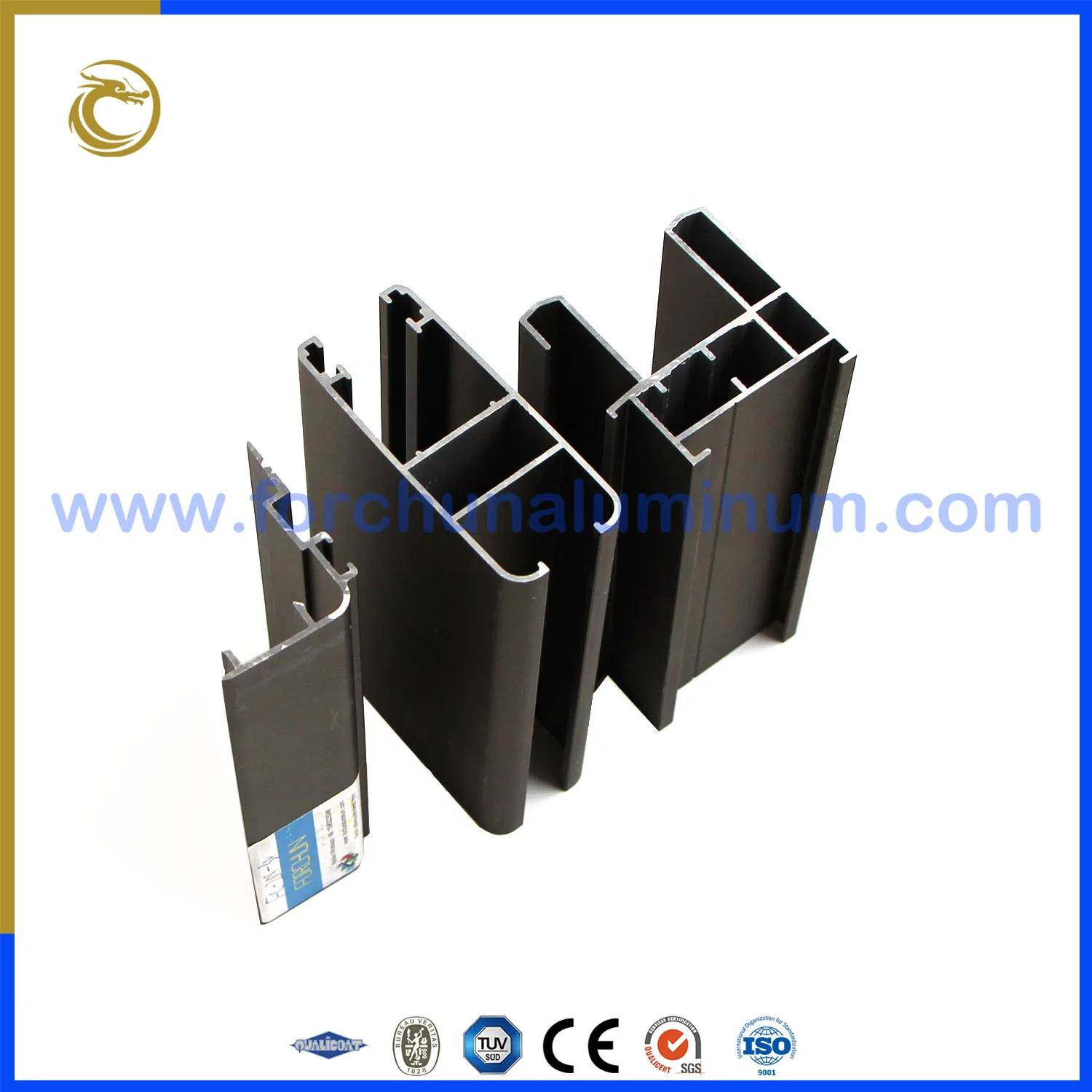

6. Forchun Aluminum – Aluminum Profiles & Accessories

Domain: linkedin.com

Registered: 2002 (23 years)

Introduction: This company, Forchun Aluminum – Aluminum Profiles & Accessories, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Qingdao Vatti Glass – Aluminum Profiles

Domain: qdvattiglass.goldsupplier.com

Registered: 2000 (25 years)

Introduction: Aluminum Profile from Qingdao Vatti Glass Co., Ltd.\n- FOB Price: US$ 2.55 / Kilogram\n- Minimum Order: 1000 Kilograms\n- Main Types: \n – Aluminum profile for channel letter\n – Industrial aluminum profile\n – Aluminum window extrusion profile\n – Aluminum profile for insulated glass window\n – Aluminum profile for LED display\n – Aluminum profile for kitchen cabinet\n – Anodic oxidation …

Strategic Sourcing Conclusion and Outlook for qingdao aluminum profile trading

In navigating the competitive landscape of aluminum profile trading from Qingdao, international buyers must prioritize strategic sourcing to maximize quality, cost-efficiency, and reliability. Key takeaways include the importance of selecting suppliers with robust certifications, proven track records, and strong logistical capabilities. Buyers should focus on manufacturers that offer customizable solutions tailored to specific project needs, ensuring that they can accommodate variations in design and production requirements.

The strategic sourcing process should emphasize establishing long-term partnerships with suppliers who demonstrate consistent quality and responsiveness. With Qingdao’s advantageous position as a manufacturing hub, buyers can benefit from streamlined shipping and access to a diverse range of aluminum profiles suited for various applications, from architectural projects to industrial uses.

Looking ahead, the aluminum profile market is poised for growth, driven by increasing global demand for sustainable construction materials. International B2B buyers from Africa, South America, the Middle East, and Europe are encouraged to leverage Qingdao’s manufacturing strengths to secure high-quality aluminum solutions that align with their business objectives. Engage with trusted suppliers today to explore the potential for innovation and efficiency in your projects.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.