Top 7 Glowen Clutch Suppliers (And How to Choose)

Introduction: Navigating the Global Market for glowen clutch

As international B2B buyers increasingly seek reliable components for their machinery, sourcing the right glowen clutch can pose significant challenges. Understanding the diverse types, applications, and specifications of glowen clutches is essential for making informed purchasing decisions. This guide comprehensively addresses the critical aspects of the glowen clutch market, covering everything from the various types available, their intended applications, to effective supplier vetting processes and cost considerations.

Navigating the global market for glowen clutches requires an informed approach, particularly for buyers in regions such as Africa, South America, the Middle East, and Europe, including countries like Vietnam and Saudi Arabia. This guide empowers you by providing actionable insights and practical strategies to streamline your procurement process. By delving into the intricacies of product specifications, compatibility issues, and quality benchmarks, you will be better equipped to assess suppliers and negotiate favorable terms.

In an industry where precision and reliability are paramount, having a solid understanding of the glowen clutch landscape not only enhances your purchasing power but also ensures that your investments yield optimal performance and longevity. This guide serves as a valuable resource, enabling you to make strategic decisions that align with your operational needs and business objectives.

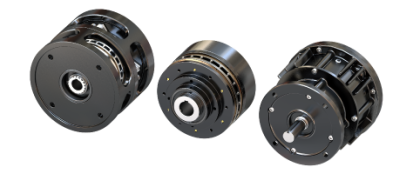

Understanding glowen clutch Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Polaris SOHC PRO Clutch System | Complete system, designed for smooth drivability | Utility vehicles, recreational use | Pros: Enhanced performance; Cons: Higher initial cost. |

| THETA Adjustable Clutch Kit | Customizable weights and springs for tailored performance | Off-road vehicles, racing | Pros: Versatile; Cons: Requires technical knowledge for adjustments. |

| FIRE LINK Primary Clutch | Built for heavy-duty use with extreme durability | Heavy machinery, utility work | Pros: Robust design; Cons: Heavier than standard options. |

| OEM Polaris Turbo Primary Clutch | Latest OEM updates for specific models | OEM replacements | Pros: Direct fit; Cons: Limited to specific models. |

| Torque Monster Clutch Kit | Engineered for maximum belt grip and low-end torque | Heavy-duty vehicles, work vehicles | Pros: Excellent power delivery; Cons: May not suit light applications. |

What are the Key Characteristics of the Polaris SOHC PRO Clutch System?

The Polaris SOHC PRO Clutch System is designed for seamless integration and enhanced performance in utility and recreational vehicles. It focuses on drivability, smoothness, and longevity, making it ideal for businesses that prioritize reliability in demanding environments. B2B buyers should consider the system’s balance and precision engineering, which can lead to reduced maintenance costs over time, though the initial investment may be higher.

How Does the THETA Adjustable Clutch Kit Stand Out?

The THETA Adjustable Clutch Kit offers a customizable solution with adjustable primary clutch weights and springs, enabling businesses to fine-tune their vehicles for optimal performance. This flexibility is particularly beneficial for off-road and racing applications, where varied terrain requires different clutch responses. However, buyers must be prepared for a learning curve, as technical knowledge is necessary for effective adjustments.

What Makes the FIRE LINK Primary Clutch Suitable for Heavy-Duty Use?

The FIRE LINK Primary Clutch is engineered for extreme durability and performance, making it an ideal choice for heavy machinery and utility work. Its robust construction allows it to withstand rigorous conditions, providing B2B buyers with confidence in its longevity. While this clutch excels in demanding scenarios, its weight may be a drawback for applications requiring lighter components.

Why Choose the OEM Polaris Turbo Primary Clutch?

The OEM Polaris Turbo Primary Clutch provides the latest updates directly from the manufacturer, ensuring compatibility with specific models. This option is perfect for businesses looking for reliable OEM replacements that guarantee performance and fit. However, its limited application range may restrict some buyers, particularly those with varied vehicle fleets.

What Advantages Does the Torque Monster Clutch Kit Offer?

The Torque Monster Clutch Kit is specifically designed to deliver maximum belt grip and low-end torque, making it a valuable asset for heavy-duty vehicles and work applications. This clutch kit enhances power delivery, which is essential for businesses that require robust performance under load. However, it may not be suitable for lighter applications, so businesses should assess their specific needs before purchasing.

Key Industrial Applications of glowen clutch

| Industry/Sector | Specific Application of glowen clutch | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Performance upgrades in off-road vehicles | Enhanced drivability, acceleration, and durability | OEM compatibility, performance specifications, and reliability |

| Construction | Utility vehicles for heavy lifting and transport | Increased efficiency and reduced downtime | Load capacity, environmental conditions, and maintenance support |

| Agriculture | Tractors and farming equipment | Improved power transfer and fuel efficiency | Adaptability to different terrains and equipment types |

| Mining | Heavy machinery for ore extraction | Enhanced operational reliability and safety | Compliance with safety regulations and harsh environment durability |

| Recreation | All-terrain vehicles and snowmobiles | Superior handling and performance | Customization options and ease of installation |

How is the glowen clutch used in the automotive industry?

In the automotive sector, particularly for off-road vehicles, the glowen clutch is integral for performance upgrades. It enhances drivability and provides smoother acceleration, which is crucial for navigating rugged terrains. Businesses require clutches that are OEM compatible and offer high-performance specifications. International buyers should consider reliability and the ability of the clutch to withstand extreme conditions, ensuring reduced maintenance costs and increased vehicle longevity.

What role does the glowen clutch play in construction vehicles?

In construction, glowen clutches are vital for utility vehicles that perform heavy lifting and transportation tasks. These clutches improve the efficiency of power transfer, which is essential for reducing downtime during critical operations. Buyers must prioritize load capacity and the ability of the clutch to function in various environmental conditions. Ensuring robust maintenance support is also important for minimizing operational disruptions, especially in remote areas.

How does the glowen clutch enhance agricultural equipment performance?

In agriculture, the glowen clutch is utilized in tractors and other farming equipment to enhance power transfer and fuel efficiency. This application is crucial for ensuring that machinery can operate effectively across diverse terrains. Buyers in this sector need clutches that adapt to different equipment types and are durable enough to handle the rigors of farming. Additionally, international purchasers should be aware of the specific requirements for local agricultural practices to ensure compatibility.

Why is the glowen clutch essential for mining machinery?

The mining industry relies heavily on heavy machinery for ore extraction, where the glowen clutch plays a critical role in enhancing operational reliability and safety. By providing efficient power transfer, it helps reduce the risk of mechanical failures, which can lead to costly downtime. Buyers must consider compliance with safety regulations and the durability of the clutch in harsh environments. This is particularly important for international buyers operating in remote or challenging locations.

In what ways does the glowen clutch improve recreation vehicles?

In the recreational sector, the glowen clutch is commonly found in all-terrain vehicles (ATVs) and snowmobiles, where it significantly enhances handling and overall performance. The ability to customize clutches for specific vehicle models allows businesses to cater to diverse consumer preferences. For international B2B buyers, ease of installation and the availability of customization options are crucial factors in sourcing decisions, ensuring that they can meet the varying demands of the recreational market.

3 Common User Pain Points for ‘glowen clutch’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality Glowen Clutches

The Problem: B2B buyers often struggle to find reliable suppliers who can provide high-quality glowen clutches. This is particularly true for businesses operating in regions where local suppliers may lack the necessary expertise or inventory. Issues such as inconsistent quality, high lead times, and lack of technical support can lead to significant operational delays, impacting productivity and profitability. Buyers may also find themselves overwhelmed by the variety of options available, making it challenging to choose the right product for their specific needs.

The Solution: To effectively source quality glowen clutches, buyers should prioritize establishing relationships with trusted manufacturers or suppliers who specialize in this area. Conduct thorough research to identify suppliers with a solid reputation in the industry, and consider reaching out for references or customer testimonials. Moreover, engaging in direct conversations with suppliers about their production processes, quality control measures, and customer service can provide deeper insights into their reliability. Utilizing platforms such as trade shows or industry-specific online marketplaces can also help buyers connect with reputable manufacturers. Additionally, consider forming strategic partnerships with suppliers that offer not only products but also ongoing support and training, ensuring that you can maximize the performance of your glowen clutches.

Scenario 2: Technical Challenges with Glowen Clutch Installation

The Problem: Another common pain point for B2B buyers is the technical complexity involved in installing glowen clutches. Companies often face difficulties when integrating these components into their existing systems, particularly if their staff lacks the necessary training or experience. Misinstallation can lead to performance issues, increased wear and tear, and ultimately, higher maintenance costs. This scenario is particularly prevalent among businesses in sectors such as automotive and heavy machinery, where the stakes are high for operational efficiency.

The Solution: To mitigate installation challenges, buyers should invest in comprehensive training programs for their staff, focusing specifically on the installation and maintenance of glowen clutches. This could involve collaborating with suppliers to provide on-site training or workshops to enhance their team’s technical skills. Additionally, ensure that all installation manuals and technical documentation are readily available and easily understandable. Consider implementing a peer-review system where experienced technicians can assist less experienced staff during installation. Investing in the right tools and equipment for installation can also streamline the process and reduce the risk of errors. Finally, having a support line or technical assistance from the supplier can prove invaluable if unexpected issues arise during installation.

Scenario 3: Limited Performance Insights and Data

The Problem: B2B buyers often find themselves lacking critical performance insights and data on glowen clutches, which can hinder their ability to make informed decisions. Without access to performance metrics, businesses may struggle to optimize their machinery, leading to inefficiencies and increased operational costs. This is especially relevant in industries where precision and reliability are crucial, such as construction or agriculture, where the performance of machinery directly impacts productivity.

The Solution: To overcome this challenge, buyers should advocate for more transparency from suppliers regarding the performance data of their glowen clutches. This includes requesting detailed specifications, testing results, and case studies that demonstrate how the clutches perform in real-world scenarios. Implementing data analytics tools to monitor the performance of clutches in their operations can provide valuable insights. Additionally, buyers can establish a feedback loop with their teams to gather firsthand experiences and suggestions on how the clutches are performing under various conditions. Collaborating with suppliers to develop tailored performance benchmarks can also help in assessing the effectiveness of the clutches over time, allowing for proactive adjustments and improvements in operational strategies.

Strategic Material Selection Guide for glowen clutch

When selecting materials for the glowen clutch, it is essential to consider the specific performance requirements and operational environments. Below, we analyze four common materials used in clutch manufacturing, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

What are the Key Properties of Aluminum for Glowen Clutches?

Aluminum is widely used in clutch components due to its favorable strength-to-weight ratio and excellent thermal conductivity. It typically has a temperature rating of up to 150°C and is resistant to corrosion, making it suitable for various environments.

Pros: Aluminum is lightweight, which enhances performance by reducing overall vehicle weight. It also provides good machinability, allowing for complex designs and precision manufacturing.

Illustrative image related to glowen clutch

Cons: While aluminum is durable, it can be less effective under high-stress conditions compared to other metals, such as steel. Additionally, its cost can be moderate depending on the alloy used.

Impact on Application: Aluminum is compatible with a variety of media, including oils and fuels, making it versatile for different applications. However, care must be taken in high-temperature scenarios where thermal expansion could affect performance.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial. Buyers in regions like Africa and the Middle East should consider local sourcing options to minimize costs and ensure compliance with regional regulations.

How Does Steel Compare as a Material for Glowen Clutches?

Steel is another common material for clutch systems, known for its high strength and durability. It can withstand higher temperatures and pressures, making it suitable for heavy-duty applications.

Illustrative image related to glowen clutch

Pros: Steel offers excellent wear resistance and can handle extreme conditions, providing longevity and reliability. Its cost is generally lower than aluminum for equivalent performance specifications.

Cons: The weight of steel can be a disadvantage in applications where weight reduction is critical. Additionally, steel is prone to corrosion if not properly treated or coated.

Impact on Application: Steel clutches perform well in high-load environments, making them ideal for off-road and heavy machinery applications. However, they may not be suitable for environments with high exposure to corrosive elements unless adequately protected.

Illustrative image related to glowen clutch

Considerations for International Buyers: Buyers from Europe and South America should ensure that steel components meet local quality standards and certifications, such as ISO and JIS, to ensure product reliability and safety.

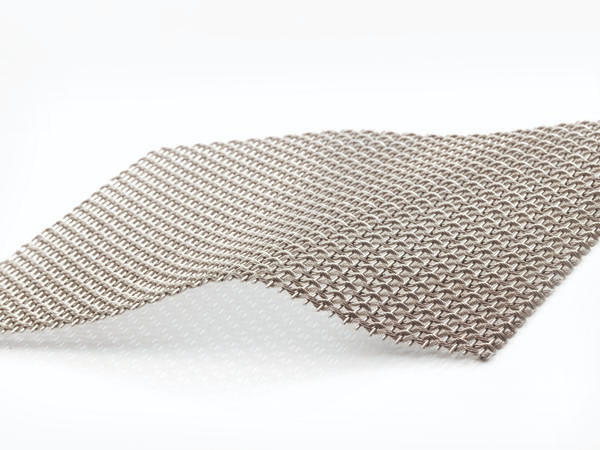

What Role Does Composite Material Play in Glowen Clutch Design?

Composite materials, particularly those reinforced with fibers, are increasingly being used in clutch systems due to their lightweight and high strength characteristics.

Pros: Composites can significantly reduce weight while maintaining strength, making them ideal for performance applications. They also exhibit excellent resistance to wear and thermal expansion.

Cons: The manufacturing process for composites can be complex and costly, which may affect the overall price of the clutch. Additionally, they may have limitations in terms of temperature resistance compared to metals.

Impact on Application: Composites are particularly effective in applications requiring high performance and low weight, such as in racing or high-performance vehicles. However, they may not be suitable for all environments, especially those with extreme temperatures.

Considerations for International Buyers: Buyers should be aware of the specific manufacturing standards for composites in their regions. Compliance with ASTM and other international standards is crucial to ensure product integrity.

Illustrative image related to glowen clutch

Why is Plastic Used in Some Glowen Clutch Applications?

Certain plastic materials, such as nylon or polyamide, are used in specific clutch components due to their lightweight and good wear resistance.

Pros: Plastics are highly resistant to corrosion and can be manufactured at a lower cost. They are also lightweight, which can improve overall vehicle performance.

Cons: Plastics typically have lower temperature and pressure ratings compared to metals, which can limit their application in high-stress environments. They may also degrade over time when exposed to certain chemicals.

Illustrative image related to glowen clutch

Impact on Application: Plastic components are well-suited for applications where weight savings and corrosion resistance are prioritized. However, they may not perform well in high-load or high-temperature situations.

Considerations for International Buyers: Buyers should ensure that plastic materials comply with relevant standards and regulations in their regions, particularly in terms of chemical resistance and durability.

Summary Table of Material Selection for Glowen Clutch

| Material | Typical Use Case for glowen clutch | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight clutches for performance vehicles | Excellent strength-to-weight ratio | Less effective under high stress | Medium |

| Steel | Heavy-duty clutches for off-road applications | High strength and durability | Heavier, prone to corrosion | Low |

| Composite | High-performance racing clutches | Lightweight with high strength | Complex manufacturing process | High |

| Plastic | Low-load applications, corrosion-resistant parts | Cost-effective and lightweight | Lower temperature ratings | Low |

This strategic material selection guide should assist international B2B buyers in making informed decisions regarding the material choices for glowen clutches, ensuring optimal performance and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for glowen clutch

What Are the Main Stages of Manufacturing a Glowen Clutch?

The manufacturing of a glowen clutch involves several critical stages, each designed to ensure performance, reliability, and durability. The main stages include material preparation, forming, assembly, and finishing.

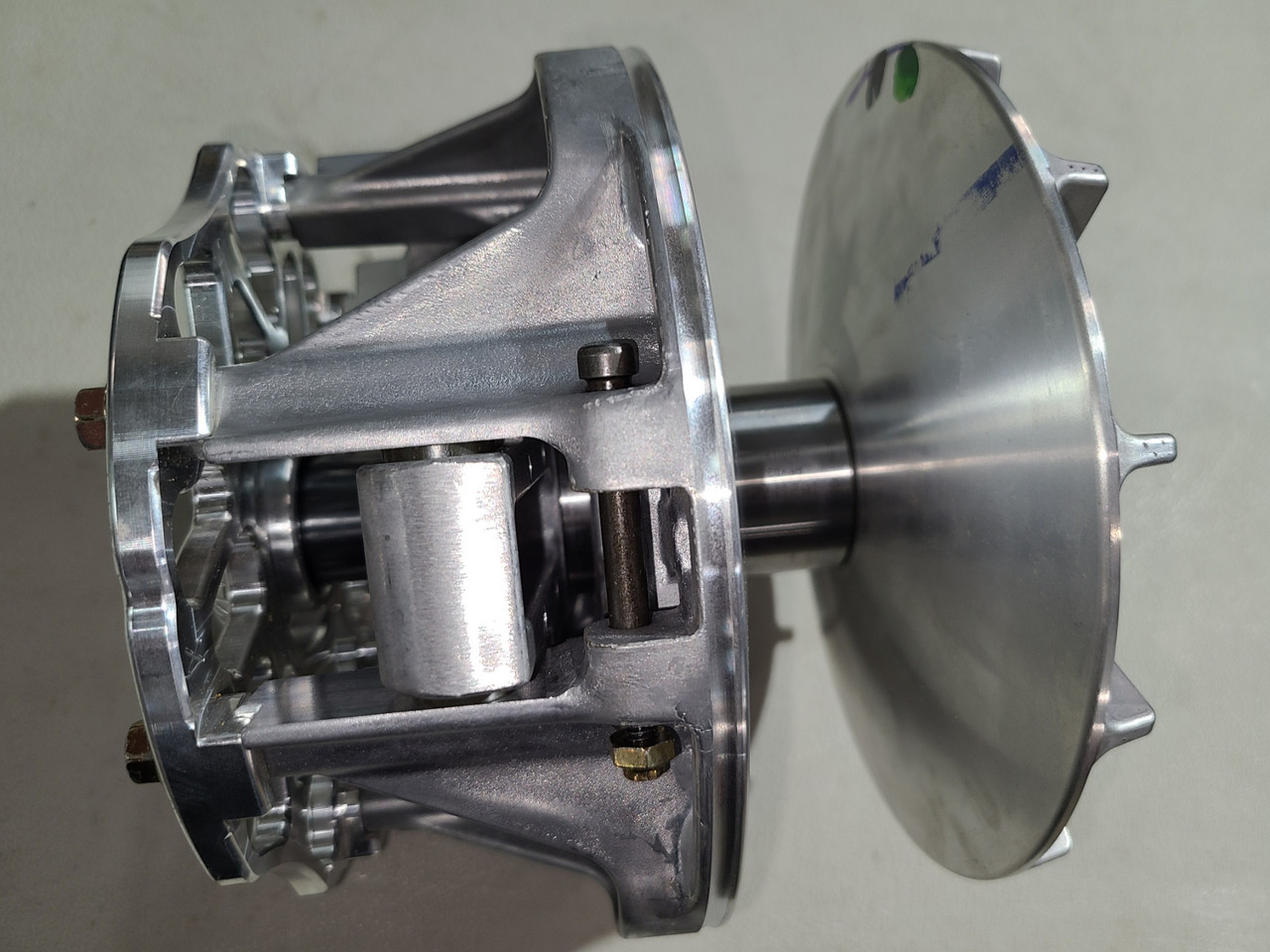

How Is Material Prepared for the Production of Glowen Clutches?

Material preparation is the first step in manufacturing glowen clutches. High-quality raw materials, such as aluminum alloys and advanced composites, are selected based on their mechanical properties, weight, and resistance to wear and tear. These materials undergo rigorous testing to confirm their suitability for clutch applications. This may include tensile strength tests and fatigue testing to ensure they can withstand the operational stresses of high-performance vehicles.

Illustrative image related to glowen clutch

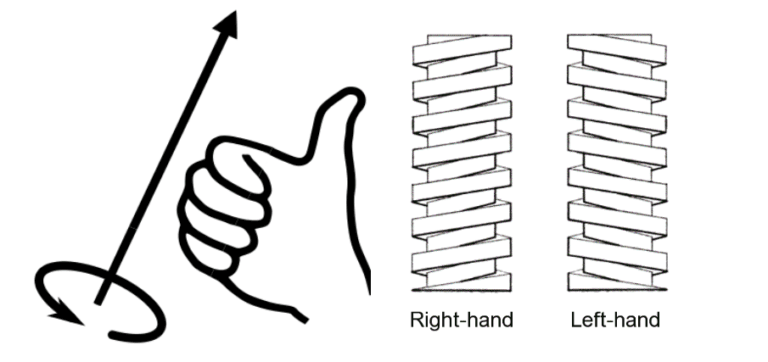

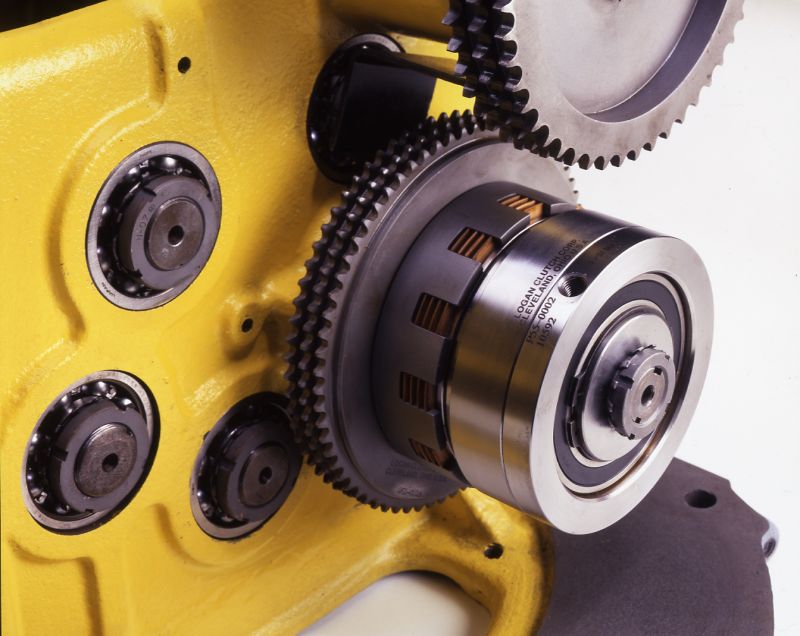

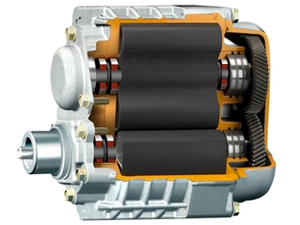

What Forming Techniques Are Used in Glowen Clutch Manufacturing?

Once the materials are prepared, they proceed to the forming stage. This typically involves processes such as forging, machining, and die-casting. Forging is often employed to create a strong, lightweight structure, while machining is used to achieve precise dimensions and tolerances essential for optimal performance. Advanced CNC machines ensure that every component fits perfectly, reducing wear and enhancing efficiency. Techniques like heat treatment may also be applied to increase the hardness and durability of specific components, particularly those subjected to high stress.

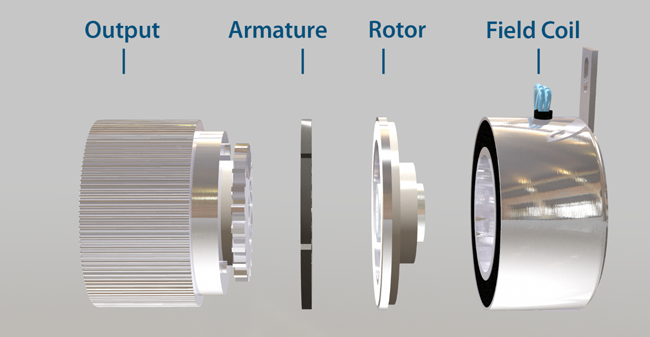

How Are Glowen Clutches Assembled?

The assembly stage follows forming, where various components of the glowen clutch are brought together. This includes the primary and secondary clutch assemblies, springs, and weights. The assembly process is often automated to ensure precision and consistency. Each component is meticulously inspected during assembly to ensure it meets quality standards. For instance, the alignment of the clutch plates is critical for proper engagement and disengagement, which directly affects drivability and performance.

What Finishing Processes Are Applied to Glowen Clutches?

Finishing processes enhance the appearance and functional properties of the glowen clutch. This may involve surface treatments such as anodizing or coating to improve corrosion resistance and reduce friction. Additionally, balancing and truing processes are performed to ensure smooth operation at various speeds. These finishing touches not only contribute to the aesthetic appeal but also significantly enhance the longevity and reliability of the clutch in demanding environments.

How Is Quality Assurance Implemented in Glowen Clutch Production?

Quality assurance is a cornerstone of the manufacturing process for glowen clutches. Adhering to international standards such as ISO 9001 ensures that processes meet strict quality management criteria. This commitment to quality is crucial for B2B buyers seeking reliable performance in their products.

Illustrative image related to glowen clutch

What International Standards Are Relevant for Glowen Clutch Quality Control?

Manufacturers often comply with various international standards to ensure product safety and reliability. ISO 9001 focuses on quality management systems, while CE marking indicates conformity with European health, safety, and environmental protection standards. For clutches used in specific applications, compliance with API (American Petroleum Institute) standards may also be relevant, especially for those used in automotive and industrial applications.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

To maintain high standards, multiple quality control checkpoints are integrated into the manufacturing process:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Quality checks are performed at various stages of production to identify and rectify issues before they escalate.

- Final Quality Control (FQC): The finished products undergo rigorous testing, which may include performance tests and dimensional checks, ensuring they meet all functional requirements.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial. Here are some effective strategies:

What Audits and Reports Can B2B Buyers Request?

Buyers should request comprehensive quality management reports, including audit results from third-party inspections. These audits provide insights into the supplier’s adherence to quality standards and highlight areas for improvement. Regular audits also demonstrate a supplier’s commitment to maintaining quality over time.

Illustrative image related to glowen clutch

How Do Third-Party Inspections Enhance Quality Assurance?

Engaging third-party inspection services can further assure buyers of product quality. These services offer unbiased assessments of the manufacturing process and product quality, allowing buyers to make informed decisions. Third-party inspectors often have the expertise to identify potential issues that internal teams may overlook.

What Nuances Should International B2B Buyers Consider Regarding Quality Control?

International B2B buyers must be aware of the nuances in quality control specific to their regions. For instance, varying regulations and standards may affect product compliance and safety requirements. Buyers should familiarize themselves with local regulations and how they align with international standards to ensure that the products they import meet all necessary criteria.

Additionally, cultural differences in business practices can influence how quality control is perceived and implemented. Buyers should establish clear communication with suppliers regarding quality expectations and compliance requirements. Building strong relationships with suppliers can facilitate better quality assurance practices and ensure consistent product delivery.

Illustrative image related to glowen clutch

Conclusion

Understanding the manufacturing processes and quality assurance practices of glowen clutches is essential for B2B buyers looking to source reliable components. By focusing on material preparation, forming, assembly, and finishing, alongside rigorous quality control measures, manufacturers can deliver products that meet the demanding needs of international markets. Buyers are encouraged to actively engage in verifying supplier practices to ensure they receive high-quality products that comply with international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘glowen clutch’

Introduction

Sourcing the right glowen clutch is vital for ensuring optimal performance in your machinery. This step-by-step checklist is designed to guide B2B buyers through the procurement process, helping you make informed decisions that align with your operational needs and quality standards. By following these steps, you can streamline your sourcing efforts and secure the best products for your business.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of a successful sourcing process. Identify the specific requirements of the glowen clutch you need, such as size, weight capacity, and compatibility with existing equipment. This clarity will help you communicate effectively with suppliers and ensure that the products meet your operational demands.

- Consider Performance Needs: Assess the load and performance requirements of your machinery to determine the necessary specifications.

- Compatibility Check: Ensure that the clutch is compatible with your existing systems to avoid costly modifications.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers of glowen clutches. Utilize industry-specific directories, trade shows, and online platforms to compile a list of reputable manufacturers and distributors. This step is crucial for building a pool of suppliers that meet your quality and service expectations.

- Review Supplier Backgrounds: Look for suppliers with a strong track record in the industry and positive customer feedback.

- Assess Market Reach: Consider suppliers that have experience in your region, as they may better understand local regulations and market conditions.

Step 3: Evaluate Supplier Certifications

Before making a commitment, verify the certifications and standards of potential suppliers. Certifications such as ISO, CE, or industry-specific endorsements indicate a supplier’s adherence to quality and safety standards. This evaluation helps mitigate risks associated with product quality and compliance.

- Request Documentation: Ask suppliers for copies of their certifications and quality management systems.

- Check Compliance History: Investigate any past compliance issues that could impact product reliability.

Step 4: Request Samples for Testing

Once you’ve shortlisted suppliers, request samples of the glowen clutches for testing. Evaluating the product firsthand allows you to assess its quality, durability, and performance under real-world conditions. This step is essential for ensuring that the product meets your operational standards before placing a bulk order.

- Conduct Rigorous Testing: Test the samples in the actual working conditions to evaluate performance.

- Gather Feedback from Technicians: Involve your technical team in the testing process to gain insights into usability and functionality.

Step 5: Negotiate Terms and Pricing

Negotiating favorable terms and pricing is crucial for maximizing your procurement budget. Discuss payment terms, delivery schedules, and warranty conditions with your chosen supplier. A well-negotiated agreement can lead to cost savings and improved supply chain efficiency.

- Consider Long-Term Relationships: Explore opportunities for volume discounts or long-term contracts, which can provide additional savings.

- Clarify Warranty and Support: Ensure that you understand the warranty terms and after-sales support offered by the supplier.

Step 6: Finalize the Order and Monitor Delivery

After finalizing the terms, place your order and closely monitor the delivery process. Maintain communication with the supplier to address any potential delays or issues. Effective delivery management ensures that you receive your glowen clutches on time, minimizing disruptions to your operations.

Illustrative image related to glowen clutch

- Track Shipment Progress: Use tracking tools to stay updated on the shipment status.

- Prepare for Receipt: Ensure that your facility is ready to receive the products and that inspection protocols are in place.

Step 7: Evaluate Performance Post-Purchase

Once the glowen clutches are in use, evaluate their performance regularly. Gather feedback from your team to assess whether the products meet your expectations. Continuous evaluation helps identify any issues early and informs future sourcing decisions.

- Document Performance Metrics: Keep track of operational efficiency and any maintenance needs.

- Solicit User Feedback: Regularly engage with your team to gather insights on performance and areas for improvement.

By following these steps, B2B buyers can ensure a comprehensive and effective sourcing process for glowen clutches, leading to improved operational efficiency and product reliability.

Comprehensive Cost and Pricing Analysis for glowen clutch Sourcing

What Are the Key Cost Components in Sourcing Glowen Clutches?

When evaluating the cost structure for sourcing glowen clutches, several critical components come into play. The primary cost elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the supplier’s profit margin.

-

Materials: The selection of raw materials significantly impacts the cost. High-quality materials that enhance durability and performance may raise initial expenses but can lead to lower maintenance costs in the long run.

-

Labor: Labor costs vary by region and skill level. Countries with a robust manufacturing workforce, such as Vietnam, may offer competitive rates, while regions with higher labor costs could reflect this in the pricing.

-

Manufacturing Overhead: This includes expenses related to utilities, rent, and equipment. Efficient production processes can minimize overhead, contributing to a more favorable cost structure.

-

Tooling: Custom tooling for specific clutch designs can be a substantial upfront investment. Buyers should consider these costs when assessing overall pricing.

-

Quality Control: Ensuring quality through rigorous QC processes can increase costs but is essential for minimizing defects and enhancing product reliability.

-

Logistics: Shipping and handling costs can vary widely, especially for international buyers. Factors such as shipping distance, mode of transport, and customs duties play a crucial role.

-

Margin: Supplier margins can fluctuate based on market competition and demand. Understanding the typical margins in the industry can aid in negotiation.

How Do Price Influencers Affect Glowen Clutch Costs?

Various price influencers can significantly affect the overall cost of glowen clutches. Key factors include:

Illustrative image related to glowen clutch

-

Volume and Minimum Order Quantity (MOQ): Suppliers often provide discounts for bulk purchases. Buyers should negotiate favorable terms based on their projected needs to achieve cost efficiencies.

-

Specifications and Customization: Custom features, such as specific performance metrics or design alterations, can lead to increased costs. Buyers should balance the need for customization with budget constraints.

-

Materials and Quality Certifications: High-quality materials and certifications (like ISO standards) can lead to higher initial costs but may result in lower total cost of ownership due to enhanced durability and reduced failure rates.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium, but their consistency can justify the cost.

-

Incoterms: The terms of shipping (Incoterms) dictate responsibilities and risks. Understanding these can help buyers avoid unexpected costs related to shipping and customs.

What Tips Can Help Buyers Optimize Costs in Glowen Clutch Sourcing?

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, can leverage several strategies to optimize costs when sourcing glowen clutches:

-

Negotiation Strategies: Engaging in thorough negotiations can yield better pricing and terms. Buyers should be prepared with market data to support their position during discussions.

-

Focus on Total Cost of Ownership (TCO): Rather than concentrating solely on the purchase price, consider the TCO, which includes maintenance, operational efficiency, and the lifespan of the product. This holistic view can lead to more informed purchasing decisions.

-

Understanding Pricing Nuances: Be aware of regional pricing differences and factors that may influence costs, such as tariffs or local economic conditions. This knowledge can empower buyers to make strategic sourcing decisions.

-

Supplier Relationships: Building strong relationships with suppliers can lead to better service and pricing. Long-term partnerships often result in preferential treatment and pricing advantages.

Disclaimer on Indicative Prices

The prices referenced in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough market research and supplier assessments to obtain the most accurate and current pricing information.

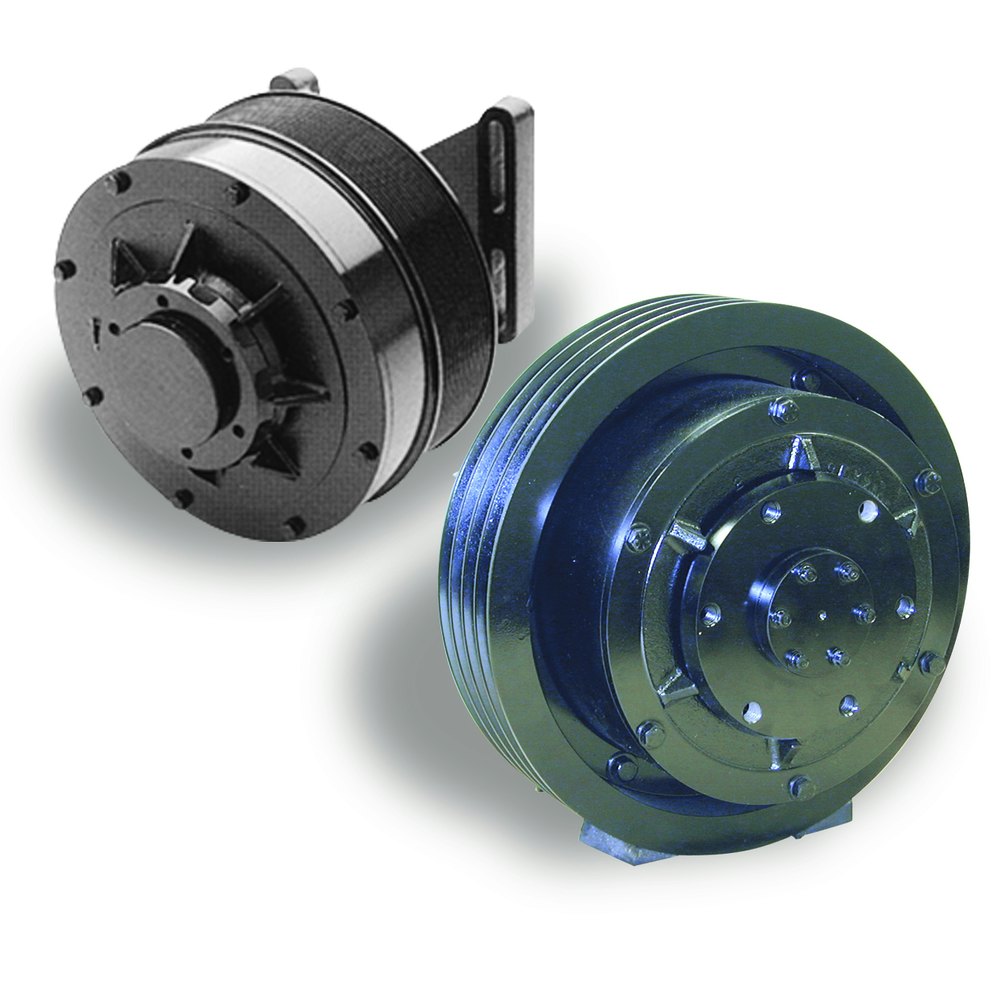

Alternatives Analysis: Comparing glowen clutch With Other Solutions

When evaluating the options for clutch systems, it is essential for B2B buyers to understand the landscape of available solutions. The ‘Glowen Clutch’ stands as a robust choice, but several alternatives exist that may better suit specific operational needs or budget constraints. This analysis will compare the Glowen Clutch with two viable alternatives, offering insights into performance, cost, ease of implementation, maintenance, and ideal use cases.

Illustrative image related to glowen clutch

| Comparison Aspect | Glowen Clutch | Duraclutch System | Polaris OEM Clutch |

|---|---|---|---|

| Performance | High durability and smooth operation | Enhanced torque transfer, suitable for heavy-duty applications | Reliable but may lack advanced features |

| Cost | $1,725.00 | $1,190.00 | $699.00 |

| Ease of Implementation | Easy to install with plug-and-play design | Requires specific installation knowledge | Straightforward installation, OEM fit |

| Maintenance | Low maintenance needs | Moderate, periodic checks required | Low, typical OEM maintenance |

| Best Use Case | Performance-focused applications | Heavy-duty utility work and off-road use | Standard utility vehicles, budget-conscious buyers |

What Are the Advantages and Disadvantages of the Duraclutch System Compared to Glowen Clutch?

The Duraclutch System is designed for heavy-duty applications, offering enhanced torque transfer and performance under strenuous conditions. One of its standout features is its adaptability to various terrains, making it ideal for utility work and off-road vehicles. However, it does require more specialized knowledge for installation, which could lead to additional labor costs. While it is priced lower than the Glowen Clutch, the trade-off may involve a more complex maintenance routine to ensure optimal performance.

How Does the Polaris OEM Clutch Stack Up Against Glowen Clutch?

The Polaris OEM Clutch is an excellent choice for buyers looking for a reliable, cost-effective solution. At a significantly lower price point of $699.00, it provides decent performance for standard utility vehicles. Its straightforward installation process is a plus for companies with limited technical expertise. However, it may not deliver the same level of performance or longevity as the Glowen Clutch, particularly in demanding environments. Buyers who prioritize cost savings over advanced features may find this option appealing.

How Should B2B Buyers Decide on the Best Clutch Solution for Their Needs?

Selecting the right clutch system requires a careful assessment of operational requirements and budget constraints. Buyers should consider the specific application of the vehicle, the expected load and terrain, and maintenance capabilities. For high-performance needs, the Glowen Clutch may be the best fit despite its higher price tag. In contrast, if budget is a significant concern and the application is standard, the Polaris OEM Clutch might be more suitable. Meanwhile, the Duraclutch System serves as an excellent middle-ground for those needing robust performance without fully committing to the premium price of the Glowen Clutch. Ultimately, aligning the choice with the operational goals will yield the best return on investment.

Illustrative image related to glowen clutch

Essential Technical Properties and Trade Terminology for glowen clutch

What Are the Key Technical Properties of a Glowen Clutch?

When considering a glowen clutch, understanding its technical properties is crucial for B2B buyers. These properties not only affect performance but also influence durability and application suitability.

1. Material Grade

The material grade of a glowen clutch typically refers to the type of metals or composites used in its construction. High-grade materials such as aluminum alloys or hardened steels are commonly employed to enhance strength and reduce weight. In a B2B context, selecting a clutch made from superior materials can lead to increased longevity and improved performance, reducing replacement costs over time.

2. Tolerance Levels

Tolerance levels indicate the acceptable limits of variation in dimensions during manufacturing. For clutches, tight tolerances ensure a precise fit, which is essential for optimal performance and efficiency. In B2B transactions, understanding tolerance specifications can aid buyers in assessing compatibility with existing systems, minimizing operational disruptions.

3. Weight and Balance

The weight and balance of a glowen clutch are critical for performance, particularly in applications requiring quick acceleration or high torque. A well-balanced clutch reduces vibration and wear, enhancing the overall reliability of the machinery it operates within. Buyers should consider these factors to ensure that the clutch meets the demands of their specific applications.

4. Engagement RPM

The engagement RPM (Revolutions Per Minute) denotes the engine speed at which the clutch begins to engage. This specification is vital for applications requiring rapid acceleration or specific performance characteristics. For B2B buyers, understanding the engagement RPM helps in selecting a clutch that aligns with the operational needs of their machinery.

5. Load Capacity

Load capacity refers to the maximum amount of force or weight the clutch can handle without failure. This property is particularly important in heavy-duty applications. Buyers need to ensure that the chosen clutch can accommodate their machinery’s load requirements to avoid premature failure and costly downtimes.

What Are Common Trade Terminology and Jargon Related to Glowen Clutches?

Familiarizing yourself with industry-specific terminology can enhance communication and streamline procurement processes for glowen clutches.

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand name. In the context of glowen clutches, OEM parts are designed to meet the specific standards and specifications of the original equipment. For B2B buyers, using OEM parts can ensure compatibility and maintain warranty coverage.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers, as it affects inventory management and cost-effectiveness. Suppliers may set MOQs based on production runs or material costs, so buyers should assess their needs accordingly.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and terms for specific goods. In the context of glowen clutches, submitting an RFQ can help buyers compare prices and negotiate better terms. This process is crucial for ensuring that the procurement aligns with budgetary constraints.

4. Incoterms (International Commercial Terms)

Incoterms are a series of international sales terms that define the responsibilities of buyers and sellers in the shipping process. Familiarity with Incoterms helps B2B buyers understand shipping costs, risk management, and the logistics involved in acquiring glowen clutches from different regions.

5. Aftermarket Parts

Aftermarket parts are components made by a third-party manufacturer, often designed to replace OEM parts. While they can be more cost-effective, it is crucial for buyers to assess their quality and compatibility with existing systems. Understanding the difference between OEM and aftermarket parts can influence purchasing decisions and warranty considerations.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when purchasing glowen clutches, ensuring they select the right components for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the glowen clutch Sector

What Are the Current Market Dynamics and Key Trends in the Glowen Clutch Sector?

The global glowen clutch market is currently experiencing significant growth driven by advancements in technology and increasing demand for high-performance vehicles. The rise of electric vehicles (EVs) and hybrid systems is reshaping the landscape, as manufacturers seek efficient and durable clutch systems that can handle varied torque demands. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe increasingly focus on performance and reliability, suppliers must adapt to these evolving requirements.

Key trends include a shift towards customizable solutions, where buyers are looking for clutches that can be tailored to specific performance parameters. This customization trend is further fueled by the growing popularity of off-road vehicles and motorsport applications, especially in regions with rugged terrains like Saudi Arabia and South America. Additionally, the integration of digital technologies such as IoT for predictive maintenance is becoming prevalent, allowing buyers to monitor clutch performance and reduce downtime.

Moreover, sustainability is emerging as a critical factor in the sourcing process. Buyers are increasingly seeking suppliers who adhere to ethical manufacturing practices and offer products that minimize environmental impact. This trend aligns with global regulations aimed at reducing emissions and promoting eco-friendly manufacturing processes.

How Is Sustainability Shaping Ethical Sourcing in the Glowen Clutch Sector?

Sustainability and ethical sourcing are becoming paramount in the glowen clutch sector as international buyers place greater emphasis on environmental responsibility. The manufacturing of clutches can have a significant ecological footprint, from resource extraction to production waste. Therefore, buyers are increasingly scrutinizing their supply chains to ensure that they partner with manufacturers who prioritize sustainable practices.

Green certifications, such as ISO 14001 for environmental management, are becoming essential for suppliers aiming to attract international B2B buyers. These certifications not only demonstrate compliance with environmental regulations but also signal a commitment to reducing waste and energy consumption. Furthermore, the use of eco-friendly materials, such as recycled metals and sustainable composites, is gaining traction among manufacturers looking to appeal to environmentally conscious buyers.

Illustrative image related to glowen clutch

Ethical sourcing also encompasses fair labor practices and transparency within the supply chain. Buyers are now more inclined to work with suppliers who provide clear documentation of their sourcing practices and can demonstrate a commitment to ethical labor standards. This focus on sustainability and ethics not only enhances brand reputation but also aligns with the values of consumers in key markets across Africa, South America, and Europe.

How Has the Glowen Clutch Sector Evolved Over Time?

The evolution of the glowen clutch sector reflects broader changes in the automotive industry, driven by technological advancements and shifting consumer preferences. Initially, clutches were primarily designed for basic functionality, focusing on durability and cost-effectiveness. However, as vehicles have become more complex, the demand for high-performance clutches that enhance drivability and efficiency has surged.

Over the past two decades, innovations such as adjustable clutch systems and lightweight materials have transformed the market, allowing for improved performance in various applications, from recreational vehicles to heavy-duty machinery. The rise of motorsports and off-road driving has further propelled the development of specialized clutch systems designed for extreme conditions.

Today, the market is characterized by a diverse range of products tailored to meet specific needs, with a growing emphasis on sustainability and ethical practices. As international B2B buyers continue to seek out advanced, reliable, and environmentally friendly solutions, the glowen clutch sector is poised for further innovation and expansion.

Frequently Asked Questions (FAQs) for B2B Buyers of glowen clutch

-

How do I choose the right glowen clutch for my vehicle?

Choosing the right glowen clutch involves understanding your vehicle’s specifications and intended use. Start by reviewing the compatibility of the clutch with your vehicle model, considering factors like engine type and performance requirements. Additionally, assess the clutch’s material and design features, such as balance and durability, to ensure optimal performance. Consulting with suppliers for recommendations based on your specific application—be it utility, racing, or off-road—can also provide valuable insights. -

What are the key features to look for in a glowen clutch?

When evaluating a glowen clutch, prioritize features such as build quality, material composition, and performance specifications. A high-quality clutch should offer excellent drivability, smooth engagement, and longevity. Look for clutches that are balanced and trued, as these attributes enhance performance and reduce wear. Additionally, consider adjustable components that allow for customization based on driving conditions or personal preferences. -

What is the minimum order quantity (MOQ) for glowen clutches?

The minimum order quantity (MOQ) for glowen clutches can vary significantly based on the supplier and specific product line. Generally, MOQs can range from a few units for smaller suppliers to larger quantities for manufacturers. It’s essential to communicate with your supplier to determine their MOQ policies, as negotiating lower quantities may be possible for first-time orders or long-term partnerships. -

What payment terms should I expect when purchasing glowen clutches internationally?

Payment terms for international purchases of glowen clutches typically include options like advance payment, letter of credit, or net 30/60 days. Suppliers may request a deposit upfront, especially for custom orders, with the remaining balance due upon shipment or delivery. Always confirm payment terms before finalizing your order to avoid misunderstandings, and consider using secure payment methods to protect your transaction. -

How do I vet a supplier of glowen clutches for quality assurance?

Vetting a supplier for glowen clutches involves several steps. First, check their industry reputation through reviews, testimonials, and case studies. Request certifications or quality assurance documents, such as ISO standards, that demonstrate their commitment to quality. Additionally, consider visiting the supplier’s facility if possible or asking for references from previous clients to assess their reliability and production capabilities. -

What logistics considerations should I keep in mind when importing glowen clutches?

When importing glowen clutches, consider logistics factors such as shipping methods, customs duties, and delivery timelines. Assess whether air or sea freight is more suitable based on your urgency and budget. Ensure all necessary documentation, including invoices and packing lists, is prepared for customs clearance. Collaborating with a reliable freight forwarder can streamline this process and help navigate international shipping regulations. -

Can I customize glowen clutches for specific applications?

Many suppliers offer customization options for glowen clutches to meet specific application needs. Customizations may include adjustments in weight, spring rates, or even the overall design to enhance performance characteristics. Discuss your requirements with the supplier, including any performance goals or environmental conditions the clutch will face, to ensure the final product aligns with your operational needs. -

What warranty options are typically available for glowen clutches?

Warranty options for glowen clutches can vary by supplier but generally cover manufacturing defects and performance issues. It’s important to inquire about the warranty duration and the conditions under which it applies. Some suppliers may offer extended warranties for an additional cost, while others may have specific usage requirements that could affect warranty validity. Always read the warranty policy carefully to understand your rights and responsibilities.

Top 7 Glowen Clutch Manufacturers & Suppliers List

1. Gilomen Innovations – Free Delivery & Easy Returns

Domain: gilomeninnovations.com

Registered: 2007 (18 years)

Introduction: This company, Gilomen Innovations – Free Delivery & Easy Returns, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Gilomen – Clutch Kit for Polaris Ranger

Domain: rangerforums.net

Registered: 2005 (20 years)

Introduction: Gilomen clutch kit for Polaris Ranger; designed for improved performance; compatible with 2022 Ranger 1000 premium Crew SOHC; options include “Fuel Saver” clutch kit with fixed weights and primary spring; enhances low RPM power, torque, and acceleration; reported improvements in fuel efficiency, achieving up to 20.8 MPG; recommended for various riding conditions including farm, utility, and leisur…

3. Gilomen Innovations – Turbo Upgrade Primary Clutch

Domain: digrigpowersports.com

Registered: 2018 (7 years)

Introduction: {“product_name”: “Gilomen Innovations – Turbo Upgrade Primary Clutch”, “model”: “RZR Turbo 2016”, “price”: “$750.00”, “sku”: “GI-1185”, “shipping”: “Free Shipping to the lower 48 US States”, “description”: “This is the upgrade primary clutch to replace the weak 2016 clutch. This is the 2017+ design with the newest best components.”, “additional_info”: “You will need to order a clutch kit or use yo…

4. DIY Go Karts – Glowing Clutch Issue

Domain: diygokarts.com

Registered: 2005 (20 years)

Introduction: The discussion revolves around a “glowing clutch” issue experienced by a user after riding a bike. Key points include: 1. The clutch began to glow red after the user attempted to climb a hill at full throttle. 2. The user reported that the bike tries to move without revs, indicating potential clutch failure. 3. The clutch’s brushing melted, leading to further damage. 4. Recommendations were made t…

5. Reddit – Blue Glowing Clutch Claw Guide

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The blue glowing clutch claw can be obtained by equipping specific armor pieces that do not have a clutch claw model. Notable examples mentioned include the Astral layered arms and Dante layered arms, which provide a special claw effect. Other arm pieces like the Oolong arms also have unique claw designs.

6. Kimcig – Color Changing Clutch

Domain: kimcig.com

Registered: 2021 (4 years)

Introduction: {“name”: “Color Changing Clutch in Multi/Gold”, “price”: “$758.00”, “shipping_info”: “Shipping calculated at checkout.”, “features”: [{“handcrafted”: “Yes”}, {“material”: “Transparent acrylic”}, {“design”: “Graphic design”}, {“hardware”: “Polished gold electro-plated”}, {“LED_colors”: [“White”, “Pink”, “Blue”, “Green”]}, {“charging_ports”: “Yes, includes a port for charging the handbag and a USB p…

7. Facebook – Hammerhead Go-Kart 459cc Engine

Strategic Sourcing Conclusion and Outlook for glowen clutch

How Can Strategic Sourcing Enhance Your Procurement of Glowen Clutches?

In conclusion, effective strategic sourcing is pivotal for B2B buyers seeking high-quality glowen clutches. By prioritizing supplier relationships, understanding market trends, and leveraging competitive pricing, businesses can secure superior products that enhance performance and reliability. The glowen clutch offerings demonstrate a commitment to quality, evidenced by features such as enhanced drivability, smooth operation, and long-lasting durability.

For international buyers from Africa, South America, the Middle East, and Europe, engaging in strategic sourcing opens doors to innovative solutions tailored to diverse operational needs. As the demand for high-performance clutches continues to grow, it is essential to remain informed about emerging technologies and supplier capabilities.

As you explore your sourcing options, consider reaching out to reputable manufacturers and distributors to discuss your specific requirements. Embrace the opportunity to build partnerships that can drive efficiency and profitability in your operations. The future of your procurement strategy depends on the decisions you make today—act now to secure the best glowen clutch solutions for your business.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.