Top 7 Keeper Latch Suppliers (And How to Choose)

Introduction: Navigating the Global Market for keeper latch

In the ever-evolving landscape of global trade, sourcing reliable keeper latches presents a unique challenge for international B2B buyers. The need for high-quality, durable latches that meet diverse application requirements—from construction and manufacturing to commercial use—can complicate procurement processes. This guide aims to equip buyers with the knowledge necessary to navigate the complexities of the keeper latch market, addressing critical factors such as types, applications, supplier vetting, and pricing strategies.

Throughout this comprehensive resource, you will discover the various types of keeper latches available, including surface-mounted and inswing models, and their specific applications across different industries. We will delve into effective strategies for vetting suppliers to ensure you partner with reputable manufacturers who meet international quality standards. Additionally, insights into cost structures and pricing variations will empower you to make informed purchasing decisions that align with your budget and operational needs.

By leveraging this guide, B2B buyers from Africa, South America, the Middle East, and Europe—including key markets like Germany and Saudi Arabia—will enhance their sourcing capabilities. This resource not only simplifies the procurement process but also fosters confidence in selecting the right keeper latches for your business needs, ultimately driving efficiency and enhancing product security in your operations.

Understanding keeper latch Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Keeper Latch | Typically made from metal; fits standard latch pins. | General door security in commercial settings. | Pros: Cost-effective, widely available. Cons: May lack customization options. |

| Surface-Mounted Keeper Latch | Installed on the surface of the door; easy to install. | Partition stalls, restroom doors. | Pros: Simple installation; minimal hardware required. Cons: Aesthetic may not suit all designs. |

| T-Handle Keeper Latch | Features a T-shaped handle for easy operation. | Used in commercial vehicles and equipment. | Pros: Ergonomic; secure locking mechanism. Cons: May require specific installation space. |

| Throw Latch Keeper | Utilizes a bolt mechanism for added security. | Heavy-duty applications, including storage units. | Pros: High security; durable. Cons: More complex installation process. |

| Adjustable Keeper Latch | Allows for height adjustments to fit various latch sizes. | Custom applications where flexibility is needed. | Pros: Versatile; accommodates different door heights. Cons: Potentially higher cost. |

What are the characteristics and suitability of a Standard Keeper Latch?

Standard keeper latches are often made from durable metals and are designed to fit standard latch pins, making them a common choice for many commercial applications. Their straightforward design allows for easy installation and maintenance, making them ideal for general door security in office buildings, schools, and hospitals. Buyers should consider their cost-effectiveness and availability, but also note that they may lack customization options for specific security needs.

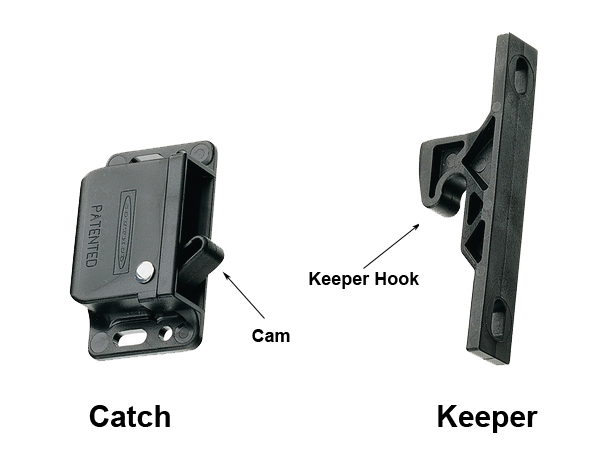

How does a Surface-Mounted Keeper Latch differ in application?

Surface-mounted keeper latches are installed directly onto the door’s surface, which makes them particularly easy to install and replace. They are commonly used in partition stalls and restroom doors, where quick access and minimal hardware are essential. While they offer a straightforward solution, buyers should assess their aesthetic appeal, as they may not blend seamlessly with all architectural designs.

What advantages does a T-Handle Keeper Latch offer?

The T-handle keeper latch is distinguished by its ergonomic T-shaped handle, allowing for easy operation, especially in commercial vehicles and equipment. This type of latch is designed for secure locking, making it suitable for environments where safety is a priority. Buyers will appreciate its ease of use and security features, although they should also consider the specific installation space required.

Why choose a Throw Latch Keeper for heavy-duty applications?

Throw latch keepers use a bolt mechanism that provides an enhanced level of security, making them ideal for heavy-duty applications such as storage units and industrial doors. Their robust construction ensures durability under frequent use. Buyers should weigh the benefits of high security against the more complex installation process, which may require specialized knowledge or tools.

What makes an Adjustable Keeper Latch a versatile option?

Adjustable keeper latches are unique in their ability to accommodate various latch sizes through height adjustments. This flexibility makes them suitable for custom applications where standard sizes may not fit. While they offer versatility, buyers should consider the potential for higher costs and ensure that the adjustable features meet their specific needs for door installations.

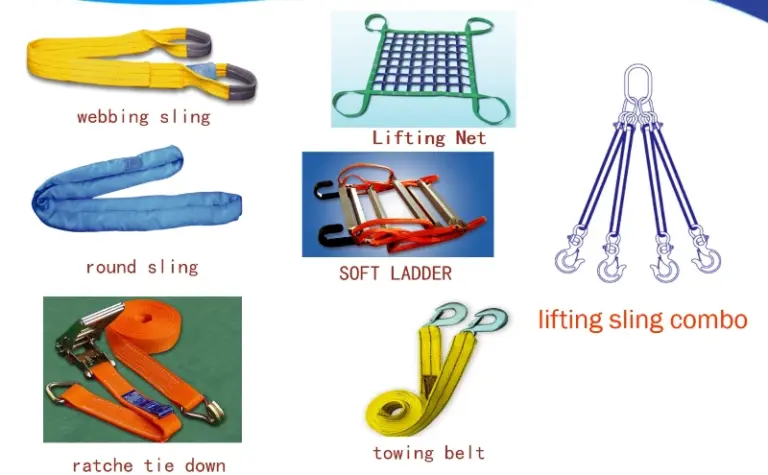

Key Industrial Applications of keeper latch

| Industry/Sector | Specific Application of keeper latch | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Door hardware for commercial buildings | Enhances security and access control | Material durability, compliance with local standards |

| Transportation | Latching systems for cargo containers | Ensures cargo safety during transit | Weather resistance, load capacity, ease of installation |

| Hospitality | Partition latches in restrooms | Provides privacy and accessibility | Aesthetic appeal, corrosion resistance, maintenance |

| Manufacturing | Equipment safety latches | Prevents accidental openings, enhances safety | Compatibility with machinery, reliability under stress |

| Retail | Security latches for display cases | Protects merchandise, reduces theft risk | Locking mechanism strength, ease of use, cost efficiency |

How Is a Keeper Latch Used in the Construction Industry?

In the construction sector, keeper latches are integral components in door hardware for commercial buildings. They provide robust security and facilitate smooth access control, ensuring that doors remain securely closed while allowing for easy operation. Buyers in this sector should prioritize materials that offer durability and comply with local building regulations. Given the international nature of construction projects, sourcing latches that meet various compliance standards across regions such as Europe, Africa, and the Middle East is crucial.

What Role Do Keeper Latches Play in Transportation Applications?

In the transportation industry, keeper latches are vital for securing cargo containers during transit. These latches ensure that the cargo remains intact and secure, preventing losses and damage. Buyers in this sector must consider the latches’ weather resistance and load capacity, particularly for international shipping where containers may face harsh environmental conditions. Selecting latches that are easy to install and maintain can also enhance operational efficiency.

How Are Keeper Latches Utilized in the Hospitality Sector?

Within the hospitality industry, keeper latches are commonly used in restroom partition systems. They ensure privacy for users while providing easy access for maintenance staff. The aesthetic appeal of the latches is also significant, as they contribute to the overall ambiance of the facilities. For international buyers, it’s important to source latches that are not only visually appealing but also resistant to corrosion, especially in humid environments.

Why Are Keeper Latches Important in Manufacturing?

In manufacturing, keeper latches are essential for equipment safety, preventing accidental openings that could lead to workplace injuries. These latches enhance the overall safety of machinery by ensuring that access points remain secure during operation. Buyers should focus on sourcing latches compatible with specific machinery and capable of withstanding stress, which is particularly important in high-volume production environments. Reliability is key, as equipment downtime can significantly impact productivity.

How Do Keeper Latches Benefit Retail Security?

For the retail sector, keeper latches play a critical role in securing display cases and merchandise, thereby reducing the risk of theft. These latches must be robust yet user-friendly, allowing staff to access items quickly while deterring unauthorized access. When sourcing latches for retail applications, businesses should consider the strength of the locking mechanism and the overall cost efficiency to ensure they are investing wisely in their security solutions.

3 Common User Pain Points for ‘keeper latch’ & Their Solutions

Scenario 1: Compatibility Issues with Existing Hardware

The Problem: B2B buyers often encounter challenges when integrating new keeper latches with existing door systems. Variability in dimensions and mounting styles can lead to compatibility issues, resulting in delays and increased costs during installation. For instance, a buyer sourcing latches for a facility in South America may find that the latch dimensions do not match the existing door frames designed for European specifications, necessitating additional modifications. This can not only disrupt project timelines but also affect operational efficiency.

The Solution: To mitigate compatibility issues, buyers should conduct a thorough assessment of their existing hardware before purchasing keeper latches. It is advisable to take precise measurements of the door and frame specifications, including the width, height, and any existing mounting holes. Additionally, when sourcing keeper latches, look for suppliers that provide detailed technical drawings and compatibility charts. For example, suppliers like TPH Supply and Spring Creek Products offer detailed specifications on their websites, enabling buyers to make informed decisions. Engaging with manufacturers or distributors who can provide tailored recommendations based on specific needs will also streamline the selection process and ensure a seamless integration.

Scenario 2: Durability Concerns in Harsh Environments

The Problem: In regions with extreme weather conditions, such as the Middle East or parts of Africa, the durability of keeper latches can be a significant concern. Buyers often report issues with latches corroding or failing due to high humidity, temperature fluctuations, or exposure to harsh chemicals. This not only affects the longevity of the hardware but can also lead to safety risks and increased maintenance costs, as damaged latches may compromise door security.

The Solution: To address durability concerns, B2B buyers should prioritize keeper latches made from high-quality materials that are specifically designed for challenging environments. Stainless steel options are often recommended due to their corrosion resistance and strength. Buyers should look for products that meet industry standards for environmental resistance, such as ASTM ratings. Additionally, consider investing in latches with protective coatings, such as powder coating or plating, to further enhance their lifespan. Collaborating with suppliers who offer warranties or guarantees on their products can also provide peace of mind, ensuring that replacements or repairs are manageable and cost-effective.

Scenario 3: Difficulty in Securing Proper Installation

The Problem: Many buyers face challenges with the installation process of keeper latches, especially when personnel are not adequately trained. Incorrect installation can lead to malfunctioning latches, which can compromise security and usability. For instance, in a commercial setting, a poorly installed latch can result in doors not closing properly, creating safety hazards and operational disruptions.

The Solution: To ensure proper installation of keeper latches, B2B buyers should invest in training programs for installation teams. Suppliers often provide installation guides and video tutorials, which can serve as valuable resources. Additionally, consider sourcing latches from manufacturers that offer installation assistance or on-site consultations. Engaging a professional installation service, especially for large projects, can also prevent costly mistakes. Furthermore, establishing a clear communication channel with the supplier for troubleshooting can help resolve any installation issues swiftly. Providing ongoing training and resources will not only enhance installation accuracy but also empower teams to maintain the hardware effectively over time.

Strategic Material Selection Guide for keeper latch

What are the Key Properties of Common Materials Used for Keeper Latches?

When selecting a keeper latch, the choice of material is critical for ensuring optimal performance and longevity. Here, we analyze four common materials: Stainless Steel, Zamac (Zinc-Aluminum Alloy), Aluminum, and Plastic. Each material has unique properties that influence its suitability for various applications.

How Does Stainless Steel Perform as a Material for Keeper Latches?

Stainless steel is widely recognized for its exceptional corrosion resistance and strength, making it suitable for both indoor and outdoor applications. It can withstand high temperatures and pressures, which is crucial in environments that experience extreme conditions. The durability of stainless steel ensures a long lifespan, reducing the need for frequent replacements.

Pros: High durability, excellent resistance to corrosion and temperature extremes, and a professional appearance.

Cons: Higher cost compared to other materials, and it can be heavier, potentially complicating installation.

For international buyers, compliance with standards such as ASTM A240 and DIN EN 10088 is essential to ensure quality. In regions like Europe, where environmental regulations are stringent, stainless steel is often preferred for its recyclability.

What Advantages and Disadvantages Does Zamac Offer for Keeper Latches?

Zamac, an alloy of zinc and aluminum, is another popular choice for keeper latches. It is known for its good mechanical properties and resistance to corrosion, particularly in indoor environments. Zamac is also relatively easy to manufacture, allowing for complex shapes and designs.

Pros: Cost-effective, lightweight, and easy to cast, making it suitable for mass production.

Cons: Lower corrosion resistance compared to stainless steel, which may limit its use in outdoor applications. It is also less durable under extreme conditions.

International buyers should be aware of compliance with standards like ASTM B86 and JIS H 5302. Zamac is often favored in regions where cost is a significant factor, such as parts of South America and Africa.

How Does Aluminum Compare as a Material for Keeper Latches?

Aluminum is lightweight and offers good corrosion resistance, making it a practical choice for various applications. It is particularly useful in environments where weight is a concern, such as portable or mobile structures.

Pros: Lightweight, good corrosion resistance, and cost-effective.

Cons: Not as strong as stainless steel or Zamac, and can be prone to deformation under heavy loads.

For international buyers, compliance with standards such as ASTM B221 and DIN EN 573 is crucial. Aluminum is often preferred in regions like the Middle East, where lightweight materials are advantageous for construction.

What Role Does Plastic Play in Keeper Latch Applications?

Plastic materials, particularly high-density polyethylene (HDPE) and polycarbonate, are increasingly used in keeper latch applications due to their resistance to moisture and chemicals. They are lightweight and can be molded into complex shapes.

Pros: Low cost, lightweight, and resistant to moisture and chemicals.

Cons: Limited mechanical strength and temperature resistance compared to metals, which may affect performance in high-stress applications.

International buyers should consider compliance with standards such as ASTM D638 and ISO 527. Plastic latches are often favored in regions where cost and weight are primary considerations, such as in various sectors in Africa and South America.

Summary Table of Material Selection for Keeper Latches

| Material | Typical Use Case for keeper latch | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Outdoor gates, industrial applications | High durability and corrosion resistance | Higher cost and weight | High |

| Zamac | Indoor partitions, commercial settings | Cost-effective and easy to manufacture | Lower corrosion resistance | Medium |

| Aluminum | Portable structures, lightweight applications | Lightweight and good corrosion resistance | Not as strong as metals | Medium |

| Plastic | Moisture-prone environments, low-stress applications | Low cost and moisture resistant | Limited strength and temperature resistance | Low |

This comprehensive analysis should aid international B2B buyers in making informed decisions regarding material selection for keeper latches, taking into account performance requirements, cost considerations, and compliance with regional standards.

Illustrative image related to keeper latch

In-depth Look: Manufacturing Processes and Quality Assurance for keeper latch

What Are the Main Stages of Manufacturing a Keeper Latch?

The manufacturing process for a keeper latch involves several critical stages that ensure the final product meets quality standards and functional requirements. The main stages include material preparation, forming, assembly, and finishing.

How is Material Prepared for Keeper Latch Production?

Material preparation is the foundational step in manufacturing keeper latches. Typically, high-quality metals such as stainless steel, zamac (a zinc-aluminum alloy), or aluminum are selected for their strength, durability, and resistance to corrosion. The materials undergo several processes, including cutting, shearing, and surface treatment, to ensure they meet the specifications required for the final product. In some cases, suppliers may opt for pre-coated materials to enhance corrosion resistance, particularly relevant for environments in humid or coastal regions.

What Forming Techniques Are Used in Keeper Latch Manufacturing?

Once the materials are prepared, forming techniques are employed to create the desired shapes and features of the keeper latch. Common techniques include stamping, forging, and machining.

- Stamping involves pressing metal sheets into molds to create specific shapes, allowing for high-volume production with minimal waste.

- Forging is often used for parts requiring enhanced strength and durability, where heated metal is shaped under pressure.

- Machining, including processes like drilling and milling, is utilized for precision components that require tight tolerances.

These forming methods contribute to the overall structural integrity and reliability of the latch, which are crucial for its performance in various applications.

How is Assembly Conducted for Keeper Latches?

The assembly stage involves combining the formed parts into a complete latch mechanism. This process may include attaching the keeper to the strike plate and ensuring all components function smoothly together. Assembly can be done manually or through automated systems, depending on the production scale and complexity of the design.

Quality control measures are integrated into this stage to ensure proper alignment and fit of components. Regular checks during assembly can identify any deviations that may affect the latch’s functionality, allowing for immediate corrective actions.

What Finishing Processes Are Applied to Keeper Latches?

Finishing processes enhance the aesthetic appeal and functional performance of the keeper latch. Common finishing techniques include:

- Electroplating: This process involves applying a thin layer of metal (such as chrome) to improve corrosion resistance and provide a polished look.

- Powder Coating: A dry finishing process that provides a durable and protective layer, particularly important for latches exposed to harsh environments.

- Anodizing: Commonly used for aluminum, this process increases corrosion resistance and allows for dyeing to achieve different colors.

These finishing techniques not only improve the latch’s longevity but also contribute to its market appeal, particularly for buyers focusing on aesthetics.

What Quality Assurance Standards Are Relevant for Keeper Latches?

Quality assurance (QA) is vital in manufacturing keeper latches, ensuring that products meet both international and industry-specific standards. Key standards include:

- ISO 9001: This globally recognized standard focuses on quality management systems and is essential for manufacturers aiming to demonstrate their commitment to quality and customer satisfaction.

- CE Marking: Particularly important for products sold in Europe, CE marking indicates conformity with health, safety, and environmental protection standards.

- API Standards: Applicable for latches used in oil and gas industries, these standards ensure that products can withstand harsh conditions.

Compliance with these standards can enhance a manufacturer’s reputation and facilitate entry into international markets.

How Are Quality Control Checkpoints Structured in the Manufacturing Process?

Quality control in keeper latch manufacturing typically involves several checkpoints throughout the production process, commonly referred to as Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

- IQC: This phase checks the quality of incoming materials before they enter the production line. Ensuring that raw materials meet specified standards is crucial for maintaining product quality.

- IPQC: Conducted during various stages of production, this involves monitoring processes and inspecting components to ensure they meet design specifications and tolerances.

- FQC: The final stage of quality control occurs after assembly, where the complete latch is tested for functionality, durability, and compliance with specifications before packaging and shipment.

These checkpoints help to minimize defects and ensure consistent product quality, which is essential for maintaining buyer trust.

What Common Testing Methods Are Used to Ensure Quality in Keeper Latch Production?

Testing methods for keeper latches vary based on their intended use and industry requirements. Common testing methods include:

- Functional Testing: Evaluates the latch’s operation, ensuring it engages and disengages smoothly without excessive force.

- Durability Testing: Simulates real-world use to assess the latch’s lifespan and performance under stress.

- Corrosion Resistance Testing: Particularly important for latches used in outdoor or high-humidity environments, this test evaluates how well the latch withstands corrosive elements.

- Dimensional Inspection: Ensures that all dimensions of the latch conform to specifications, which is vital for proper fit and function.

These testing methods provide assurance that the latches will perform reliably in their intended applications.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers, particularly those operating in international markets, should take proactive steps to verify the quality control practices of their suppliers. Here are several strategies:

Illustrative image related to keeper latch

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control measures, and overall compliance with standards firsthand.

- Requesting Quality Reports: Suppliers should provide documentation of quality control measures, including results from testing and compliance with relevant standards.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s quality control processes and product compliance.

Buyers should also consider the supplier’s history and reputation in the industry, particularly in regions like Africa, South America, the Middle East, and Europe, where adherence to local regulations and standards can vary significantly.

What Are the Quality Control Nuances for International Buyers?

International buyers face unique challenges regarding quality control, including differing standards and regulations across regions. Buyers should be aware of the following nuances:

- Local Regulations: Understanding the specific quality and safety regulations in the buyer’s country is essential. For example, products exported to the EU must comply with CE marking requirements.

- Cultural Differences: Business practices, including quality expectations, can vary significantly across regions. Buyers should familiarize themselves with local business customs and practices to foster better relationships with suppliers.

- Language Barriers: Clear communication is vital for ensuring quality. Buyers may need to engage translators or local representatives to facilitate discussions about quality expectations and specifications.

By navigating these nuances effectively, B2B buyers can ensure they partner with suppliers who adhere to stringent quality control practices, thus safeguarding their investments and enhancing customer satisfaction.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘keeper latch’

To successfully procure keeper latches for your business needs, it’s essential to follow a structured sourcing approach. This guide provides a step-by-step checklist to assist B2B buyers in identifying, evaluating, and selecting the right keeper latch solutions.

Step 1: Define Your Technical Specifications

Before beginning your search, it’s critical to establish clear technical specifications for the keeper latches you require. Consider factors such as material (e.g., stainless steel, zamac), dimensions, pin size, and any specific design features needed for your application. This clarity will streamline your sourcing process and ensure compatibility with existing hardware.

Step 2: Research Market Trends and Requirements

Understanding current market trends is vital. Analyze the specific demands of your target markets in regions like Africa, South America, the Middle East, and Europe. This may include preferences for sustainability, durability, or design aesthetics. Engaging with industry reports and trade publications can provide insights that align your procurement strategy with market expectations.

Step 3: Evaluate Potential Suppliers

Vetting suppliers is a critical step in ensuring quality and reliability. Look for suppliers with a proven track record in manufacturing keeper latches and request documentation such as certifications, case studies, and references from similar industries. Pay attention to their experience in your target regions, as local market knowledge can facilitate smoother transactions.

Illustrative image related to keeper latch

Step 4: Request Samples and Prototypes

Once you have shortlisted suppliers, request samples or prototypes of the keeper latches. This allows you to assess the quality, fit, and finish of the products before making a bulk order. Test the samples in real-world conditions to ensure they meet your operational needs and durability standards.

Step 5: Check Compliance with International Standards

Confirm that the keeper latches comply with relevant international standards and regulations. This is particularly important if you plan to distribute in regions with stringent safety and quality requirements, such as Europe. Ensure that the products are certified by recognized bodies, which can also enhance your brand’s credibility.

Step 6: Negotiate Terms and Pricing

Engage in negotiations with your selected suppliers to secure favorable terms. Discuss pricing structures, payment terms, and delivery schedules. Consider bulk purchasing discounts and the possibility of establishing long-term partnerships, which can lead to better pricing and service in the future.

Step 7: Finalize the Purchase and Monitor Delivery

Once terms are agreed upon, finalize the purchase and ensure that all details are documented clearly. Keep communication lines open with the supplier to monitor the production and shipping processes. Establish a timeline for delivery and plan for quality checks upon arrival to prevent any discrepancies.

By following these structured steps, B2B buyers can effectively navigate the procurement process for keeper latches, ensuring they secure products that meet their operational needs while aligning with market demands.

Comprehensive Cost and Pricing Analysis for keeper latch Sourcing

What are the Key Cost Components in Keeper Latch Sourcing?

When sourcing keeper latches, understanding the cost structure is critical for effective budgeting and negotiation. The primary cost components include:

-

Materials: The choice of materials significantly impacts the pricing of keeper latches. Common materials include chrome-plated zamac, stainless steel, and aluminum. Each material has varying costs based on market demand and availability. For instance, stainless steel tends to be more expensive due to its durability and resistance to corrosion, making it suitable for high-quality applications.

-

Labor: Labor costs vary depending on the manufacturing location. Regions with higher labor costs, such as parts of Europe, may see increased prices. In contrast, countries with lower labor costs might offer more competitive pricing, although this could affect quality.

-

Manufacturing Overhead: This includes expenses related to production facilities, utilities, and equipment maintenance. Manufacturers in countries with stringent regulations may incur higher overhead costs, which can influence the final price of keeper latches.

-

Tooling: The initial setup costs for tooling can be substantial, especially for customized latches. If a buyer requires specific designs, these costs must be factored into the overall pricing.

-

Quality Control (QC): Implementing quality control measures adds to the production costs. Suppliers that prioritize quality assurance may charge more, reflecting their commitment to delivering reliable products.

-

Logistics: Shipping and handling costs are essential considerations, particularly for international buyers. Factors such as shipping distance, mode of transport, and customs duties can significantly affect the total cost.

-

Margin: Finally, suppliers will include their profit margin in the pricing structure. This can vary widely based on the supplier’s market position and the level of competition.

What Influences the Pricing of Keeper Latches?

Several factors influence the pricing of keeper latches, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their needs to optimize costs.

-

Specifications and Customization: Custom designs or specific material requirements can drive up costs. Buyers should clearly define their needs to avoid unexpected price increases.

-

Quality and Certifications: Latches that meet specific quality standards or certifications (like ISO or CE marks) may command higher prices. Buyers should assess the importance of these certifications relative to their applications.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers with a history of quality may charge a premium, while new entrants might offer lower prices to gain market share.

-

Incoterms: Understanding shipping terms (Incoterms) is crucial for international transactions. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect the total landed cost of the products.

What Tips Can Help Buyers Optimize Costs in Keeper Latch Sourcing?

-

Negotiation Strategies: Buyers should approach negotiations with a clear understanding of their needs and market prices. Being informed about material costs and supplier margins can provide leverage during discussions.

-

Focus on Total Cost of Ownership (TCO): Instead of solely considering the purchase price, buyers should assess the long-term costs associated with maintenance, durability, and potential replacements. This approach often reveals that investing in higher-quality latches can lead to significant savings over time.

-

Understand Pricing Nuances for International Transactions: International buyers should be aware of currency fluctuations, import taxes, and tariffs that may affect final costs. Building relationships with local suppliers can also mitigate some logistical costs.

-

Explore Multiple Suppliers: Engaging with various suppliers allows buyers to compare quotes and terms, fostering a competitive environment that can lead to better pricing.

Disclaimer on Indicative Prices

Prices for keeper latches can vary widely based on the factors discussed above. The figures mentioned in this analysis are indicative and may not reflect current market conditions. Buyers are encouraged to conduct thorough market research and obtain multiple quotes to ensure accurate pricing for their specific needs.

Alternatives Analysis: Comparing keeper latch With Other Solutions

Exploring Alternatives to Keeper Latch Solutions

In the realm of hardware solutions for doors and compartments, the keeper latch is a widely utilized option. However, businesses may find themselves exploring alternatives that can offer unique advantages tailored to their specific needs. Here, we will compare the keeper latch with two viable alternatives: the sliding bolt latch and the deadbolt lock.

Comparison Table

| Comparison Aspect | Keeper Latch | Sliding Bolt Latch | Deadbolt Lock |

|---|---|---|---|

| Performance | Reliable for light to medium use | Provides strong security | High security, resistant to forced entry |

| Cost | Typically low-cost (approx. $10-$30) | Moderate cost (approx. $15-$50) | Higher cost (approx. $30-$100) |

| Ease of Implementation | Simple installation, minimal tools required | Requires additional alignment for optimal function | May need professional installation |

| Maintenance | Low maintenance, occasional lubrication | Moderate maintenance, check alignment regularly | Low maintenance, but may require rekeying |

| Best Use Case | Interior doors, office partitions | Exterior doors, storage units | Main entry points, high-security areas |

Detailed Breakdown of Alternatives

1. Sliding Bolt Latch

The sliding bolt latch is a straightforward mechanism that slides a bolt into a receptacle, securing the door. This type of latch offers robust security, making it ideal for exterior doors and storage units. The primary advantage of a sliding bolt latch is its strength; it can withstand significant force, providing peace of mind for businesses requiring enhanced security. However, the installation can be slightly more complicated, as it requires precise alignment. Additionally, its cost is generally higher than that of a keeper latch, which may be a consideration for budget-conscious buyers.

2. Deadbolt Lock

Deadbolt locks are synonymous with security and are often the preferred choice for main entry points. They provide superior resistance against forced entry, making them suitable for businesses with high-value assets. While the performance of a deadbolt is unmatched in terms of security, the cost can be significantly higher than both the keeper latch and sliding bolt latch. Installation may also require professional help, which can further increase upfront expenses. Maintenance is relatively low, but rekeying may be necessary if security is compromised. This option is best for businesses that prioritize security over cost.

Conclusion: How to Choose the Right Solution for Your Business

When selecting between a keeper latch and its alternatives, B2B buyers should consider their specific security needs, budget constraints, and the context in which the latch will be used. If the primary requirement is cost-effectiveness and ease of installation, a keeper latch is an excellent choice. Conversely, for businesses needing enhanced security, investing in a sliding bolt latch or deadbolt lock may be warranted. Understanding the unique advantages and limitations of each option will empower buyers to make informed decisions that align with their operational needs and security requirements.

Essential Technical Properties and Trade Terminology for keeper latch

What Are the Key Technical Properties of a Keeper Latch?

When sourcing keeper latches, understanding their technical properties is crucial for ensuring compatibility, durability, and performance. Here are some essential specifications to consider:

Material Grade

The material of a keeper latch significantly impacts its strength, corrosion resistance, and overall longevity. Common materials include stainless steel, zinc alloy (often referred to as Zamac), and aluminum. Stainless steel is preferred for its high resistance to rust and wear, making it suitable for outdoor and high-humidity environments. Zinc alloys provide good strength at a lower cost but may require a protective coating to prevent corrosion.

Size and Pin Diameter

Keeper latches come in various sizes, with pin diameters typically ranging from 5/8 inches to larger sizes. This specification is critical as it determines compatibility with existing latch systems. B2B buyers should ensure that the pin diameter aligns with their latch requirements to avoid mismatched components, which can lead to installation issues.

Tolerance

Tolerance refers to the allowable deviation from specified dimensions in manufacturing. For keeper latches, a tighter tolerance ensures a better fit, which is essential for security and functionality. Loose tolerances can lead to improper latching, increased wear, and potential failures, making it a key specification to verify during procurement.

Finish

The finish of a keeper latch not only affects aesthetics but also provides additional protection against environmental factors. Common finishes include chrome plating, satin stainless steel, and powder coating. Each finish has different properties in terms of scratch resistance and appearance. For example, chrome plating offers a shiny look but may be less durable in abrasive environments compared to a matte finish.

Load Capacity

The load capacity of a keeper latch indicates the amount of weight it can securely hold when the door is closed. This specification is particularly important in commercial applications where heavy doors or frequent use can stress the latch. Buyers should ensure that the load capacity meets or exceeds the demands of their specific application to maintain safety and functionality.

What Are Common Trade Terminology and Concepts Related to Keeper Latches?

Understanding industry terminology is essential for effective communication and negotiation in B2B transactions. Here are some common terms related to keeper latches:

Illustrative image related to keeper latch

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of keeper latches, an OEM may provide custom latches that fit specific designs or requirements set by the purchasing company. Buyers should clarify if they are dealing with OEM products to ensure they receive components that meet their specifications.

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. This term is crucial for B2B buyers, as it can affect purchasing decisions, particularly for smaller projects or companies with limited budgets. Understanding MOQ helps buyers plan their inventory and budget effectively.

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request price quotes for specific products. In the context of keeper latches, issuing an RFQ can help buyers compare pricing, lead times, and terms from multiple suppliers, facilitating informed decision-making.

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers regarding the delivery of goods. Familiarity with these terms is vital for international B2B transactions involving keeper latches, as they clarify shipping costs, risk transfer, and insurance obligations.

Lead Time

Lead time refers to the period between placing an order and receiving the product. For keeper latches, understanding lead times is essential for project planning and avoiding delays in construction or manufacturing processes. Buyers should inquire about lead times during negotiations to ensure timely delivery.

By grasping these technical properties and industry terms, B2B buyers can make more informed decisions when sourcing keeper latches, ultimately leading to better procurement outcomes and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the keeper latch Sector

What Are the Current Market Dynamics and Key Trends in the Keeper Latch Sector?

The keeper latch sector is currently experiencing a transformative phase driven by several global factors. The increasing demand for secure and reliable locking mechanisms across various industries, including construction, automotive, and commercial furniture, is a key driver. The rise of smart technology is also influencing product development, with more manufacturers integrating electronic and wireless features into traditional latch systems. This shift not only enhances convenience but also aligns with the growing consumer preference for smart home solutions.

Emerging B2B tech trends are reshaping sourcing strategies. For instance, the adoption of advanced manufacturing techniques, such as 3D printing and automation, is enabling companies to reduce lead times and improve customization options. Furthermore, the use of digital platforms for procurement is gaining traction, providing international buyers with access to a broader range of suppliers and products. This trend is particularly relevant for B2B buyers from Africa, South America, the Middle East, and Europe, who are increasingly seeking efficient supply chain solutions to meet local demands.

Geopolitical factors and trade agreements also play a significant role in shaping market dynamics. For example, the European Union’s regulatory frameworks can influence product standards and certifications, impacting sourcing decisions for buyers in Germany and other EU countries. Similarly, buyers in the Middle East, such as those in Saudi Arabia, are adapting to regional regulations that govern product safety and environmental impact, necessitating a keen understanding of local compliance requirements.

How Can Sustainability and Ethical Sourcing Impact the Keeper Latch Supply Chain?

Sustainability is becoming a critical consideration for B2B buyers in the keeper latch sector. The environmental impact of manufacturing processes, particularly the use of non-renewable materials and excessive waste, has prompted many companies to reassess their supply chains. By prioritizing sustainable practices, businesses can not only reduce their carbon footprint but also appeal to a growing base of environmentally conscious consumers.

Ethical sourcing is closely tied to sustainability, emphasizing the importance of transparency and fairness throughout the supply chain. Buyers should seek suppliers who demonstrate a commitment to ethical labor practices, ensuring that their products are made in safe working conditions and without exploitative labor. Certifications such as ISO 14001 for environmental management or Fair Trade certification can serve as indicators of a supplier’s commitment to these values.

Furthermore, the use of ‘green’ materials in the production of keeper latches—such as recycled metals or sustainably sourced plastics—can enhance a company’s brand reputation and align with global sustainability goals. As international buyers increasingly prioritize these factors, suppliers who can demonstrate their sustainability credentials will be better positioned in the competitive landscape.

What Is the Evolution and Historical Context of the Keeper Latch?

The keeper latch has evolved significantly from its rudimentary beginnings. Initially, these mechanisms were simple wooden or metal devices used primarily in residential settings. However, as architectural designs became more complex and the demand for security increased, the keeper latch began to adapt. The introduction of materials like stainless steel and zamac not only improved durability but also offered aesthetic versatility.

In the latter half of the 20th century, the keeper latch saw innovations that incorporated advanced locking mechanisms and finishes, catering to a wider range of applications, including commercial and industrial uses. This evolution has continued into the 21st century, with a notable shift towards integrating technology, such as keyless entry systems and smart latches, reflecting the changing demands of modern consumers.

Today, the keeper latch is not just a functional component; it represents a convergence of security, technology, and design, making it a vital consideration for international B2B buyers looking to enhance the safety and functionality of their offerings.

Frequently Asked Questions (FAQs) for B2B Buyers of keeper latch

-

1. How do I solve compatibility issues when sourcing keeper latches?

To address compatibility concerns, it’s crucial to determine the specifications of the latches you need, including dimensions, pin sizes, and materials. Start by identifying the type of latch system in use, as many keepers are designed to fit specific latch models. Communicating these requirements with potential suppliers can help ensure you receive compatible products. Additionally, requesting samples before making bulk purchases can help you verify compatibility with your existing hardware. -

2. What is the best material for keeper latches in outdoor applications?

For outdoor applications, stainless steel and zinc-plated materials are generally the best choices for keeper latches due to their corrosion resistance and durability. Stainless steel offers superior strength and resistance to rust, making it ideal for environments with high humidity or exposure to the elements. If budget constraints are a concern, consider zinc-plated options, which provide decent protection against corrosion at a lower cost. Always assess the specific environmental conditions where the latches will be installed. -

3. How can I ensure the quality of keeper latches from international suppliers?

To ensure the quality of keeper latches, conduct thorough research on potential suppliers. Look for certifications such as ISO 9001, which indicates adherence to quality management standards. Request references from previous clients and check reviews online. It is also advisable to request product samples for quality assessment before placing a large order. Establishing clear quality assurance criteria in your purchase agreements can further mitigate risks. -

4. What are the typical minimum order quantities (MOQ) for keeper latches?

Minimum order quantities for keeper latches can vary significantly based on the supplier and the specific product. Generally, MOQs can range from as low as 100 units to several thousand. When sourcing, inquire about the MOQ upfront to understand if it aligns with your purchasing capacity. Some suppliers may be flexible on MOQs for repeat customers or larger orders, so it’s beneficial to discuss your needs directly with them. -

5. What payment terms should I negotiate with keeper latch suppliers?

When negotiating payment terms, consider options such as net 30, 60, or 90 days, which allow time for quality inspection and reselling. It’s also advisable to explore partial payments or deposits, especially for large orders, to reduce financial risk. For international transactions, be mindful of currency fluctuations and consider using secure payment methods like letters of credit or escrow services to protect your investment. -

6. How can I customize keeper latches for my specific needs?

Customization options for keeper latches often include variations in size, material, finish, and functionality. To initiate the customization process, clearly outline your requirements to the supplier, including any specific dimensions or design features. Many manufacturers have the capability to produce tailored products, but this may come with additional costs or longer lead times. Ensure you receive prototypes or CAD designs for approval before final production. -

7. What logistics considerations should I keep in mind when importing keeper latches?

When importing keeper latches, consider factors such as shipping costs, lead times, and customs regulations. Work with logistics partners familiar with your target market to navigate import duties and tariffs. Ensure that all documentation, including invoices and certificates of origin, is in order to avoid delays. Additionally, factor in the potential for damaged goods during transit and discuss insurance options with your shipping provider. -

8. How do I handle warranty claims for keeper latches purchased internationally?

Handling warranty claims for internationally sourced keeper latches requires understanding the supplier’s warranty policy. Ensure you have documentation of the purchase, including invoices and correspondence regarding the product specifications. Familiarize yourself with the claims process and any required documentation. Communication is key; maintain a professional relationship with your supplier to facilitate a smoother resolution should any issues arise.

Top 7 Keeper Latch Manufacturers & Suppliers List

1. TPH Supply – Latch Stops and Keepers

Domain: tphsupply.com

Registered: 2008 (17 years)

Introduction: Latch Stops and Keepers are essential components for partition doors, ensuring they remain closed while occupied. A keeper is a metal latch plate that secures the door latch, while a stop (or strike) is a rubber bumper that controls the door closure for the latch to fit into the keeper. The collection includes various products such as:

1. Hadrian Chrome, 1/2 Height Stop & Keeper for Baked Enamel …

2. Bauer – Handle Keeper Latch

Domain: cimarrontrailers.com

Registered: 2001 (24 years)

Introduction: {“product_name”: “Handle Keeper Latch”, “price”: “$50.53”, “brand”: “Bauer”, “replacement_info”: “Will replace older Fastec Brand latches.”, “included_items”: [“key cylinder”, “2 keys”, “all mounting hardware”]}

3. Bunn – KEEPER Door Latch

Domain: commercial.bunn.com

Registered: 1998 (27 years)

Introduction: Product Name: KEEPER, DOOR LATCH

Part Number: 34667.0000

Category: Hardware

Note: Warranty is void if commercial equipment is used for residential or non-commercial use.

4. Spring Creek Products – Generic Latch Keeper

Domain: springcreekproducts.com

Registered: 2008 (17 years)

Introduction: This company, Spring Creek Products – Generic Latch Keeper, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Reliable Hardware – Valance Spanning Latch Accessory

Domain: reliablehardware.com

Registered: 1996 (29 years)

Introduction: This company, Reliable Hardware – Valance Spanning Latch Accessory, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

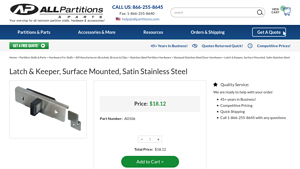

6. AllPartitions – Restroom Stall Door Latch

Domain: allpartitions.com

Registered: 2001 (24 years)

Introduction: {“Product Name”: “Restroom Stall Door Latch: Latch Inswing”, “Price”: “$18.12”, “Part Number”: “A0106”, “Material”: “Satin Stainless Steel”, “Type”: “Surface mounted latch and keeper”, “Compatibility”: “For inswing or outswing doors”, “Related Item”: {“Name”: “Slide latch with ‘Occupied’ Indicator”, “Part Number”: “A6069”, “Price”: “$24”}, “Company Info”: {“Years in Business”: “45+”, “Contact Phon…

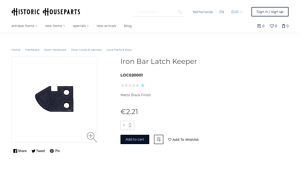

7. Historic House Parts – Iron Bar Latch Keeper

Domain: historichouseparts.com

Registered: 1998 (27 years)

Introduction: This company, Historic House Parts – Iron Bar Latch Keeper, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for keeper latch

As the global market for keeper latches continues to expand, strategic sourcing emerges as a critical component for international B2B buyers. Key takeaways emphasize the importance of selecting high-quality materials and reliable suppliers, ensuring that products meet regional standards and operational needs. The diverse range of options—from chrome-plated zamac to stainless steel—offers buyers the flexibility to choose solutions that align with their specific applications, whether in commercial, industrial, or residential settings.

Investing time in strategic sourcing not only enhances product quality but also fosters long-term relationships with suppliers, which can lead to better pricing and improved service. For buyers in Africa, South America, the Middle East, and Europe, understanding the nuances of local markets and regulations is essential in making informed purchasing decisions.

Looking ahead, embracing innovative sourcing strategies will be vital as market demands evolve. By leveraging technology and data-driven insights, businesses can streamline procurement processes and enhance operational efficiency. Now is the time for international B2B buyers to take proactive steps in their sourcing strategies, ensuring they remain competitive in an ever-changing landscape. Explore your options today and position your business for future success.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.