Top 6 Glue Properties Suppliers (And How to Choose)

Introduction: Navigating the Global Market for glue properties

In an increasingly interconnected global marketplace, sourcing high-quality glue properties presents a significant challenge for B2B buyers. With a myriad of adhesive types available, understanding their specific characteristics and applications can be daunting. This guide serves as a comprehensive resource for international buyers, particularly those in Africa, South America, the Middle East, and Europe, including countries like Vietnam and Brazil. By delving into the intricacies of adhesive properties, we aim to demystify the selection process, ensuring you can make informed purchasing decisions tailored to your unique needs.

Throughout this guide, you will explore various adhesive types, their applications across multiple industries, and critical factors for vetting suppliers. We will also cover cost considerations, helping you balance quality with budget constraints. Each section is designed to empower you with the knowledge required to navigate the complexities of the adhesive market effectively.

Whether you are seeking adhesives for electronics, automotive manufacturing, or construction, this resource will equip you with the insights necessary to select the right products for your projects. By understanding glue properties and their implications, you can enhance your operational efficiency and drive success in your business ventures.

Understanding glue properties Types and Variations

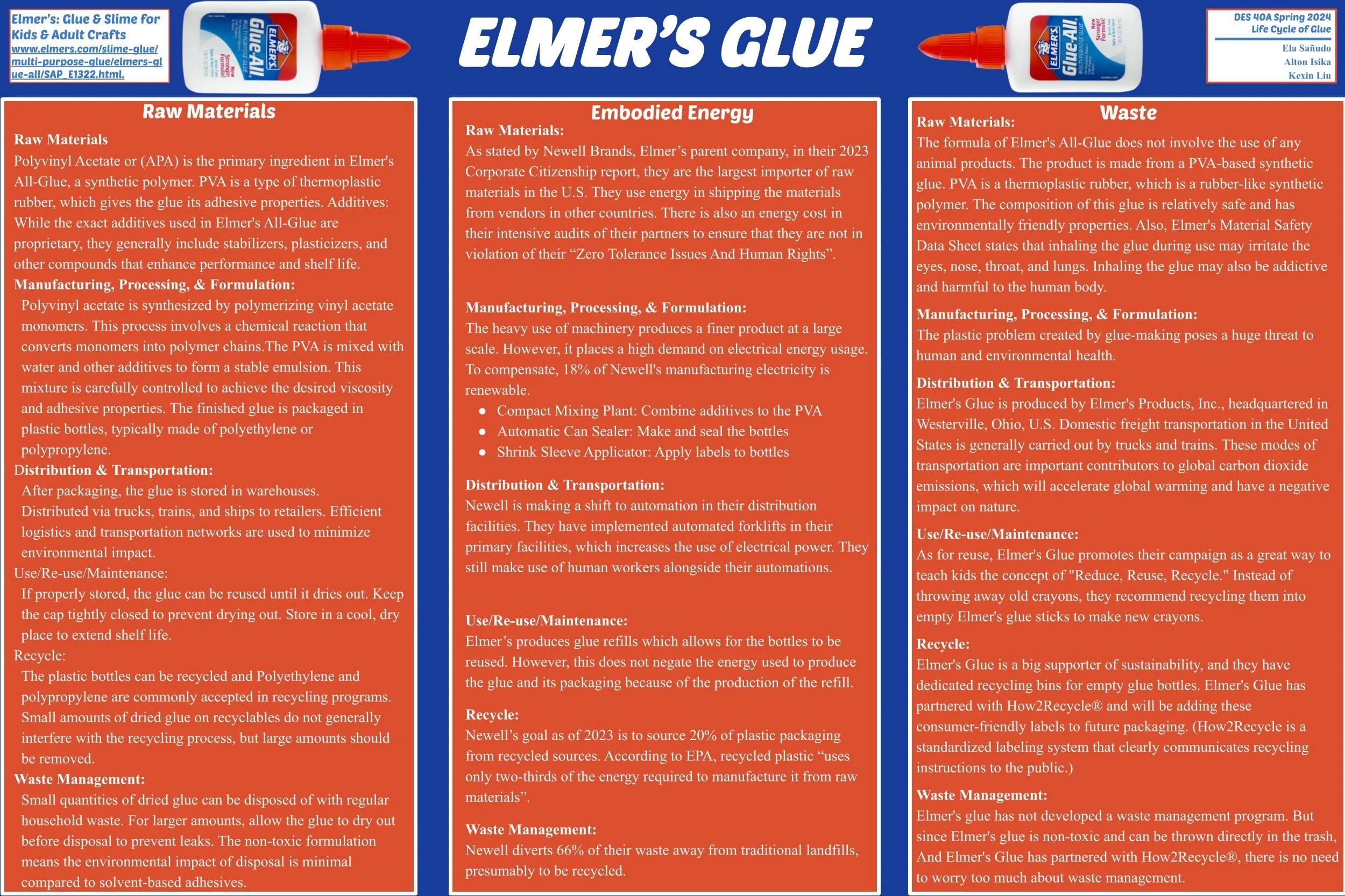

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Acrylic Adhesives | Fast curing, high clarity, good UV resistance | Automotive, construction, electronics | Pros: Excellent adhesion to various substrates; Cons: Less effective in high-temperature environments. |

| Epoxy Adhesives | Strong bonding, chemical resistance, versatile | Aerospace, manufacturing, construction | Pros: Superior strength and durability; Cons: Longer curing time and can be more expensive. |

| Silicone Adhesives | Flexibility, high-temperature resistance, waterproof | HVAC, automotive, electronics | Pros: Excellent weather resistance; Cons: Lower tensile strength compared to epoxies. |

| Polyurethane Adhesives | High elasticity, moisture resistance, versatile application | Woodworking, automotive, construction | Pros: Strong bond on porous materials; Cons: Longer curing time, sensitive to moisture during curing. |

| Hot Melt Adhesives | Quick application, solid at room temperature, easy to use | Packaging, woodworking, textiles | Pros: Fast setting time; Cons: Limited temperature resistance, can become brittle over time. |

What are the characteristics and suitability of Acrylic Adhesives for B2B buyers?

Acrylic adhesives are known for their rapid curing properties and high clarity, making them ideal for applications where transparency is crucial, such as in automotive and electronic industries. Their good UV resistance allows them to maintain performance in outdoor applications. When purchasing, buyers should consider the adhesive’s compatibility with various substrates and its performance in high-temperature environments, as acrylics can be less effective under extreme conditions.

How do Epoxy Adhesives stand out in terms of performance and applications?

Epoxy adhesives are celebrated for their exceptional bonding strength and chemical resistance, making them suitable for demanding applications in aerospace and construction. Their versatility allows them to bond a wide range of materials, including metals and plastics. However, buyers should be aware of the longer curing times associated with epoxies and their higher cost compared to other adhesives. Evaluating the specific requirements of the application, such as load-bearing capacity and environmental exposure, is crucial when selecting an epoxy adhesive.

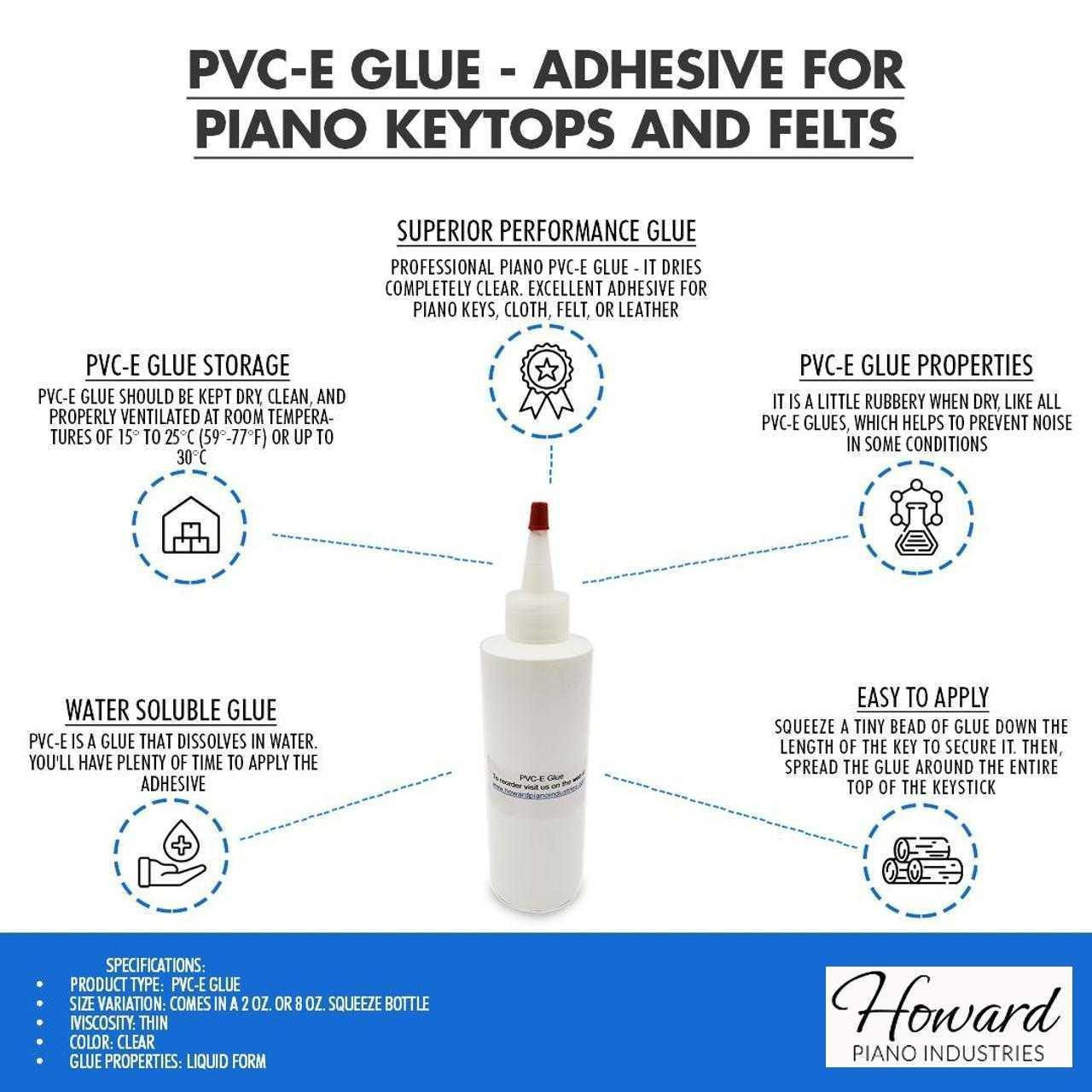

Illustrative image related to glue properties

Why are Silicone Adhesives preferred in specific industries?

Silicone adhesives are characterized by their flexibility and high-temperature resistance, making them an excellent choice for applications in HVAC and automotive sectors. Their waterproof nature ensures durability in outdoor and moisture-prone environments. While silicone adhesives offer excellent weather resistance, they typically have lower tensile strength compared to epoxies. Buyers should assess their specific needs for flexibility and environmental exposure when considering silicone adhesives.

What advantages do Polyurethane Adhesives offer for B2B applications?

Polyurethane adhesives are known for their high elasticity and moisture resistance, making them particularly effective for bonding porous materials in woodworking and construction. Their ability to form strong bonds even in the presence of moisture is a significant advantage. However, buyers should note the longer curing times and sensitivity to moisture during the curing process. Understanding the specific application requirements, such as the types of materials being bonded and environmental conditions, is essential for selecting the right polyurethane adhesive.

How do Hot Melt Adhesives benefit manufacturing processes?

Hot melt adhesives provide a fast and efficient bonding solution, making them ideal for packaging, woodworking, and textiles. Their quick setting time allows for streamlined production processes, which is particularly beneficial in high-volume environments. However, hot melt adhesives have limitations, such as lower temperature resistance and potential brittleness over time. Buyers should consider the operational environment and the longevity of the bond when opting for hot melt adhesives.

Key Industrial Applications of glue properties

| Industry/Sector | Specific Application of glue properties | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Bonding components in vehicle assembly | Enhanced structural integrity and safety | Adhesive type, temperature resistance, and curing time |

| Electronics | Encapsulation of electronic components | Improved durability and performance | Electrical insulation properties and thermal stability |

| Construction | Adhesives for structural bonding of materials | Increased load-bearing capacity and longevity | Compatibility with various substrates and environmental factors |

| Packaging | Sealing and bonding in packaging materials | Enhanced product protection and shelf life | Adhesive strength, drying time, and material compatibility |

| Furniture Manufacturing | Bonding wood and composite materials | Better aesthetics and strength of joints | Ease of application, curing time, and finish compatibility |

How Are Glue Properties Utilized in the Automotive Industry?

In the automotive sector, glue properties are critical for bonding various components during assembly. Adhesives enhance structural integrity, ensuring that parts withstand high stress and vibration during operation. Buyers from emerging markets must consider factors such as adhesive type, temperature resistance, and curing time to meet local manufacturing standards and climate conditions. Selecting the right adhesive can significantly impact vehicle safety and longevity.

What Role Do Glue Properties Play in Electronics?

In electronics, glue properties are essential for encapsulating components, protecting them from environmental factors like moisture and dust. The right adhesive can improve durability and performance, which is crucial in high-tech applications. International buyers need to focus on electrical insulation properties and thermal stability to ensure that adhesives can withstand varying operational conditions, particularly in regions with extreme temperatures.

Illustrative image related to glue properties

How Are Adhesives Used in Construction?

In the construction industry, adhesives are utilized for structural bonding between various materials, such as concrete, wood, and metal. This application enhances load-bearing capacity and overall durability of structures. Buyers must consider compatibility with different substrates and the environmental factors that could affect adhesive performance, such as humidity and temperature fluctuations, especially in diverse climates found in Africa and South America.

How Do Glue Properties Enhance Packaging Solutions?

Glue properties are vital in the packaging industry for sealing and bonding materials, which protects products and extends shelf life. The right adhesive ensures that packages remain intact during transport and storage. When sourcing adhesives, businesses should evaluate adhesive strength, drying time, and compatibility with various packaging materials to meet regulatory and consumer expectations across different markets.

Why Are Glue Properties Important in Furniture Manufacturing?

In furniture manufacturing, adhesives are crucial for bonding wood and composite materials, providing strength and aesthetic appeal to joints. Proper adhesive selection can enhance the durability of furniture products, contributing to customer satisfaction and brand reputation. Buyers should focus on ease of application, curing time, and finish compatibility to ensure that the final product meets design specifications and quality standards, especially in competitive international markets.

3 Common User Pain Points for ‘glue properties’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Adhesive for Temperature Variability

The Problem:

In industries such as electronics and automotive manufacturing, products often undergo significant temperature fluctuations. For instance, a B2B buyer in the electronics sector might face the challenge of selecting an adhesive that can withstand both high operational temperatures and low ambient conditions without degrading. The concern here is that many adhesives have specific temperature ranges they can operate within, and exceeding these limits can lead to bond failure, impacting product reliability and safety.

The Solution:

To address this issue, buyers should focus on sourcing adhesives with a clearly defined thermal stability range. This involves conducting thorough research on adhesive properties such as glass transition temperature (Tg) and thermal expansion coefficients. Buyers should seek suppliers that provide detailed technical data sheets, which include thermal performance metrics. Engaging in discussions with adhesive manufacturers can also help clarify the best adhesive for specific applications. Furthermore, conducting real-world testing of adhesives under expected operational conditions before full-scale implementation can ensure that the selected adhesive performs reliably under temperature stress.

Scenario 2: Managing Adhesive Viscosity for Precision Applications

The Problem:

Precision applications, such as in medical device manufacturing or microelectronics assembly, require adhesives with very specific viscosity characteristics. A common pain point is that buyers often find that adhesives either flow too much, leading to excess application and mess, or not enough, resulting in inadequate bonding in tight spaces. This not only affects production efficiency but can also compromise the integrity of the final product.

The Solution:

To mitigate these issues, buyers should prioritize adhesives with tailored viscosity profiles, specifically designed for their application needs. This can be achieved by collaborating closely with manufacturers to understand the rheological properties of adhesives. Buyers can also consider using thixotropic adhesives that become less viscous when agitated, allowing for easier application while maintaining their position once applied. Additionally, implementing dispensing systems that can control the amount and flow of adhesive applied can greatly enhance precision. Regular training for production staff on the specific handling and application techniques for these adhesives can also lead to improved outcomes.

Scenario 3: Overcoming the Challenge of Adhesive Bleeding and Wicking

The Problem:

In sectors like construction and automotive, adhesive bleeding—where excess adhesive seeps out from joints—can lead to aesthetic issues and functional failures. A B2B buyer may find themselves in a situation where an adhesive used for bonding various materials, such as plastics or metals, results in visible adhesive lines or compromised joint strength due to improper adhesion. This not only affects the appearance of the product but can also lead to customer dissatisfaction and increased production costs.

The Solution:

To combat adhesive bleeding, buyers should opt for low-bleed adhesives specifically formulated to minimize the migration of adhesive components. It’s essential to examine the adhesive’s formulation, looking for those that incorporate fillers or thickening agents that help control flow. Additionally, using surface treatment or primers on substrates can improve adhesion and reduce the risk of bleeding. Buyers should also conduct thorough testing on different substrates to identify the best adhesion solutions that meet their specific requirements. Working with suppliers who can provide samples for pilot testing before large-scale application can help refine the adhesive selection process and ensure optimal performance in real-world conditions.

Strategic Material Selection Guide for glue properties

What Are the Key Properties of Common Glue Materials?

When selecting adhesives for industrial applications, understanding the properties of different materials is crucial for ensuring optimal performance. Here, we analyze four common adhesive materials: epoxy, polyurethane, cyanoacrylate, and silicone. Each material has unique characteristics that can significantly impact product performance, manufacturing processes, and end-user satisfaction.

How Do Epoxy Adhesives Perform in Various Environments?

Epoxy adhesives are known for their exceptional strength and durability. They can withstand high temperatures (up to 150°C or more) and are resistant to chemicals, making them suitable for harsh environments. Their excellent adhesion to a variety of substrates, including metals and plastics, makes them a popular choice in automotive and aerospace industries.

Pros: Epoxy adhesives provide high tensile strength, excellent thermal resistance, and good moisture resistance. They are versatile and can be formulated for specific applications.

Cons: The curing process can be complex, requiring precise mixing and application conditions. Additionally, the initial cost can be higher compared to other adhesives.

Illustrative image related to glue properties

Impact on Application: Epoxy is compatible with a wide range of media, including oils and solvents, making it ideal for applications in automotive and machinery sectors.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is essential. Buyers from regions like Africa and South America should ensure that the epoxy formulations meet local environmental regulations.

What Advantages Do Polyurethane Adhesives Offer?

Polyurethane adhesives are flexible and can bond dissimilar materials effectively. They exhibit good resistance to moisture and UV light, making them suitable for outdoor applications. Their elasticity allows for movement between bonded surfaces, which is advantageous in construction and automotive applications.

Pros: They are easy to apply and cure at room temperature, providing a strong bond without the need for high temperatures.

Illustrative image related to glue properties

Cons: Polyurethane adhesives can be sensitive to moisture during the curing process, which may affect bond strength if not managed properly. They can also be more expensive than traditional adhesives.

Impact on Application: Their flexibility makes them ideal for applications involving thermal expansion or contraction, such as in building materials.

Considerations for International Buyers: Buyers should check for compliance with local building codes and safety standards, especially in regions with stringent construction regulations.

Illustrative image related to glue properties

Why Are Cyanoacrylate Adhesives Popular for Quick Fixes?

Cyanoacrylate adhesives, commonly known as superglue, are renowned for their rapid bonding capabilities. They cure quickly upon exposure to moisture, making them ideal for quick repairs in various industries, including electronics and consumer goods.

Pros: They bond quickly and are easy to use, requiring minimal surface preparation. Their small packaging makes them convenient for field repairs.

Cons: They have limited resistance to heat and moisture over time, which can lead to bond failure under extreme conditions.

Impact on Application: Cyanoacrylate is suitable for bonding small parts and applications where time is critical. However, they may not be suitable for structural applications requiring high durability.

Considerations for International Buyers: Ensure that the product complies with safety standards, as some formulations may contain hazardous components. Buyers in Europe should be aware of REACH regulations.

What Role Do Silicone Adhesives Play in Sealing and Bonding?

Silicone adhesives are known for their excellent flexibility and resistance to extreme temperatures and environmental conditions. They are commonly used in sealing applications, particularly in the construction and automotive industries.

Pros: Silicones remain flexible after curing, allowing for movement without cracking. They are also resistant to UV light and moisture.

Cons: Silicone adhesives typically have lower tensile strength compared to epoxy and polyurethane, which may limit their use in load-bearing applications.

Illustrative image related to glue properties

Impact on Application: Their ability to withstand extreme temperatures makes them ideal for applications in HVAC systems and outdoor environments.

Considerations for International Buyers: Buyers should verify compliance with local standards and certifications, especially in regions with specific environmental regulations.

Summary Table of Common Glue Materials

| Material | Typical Use Case for glue properties | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Epoxy | Automotive, aerospace, machinery | High tensile strength and thermal resistance | Complex curing process | High |

| Polyurethane | Construction, automotive, outdoor applications | Flexibility and moisture resistance | Sensitive to moisture during curing | Medium |

| Cyanoacrylate | Quick repairs in electronics and consumer goods | Rapid bonding capability | Limited heat and moisture resistance | Low |

| Silicone | Sealing in construction and automotive | Excellent flexibility and environmental resistance | Lower tensile strength | Medium |

This guide provides a comprehensive overview of adhesive materials, offering valuable insights for B2B buyers in various international markets. Understanding these properties will enable buyers to make informed decisions that align with their specific application needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for glue properties

What Are the Main Stages of Manufacturing Glue and How Do They Affect Properties?

Manufacturing glue involves several crucial stages that significantly impact the final product’s properties. Understanding these stages is essential for B2B buyers, particularly those in diverse markets such as Africa, South America, the Middle East, and Europe.

Illustrative image related to glue properties

1. Material Preparation: How Do Raw Materials Influence Glue Properties?

The first step in glue manufacturing is material preparation, where raw materials like polymers, solvents, fillers, and additives are sourced and processed. The quality of these raw materials directly affects the adhesive properties of the final product. For instance, the type of polymer used can determine the glue’s viscosity, tackiness, and curing time. Suppliers should provide certificates of analysis (CoA) for raw materials, ensuring they meet the necessary specifications and standards.

2. Forming: What Techniques Are Used to Create Glue?

In the forming stage, the prepared materials are combined using various techniques such as mixing, emulsification, or polymerization. Advanced methods like high-shear mixing or ultrasonic emulsification can enhance the uniformity of the glue, which is vital for consistent performance. It is essential for buyers to inquire about the specific techniques used by suppliers, as these can influence the adhesive’s physical properties, such as viscosity and shear strength.

3. Assembly: How Is Quality Maintained During Glue Production?

During the assembly phase, glue is packaged into containers that protect it from contamination and degradation. This stage often involves automated systems to ensure accuracy in filling and labeling. Quality assurance measures should be in place to monitor the assembly process, ensuring that the right quantities are packaged and that all containers are sealed properly to prevent leaks or contamination.

4. Finishing: What Final Touches Are Applied to Enhance Glue Performance?

The finishing stage includes processes such as filtration, where the glue is passed through filters to remove any impurities or undissolved particles. Additionally, additives may be incorporated to improve specific properties like UV stability or flexibility. B2B buyers should consider the finishing processes used, as these can significantly affect the glue’s performance in its intended application.

How is Quality Control Implemented in Glue Manufacturing?

Quality control (QC) is a critical aspect of glue manufacturing, ensuring that products meet international standards and customer expectations.

Relevant International Standards: Which Certifications Should Buyers Look For?

Manufacturers often adhere to international quality standards such as ISO 9001, which focuses on quality management systems, and industry-specific standards like CE for European markets or API for pharmaceutical applications. Understanding these standards is vital for B2B buyers to ensure they are sourcing from compliant suppliers.

What Are the Key QC Checkpoints in Glue Production?

Quality control checkpoints are established at various stages of the production process:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify issues in real-time.

- Final Quality Control (FQC): The finished product undergoes rigorous testing to ensure it meets performance criteria and safety standards.

What Common Testing Methods Are Used to Ensure Glue Quality?

Several testing methods are employed to verify the properties of glue, including:

- Viscosity Testing: Measures the thickness of the glue, crucial for application efficiency.

- Tensile Strength Testing: Assesses the glue’s ability to withstand pulling forces.

- Shear Strength Testing: Evaluates the glue’s performance under lateral forces.

- Thermal Stability Testing: Determines how the glue performs under varying temperature conditions.

These tests should align with the specific applications for which the glue is intended, ensuring suitability and reliability.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several steps to verify the quality control practices of their suppliers:

- Conduct Audits: Regular audits of suppliers can help assess their adherence to quality standards and manufacturing processes.

- Request Quality Reports: Suppliers should provide detailed reports outlining their QC processes, results of testing, and compliance with relevant standards.

- Engage Third-Party Inspectors: Utilizing independent inspection services can provide an unbiased assessment of the supplier’s quality control measures.

What Are the QC and Certification Nuances for International B2B Buyers?

For international buyers, understanding the nuances of QC and certification is essential, particularly when sourcing from regions with different regulatory standards. Buyers should be aware of:

- Regional Regulations: Different countries may have specific regulations regarding adhesive properties and safety, which can affect compliance and market entry.

- Cultural Expectations: Communication styles and business practices can vary, necessitating a tailored approach to supplier relationships.

- Language Barriers: Documentation and certifications may be in different languages, requiring careful translation and verification.

By understanding these factors, B2B buyers can make informed decisions and establish robust partnerships with suppliers that meet their quality standards and business needs.

Conclusion

The manufacturing processes and quality assurance protocols for glue properties are integral to delivering high-performance adhesive solutions. By understanding these processes, testing methods, and quality standards, B2B buyers can ensure they are making informed decisions that align with their operational needs and market demands.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘glue properties’

In the competitive landscape of adhesive procurement, understanding glue properties is essential for B2B buyers. This guide provides a structured checklist to help you navigate the complexities of sourcing adhesives effectively.

Step 1: Define Your Technical Specifications

Identifying your specific requirements is the first critical step in the procurement process. Consider factors such as the intended application, substrate materials, environmental conditions, and performance expectations. Detailed specifications will guide supplier discussions and ensure that you select adhesives that meet your operational needs.

Step 2: Research Different Types of Adhesives

Familiarize yourself with the various types of adhesives available, such as epoxy, polyurethane, and acrylic. Each type has unique properties, including bonding strength, flexibility, and resistance to environmental factors. Understanding these differences will help you choose the right adhesive for your specific application and industry.

Step 3: Evaluate Potential Suppliers

Before making a commitment, thoroughly vet potential suppliers. Request company profiles, case studies, and references from businesses in your sector or geographic area. Look for suppliers with a proven track record of reliability and quality, ensuring they can meet your technical and logistical requirements.

Step 4: Verify Product Certifications and Compliance

Ensure that the adhesives you are considering comply with relevant industry standards and regulations. Certifications such as ISO, ASTM, or RoHS indicate that the products meet specific safety and quality benchmarks. This step is crucial not only for product performance but also for regulatory compliance in your region.

Step 5: Request Samples for Testing

Once you have narrowed down your options, request samples of the adhesives you are considering. Conduct thorough testing under your specific application conditions to evaluate performance characteristics such as adhesion strength, curing time, and resistance to temperature and moisture. Real-world testing is vital to confirm that the product meets your expectations.

Step 6: Assess Pricing and Delivery Terms

While quality should be your primary focus, it’s essential to evaluate the cost-effectiveness of the adhesives. Compare pricing among suppliers while considering factors like bulk discounts, shipping costs, and lead times. Ensure that the delivery terms align with your project timelines and inventory needs.

Step 7: Establish Clear Communication Channels

Effective communication with your chosen supplier is crucial for a successful partnership. Set expectations for response times, order tracking, and support for technical inquiries. Establishing a clear line of communication will facilitate smoother transactions and help address any issues that arise during the procurement process.

By following this checklist, you will be well-equipped to source adhesives that meet your technical and operational requirements, ultimately enhancing your business’s efficiency and product quality.

Comprehensive Cost and Pricing Analysis for glue properties Sourcing

What Are the Key Cost Components in Glue Properties Sourcing?

When sourcing glue properties, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

Illustrative image related to glue properties

-

Materials: The selection of raw materials significantly influences the overall cost. Adhesives can be formulated from various chemical compounds, and their prices can vary based on availability and purity levels. For instance, specialty resins or eco-friendly components may come at a premium.

-

Labor: Labor costs encompass the workforce needed for production, which varies by region. In countries with lower labor costs, such as some in Africa and South America, overall production costs may be more favorable, impacting the pricing strategy.

-

Manufacturing Overhead: This includes indirect costs related to production, such as utilities, maintenance, and facility management. Efficient manufacturing processes can reduce overhead costs, allowing suppliers to offer competitive pricing.

-

Tooling: Initial tooling costs for specialized production equipment can be significant. For customized adhesives, these costs are often amortized over higher production volumes, making it essential to evaluate minimum order quantities (MOQs).

-

Quality Control (QC): Rigorous QC processes ensure that adhesives meet specifications and certifications, which can add to costs. Compliance with international standards is particularly important for buyers in Europe and the Middle East.

-

Logistics: Transportation and warehousing costs are critical, especially for international shipments. Incoterms play a significant role in determining who bears these costs and can significantly impact the final price.

-

Margin: Suppliers will factor in their desired profit margin, which can vary based on market competition, demand fluctuations, and the perceived value of the adhesive properties.

How Do Price Influencers Affect Glue Properties Sourcing?

Several factors can influence the pricing of glue properties:

-

Volume/MOQ: Larger orders typically lead to lower per-unit costs. Negotiating for higher volumes can secure better pricing and terms, particularly for repetitive orders.

-

Specifications and Customization: Custom formulations may incur additional costs due to specialized processes and materials. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Material Choices: The type of adhesive—whether it’s water-based, solvent-based, or hot melt—will impact the cost. More advanced or eco-friendly materials generally command higher prices.

-

Quality and Certifications: Adhesives that meet specific regulatory standards or certifications (such as ISO or RoHS) may be priced higher due to the additional QC processes involved.

-

Supplier Factors: The supplier’s location, reputation, and production capacity can all influence pricing. Established suppliers may offer reliability but at a premium compared to emerging suppliers.

-

Incoterms: Understanding the Incoterms agreed upon can help clarify who is responsible for shipping, insurance, and tariffs, which can affect total costs.

What Are the Best Practices for Negotiating Glue Properties Pricing?

For international B2B buyers, particularly in regions like Africa, South America, and Europe, effective negotiation strategies can enhance cost efficiency:

-

Understand Total Cost of Ownership (TCO): Beyond initial prices, consider long-term costs related to performance, durability, and logistics. A lower upfront cost may lead to higher operational costs if the adhesive fails to perform as expected.

-

Leverage Market Research: Knowing market rates and competitor offerings can provide leverage during negotiations. Buyers should be aware of regional pricing trends, especially when sourcing from developing markets.

-

Build Relationships with Suppliers: Establishing a long-term partnership can lead to better pricing and terms. Suppliers may be more inclined to offer discounts or favorable terms to repeat customers.

-

Seek Multiple Quotes: Obtaining quotes from various suppliers can provide insights into pricing structures and help identify the best value.

-

Be Clear About Requirements: Clearly communicating specifications and expectations can minimize misunderstandings and ensure accurate pricing.

What Should Buyers Keep in Mind Regarding Indicative Prices?

While indicative prices can provide a baseline for budgeting, they are subject to fluctuations based on market conditions, raw material availability, and currency exchange rates. Buyers should always request updated quotes and consider potential price adjustments in their planning.

Alternatives Analysis: Comparing glue properties With Other Solutions

Understanding Alternatives to Glue Properties

In the quest for effective bonding solutions, businesses often explore various alternatives to traditional adhesives. Each option presents unique advantages and limitations, making it essential for B2B buyers to evaluate these alternatives against glue properties. This analysis focuses on comparing glue properties with two alternative solutions: mechanical fastening and thermal bonding. By understanding the strengths and weaknesses of each method, buyers can make informed decisions tailored to their specific applications.

Comparison Table

| Comparison Aspect | Glue Properties | Mechanical Fastening | Thermal Bonding |

|---|---|---|---|

| Performance | Strong adhesion; versatile for various materials | High strength; suitable for heavy loads | Good for thermoplastics; quick bonding |

| Cost | Moderate; varies by type and application | Often lower initial cost; requires hardware | Moderate; depends on equipment |

| Ease of Implementation | Requires precision application | Simple installation; may need specialized tools | Requires heat source; training may be needed |

| Maintenance | Low; durable once set | Moderate; may require periodic checks | Low; permanent joints |

| Best Use Case | Electronics, crafts, automotive | Construction, machinery assembly | Packaging, textiles, automotive |

Detailed Breakdown of Alternatives

Mechanical Fastening

Mechanical fastening methods, such as screws, bolts, and rivets, offer a straightforward approach to joining materials. They provide high strength and durability, making them ideal for applications that involve heavy loads or structural integrity. The initial cost is often lower than adhesives, as they do not require curing times. However, mechanical fasteners may increase the weight of the assembly and can be more labor-intensive during installation. Maintenance is required to ensure the fasteners remain tight, especially in dynamic environments where vibration can loosen them.

Thermal Bonding

Thermal bonding utilizes heat to fuse materials together, primarily used with thermoplastics. This method offers quick bonding times, making it efficient for high-volume production processes, such as in packaging or automotive applications. The strength of the bond can be impressive, particularly when dealing with compatible materials. However, the need for specialized equipment and training can increase initial setup costs. Additionally, thermal bonding may not be suitable for all materials, particularly those that are sensitive to heat, which can limit its applicability in diverse manufacturing environments.

Conclusion: Choosing the Right Solution for Your Needs

When selecting the right bonding solution, B2B buyers should carefully assess their specific needs, including material compatibility, strength requirements, cost considerations, and ease of implementation. Glue properties are highly versatile and can cater to a wide range of applications, making them suitable for intricate assemblies. However, in scenarios requiring more robust mechanical strength or heat-sensitive materials, mechanical fastening or thermal bonding may present more effective alternatives. Ultimately, understanding the unique characteristics of each method enables buyers to make choices that align with their operational goals and production processes.

Essential Technical Properties and Trade Terminology for glue properties

What Are the Key Technical Properties of Glue That B2B Buyers Should Consider?

Understanding the technical properties of adhesives is crucial for B2B buyers in ensuring that they select the appropriate product for their specific applications. Here are some essential properties to consider:

1. Viscosity

Viscosity measures the thickness or resistance to flow of a glue. It directly affects how the adhesive spreads and adheres to surfaces. High-viscosity adhesives are better for applications requiring a thicker layer, while low-viscosity adhesives are ideal for thin applications, such as in electronics. Choosing the right viscosity helps in achieving optimal bonding without wastage.

2. Elastic Modulus

Elastic modulus indicates the stiffness of the cured adhesive. A higher modulus means that the glue will be more rigid, making it suitable for structural applications. Conversely, a lower modulus allows for more flexibility, which is essential in applications subject to thermal expansion or mechanical stress. Understanding this property helps in selecting an adhesive that can withstand the conditions of its intended use.

Illustrative image related to glue properties

3. Cure Time

Cure time is the duration it takes for an adhesive to reach its optimal bonding strength. This property is vital in manufacturing and assembly processes where time efficiency is crucial. Fast-curing adhesives can significantly reduce production times, while slower-curing options may be preferred for applications requiring more working time for adjustments.

4. Thermal Stability

Thermal stability refers to how well an adhesive maintains its properties under temperature fluctuations. This is particularly important for applications in automotive, aerospace, and electronics, where exposure to high or low temperatures is common. Selecting an adhesive with appropriate thermal stability ensures long-term performance and reliability.

5. Chemical Resistance

Chemical resistance indicates the adhesive’s ability to withstand exposure to various chemicals without degrading. This property is crucial for applications in industries such as automotive and pharmaceuticals, where adhesives may come into contact with oils, solvents, or other harsh substances. Choosing a chemically resistant adhesive can prevent failures and prolong the lifespan of the bonded materials.

What Are Common Terms Used in the Adhesive Industry?

Familiarity with industry jargon can facilitate smoother transactions and negotiations. Here are some key terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products for other brands. In the adhesive industry, this might involve producing specialized adhesives tailored to the specifications of a particular brand. Understanding OEM relationships can help buyers identify reliable partners who can meet their specific needs.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. This term is crucial for buyers to understand as it impacts inventory management and budgeting. Knowing the MOQ helps businesses plan their purchases effectively, ensuring they meet production needs without overcommitting financially.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for pricing and other terms for specific products. This is a standard practice in B2B transactions, allowing buyers to compare quotes and make informed decisions. A well-prepared RFQ can streamline the procurement process and lead to better pricing and terms.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. These terms clarify who is responsible for shipping, insurance, and tariffs. Familiarity with Incoterms helps B2B buyers navigate international trade logistics and reduce potential disputes.

5. TDS (Technical Data Sheet)

A TDS provides essential information about a product’s properties, usage guidelines, and safety precautions. For buyers, reviewing the TDS is crucial to ensure that the selected adhesive meets their requirements and safety standards. It serves as a reference point for making informed decisions about product selection and application.

Understanding these properties and terms can empower B2B buyers to make informed purchasing decisions, ensuring they select the right adhesive for their specific applications while facilitating smoother negotiations and transactions.

Navigating Market Dynamics and Sourcing Trends in the glue properties Sector

Market Overview & Key Trends in Glue Properties

The global adhesive market is experiencing robust growth, driven by increased demand across various industries, including automotive, construction, electronics, and packaging. The rise in manufacturing activities, especially in emerging economies like Brazil and Vietnam, is fueling this demand. Key trends include the adoption of advanced adhesives that enhance performance, such as UV-curable and thermosetting adhesives, which are favored for their quick curing times and superior bond strength.

Moreover, digital transformation is reshaping sourcing practices in the adhesive sector. Technologies like artificial intelligence and machine learning are being utilized to optimize supply chain management and improve inventory control, enabling businesses to respond swiftly to market changes. International B2B buyers are increasingly looking for suppliers who can provide not just products, but also comprehensive solutions that include technical support and customization options.

Another notable trend is the focus on performance attributes such as viscosity, elasticity, and thermal stability, which are crucial for specific applications. As manufacturing processes become more complex, understanding these properties becomes essential for buyers in selecting the right adhesive solutions. This evolution necessitates a collaborative approach between suppliers and buyers, fostering partnerships that can lead to innovation and efficiency in product application.

Sustainability & Ethical Sourcing in B2B Adhesive Markets

The environmental impact of adhesive products has become a critical concern for international buyers. The industry is under increasing pressure to adopt sustainable practices, leading to a rise in the development of eco-friendly adhesives made from renewable resources. Buyers are now prioritizing suppliers who demonstrate a commitment to sustainability through the use of non-toxic, biodegradable materials and processes that minimize waste.

Ethical sourcing is equally important in the adhesive sector, as it directly affects brand reputation and consumer trust. B2B buyers are increasingly scrutinizing their supply chains to ensure compliance with ethical standards, seeking suppliers who adhere to fair labor practices and transparency. Certifications such as ISO 14001 (Environmental Management) and FSC (Forest Stewardship Council) are becoming essential benchmarks for assessing supplier sustainability.

Incorporating ‘green’ certifications and materials into sourcing strategies not only helps mitigate environmental impact but also aligns with the growing consumer demand for sustainable products. As the market evolves, buyers who prioritize sustainability and ethical sourcing will likely gain a competitive edge, appealing to environmentally conscious consumers and businesses.

Brief Evolution/History of Adhesives in the B2B Context

The history of adhesives can be traced back thousands of years, with early forms derived from natural substances like animal glues and plant resins. Over time, the industry has evolved significantly, particularly with the introduction of synthetic adhesives in the 20th century, which offered enhanced performance and versatility.

The advent of advanced technologies in the 21st century has further transformed adhesive applications, leading to the development of high-performance adhesives suitable for complex manufacturing processes. Today, the adhesive industry is characterized by a continuous push for innovation, driven by the need for specialized solutions across diverse sectors. As a result, B2B buyers are now faced with a vast array of choices, making informed sourcing decisions more critical than ever.

Frequently Asked Questions (FAQs) for B2B Buyers of glue properties

1. How do I solve issues with adhesive performance in extreme temperatures?

To address adhesive performance issues in extreme temperatures, it’s essential to select adhesives with suitable thermal properties. Look for products with a low coefficient of thermal expansion (CTE) to minimize stress during temperature fluctuations. Test adhesives under the specific conditions they will encounter in application to ensure reliability. Additionally, consider using thermal cycling tests to evaluate long-term performance. Collaborating with suppliers to customize formulations may also provide solutions tailored to your unique environmental conditions.

2. What is the best adhesive type for bonding plastics?

When bonding plastics, epoxy and cyanoacrylate adhesives are typically the best choices. Epoxy offers excellent strength and durability, making it suitable for structural applications, while cyanoacrylate provides quick bonding for lighter applications. Ensure the adhesive is compatible with the specific type of plastic, as some adhesives may not bond effectively with certain materials like polyethylene or polypropylene. Always conduct adhesion tests to verify the effectiveness of the adhesive in your specific application.

3. How can I ensure consistent quality in adhesive products?

To ensure consistent quality in adhesive products, establish clear specifications for the properties you require, such as viscosity, curing time, and tensile strength. Choose suppliers with robust quality assurance (QA) processes, including regular testing of raw materials and finished products. Request certificates of analysis (COA) for each batch, and consider third-party testing for critical applications. Building a strong relationship with your supplier can also facilitate better communication regarding quality concerns.

4. What are the minimum order quantities (MOQs) for adhesive products?

Minimum order quantities (MOQs) for adhesive products vary widely among suppliers and depend on factors such as product type and formulation. Typically, industrial adhesives may have MOQs ranging from 50 to 500 kilograms. For specialized or custom formulations, MOQs might be higher due to production costs. Discuss your needs with potential suppliers to negotiate MOQs that align with your business requirements, especially if you are looking to trial a new product or require small quantities for specific projects.

5. How can I vet international suppliers of adhesives?

Vetting international suppliers of adhesives involves several steps. Start by checking their reputation through industry references and customer reviews. Evaluate their certifications, such as ISO 9001 for quality management, to ensure they adhere to international standards. Request samples to assess product quality and suitability for your application. Additionally, consider visiting their facilities if feasible, or use third-party services for audits to ensure compliance with safety and quality standards.

Illustrative image related to glue properties

6. What payment terms are common in international adhesive trade?

Common payment terms in international adhesive trade include advance payment, letters of credit (LC), and payment upon delivery. Advance payment is often requested for new customers, while established relationships may allow for more flexible terms such as net 30 or 60 days. Letters of credit provide security for both parties but can involve additional costs. It’s crucial to negotiate payment terms that align with your cash flow and risk tolerance while ensuring clarity in the contract to avoid disputes.

7. How do logistics impact the sourcing of adhesives internationally?

Logistics play a critical role in the sourcing of adhesives internationally, affecting lead times, costs, and product integrity. Consider the shipping methods available, such as air or sea freight, and their associated transit times and costs. Ensure that the supplier has experience in exporting adhesives, including compliance with international regulations. Discuss packaging options to protect the product during transit and avoid contamination. Efficient logistics management will help mitigate delays and ensure timely delivery of your adhesive products.

8. Can I customize adhesive formulations to suit my specific needs?

Yes, many adhesive suppliers offer customization of formulations to meet specific application needs. Customization can include altering viscosity, curing times, or specific adhesion properties for particular substrates. Engage with your supplier to discuss your requirements, providing details about the materials you are bonding and the environmental conditions they will face. Collaborating early in the development process can lead to optimized formulations that enhance performance and reduce the risk of failures in your applications.

Top 6 Glue Properties Manufacturers & Suppliers List

1. Dexerials – Key Adhesive Characteristics

Domain: techtimes.dexerials.jp

Registered: 2012 (13 years)

Introduction: Key characteristics of adhesives include: 1. Liquid characteristics: Thixotropy – adhesives behave as thixotropic fluids, changing viscosity under applied force; Viscosity – affects stringiness and flow into small gaps; 2. Hardened material characteristics: Elastic modulus – indicates resistance to deformation; Linear expansion coefficient – measures size change with temperature; 3. Bleed control …

2. 3M – Key Adhesive Products

Domain: 3m.com

Registered: 1988 (37 years)

Introduction: 3M offers a variety of adhesives classified by form and strength. Key products include: 1. 3M™ VHB™ Tapes – strong bonding tapes. 2. 3M™ Scotch-Weld™ Structural Adhesives – high strength adhesives for load-bearing parts. 3. Adhesive Transfer Tapes and Double Coated Tapes – versatile bonding solutions. 4. Spray Adhesives – for large area coverage. 5. Reclosable Fasteners – combine adhesive and mech…

3. Puuproffa – Adhesive Properties Insights

Domain: puuproffa.fi

Registered: 2004 (21 years)

Introduction: The properties of glues vary significantly, affecting factors such as moisture resistance, dry matter content, viscosity, acidity, and aging properties. Dry matter content is crucial as it forms the actual joint after solvent evaporation, which can create tensions due to shrinkage. Viscosity is influenced by the addition of fillers or solvents, with thicker glue required for porous or moist wood a…

4. ScienceDirect – Adhesive Properties

Domain: sciencedirect.com

Registered: 1997 (28 years)

Introduction: Adhesive properties refer to the chemical, physical, electrical, and mechanical characteristics of adhesives that influence their performance in various applications. Key factors include glass transition and viscoelasticity. The breadth of adhesive properties has increased their use across diverse industries. Important properties characterized include glass transition temperature, viscosity, gel t…

5. Journeyman’s Journal – Glue Composition

Domain: journeymansjournel.wordpress.com

Registered: 2000 (25 years)

Introduction: Glue is an animal product that undergoes several transformations during manufacturing. It is composed of carbon (49.1%), hydrogen (6.5%), nitrogen (18.3%), oxygen, and sulphur (26.1%). Glue consists of two main components: gluten and chondrinid. Gluten has greater adhesive power than chondrinid and is almost colorless, transparent, and hard when dry. It is insoluble in spirits of wine, ether, fat,…

6. Britannica – Synthetic Adhesives

Domain: britannica.com

Registered: 1995 (30 years)

Introduction: Synthetic adhesives are based on synthetic resins and rubbers, offering versatility and performance. They can be categorized into thermoplastics and thermosets. Thermoplastics provide strong adhesion at normal temperatures and can be softened by heating. Common thermoplastic resins include nitrocellulose, polyvinyl acetate, and acrylics. Thermosetting adhesives form permanent, heat-resistant bonds…

Strategic Sourcing Conclusion and Outlook for glue properties

In today’s competitive landscape, understanding glue properties is essential for optimizing procurement processes and ensuring product reliability. Key takeaways emphasize the importance of selecting adhesives based on their unique physical properties—such as viscosity, thixotropy, and elasticity—tailored to specific applications. This strategic sourcing approach not only enhances product performance but also minimizes risks associated with material failure and production delays.

Illustrative image related to glue properties

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, must prioritize sourcing adhesives that align with their operational needs and environmental conditions. Engaging with suppliers who offer comprehensive technical support and customization options can significantly improve adhesive selection and application processes.

As we look ahead, the adhesive market is poised for innovation, driven by advancements in technology and sustainability. Buyers should remain proactive in exploring new formulations and techniques that can enhance bonding performance while addressing environmental concerns. Now is the time to foster partnerships with reliable adhesive manufacturers to secure a competitive edge in your industry. Embrace this opportunity to elevate your sourcing strategy and ensure the success of your projects.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.