Top 6 Semi Truck Electrical Connectors Suppliers (And How to Choose)

Introduction: Navigating the Global Market for semi truck electrical connectors

In the ever-evolving landscape of logistics and transportation, sourcing reliable semi truck electrical connectors poses a significant challenge for international B2B buyers. As the backbone of vehicle functionality, these connectors ensure seamless communication between critical systems, impacting everything from safety to operational efficiency. Whether you’re a fleet manager in Nigeria, a procurement officer in Germany, or a supplier in South America, understanding the diverse types of connectors—such as trailer, junction box, and heavy-duty options—is essential for maintaining optimal performance in your operations.

This comprehensive guide serves as an invaluable resource, diving deep into the various types and applications of semi truck electrical connectors, supplier vetting processes, and cost considerations. It highlights the importance of selecting connectors that can withstand harsh environments and heavy usage, which is particularly relevant for regions with extreme weather conditions. By equipping you with actionable insights and best practices, this guide empowers informed purchasing decisions, enabling you to navigate the complexities of the global market effectively.

Whether you are looking to enhance your supply chain or ensure compliance with international standards, our guide will help you identify reputable suppliers, assess product quality, and ultimately choose the right connectors that meet your specific needs. With a focus on fostering reliability and efficiency, we aim to support your business in achieving success in the competitive landscape of commercial trucking.

Understanding semi truck electrical connectors Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 7-Pin Trailer Connector | Standardized for trailers, supports lighting & braking | Common in North America for truck-trailer connections | Pros: Widely available, easy to replace. Cons: Limited to specific applications. |

| DEUTSCH Connectors | Rugged design, sealed against moisture and dust | Heavy-duty applications in trucks and buses | Pros: High durability, excellent sealing. Cons: Higher cost compared to standard connectors. |

| AMPSEAL Connectors | Compact, weather-resistant, multiple pin configurations | Used in various commercial vehicles | Pros: Versatile and reliable. Cons: Requires specific installation tools. |

| Magnetic Electrical Connectors | Quick-connect feature, ideal for dynamic applications | Used in military and emergency vehicles | Pros: Fast connections, reduces wear. Cons: May not be suitable for all environments. |

| 4-Pin and 6-Pin Connectors | Simpler configurations for basic lighting and signals | Light-duty trailers and utility vehicles | Pros: Cost-effective, easy to install. Cons: Limited functionality for complex systems. |

What are the Key Characteristics of 7-Pin Trailer Connectors?

7-pin trailer connectors are the standard choice for truck-trailer connections in North America, designed to handle both lighting and braking systems. Their standardized design ensures compatibility across various vehicle models, making them a reliable choice for B2B buyers in logistics and transportation. When purchasing, consider the ease of replacement and the availability of adapters for different trailer configurations, which can be critical for international operations.

Why Choose DEUTSCH Connectors for Heavy-Duty Applications?

DEUTSCH connectors are renowned for their rugged construction, designed to withstand harsh environmental conditions typical in heavy-duty applications. Their sealed design protects against moisture, dust, and vibrations, making them an ideal choice for trucks and buses operating in challenging terrains. B2B buyers should weigh the higher initial investment against the long-term durability and reduced maintenance costs, especially for fleets operating in regions with extreme weather.

How Do AMPSEAL Connectors Enhance Versatility?

AMPSEAL connectors offer a versatile solution with multiple pin configurations, making them suitable for a wide range of commercial vehicles. Their weather-resistant design ensures reliable performance in outdoor conditions, appealing to B2B buyers needing dependable connectivity. When considering AMPSEAL connectors, it’s essential to factor in the need for specific installation tools and training, which may increase initial setup costs but provide long-term reliability.

What Advantages Do Magnetic Electrical Connectors Offer?

Magnetic electrical connectors provide a fast and efficient way to connect and disconnect electrical systems, ideal for applications requiring frequent changes, such as military and emergency response vehicles. Their quick-connect feature reduces wear and tear on connection points, enhancing longevity. However, B2B buyers should assess the suitability of magnetic connectors for their specific environments, as they may not perform optimally in all conditions.

When to Use 4-Pin and 6-Pin Connectors?

4-pin and 6-pin connectors are simpler options for basic lighting and signaling systems, commonly used in light-duty trailers and utility vehicles. Their cost-effectiveness and ease of installation make them attractive to B2B buyers looking for budget-friendly solutions. However, their limited functionality means they may not be suitable for more complex electrical systems, making it essential to evaluate the specific needs of the application before purchase.

Key Industrial Applications of semi truck electrical connectors

| Industry/Sector | Specific Application of semi truck electrical connectors | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Transportation & Logistics | Connecting trailers to trucks via 7-way connectors | Ensures reliable communication and power supply, enhancing safety and operational efficiency. | Compatibility with various trailer types, weather resistance, and ease of installation. |

| Construction Equipment | Powering heavy machinery and equipment | Facilitates seamless operation of construction vehicles, reducing downtime. | Durability under harsh conditions, high amperage ratings, and custom configurations. |

| Agricultural Vehicles | Electrical connections for harvesters and tractors | Promotes efficient power distribution for machinery, ensuring optimal performance during peak seasons. | Resistance to moisture and dust, as well as compliance with agricultural standards. |

| Emergency Services | Quick disconnect connectors for emergency response vehicles | Ensures rapid deployment and reliability during critical situations, enhancing response times. | High reliability, ruggedness, and ease of maintenance in emergency scenarios. |

| Marine Transportation | Electrical connections for truck-mounted marine equipment | Provides seamless integration for transporting marine vehicles, ensuring safety and compliance. | Corrosion resistance, waterproofing, and compatibility with marine electrical systems. |

How Are Semi Truck Electrical Connectors Used in Transportation and Logistics?

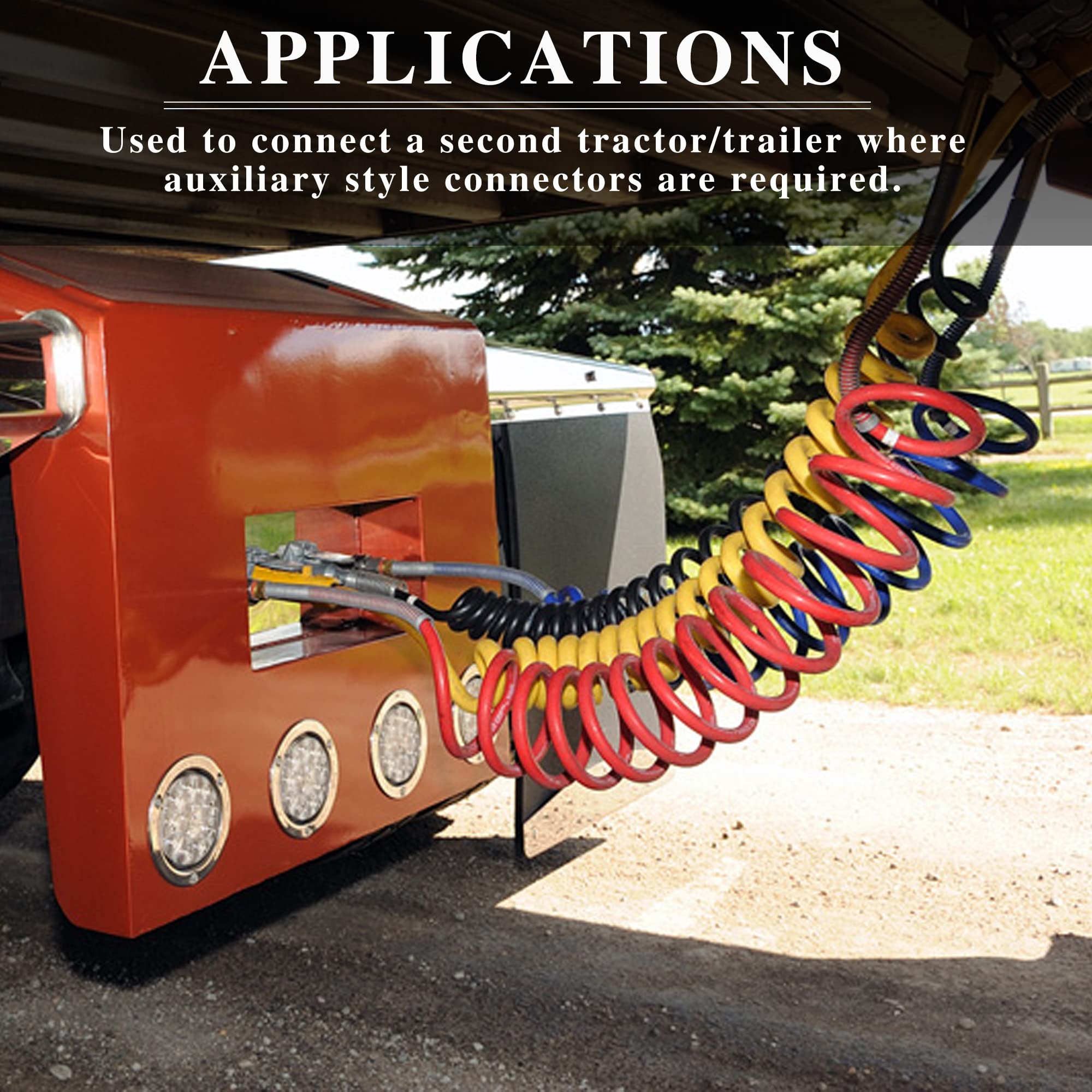

In the transportation and logistics sector, semi truck electrical connectors, particularly 7-way connectors, are pivotal for linking trailers to trucks. These connectors ensure reliable communication and power supply for trailer lights, brakes, and auxiliary systems. The benefit to businesses lies in improved safety and operational efficiency, as reliable connections minimize the risk of electrical failures during transit. International buyers must consider compatibility with various trailer types, weather resistance, and ease of installation to ensure seamless integration.

What Role Do Semi Truck Electrical Connectors Play in Construction Equipment?

In construction, semi truck electrical connectors facilitate the powering of heavy machinery, such as excavators and bulldozers. These connectors enable seamless operation, ensuring that construction vehicles function efficiently without electrical interruptions. This reliability translates to reduced downtime and increased productivity on job sites. Buyers should prioritize connectors that offer durability under harsh conditions, high amperage ratings, and the ability to be customized for specific machinery requirements.

How Are Semi Truck Electrical Connectors Essential for Agricultural Vehicles?

For agricultural vehicles like tractors and harvesters, semi truck electrical connectors are crucial for efficient power distribution. These connectors support the electrical systems that drive various functions of the machinery, ensuring optimal performance, especially during peak harvest seasons. The value for agricultural businesses is significant, as reliable connections directly impact productivity and operational efficiency. Buyers in this sector must seek connectors that resist moisture and dust while complying with agricultural standards to maintain functionality in diverse environments.

Why Are Semi Truck Electrical Connectors Important for Emergency Services?

In emergency services, quick disconnect connectors are vital for emergency response vehicles, allowing for rapid deployment in critical situations. These connectors ensure that essential equipment functions reliably, enhancing response times during emergencies. The benefit to emergency services is clear: increased reliability can save lives. Buyers should focus on high reliability, ruggedness, and ease of maintenance to ensure that connectors perform well under pressure and in challenging conditions.

How Do Semi Truck Electrical Connectors Support Marine Transportation?

In marine transportation, semi truck electrical connectors are used to connect truck-mounted equipment with marine vehicles. These connectors ensure that electrical systems function properly during transport, adhering to safety and compliance regulations. The value for businesses lies in the seamless integration of marine and transport systems, which minimizes delays and enhances operational efficiency. Buyers should prioritize corrosion resistance, waterproofing, and compatibility with marine electrical systems to ensure long-term reliability.

3 Common User Pain Points for ‘semi truck electrical connectors’ & Their Solutions

Scenario 1: Inconsistent Electrical Connections Leading to Downtime

The Problem: B2B buyers often face the issue of inconsistent electrical connections in semi trucks, which can lead to unexpected downtime. This problem can stem from using low-quality connectors that do not withstand harsh environmental conditions, such as extreme temperatures or moisture. When connectors fail, it can disrupt the entire electrical system of the truck, affecting critical functions like lighting and trailer braking, resulting in costly delays and repairs.

The Solution: To combat this issue, buyers should prioritize sourcing high-quality, ruggedized connectors specifically designed for heavy-duty applications. Look for connectors with robust sealing mechanisms, such as weather-tight and corrosion-resistant features, to ensure durability in various climates. Additionally, consider investing in connectors from reputable manufacturers known for their reliability, like TE Connectivity or Phillips Industries. Regular maintenance checks should also be instituted to identify signs of wear and tear before they lead to significant failures. Implementing a preventive maintenance schedule that includes inspections of electrical connections can help mitigate the risk of unexpected downtimes.

Scenario 2: Difficulty in Finding Compatible Connector Types

The Problem: Another common pain point for B2B buyers is the challenge of finding compatible electrical connectors for specific semi truck models or trailers. With numerous connector types available—such as 7-pin, 6-pin, and various proprietary designs—buyers can easily become overwhelmed. This can lead to misordering parts, increased inventory costs, and ultimately, delays in getting trucks back on the road.

The Solution: To streamline the sourcing process, buyers should create a comprehensive inventory list of all the connectors currently in use across their fleet. This should include specifications such as the number of pins, connector types, and compatibility with various truck brands. Engaging with suppliers who offer a wide range of connectors and can provide detailed product compatibility information is crucial. Utilizing online catalogs from trusted suppliers like Class 8 Truck Parts or TE Connectivity can also help. Furthermore, consider building relationships with manufacturers who can offer guidance on the best connector solutions for specific applications, thus reducing the risk of compatibility issues.

Scenario 3: High Replacement Costs Due to Poor Quality Connectors

The Problem: Many companies experience high replacement costs associated with electrical connectors due to poor-quality products that fail prematurely. This not only affects the budget but also impacts operational efficiency. Buyers often find themselves caught in a cycle of replacing low-cost connectors that cannot withstand the demands of heavy-duty use, leading to a false economy.

The Solution: To address this issue, it is advisable for B2B buyers to adopt a long-term investment approach by prioritizing quality over price when selecting electrical connectors. Investing in connectors from established brands known for their durability and reliability can lead to significant cost savings in the long run. Buyers should conduct thorough research and read customer reviews to understand the performance of connectors before making a purchase. Additionally, consider bulk purchasing options from suppliers, which can often yield better pricing and reduce overall costs. Implementing a policy that emphasizes quality assurance in sourcing decisions will help ensure that only reliable connectors are used in their fleet, ultimately reducing replacement frequency and associated costs.

Strategic Material Selection Guide for semi truck electrical connectors

When selecting materials for semi truck electrical connectors, understanding the properties, advantages, and limitations of common materials is crucial for ensuring optimal performance and compliance with international standards. Below is an analysis of four prevalent materials used in the manufacturing of these connectors: copper, aluminum, thermoplastic, and stainless steel.

What are the Key Properties of Copper in Semi Truck Electrical Connectors?

Copper is widely recognized for its excellent electrical conductivity, making it a preferred choice for electrical connectors. It typically operates effectively within a temperature range of -40°C to 125°C, withstanding significant electrical loads. Additionally, copper exhibits good corrosion resistance, especially when coated with tin or nickel.

Pros and Cons of Copper Connectors

The primary advantage of copper connectors is their superior conductivity, which ensures minimal energy loss during transmission. However, copper is relatively heavy and can be more expensive than alternatives. Its susceptibility to corrosion in harsh environments can also necessitate protective coatings, adding to manufacturing complexity.

Impact on Application

Copper connectors are well-suited for applications requiring high current and low resistance, such as heavy-duty trucks and trailers. However, buyers must consider the compatibility of copper with specific media, especially in environments with high moisture or corrosive elements.

How Does Aluminum Perform as a Material for Electrical Connectors?

Aluminum is another common material used in semi truck electrical connectors, valued for its lightweight properties and reasonable conductivity. It generally operates effectively within a temperature range of -40°C to 100°C. While aluminum has lower conductivity than copper, it is often treated with protective coatings to enhance its corrosion resistance.

Pros and Cons of Aluminum Connectors

The lightweight nature of aluminum connectors reduces overall vehicle weight, improving fuel efficiency. However, they may not handle high currents as effectively as copper, which can limit their application in certain high-demand scenarios. Additionally, aluminum connectors can be more prone to galvanic corrosion when in contact with dissimilar metals.

Impact on Application

Aluminum connectors are ideal for applications where weight savings are critical, such as in long-haul trucks. International buyers must ensure that aluminum connectors meet relevant standards for corrosion resistance, especially in humid or coastal regions.

What Role Does Thermoplastic Play in Electrical Connector Design?

Thermoplastic materials, such as nylon or polycarbonate, are increasingly used in connector housings due to their excellent insulation properties and resistance to environmental factors. These materials can typically withstand temperatures from -40°C to 85°C and are known for their durability and flexibility.

Pros and Cons of Thermoplastic Connectors

Thermoplastics offer significant advantages in terms of weight reduction and ease of manufacturing. They can be molded into complex shapes, allowing for innovative designs. However, thermoplastics may not be suitable for high-temperature applications and can degrade under prolonged exposure to UV light.

Impact on Application

Thermoplastic connectors are particularly effective in applications requiring electrical insulation and mechanical protection. Buyers should consider the thermal and environmental conditions the connectors will face, ensuring compliance with international standards like ASTM or DIN.

Why is Stainless Steel Considered for Electrical Connectors?

Stainless steel is often used for its exceptional strength and corrosion resistance, particularly in harsh environments. It can withstand temperatures ranging from -50°C to 800°C, making it suitable for extreme conditions.

Pros and Cons of Stainless Steel Connectors

The primary advantage of stainless steel connectors is their durability and resistance to corrosion, making them ideal for long-term use in challenging environments. However, they are heavier and more expensive than other materials, which may not be suitable for all applications.

Impact on Application

Stainless steel connectors are ideal for heavy-duty applications where strength and durability are paramount. International buyers must ensure compliance with relevant standards, particularly in industries where safety and reliability are critical.

Summary Table of Material Selection for Semi Truck Electrical Connectors

| Material | Typical Use Case for semi truck electrical connectors | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | High-current applications in heavy-duty trucks | Superior electrical conductivity | Heavier and more expensive | High |

| Aluminum | Weight-sensitive applications in long-haul trucks | Lightweight and fuel-efficient | Lower conductivity and corrosion risks | Medium |

| Thermoplastic | Insulation and protection in various connectors | Lightweight and easy to manufacture | Limited high-temperature performance | Low |

| Stainless Steel | Extreme environments requiring durability | Exceptional strength and corrosion resistance | Heavier and more costly | High |

This analysis provides B2B buyers with actionable insights into material selection for semi truck electrical connectors, helping them make informed decisions that align with their operational needs and compliance requirements across different regions.

In-depth Look: Manufacturing Processes and Quality Assurance for semi truck electrical connectors

What Are the Key Stages in the Manufacturing Process of Semi Truck Electrical Connectors?

The manufacturing of semi truck electrical connectors involves several critical stages, each essential for ensuring the final product meets industry standards and customer expectations. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation: How Are Raw Materials Selected and Processed?

The manufacturing process begins with the selection of high-quality raw materials. Typically, these materials include copper for conductors, thermoplastic or thermoset polymers for insulation, and metal alloys for terminals. The chosen materials must possess high conductivity, resistance to corrosion, and durability to withstand harsh environmental conditions.

Once selected, raw materials undergo preparation processes such as cutting, bending, and treatment. Copper wires are often drawn to specific diameters, while terminal materials are stamped or cut into precise shapes. This meticulous preparation ensures that the materials will perform reliably in the demanding applications typical of semi trucks.

What Techniques Are Used in Forming Electrical Connectors?

Forming electrical connectors involves various techniques tailored to the design specifications of the connectors. These techniques often include stamping, molding, and extrusion.

-

Stamping: This process is widely used for creating metal components, such as terminals and housings. Stamping allows for high-volume production with consistent precision.

-

Injection Molding: For plastic components, injection molding is employed. This method provides the ability to create complex shapes and ensures uniformity in the insulation parts of connectors.

-

Extrusion: In some cases, wires are extruded with insulation materials to create a single, unified component, simplifying the assembly process.

These forming techniques are essential for creating connectors that are not only functional but also robust enough to endure the rigors of transportation environments.

How Is the Assembly Process Conducted?

The assembly of semi truck electrical connectors is a critical step that combines various components into a final product. This stage typically involves several operations:

-

Wiring: The prepared wires are attached to terminals using methods such as crimping or soldering, ensuring a secure electrical connection.

-

Housing Assembly: After wiring, the terminals are inserted into housings. This step often includes sealing processes to enhance waterproofing and protect against contaminants.

-

Quality Control Checks: During assembly, initial quality checks are conducted to ensure that each connector meets design specifications. This may involve visual inspections and functional testing.

Efficient assembly lines are often employed to streamline production and maintain high output rates, which is crucial for meeting the demands of B2B buyers.

What Finishing Techniques Ensure the Quality of Electrical Connectors?

Finishing processes enhance the appearance and durability of electrical connectors. Common finishing techniques include:

-

Surface Treatments: Processes such as plating (e.g., nickel or gold plating) improve corrosion resistance and conductivity.

-

Coating: Protective coatings can be applied to insulators to prevent wear and enhance durability against environmental factors.

-

Labeling and Packaging: Proper labeling is essential for identification and traceability, while packaging ensures the connectors are protected during shipping.

These finishing touches not only improve the aesthetic appeal but also significantly enhance the product’s lifespan and reliability in the field.

What Quality Assurance Measures Are Implemented in the Production of Electrical Connectors?

Quality assurance (QA) is integral to the manufacturing process of semi truck electrical connectors, ensuring that each product meets stringent industry standards and customer expectations.

Illustrative image related to semi truck electrical connectors

Which International Standards Are Relevant for Quality Assurance?

Manufacturers often adhere to various international quality standards, such as:

-

ISO 9001: This standard outlines the requirements for a quality management system, emphasizing customer satisfaction and continuous improvement.

-

CE Certification: For products sold in Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

-

API Standards: In specific applications, such as those involving oil and gas, API standards may apply, ensuring connectors are suitable for demanding environments.

These standards are crucial for establishing credibility and trust among B2B buyers, particularly in diverse markets like Africa, South America, the Middle East, and Europe.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is performed at various checkpoints throughout the manufacturing process to ensure that products meet the required specifications. Key checkpoints include:

-

Incoming Quality Control (IQC): Raw materials are inspected upon arrival to confirm they meet the required standards before production begins.

-

In-Process Quality Control (IPQC): This involves monitoring production processes and conducting tests at various stages to identify any deviations from quality standards.

-

Final Quality Control (FQC): After assembly, connectors undergo rigorous testing, including electrical conductivity tests, mechanical stress tests, and environmental simulations, to ensure they can withstand real-world conditions.

These QC checkpoints help to minimize defects and ensure that only high-quality products reach the market.

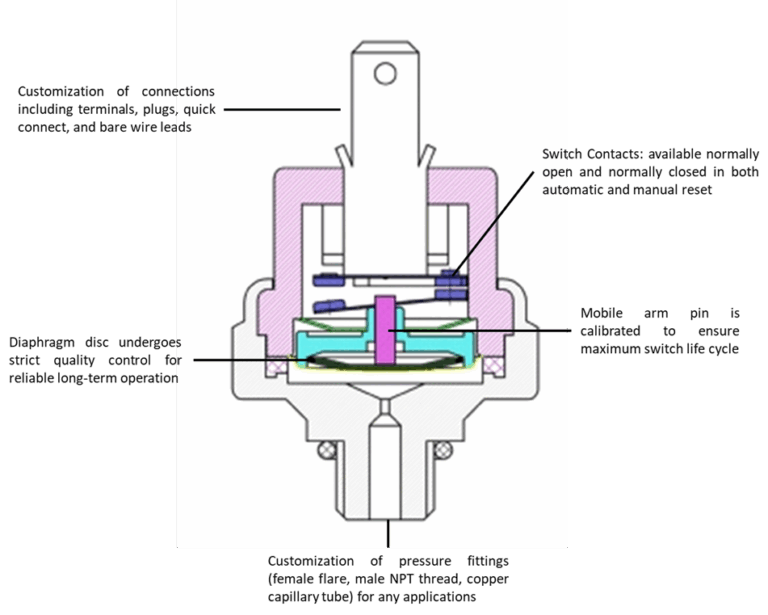

Illustrative image related to semi truck electrical connectors

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers have several avenues to verify the quality control practices of their suppliers:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality management systems, and adherence to relevant standards.

-

Quality Reports: Requesting documentation of quality control processes and test results can provide insights into the reliability of the products.

-

Third-Party Inspections: Engaging independent third-party inspection services can offer an unbiased evaluation of a supplier’s quality assurance practices.

-

Certifications: Buyers should check for certifications that validate a manufacturer’s compliance with international standards. This is particularly important for B2B buyers in regions with varying regulatory requirements.

What Are the Quality Control Nuances for International Buyers?

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of several nuances in quality control:

-

Regulatory Compliance: Different regions may have specific regulatory requirements. Buyers should ensure that suppliers are compliant with local regulations in their target markets.

-

Cultural Differences: Understanding cultural perspectives on quality and business practices can aid in establishing effective communication and expectations with suppliers.

-

Supply Chain Considerations: International logistics can affect product quality. Buyers should assess how suppliers manage transportation and storage to maintain product integrity.

By understanding these factors, B2B buyers can make informed decisions, ensuring they procure high-quality semi truck electrical connectors that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘semi truck electrical connectors’

To assist B2B buyers in procuring semi truck electrical connectors, this guide provides a practical checklist that outlines essential steps for effective sourcing. Ensuring the right components are selected can significantly impact vehicle performance and reliability, making this process crucial for businesses in various industries.

Step 1: Define Your Technical Specifications

Understanding the specific requirements for your semi truck electrical connectors is foundational. Consider factors such as voltage ratings, pin configurations, and environmental conditions (e.g., exposure to moisture, temperature extremes). This clarity will guide you in identifying the right products that meet your operational needs.

Step 2: Research Quality Standards and Certifications

Before sourcing, it’s vital to check for industry standards and certifications related to electrical connectors. Look for compliance with ISO, SAE, or other relevant standards that ensure reliability and safety. This can help avoid potential issues related to product performance and liability.

Step 3: Evaluate Potential Suppliers

Conduct thorough research on potential suppliers. Request company profiles, certifications, and references from other businesses in your industry or region. Assess their reputation by reading reviews and testimonials to ensure they have a track record of delivering quality products consistently.

- Consider their specialization in semi truck connectors and their experience in your specific market.

- Ask about their manufacturing processes to understand how they ensure quality and reliability.

Step 4: Request Samples or Prototypes

Before making a bulk purchase, request samples or prototypes of the connectors you’re considering. This allows you to evaluate the quality, durability, and compatibility with your existing systems. Testing samples can also help identify any potential issues early on.

Step 5: Negotiate Terms and Pricing

Once you’ve selected a supplier, negotiate pricing, payment terms, and delivery schedules. Understand the total cost of ownership, including shipping, taxes, and potential duties, especially when sourcing internationally. Ensure that terms are clear to avoid misunderstandings later on.

- Inquire about bulk pricing and discounts for larger orders.

- Clarify warranty and return policies to protect your investment.

Step 6: Assess Logistics and Shipping Options

Evaluate the logistics involved in receiving your order. Consider lead times, shipping methods, and whether the supplier can accommodate your delivery requirements. Efficient logistics are crucial for minimizing downtime and maintaining operational efficiency.

Step 7: Establish a Long-Term Relationship

Once you’ve successfully sourced your connectors, aim to build a long-term relationship with your supplier. Regular communication can lead to better service, favorable terms, and access to new products or innovations in the market. A reliable partnership is invaluable for ongoing support and future sourcing needs.

By following these steps, B2B buyers can streamline the procurement process for semi truck electrical connectors, ensuring they select high-quality products that meet their specific requirements while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for semi truck electrical connectors Sourcing

Understanding the cost structure and pricing dynamics of semi truck electrical connectors is crucial for international B2B buyers looking to optimize their sourcing strategies. This analysis delves into the various cost components, price influencers, and provides actionable tips for buyers, particularly those operating in regions such as Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Semi Truck Electrical Connectors?

The total cost of semi truck electrical connectors can be broken down into several key components:

-

Materials: The choice of materials directly impacts cost. High-quality plastics, metals, and specialized coatings that provide corrosion resistance or weatherproofing can elevate costs. For instance, connectors designed for harsh environments may utilize more robust materials, increasing their price.

-

Labor: Labor costs vary based on the manufacturing location. Countries with higher labor rates will naturally lead to increased production costs. It’s essential to consider the skill level of the labor force, especially in regions with advanced manufacturing capabilities.

-

Manufacturing Overhead: This includes costs associated with utilities, facility maintenance, and general administrative expenses. Efficient manufacturing processes can help minimize these costs, making it vital to partner with suppliers who prioritize operational efficiency.

-

Tooling: Initial tooling costs can be significant, especially for customized connectors. These costs are often amortized over larger production runs, making it more cost-effective for buyers to order in higher volumes.

-

Quality Control (QC): Robust QC measures ensure product reliability and compliance with industry standards, but they also add to the overall cost. Buyers should inquire about the QC processes of potential suppliers to understand their impact on pricing.

-

Logistics: Transportation costs can vary significantly based on the distance from the manufacturer to the buyer, as well as the mode of transport used. Factors such as import duties and customs fees also play a role in the total logistics cost.

-

Margin: The supplier’s profit margin is a vital component of the final price. Understanding the market landscape can help buyers gauge whether the margins are reasonable.

How Do Volume and Customization Affect Pricing?

Several factors can influence the pricing of semi truck electrical connectors:

-

Volume/MOQ: Suppliers often offer better pricing for larger orders. Minimum Order Quantities (MOQs) can affect cost efficiency, making bulk purchases more advantageous for cost-conscious buyers.

-

Specifications and Customization: Customized connectors tailored to specific applications may incur higher costs due to additional design and manufacturing processes. Buyers should weigh the necessity of customization against potential cost increases.

-

Materials and Certifications: The use of specialized materials or components that meet specific certifications (e.g., ISO, CE) can increase costs. However, these certifications often lead to improved product performance and reliability, justifying the investment.

-

Supplier Factors: The reputation and reliability of a supplier can impact pricing. Established suppliers may charge a premium for their products due to their proven quality and service.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international transactions. They define the responsibilities of buyers and sellers in terms of shipping, insurance, and customs clearance, directly influencing total costs.

What Are Effective Negotiation and Cost-Efficiency Strategies?

For B2B buyers, particularly in diverse markets like Nigeria, Germany, and other regions, the following tips can enhance negotiation and cost-efficiency:

-

Research and Benchmarking: Conduct market research to understand average pricing and common terms in the industry. This knowledge empowers buyers during negotiations.

-

Total Cost of Ownership (TCO): Consider not just the purchase price but the TCO, which includes installation, maintenance, and potential downtime costs. This comprehensive view helps in making informed purchasing decisions.

-

Long-term Relationships: Building strong relationships with suppliers can lead to better pricing and terms over time. Loyalty can sometimes result in discounts or favorable payment terms.

-

Flexibility in Orders: If possible, negotiate flexible order quantities to adapt to changing needs without incurring penalties or higher prices.

In conclusion, understanding the comprehensive cost structure, the factors influencing pricing, and employing effective negotiation strategies are essential for international B2B buyers sourcing semi truck electrical connectors. By focusing on these elements, buyers can make informed decisions that align with their operational goals and budgetary constraints.

Alternatives Analysis: Comparing semi truck electrical connectors With Other Solutions

When evaluating the best connectivity solutions for semi trucks, it’s essential to consider not only traditional semi truck electrical connectors but also alternative technologies that can fulfill similar roles. This analysis will compare semi truck electrical connectors with magnetic electrical connectors and wireless connectivity solutions, providing insights into their respective advantages and disadvantages.

| Comparison Aspect | Semi Truck Electrical Connectors | Magnetic Electrical Connectors | Wireless Connectivity Solutions |

|---|---|---|---|

| Performance | High reliability in harsh environments | Excellent for quick disconnects and reliability | Variable performance, dependent on environmental factors |

| Cost | Generally affordable; bulk pricing available | Higher initial investment | Potentially lower installation costs, but ongoing data costs |

| Ease of Implementation | Straightforward installation with wiring | Requires special mounts and alignment | Requires integration with existing systems and can be complex |

| Maintenance | Regular checks needed for wear and corrosion | Minimal maintenance; durable | Dependent on software and signal integrity; may require updates |

| Best Use Case | Standard trailer and truck connections | Heavy-duty applications needing frequent connect/disconnect | Applications where physical wiring is impractical or impossible |

What Are the Advantages and Disadvantages of Magnetic Electrical Connectors?

Magnetic electrical connectors offer a unique solution for semi truck applications where quick disconnects are vital, such as in scenarios involving frequent trailer changes or equipment that may require rapid reconfiguration. These connectors use magnetic fields to create a secure connection, which can be beneficial in environments where traditional connectors might fail due to wear or misalignment. However, the initial cost can be higher than that of traditional connectors, and installation may require specialized mounting solutions. Additionally, while they excel in durability, their performance can be affected by external magnetic fields or debris.

How Do Wireless Connectivity Solutions Compare?

Wireless connectivity solutions represent a more futuristic approach to truck connectivity, utilizing radio frequencies or Bluetooth technology to maintain connections. This option eliminates the need for physical connectors, significantly reducing wear and tear over time. It can be particularly advantageous in applications where wiring is impractical, such as in modular trailer setups or in environments with harsh weather conditions. However, wireless solutions can suffer from variable performance due to signal interference, and they may incur ongoing data costs. Additionally, they require careful integration with existing systems, which can complicate implementation.

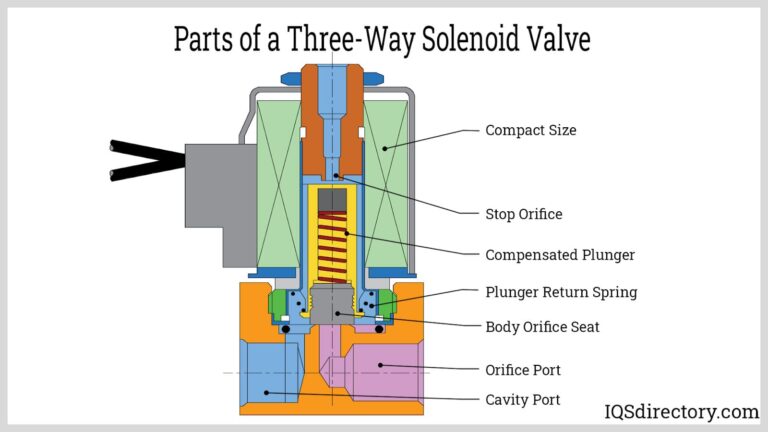

Illustrative image related to semi truck electrical connectors

Conclusion: How Should B2B Buyers Choose the Right Solution?

Selecting the appropriate connectivity solution for semi trucks hinges on the specific needs and operational context of the buyer. For traditional applications where reliability and straightforward installation are paramount, semi truck electrical connectors remain a strong choice. However, buyers should consider the operational environment and frequency of connector usage when evaluating alternatives like magnetic connectors or wireless solutions. By understanding the performance, cost implications, and maintenance requirements of each option, B2B buyers can make informed decisions that align with their logistical needs and budget constraints.

Essential Technical Properties and Trade Terminology for semi truck electrical connectors

What Are the Key Technical Properties of Semi Truck Electrical Connectors?

Understanding the technical specifications of semi truck electrical connectors is essential for ensuring reliable performance and compatibility in various applications. Here are some critical properties that B2B buyers should consider:

-

Material Grade

– Definition: The material used in connectors typically includes metals like copper for conductivity and plastics like polyamide for insulation.

– B2B Importance: High-quality materials enhance durability and resistance to corrosion, which is crucial for connectors exposed to harsh environments. Buyers should prioritize connectors made from materials that meet industry standards to ensure longevity and reliability. -

Current Rating

– Definition: This specification indicates the maximum current a connector can safely carry, usually measured in amperes (A).

– B2B Importance: Selecting a connector with an appropriate current rating is vital to prevent overheating and potential failure. Understanding the electrical load requirements of the specific application helps in choosing the right connector, minimizing downtime and maintenance costs. -

IP Rating (Ingress Protection)

– Definition: This rating classifies the degree of protection provided against dust and water ingress, typically indicated by two digits (e.g., IP67).

– B2B Importance: A higher IP rating means better protection against environmental factors, essential for connectors used in outdoor or extreme conditions. Buyers should consider the operational environment to ensure connectors can withstand potential exposure to moisture and debris. -

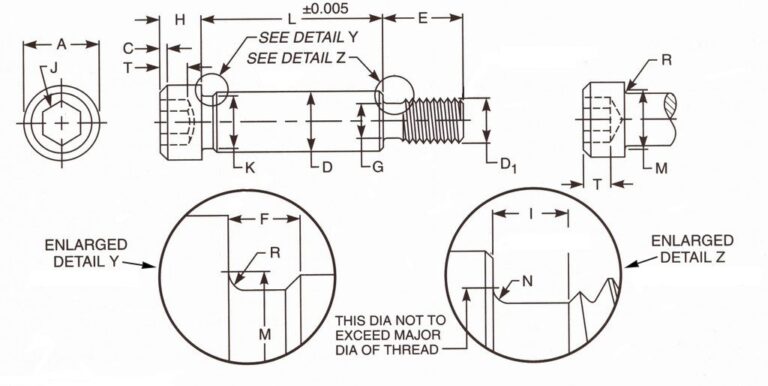

Tolerance and Fit

– Definition: Tolerance refers to the allowable deviation in dimensions, ensuring connectors fit together securely without excessive force.

– B2B Importance: Proper tolerance levels are crucial for ensuring a tight and reliable connection, which reduces the risk of electrical failures. This is particularly important in high-vibration environments, such as those experienced by semi trucks. -

Temperature Range

– Definition: The operational temperature range defines the minimum and maximum temperatures within which a connector can function effectively.

– B2B Importance: Connectors must operate reliably in varying temperatures, especially in regions with extreme climates. Understanding the temperature tolerance helps buyers select connectors that will perform consistently, regardless of environmental conditions.

What Are Common Trade Terms in the Semi Truck Electrical Connector Industry?

Familiarity with industry terminology can greatly enhance communication and decision-making for B2B buyers. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts and equipment that may be marketed by another manufacturer.

– Importance: OEM connectors are often regarded as high-quality components that are specifically designed for compatibility with a manufacturer’s equipment, ensuring optimal performance and reliability. -

MOQ (Minimum Order Quantity)

– Definition: The smallest amount of product that a supplier is willing to sell.

– Importance: Understanding MOQ is crucial for budgeting and inventory management, especially for businesses that may not require large quantities but still want to maintain stock. -

RFQ (Request for Quotation)

– Definition: A business process where a buyer requests price quotes from suppliers for specified products.

– Importance: RFQs allow buyers to compare prices and terms from multiple suppliers, enabling informed purchasing decisions and potentially reducing costs. -

Incoterms (International Commercial Terms)

– Definition: A series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that clarify responsibilities for shipping, insurance, and tariffs.

– Importance: Familiarity with Incoterms helps buyers understand shipping responsibilities and costs, facilitating smoother international transactions and reducing the risk of unexpected expenses. -

Lead Time

– Definition: The amount of time from the initiation of an order until its completion or delivery.

– Importance: Understanding lead times is essential for planning and supply chain management, ensuring that businesses can maintain operations without delays due to missing components.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance their procurement processes and ensure the reliability of their semi truck electrical systems.

Navigating Market Dynamics and Sourcing Trends in the semi truck electrical connectors Sector

What Are the Current Market Dynamics and Key Trends in the Semi Truck Electrical Connectors Sector?

The semi truck electrical connectors market is witnessing robust growth driven by several global factors. Increasing demand for heavy-duty trucks in emerging markets, particularly in Africa, South America, and the Middle East, is propelling the need for efficient and reliable electrical systems. Additionally, advancements in technology, such as the integration of IoT devices in transportation, are pushing manufacturers to develop connectors that support enhanced connectivity and data transmission. This trend is particularly relevant for international buyers who are looking to invest in modernized fleets that can adapt to smart logistics solutions.

Illustrative image related to semi truck electrical connectors

Moreover, as the European market emphasizes stricter regulations on emissions and sustainability, there is a growing demand for electrical connectors that support electric and hybrid vehicles. Buyers are increasingly interested in suppliers that offer a range of products, including advanced connectors designed for high-voltage applications. The proliferation of e-commerce and the need for faster logistics are also influencing sourcing strategies, prompting buyers to seek suppliers with efficient distribution networks.

Emerging technologies, such as magnetic connectors and sealed systems that enhance durability, are becoming essential in the market. These innovations not only improve the longevity of the connectors but also reduce maintenance costs, a significant consideration for fleet operators. International buyers should also pay attention to the availability of customization options, allowing them to tailor products to specific operational needs.

How Important Is Sustainability and Ethical Sourcing in the Semi Truck Electrical Connectors Market?

Sustainability and ethical sourcing are becoming increasingly vital in the semi truck electrical connectors sector. With growing awareness of environmental issues, companies are under pressure to adopt practices that minimize their ecological footprint. Buyers from regions like Europe, which prioritize sustainability, are actively seeking suppliers who demonstrate a commitment to environmentally friendly practices. This includes the use of recyclable materials and sustainable manufacturing processes.

The importance of ethical supply chains cannot be overstated. Buyers are looking for manufacturers who adhere to international labor standards and promote fair working conditions. Certifications such as ISO 14001 for environmental management and ISO 9001 for quality management are becoming essential for suppliers aiming to capture the attention of conscientious buyers.

In addition to ethical considerations, the demand for “green” products, such as connectors made from eco-friendly materials or those designed to enhance energy efficiency, is on the rise. As electric vehicles gain traction, connectors that support these technologies will not only meet regulatory standards but also align with the values of environmentally conscious consumers. Buyers should prioritize partnerships with manufacturers who can provide transparency regarding their sourcing and production methods.

What Is the Brief Evolution and History of the Semi Truck Electrical Connectors Market?

The evolution of the semi truck electrical connectors market reflects broader technological advancements in the automotive and transportation sectors. Initially, connectors were rudimentary, designed primarily for basic electrical functions. However, as vehicles became more complex with the introduction of advanced electronics, the demand for robust, reliable connectors surged.

The late 20th century saw significant developments in materials and design, leading to the introduction of sealed and weather-resistant connectors that improved performance in harsh environments. With the rise of globalization and international trade, manufacturers began to standardize their products, making it easier for buyers across different regions to source compatible components.

In recent years, the focus has shifted towards smart technologies and sustainability, pushing manufacturers to innovate further. Today, the market is characterized by a diverse range of products, from high-voltage connectors for electric trucks to advanced data transmission systems, reflecting the ongoing transformation in the transportation industry. This historical context is crucial for B2B buyers as they navigate their sourcing strategies in a rapidly evolving marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of semi truck electrical connectors

-

How do I solve connectivity issues with semi truck electrical connectors?

To address connectivity issues, first, inspect the connectors for corrosion, damage, or dirt. Ensure that all connections are secure and properly seated. If the problem persists, consider replacing the connectors with high-quality, weather-resistant options that are designed for heavy-duty use. For international buyers, sourcing from reputable suppliers who offer a warranty can also minimize future connectivity problems. -

What is the best electrical connector for heavy-duty semi trucks?

The best electrical connectors for heavy-duty semi trucks are those that are specifically designed to withstand harsh environments. Look for connectors with robust sealing features, such as TE Connectivity’s AMPSEAL series or Phillips Industries’ WEATHER-TITE™ connectors, which are resistant to moisture and contaminants. Selecting connectors that meet industry standards ensures reliability and longevity in performance, especially in challenging conditions. -

What are the common minimum order quantities (MOQs) for semi truck electrical connectors?

Minimum order quantities (MOQs) can vary significantly by supplier and product type. Typically, MOQs for semi truck electrical connectors range from 100 to 1,000 units. It’s important to communicate with suppliers directly to negotiate MOQs, especially if you’re a smaller business or a new buyer. Some manufacturers may offer flexibility in MOQs, particularly for bulk orders or long-term contracts. -

What payment terms should I expect when purchasing semi truck electrical connectors internationally?

Payment terms for international purchases typically include options like advance payment, letters of credit, or net 30/60 days. It’s essential to clarify these terms before placing an order. Some suppliers may require a deposit upfront, especially for large orders, while others may offer more lenient terms for established buyers. Always ensure that the payment method is secure and traceable to avoid potential fraud. -

How can I vet suppliers of semi truck electrical connectors?

To vet suppliers, start by researching their reputation through reviews, industry certifications, and customer testimonials. Request samples to evaluate product quality before committing to a larger order. Additionally, inquire about their manufacturing processes, quality assurance measures, and compliance with international standards. Engaging in direct communication can also help assess their responsiveness and reliability. -

What customization options are available for semi truck electrical connectors?

Many manufacturers offer customization options such as specific connector types, lengths, and configurations tailored to your needs. Discuss your requirements with potential suppliers to explore available options, including branding or unique features that suit your operational demands. Custom connectors can enhance compatibility and performance, especially in specialized applications or harsh environments. -

What quality assurance measures should I look for in electrical connectors?

When sourcing electrical connectors, seek suppliers that implement rigorous quality assurance measures. This includes adherence to international standards such as ISO 9001, thorough testing for durability and performance, and certifications for environmental resistance. Request documentation that outlines their QA processes and any warranties offered, as this can provide assurance of product reliability and longevity. -

What logistics considerations should I keep in mind for international shipments of electrical connectors?

Logistics considerations include shipping methods, customs regulations, and delivery timelines. Ensure your supplier is experienced in international shipping and can provide accurate shipping costs and estimated delivery times. Familiarize yourself with the import regulations in your country to avoid delays. Additionally, consider using freight forwarders who specialize in B2B shipments to streamline the process and ensure that all documentation is correctly handled.

Top 6 Semi Truck Electrical Connectors Manufacturers & Suppliers List

1. Tracey Truck Parts – Freightliner Connectors

Domain: traceytruckparts.com

Registered: 2019 (6 years)

Introduction: {“products”:[{“name”:”Freightliner Female Minifuse Connector”,”sku”:”# 23-13215-301″,”sale_price”:”$0.90″,”regular_price”:”$1.36″},{“name”:”Freightliner Female Terminal MCP1.5KS”,”sku”:”# AI 1241381 3″,”sale_price”:”$0.48″,”regular_price”:”$0.75″},{“name”:”Freightliner Female Terminal”,”sku”:”# AI 927775 3″,”sale_price”:”$0.94″,”regular_price”:”$1.48″},{“name”:”Freightliner Female MCP Terminal”,”s…

2. TE Connectivity – Vehicle Connectors

Domain: te.com

Registered: 1992 (33 years)

Introduction: Connectors for Truck, Bus and Off-Road Vehicles by TE Connectivity include a wide range of connector types such as circular connectors, D-shaped connectors, power connectors, and terminal blocks. These connectors are designed for durability and reliability in demanding environments typical of commercial and industrial vehicles. TE Connectivity offers solutions that support various applications wit…

3. Phillips Industries – EC47 Electrical Connectors

Domain: phillipsind.com

Registered: 1996 (29 years)

Introduction: Electrical Connectors: EC47 (Ethernet, CAN, 4 AUX, 7-Way) – Next level of tractor-trailer communication, power transfer, and safety. Junction Boxes: Quick and easy trailer wiring management, Quick-Connect Junction Box adaptable to most trailer wiring systems. Heavy Duty Liftgate Solenoids: Intermittent Duty and Continuous Duty heavy-duty solenoids for liftgates. Liftgate Charging Plugs: Dual Pole …

4. 7-Way Round Connector – New Semi Truck Accessory

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “7-Way Round Electrical Connector for Semi Trucks and Trailers”, “Condition”: “New”, “Price”: “US $22.37”, “Quantity Available”: “3”, “Quantity Sold”: “6”, “Shipping”: “Free 2-4 day delivery”, “Location”: “Brooklyn, New York, United States”, “Returns”: “Seller does not accept returns”, “Brand”: “MECMO”, “Color”: “Silver”, “EAN”: “6975286150364”, “Package Dimensions”: “4.33×3.03×2….

5. EZ Connector – High-Reliability Magnetic Electrical Connectors

Domain: ezconnector.com

Registered: 2006 (19 years)

Introduction: EZ Connector, Inc. offers high-reliability magnetic electrical connectors designed for various applications including snow removal equipment, tree services, fleets, military, horse trailers, boat trailers, agriculture, RVs, 5th wheels, and construction equipment. The connectors are known for their durability in harsh environments and are available in standard and custom designs. Product categories…

6. Waytek – Trailer Electrical Connectors

Domain: waytekwire.com

Registered: 1998 (27 years)

Introduction: This company, Waytek – Trailer Electrical Connectors, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for semi truck electrical connectors

In navigating the complex landscape of semi truck electrical connectors, international B2B buyers must prioritize strategic sourcing to ensure they secure high-quality components that meet their operational needs. The diverse range of connectors available—such as 7-pin, 6-pin, and customized solutions—highlights the importance of selecting products that align with both compatibility and durability standards specific to each market, including regions like Africa, South America, the Middle East, and Europe.

Investing in reliable suppliers who offer robust warranties and superior customer support can significantly enhance supply chain efficiency, reduce downtime, and ultimately lead to cost savings. As trends shift towards more advanced technologies, including electric vehicles and smart connectivity, staying ahead of these changes will be crucial for maintaining a competitive edge.

Looking forward, we encourage international buyers to actively explore partnerships with reputable manufacturers and distributors. By leveraging strategic sourcing practices, businesses can not only secure essential components but also contribute to the growth and innovation of the trucking industry. Engage with trusted suppliers today to future-proof your operations and ensure seamless connectivity in your fleet.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.