Top 6 Plumbing Expansion Joint Suppliers (And How to Choose)

Introduction: Navigating the Global Market for plumbing expansion joint

In the realm of plumbing systems, sourcing effective plumbing expansion joints presents a significant challenge for B2B buyers, particularly in dynamic markets across Africa, South America, the Middle East, and Europe. These critical components not only accommodate thermal expansion and contraction but also enhance system flexibility and longevity. However, navigating the complexities of selection—from types and applications to cost considerations—can be daunting.

This comprehensive guide aims to demystify the global market for plumbing expansion joints. It covers various types, including metal bellows and rubber expansion joints, along with their specific applications in diverse environments such as residential, commercial, and industrial settings. Additionally, it provides valuable insights into supplier vetting processes, ensuring that buyers can identify reputable manufacturers that meet international standards.

By equipping B2B buyers with actionable knowledge, this guide empowers informed purchasing decisions. It highlights the importance of understanding design basics, movement capabilities, and lifecycle considerations, which are crucial for optimizing system performance. For businesses in regions like Germany and Brazil, where quality and reliability are paramount, this resource serves as an essential tool for sourcing the right plumbing expansion joints that ensure operational efficiency and cost-effectiveness.

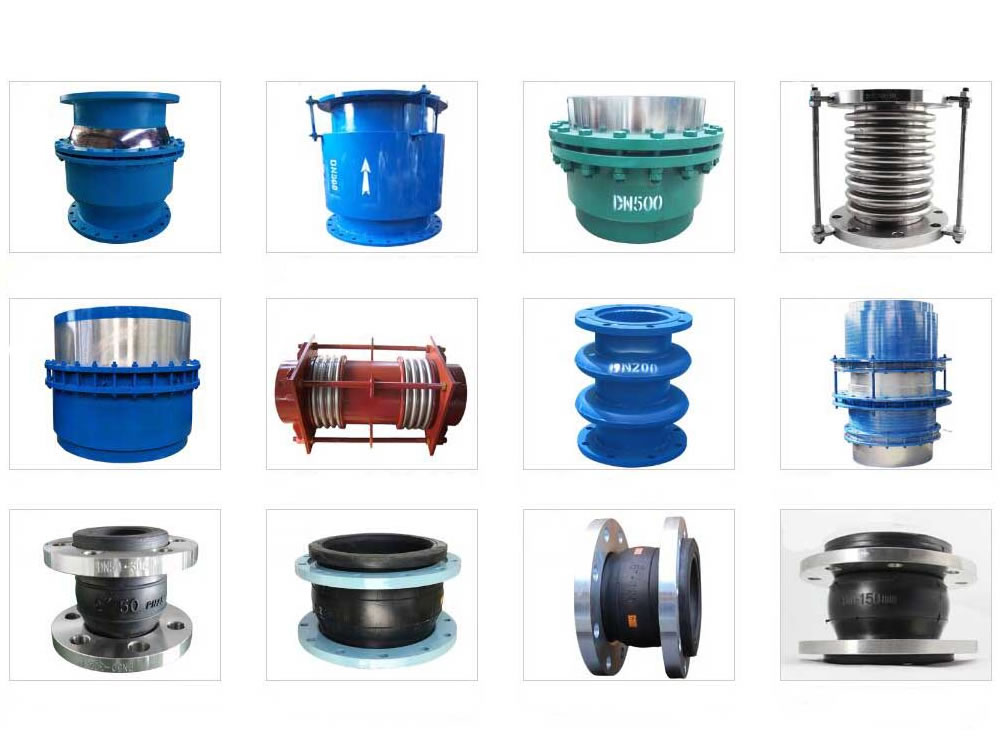

Understanding plumbing expansion joint Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Metal Bellows Expansion Joint | Flexible bellows made from thin-walled metal, suitable for high pressure. | Oil & gas, chemical processing, power generation | Pros: High durability, excellent pressure handling. Cons: Higher initial cost, potential for fatigue over time. |

| Rubber Expansion Joint | Constructed from elastomeric materials, provides significant flexibility. | Water treatment, HVAC systems, mining | Pros: Cost-effective, good vibration absorption. Cons: Limited temperature and pressure ratings. |

| Fabric Expansion Joint | Made from reinforced fabric, lightweight and flexible. | Power generation, aerospace applications | Pros: Lightweight, easy installation. Cons: Limited pressure capacity, less durable than metal options. |

| Universal Expansion Joint | Allows for multiple movements (axial, lateral, angular). | Pulp and paper, wastewater treatment | Pros: Versatile movement capabilities. Cons: Can be complex to install and maintain. |

| Single Sphere Expansion Joint | A single, spherical shape providing flexibility in all directions. | HVAC, plumbing, industrial applications | Pros: Compact design, effective for small spaces. Cons: Limited movement range compared to multi-directional options. |

What Are Metal Bellows Expansion Joints and Their Applications?

Metal bellows expansion joints are designed for high-pressure environments, often found in industries such as oil and gas, chemical processing, and power generation. Their flexible bellows can handle significant thermal expansion and contraction while maintaining structural integrity. When purchasing, consider factors like material compatibility, pressure ratings, and potential fatigue from cycling. While they offer durability, the initial investment can be higher compared to other types, necessitating careful budget considerations.

How Do Rubber Expansion Joints Stand Out in the Market?

Rubber expansion joints are highly valued for their flexibility and cost-effectiveness, making them ideal for applications in water treatment, HVAC systems, and mining. These joints effectively absorb vibrations and accommodate misalignments in piping systems. Buyers should evaluate temperature and pressure limits to ensure suitability for their specific applications. While they are less expensive upfront, their lifespan may be shorter in extreme conditions, which could lead to increased maintenance costs.

What Are the Key Features of Fabric Expansion Joints?

Fabric expansion joints are lightweight and made from reinforced materials, making them suitable for applications in power generation and aerospace. They are easy to install and can accommodate various movements, providing significant flexibility. However, their pressure capacity is limited compared to metal options, so it’s crucial for buyers to assess the operational environment. While they can be a practical choice for specific applications, their durability may not match that of metal or rubber joints.

Why Choose Universal Expansion Joints for Complex Systems?

Universal expansion joints are designed to accommodate multiple movements, including axial, lateral, and angular displacement. This versatility makes them suitable for industries such as pulp and paper and wastewater treatment. Buyers should consider installation complexity and maintenance needs, as these joints can be more complicated than simpler designs. While they provide excellent flexibility, the potential for increased installation costs should be factored into the purchasing decision.

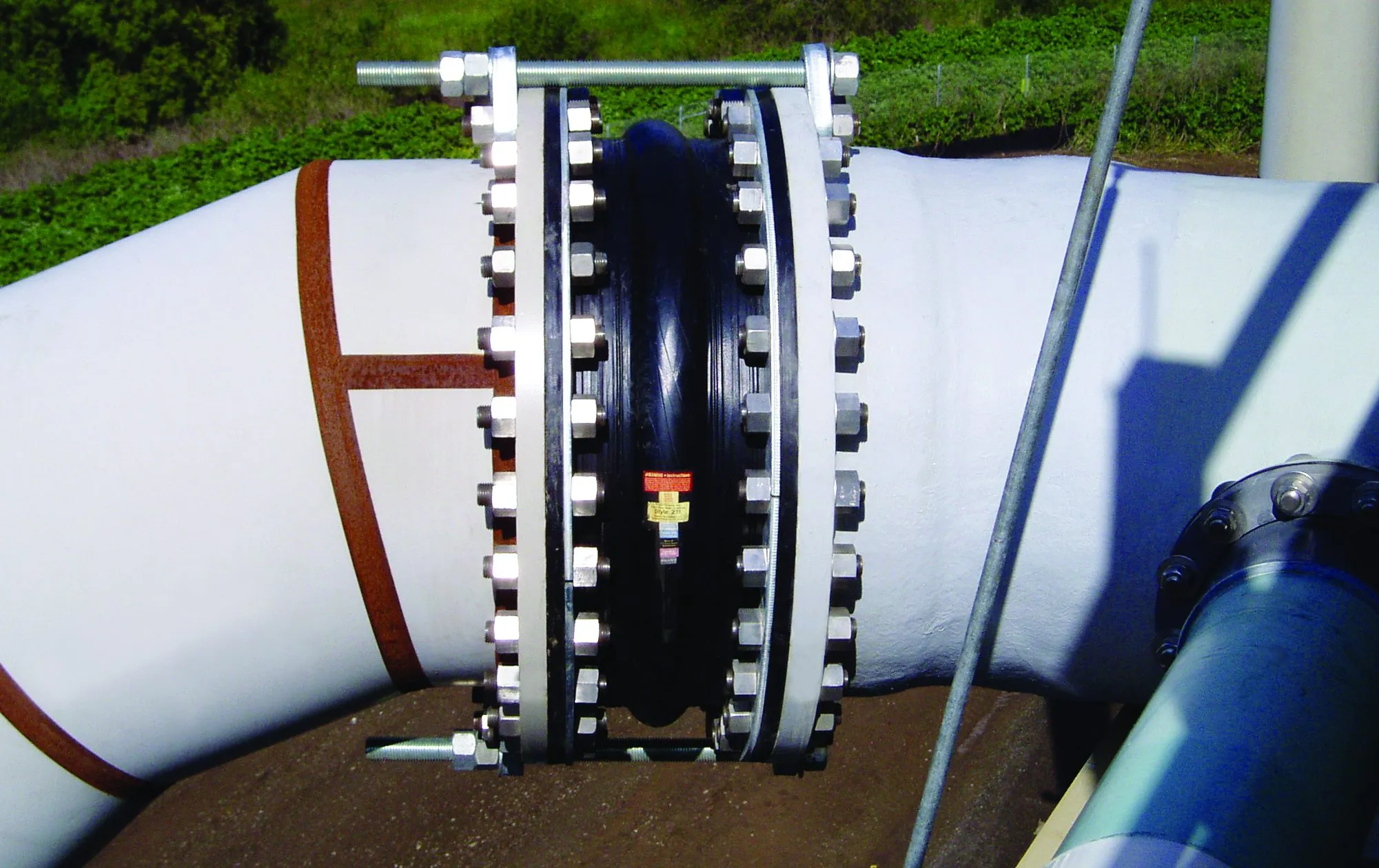

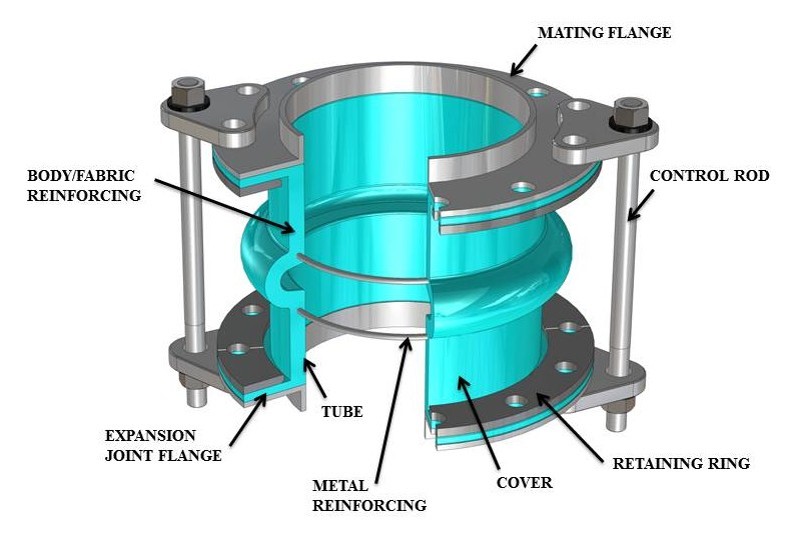

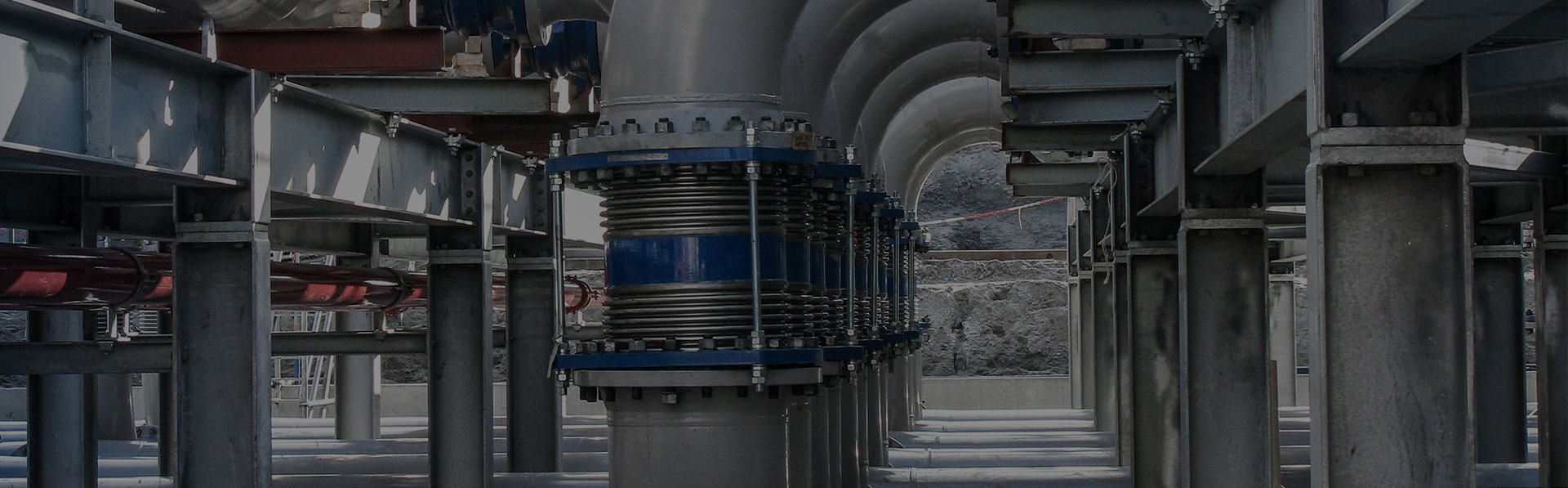

Illustrative image related to plumbing expansion joint

What Are the Advantages of Single Sphere Expansion Joints?

Single sphere expansion joints are compact and ideal for small spaces, often used in HVAC and plumbing systems. They provide flexibility in all directions, making them suitable for various industrial applications. Buyers should weigh their limited movement range against the need for a compact design. While their simplicity can be an advantage, it may also lead to limitations in more complex piping systems where greater flexibility is required.

Key Industrial Applications of plumbing expansion joint

| Industry/Sector | Specific Application of Plumbing Expansion Joint | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil and Gas | Connecting pipelines in offshore drilling operations | Reduces stress on pipes, enhancing durability and safety | Corrosion resistance, temperature tolerance, and pressure ratings |

| Water and Wastewater | Integration in sewage systems for flexible connections | Prevents leaks and accommodates ground movement | Compliance with local regulations, material compatibility, and lifespan |

| Chemical Processing | Use in chemical transport pipelines | Ensures safe transfer of corrosive materials | Chemical compatibility, custom sizes, and pressure ratings |

| Power Generation | Application in steam and cooling water systems | Enhances system efficiency and reduces maintenance costs | High-temperature resistance, vibration absorption capabilities |

| HVAC Systems | Installation in heating and cooling systems | Improves system longevity and operational flexibility | Noise reduction features, temperature range, and installation ease |

How Are Plumbing Expansion Joints Used in the Oil and Gas Industry?

In the oil and gas sector, plumbing expansion joints are crucial for connecting pipelines in offshore drilling operations. They accommodate the thermal expansion and contraction of pipes caused by fluctuating temperatures. This flexibility reduces the risk of stress fractures, thereby enhancing the safety and durability of the pipeline system. B2B buyers in this industry must consider factors like corrosion resistance and pressure ratings to ensure the joints can withstand harsh marine environments.

What Role Do Plumbing Expansion Joints Play in Water and Wastewater Management?

Within water and wastewater management, plumbing expansion joints are integrated into sewage systems to create flexible connections that can adapt to ground movements. This adaptability prevents leaks and enhances the longevity of the piping infrastructure. For international buyers, particularly in developing regions, compliance with local regulations and material compatibility are critical considerations to ensure optimal performance and sustainability of the system.

How Are Plumbing Expansion Joints Utilized in Chemical Processing?

In chemical processing, plumbing expansion joints are employed in pipelines that transport various chemicals. They are essential for maintaining safe and efficient operations by accommodating thermal expansions and preventing leaks. B2B buyers must focus on chemical compatibility and pressure ratings when sourcing these joints, ensuring they meet the specific requirements of the substances being transported.

Why Are Plumbing Expansion Joints Important in Power Generation?

Plumbing expansion joints find significant application in steam and cooling water systems within power generation facilities. They help enhance system efficiency by allowing for thermal movement, which reduces the risk of mechanical failure and maintenance costs. Buyers in this sector should prioritize high-temperature resistance and vibration absorption capabilities to ensure the joints can withstand the demanding operational conditions.

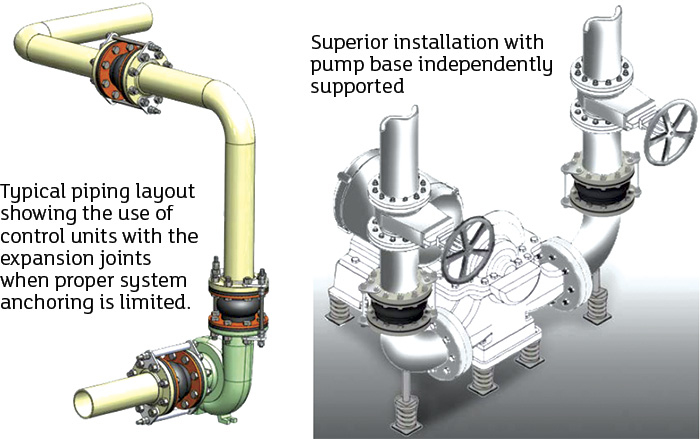

How Do Plumbing Expansion Joints Benefit HVAC Systems?

In HVAC systems, plumbing expansion joints are installed to improve flexibility and reduce noise levels. They help accommodate the thermal expansion of pipes and ductwork, ultimately enhancing system longevity. For B2B buyers, features like noise reduction capabilities and temperature range are essential factors to consider, ensuring the joints effectively contribute to a quieter and more efficient HVAC operation.

3 Common User Pain Points for ‘plumbing expansion joint’ & Their Solutions

Scenario 1: Misalignment and Stress on Piping Systems

The Problem: In many industrial applications, B2B buyers often encounter issues with misalignment of piping systems due to thermal expansion or ground settlement. This misalignment can lead to excessive stress on pipes and fittings, causing leaks, premature wear, or even catastrophic failures. Such challenges are especially prevalent in regions with significant temperature fluctuations or where ground movement is common, making it crucial for buyers to find effective solutions.

The Solution: To mitigate these risks, buyers should prioritize the selection of high-quality plumbing expansion joints designed specifically for their operational conditions. When sourcing expansion joints, it is essential to consider factors such as the expected movement range, material compatibility, and environmental conditions. A thorough understanding of the piping system’s layout can help buyers specify the correct type of expansion joint—whether it be axial, lateral, or angular—to absorb movements effectively. Additionally, regular maintenance checks should be instituted to ensure proper alignment and functionality of the joints, thus prolonging the life of the piping system and preventing costly repairs.

Scenario 2: Vibration and Noise Transfer Issues

The Problem: In many facilities, mechanical equipment generates significant vibrations that can transfer through plumbing systems, leading to noise and potential damage over time. B2B buyers in sectors such as manufacturing or chemical processing often face the challenge of isolating these vibrations to protect both their infrastructure and employee comfort. Ignoring this issue can result in not only equipment failure but also decreased workplace productivity due to noise disturbances.

The Solution: To address vibration and noise transfer, buyers should utilize expansion joints specifically designed for vibration isolation. When selecting these joints, consider those with built-in damping capabilities or materials that can absorb vibrations effectively. For instance, rubber or elastomeric expansion joints can be particularly effective in mitigating vibration transmission. Furthermore, buyers should evaluate the installation process to ensure that these joints are placed correctly within the system. Partnering with experienced suppliers who can provide technical support and guidance on proper installation techniques will enhance the effectiveness of vibration isolation measures, ultimately improving system longevity and workplace comfort.

Scenario 3: Inadequate Sizing Leading to System Inefficiencies

The Problem: A common pitfall for B2B buyers is the inadequate sizing of plumbing expansion joints, which can lead to inefficient system performance. If the expansion joint is too small, it may not accommodate the necessary movements, resulting in stress and potential failure. Conversely, oversized joints can lead to increased pressure drops and flow restrictions, ultimately affecting operational efficiency. This challenge is particularly pronounced in large-scale industrial applications where precision is key.

The Solution: To ensure proper sizing, buyers should conduct a comprehensive analysis of their piping system’s thermal expansion requirements, taking into account factors such as temperature variations, pipe material, and system pressure. Engaging with manufacturers or suppliers who offer sizing calculators or technical resources can provide invaluable assistance in selecting the right expansion joint. Additionally, it is advisable to consult industry standards and guidelines that outline sizing criteria for specific applications. By investing time in the correct sizing of expansion joints, buyers can optimize their system’s performance, reduce maintenance costs, and enhance overall operational efficiency.

Strategic Material Selection Guide for plumbing expansion joint

What are the Key Properties of Common Materials Used in Plumbing Expansion Joints?

When selecting materials for plumbing expansion joints, it is essential to consider their key properties, which directly influence performance under various conditions. The most commonly used materials include stainless steel, rubber, PTFE (Polytetrafluoroethylene), and composite materials. Each material offers unique advantages and disadvantages that can affect the suitability for specific applications.

How Does Stainless Steel Perform in Plumbing Expansion Joints?

Stainless steel is renowned for its excellent strength and durability, making it suitable for high-pressure and high-temperature applications. Its resistance to corrosion, particularly in harsh environments, is a significant advantage, ensuring longevity and reliability. However, stainless steel can be costly and may require complex manufacturing processes, particularly when forming intricate shapes. In plumbing applications, stainless steel expansion joints are ideal for systems that transport water, steam, and various chemicals, given its compatibility with a wide range of media.

For international buyers, compliance with standards such as ASTM A312 for stainless steel pipes is crucial. Countries in Europe and the Middle East often have stringent regulations regarding material specifications, which can affect procurement decisions.

What Are the Advantages of Rubber in Plumbing Expansion Joints?

Rubber expansion joints are favored for their flexibility and ability to absorb vibrations and movements, making them ideal for applications involving dynamic loads. They are typically more cost-effective than metal alternatives, allowing for easier installation and maintenance. However, rubber has limitations in terms of temperature and pressure ratings, which can restrict its use in high-stress environments. Moreover, certain chemicals can degrade rubber, making it less suitable for transporting aggressive media.

Illustrative image related to plumbing expansion joint

B2B buyers in regions like Africa and South America should consider local climate conditions, as extreme temperatures can affect rubber’s performance. Compliance with standards such as ISO 4633 can also influence the selection process.

How Does PTFE Enhance the Performance of Plumbing Expansion Joints?

PTFE is recognized for its exceptional chemical resistance and ability to operate at high temperatures, making it suitable for applications involving corrosive substances. Its low friction properties also contribute to reduced wear and tear on connected systems. However, PTFE expansion joints can be more expensive than rubber and may require specialized manufacturing techniques. They are particularly beneficial in industries such as pharmaceuticals and food processing, where media purity is paramount.

For international buyers, understanding local regulations regarding material safety and chemical compatibility is essential. Compliance with standards such as FDA regulations for food-grade applications is particularly relevant in Europe and the Middle East.

What Role Do Composite Materials Play in Plumbing Expansion Joints?

Composite materials combine the benefits of various substances to create lightweight, durable expansion joints. They often exhibit excellent resistance to corrosion and can be engineered to meet specific performance criteria. However, the manufacturing complexity can lead to higher costs. Composite joints are increasingly used in modern plumbing systems where weight and space are concerns, such as in high-rise buildings.

International buyers should be aware of the varying standards for composite materials across regions. For example, compliance with ASTM D638 for tensile properties is crucial for ensuring product reliability.

Illustrative image related to plumbing expansion joint

Summary Table of Material Selection for Plumbing Expansion Joints

| Material | Typical Use Case for plumbing expansion joint | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | High-pressure water and steam systems | Excellent strength and corrosion resistance | Higher cost and manufacturing complexity | High |

| Rubber | Low to medium pressure applications | Flexibility and cost-effective | Limited temperature/pressure ratings | Low |

| PTFE | Chemical processing and food applications | Exceptional chemical resistance | Higher cost and specialized manufacturing | High |

| Composite | Lightweight plumbing systems in high-rises | Lightweight and customizable | Higher manufacturing complexity | Medium |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of various materials used in plumbing expansion joints, enabling informed procurement decisions tailored to specific applications and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for plumbing expansion joint

What are the Key Stages in the Manufacturing Process of Plumbing Expansion Joints?

Manufacturing plumbing expansion joints involves several critical stages that ensure the final product meets rigorous performance standards. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation: What Materials are Used and How are They Processed?

The choice of materials is paramount in the production of plumbing expansion joints. Common materials include stainless steel, rubber, and various alloys, selected based on the intended application and environmental conditions.

In the material preparation stage, raw materials undergo rigorous inspection and testing to verify their quality. This includes checking for impurities, verifying chemical compositions, and ensuring that they meet specified industry standards. Suppliers often maintain certifications such as ISO 9001 to assure quality and reliability.

How are Plumbing Expansion Joints Formed?

The forming stage involves shaping the raw materials into the required components of the expansion joint. For metal bellows, a common design for these joints, the process typically includes:

- Tube Cutting: Raw metal tubes are cut to precise lengths based on design specifications.

- Corrugation: The cut tubes are then processed through machines that create convolutions or corrugations, which provide flexibility and strength. This is often achieved through hydroforming or mechanical processes that shape the metal without compromising its integrity.

- End Fittings: Flanges or butt-weld ends are attached to the bellows, allowing for easy integration into piping systems. These fittings are usually welded or bolted and must meet strict alignment and tolerance specifications.

What Does the Assembly Process Entail?

During the assembly phase, various components are combined to create a complete expansion joint. This includes:

- Integration of Components: The bellows, end fittings, and any necessary accessories are assembled. Precision in this stage is crucial to ensure that the joint performs effectively under operational conditions.

- Quality Checks: This is a critical point where initial quality checks occur. Assemblies are inspected for proper alignment, fitting, and potential leaks before moving to the finishing stage.

How is the Finishing Process Conducted?

The finishing stage involves several steps to ensure the expansion joints are ready for the market:

- Surface Treatment: To enhance durability and resistance to corrosion, components may undergo surface treatments such as galvanization or coating.

- Final Inspection: Each joint is subjected to a final inspection to ensure it meets all specifications. This includes checking dimensions, surface quality, and overall assembly integrity.

What Quality Assurance Measures Are Implemented in the Manufacturing of Plumbing Expansion Joints?

Quality assurance is integral to ensuring that plumbing expansion joints perform reliably in diverse applications. Manufacturers adhere to international standards such as ISO 9001, which outlines requirements for quality management systems.

Which International Standards Are Relevant for Plumbing Expansion Joints?

For B2B buyers, understanding the relevant certifications can guide purchasing decisions. Key standards include:

- ISO 9001: Focuses on quality management systems and is applicable across industries.

- CE Marking: Indicates compliance with EU safety, health, and environmental requirements.

- API Standards: Particularly relevant for joints used in oil and gas applications, ensuring they meet industry-specific safety and performance criteria.

What Are the Critical Quality Control Checkpoints?

Quality control involves systematic checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet predefined specifications.

- In-Process Quality Control (IPQC): During manufacturing, periodic checks are conducted to monitor processes and identify defects early.

- Final Quality Control (FQC): A comprehensive inspection of the finished product ensures it meets all specifications before shipping.

What Common Testing Methods Are Used for Plumbing Expansion Joints?

Testing methods are vital for verifying the integrity and performance of plumbing expansion joints. Common tests include:

- Pressure Testing: To check for leaks and ensure the joint can withstand operational pressures.

- Flexibility Tests: Assess the ability of the bellows to accommodate expansion and contraction without failure.

- Material Testing: This may include tensile strength tests and corrosion resistance evaluations.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure a reliable supply chain, B2B buyers should actively engage in verifying supplier quality control measures:

What Steps Can Buyers Take to Audit Supplier Quality Control?

- Supplier Audits: Conducting on-site audits can provide insights into the manufacturing processes and quality control systems in place.

- Requesting Quality Reports: Buyers should request documentation of quality control measures, including test results and compliance certifications.

- Third-Party Inspections: Engaging independent inspectors can offer an unbiased assessment of the supplier’s quality assurance processes.

What Are the Unique Quality Control Considerations for International Buyers?

For buyers from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential:

Illustrative image related to plumbing expansion joint

- Regulatory Compliance: Different regions may have specific regulations that affect product standards. Familiarity with local regulations can prevent compliance issues.

- Cultural Considerations: Building relationships with suppliers may require understanding cultural differences in business practices, especially in regions like Africa and the Middle East.

- Logistical Challenges: International shipping can introduce risks, making it essential to verify that quality control measures are maintained throughout the supply chain.

In conclusion, the manufacturing processes and quality assurance measures for plumbing expansion joints are intricate and crucial for ensuring product reliability. By understanding these processes, B2B buyers can make informed decisions, ensuring they procure high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘plumbing expansion joint’

When sourcing plumbing expansion joints, a systematic approach can ensure that you select the best solution for your specific needs. This guide outlines a checklist to help international B2B buyers navigate the procurement process effectively.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the expansion joints you need. This includes factors such as size, material (e.g., rubber, metal), pressure ratings, and temperature tolerances. Knowing these specifications upfront helps in narrowing down options and ensures compatibility with your existing plumbing systems.

Step 2: Identify Application Needs

Consider the specific application for which the expansion joints will be used. Different environments, such as chemical processing or high-temperature systems, may require specialized joints. Take into account:

– Environmental Conditions: Will the joints be exposed to corrosive substances?

– Movement Requirements: What types of movement (axial, angular, lateral) will the joints need to accommodate?

Step 3: Evaluate Potential Suppliers

Before making a purchase, conduct thorough research on potential suppliers. Assess their reliability by reviewing company profiles, case studies, and testimonials from other buyers in your industry. Key considerations include:

– Experience in Your Industry: Ensure the supplier has a proven track record with similar applications.

– Certifications and Standards: Verify that they comply with relevant industry standards (e.g., ISO, ASTM).

Step 4: Request Samples and Technical Data

Before finalizing your order, request samples of the expansion joints and any technical documentation. This allows you to evaluate the quality of the materials and construction. Important aspects to check include:

– Material Quality: Ensure the materials meet your specifications for durability and performance.

– Performance Data: Review the joint’s performance metrics, including cycle life and flexibility.

Step 5: Assess Pricing and Payment Terms

Obtain detailed quotes from multiple suppliers to compare pricing. Keep in mind that the lowest price may not always reflect the best value. Consider:

– Bulk Discounts: Inquire about pricing breaks for larger orders.

– Payment Terms: Understand the payment structure, including any upfront deposits or financing options available.

Step 6: Verify Warranty and After-Sales Support

A robust warranty and responsive after-sales support are critical in ensuring long-term satisfaction with your purchase. Confirm:

– Warranty Duration: What does the warranty cover, and how long is it valid?

– Support Services: Is there a dedicated support team available for troubleshooting or replacement parts?

Step 7: Finalize Logistics and Delivery Terms

Coordinate with your supplier regarding logistics and delivery schedules. Ensure that the terms align with your project timelines. Important considerations include:

– Shipping Options: Evaluate international shipping costs and timelines.

– Customs and Duties: Understand any potential import regulations and costs that may affect delivery in your region.

By following these steps, you can streamline the sourcing process for plumbing expansion joints, ensuring that your procurement aligns with technical requirements and business objectives.

Comprehensive Cost and Pricing Analysis for plumbing expansion joint Sourcing

What Are the Key Cost Components in Plumbing Expansion Joint Sourcing?

Understanding the cost structure of plumbing expansion joints is crucial for B2B buyers looking to optimize their procurement process. The main cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. Common materials used in manufacturing plumbing expansion joints include rubber, metal, and plastic. Metal bellows, for instance, tend to be more expensive due to their durability and performance under high pressures.

-

Labor: Labor costs can vary depending on the region and the complexity of the manufacturing process. Skilled labor is often required for quality assembly and testing of expansion joints, particularly for custom designs.

-

Manufacturing Overhead: This encompasses costs related to the production facility, utilities, and administrative expenses. Efficient production processes can help minimize overhead costs.

-

Tooling: Specialized tools and molds are necessary for producing custom expansion joints. The initial investment in tooling can be significant, but it can be amortized over large production runs.

-

Quality Control (QC): Ensuring product reliability and compliance with international standards requires a robust QC process. This may add to the cost but is essential for maintaining high-quality standards, especially in international markets.

-

Logistics: Shipping and handling costs should not be overlooked, particularly for international buyers. Incoterms will dictate who is responsible for these costs and can influence the final pricing.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks. This margin can vary based on the supplier’s market positioning and the competitive landscape.

How Do Volume and Customization Affect Pricing?

Pricing for plumbing expansion joints is highly influenced by the volume of the order and the level of customization required. Larger orders often qualify for lower unit prices due to economies of scale. Negotiating minimum order quantities (MOQs) can lead to significant savings.

Customization also plays a crucial role. Tailored designs, specific materials, or unique specifications can increase costs due to the additional labor and materials involved. Buyers should weigh the benefits of customization against the potential cost increase to determine the best value.

What Factors Influence Pricing for International Buyers?

International B2B buyers must navigate various pricing influencers that can affect their total cost of ownership:

-

Quality and Certifications: The quality of the expansion joints and any relevant certifications (e.g., ISO, ASTM) can affect pricing. High-quality products often come at a premium but can lead to lower maintenance and replacement costs over time.

-

Supplier Factors: Reliability, reputation, and service levels of suppliers can impact pricing. Established suppliers may charge more, but their products may offer better long-term value.

-

Incoterms: Understanding Incoterms is essential for international transactions, as they define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Choosing the right Incoterm can help manage costs effectively.

What Are Some Effective Buyer Tips for Negotiation?

Negotiation is a critical skill for B2B buyers, especially when sourcing plumbing expansion joints. Here are some actionable tips:

-

Leverage Volume Discounts: When placing larger orders, always inquire about volume discounts. Suppliers may be more willing to negotiate on pricing for bulk orders.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also the long-term costs associated with maintenance, replacements, and operational efficiency. A higher upfront cost may be justified if the product has a longer lifespan or lower operational costs.

-

Request Multiple Quotes: Obtaining quotes from several suppliers can provide leverage during negotiations. It helps in understanding the market rate and can lead to better pricing.

-

Build Relationships: Developing a good relationship with suppliers can yield benefits in the long run, including better pricing, priority service, and access to new products.

Conclusion: What Should Buyers Keep in Mind?

While indicative prices can provide a starting point, international B2B buyers should conduct thorough market research and consider the various cost components and price influencers outlined above. By understanding these factors, buyers can make informed decisions that optimize their sourcing strategy for plumbing expansion joints.

Illustrative image related to plumbing expansion joint

Alternatives Analysis: Comparing plumbing expansion joint With Other Solutions

When evaluating solutions for managing thermal expansion and contraction in plumbing systems, it is essential to consider alternatives to plumbing expansion joints. Various technologies and methods can serve similar functions, each with distinct advantages and disadvantages. This analysis provides a comparative overview of plumbing expansion joints against other viable options, helping B2B buyers make informed decisions.

| Comparison Aspect | Plumbing Expansion Joint | Pipe Loops | Flexible Hoses |

|---|---|---|---|

| Performance | Excellent for thermal expansion, vibration isolation, and seismic deflection. | Good flexibility but may require more space and can lead to pressure drops. | Effective in short runs and for minor movements, but not ideal for high pressure. |

| Cost | Moderate initial investment; longevity can justify the expense. | Higher initial costs due to additional piping and supports. | Generally low cost, but may require frequent replacement. |

| Ease of Implementation | Relatively straightforward installation with minimal additional infrastructure. | Complex installation requiring careful design and routing. | Easy to install in flexible configurations; suitable for quick adjustments. |

| Maintenance | Low maintenance if properly installed; periodic inspections recommended. | Requires ongoing inspection to ensure integrity; may need adjustments over time. | Moderate maintenance; needs replacement more frequently than rigid solutions. |

| Best Use Case | Ideal for high-stress environments where vibration and thermal expansion are significant. | Suitable for large systems where space allows for loop configurations. | Best for temporary setups or where flexibility is paramount in short runs. |

What are the Pros and Cons of Using Pipe Loops as an Alternative?

Pipe loops are a traditional method of accommodating thermal expansion in piping systems. They consist of additional lengths of pipe bent into loops, providing flexibility.

Pros: Pipe loops can effectively absorb thermal expansion and contraction. They allow for greater movement and can be designed to fit specific system requirements.

Cons: However, they require more space and can increase the complexity of installation. Additionally, the added bends may lead to pressure drops, increasing operational costs over time, making them less efficient in some applications.

How do Flexible Hoses Compare in Plumbing Systems?

Flexible hoses are another alternative, often used in plumbing systems for their ease of installation and adaptability.

Pros: They are lightweight, easy to install, and can accommodate minor movements without significant structural changes. Flexible hoses are particularly useful in temporary setups or when rapid adjustments are necessary.

Cons: However, they are not suitable for high-pressure applications and may require more frequent replacements due to wear and tear. Their lifespan can be shorter compared to plumbing expansion joints, making them less cost-effective for long-term use.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When selecting the appropriate solution for managing thermal expansion in plumbing systems, B2B buyers should consider their specific operational needs, budget constraints, and the physical limitations of their installation environment. Plumbing expansion joints offer a robust solution for high-stress applications, while pipe loops may be preferable in larger systems with adequate space. Flexible hoses provide a quick and cost-effective solution for less demanding situations. Ultimately, understanding the nuances of each alternative will empower buyers to make the best choice for their unique requirements.

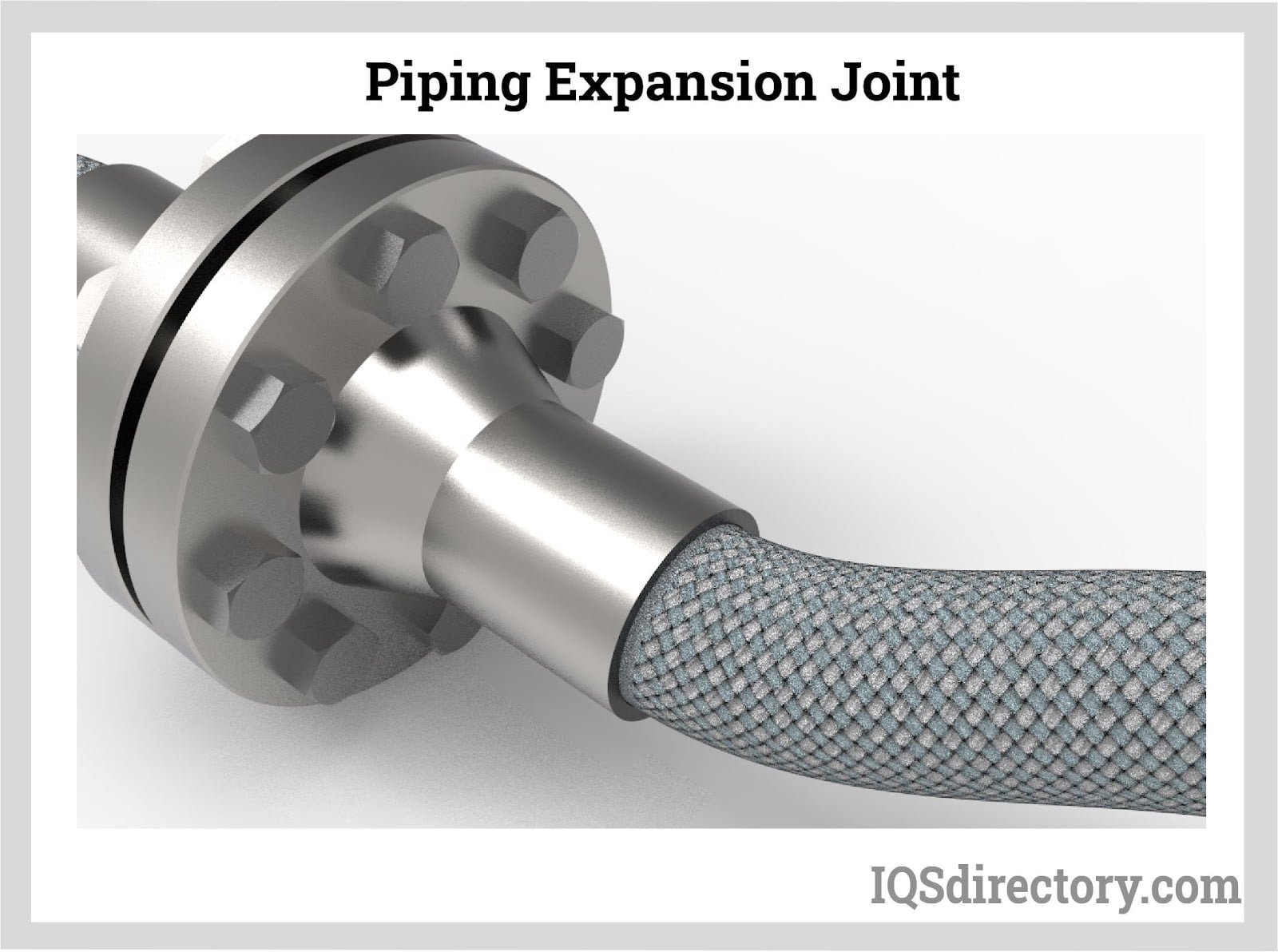

Essential Technical Properties and Trade Terminology for plumbing expansion joint

What Are the Key Technical Properties of Plumbing Expansion Joints?

Understanding the essential technical properties of plumbing expansion joints is crucial for B2B buyers looking to make informed decisions. Here are some critical specifications that should be considered:

-

Material Grade

Expansion joints are typically made from materials such as stainless steel, rubber, or PTFE (polytetrafluoroethylene). The choice of material affects durability, flexibility, and resistance to corrosion or chemical exposure. For example, stainless steel is preferred in high-temperature and high-pressure applications due to its strength and resistance to oxidation. Buyers should evaluate the material grade to ensure it meets the specific demands of their plumbing systems. -

Temperature and Pressure Ratings

Each expansion joint comes with specified temperature and pressure ratings, indicating the maximum conditions under which they can operate safely. These ratings are essential for ensuring the longevity of the joint and preventing failures that could lead to costly downtime or repairs. When sourcing expansion joints, it’s vital to match these ratings with the operational conditions of the intended application. -

Movement Capabilities

Plumbing expansion joints are designed to accommodate various types of movement, including axial compression, axial extension, lateral offset, and angular rotation. Understanding these capabilities helps buyers select the right joint for their specific needs, ensuring that it can handle the expected thermal expansions and contractions without compromising system integrity. -

Cycle Life

The cycle life of an expansion joint refers to the number of movement cycles it can endure before failure. This specification is crucial for applications with frequent thermal cycling, as a longer cycle life translates to reduced maintenance costs and increased reliability. Buyers should inquire about the cycle life and consider it in relation to their operational demands. -

End Connection Types

The method of connecting the expansion joint to existing piping systems is another critical property. Common connection types include flanged, butt-welded, or threaded ends. Understanding the compatibility of these connection types with existing systems can prevent installation issues and ensure a seamless integration.

What Are Common Trade Terms Related to Plumbing Expansion Joints?

Familiarity with industry jargon can significantly enhance communication and negotiation processes in the procurement of plumbing expansion joints. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. For buyers, choosing an OEM can ensure quality and compatibility with existing systems, as these manufacturers typically adhere to industry standards. -

MOQ (Minimum Order Quantity)

This term indicates the smallest number of units a supplier is willing to sell. Understanding MOQ is essential for buyers to avoid overstocking and to align their purchasing strategies with their project requirements. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and terms for specific products. Crafting a precise RFQ can streamline the procurement process and ensure that all parties have a clear understanding of requirements. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with these terms can help buyers avoid misunderstandings regarding costs and liabilities during international trade. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. Understanding lead times is crucial for project planning, as delays can impact construction schedules and operational timelines. -

Testing Standards

This term encompasses the various benchmarks and protocols that expansion joints must meet to ensure safety and reliability. Familiarity with testing standards is vital for buyers to ensure that the products they are sourcing meet industry compliance and performance expectations.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions regarding plumbing expansion joints, ultimately leading to more efficient and effective project execution.

Navigating Market Dynamics and Sourcing Trends in the plumbing expansion joint Sector

What Are the Current Market Dynamics and Key Trends in the Plumbing Expansion Joint Sector?

The plumbing expansion joint sector is experiencing a transformative period driven by several global factors. The increasing demand for infrastructure development in emerging markets, especially in Africa and South America, is a key growth driver. These regions are witnessing rapid urbanization, which necessitates robust plumbing systems capable of handling temperature fluctuations and mechanical stresses. Moreover, the Middle East and Europe are focusing on upgrading aging infrastructure, creating a steady demand for advanced plumbing solutions.

In terms of technology, the integration of IoT (Internet of Things) in plumbing systems is gaining traction. Smart plumbing solutions equipped with sensors can monitor pressure and temperature, ensuring optimal performance and reducing maintenance costs. Additionally, advancements in materials science, such as the use of high-performance polymers and composites, are enhancing the durability and flexibility of expansion joints. International buyers should also note the shift towards customized solutions, as manufacturers increasingly cater to specific project requirements, improving system efficiency and reducing installation complexities.

Furthermore, regulatory frameworks in Europe and North America are becoming stringent regarding product standards and performance metrics. This trend is pushing manufacturers to innovate and comply with enhanced safety and quality requirements, thereby influencing sourcing decisions for international buyers.

How Are Sustainability and Ethical Sourcing Impacting the Plumbing Expansion Joint Sector?

Sustainability is becoming a cornerstone of the plumbing expansion joint sector. Environmental considerations are compelling manufacturers to adopt eco-friendly practices and materials. The production processes are increasingly scrutinized for their carbon footprint, leading to a demand for sustainable sourcing of raw materials. International buyers are advised to prioritize suppliers who demonstrate a commitment to reducing environmental impact through sustainable practices.

Illustrative image related to plumbing expansion joint

Certifications such as ISO 14001 for environmental management and LEED (Leadership in Energy and Environmental Design) are becoming crucial in supplier selection. These certifications not only indicate a supplier’s dedication to sustainability but also ensure that the materials used in expansion joints are environmentally friendly. For instance, manufacturers are turning to recycled materials and biodegradable options that do not compromise on performance.

Moreover, ethical sourcing is gaining prominence as buyers become more aware of the social and environmental implications of their procurement choices. Establishing a transparent supply chain that adheres to ethical labor practices and sustainable resource management is essential. By aligning with suppliers who prioritize ethical sourcing, businesses can enhance their brand reputation and appeal to a more environmentally conscious market segment.

What Is the Evolution of Plumbing Expansion Joints and Its Relevance Today?

The evolution of plumbing expansion joints can be traced back to the early 20th century when the need for flexible piping systems became apparent. Initially, simple rubber and metal joints were employed to accommodate thermal expansion and mechanical vibrations. As industries advanced, so did the technology behind expansion joints. The introduction of bellows technology in the mid-1900s marked a significant milestone, allowing for greater flexibility and durability.

In recent years, the focus has shifted towards high-performance materials and advanced manufacturing techniques, such as 3D printing and computer-aided design (CAD). These innovations enable manufacturers to produce customized solutions that cater to specific industrial applications. The historical context of plumbing expansion joints highlights their essential role in modern plumbing systems, emphasizing the importance of sourcing high-quality, reliable products for current and future projects. International buyers should leverage this knowledge to make informed decisions that enhance operational efficiency and sustainability in their plumbing systems.

Frequently Asked Questions (FAQs) for B2B Buyers of plumbing expansion joint

-

How do I solve issues related to thermal expansion in plumbing systems?

To address thermal expansion in plumbing systems, utilizing plumbing expansion joints is essential. These joints absorb movement caused by temperature fluctuations, preventing stress on the pipes. When selecting expansion joints, consider factors such as the type of material, pressure rating, and expected movement capabilities. Consulting with a supplier or manufacturer can also provide insights into the best options for your specific application, ensuring a solution that minimizes the risk of leaks or system failures. -

What is the best type of expansion joint for high-pressure plumbing systems?

For high-pressure plumbing systems, metal bellows expansion joints are typically the best choice. These joints are designed to withstand significant pressure and temperature variations while providing flexibility. They consist of a series of convolutions that allow for axial movement, angular rotation, and lateral offset. When sourcing, ensure that the selected expansion joint meets the specific pressure and temperature requirements of your system, and inquire about certifications that validate their performance under extreme conditions. -

How can I ensure the quality of plumbing expansion joints from international suppliers?

To ensure quality when sourcing plumbing expansion joints internationally, perform thorough vetting of suppliers. Request certifications such as ISO 9001 to confirm adherence to quality management standards. Additionally, ask for product samples or test reports to evaluate performance. Engaging in direct communication with suppliers can also provide insights into their manufacturing processes and quality control measures. Consider visiting manufacturing facilities if possible, or utilizing third-party inspection services to verify product quality before placing large orders. -

What customization options are available for plumbing expansion joints?

Customization options for plumbing expansion joints can include variations in size, material, and design features such as additional flanges or specialized coatings. Suppliers often provide tailored solutions to meet specific project requirements, including unique pressure ratings or environmental conditions. When discussing customization, clearly communicate your specifications and application needs to the supplier, and inquire about the lead times and costs associated with custom products to align with your project timeline and budget. -

What are the typical minimum order quantities (MOQs) for plumbing expansion joints?

Minimum order quantities (MOQs) for plumbing expansion joints can vary significantly between suppliers and depend on the specific product type. Generally, MOQs may range from a few pieces to hundreds, especially for custom designs. It’s advisable to discuss MOQs directly with potential suppliers during the negotiation phase. Understanding their production capabilities and stock levels can also provide leverage in negotiating lower MOQs, particularly if you are a new buyer or if you have ongoing needs. -

What payment terms should I expect when sourcing plumbing expansion joints internationally?

Payment terms for international purchases of plumbing expansion joints typically vary by supplier and may include options such as advance payment, letters of credit, or payment upon delivery. Commonly, suppliers may request a deposit upfront, with the balance due before shipment or upon delivery. It is essential to clarify payment terms early in negotiations to avoid misunderstandings. Additionally, consider using secure payment methods that offer buyer protection to mitigate risks associated with international transactions. -

How do I handle logistics and shipping for international orders of plumbing expansion joints?

Handling logistics for international orders involves coordinating with suppliers to determine shipping methods, costs, and delivery timelines. Discuss whether the supplier provides shipping services or if you need to arrange your own logistics. Consider factors such as customs clearance, import duties, and local regulations in your country. Engaging a freight forwarder can simplify the process by managing documentation and ensuring compliance with international shipping laws, ultimately facilitating a smoother delivery experience. -

What should I look for in terms of warranty and after-sales support for plumbing expansion joints?

When sourcing plumbing expansion joints, inquire about warranty terms and after-sales support. A reputable supplier should offer a clear warranty that covers defects in materials and workmanship for a specified period. Additionally, assess the supplier’s commitment to after-sales support, including availability for technical assistance, replacement parts, or troubleshooting. Understanding these aspects upfront can help ensure that you receive adequate support throughout the lifespan of the product, minimizing downtime and maintenance costs.

Top 6 Plumbing Expansion Joint Manufacturers & Suppliers List

1. Flexonics – Piping Expansion Joints

Domain: flexonics.com

Registered: 1996 (29 years)

Introduction: Flexonics offers a range of piping expansion joints designed to accommodate thermal expansion and contraction in piping systems. Key product details include:

– **Sizes Available:** Expansion joints are available in various sizes ranging from 2″ to 144″ in diameter, including specific sizes like 2″, 2.5″, 3″, 3.5″, 4″, 5″, 6″, 8″, 10″, 12″, 14″, 16″, 18″, 20″, 22″, 24″, 26″, 28″, 30″, 32″, 34″, 36…

2. Log Home Store – Plumbing Expansion Joints – PVC

Domain: loghomestore.com

Registered: 2000 (25 years)

Introduction: {“product_name”: “Plumbing Expansion Joints – PVC”, “price_range”: “$39.99 – $114.95”, “sku”: “1721”, “category”: “Settling and Accessories”, “description”: “PVC schedule 40 expansion joints ensure for proper compression/settling in your plumbing pipes as the log walls settle.”, “features”: {“lubricated_o_ring”: “maintains effective seal”, “settling_capacity”: “allows for up to 3 inches of settlin…

3. Canplas – Expansion Joints

Domain: canplas.com

Registered: 1995 (30 years)

Introduction: Expansion Joints – Specialty Plumbing Products

– Available Sizes: 1 1/2″, 2″, 3″, 4″

– Types: Type 1 (HxH, HxSPG) and Type II (HxH)

– Colors: Black, Grey, White, Clear

– Certifications: PVC and ABS options available

– Product Codes:

– 213814AWBC: 4″ PVC White DWV Type II Expansion Joint, Hub x Hub

– 213814ABC: 4″ PVC DWV Type II Expansion Joint, Hub x Hub

– 213813AWBC: 3″ PVC White DWV Type…

4. Proco Products – Expansion Joints

Domain: procoproducts.com

Registered: 1998 (27 years)

Introduction: Proco Products is a leading manufacturer of expansion joints for piping and ducting systems, offering a variety of designs in rubber, stainless steel, and polytetrafluoroethylene (PTFE). Their expansion joints are designed to protect equipment from thermal expansion, vibration, and ground movement, ensuring safe and reliable operations while minimizing maintenance downtime. Key features include:

…

5. PVC Fittings Online – DWV Expansion Joints

Domain: pvcfittingsonline.com

Registered: 2011 (14 years)

Introduction: DWV Expansion Joints: Use to accommodate for thermal expansion of pipe; ASTM D 3311, 1866, 1784 Standards; Available sizes: 1″ to 4″ in spigot or hub ends; NSF International Standard 14 Certified; Maximum Operating Temperature: 140°F; For use with other DWV pipe and fittings; 14 products available.

6. Fernco – Expansion Joints

Domain: fernco.com

Registered: 1996 (29 years)

Introduction: {‘product_name’: ‘Expansion Joints’, ‘description’: ‘Fernco’s one-piece expansion joints allow thermal expansion and contraction of drain, waste and vent pipes and inside rain water conductor systems. Eliminating costly offsets normally used to accommodate expansion and contraction, this coupling is an ideal solution for vertical pipe installations.’, ‘features’: [‘Unique one-piece construction’, …

Strategic Sourcing Conclusion and Outlook for plumbing expansion joint

In today’s dynamic global market, strategic sourcing of plumbing expansion joints is essential for ensuring operational efficiency and longevity of piping systems. By prioritizing quality and reliability, international B2B buyers can mitigate risks associated with system failures, reduce maintenance costs, and enhance overall performance. Considerations such as material selection, design capabilities, and compatibility with existing infrastructure are critical for making informed purchasing decisions.

Illustrative image related to plumbing expansion joint

As the demand for sustainable and efficient plumbing solutions continues to rise, suppliers from diverse regions—including Africa, South America, the Middle East, and Europe—must adapt to local needs while maintaining high-quality standards. Engaging with reputable manufacturers who provide comprehensive support and technical expertise can significantly influence project outcomes.

Looking ahead, the integration of advanced technologies and innovative materials in expansion joint design will shape the future landscape of plumbing systems. B2B buyers are encouraged to remain proactive in their sourcing strategies, leveraging partnerships that not only meet immediate needs but also align with long-term sustainability goals. Investing in quality plumbing expansion joints today will pave the way for resilient infrastructure tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to plumbing expansion joint