Top 6 Type M Plug Adapter Suppliers (And How to Choose)

Introduction: Navigating the Global Market for type m plug adapter

In today’s interconnected world, sourcing the right type M plug adapter can be a daunting challenge for international B2B buyers. As businesses expand their operations across borders, the need for reliable electrical connectivity becomes paramount. This guide aims to simplify the complexities of navigating the global market for type M plug adapters, offering insights into various types, applications, and the critical factors to consider when selecting suppliers.

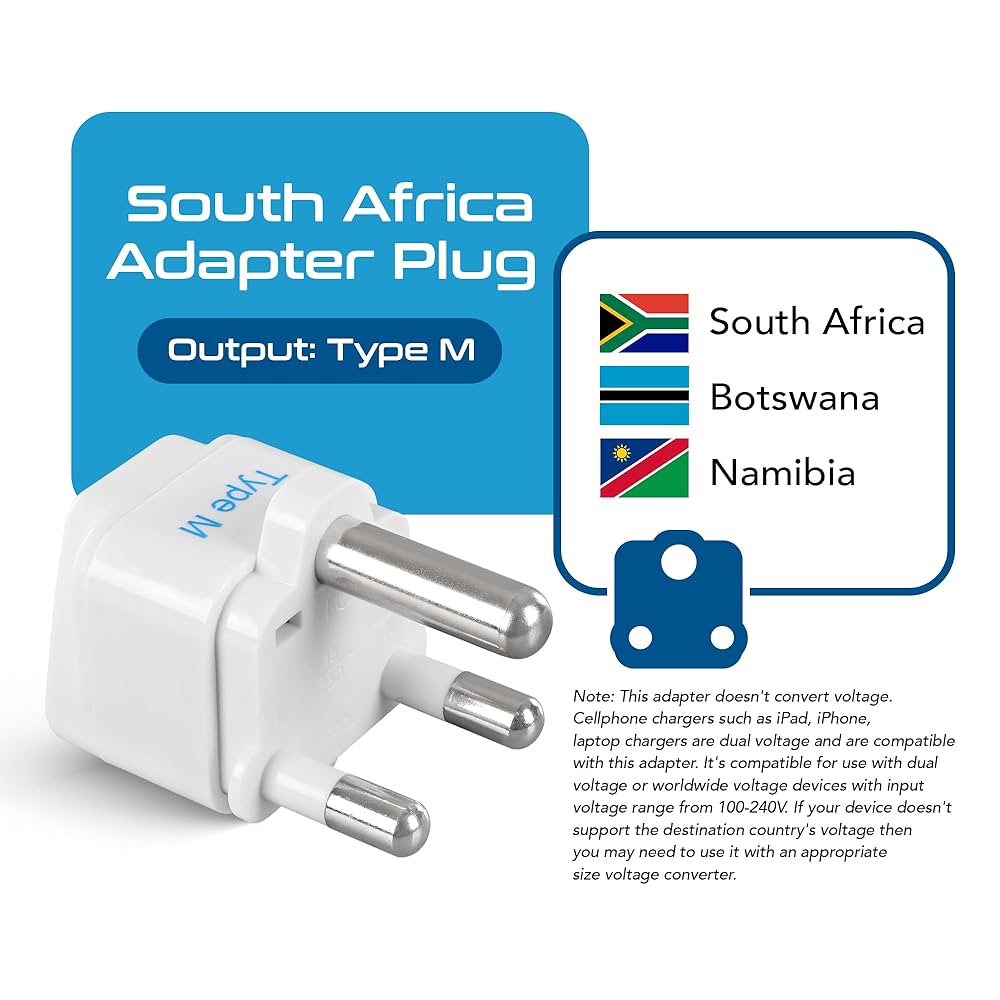

From understanding the distinct features of type M adapters—commonly used in regions such as South Africa, Mozambique, and Afghanistan—to evaluating the compliance standards and certifications that ensure safety and reliability, this comprehensive resource equips decision-makers with the knowledge necessary to make informed purchasing choices. Buyers will benefit from detailed discussions on the vetting process for suppliers, cost considerations, and the importance of compatibility with dual-voltage devices, which is particularly relevant for businesses operating in diverse markets across Africa, South America, the Middle East, and Europe.

With this guide, you will gain the confidence to navigate supplier options effectively, ensuring that your business remains connected and operational no matter where your needs arise. Empower your purchasing decisions with expert insights tailored to the unique challenges faced by international buyers in sourcing type M plug adapters.

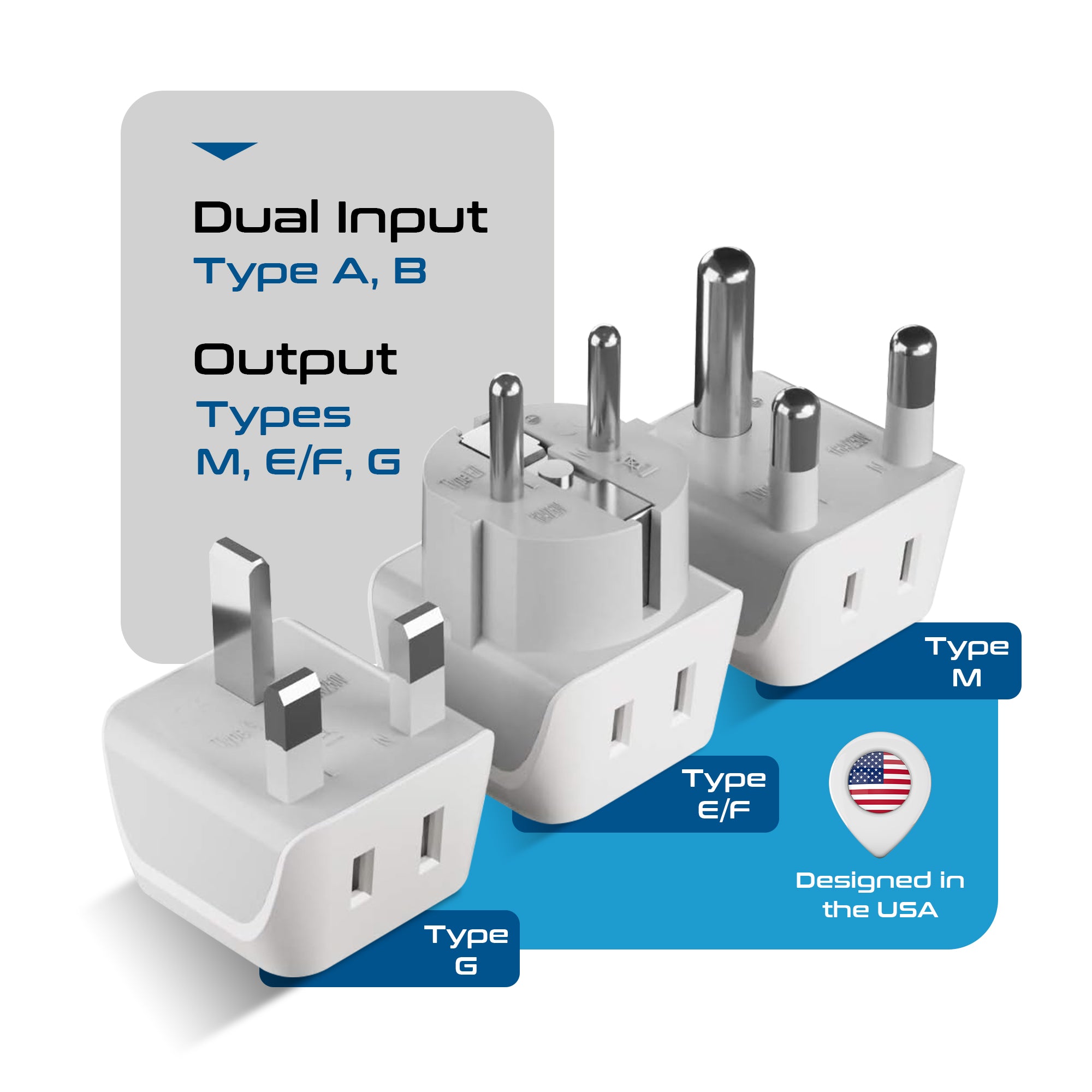

Understanding type m plug adapter Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Type M Standard Adapter | Grounded 3-prong design, accepts Type A and B devices | Electronics, travel, hospitality | Pros: Reliable connection, suitable for various devices. Cons: Limited voltage conversion capabilities. |

| Type M Universal Adapter | Multi-socket, accepts various plug types, USB charging ports | International travel, trade shows | Pros: Versatile, can charge multiple devices. Cons: May be bulkier than standard adapters. |

| Type M Surge Protector | Built-in surge protection, grounded, high amperage support | IT equipment, industrial applications | Pros: Protects sensitive electronics, high durability. Cons: Higher cost, potential over-specification for simple needs. |

| Type M Travel Adapter | Compact design, lightweight, often includes USB ports | Travel, expatriate workers | Pros: Portability, ease of use. Cons: Limited to dual-voltage devices only. |

| Type M Heavy-Duty Adapter | Industrial-grade materials, high power rating | Manufacturing, construction sites | Pros: Robust, suitable for high-demand environments. Cons: Not suitable for casual use or travel. |

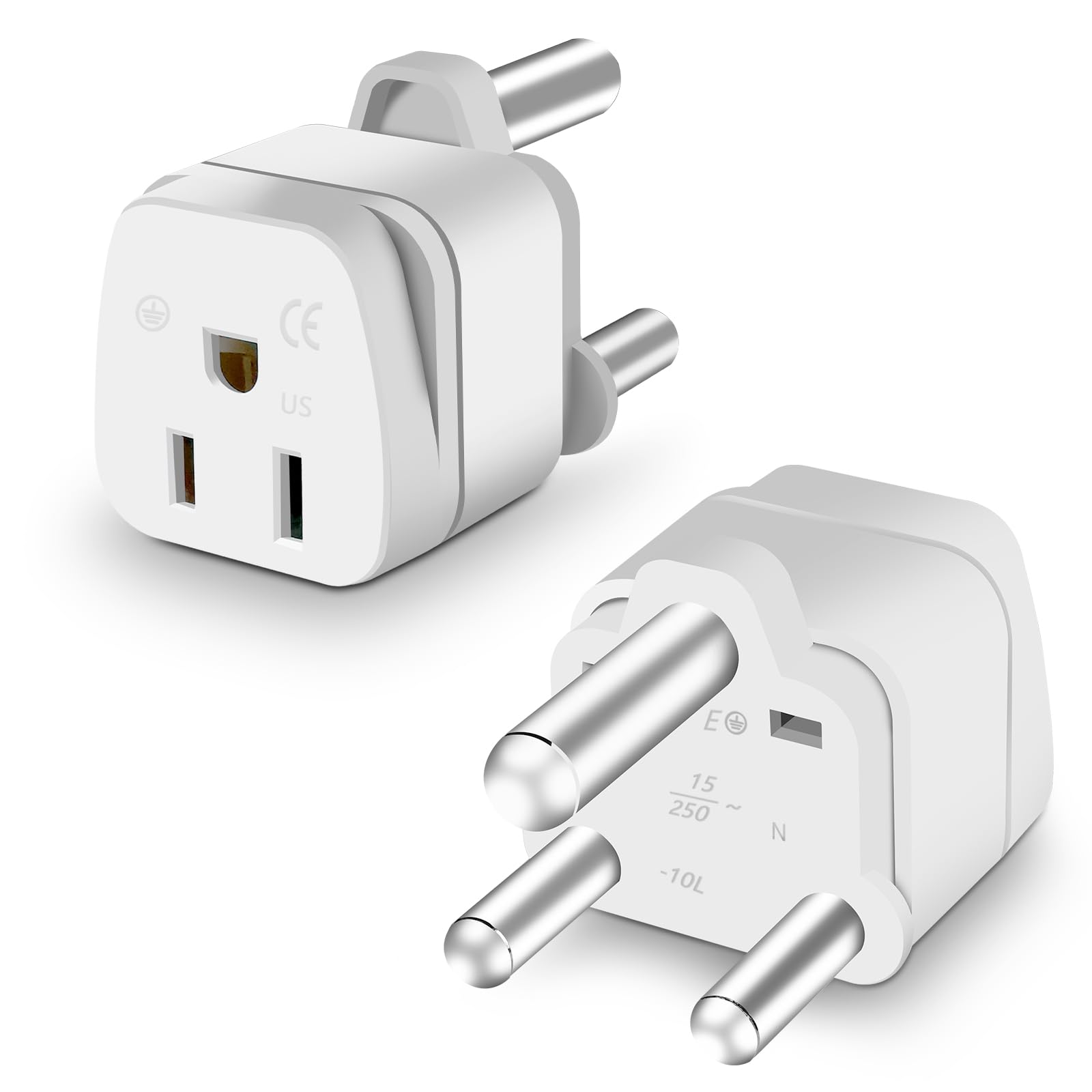

What Are the Characteristics of the Type M Standard Adapter?

The Type M Standard Adapter features a grounded 3-prong design, primarily used in South Africa and some neighboring countries. It is compatible with both Type A and B plugs, making it suitable for a wide range of electronic devices. Businesses in electronics, travel, and hospitality sectors find this adapter essential for ensuring reliable connections for various devices. Buyers should consider its limited voltage conversion capabilities, which may necessitate additional equipment for certain devices.

How Does the Type M Universal Adapter Benefit Businesses?

The Type M Universal Adapter stands out with its ability to accommodate multiple plug types, often featuring USB charging ports for added convenience. This versatility makes it particularly valuable for international businesses participating in trade shows or for organizations with employees frequently traveling abroad. While it offers the advantage of charging multiple devices simultaneously, its bulkier design may not be ideal for all users, especially those seeking compact solutions.

What Is Unique About the Type M Surge Protector?

Designed with built-in surge protection, the Type M Surge Protector is crucial for businesses relying on IT equipment and sensitive electronics. Its grounded design and high amperage support ensure that devices remain safe from power surges, making it a staple in industrial applications. Although it provides robust protection, the higher cost may deter businesses with simpler needs or tighter budgets.

Illustrative image related to type m plug adapter

Why Choose the Type M Travel Adapter?

The Type M Travel Adapter is characterized by its compact and lightweight design, making it perfect for frequent travelers or expatriate workers. Often equipped with USB ports, it allows for easy charging of mobile devices without the need for multiple adapters. However, it is important to note that this adapter is only suitable for dual-voltage devices, which may limit its applicability for some users.

In What Scenarios Is the Type M Heavy-Duty Adapter Ideal?

The Type M Heavy-Duty Adapter is built from industrial-grade materials, designed to withstand high power demands. It is an excellent choice for manufacturing and construction sites where equipment requires a robust power supply. While its durability is a significant advantage, it is not suited for casual use or travel, making it a more specialized option for businesses with high electrical needs.

Key Industrial Applications of type m plug adapter

| Industry/Sector | Specific Application of type m plug adapter | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Connecting electronic devices in hotels and resorts | Enhances guest experience by accommodating diverse devices | Ensure the adapter is compact and can handle multiple devices |

| Construction | Powering tools and equipment on job sites | Improves efficiency by providing reliable power sources | Look for durability and safety certifications |

| Telecommunications | Supporting network equipment in data centers | Ensures uninterrupted service and connectivity | Check compatibility with different voltages and plug types |

| Manufacturing | Operating machinery and equipment in factories | Increases productivity by minimizing downtime | Source adapters with high amperage ratings for heavy machinery |

| Travel and Tourism | Facilitating the use of personal electronics for travelers | Provides convenience for international travelers | Ensure adapters comply with local safety standards |

How is the Type M Plug Adapter Used in the Hospitality Sector?

In the hospitality industry, type M plug adapters are essential for connecting various electronic devices in hotels and resorts. Guests often travel with multiple devices that require different plug types, and having these adapters readily available enhances their experience. Businesses benefit from improved guest satisfaction, leading to positive reviews and repeat visits. When sourcing, it’s crucial to select compact adapters that can accommodate multiple devices simultaneously, ensuring convenience and versatility.

What Role Does the Type M Plug Adapter Play in Construction?

In construction, type M plug adapters are used to power tools and equipment on job sites, where access to electrical outlets may be limited. These adapters allow workers to connect their tools to local power sources, thereby improving efficiency and productivity. For businesses, the reliable power supply helps minimize downtime, which can be costly. When sourcing, durability and safety certifications are vital, as construction environments can be harsh and demanding.

How is the Type M Plug Adapter Critical for Telecommunications?

Telecommunications companies utilize type M plug adapters to support network equipment in data centers. These adapters ensure that servers and communication devices remain powered and operational, which is critical for maintaining uninterrupted service and connectivity. Businesses in this sector must prioritize adapters that are compatible with various voltages and plug types to accommodate different equipment. Reliability is paramount, as any power disruption can lead to significant financial losses.

Why is the Type M Plug Adapter Important in Manufacturing?

In the manufacturing sector, type M plug adapters facilitate the operation of machinery and equipment. They are crucial for connecting various machines to power sources, thereby increasing productivity and minimizing downtime. For manufacturers, sourcing adapters with high amperage ratings is essential, especially when dealing with heavy machinery that requires more power. Ensuring that these adapters meet safety standards is also critical to prevent electrical hazards.

How Does the Type M Plug Adapter Benefit Travel and Tourism?

For the travel and tourism industry, type M plug adapters provide essential support for international travelers who need to charge their personal electronics. Offering these adapters at airports, hotels, and tourist attractions adds value to the customer experience by providing convenience and accessibility. When sourcing, businesses should ensure that the adapters comply with local safety standards to avoid liability issues while catering to diverse customer needs.

3 Common User Pain Points for ‘type m plug adapter’ & Their Solutions

Scenario 1: Compatibility Issues with Diverse Devices

The Problem: Many B2B buyers face compatibility challenges when sourcing Type M plug adapters for their equipment. For instance, a company looking to expand its operations in South Africa might have devices that require different plug types, leading to confusion and potential downtime. Devices from North America, which commonly use Type A and B plugs, may not fit the Type M outlets without proper adapters. This mismatch can create significant delays in operations, especially if the company has a tight project deadline or needs to ensure that employees can charge their devices easily.

Illustrative image related to type m plug adapter

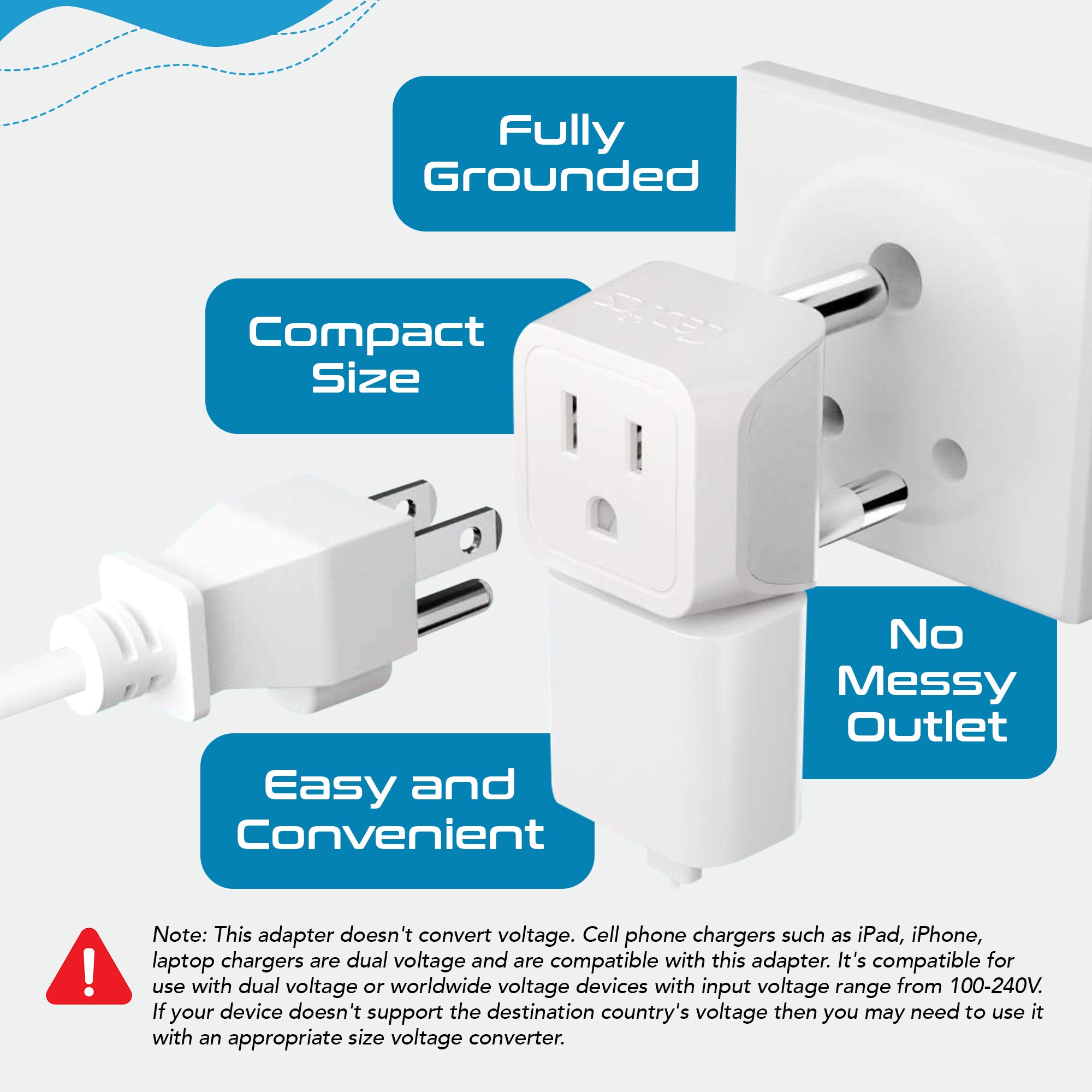

The Solution: To overcome compatibility issues, businesses should look for Type M plug adapters that feature multiple input options. A versatile adapter, such as a 5-in-1 model, can accept both Type A and B plugs while also providing USB ports for charging multiple devices simultaneously. When sourcing, ensure the adapter is CE certified and RoHS compliant to guarantee safety and reliability. Additionally, consider purchasing adapters in bulk to ensure that all employees have the necessary equipment without delays. Establishing a relationship with suppliers who specialize in international adapters will also help streamline this process, ensuring that your team can focus on their core tasks without worrying about power connectivity.

Scenario 2: Voltage Conversion Confusion

The Problem: Another common pain point for B2B buyers is the misunderstanding surrounding voltage compatibility. Many devices operate on different voltage levels, and the Type M plug adapter does not convert voltage; it only facilitates the connection. This can be problematic if a company brings in equipment that requires a higher voltage than what is available in the region, leading to equipment damage or failure to operate.

The Solution: It is crucial for businesses to conduct thorough research on the voltage requirements of their devices before traveling or expanding into regions using Type M plugs. When specifying adapters, make sure to choose those that explicitly state their limitations regarding voltage conversion. For devices that require voltage adjustments, companies should invest in appropriate voltage converters alongside their Type M plug adapters. This two-pronged approach ensures that all devices operate safely and efficiently. Additionally, create a checklist that includes voltage requirements for each device to prevent oversight during the procurement process.

Scenario 3: Limited Access to Reliable Power Sources

The Problem: In regions where Type M plugs are standard, such as parts of Africa and the Middle East, businesses may encounter limited access to reliable power sources. This can be especially frustrating for international teams or businesses that rely heavily on technology for operations, leading to potential productivity losses. Adapters might be readily available, but without a stable power supply, the devices may not function correctly, impacting overall business operations.

The Solution: To mitigate this issue, B2B buyers should prioritize sourcing Type M plug adapters with built-in surge protection and grounding features. These features help safeguard devices against power fluctuations common in regions with inconsistent power supply. Additionally, consider investing in power strips that accommodate multiple Type M outlets, allowing for the simultaneous charging of several devices. For further reliability, companies can explore local energy solutions, such as generators or uninterruptible power supplies (UPS), to ensure continuous operation. Establishing partnerships with local suppliers who understand the regional power landscape can also provide valuable insights into reliable energy sources and backup solutions.

Strategic Material Selection Guide for type m plug adapter

What Are the Key Materials Used in Type M Plug Adapters?

When selecting materials for type M plug adapters, it is essential to consider their properties, advantages, disadvantages, and the impact on applications. The choice of material affects not only the performance and durability of the adapter but also its compliance with international standards, particularly for B2B buyers in regions like Africa, South America, the Middle East, and Europe.

How Does Polycarbonate Contribute to the Performance of Type M Plug Adapters?

Polycarbonate is a common choice for the casing of type M plug adapters due to its high impact resistance and thermal stability. This thermoplastic can withstand temperatures up to 125°C and offers excellent electrical insulation properties.

Pros: Polycarbonate is lightweight, highly durable, and resistant to UV radiation, making it suitable for outdoor use. Its manufacturing process is relatively straightforward, allowing for cost-effective production.

Cons: While polycarbonate is robust, it can be prone to scratching and may not perform well in extreme temperatures beyond its rating. Additionally, its higher cost compared to other plastics may be a consideration for budget-sensitive projects.

Impact on Application: Polycarbonate’s electrical insulation properties make it ideal for ensuring safety in high-voltage environments. However, it is essential to verify compliance with international standards such as IEC and SANS for users in different regions.

What Role Does Copper Play in Electrical Conductivity for Type M Plug Adapters?

Copper is often used for the internal wiring and connectors of type M plug adapters due to its excellent electrical conductivity and thermal properties.

Pros: Copper’s high conductivity ensures minimal energy loss, making it efficient for power transfer. It is also relatively easy to work with during manufacturing, allowing for precise connections.

Cons: Copper is susceptible to corrosion, especially in humid environments, which may lead to reduced performance over time. Additionally, the cost of copper can be higher compared to aluminum, making it less appealing for large-scale production.

Impact on Application: The choice of copper enhances the performance of type M plug adapters in terms of power delivery. B2B buyers must consider environmental factors, such as humidity, that could affect the longevity of copper components.

Why Is PVC a Popular Choice for Type M Plug Adapter Insulation?

Polyvinyl chloride (PVC) is frequently used for insulation in type M plug adapters due to its excellent electrical insulating properties and flexibility.

Illustrative image related to type m plug adapter

Pros: PVC is cost-effective, easy to manufacture, and provides good resistance to chemicals and moisture. It also has a wide temperature range, making it suitable for various applications.

Cons: PVC can become brittle over time, especially when exposed to UV light or extreme temperatures. Its environmental impact is also a concern, as it is not biodegradable.

Impact on Application: PVC insulation ensures that the electrical components of the adapter remain protected from external elements. However, B2B buyers should be aware of regional regulations regarding the use of PVC in electrical products, particularly in Europe.

Illustrative image related to type m plug adapter

How Does Aluminum Compare as a Material for Type M Plug Adapters?

Aluminum is sometimes used for the casing of type M plug adapters due to its lightweight and corrosion-resistant properties.

Pros: Aluminum is significantly lighter than copper and offers good thermal conductivity. It is also resistant to corrosion, making it suitable for various environments.

Cons: Although aluminum is cost-effective, it has lower electrical conductivity compared to copper, which may affect performance in high-demand applications. Additionally, it can be more challenging to work with during manufacturing.

Impact on Application: Aluminum’s lightweight nature makes it ideal for portable adapters. However, B2B buyers should consider the trade-offs in conductivity and ensure that the product meets the necessary electrical standards for their specific region.

Summary Table of Material Selection for Type M Plug Adapters

| Material | Typical Use Case for type m plug adapter | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate | Adapter casing | High impact resistance | Prone to scratching | Medium |

| Copper | Internal wiring and connectors | Excellent electrical conductivity | Susceptible to corrosion | High |

| PVC | Insulation for electrical components | Cost-effective and flexible | Can become brittle over time | Low |

| Aluminum | Casing for portable adapters | Lightweight and corrosion-resistant | Lower conductivity than copper | Medium |

This guide provides a comprehensive overview of the materials used in type M plug adapters, highlighting their properties and considerations for international B2B buyers. Understanding these factors can aid in making informed purchasing decisions that align with regional standards and application requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for type m plug adapter

What Are the Key Stages in the Manufacturing Process of Type M Plug Adapters?

The manufacturing process of Type M plug adapters involves several critical stages, each designed to ensure the final product meets international standards and customer expectations.

Material Preparation: What Materials Are Used in Type M Plug Adapters?

The first step involves sourcing high-quality materials that meet specific electrical and safety requirements. Common materials used in Type M plug adapters include:

- Plastic Casings: Typically made from high-grade thermoplastics, these materials provide insulation and durability.

- Copper and Brass Conductors: These metals are essential for efficient electrical conductivity and corrosion resistance.

- Rubber or Silicone Gaskets: Used to enhance safety by providing insulation and preventing electrical shocks.

Suppliers often conduct material inspections to confirm compliance with international safety standards, ensuring that the materials are free from defects.

How Is the Forming Process Conducted for Type M Plug Adapters?

In the forming stage, the raw materials undergo various processes to shape them into usable components. This typically involves:

- Injection Molding: This technique is widely used for creating the plastic casing of the adapter. It ensures uniformity and precision, allowing for complex designs that accommodate multiple plug types.

- Metal Stamping: For the internal components, metal stamping processes shape the copper and brass pieces into connectors that will fit securely into the plug design.

These techniques are crucial for achieving the required specifications and ensuring the longevity of the adapters under different usage conditions.

Illustrative image related to type m plug adapter

What Assembly Techniques Are Commonly Used in Type M Plug Adapter Manufacturing?

Once the individual components are formed, the assembly stage begins. This can involve:

- Automated Assembly Lines: Many manufacturers use automated systems to streamline the assembly process. This increases efficiency and reduces human error.

- Manual Assembly: For more complex designs or quality control reasons, skilled technicians may manually assemble certain parts of the adapter.

During this phase, components are meticulously connected, ensuring that electrical connections are secure and that the adapter functions correctly.

How Is the Finishing Process Executed for Type M Plug Adapters?

The final stage of manufacturing is the finishing process, which enhances the product’s aesthetic appeal and ensures compliance with safety standards. Key activities include:

- Surface Treatment: This may involve applying coatings that enhance durability and resistance to environmental factors.

- Labeling: Proper labeling according to international standards (e.g., CE marking) is essential for compliance and consumer safety.

Quality checks are performed during this phase to ensure that the finished adapters meet all specifications and are ready for distribution.

Illustrative image related to type m plug adapter

What Quality Assurance Standards Are Relevant for Type M Plug Adapters?

Quality assurance is a vital component of the manufacturing process, especially for electrical products like Type M plug adapters. Relevant international standards include:

- ISO 9001: This standard focuses on quality management systems and is applicable across various industries, ensuring manufacturers adhere to a consistent level of quality.

- CE Certification: Required for products sold in the European market, this certification confirms that the product meets health, safety, and environmental protection standards.

- RoHS Compliance: This directive restricts the use of specific hazardous substances in electrical and electronic equipment, ensuring safety and environmental sustainability.

Adhering to these standards not only ensures product quality but also enhances marketability in diverse regions.

What Are the Quality Control Checkpoints in Type M Plug Adapter Production?

Quality control (QC) is integrated throughout the manufacturing process, with specific checkpoints designed to catch defects and ensure compliance. Key checkpoints include:

- Incoming Quality Control (IQC): This initial inspection verifies that raw materials meet specified requirements before production begins.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, periodic checks are conducted to monitor the quality of the assembly and ensure that standards are maintained.

- Final Quality Control (FQC): Once production is complete, a thorough inspection is conducted to assess the final product before it is shipped to customers.

These checkpoints are critical in identifying issues early in the production cycle, thereby reducing waste and improving overall efficiency.

Illustrative image related to type m plug adapter

How Can B2B Buyers Verify Supplier Quality Assurance Practices?

International B2B buyers should take proactive steps to verify the quality assurance practices of potential suppliers. Recommended actions include:

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control measures, and compliance with international standards firsthand.

- Requesting Quality Assurance Reports: Suppliers should provide documentation that details their quality management processes, including certifications and test results.

- Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s quality practices and product integrity.

Understanding the nuances of QC certifications is particularly important for buyers from Africa, South America, the Middle East, and Europe, as varying regional standards may apply.

What Are the Common Testing Methods for Type M Plug Adapters?

Testing is crucial for ensuring that Type M plug adapters are safe and functional. Common methods include:

- Electrical Testing: This includes checks for voltage, current, and resistance to ensure the adapter can handle specified loads.

- Mechanical Testing: Durability tests assess the strength of the materials and connections, ensuring that the adapter can withstand everyday usage.

- Environmental Testing: Adapters are subjected to conditions such as temperature variations and humidity to ensure they perform reliably in diverse environments.

By prioritizing rigorous testing protocols, manufacturers can assure buyers of the quality and reliability of their products.

Conclusion: The Importance of Quality in Type M Plug Adapter Manufacturing

For B2B buyers, understanding the manufacturing processes and quality assurance measures behind Type M plug adapters is essential. This knowledge not only aids in selecting reliable suppliers but also ensures that the products meet international safety standards, ultimately protecting businesses and consumers alike. By focusing on quality from the outset, manufacturers can enhance their reputation and foster long-term relationships with buyers across the globe.

Illustrative image related to type m plug adapter

Practical Sourcing Guide: A Step-by-Step Checklist for ‘type m plug adapter’

To assist B2B buyers in sourcing Type M plug adapters effectively, this guide provides a structured checklist designed to ensure that all critical factors are considered during the procurement process. This guide is particularly relevant for international buyers operating in regions such as Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Understanding the technical requirements of the Type M plug adapter is crucial. This includes knowing the voltage and amperage ratings that your devices will require. For example, Type M adapters typically support a maximum voltage of 250V and current ratings up to 16A, which is essential for ensuring compatibility with your devices.

Step 2: Research Compliance and Safety Standards

Verify that the adapters meet relevant compliance standards such as CE certification and RoHS compliance. This is important not only for safety but also to ensure that the products are permissible for import into your region. Check for certifications that align with local regulations to avoid any legal issues.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct a thorough evaluation. Look for company profiles, case studies, and references from buyers in similar industries or regions. Assess their experience with Type M adapters and request product samples to evaluate quality and performance.

Step 4: Assess Product Features

Identify the features that are essential for your operations. For instance, some Type M adapters come with multiple USB ports, surge protection, and compatibility with various plug types. Assessing these features can enhance functionality and offer better value for your investment.

- USB Charging Capability: Look for adapters that include USB ports for easy charging of devices like smartphones and tablets.

- Grounded Connections: Ensure the adapter is grounded for safety and to prevent electrical hazards.

Step 5: Verify Warranty and Support Options

Check the warranty terms and after-sales support provided by the supplier. A robust warranty (e.g., 2 years or more) can protect your investment against defects and malfunctions. Additionally, confirm that the supplier offers responsive customer support to assist with any potential issues after purchase.

Illustrative image related to type m plug adapter

Step 6: Consider Pricing and Volume Discounts

Request quotes from multiple suppliers to compare pricing. Inquire about volume discounts if you plan to purchase in bulk. Understanding the total cost of ownership, including shipping and potential customs duties, will help you make a more informed decision.

Step 7: Plan for Logistics and Delivery

Lastly, consider the logistics involved in importing Type M plug adapters. Assess shipping options, delivery times, and potential customs regulations that may affect your order. Efficient logistics planning can help avoid delays and ensure that your products arrive when needed.

By following this checklist, B2B buyers can navigate the complexities of sourcing Type M plug adapters with greater confidence, ensuring that they select the right products from reliable suppliers.

Comprehensive Cost and Pricing Analysis for type m plug adapter Sourcing

Understanding the cost structure and pricing dynamics of Type M plug adapters is essential for international B2B buyers, especially those operating in regions such as Africa, South America, the Middle East, and Europe. This analysis will delve into the key cost components, price influencers, and actionable buyer tips to enhance sourcing strategies.

What Are the Key Cost Components in Type M Plug Adapter Production?

The cost structure of Type M plug adapters can be broken down into several critical components:

-

Materials: The primary materials used in manufacturing Type M adapters include high-grade plastic for the casing and copper for the wiring. The quality of these materials significantly impacts durability and compliance with safety standards.

-

Labor: Labor costs vary based on the manufacturing location. In regions with lower labor costs, such as parts of Asia, you may find more competitive pricing. However, labor costs in Europe or North America may be higher but could lead to enhanced quality and compliance.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and equipment maintenance. Efficient production processes can help reduce these costs, benefiting the final pricing.

-

Tooling: Initial tooling costs can be substantial, especially for custom designs. However, once the tooling is established, the per-unit cost decreases significantly, making it essential to consider order volumes.

-

Quality Control (QC): Ensuring that each adapter meets safety and performance standards incurs additional costs. Compliance with international certifications (such as CE and RoHS) is crucial, particularly for markets with stringent regulations.

-

Logistics: Shipping costs, including freight, duties, and insurance, can fluctuate based on the delivery location and Incoterms used. International buyers should be mindful of these costs as they can affect the total landed cost.

-

Margin: Suppliers typically add a margin to cover their costs and profit. Understanding the markup can help buyers negotiate better pricing.

What Influences the Pricing of Type M Plug Adapters?

Several factors influence the pricing of Type M plug adapters, including:

-

Volume/MOQ: Suppliers often offer better pricing for bulk orders. Understanding minimum order quantities (MOQs) can help buyers optimize their costs.

-

Specifications and Customization: Custom features, such as additional USB ports or unique designs, can increase costs. Buyers should weigh the benefits of customization against the added expense.

-

Quality and Certifications: Higher quality standards and certifications often result in higher prices. Buyers should assess the value of these certifications relative to their market requirements.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge a premium for their products, reflecting their quality assurance and service levels.

-

Incoterms: The choice of Incoterms (e.g., FOB, CIF) can significantly affect the final price. Understanding these terms helps buyers manage logistics costs effectively.

What Tips Can Help Buyers Negotiate Better Pricing?

To achieve cost efficiency and improve procurement strategies, buyers should consider the following tips:

Illustrative image related to type m plug adapter

-

Negotiate Volume Discounts: Leverage order size to negotiate lower prices. Suppliers are often willing to offer better rates for larger quantities.

-

Assess Total Cost of Ownership: Beyond the initial purchase price, consider the total cost of ownership, including maintenance, longevity, and potential failure rates. A slightly higher upfront cost may lead to lower long-term expenses.

-

Research and Compare Suppliers: Obtain quotes from multiple suppliers to understand the market rate. This competitive analysis can provide leverage during negotiations.

-

Be Aware of Pricing Nuances: Different regions may have varying pricing structures based on local demand and supply dynamics. Understanding these nuances can help in making informed purchasing decisions.

-

Consider Long-Term Relationships: Building relationships with suppliers can lead to better pricing and service over time. Long-term partnerships can result in favorable terms and conditions.

Disclaimer on Pricing

Please note that the prices mentioned in this analysis are indicative and subject to change based on market conditions, supplier pricing strategies, and economic factors. Buyers should conduct due diligence and engage in thorough negotiations to secure the best possible pricing for Type M plug adapters.

Alternatives Analysis: Comparing type m plug adapter With Other Solutions

When evaluating power connectivity solutions for international travel and business operations, understanding the alternatives to the Type M plug adapter is crucial. The Type M adapter, primarily used in South Africa and a few other regions, facilitates the connection of various devices to the local power supply. However, several other solutions can provide similar functionalities, each with its unique advantages and drawbacks.

Comparison Table

| Comparison Aspect | Type M Plug Adapter | Universal Travel Adapter | Voltage Converter |

|---|---|---|---|

| Performance | Connects devices with Type M plugs; supports multiple USB ports | Adaptable for multiple plug types; versatile for global use | Converts voltage to match device requirements |

| Cost | Moderate; typically around $18-$25 | Varies widely; generally $20-$50 | Higher initial cost; ranges from $30 to $100+ |

| Ease of Implementation | Plug-and-play; straightforward setup | Simple to use; may require manual adjustments | Requires careful selection based on device voltage |

| Maintenance | Low; durable design with minimal wear | Low; generally requires no upkeep | Moderate; may require replacement over time |

| Best Use Case | Ideal for South Africa and neighboring countries | Best for travelers visiting multiple countries | Necessary for devices with incompatible voltage requirements |

Detailed Breakdown of Alternatives

Universal Travel Adapter

Universal travel adapters are designed to accommodate a variety of plug types and are ideal for international travelers. They typically come with multiple socket configurations, allowing users to plug in devices from different regions. The primary advantage of universal adapters is their versatility; they can be used in many countries, making them a go-to solution for frequent travelers. However, they may not support high-power devices and might lack grounded connections, which can be a concern for safety and performance.

Illustrative image related to type m plug adapter

Voltage Converter

Voltage converters are essential for devices that do not support dual voltage (100-240V). They convert the voltage from the local supply to match the device’s requirements, making them crucial for equipment that cannot handle the local voltage. While they provide a necessary function for certain devices, voltage converters can be more expensive and bulkier than adapters. Additionally, they often require careful selection to ensure compatibility with the device in use, which can complicate the travel experience.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the right power connectivity solution, B2B buyers should consider the specific requirements of their devices and the regions they operate in. For businesses primarily dealing with South African markets, the Type M plug adapter offers a reliable and straightforward solution. Conversely, companies with a diverse international footprint may benefit from universal travel adapters for their flexibility. Lastly, businesses using sensitive equipment requiring voltage adjustments should invest in voltage converters to ensure device safety and functionality. Understanding these alternatives will empower buyers to make informed decisions that align with their operational needs.

Essential Technical Properties and Trade Terminology for type m plug adapter

Understanding the critical technical properties and terminology associated with Type M plug adapters is essential for B2B buyers navigating the international electrical equipment landscape. This section aims to clarify these aspects for stakeholders, particularly those engaged in sourcing, procurement, and distribution across diverse regions such as Africa, South America, the Middle East, and Europe.

What Are the Key Technical Properties of Type M Plug Adapters?

-

Material Grade

– Type M plug adapters are typically constructed from high-quality thermoplastic materials that ensure durability and resistance to heat. The choice of material affects the adapter’s longevity and safety, making it crucial for B2B buyers to prioritize adapters made from flame-retardant and impact-resistant materials, especially in industrial applications. -

Current Rating

– The current rating, usually expressed in Amperes (A), indicates the maximum current the adapter can handle safely. For Type M adapters, this is often rated at 15A or 16A. Understanding current ratings is vital for ensuring compatibility with the devices being powered and preventing potential overloads that could lead to equipment failure or safety hazards. -

Voltage Compatibility

– Type M adapters are designed for use with voltage ranges typically between 100V to 250V. This flexibility allows them to be used in multiple countries, making them ideal for international trade. B2B buyers must ensure that the adapters they purchase are suitable for the voltage requirements of their target markets to avoid damage to connected devices. -

USB Charging Capability

– Many modern Type M adapters come equipped with USB ports, enabling the simultaneous charging of multiple devices. This feature is particularly attractive to businesses in sectors like hospitality and travel, where charging options for multiple devices are essential for customer satisfaction. -

Safety Certifications

– Certification marks such as CE (Conformité Européenne) and RoHS (Restriction of Hazardous Substances) are critical indicators of compliance with safety and environmental standards. B2B buyers should prioritize adapters with these certifications to ensure product safety and avoid regulatory issues in their respective markets. -

Compact Design

– The physical dimensions and design of the adapter impact its portability and ease of use. Compact designs are particularly advantageous for travelers and businesses needing to save space. An adapter’s weight and size should be considered in relation to shipping costs and storage efficiency.

Which Trade Terms Are Essential When Sourcing Type M Plug Adapters?

-

OEM (Original Equipment Manufacturer)

– OEM refers to companies that manufacture products that are sold under another company’s brand. In the context of Type M plug adapters, understanding OEM partnerships can help businesses source high-quality products that meet specific requirements. -

MOQ (Minimum Order Quantity)

– MOQ indicates the smallest number of units that a supplier is willing to sell. This term is crucial for B2B buyers as it affects inventory management and cash flow, especially when entering new markets or testing new products. -

RFQ (Request for Quotation)

– An RFQ is a document issued by a buyer to suppliers asking for a price quote for specific products or services. This process is vital in the procurement phase, enabling buyers to compare prices and terms from different suppliers for Type M plug adapters. -

Incoterms (International Commercial Terms)

– Incoterms define the responsibilities of buyers and sellers in international trade, including shipping, insurance, and tariffs. Understanding these terms is essential for B2B transactions involving Type M plug adapters, as they dictate who bears the risk during transport. -

Lead Time

– Lead time refers to the amount of time from placing an order to receiving the goods. This term is crucial for B2B buyers to understand, especially in industries where timely delivery is critical to maintaining operations and meeting customer demands. -

Warranty Terms

– Warranty terms outline the conditions under which a product can be repaired or replaced. For Type M plug adapters, knowing the warranty period and conditions is essential for assessing long-term value and reliability, particularly for bulk purchases.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions when sourcing Type M plug adapters, ensuring they meet both operational needs and regulatory requirements.

Navigating Market Dynamics and Sourcing Trends in the type m plug adapter Sector

What Are the Current Market Dynamics and Key Trends Impacting the Type M Plug Adapter Sector?

The global market for type M plug adapters is significantly influenced by the rise in international travel and the increasing interconnectedness of global economies. Key drivers include the surge in tourism, particularly to regions like South Africa and several countries in Southern Africa, where type M adapters are essential. Additionally, the expansion of e-commerce platforms has made sourcing easier for international buyers. Emerging trends indicate a growing preference for multifunctional adapters that accommodate various plug types and include USB charging options, catering to the needs of tech-savvy consumers and businesses alike.

Furthermore, as businesses expand operations internationally, the demand for reliable power solutions has increased. B2B buyers from Africa, South America, the Middle East, and Europe are seeking high-quality, certified products that ensure safety and compliance with local regulations. The focus is also shifting toward compact and lightweight designs, ideal for frequent travelers and businesses that require portable solutions. As the market evolves, suppliers must remain agile and responsive to these emerging needs, ensuring they provide innovative products that meet the expectations of a diverse clientele.

How Are Sustainability and Ethical Sourcing Practices Shaping the Type M Plug Adapter Market?

Sustainability is becoming a crucial consideration for B2B buyers in the type M plug adapter market. The environmental impact of manufacturing processes, including the use of non-recyclable materials and excessive energy consumption, is under scrutiny. Ethical sourcing practices are gaining traction as businesses prioritize partnerships with manufacturers who adhere to environmental standards and promote fair labor practices.

Buyers are increasingly looking for products that are CE Certified and RoHS Compliant, indicating a commitment to reducing hazardous substances in electrical equipment. Moreover, the use of ‘green’ certifications, such as Energy Star ratings for energy-efficient products, is becoming a significant factor in purchasing decisions. Manufacturers that can demonstrate sustainable practices, such as utilizing recycled materials or energy-efficient production methods, will likely have a competitive advantage in attracting environmentally-conscious buyers.

How Has the Type M Plug Adapter Evolved Over Time?

The evolution of the type M plug adapter reflects broader changes in global electrical standards and consumer needs. Initially designed for use in South Africa, the type M adapter has adapted to accommodate various plug configurations, including features that allow for multiple device connections. The introduction of USB ports in modern adapters highlights the shift toward multifunctionality, catering to the increasing reliance on mobile devices.

As international travel surged in the late 20th century, the demand for reliable plug adapters increased, leading to innovations that prioritize safety, portability, and versatility. The modern type M plug adapter is not only a tool for connectivity but also a reflection of the growing emphasis on user-friendly designs that support the diverse needs of global travelers and businesses. This evolution continues to drive manufacturers to innovate, ensuring that their products meet the dynamic demands of the international market.

Illustrative image related to type m plug adapter

Frequently Asked Questions (FAQs) for B2B Buyers of type m plug adapter

-

How do I solve compatibility issues when using type M plug adapters?

To address compatibility issues with type M plug adapters, ensure that your devices are rated for the correct voltage and frequency. Type M adapters are primarily designed for use in regions like South Africa and Afghanistan, which operate on a 230V supply. If your device is dual voltage (100-240V), it should work seamlessly. For devices not rated for this voltage, a voltage converter may be necessary to prevent damage. Always verify the plug type and voltage specifications before connecting your devices. -

What is the best type M plug adapter for charging multiple devices?

The best type M plug adapter for charging multiple devices is one that features multiple output options, including USB ports. Look for adapters that offer at least one grounded outlet and additional USB-A and USB-C ports. This configuration allows you to charge smartphones, tablets, and other electronics simultaneously. Ensure the adapter supports fast charging capabilities and is CE certified for safety. A compact design is also beneficial for travel, especially for businesses operating across different regions. -

What should I consider when sourcing type M plug adapters from suppliers?

When sourcing type M plug adapters, prioritize suppliers with a proven track record in quality and compliance. Verify that they hold necessary certifications, such as CE and RoHS, ensuring safety and environmental standards. Evaluate their manufacturing capabilities, including quality assurance processes, to ensure consistent product quality. It’s also wise to request samples before placing larger orders, allowing you to assess the product’s performance and reliability in real-world applications. -

What are the typical minimum order quantities (MOQs) for type M plug adapters?

Minimum order quantities (MOQs) for type M plug adapters can vary significantly between suppliers. Common MOQs range from 100 to 500 units, depending on the manufacturer and the complexity of the product. Some suppliers may offer lower MOQs for standard models but higher for custom designs. Always clarify MOQs upfront to avoid unexpected costs and ensure that your order aligns with your inventory management strategy. -

What payment terms are generally acceptable for international purchases of type M plug adapters?

Payment terms for international purchases of type M plug adapters often include options like upfront payment, letter of credit, or partial payment with a balance upon shipment. Commonly, suppliers may request a deposit (20-30%) before production begins, with the remainder due before shipment. Always negotiate terms that work for both parties, and ensure that payment methods are secure to mitigate risks associated with international transactions. -

How can I ensure the quality of type M plug adapters before accepting delivery?

To ensure the quality of type M plug adapters before accepting delivery, implement a rigorous quality assurance process. This can include pre-shipment inspections conducted by third-party quality control agencies, which can verify compliance with safety standards and specifications. Additionally, review the supplier’s testing certifications and product warranties. Establish a clear return policy for defective items to safeguard your investment and maintain product integrity. -

What logistics considerations should I keep in mind when importing type M plug adapters?

When importing type M plug adapters, consider logistics factors such as shipping methods, customs regulations, and lead times. Choose a reliable freight forwarder familiar with electrical goods to streamline customs clearance. Be aware of any import duties and taxes that may apply to your shipment, as these can impact overall costs. Planning for potential delays and ensuring proper documentation will facilitate smoother logistics and timely delivery. -

Can I customize type M plug adapters for my business needs?

Yes, many manufacturers offer customization options for type M plug adapters, including branding, color, and specific features tailored to your business needs. Custom designs can enhance your brand identity and meet unique functional requirements. Discuss your specifications with suppliers and inquire about the feasibility of custom orders, including any additional costs and lead times associated with the process. Customization can significantly improve product relevance in your target market.

Top 6 Type M Plug Adapter Manufacturers & Suppliers List

1. Ceptics – South Africa Travel Plug Adapter – Type M – 5 in 1

Domain: ceptics.com

Registered: 2011 (14 years)

Introduction: {“product_name”:”South Africa Travel Plug Adapter – Type M – 5 in 1 – Ultra Compact (PTU-10L)”,”sale_price”:”$17.99″,”key_features”:[“Connects up to 5 Devices: 1 Grounded Outlet, 1 Non-Grounded Outlet”,”Accepts Type A, B outlet with 1 USB and 2 USB-C”,”Standard: Type M plug, SABS1661 Grounded 3-Prong plug”,”Designed in the USA – ultra compact, simple, safe and easy to use adapter”,”Safe and fully …

2. International Config – TYPE M Adapters

Domain: internationalconfig.com

Registered: 1999 (26 years)

Introduction: Primary Country known for using TYPE M adapters is Afghanistan, India, South Africa.

3. Reddit – Power Adapter Guide for South Africa

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Type M power adapter is the most common in South Africa, but types C, F, and N are also used. Travelers may need to consider carrying adapters for these types, especially if using multiple devices.

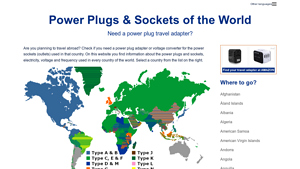

4. Power Plugs & Sockets – Global Plug Information

Domain: power-plugs-sockets.com

Registered: 2013 (12 years)

Introduction: World Power Plugs & Sockets: Provides information about power plugs and sockets used in every country. Types of plugs include: A (North/Central America, China, Japan), B (like A with grounding), C (Euro plug), D (India, Sri Lanka, Nepal), E (French origin), F (Schuko), G (British origin), H (Israel), I (Australia, New Zealand), J (Switzerland), K (Danish origin), L (Italian origin), M (larger pins…

5. Tessan – Universal Travel Adapters

Domain: tessan.com

Registered: 2001 (24 years)

Introduction: The Best Travel Plug Adapter of 2024 – Tessan.com offers a variety of travel adapters including:

– 35W Universal Travel Adapter – $29.99 (2 colors available)

– 65W Universal Travel Adapter – $39.99 (2 colors available)

– 100W Universal Travel Adapter – $59.99 (2 colors available)

– 140W Universal Travel Adapter – $69.99 (2 colors available)

– TESSAN Universal Travel Adapter With USB Ports, GaN Fas…

6. ACUPWR – Universal to Type M Plug Adapter

Domain: acupwr.com

Registered: 2010 (15 years)

Introduction: {“product_name”: “Universal to Type M Plug Adapter”, “brand”: “ACUPWR”, “price”: “$29.99”, “availability”: “back-ordered, will ship in 10 to 15 days”, “description”: “ACUPWR’s line of wall plug adapters let you use plug your appliance into any wall in the world, regardless of plug type! Our US3F8G model allows compatibility between appliances using any plug shape (via universal input) and countrie…

Strategic Sourcing Conclusion and Outlook for type m plug adapter

In the increasingly interconnected global marketplace, the strategic sourcing of Type M plug adapters is crucial for businesses operating in regions such as Africa, South America, the Middle East, and Europe. These adapters not only facilitate seamless connectivity for a range of devices but also enhance operational efficiency by ensuring that equipment is compatible with local electrical standards. By leveraging high-quality, certified products, international buyers can mitigate risks associated with electrical failures and enhance the safety of their operations.

Investing in Type M plug adapters that feature advanced specifications, such as multiple USB ports and compatibility with dual-voltage devices, presents a compelling value proposition. This versatility allows businesses to streamline their power solutions while accommodating a variety of devices, ultimately leading to cost savings and improved productivity.

As you consider your sourcing strategy, prioritize partnerships with reliable manufacturers who offer comprehensive support and warranty options. Looking ahead, the demand for Type M plug adapters is expected to grow as global travel and international trade continue to rise. Now is the time to secure your supply chain and ensure that your business remains ahead of the curve. Embrace this opportunity to enhance your operational capabilities and connect with trusted suppliers today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.