Top 7 Band Heaters Suppliers (And How to Choose)

Introduction: Navigating the Global Market for band heaters

In an increasingly competitive global landscape, sourcing the right band heaters can pose significant challenges for B2B buyers. Whether you’re in the plastic processing industry or food manufacturing, understanding the nuances of band heaters—such as their construction, wattage options, and thermal performance—is crucial for optimizing your operations. This comprehensive guide delves into the myriad types of band heaters available, including mica, silicone, and metal sheathed variants, while also exploring their applications across various sectors.

International buyers from regions like Africa, South America, the Middle East, and Europe, including markets like Saudi Arabia and Brazil, will find actionable insights tailored to their specific needs. We cover essential considerations for supplier vetting, ensuring you align with manufacturers who meet global standards for quality and reliability. Additionally, the guide will address cost factors, helping you make informed purchasing decisions that enhance your operational efficiency.

By equipping you with in-depth knowledge about band heaters, this guide empowers your organization to navigate the complexities of sourcing and procurement confidently. With the right information at your fingertips, you can select the most suitable heating solutions that meet both your performance requirements and budget constraints, ultimately driving your business forward.

Understanding band heaters Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Mica Band Heaters | High-temperature capabilities, available in one or two-piece designs | Plastic injection molding, extrusion, food processing | Pros: Versatile, durable, customizable; Cons: Limited to certain watt densities and temperatures. |

| MI Better Bands | High watt density, alumina oxide insulation, stainless steel sheath | High-temperature applications, chemical processing | Pros: Excellent heat transfer, high durability; Cons: Higher initial cost compared to basic models. |

| Permaheat Bands | Durable construction, effective heat transfer, up to 600°F | Food service, chemical processing, textile applications | Pros: Cost-effective, reliable performance; Cons: Limited temperature range compared to other types. |

| Ultima Bands | Rugged design, suitable for harsh environments, up to 700°F | Extrusion processes, agricultural applications | Pros: Extremely durable, customizable; Cons: Heavier than other options, which may affect installation. |

| HT Mica Bands | Customizable, high-temperature performance, up to 900°F | Scientific testing, plastics processing | Pros: Flexible configurations, high performance; Cons: May require specific maintenance protocols. |

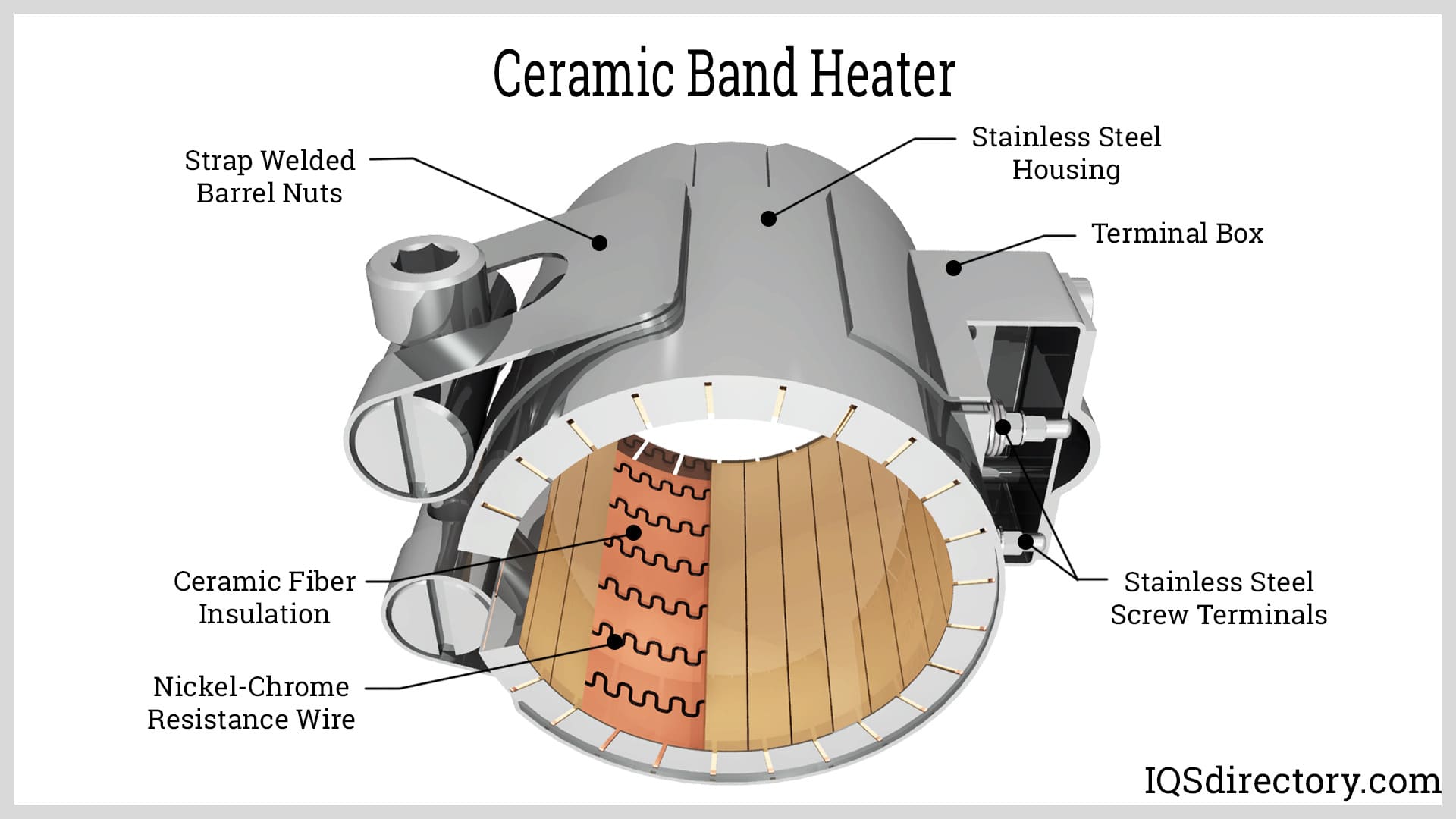

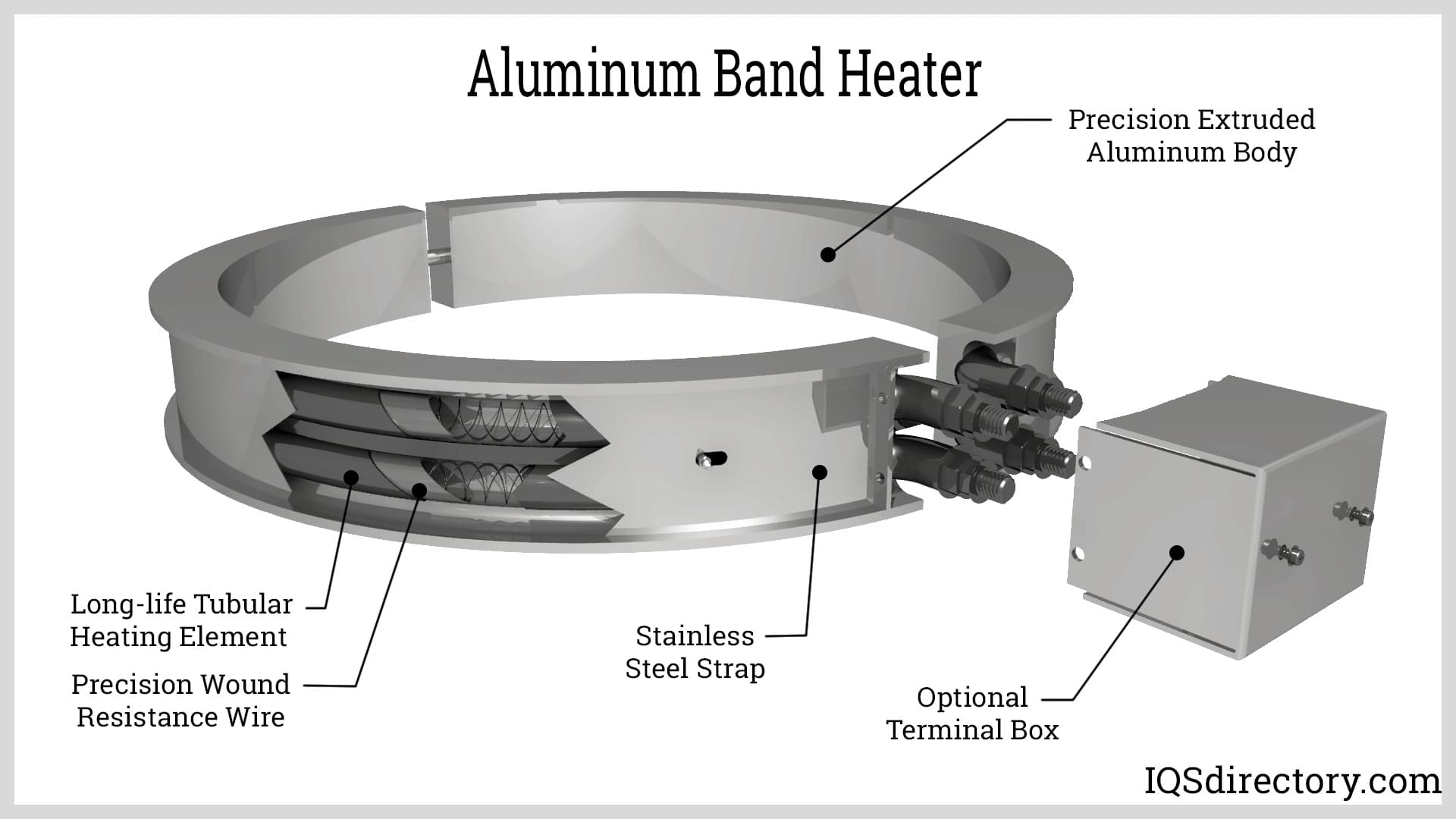

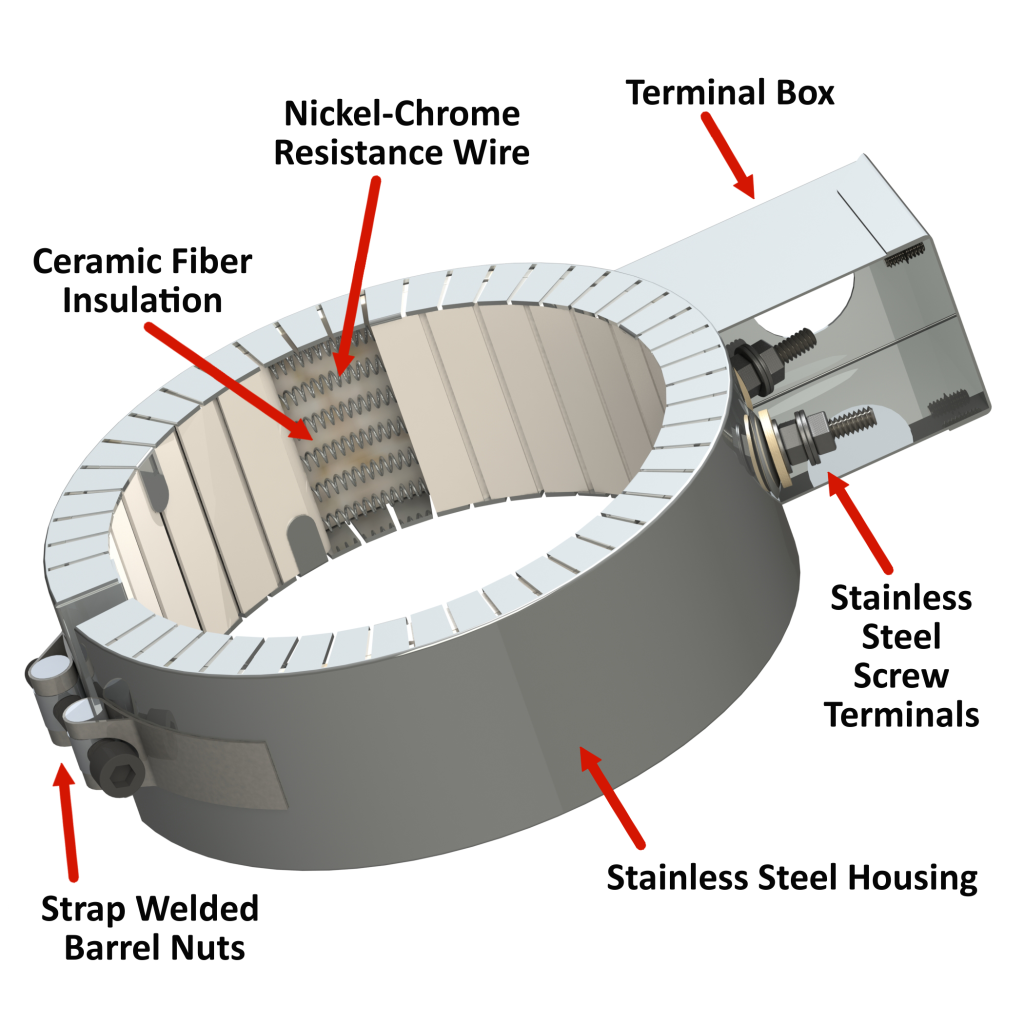

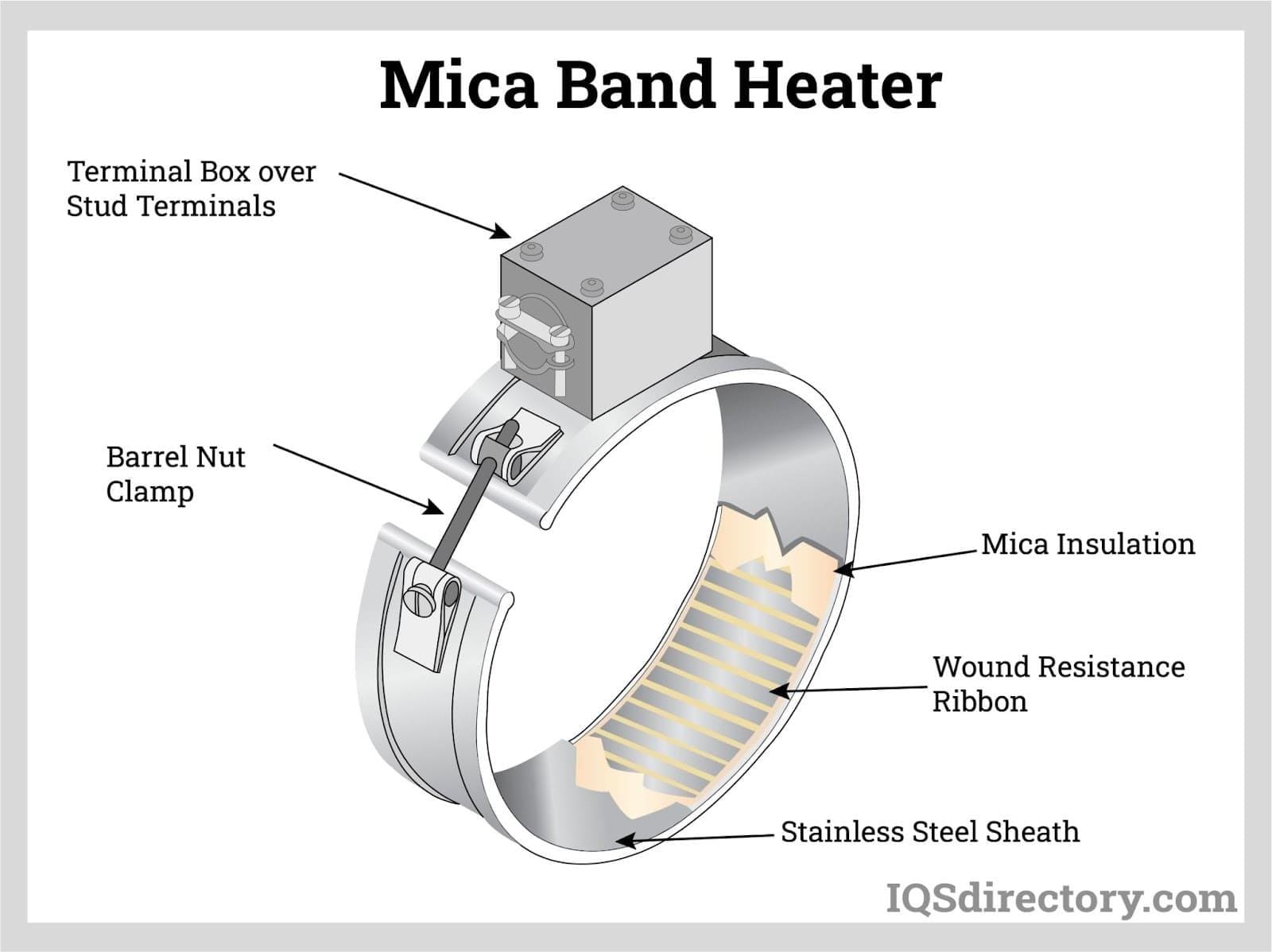

What are Mica Band Heaters and When Should You Use Them?

Mica band heaters are designed for high-temperature applications, making them ideal for heating cylindrical surfaces in processes such as plastic injection molding and food processing. Their one or two-piece construction allows for easy installation and adaptability to various sizes. Buyers should consider watt density and maximum operating temperatures when purchasing, as these factors can influence heating efficiency and application suitability.

How Do MI Better Bands Stand Out?

MI Better Bands are characterized by their high watt density and robust alumina oxide insulation. With a maximum temperature capability of 1400°F, these heaters are particularly effective in high-demand chemical processing applications. When purchasing, businesses should evaluate their thermal requirements and consider the initial investment against long-term performance and energy efficiency.

Why Choose Permaheat Bands for Your Business?

Permaheat bands offer a cost-effective solution for businesses needing reliable heating up to 600°F. They excel in food service and textile applications, where consistent temperature maintenance is crucial. Buyers should weigh the benefits of durability and cost against the limited temperature range when deciding if this option fits their operational needs.

What Makes Ultima Bands Ideal for Harsh Environments?

Ultima bands are engineered for ruggedness, making them suitable for challenging industrial settings. With a temperature capacity of up to 700°F, they are commonly used in extrusion and agricultural applications. When considering Ultima bands, buyers should assess their specific environmental challenges and the need for customization in design.

How Do HT Mica Bands Enhance Scientific Testing?

HT Mica Bands are particularly valued in scientific testing and plastics processing due to their customizable configurations and high-temperature performance of up to 900°F. This versatility makes them suitable for a range of applications, but buyers should be aware of the potential need for specialized maintenance to ensure optimal functionality over time.

Key Industrial Applications of band heaters

| Industry/Sector | Specific Application of band heaters | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Plastics Manufacturing | Plastic Injection Molding | Ensures consistent heating for quality product formation. | Custom sizes and watt densities to match machine specifications. |

| Food Processing | Candy Extrusion and Food Warming | Maintains product integrity and safety during processing. | Compliance with food safety standards; materials that resist corrosion. |

| Chemical Processing | Heating Reaction Vessels and Storage Tanks | Facilitates precise temperature control for chemical reactions. | High-temperature capabilities and durability against corrosive materials. |

| Textile Industry | Heated Fabric Presses and Dyeing Machines | Enhances efficiency in fabric processing and dye application. | Custom configurations to accommodate machine designs and sizes. |

| Medical Equipment | Heating Elements in Medical Devices | Ensures reliable performance and safety in medical applications. | Compliance with medical industry standards and certifications. |

How are Band Heaters Used in Plastics Manufacturing?

In plastics manufacturing, band heaters are crucial for applications like plastic injection molding. They provide uniform heating to the molds, ensuring that the plastic material is properly melted and shaped. This consistent heating is vital for maintaining product quality and reducing defects. Buyers must consider the specific watt densities and sizes that align with their machinery, ensuring that the heaters can withstand the high temperatures typically required in these processes.

What Role Do Band Heaters Play in Food Processing?

In the food processing industry, band heaters are often utilized in applications such as candy extrusion and food warming. They help maintain the desired temperature of food products, preventing crystallization in candy and ensuring safe serving temperatures. For B2B buyers, it is essential to source heaters made from materials that comply with food safety regulations, as well as those that can resist corrosion from various food substances.

Why Are Band Heaters Essential for Chemical Processing?

Band heaters are integral to chemical processing, particularly for heating reaction vessels and storage tanks. They enable precise temperature control, which is critical for facilitating chemical reactions and ensuring product quality. When sourcing band heaters for this sector, businesses should prioritize high-temperature capabilities and durability, especially in environments where exposure to corrosive chemicals is common.

How Do Band Heaters Enhance Efficiency in the Textile Industry?

In the textile industry, band heaters are employed in heated fabric presses and dyeing machines to ensure that fabrics are uniformly heated for effective processing. This leads to improved efficiency and consistency in dye application, which is essential for product quality. Buyers should focus on obtaining custom configurations that fit their specific machine designs, as well as ensuring the heaters are robust enough to handle the operational demands.

What Are the Applications of Band Heaters in Medical Equipment?

In medical equipment, band heaters serve as critical heating elements in devices that require precise temperature regulation. They ensure reliable performance, which is vital for patient safety and equipment efficacy. Buyers in the medical sector must ensure that their heaters comply with industry standards and certifications, focusing on quality and safety to meet stringent regulatory requirements.

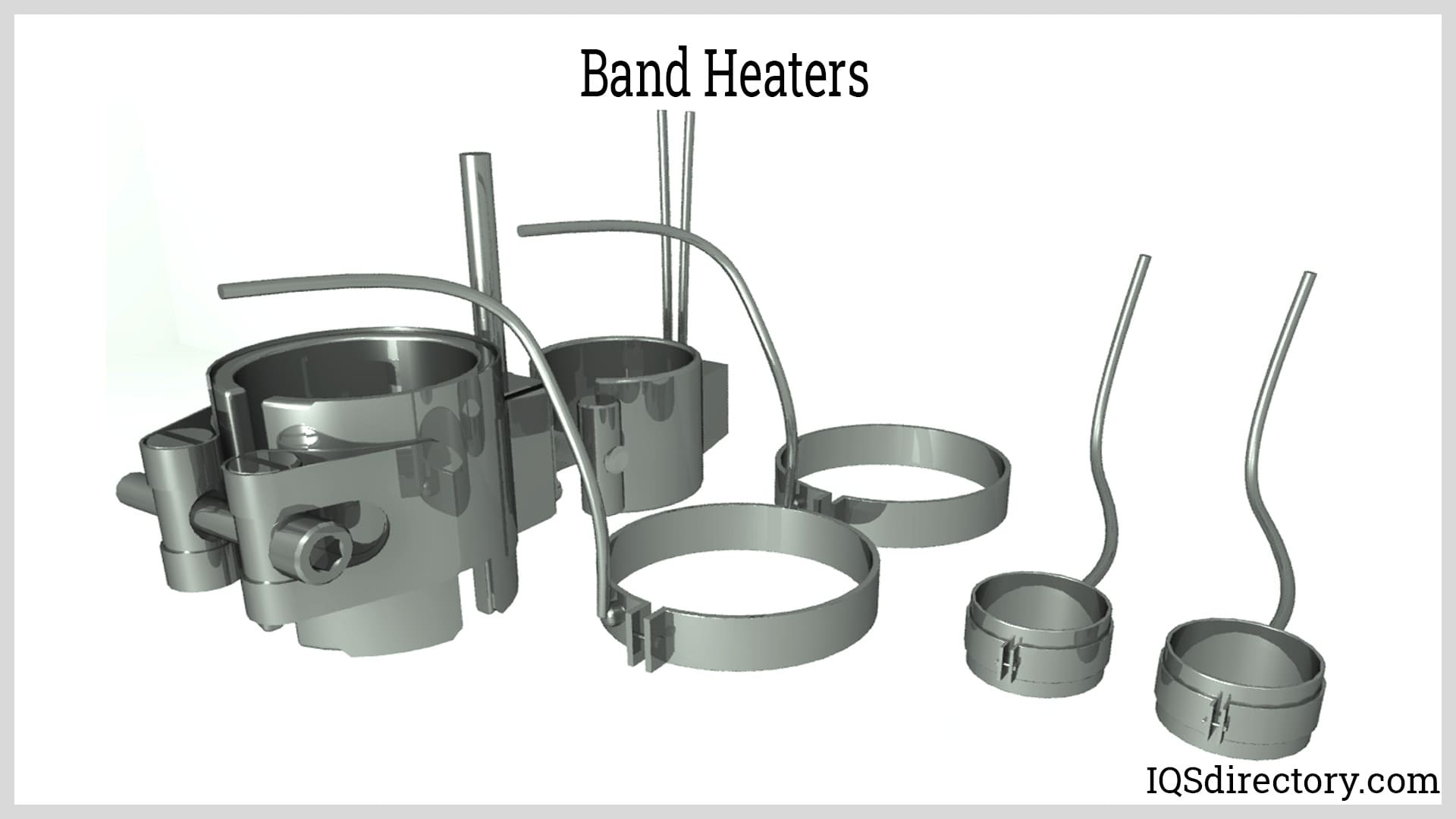

Illustrative image related to band heaters

3 Common User Pain Points for ‘band heaters’ & Their Solutions

Scenario 1: Inconsistent Heating Leading to Production Delays

The Problem: A manufacturing plant in Brazil relies heavily on band heaters for their plastic injection molding processes. Recently, they have experienced inconsistent heating, resulting in uneven temperatures across the molds. This inconsistency leads to defects in the final product, causing production delays and increased waste. The issue has escalated to the point where the plant is struggling to meet customer demands and maintain quality standards.

The Solution: To address this problem, the plant should first conduct a thorough audit of their existing band heater setup. This includes checking the watt density and ensuring that the heaters are properly sized for the application. Utilizing the watt density formulas specific to band heaters, they can calculate the optimal wattage required based on the size of the molds and the desired operating temperature. Additionally, investing in advanced temperature control systems with feedback mechanisms can help maintain consistent heating. These systems can automatically adjust the power supplied to the heaters based on real-time temperature readings, ensuring uniform heat distribution and reducing the risk of defects. Regular maintenance checks and timely replacement of faulty heaters will also minimize downtime and enhance overall production efficiency.

Scenario 2: Difficulty in Finding Custom Solutions for Unique Applications

The Problem: A company in Saudi Arabia that specializes in chemical processing faces challenges when trying to find band heaters tailored to their specific equipment, which often includes non-standard shapes and sizes. Off-the-shelf solutions frequently fail to meet their requirements, leading to inefficient heating and increased operational costs.

The Solution: The company should engage with manufacturers that offer customizable band heaters. When sourcing these heaters, they should provide detailed specifications of their equipment, including dimensions, operating temperature ranges, and any obstructions that may affect heater placement. Collaborating closely with the manufacturer during the design phase will ensure that the band heaters are tailored to their unique applications. Manufacturers can create heaters with specific cutouts, holes, or slots to fit around obstructions. It’s also beneficial to discuss materials that provide durability and high thermal efficiency for their specific chemicals, ensuring that the heaters can withstand the operating environment without degrading. This proactive approach not only enhances operational efficiency but also extends the lifespan of the heating elements.

Illustrative image related to band heaters

Scenario 3: High Energy Costs Due to Inefficient Heating Systems

The Problem: A food processing facility in South America is grappling with rising energy costs attributed to their aging band heater systems. These older models are not energy-efficient, consuming more power than necessary to maintain the required temperatures for food preparation and processing.

The Solution: To mitigate these rising costs, the facility should consider upgrading to modern, energy-efficient band heaters. They should evaluate options such as mica or ceramic band heaters that offer better insulation and heat retention, which can significantly reduce energy consumption. Conducting an energy audit can help identify the current energy usage and pinpoint areas for improvement. When selecting new heaters, they should look for features such as advanced thermal insulation, higher watt density capabilities, and variable wattage options that allow for better control of heating based on real-time needs. Additionally, implementing a preventative maintenance schedule will ensure that the heaters operate at peak efficiency, further reducing unnecessary energy expenditures. By investing in more efficient technology and practices, the facility can not only lower energy costs but also improve overall productivity and sustainability.

Strategic Material Selection Guide for band heaters

What Are the Key Materials Used in Band Heaters and Their Properties?

When selecting band heaters for industrial applications, understanding the materials involved is crucial for ensuring optimal performance and durability. Here, we analyze four common materials used in band heaters, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Mica

Key Properties:

Mica is known for its excellent electrical insulation and high-temperature resistance, typically rated up to 850°F (454°C). It provides dielectric strength, making it ideal for high-voltage applications.

Pros & Cons:

Mica band heaters are relatively lightweight and can be manufactured in various sizes and configurations. However, they can be prone to cracking under mechanical stress, which may affect longevity. The cost is moderate, making them accessible for many applications.

Impact on Application:

Mica is particularly suitable for plastic processing industries, such as injection molding and extrusion, where high temperatures are essential.

Considerations for International Buyers:

Mica heaters must comply with international standards such as UL and CE, especially in regions like Europe and the Middle East. Buyers should ensure that their suppliers provide documentation for compliance.

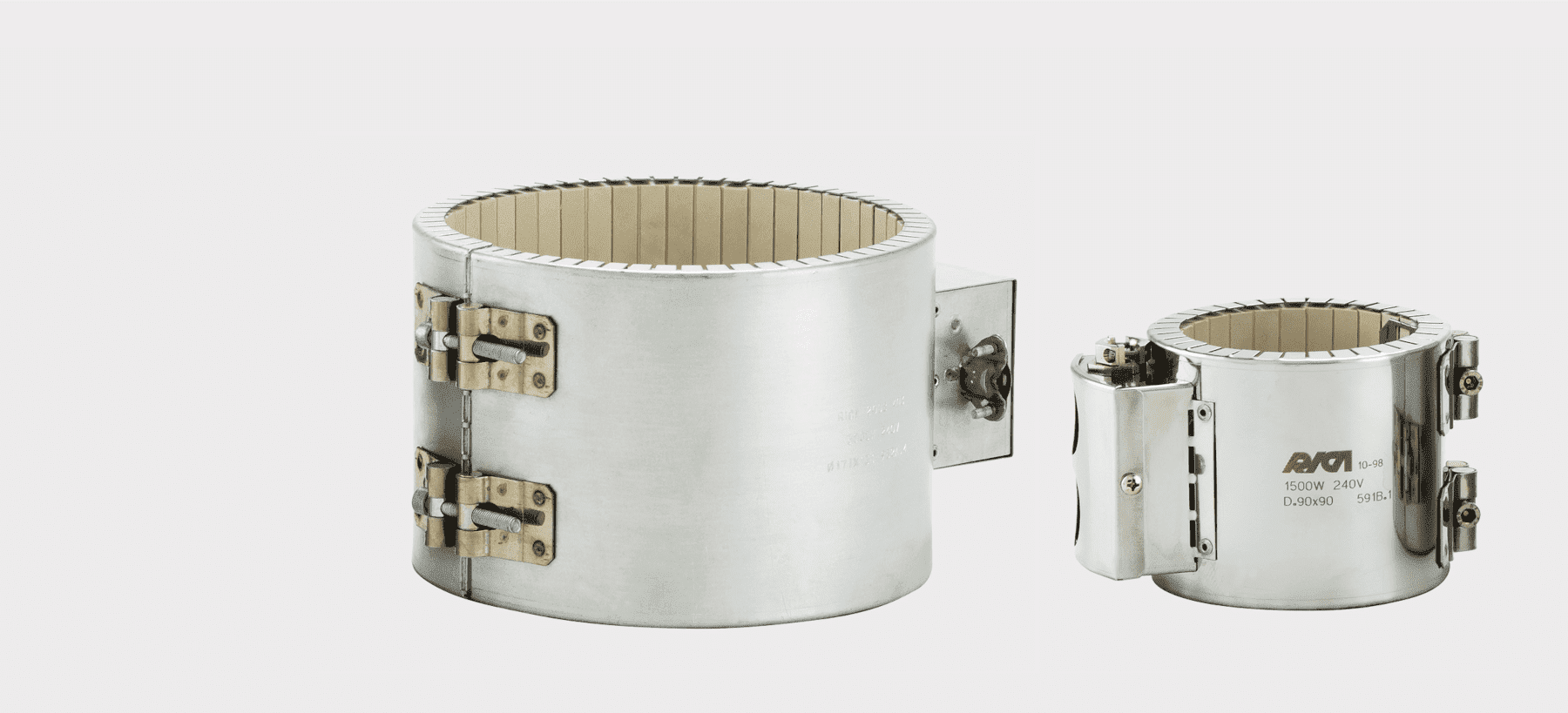

2. Stainless Steel

Key Properties:

Stainless steel offers excellent corrosion resistance and can withstand high temperatures, typically up to 1400°F (760°C). Its mechanical strength makes it suitable for demanding environments.

Illustrative image related to band heaters

Pros & Cons:

The durability of stainless steel band heaters is a significant advantage, as they resist wear and tear. However, they tend to be more expensive than mica heaters and can be heavier, which may complicate installation.

Impact on Application:

Stainless steel is ideal for food processing and chemical applications, where hygiene and resistance to corrosive substances are paramount.

Considerations for International Buyers:

Buyers should consider the specific grades of stainless steel required for their applications, as different grades offer varying levels of corrosion resistance. Compliance with food safety standards is also crucial in regions like Europe and the Middle East.

3. Silicone Rubber

Key Properties:

Silicone rubber can operate at temperatures up to 500°F (260°C) and is known for its flexibility and lightweight nature. It provides good electrical insulation and is resistant to moisture and chemicals.

Pros & Cons:

The flexibility of silicone rubber heaters allows for easy installation on irregular shapes, making them versatile. However, their lower temperature rating compared to mica and stainless steel limits their use in high-temperature applications. They are generally more affordable.

Impact on Application:

Silicone rubber band heaters are commonly used in applications that require gentle heating, such as food service and medical equipment.

Considerations for International Buyers:

Buyers should check for compliance with relevant safety and material standards, especially in the medical and food sectors. The ability to customize silicone heaters for specific applications is an added advantage.

4. Alumina Oxide

Key Properties:

Alumina oxide insulation can handle temperatures up to 1400°F (760°C) and is known for its high thermal conductivity and durability.

Illustrative image related to band heaters

Pros & Cons:

Alumina oxide band heaters provide high watt density and are suitable for applications requiring rapid heating. However, they can be more complex to manufacture, leading to higher costs.

Impact on Application:

These heaters are ideal for plastic processing and scientific testing, where precise temperature control is essential.

Considerations for International Buyers:

Ensure that suppliers can provide the necessary certifications for alumina oxide heaters, particularly in regions with strict manufacturing standards, such as Europe.

Summary Table

| Material | Typical Use Case for Band Heaters | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Mica | Plastic processing, injection molding | Lightweight and versatile | Prone to cracking under stress | Medium |

| Stainless Steel | Food processing, chemical applications | Excellent corrosion resistance | Higher cost and weight | High |

| Silicone Rubber | Food service, medical equipment | Flexible and easy to install | Lower temperature rating | Low |

| Alumina Oxide | Plastic processing, scientific testing | High watt density and rapid heating | Complex manufacturing process | High |

This strategic material selection guide provides essential insights into the various materials used in band heaters, helping international B2B buyers make informed decisions based on their specific applications and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for band heaters

What Are the Key Stages in the Manufacturing Process of Band Heaters?

The manufacturing process of band heaters involves several critical stages that ensure product quality and performance. These stages typically include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Band Heaters?

The first step in the manufacturing process is material preparation. High-quality materials such as mica, stainless steel, and various insulation materials are sourced based on specific application requirements. Mica is often chosen for its excellent thermal insulation properties, making it ideal for high-temperature applications. The materials undergo rigorous inspection to confirm they meet the specified standards before entering production.

What Techniques Are Used in the Forming Stage of Band Heater Production?

Once materials are prepared, they move to the forming stage. This involves cutting and shaping the metal sheaths and insulation to the required dimensions. Advanced techniques such as CNC machining and laser cutting are frequently employed to ensure precision. For instance, the sheath is typically formed into a cylindrical shape, which is crucial for the efficient transfer of heat.

How Does Assembly Work in the Band Heater Manufacturing Process?

The assembly stage is where the components come together. Electrical elements are integrated into the formed metal sheaths, and additional features such as clamps and terminals are attached. This stage may also involve customization options, such as adding holes or cutouts to accommodate specific applications. Quality checks are performed at this point to ensure that all connections are secure and meet design specifications.

Illustrative image related to band heaters

What Finishing Processes Are Critical for Band Heaters?

Finishing processes add the final touches to the band heaters. This may include surface treatments to enhance corrosion resistance and improve durability. For example, a high-temperature galvanized coating may be applied to protect against oxidation. Additionally, heaters are often tested for functionality before being packaged for shipping.

What Quality Assurance Standards Are Relevant for Band Heaters?

Quality assurance is a critical aspect of manufacturing band heaters. Manufacturers typically adhere to international standards such as ISO 9001, which focuses on quality management systems. Compliance with these standards ensures that manufacturers maintain consistent quality and are committed to continuous improvement.

Which Industry-Specific Certifications Should B2B Buyers Look For?

In addition to ISO standards, industry-specific certifications such as CE marking and API certifications are important for ensuring safety and performance. CE marking indicates compliance with European health, safety, and environmental protection standards, while API certifications are relevant for applications in the petroleum and natural gas industries. B2B buyers should verify these certifications to ensure that the products meet necessary regulatory requirements.

What Are the Key Quality Control Checkpoints During Band Heater Manufacturing?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to identify any defects or issues early on. These checkpoints typically include:

Illustrative image related to band heaters

- Incoming Quality Control (IQC): This stage involves inspecting raw materials before they are used in production to ensure they meet specifications.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, random samples may be tested for dimensional accuracy and electrical performance to catch any deviations from standards.

- Final Quality Control (FQC): Once assembly is complete, each band heater undergoes a comprehensive inspection that may include functional testing and visual checks to ensure the product is free from defects.

What Common Testing Methods Are Used for Band Heaters?

Manufacturers employ various testing methods to validate the performance and safety of band heaters. Common testing techniques include:

- Electrical Resistance Testing: This checks the electrical integrity of the heater and ensures that it operates within specified parameters.

- Thermal Imaging: This method helps identify hot spots and ensure uniform heat distribution across the heater’s surface.

- Insulation Resistance Testing: This assesses the effectiveness of the insulation material, ensuring that it can withstand the operating conditions without failure.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should take proactive steps to verify the quality control practices of potential suppliers. This can include:

- Supplier Audits: Conducting on-site audits allows buyers to assess manufacturing practices, quality control processes, and compliance with relevant standards.

- Requesting Quality Reports: Buyers should ask suppliers for detailed quality assurance reports, including results from IQC, IPQC, and FQC processes.

- Third-Party Inspections: Engaging independent inspection agencies can provide an unbiased assessment of a supplier’s quality control measures.

What Nuances Should International Buyers Consider Regarding Quality Control?

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control. Variations in regulatory requirements and standards across different countries can affect product compliance. For example, while CE marking is crucial for products sold in the European market, other regions may have different certification requirements.

Additionally, language barriers and cultural differences may impact communication regarding quality expectations. Establishing clear lines of communication and setting expectations upfront can help mitigate these challenges.

Conclusion

Understanding the manufacturing processes and quality assurance practices for band heaters is essential for B2B buyers looking to source reliable heating solutions. By focusing on the key stages of manufacturing, relevant quality standards, and effective verification methods, buyers can make informed decisions that ensure they receive high-quality products that meet their specific needs. Engaging with suppliers that prioritize quality assurance can lead to long-term partnerships and successful outcomes in various industrial applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘band heaters’

Introduction

This sourcing guide aims to assist B2B buyers in effectively procuring band heaters, which are essential for a variety of industrial applications, including plastic processing and food production. By following this checklist, you will ensure that your purchase meets your technical requirements and aligns with your operational goals.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is vital for selecting the right band heater for your application. Consider factors such as the heater’s diameter, width, voltage, wattage, and maximum operating temperature. Knowing these details will help you narrow down your options and ensure compatibility with your equipment.

- Diameter and Width: Ensure the dimensions match your machinery to avoid installation issues.

- Voltage and Wattage: Select heaters that align with your power supply capabilities to prevent electrical complications.

Step 2: Assess Application Requirements

Different applications demand specific heating capabilities. Identify the intended use of the band heaters, as this will affect the type of heater you need. For instance, high-temperature applications may require mica band heaters, while lower temperature processes could utilize silicone rubber heaters.

- Temperature Range: Verify the maximum temperature the heater can handle.

- Environmental Conditions: Consider factors like humidity, exposure to chemicals, or potential obstructions in the heating environment.

Step 3: Evaluate Supplier Certifications

Before making a purchase, it’s critical to assess the certifications and compliance of potential suppliers. Look for industry-standard certifications such as UL or CE, which indicate that the products meet specific safety and performance criteria.

Illustrative image related to band heaters

- Quality Assurance: Certified products typically adhere to rigorous quality control measures.

- Regulatory Compliance: Compliance with local regulations is essential, especially in regions like Europe or the Middle East, where standards may be stringent.

Step 4: Request Customization Options

Given the variety of applications for band heaters, inquire about customization options. Many suppliers offer the ability to tailor designs to fit unique requirements, such as custom dimensions or integrated features like cutouts for obstructions.

- Flexibility in Design: Custom options can enhance efficiency and performance in specific applications.

- Long-term Investment: Tailored solutions often lead to better longevity and reduced operational costs.

Step 5: Analyze Supplier Reputation and Experience

Research potential suppliers to gauge their reputation in the market. Look for reviews, testimonials, and case studies that demonstrate their experience, particularly in your industry or region.

- Industry Expertise: Suppliers with a proven track record in your specific application area are more likely to meet your needs.

- Customer Support: A reputable supplier should offer robust customer service and technical support to assist you before and after the purchase.

Step 6: Compare Pricing and Delivery Terms

Once you have shortlisted potential suppliers, compare pricing structures and delivery terms. Ensure that you are getting value for your investment while also considering lead times that align with your project schedules.

- Total Cost of Ownership: Look beyond the initial purchase price; factor in installation, maintenance, and operational costs.

- Delivery Reliability: Confirm that the supplier can meet your deadlines to avoid production delays.

Step 7: Finalize Contracts and Terms

After selecting a supplier, it’s important to finalize all contractual terms. This includes payment schedules, warranty details, and return policies. A well-defined agreement protects both parties and ensures clarity throughout the transaction.

- Legal Protections: Ensure that your contract includes clauses that safeguard your interests.

- Clear Deliverables: Specify the expected outcomes and responsibilities to prevent misunderstandings.

By following this practical checklist, you can streamline the procurement process for band heaters, ensuring that your purchase is both effective and efficient.

Comprehensive Cost and Pricing Analysis for band heaters Sourcing

What Are the Key Cost Components in Band Heaters Sourcing?

When sourcing band heaters, understanding the cost structure is crucial for effective budgeting and negotiation. The primary cost components include:

-

Materials: The choice of materials significantly impacts costs. Mica, stainless steel, and various insulative materials are commonly used. Premium materials can enhance durability and efficiency but increase the initial cost.

-

Labor: Labor costs vary depending on the complexity of the manufacturing process and the region of production. Regions with higher labor costs may offer better-skilled labor, which can improve product quality.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, including utilities, rent, and equipment maintenance. Efficient manufacturing processes can minimize overhead costs, thus affecting pricing.

-

Tooling: Custom tooling for specialized band heaters can be a significant upfront investment. The costs can be amortized over larger production runs, so economies of scale are essential.

-

Quality Control (QC): Ensuring that the heaters meet safety and performance standards incurs additional costs. Rigorous QC processes can prevent defects, ultimately saving costs related to warranty claims and customer dissatisfaction.

-

Logistics: Shipping costs depend on the origin and destination, as well as the mode of transport. International shipping often includes tariffs and import duties, which should be factored into the total cost.

-

Margin: Suppliers typically add a markup to cover their costs and profit. Understanding the supplier’s margin expectations can aid in negotiations.

How Do Price Influencers Impact Band Heaters Pricing?

Several factors can influence the pricing of band heaters, including:

-

Volume/MOQ: Buying in larger quantities often leads to discounts. Understanding the minimum order quantities (MOQ) can help in planning purchases effectively.

-

Specifications and Customization: Customized heaters that meet specific application requirements can significantly vary in price. Standard models are generally more cost-effective.

-

Materials: The choice between standard and high-performance materials affects pricing. High-temperature capabilities and specialized coatings can increase costs.

-

Quality and Certifications: Products with industry certifications (e.g., UL, CE) often come with higher price tags due to the additional testing and compliance costs.

-

Supplier Factors: Supplier reputation, reliability, and geographical location can affect pricing. Suppliers with a robust quality assurance process may charge more but offer better long-term value.

-

Incoterms: The terms of shipment (like FOB, CIF) can influence the final cost. Understanding these terms is vital for calculating total landed costs.

What Are Some Effective Buyer Tips for Sourcing Band Heaters?

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should consider several strategies:

-

Negotiate: Always negotiate pricing, especially for larger orders. Suppliers may have flexibility, particularly if you establish a long-term relationship.

-

Focus on Cost-Efficiency: Assess not only the purchase price but also the total cost of ownership, which includes installation, maintenance, and energy efficiency. Higher upfront costs can sometimes translate into lower operational costs.

-

Understand Pricing Nuances: Be aware of regional pricing differences, especially in relation to import taxes and tariffs. Understanding the local market can help in making informed decisions.

-

Request Multiple Quotes: Obtaining quotes from various suppliers allows for better comparison and can provide leverage in negotiations.

-

Verify Supplier Credentials: Research suppliers to ensure they meet quality and safety standards. Ask for certifications and references to gauge reliability.

Conclusion

Understanding the cost components and price influencers in band heaters sourcing is essential for making informed purchasing decisions. By leveraging strategic negotiation and focusing on total cost efficiency, international B2B buyers can secure high-quality band heaters that meet their specific needs while optimizing their budgets. Remember to consider the indicative nature of pricing, as factors such as market fluctuations and supply chain dynamics can affect final costs.

Alternatives Analysis: Comparing band heaters With Other Solutions

When evaluating heating solutions for industrial applications, it’s essential to consider alternatives to band heaters that may suit specific operational needs. Band heaters are widely used for heating cylindrical surfaces in various sectors, but other technologies can provide similar heating capabilities. This analysis compares band heaters against two viable alternatives: cartridge heaters and infrared heaters.

Comparison Table

| Comparison Aspect | Band Heaters | Cartridge Heaters | Infrared Heaters |

|---|---|---|---|

| Performance | High watt density, effective for cylindrical surfaces | Excellent for localized heating, quick response time | Rapid heating, ideal for large areas |

| Cost | Moderate initial investment; variable based on size and wattage | Generally lower cost but can vary with specifications | Higher upfront cost; efficiency can reduce long-term expenses |

| Ease of Implementation | Requires precise fitting and installation | Easy to install in pre-drilled holes | Minimal installation; often portable |

| Maintenance | Regular checks needed for wear and tear | Low maintenance; typically long-lasting | Minimal; requires occasional cleaning |

| Best Use Case | Plastic processing, food service, and chemical applications | Injection molding and localized heating in machinery | Large surface heating, drying applications, and curing processes |

In-Depth Comparison of Alternatives

Cartridge Heaters

Cartridge heaters are compact and versatile heating elements designed to fit into drilled holes in machinery or equipment. They offer excellent performance for localized heating, making them ideal for applications such as injection molding and other precise heating processes. One of the significant advantages of cartridge heaters is their quick response time, enabling faster heating cycles. However, their effectiveness is limited to specific applications, and they may not be suitable for all heating scenarios. Additionally, they require pre-drilled holes, which can add complexity during the installation phase.

Infrared Heaters

Infrared heaters utilize radiant heat to warm objects directly, making them suitable for large areas and processes that require uniform heating. They are particularly effective in applications such as curing, drying, and even food service environments. The primary benefit of infrared heaters is their speed; they can heat surfaces rapidly without needing extensive preheating. However, the initial investment can be higher compared to other heating solutions, and they may require a more extensive setup. Moreover, their effectiveness diminishes with distance, which could limit their application in larger spaces.

Conclusion: How to Choose the Right Heating Solution for Your Needs

Selecting the appropriate heating solution depends on various factors, including the specific application requirements, budget constraints, and operational efficiency. Band heaters excel in applications involving cylindrical surfaces and offer reliable performance across various industries. However, for localized heating needs, cartridge heaters may provide a more efficient solution, while infrared heaters are ideal for rapid and expansive heating tasks. B2B buyers should carefully evaluate their operational requirements, considering factors such as installation complexity, maintenance needs, and long-term costs, to determine the best heating solution tailored to their unique business needs.

Essential Technical Properties and Trade Terminology for band heaters

What Are the Key Technical Properties of Band Heaters?

When evaluating band heaters for industrial applications, understanding their technical specifications is essential for making informed purchasing decisions. Here are some critical properties that buyers should consider:

-

Material Composition

Band heaters are typically constructed from materials such as mica, stainless steel, or aluminum. Mica provides excellent insulation and thermal stability, making it suitable for high-temperature applications. Stainless steel offers durability and corrosion resistance, which is crucial for environments prone to moisture or chemical exposure. Understanding the material grade is vital for ensuring the heater meets specific performance requirements and can withstand operational conditions. -

Watt Density

Watt density refers to the amount of power (watts) supplied per square inch of the heating element. It significantly impacts the heater’s efficiency and its ability to maintain desired temperatures. Higher watt densities allow for faster heating but can also lead to overheating if not managed correctly. Buyers should consult manufacturers to determine the appropriate watt density for their application, especially in processes like plastic injection molding or food processing. -

Operating Temperature Range

Band heaters are designed to operate within specific temperature ranges, often exceeding 900°F (482°C) depending on the type. This specification is crucial for ensuring that the heater can perform effectively under the conditions it will face. For example, if a band heater is needed for applications like die casting or extrusion, selecting one with a higher temperature capability will prevent premature failure and reduce maintenance costs. -

Voltage and Phase Options

Band heaters are available in various voltage configurations (e.g., 120V, 240V, up to 480V) and can be single-phase or three-phase. This flexibility allows businesses to integrate heaters into existing systems without requiring extensive modifications. Understanding these electrical specifications is essential for compatibility with local power supplies and operational efficiency. -

Customizability

Many manufacturers offer customizable options for band heaters, such as sizes, wattages, and even cut-outs for obstructions. Custom solutions can enhance efficiency and performance in specific applications. Buyers should assess their unique requirements and communicate them clearly to suppliers to achieve optimal results.

What Are Common Trade Terms Related to Band Heaters?

Navigating the purchasing process for band heaters involves understanding key trade terminology. Here are several commonly used terms:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of band heaters, partnering with an OEM can ensure high-quality components that meet specific application needs. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity a supplier is willing to sell. Understanding MOQ is crucial for budget-conscious buyers, as it can affect inventory management and cash flow. Businesses should negotiate MOQs that align with their operational demands. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to solicit price quotes for specific products or services. It’s an essential step in the procurement process that helps buyers compare prices and terms from multiple suppliers, ensuring they receive competitive offers. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. These terms clarify aspects like shipping, insurance, and customs clearance, which are critical for B2B buyers sourcing products across borders. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is vital for planning and ensuring that production schedules are not disrupted due to delays in equipment delivery.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when selecting band heaters for their specific applications. This knowledge not only aids in purchasing but also enhances communication with suppliers, ultimately leading to more successful procurement outcomes.

Navigating Market Dynamics and Sourcing Trends in the band heaters Sector

What Are the Current Market Dynamics and Key Trends in the Band Heaters Sector?

The band heaters market is experiencing significant growth driven by the increasing demand for efficient heating solutions across various industries, including plastics, food processing, and chemical manufacturing. Key trends include the rise of customizable solutions that cater to specific application needs, such as varying diameters, watt densities, and temperature capabilities. As manufacturers seek to improve their operational efficiency, there is an increased focus on high-performance band heaters that can withstand extreme conditions, with many products now offering temperature ratings exceeding 900°F (482°C).

Emerging technologies such as IoT-enabled heating systems are gaining traction, allowing for real-time monitoring and control of heating processes. This technology enables businesses to optimize energy consumption and reduce operational costs, making it particularly appealing for international buyers in regions like Africa and South America, where energy costs can be a significant concern. Furthermore, the global push for energy-efficient solutions is prompting buyers from the Middle East and Europe to prioritize suppliers that offer advanced thermal management technologies.

How Can Sustainability and Ethical Sourcing Impact the Band Heaters Market?

Sustainability is becoming a critical consideration in the band heaters sector, with buyers increasingly prioritizing products that minimize environmental impact. Manufacturers are responding by adopting eco-friendly materials and processes, such as using recyclable materials for insulation and heating elements. The importance of ethical supply chains cannot be overstated, as B2B buyers are now more vigilant about sourcing from suppliers who adhere to responsible labor practices and environmental regulations.

Green certifications, such as RoHS (Restriction of Hazardous Substances) and ISO 14001 (Environmental Management), are increasingly sought after by buyers aiming to align their procurement processes with sustainability goals. Suppliers that demonstrate a commitment to ethical sourcing and sustainability are likely to gain a competitive advantage in the global market, particularly among conscious buyers from Europe and North America. This trend also resonates in emerging markets like Brazil and Saudi Arabia, where there is a growing awareness of environmental issues.

What is the Brief Evolution and History of Band Heaters in the B2B Sector?

The evolution of band heaters can be traced back to the early 20th century when they were primarily used in industrial applications for heating cylindrical objects. Initially, these heaters were rudimentary, constructed using basic materials and offering limited temperature control. As industries evolved, so did the technology behind band heaters.

Illustrative image related to band heaters

By the mid-20th century, advancements in materials science led to the development of mica and ceramic insulation, enhancing the efficiency and durability of band heaters. Today, band heaters are engineered with high-performance materials that can withstand extreme temperatures and harsh environments, making them indispensable in various industrial processes. The ongoing evolution in design and technology reflects the sector’s responsiveness to the changing needs of B2B buyers, who now demand more versatile, efficient, and sustainable heating solutions.

In summary, understanding these market dynamics, sustainability considerations, and the historical context will empower international B2B buyers to make informed sourcing decisions in the band heaters sector.

Frequently Asked Questions (FAQs) for B2B Buyers of band heaters

-

How do I choose the right band heater for my application?

Selecting the appropriate band heater involves assessing the specific needs of your application. Consider factors such as the diameter of the cylinder, the required watt density, and the maximum operating temperature. Additionally, evaluate the materials to be heated and their thermal characteristics. Customization options, including cut-outs for obstructions, should also be taken into account. Collaborating with a reputable supplier can provide insights into the best choices tailored to your operational requirements. -

What is the best band heater for high-temperature applications?

For high-temperature applications, consider band heaters made with durable materials like alumina oxide insulation or stainless steel sheaths. Models such as MI Better Bands can handle temperatures up to 1400°F (760°C), making them suitable for demanding environments like plastic processing and chemical applications. Ensure the heater’s design supports your specific application needs, including watt density and size requirements. -

What are the customization options available for band heaters?

Many suppliers offer extensive customization for band heaters, including options for size, wattage, and shape. Custom features may include holes, cut-outs, or specific clamping styles to accommodate obstructions on the cylinder. Discuss your requirements with the manufacturer to ensure they can meet your specifications, enhancing the heater’s efficiency and effectiveness in your application. -

What are the typical minimum order quantities (MOQs) for band heaters?

Minimum order quantities for band heaters can vary significantly based on the supplier and the complexity of the order. Generally, MOQs can range from a few units to hundreds, particularly for customized products. It’s advisable to inquire directly with potential suppliers about their MOQs to plan your purchasing strategy and manage inventory effectively. -

What payment terms should I expect when sourcing band heaters internationally?

Payment terms for international purchases can vary widely, depending on the supplier and the region. Common practices include upfront payments, net 30, or net 60 terms. It’s crucial to establish clear payment agreements before finalizing orders. Additionally, consider using secure payment methods, such as letters of credit, to mitigate risks associated with international transactions. -

How do I ensure quality assurance for band heaters from international suppliers?

To ensure quality assurance, consider suppliers that provide third-party certifications, such as UL or CE compliance. Request detailed documentation regarding manufacturing processes and materials used. Conducting a factory audit or utilizing a third-party inspection service can also help verify the quality of the products before shipment. Establishing a clear quality control agreement with the supplier is essential for maintaining standards. -

What logistics considerations should I keep in mind when importing band heaters?

When importing band heaters, consider shipping methods, customs regulations, and potential tariffs that may apply to your order. Collaborate with logistics providers experienced in handling industrial equipment to navigate these complexities. Additionally, account for lead times and shipping durations, as they can impact your production schedules. Proper documentation is crucial to avoid delays at customs. -

Are there specific regulations I need to be aware of when purchasing band heaters for use in my country?

Regulations can vary by country and may include safety standards, energy efficiency requirements, and environmental considerations. Familiarize yourself with local regulations that pertain to electrical equipment and heating devices. Engaging with local regulatory bodies or industry associations can provide valuable guidance, ensuring compliance and avoiding potential legal issues.

Top 7 Band Heaters Manufacturers & Suppliers List

1. McMaster – Band Heaters

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Band Heaters, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Tempco – Band Heaters

Domain: tempco.com

Registered: 1999 (26 years)

Introduction: Band Heaters are used to heat cylindrical surfaces and are available in several product lines designed for different operating environments. Common applications include autoclaves, blow molding machines, drum heating, food service warming pots, plastic extruders, and more. Maximum sheath temperatures range from 650°F (343°C) to 1400°F (760°C). The heaters can be used in clean or contaminated envir…

3. BriskHeat – Mica Band Heaters

Domain: briskheat.com

Registered: 1996 (29 years)

Introduction: Mica Band Heaters are designed for high-temperature applications, providing efficient heat transfer and durability. They are available in various sizes and watt densities, suitable for different industrial heating needs. The heaters feature a mica insulation layer that allows for high operating temperatures while maintaining energy efficiency. They can be customized for specific applications and a…

4. TUTCO – Conductive Band Heaters

Domain: tutco.com

Registered: 1997 (28 years)

Introduction: TUTCO CONDUCTIVE Band Heaters are engineered for a wide range of cylindrical applications, including plastic processing and scientific testing. The product line includes HT Mica Bands, MI Better Bands, Permaheat Bands, and Ultima Bands, all made in the USA. Key features include:

– **HT Mica Bands**: High temperature performance up to 900°F.

– **MI Better Bands**: Alumina Oxide insulation with wel…

5. Dwyer Omega – Precision Measurement Instruments

Domain: dwyeromega.com

Registered: 2022 (3 years)

Introduction: {“price_ranges”: [{“min”: 50, “max”: 199.99, “count”: 7}, {“min”: 200, “max”: 499.99, “count”: 9}, {“min”: 500, “max”: 999.99, “count”: 3}, {“min”: 1000, “max”: 9999.99, “count”: 3}], “barrel_diameters”: [0.9375, 1, 1.5, 1.25, 1.75, 1.375, 1.625, 1.875, 2, 2.5, 2.25, 2.75, 2.125, 2.375, 2.3125, 3, 3.5, 3.25, 3.75, 3.125, 3.625, 3.875, 3.5625, 4, 4.5, 4.75, 4.125, 4.875, 4.3125, 4.9375, 5, 5.5, 5.2…

6. Watlow – MI Band Heater

Domain: watlow.com

Registered: 1995 (30 years)

Introduction: This company, Watlow – MI Band Heater, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Heating Elements Plus – Nozzle Band Heaters

Domain: heatingelementsplus.com

Registered: 2009 (16 years)

Introduction: We offer a full line of nozzle band heaters for the plastics industry as well as slip-on heaters for the medical and analytical industries. Each nozzle band heater is designed to meet specific application requirements, including high performance, high temperature, or high watt density. Key features include: oxidation resistant metal sheath, protective sleeving where leads exit the heater, stainles…

Strategic Sourcing Conclusion and Outlook for band heaters

In the dynamic landscape of industrial heating solutions, strategic sourcing of band heaters emerges as a critical factor for optimizing operational efficiency and reducing costs. Key considerations include the diverse applications of mica band heaters in sectors ranging from plastics to food processing, highlighting their adaptability and performance under varying conditions. Buyers should prioritize suppliers offering customization options, high-temperature capabilities, and durable materials to ensure longevity and reliability in demanding environments.

Furthermore, understanding watt density specifications and compliance with international standards is essential for making informed purchasing decisions. This knowledge empowers businesses to select the right heating solutions tailored to their unique operational needs.

Looking ahead, international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are encouraged to engage with reputable manufacturers and suppliers who can provide innovative solutions that meet both current and future demands. By fostering strong partnerships and leveraging strategic sourcing, companies can enhance their competitive edge in the global market. Take the next step in optimizing your heating processes—explore your options today and position your business for success.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to band heaters