Top 7 Clay Skate Wheels Suppliers (And How to Choose)

Introduction: Navigating the Global Market for clay skate wheels

Navigating the global market for clay skate wheels presents unique challenges for international B2B buyers, particularly when it comes to sourcing high-quality products that meet diverse skating needs. As the demand for retro-style and specialized skate wheels grows, understanding the various types of clay skate wheels, their applications, and the nuances of supplier vetting becomes crucial. This guide delves into the intricacies of clay skate wheels, covering essential aspects such as performance characteristics, material differences, and the impact of environmental factors on wheel efficacy.

Buyers from regions like Africa, South America, the Middle East, and Europe—including key markets such as Germany and Saudi Arabia—will find actionable insights tailored to their specific needs. We explore the different styles available, including the popular Fo-Mac and Sure-Grip brands, and provide guidance on selecting wheels that align with specific skating disciplines, whether for recreational use or competitive performance.

Moreover, this comprehensive resource equips buyers with vital information about pricing structures, shipping considerations, and international trade regulations. By empowering B2B buyers with the knowledge to make informed purchasing decisions, this guide aims to streamline the sourcing process, ultimately enhancing your product offerings and satisfying customer demands in the thriving roller skating market.

Understanding clay skate wheels Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Freestyle / Fo-Mac | Retro-style, compression molded, unique hardness scale | Specialty skate shops, retro markets | Pros: Unique feel, nostalgia; Cons: Limited availability in certain regions. |

| Harmony | Very hard, 57mm x 30mm, designed to prevent coning | Rhythm skating, competitive events | Pros: Excellent grip and slide; Cons: May wear out faster on rough surfaces. |

| All American Plus | High durability, versatile hardness levels | General retail, performance skating | Pros: Versatile for various skating styles; Cons: Price may be higher than standard wheels. |

| Original Vanathane | Traditional clay composition, ideal for vintage setups | Vintage skate restoration, collectors | Pros: Authentic feel for retro skates; Cons: Limited production runs may affect supply. |

| Atom Poison Hybrid | Hybrid material for improved performance, available in various sizes | Skate parks, outdoor skating | Pros: Enhanced durability and performance; Cons: Higher cost due to advanced materials. |

What are the Characteristics and Suitability of Freestyle / Fo-Mac Wheels?

Freestyle or Fo-Mac wheels are distinguished by their retro design and unique compression molding process. They offer a different skating experience compared to modern urethane wheels, making them appealing to niche markets and specialty skate shops. The varying hardness levels cater to different skating styles, which can be particularly attractive for B2B buyers looking to diversify their product offerings. However, these wheels may have limited availability in certain regions, requiring buyers to establish reliable supply chains.

How Do Harmony Wheels Perform in Competitive Environments?

The Harmony wheel is specifically designed for rhythm skating, featuring a very hard composition that prevents coning and ensures longevity. With dimensions of 57mm x 30mm and a hardness rating of 103A, these wheels provide excellent grip and slide, making them suitable for competitive events and performance skating. B2B buyers should consider the specific floor types where these wheels will be used, as they perform optimally on smooth surfaces. However, their durability can be compromised on rough terrains, which may affect their appeal for certain applications.

Why Choose All American Plus Wheels for Versatility?

All American Plus wheels are known for their high durability and versatility, making them ideal for various skating styles, from recreational to competitive. They come in multiple hardness levels, allowing buyers to cater to a broader audience. This versatility is a significant selling point for retailers looking to stock wheels that appeal to both casual and serious skaters. However, potential buyers should be aware that these wheels may come at a higher price point compared to standard options, which could impact pricing strategies.

What Makes Original Vanathane Wheels a Collector’s Item?

Original Vanathane wheels are crafted from a traditional clay composition, making them perfect for vintage skate restorations and appealing to collectors. Their authentic feel is unmatched, attracting B2B buyers focused on niche markets or specialized skate shops. However, the limited production runs can lead to supply challenges, making it essential for buyers to secure inventory before stock runs out. This exclusivity can also enhance their market value, appealing to buyers interested in premium products.

How Do Atom Poison Hybrid Wheels Enhance Performance?

Atom Poison Hybrid wheels utilize advanced materials to combine the best features of both clay and urethane wheels. They are designed for outdoor skating and skate parks, offering improved performance and durability. B2B buyers should consider their target audience’s needs, as these wheels may be more appealing to serious skaters looking for high-performance options. However, the cost associated with these advanced materials may be a consideration for budget-conscious buyers.

Key Industrial Applications of clay skate wheels

| Industry/Sector | Specific Application of clay skate wheels | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Sports & Recreation | Roller Skating Rinks | Enhanced skating experience with superior grip and slide | Durability, performance metrics, and material sourcing |

| Entertainment Venues | Dance and Performance Skating | Unique aesthetic appeal and performance for artistic skating | Customization options, bulk purchasing, and delivery times |

| Manufacturing & Rentals | Roller Skate Rental Services | Cost-effective rental solutions with high customer satisfaction | Quality control, inventory management, and supplier reliability |

| Specialty Sports Equipment | Artistic Roller Skates | Tailored wheels for specific styles and performance needs | Compatibility with existing equipment and material certifications |

| International Trade | Export of Specialty Skate Wheels | Expansion into emerging markets with unique product offerings | Compliance with international regulations and shipping logistics |

How Are Clay Skate Wheels Used in Sports & Recreation?

In the sports and recreation sector, clay skate wheels are predominantly used in roller skating rinks. These wheels provide an optimal balance between grip and slide, enhancing the skating experience for users. For buyers in this sector, sourcing wheels that can withstand heavy use while offering unique performance characteristics is crucial. International buyers from regions like Europe and South America may prioritize suppliers who can guarantee quality and reliability, ensuring a high level of customer satisfaction in their venues.

What Role Do Clay Skate Wheels Play in Entertainment Venues?

Entertainment venues utilize clay skate wheels for dance and performance skating, where aesthetics and performance are paramount. The unique properties of clay wheels allow for smooth transitions and artistic expressions, making them ideal for performances. Buyers in this sector often seek customization options to match the branding of their venues. Sourcing considerations include lead times for custom orders and the ability to provide bulk quantities to meet the demands of performances.

How Are Clay Skate Wheels Beneficial for Manufacturing & Rental Services?

In the manufacturing and rental industry, clay skate wheels are essential for roller skate rental services, providing a cost-effective solution that enhances customer experiences. These wheels are designed for durability, reducing wear and tear during rentals. Buyers must consider quality control measures and the reliability of suppliers to maintain a consistent inventory. Additionally, understanding the local market’s preferences can help businesses tailor their offerings effectively.

Why Are Clay Skate Wheels Important for Specialty Sports Equipment?

Specialty sports equipment manufacturers often incorporate clay skate wheels in artistic roller skates, catering to specific performance needs. These wheels are engineered for various skating styles, allowing skaters to perform intricate movements with ease. Buyers in this market focus on compatibility with existing equipment and the need for material certifications that guarantee performance standards. Establishing relationships with suppliers who offer specialized products can be a significant advantage.

How Does International Trade Impact the Sourcing of Clay Skate Wheels?

In the realm of international trade, the export of specialty skate wheels is on the rise, particularly in emerging markets. Businesses looking to expand must navigate compliance with international regulations and manage shipping logistics effectively. Buyers from regions such as Africa and the Middle East may seek suppliers with experience in exporting to ensure that they receive products that meet local standards. This requires a keen understanding of market demands and the ability to adapt to varying customer needs across different regions.

Illustrative image related to clay skate wheels

3 Common User Pain Points for ‘clay skate wheels’ & Their Solutions

Scenario 1: Choosing the Right Hardness for Different Skating Environments

The Problem: B2B buyers often struggle with selecting the appropriate hardness of clay skate wheels for varying skating environments. For instance, a roller rink may have a polished surface that requires wheels with a specific hardness for optimal grip and slide. However, when these wheels are used on rough or outdoor surfaces, they may wear out quickly or fail to perform effectively, leading to dissatisfaction from end-users and potential returns.

The Solution: To address this issue, buyers should first assess the skating environments where the wheels will be used. It’s crucial to obtain a range of wheel hardnesses to cater to different conditions. For example, a hardness rating of 103A might be ideal for indoor rinks, providing the right balance of grip and slide. However, for outdoor use, consider sourcing wheels with a softer hardness rating (around 80A-90A) that can handle rougher surfaces without excessive wear. Additionally, communicate with suppliers about the specific needs of your target market, and ask for samples to test the performance before committing to larger orders.

Scenario 2: Managing Inventory and Demand Fluctuations

The Problem: Another common pain point for B2B buyers is managing inventory levels of clay skate wheels, especially in regions where demand can be unpredictable due to seasonal trends or local skating events. Overordering can lead to excess stock that becomes outdated, while underordering can result in lost sales opportunities during peak demand times.

The Solution: Implementing a just-in-time inventory system can help mitigate this issue. This involves closely monitoring sales data and customer feedback to predict demand more accurately. Buyers should also build strong relationships with suppliers who can provide flexible ordering options or quick restock capabilities. Furthermore, consider diversifying the product range to include various styles and colors of clay wheels to attract different customer segments. Employing an integrated inventory management system that provides real-time data analytics can further enhance decision-making and stock management.

Scenario 3: Educating Customers on Wheel Maintenance and Longevity

The Problem: Many B2B buyers face challenges in educating their customers about the maintenance and care required for clay skate wheels. Misunderstanding maintenance can lead to premature wear, dissatisfaction, and increased returns, impacting the buyer’s reputation and profitability.

Illustrative image related to clay skate wheels

The Solution: To effectively educate customers, create comprehensive guides and resources that detail best practices for maintaining clay skate wheels. This can include proper cleaning techniques, storage recommendations, and signs of wear to watch for. Consider hosting workshops or webinars to demonstrate the importance of wheel care, featuring expert skaters or technicians who can share their insights. Additionally, providing customers with a maintenance kit at the point of sale can encourage them to take care of their purchases. By investing in customer education, buyers can foster loyalty and reduce return rates, ultimately enhancing the customer experience and driving repeat business.

Strategic Material Selection Guide for clay skate wheels

What Are the Key Materials Used in Clay Skate Wheels?

When selecting materials for clay skate wheels, several options are commonly considered, each with unique properties and implications for performance. This analysis focuses on four primary materials: Vanathane, polyurethane, fiberglass, and rubber. Understanding their characteristics, advantages, and limitations is crucial for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe.

How Does Vanathane Perform in Clay Skate Wheels?

Vanathane is a proprietary material often used in the production of clay skate wheels. It is known for its unique hardness and resilience, making it suitable for various skating styles, including rhythm and freestyle. The temperature and pressure ratings of Vanathane allow it to perform well in both indoor and outdoor environments, although it may not be as resistant to extreme temperatures as some alternatives.

Illustrative image related to clay skate wheels

Pros: Vanathane provides excellent grip and slide characteristics, enhancing skating performance. Its durability ensures a longer lifespan compared to traditional materials, which can lead to cost savings over time.

Cons: The manufacturing complexity of Vanathane can lead to higher production costs. Additionally, its unique properties may not be compatible with all skating surfaces, necessitating careful consideration of the intended application.

Impact on Application: Vanathane wheels are particularly effective on smooth surfaces, such as polished wood or coated concrete, making them ideal for indoor skating rinks.

Considerations for International Buyers: Compliance with local standards, such as ASTM or DIN, is essential. Buyers in regions like Germany or Saudi Arabia should ensure that the materials meet their specific regulatory requirements.

What Are the Benefits of Polyurethane in Skate Wheels?

Polyurethane is another widely used material in skate wheels, known for its versatility and adaptability. It offers excellent abrasion resistance and can perform well under various conditions, including high temperatures.

Pros: Polyurethane wheels provide a good balance between grip and slide, making them suitable for a range of skating styles. They are also relatively cost-effective and easy to manufacture, which can be advantageous for bulk orders.

Cons: While durable, polyurethane may not offer the same level of performance as Vanathane in terms of specialized skating styles. Additionally, it can degrade over time when exposed to UV light, which is a consideration for outdoor applications.

Impact on Application: Polyurethane wheels are compatible with a wide variety of surfaces, making them a versatile choice for both indoor and outdoor skating.

Considerations for International Buyers: Buyers should be aware of the varying quality standards for polyurethane materials across different regions. Ensuring compliance with local regulations can prevent costly delays or product recalls.

Why Choose Fiberglass for Clay Skate Wheels?

Fiberglass is less common but offers unique properties that can be beneficial for specific applications. It is lightweight yet strong, making it suitable for performance-oriented skate wheels.

Pros: The lightweight nature of fiberglass allows for enhanced maneuverability and speed. It can also be molded into various shapes, providing flexibility in design.

Cons: Fiberglass wheels may not be as durable as other materials and can be more susceptible to damage from impacts. Additionally, the manufacturing process can be more complex, leading to higher costs.

Impact on Application: Fiberglass wheels are best suited for specialized skating disciplines where weight and agility are critical, such as competitive freestyle skating.

Considerations for International Buyers: Fiberglass products may require specific certifications, particularly in regions with stringent safety standards. Buyers should verify compliance with local regulations.

What Role Does Rubber Play in Skate Wheel Manufacturing?

Rubber is often used in the production of skate wheels for its excellent shock absorption and grip properties. It provides a softer feel, which can be beneficial for certain skating styles.

Pros: Rubber wheels offer superior grip on various surfaces, making them ideal for outdoor use. They also provide a comfortable ride due to their shock-absorbing qualities.

Cons: However, rubber wheels may wear out more quickly than harder materials and can be more challenging to manufacture at scale. Their performance can also be affected by temperature changes.

Illustrative image related to clay skate wheels

Impact on Application: Rubber wheels are particularly effective on rough or uneven surfaces, making them a preferred choice for outdoor skating.

Considerations for International Buyers: Buyers should consider the environmental impact of rubber production and ensure that the materials sourced comply with local sustainability standards.

Summary Table of Material Selection for Clay Skate Wheels

| Material | Typical Use Case for clay skate wheels | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Vanathane | Indoor skating rinks | Excellent grip and durability | Higher manufacturing complexity | High |

| Polyurethane | Versatile for various surfaces | Cost-effective and adaptable | UV degradation over time | Medium |

| Fiberglass | Competitive freestyle skating | Lightweight and agile | Less durable than alternatives | High |

| Rubber | Outdoor skating | Superior grip and shock absorption | Faster wear and temperature sensitivity | Medium |

This strategic material selection guide aims to equip B2B buyers with the necessary insights to make informed decisions regarding clay skate wheels, enhancing their product offerings and meeting market demands effectively.

In-depth Look: Manufacturing Processes and Quality Assurance for clay skate wheels

What Are the Main Stages of Manufacturing Clay Skate Wheels?

The manufacturing of clay skate wheels is a meticulous process that combines advanced technology with skilled craftsmanship. The main stages include material preparation, forming, assembly, and finishing.

How is Material Prepared for Clay Skate Wheels?

The first step in the manufacturing process involves sourcing high-quality raw materials. Clay wheels are typically made from a unique blend of clay compounds that provide the desired hardness and flexibility. Manufacturers may use different formulations to achieve specific performance characteristics, such as grip and slide. Once the materials are sourced, they undergo rigorous testing to ensure consistency and quality.

The preparation phase also includes mixing and processing the clay materials. This often involves the use of specialized machinery that ensures even distribution of components. Once mixed, the clay is extruded or molded into the desired shape, which is crucial for ensuring uniformity across all wheels produced.

What Techniques Are Used in Forming Clay Skate Wheels?

The forming stage is critical for defining the shape and profile of the skate wheels. Compression molding is a common technique employed in the production of clay wheels. This process involves placing the prepared clay mixture into a mold and applying heat and pressure to shape it. This method allows for precise control over the wheel dimensions and density.

In addition to compression molding, some manufacturers may utilize advanced techniques like injection molding or CNC machining for specific designs. These methods can produce more intricate wheel profiles that enhance performance for various skating styles, such as rhythm or artistic skating.

Illustrative image related to clay skate wheels

How is the Assembly Process Conducted for Clay Skate Wheels?

After forming, the wheels undergo an assembly process where they are fitted with necessary components. This may include bearings and spacers, which are essential for proper functionality. The assembly stage is often automated, but skilled workers oversee the process to ensure that each wheel meets stringent quality standards.

Quality control during assembly is vital. Each wheel must be inspected to verify that it matches specifications and is free from defects. This includes checking the alignment of the bearings and ensuring that the wheels spin freely without wobbling.

What Finishing Techniques Are Applied to Clay Skate Wheels?

The finishing stage involves several steps that enhance both the aesthetic appeal and performance of the wheels. This may include sanding, polishing, or coating the wheels with a protective layer. The goal is to achieve a smooth surface that minimizes friction and maximizes durability.

Manufacturers often conduct additional testing during this phase to measure the hardness and elasticity of the wheels. This ensures that the final product not only looks good but also performs well under various skating conditions.

Illustrative image related to clay skate wheels

What International Standards Govern Quality Assurance for Clay Skate Wheels?

Quality assurance in the manufacturing of clay skate wheels is governed by several international and industry-specific standards. One of the most recognized standards is ISO 9001, which outlines requirements for a quality management system. Compliance with ISO 9001 indicates that a manufacturer consistently meets customer and regulatory requirements.

In addition to ISO standards, certain products may need to comply with CE marking requirements in Europe, which ensure that they meet health, safety, and environmental protection standards. For buyers in specific industries, adherence to API (American Petroleum Institute) standards may also be relevant, particularly for wheels used in specialized applications.

How Are Quality Control Checkpoints Established in the Manufacturing Process?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to ensure that each stage meets predefined standards. Common QC checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon delivery to ensure they meet specifications before production begins.

-

In-Process Quality Control (IPQC): During manufacturing, samples are taken at various stages to monitor adherence to quality standards. This can include checking the dimensions of the wheels and testing the raw materials’ properties.

-

Final Quality Control (FQC): Once the wheels are assembled, a final inspection occurs to verify that each wheel is free from defects and meets performance criteria.

What Testing Methods Are Commonly Used for Clay Skate Wheels?

Various testing methods are employed to evaluate the performance and durability of clay skate wheels. Common testing methods include:

-

Hardness Testing: This is essential to determine the durometer rating of the wheels. A proper hardness level ensures that the wheels perform optimally on different surfaces.

-

Performance Testing: This includes assessing grip and slide characteristics. Wheels are often tested on various surfaces to simulate real-world skating conditions.

-

Durability Testing: Wheels undergo stress tests to evaluate their resistance to wear and tear over time, ensuring they can withstand regular use.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several steps to verify the quality control processes of suppliers:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control checkpoints, and overall production environment.

-

Requesting Quality Reports: Buyers should ask for detailed quality reports, including data from hardness testing, performance assessments, and any certifications obtained.

-

Third-Party Inspections: Engaging independent third-party inspectors can provide an unbiased evaluation of the manufacturing processes and the final product quality.

What Are the QC and Certification Nuances for International B2B Buyers?

For international B2B buyers, understanding the nuances of quality control and certification is crucial. Buyers from regions like Africa, South America, the Middle East, and Europe may face different regulatory requirements.

For example, European buyers may prioritize CE compliance, while Middle Eastern buyers might require adherence to specific local standards. Buyers should familiarize themselves with the relevant certifications for their region and ensure that suppliers can provide proof of compliance.

Additionally, language barriers and differing business practices can complicate communication. Therefore, establishing clear expectations and maintaining open lines of communication with suppliers is essential for ensuring quality standards are met.

In conclusion, the manufacturing processes and quality assurance for clay skate wheels involve a series of detailed steps designed to produce high-quality, reliable products. By understanding these processes, B2B buyers can make informed decisions and ensure they partner with suppliers that prioritize quality and compliance.

Illustrative image related to clay skate wheels

Practical Sourcing Guide: A Step-by-Step Checklist for ‘clay skate wheels’

This guide aims to equip international B2B buyers with a practical checklist for sourcing clay skate wheels. Sourcing the right wheels is essential for ensuring quality, performance, and customer satisfaction. The following steps will help you navigate the procurement process effectively.

Step 1: Define Your Technical Specifications

Start by establishing the specific requirements for the clay skate wheels you need. Consider factors such as diameter, hardness, and intended use (e.g., indoor vs. outdoor skating). For instance, wheels like the FoMac Harmony are designed for rhythm skating, with a hardness level of 103A, making them suitable for specific skating styles.

- Diameter: Common sizes range from 57mm to 62mm, which affects performance and maneuverability.

- Hardness: Understand the different hardness ratings, as they influence grip and slide on various surfaces.

Step 2: Research Market Trends and Demand

Understanding current market trends in your target regions is vital. Analyze which types of clay wheels are popular among customers in Africa, South America, the Middle East, and Europe. This insight will guide your purchasing decisions and help you stock the most sought-after products.

- Competitor Analysis: Look at competitors’ offerings and pricing strategies to identify gaps in the market.

- Consumer Preferences: Engage with local skaters or retailers to gather insights about preferred wheel characteristics.

Step 3: Evaluate Potential Suppliers

Before finalizing any supplier, conduct a thorough evaluation. Request company profiles, including their manufacturing processes and quality control measures. Reliable suppliers should provide references from other businesses in similar markets.

Illustrative image related to clay skate wheels

- Certifications: Check for compliance with international quality standards, which can assure product reliability.

- Product Samples: Always request samples to assess the quality and performance of the wheels before placing bulk orders.

Step 4: Compare Pricing and Payment Terms

Collect quotes from multiple suppliers to compare pricing structures. Ensure that you understand the terms of payment, including any upfront deposits or credit terms offered.

- Bulk Discounts: Inquire about pricing tiers for larger orders, as this can significantly reduce your costs.

- Shipping Costs: Factor in shipping fees and delivery times, especially for international transactions.

Step 5: Negotiate Contracts and Terms

Once you’ve selected a supplier, negotiate the contract terms carefully. Ensure that the agreement outlines delivery schedules, return policies, and warranty conditions.

- Return Policy: Understand the process for handling defective products, as this can impact your overall customer satisfaction.

- Performance Guarantees: Seek assurances regarding product quality and performance, which can be crucial in maintaining your brand reputation.

Step 6: Plan for Logistics and Distribution

Develop a logistics plan for receiving and distributing the clay skate wheels. Consider warehousing options and local distribution channels to ensure timely delivery to your customers.

- Inventory Management: Implement systems to track inventory levels and sales patterns, which can help in reordering efficiently.

- Local Partnerships: Explore partnerships with local distributors who understand the regional market dynamics.

Step 7: Monitor Customer Feedback and Product Performance

After sourcing and distributing the wheels, actively seek customer feedback. Understanding how the wheels perform in real-world conditions will help you refine your future sourcing strategies.

- Quality Assessment: Regularly evaluate the performance of the wheels based on customer reviews and returns.

- Adaptation: Be prepared to adapt your product offerings based on feedback to meet evolving customer needs.

By following this comprehensive checklist, B2B buyers can streamline their sourcing process for clay skate wheels, ensuring they meet market demands while maintaining high-quality standards.

Comprehensive Cost and Pricing Analysis for clay skate wheels Sourcing

What Are the Key Cost Components in Sourcing Clay Skate Wheels?

When sourcing clay skate wheels, understanding the cost structure is essential for B2B buyers. The primary cost components include:

-

Materials: The quality of clay and other materials significantly impacts the overall cost. Higher-grade materials may lead to better performance and durability but will also increase the price.

-

Labor: Skilled labor is often required for the manufacturing of clay wheels, especially when specific designs or customizations are involved. Labor costs can vary depending on the region and expertise of the workforce.

-

Manufacturing Overhead: This encompasses utilities, equipment maintenance, and factory rent. Efficient manufacturing processes can help minimize these costs, which can be especially relevant for large-scale production.

-

Tooling: Initial tooling costs can be substantial, particularly for custom designs. This includes molds and machinery specifically required for producing clay wheels.

-

Quality Control (QC): Ensuring that wheels meet industry standards requires investment in QC processes. This can include testing for hardness, durability, and performance, which is crucial for maintaining brand reputation.

-

Logistics: Transportation and shipping costs are significant, especially for international buyers. Factors such as distance, mode of transport, and shipping terms (Incoterms) can affect overall logistics costs.

-

Margin: Suppliers will typically add a profit margin to cover their costs and provide a return on investment. Understanding the margin expectations of suppliers can aid in negotiations.

How Do Price Influencers Affect the Cost of Clay Skate Wheels?

Several factors influence the pricing of clay skate wheels, which international buyers should consider:

-

Volume/MOQ: Minimum order quantities (MOQ) can greatly affect pricing. Suppliers often provide discounts for bulk orders, making it beneficial for buyers to plan ahead and purchase larger quantities.

-

Specifications and Customization: Customization options—such as specific colors, sizes, or hardness levels—can lead to higher costs. Buyers should clearly communicate their requirements to avoid unexpected expenses.

-

Materials and Quality Certifications: Premium materials and certifications (e.g., ISO, ASTM) enhance the wheel’s performance and safety, but they come at a higher price. Buyers should weigh the benefits of these certifications against their budget.

-

Supplier Factors: The supplier’s reputation, experience, and location can impact pricing. Established suppliers may charge more due to their reliability and quality assurance.

-

Incoterms: Understanding shipping terms is critical. Incoterms dictate who is responsible for shipping costs, insurance, and import duties, which can significantly affect the total landed cost of the products.

What Buyer Tips Can Help Optimize Costs When Sourcing Clay Skate Wheels?

To maximize value and minimize costs, B2B buyers should consider the following strategies:

-

Effective Negotiation: Build strong relationships with suppliers and negotiate terms that align with your purchasing strategy. Discuss pricing, payment terms, and potential discounts for bulk orders.

-

Focus on Total Cost of Ownership (TCO): Evaluate the long-term costs associated with the wheels, including maintenance, durability, and potential replacement costs. Investing in higher-quality wheels may yield lower TCO over time.

-

Understand Pricing Nuances for International Sourcing: Buyers from Africa, South America, the Middle East, and Europe should be aware of regional pricing differences due to currency fluctuations, tariffs, and shipping costs. Familiarize yourself with local market conditions to negotiate effectively.

-

Leverage Technology: Utilize online platforms to compare prices and suppliers. Many B2B marketplaces provide insights into pricing trends and supplier performance, helping buyers make informed decisions.

Conclusion

Sourcing clay skate wheels requires a thorough understanding of the cost structure and pricing influencers. By being strategic in negotiations and focusing on total cost, international buyers can optimize their sourcing processes and secure high-quality products at competitive prices. Remember to account for all cost components, from materials to logistics, to make the best purchasing decisions for your business.

Alternatives Analysis: Comparing clay skate wheels With Other Solutions

Exploring Alternatives to Clay Skate Wheels: A B2B Perspective

In the competitive landscape of roller skating products, businesses must assess various options to cater to diverse customer needs. Clay skate wheels, known for their unique performance characteristics and retro appeal, face competition from alternative materials and technologies. This analysis will help B2B buyers understand how clay wheels stack up against other solutions, enabling informed purchasing decisions.

| Comparison Aspect | Clay Skate Wheels | Urethane Wheels | Hybrid Wheels |

|---|---|---|---|

| Performance | Excellent grip on smooth surfaces; retro feel | Versatile; good grip and slide on various surfaces | Balance of grip and slide; adaptable to conditions |

| Cost | €125 – €200 per set | €50 – €150 per set | €60 – €120 per set |

| Ease of Implementation | Simple to install on compatible skates | Widely compatible; easy to replace | Generally compatible; may require adjustments |

| Maintenance | Low maintenance; durable with proper use | Moderate; may require more frequent replacements | Low; durable but depends on usage conditions |

| Best Use Case | Indoor rinks, artistic skating | All-purpose use, outdoor and indoor skating | Versatile use; suitable for varying conditions |

What Are Urethane Wheels and Their Advantages?

Urethane wheels have become the industry standard for roller skates, offering a balance of grip and slide that suits various skating styles. Their versatility allows them to perform well on both indoor and outdoor surfaces. Urethane’s durability is another significant advantage; while they may have a lower initial cost, they require periodic replacements, especially in high-use scenarios. However, urethane wheels may not provide the same nostalgic feel or aesthetic that clay wheels do, making them less appealing for certain artistic or vintage applications.

How Do Hybrid Wheels Compare?

Hybrid wheels combine the properties of both urethane and clay, designed to offer a balance of grip, slide, and durability. These wheels are particularly advantageous for skaters who frequently transition between different surfaces. Their adaptability makes them suitable for various conditions, from smooth indoor rinks to rough outdoor environments. However, the cost of hybrid wheels can be higher than both clay and urethane options, and they may require some adjustments to ensure compatibility with existing skate setups.

Conclusion: Which Wheel Type Is Right for Your Business?

Choosing the right skating wheel involves understanding the specific needs of your target market. For businesses catering to artistic skaters or those looking for a retro experience, clay wheels may be the best choice despite their higher cost. In contrast, if your clientele requires versatility and performance across different surfaces, urethane or hybrid wheels could be more advantageous. By evaluating the performance, cost, and intended use of each option, B2B buyers can make informed decisions that align with their customers’ preferences and operational requirements.

Essential Technical Properties and Trade Terminology for clay skate wheels

What Are the Key Technical Properties of Clay Skate Wheels?

Understanding the essential technical properties of clay skate wheels is crucial for B2B buyers in the roller skate industry. Here are some critical specifications:

1. Material Composition

Clay skate wheels are primarily made from specialized materials, often differing significantly from traditional urethane wheels. The unique formulations used in clay wheels can influence the skating experience, offering varying levels of grip and slide. Buyers should prioritize suppliers that provide detailed material specifications to ensure compatibility with their intended applications.

2. Wheel Diameter and Width

The dimensions of the wheels, typically measured in millimeters (mm), such as 57mm x 30mm, directly affect performance. The diameter influences speed and maneuverability, while the width impacts stability and grip. Buyers should consider the specific skating style—whether artistic, rhythm, or speed skating—when selecting wheel dimensions.

Illustrative image related to clay skate wheels

3. Hardness Rating

Hardness is a critical factor in wheel performance, usually measured on a durometer scale (e.g., 103A for certain clay wheels). This rating indicates the wheel’s firmness and affects its grip on various surfaces. Buyers must choose hardness levels that align with the floor material where the wheels will be used, as this can significantly impact performance.

4. Tolerance and Quality Control

Tolerance refers to the allowable deviation from specified dimensions during manufacturing. High-quality clay wheels should exhibit tight tolerances to ensure consistent performance and durability. Buyers should inquire about quality control processes to ensure that products meet their specifications, as this can reduce maintenance costs and improve the overall skating experience.

5. Performance Factors

Several external factors can influence wheel performance, including weight, temperature, and floor material. Buyers need to understand these variables to select the right wheels for their specific environments. For instance, softer wheels may perform better in colder temperatures but may wear out faster on rough surfaces.

What Are Common Trade Terms Used in the Clay Skate Wheel Industry?

Familiarity with industry terminology can enhance communication between buyers and suppliers. Here are some key terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components that are sold under another company’s brand. In the context of clay skate wheels, an OEM supplier might create wheels that are branded and sold by a larger roller skate manufacturer. Understanding OEM relationships can help buyers secure better pricing and product quality.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell in a single order. This term is crucial for B2B buyers to understand, as it impacts inventory management and cash flow. Buyers should negotiate MOQs based on their sales forecasts to avoid overstocking or stockouts.

3. RFQ (Request for Quotation)

An RFQ is a formal document issued by buyers to solicit price quotes from suppliers for specific products or services. For clay skate wheels, an RFQ can outline required specifications, quantities, and delivery timelines. This process helps buyers evaluate multiple suppliers and secure competitive pricing.

4. Incoterms

Incoterms are international trade terms that define the responsibilities of buyers and sellers in shipping agreements. Common terms include FOB (Free on Board) and CIF (Cost, Insurance, and Freight). Understanding Incoterms is essential for B2B buyers to manage shipping costs and responsibilities effectively.

Illustrative image related to clay skate wheels

5. Lead Time

Lead time refers to the period from placing an order to receiving the goods. It can vary based on factors such as manufacturing capacity and shipping logistics. Buyers should factor in lead times when planning inventory to ensure they meet customer demands without delays.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing clay skate wheels, ensuring they select products that meet their operational needs and market demands.

Navigating Market Dynamics and Sourcing Trends in the clay skate wheels Sector

What Are the Key Market Dynamics and Trends Influencing the Clay Skate Wheels Sector?

The global clay skate wheels market is witnessing significant growth, driven by an increase in roller skating popularity across various demographics. This resurgence is particularly pronounced in regions such as Africa, South America, the Middle East, and Europe, where a blend of traditional and modern skating styles is gaining traction. International B2B buyers are increasingly focused on sourcing high-quality products that cater to niche markets, such as artistic and rhythm skating. This demand is pushing manufacturers to innovate, with advancements in materials and manufacturing processes. For instance, the compression molding of clay wheels, as seen in products like the Fo-Mac series, is becoming a preferred method due to its ability to create unique hardness levels and performance characteristics.

Emerging technologies in e-commerce and logistics are reshaping sourcing strategies. Buyers are leveraging digital platforms for real-time inventory checks, price comparisons, and customer reviews. This trend is particularly relevant for international buyers seeking reliable suppliers. Furthermore, the rise of direct-to-consumer models allows businesses to streamline their supply chains and reduce costs, making it essential for B2B buyers to stay informed about these shifts.

Another key trend is the customization of clay skate wheels, tailored to specific skating styles and environments. For example, wheels designed for different floor types, such as coated concrete versus uncoated surfaces, are becoming increasingly popular. As a result, buyers must consider the specific needs of their markets when sourcing products.

How Is Sustainability and Ethical Sourcing Shaping the Clay Skate Wheels Market?

Sustainability has emerged as a critical consideration in the sourcing of clay skate wheels. International B2B buyers are increasingly concerned about the environmental impact of their purchases, prompting manufacturers to adopt greener practices. This includes the use of eco-friendly materials and processes in the production of clay wheels, which traditionally relied on petroleum-based products. Buyers are advised to look for suppliers who use sustainable materials or have certifications indicating their commitment to environmental responsibility.

Ethical sourcing is equally important, as consumers worldwide demand transparency in the supply chain. Buyers should prioritize suppliers who adhere to ethical labor practices and demonstrate a commitment to fair trade. This not only enhances the brand reputation but also aligns with the growing consumer preference for socially responsible products.

Green certifications, such as ISO 14001, can serve as indicators of a supplier’s commitment to environmental management. Buyers should actively seek out partnerships with manufacturers that prioritize sustainability, ensuring that their sourcing practices align with global standards and consumer expectations.

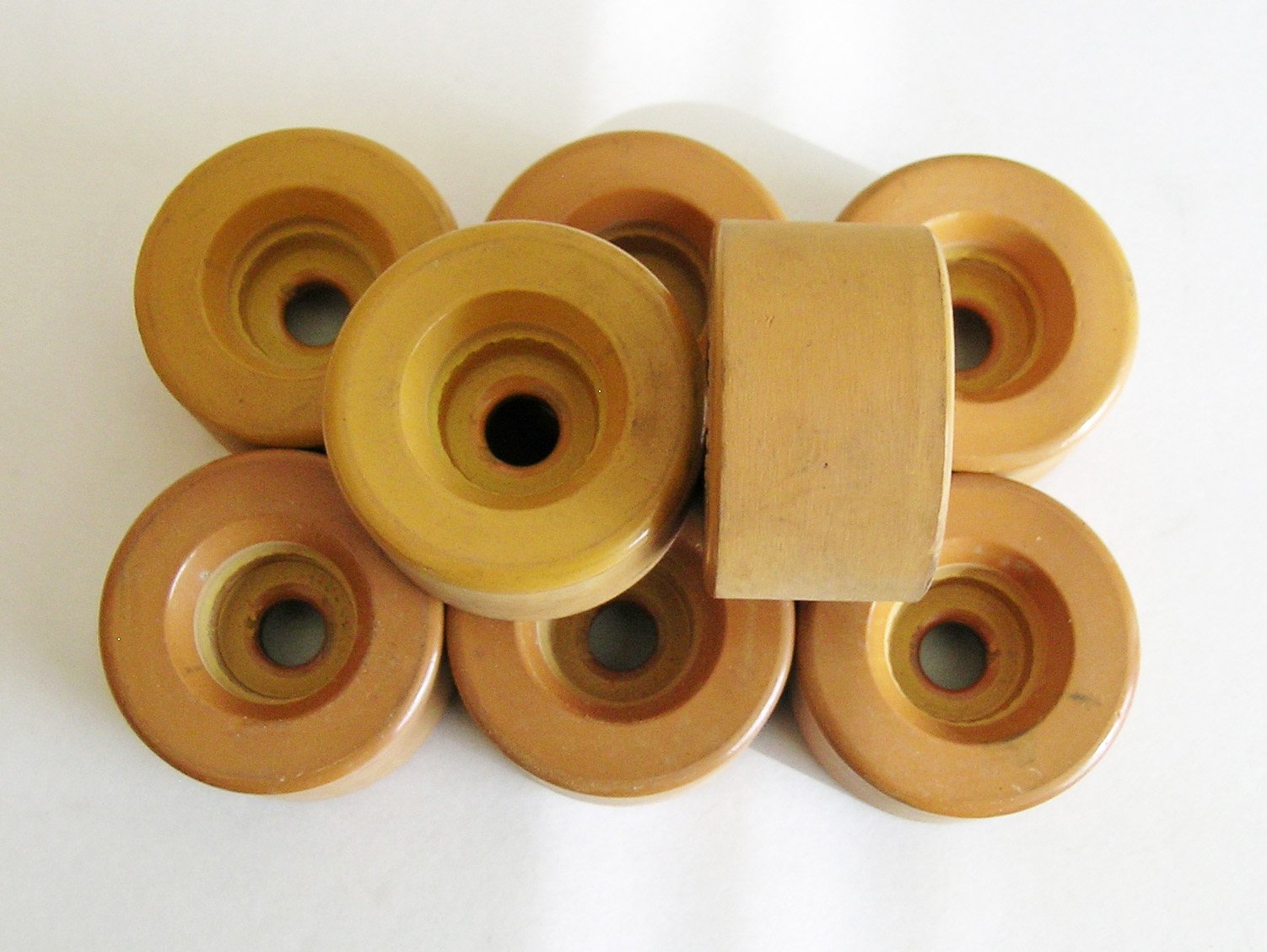

What Is the Evolution of Clay Skate Wheels and Its Significance for Today’s B2B Buyers?

The evolution of clay skate wheels dates back several decades, with early designs primarily focused on durability and performance. Initially, these wheels were made from basic materials that offered limited customization. However, advancements in material science have led to the development of specialized compounds that enhance performance characteristics such as grip, slide, and wear resistance.

Illustrative image related to clay skate wheels

Today, clay skate wheels are crafted using advanced manufacturing techniques, including compression molding and innovative formulations that cater to diverse skating styles. This evolution has not only improved the quality and performance of the wheels but has also expanded their applications, making them suitable for various skating environments.

For B2B buyers, understanding this historical context is crucial, as it highlights the importance of product quality and innovation in decision-making. By sourcing from suppliers who embrace this evolution, businesses can ensure they offer the best products to their customers, ultimately driving sales and fostering brand loyalty.

Frequently Asked Questions (FAQs) for B2B Buyers of clay skate wheels

-

How do I determine the right hardness level for clay skate wheels?

Choosing the appropriate hardness for clay skate wheels depends on the skating surface and desired performance. Harder wheels (e.g., 103A) are ideal for smooth surfaces, providing speed and minimal drag, while softer wheels offer better grip and shock absorption on rougher surfaces. Consider the primary environments where the wheels will be used—whether indoor rinks or outdoor venues—and consult with suppliers who can provide specific recommendations based on your location’s climate and surface material. -

What are the best clay skate wheels for different skating styles?

The best clay skate wheels vary according to skating style. For rhythm skating, wheels like the FoMac Harmony (57mm) are preferred due to their balance of grip and slide. Freestyle skaters may benefit from wheels that emphasize durability and performance under varied conditions. Always assess your needs based on the skater’s skill level and the intended use, and seek expert advice from suppliers familiar with various skating disciplines. -

What factors should I consider when sourcing clay skate wheels internationally?

When sourcing clay skate wheels internationally, consider factors such as shipping costs, customs regulations, and supplier reliability. Verify the manufacturer’s compliance with international quality standards and inquire about their production processes. Understanding local market demand and potential tariffs can also aid in cost management. Build relationships with trusted suppliers who can provide consistent quality and timely delivery to ensure smooth operations. -

What is the minimum order quantity (MOQ) for clay skate wheels?

Minimum order quantities for clay skate wheels can vary significantly between manufacturers. Typically, MOQs range from 50 to 100 sets, depending on the supplier’s production capabilities. Discuss your requirements with potential suppliers to negotiate MOQs that suit your business needs. Smaller orders may be available but could come with higher per-unit costs. -

How can I vet suppliers for clay skate wheels effectively?

To vet suppliers effectively, conduct thorough background checks, including reviews of their business history, customer testimonials, and case studies. Request samples to assess product quality firsthand. Additionally, verify certifications related to quality control and safety standards. Engaging in direct communication can also provide insights into their customer service and responsiveness, which are critical for long-term partnerships. -

What payment terms are commonly accepted when purchasing clay skate wheels?

Payment terms for purchasing clay skate wheels can vary widely. Common options include upfront payments, net 30 or net 60 terms, and letters of credit for international transactions. Establishing clear payment terms before finalizing orders is crucial for managing cash flow and reducing risk. Always confirm the payment methods accepted by the supplier, including bank transfers, credit cards, or escrow services. -

What quality assurance measures should I expect for clay skate wheels?

Quality assurance measures for clay skate wheels should include standardized testing for hardness, durability, and performance under different conditions. Suppliers should provide documentation verifying compliance with international quality standards. Consider requesting regular inspection reports and ensuring that the supplier has a robust return policy for defective products. Engaging in periodic quality checks can also help maintain consistency in product quality over time. -

How can I manage logistics and shipping for clay skate wheels?

Managing logistics and shipping for clay skate wheels involves coordinating with suppliers to understand their shipping capabilities and timelines. Evaluate shipping options such as air freight for faster delivery or sea freight for cost efficiency. Make sure to account for customs clearance times and potential duties. Establishing a reliable logistics partner can streamline the process, ensuring that your orders arrive on time and in good condition.

Top 7 Clay Skate Wheels Manufacturers & Suppliers List

1. SK8 Fanatics – Premium Indoor Wheels

Domain: sk8fanatics.storenvy.com

Registered: 2008 (17 years)

Introduction: Wheels (Indoor) available at SK8 Fanatics include: 1. Original Phase 5 Rental Vanathane Wheels – $150.00 2. LIMITED EDITION “Teal Green” Fiberglass Wheels – $150.00 3. Fiberglass Wheels by SK8 FANATICS – $125.00 4. All American Dream “GOLD EDITION” Wheels – $195.00 5. All American Gold by Sure Grip – $145.00 6. “Orange” Original Vanathane Rental Skate Wheels – $150.00 (Sold Out) 7. LUMINOUS LED “I…

2. Sure-Grip – Freestyle Roller Skate Wheels

Domain: suregrip.com

Registered: 1995 (30 years)

Introduction: Sure-Grip Freestyle / Fo-Mac roller skate wheels

– Sale Price: $145.00

– Original Vanathane style clay roller skate wheels

– Size: 57mm x 30mm

– Color: Black

– Retro-style wheels using a compression molding process

– Unique materials different from modern urethane wheels

– Performance influenced by factors such as weight, floor material, and temperature

– Hardness ranking: Hardest – Premier, Mini-…

3. FoMac – Harmony Rhythm Wheels

Domain: rollerskatenation.com

Registered: 2008 (17 years)

Introduction: FoMac Harmony Rhythm Wheels (8-Pack) – 57mmx30mm, MSRP: $145.00, 103A hardness, designed for rhythm style skating, very hard clay wheel to prevent coning or wear, suitable for moves at the roller rink, pack includes 8 wheels.

4. Jam Roller Skate Wheels – Grip, Agility, Style

Domain: derbycityskates.com

Registered: 2011 (14 years)

Introduction: Jam Roller Skate Wheels – Designed for jam skating with a focus on grip, agility, and style. Suitable for skaters of all levels. Available brands include Atom Skates, Riedell Roller, Rollerbones, and Sure-Grip. Sizes range from 57mm to 62mm with hardness ratings of 96A to 101A. Color options include Black, Black and Gold, Blue, Brown, Light Pink, Lime Green, Red, Ruby Red, Sky Blue, and White. Tot…

5. Surfer Today – Skateboard Wheels Innovation

Domain: surfertoday.com

Registered: 2007 (18 years)

Introduction: Skateboard wheels transitioned from clay to urethane, with Frank Nasworthy credited for this innovation in the 1970s. Urethane, a durable and resilient petroleum-based product, was first used in roller skate wheels. Nasworthy replaced clay wheels with urethane ones, resulting in a smoother and quieter ride. He later designed his own urethane wheels, named Cadillac Wheels, which retailed for $8. Th…

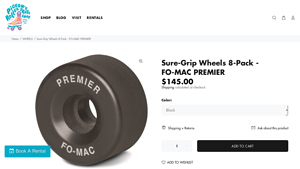

6. Sure-Grip – FO-MAC PREMIER Wheels 8-Pack

Domain: pigeonskates.com

Registered: 2020 (5 years)

Introduction: Sure-Grip Wheels 8-Pack – FO-MAC PREMIER, Price: $145.00, Size: 57mm, Available Colors: Black and Two Tone Brown, Type: Original clay roller skate wheel, Sold in packs of 8, Precision only.

7. Dose Skateboarding – Skateboard Wheels

Domain: doseskateboarding.com

Registered: 2019 (6 years)

Introduction: Skateboard wheels have evolved significantly since their inception in the 1950s. Originally made of clay, these wheels were hard and heavy, making them difficult to maneuver. In the 1960s, polyurethane wheels were introduced, offering improvements in weight, durability, and traction, though they were still expensive. The major breakthrough came in the 1970s with the introduction of rubber wheels, …

Strategic Sourcing Conclusion and Outlook for clay skate wheels

In summary, strategic sourcing of clay skate wheels offers significant opportunities for international B2B buyers to enhance their product offerings and cater to diverse market demands. The unique characteristics of clay wheels, such as their distinct performance profiles and retro appeal, position them as a valuable choice for retailers targeting both recreational and competitive skaters. By understanding the nuances of different wheel types and their applications, buyers can make informed purchasing decisions that align with consumer preferences.

Moreover, establishing strong supplier relationships is crucial for accessing high-quality products and ensuring consistent availability. Buyers should prioritize partnerships with manufacturers that demonstrate a commitment to innovation and quality assurance, as this will ultimately enhance brand reputation and customer satisfaction.

Looking ahead, the global market for clay skate wheels is poised for growth, driven by increasing interest in roller skating as a lifestyle and fitness choice. As regions like Africa, South America, the Middle East, and Europe continue to embrace this trend, there is a prime opportunity for B2B buyers to capitalize on emerging markets. Engage with trusted suppliers today to secure your competitive edge and meet the evolving needs of skaters worldwide.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.