Top 6 Expanded Metal Sheet 4X8 Suppliers (And How to Choose)

Introduction: Navigating the Global Market for expanded metal sheet 4×8

In today’s competitive landscape, sourcing expanded metal sheet 4×8 can present unique challenges for international B2B buyers, particularly those operating in emerging markets across Africa, South America, the Middle East, and Europe. With a variety of types, applications, and suppliers available, navigating this global market requires a strategic approach to ensure quality and cost-effectiveness. This comprehensive guide aims to empower buyers by providing critical insights into the diverse forms of expanded metal sheets, their functional and decorative applications, and essential criteria for vetting suppliers.

Within these pages, you’ll discover not only the specifications and characteristics of different expanded metal sheet types but also practical advice on how to evaluate potential vendors, understand pricing structures, and identify the best materials for specific projects. Whether you’re in construction, manufacturing, or interior design, the information contained herein will enable you to make informed purchasing decisions that align with your business objectives.

By addressing key considerations such as durability, weight reduction, and aesthetic appeal, this guide equips you with the knowledge needed to confidently navigate the complexities of the expanded metal market. As you explore the opportunities presented by expanded metal sheets, you will be better positioned to enhance your operations, optimize costs, and ultimately achieve success in your respective industry.

Understanding expanded metal sheet 4×8 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Diamond Expanded Metal | Features diamond-shaped openings; available in various thicknesses | Construction, security fencing, grating | Pros: Strong, versatile, lightweight. Cons: Limited aesthetic options. |

| Flattened Expanded Metal | Cold-rolled for a smooth surface; offers a refined look | Interior decor, custom fabrication | Pros: Aesthetic appeal, flat surface for easy handling. Cons: Less airflow than standard expanded metal. |

| Aluminum Expanded Metal | Lightweight and corrosion-resistant; often used in marine settings | Architectural applications, HVAC systems | Pros: Lightweight, resistant to rust. Cons: Higher cost compared to steel options. |

| Galvanized Expanded Metal | Coated with zinc for corrosion resistance; durable in harsh environments | Outdoor installations, industrial uses | Pros: Long-lasting, protective coating. Cons: Can be heavier than non-galvanized types. |

| Stainless Steel Expanded Metal | High resistance to corrosion and heat; ideal for hygienic applications | Food processing, medical equipment | Pros: Durable, hygienic, versatile. Cons: Higher initial investment. |

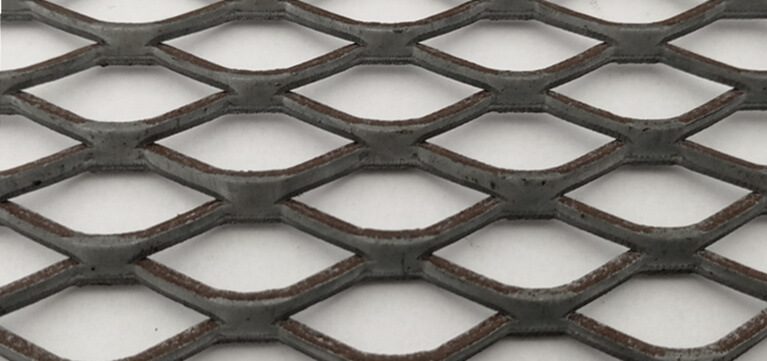

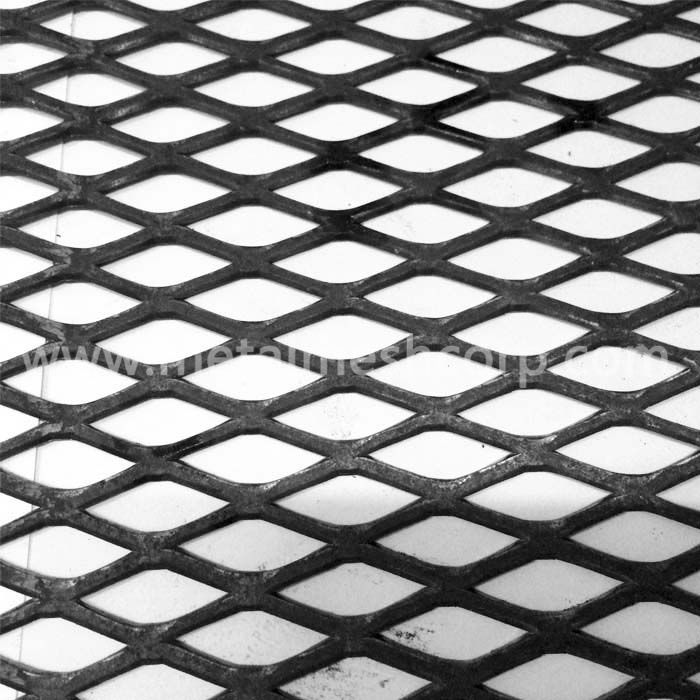

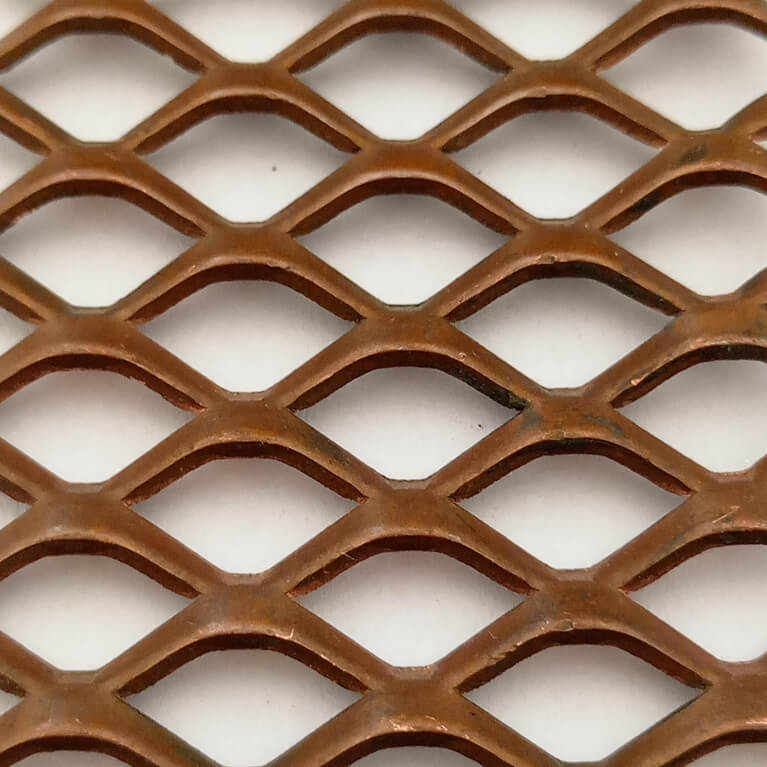

What Are the Key Characteristics of Diamond Expanded Metal?

Diamond expanded metal is the most commonly used type, characterized by its diamond-shaped openings created through a unique process of slitting and stretching. This design provides excellent strength-to-weight ratio, making it ideal for applications such as construction, security fencing, and grating. B2B buyers should consider the thickness and strand size based on their specific needs, as these factors influence the material’s load-bearing capacity and overall durability.

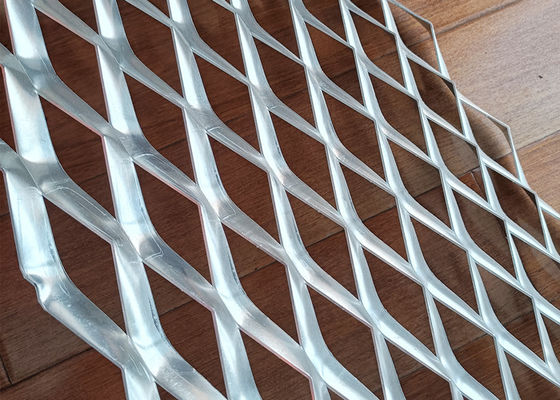

How Does Flattened Expanded Metal Differ from Other Types?

Flattened expanded metal undergoes a cold-rolling process that results in a smooth, flat surface, making it aesthetically pleasing and suitable for interior applications. This type is often used in custom fabrication projects where a refined appearance is necessary, such as in decorative panels and furniture. Buyers should weigh the benefits of its aesthetic appeal against its reduced airflow and weight-bearing capabilities compared to standard expanded metal.

Illustrative image related to expanded metal sheet 4×8

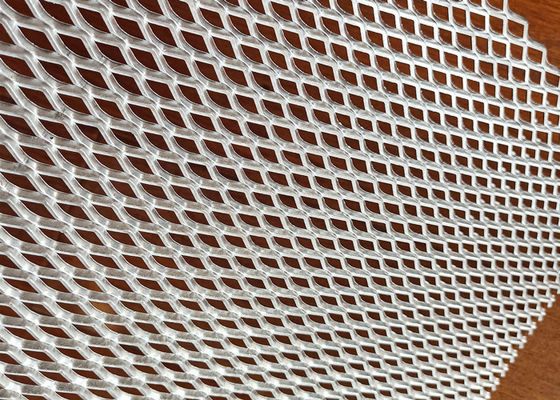

Why Choose Aluminum Expanded Metal for Your Projects?

Aluminum expanded metal is lightweight and naturally resistant to corrosion, making it a preferred choice for applications in humid or marine environments. This type is widely used in architectural designs and HVAC systems, where both strength and weight are critical factors. B2B buyers should consider the cost implications, as aluminum tends to be pricier than steel, but the long-term benefits of durability and low maintenance may justify the investment.

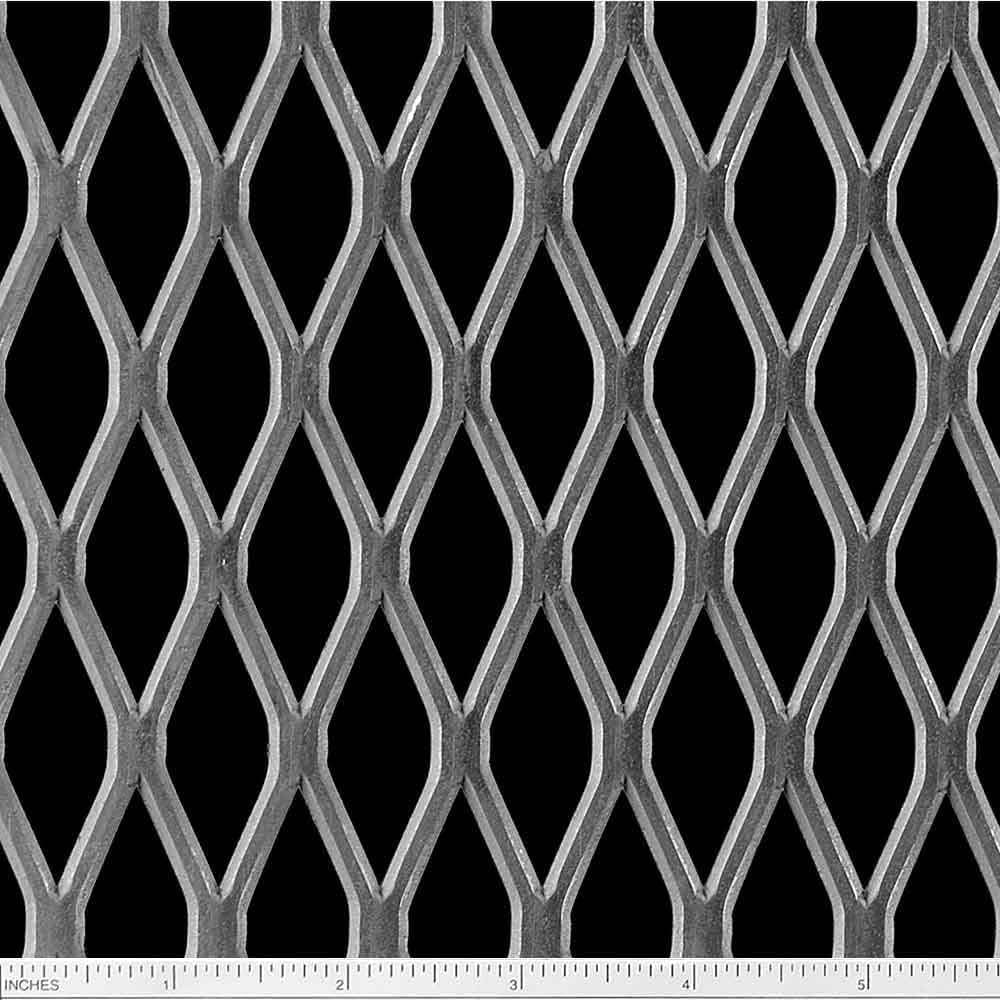

What Are the Advantages of Using Galvanized Expanded Metal?

Galvanized expanded metal features a zinc coating that provides enhanced corrosion resistance, making it suitable for outdoor applications and harsh environments. Its durability makes it ideal for industrial uses, including outdoor walkways and security barriers. Buyers should evaluate the added weight of galvanized options compared to non-galvanized types, but the longevity of the material often outweighs this concern.

In What Situations Is Stainless Steel Expanded Metal Recommended?

Stainless steel expanded metal is renowned for its resistance to corrosion and heat, making it an excellent choice for hygienic applications like food processing and medical equipment. Its durability and aesthetic appeal make it versatile for various industries. However, B2B buyers should be prepared for a higher initial investment, which can be offset by the material’s longevity and minimal maintenance requirements in the long run.

Key Industrial Applications of expanded metal sheet 4×8

| Industry/Sector | Specific Application of expanded metal sheet 4×8 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Safety barriers and fencing | Provides robust security while allowing visibility | Ensure compliance with local safety regulations and durability standards. |

| Manufacturing | Machine guards and protective enclosures | Enhances worker safety by preventing access to moving parts | Assess the weight capacity and corrosion resistance based on the environment. |

| Agriculture | Greenhouse benches and ventilation systems | Facilitates air circulation and light penetration for better crop growth | Consider climate conditions and required surface treatment for longevity. |

| Architecture & Design | Decorative facades and interior screens | Offers aesthetic appeal while maintaining functionality | Verify design specifications and potential for custom patterns. |

| Transportation & Logistics | Walkways and loading docks | Provides slip-resistant surfaces for safer operations | Look for anti-slip coatings and load-bearing specifications for heavy traffic areas. |

How is Expanded Metal Sheet 4×8 Used in Construction?

In the construction industry, expanded metal sheets are frequently utilized for safety barriers and fencing. Their unique mesh structure allows visibility while providing a strong deterrent against unauthorized access. This application is particularly vital in urban areas where security is a paramount concern. Buyers should ensure that the materials meet local safety standards and are suitable for outdoor exposure, particularly in regions with extreme weather conditions.

What Role Does Expanded Metal Sheet 4×8 Play in Manufacturing?

Manufacturers often implement expanded metal sheets as machine guards and protective enclosures. These sheets help to prevent accidental contact with moving machinery, thereby enhancing worker safety. When sourcing these materials, businesses must evaluate the weight capacity and corrosion resistance, especially in environments where exposure to oils, chemicals, or moisture is common. Selecting the right thickness and pattern can significantly impact the effectiveness of the guards.

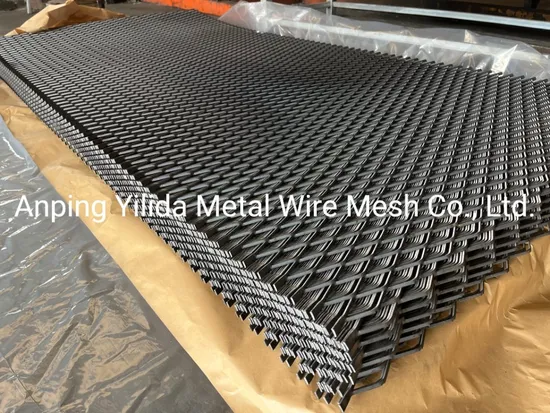

Illustrative image related to expanded metal sheet 4×8

How is Expanded Metal Sheet 4×8 Beneficial for Agriculture?

In the agricultural sector, expanded metal sheets are used for greenhouse benches and ventilation systems. They allow for optimal air circulation and light penetration, which are critical for healthy plant growth. For international buyers, especially from regions with diverse climates, it’s important to consider the specific surface treatments that can enhance durability and resistance to corrosion, ensuring longevity in various environmental conditions.

In What Ways Does Expanded Metal Sheet 4×8 Enhance Architecture and Design?

Architects and designers leverage expanded metal sheets for decorative facades and interior screens. Their versatility in design allows for both aesthetic appeal and functionality, such as light diffusion and air flow. Buyers should verify the design specifications and potential for custom patterns to meet specific project requirements, as well as consider the compatibility of materials with local architectural standards.

Why is Expanded Metal Sheet 4×8 Essential in Transportation and Logistics?

In the transportation and logistics sector, expanded metal sheets are often employed for walkways and loading docks. The slip-resistant surface provided by these sheets enhances safety for workers navigating high-traffic areas. When sourcing for this application, businesses should look for anti-slip coatings and ensure that the material can withstand heavy loads and frequent use, particularly in bustling environments.

3 Common User Pain Points for ‘expanded metal sheet 4×8’ & Their Solutions

Scenario 1: Sourcing Quality Expanded Metal Sheets at Competitive Prices

The Problem: B2B buyers often struggle with identifying reliable suppliers of expanded metal sheets, particularly the 4×8 size. They may encounter issues such as inflated pricing, subpar quality, or delays in delivery. This can lead to project delays, increased costs, and dissatisfaction among clients. Additionally, buyers may not have the technical knowledge to differentiate between various grades of expanded metal, making it challenging to assess what constitutes a fair price for quality products.

Illustrative image related to expanded metal sheet 4×8

The Solution: To overcome this challenge, buyers should conduct thorough market research to identify reputable suppliers. Look for suppliers with industry certifications, such as ISO 9001:2015, which indicate a commitment to quality. Utilize online platforms and industry-specific marketplaces that provide customer reviews and ratings. When requesting quotes, ask for detailed specifications, including material grade, thickness, and surface treatment options. This will help you compare prices more effectively and understand what you’re paying for. Establishing a relationship with a supplier that offers consistent quality and competitive pricing can lead to better long-term partnerships.

Scenario 2: Understanding the Applications and Limitations of Expanded Metal Sheet 4×8

The Problem: B2B buyers often lack clarity on the specific applications and limitations of expanded metal sheets, particularly regarding the 4×8 size. Without a comprehensive understanding, buyers may purchase sheets that do not meet their project requirements, leading to costly rework or project failures. For instance, using a lighter gauge for structural applications can compromise safety and functionality, while heavier options may exceed budget constraints.

The Solution: To address this issue, buyers should invest time in understanding the properties of expanded metal sheets, including their load-bearing capabilities and appropriate applications. Engage with technical experts or suppliers who can provide insights into various grades and thicknesses. Create a checklist of requirements for your project, including load-bearing needs, environmental conditions, and aesthetic preferences. This will help you specify the right type of expanded metal sheet for your application. Additionally, consider requesting samples before making a large order to assess the product’s suitability firsthand.

Scenario 3: Ensuring Timely Delivery and Inventory Management

The Problem: Timely delivery of expanded metal sheets can be a significant pain point for B2B buyers, especially when dealing with projects that have tight deadlines. Delays can stem from supplier issues, shipping complications, or even customs clearance for international orders. This can lead to project overruns and strained relationships with clients, especially if the buyer is relying on just-in-time inventory practices.

Illustrative image related to expanded metal sheet 4×8

The Solution: To mitigate delivery issues, buyers should develop a proactive inventory management strategy. Establish clear communication channels with suppliers to track order status and anticipated delivery dates. Consider placing orders well in advance of project timelines, factoring in potential delays. Additionally, explore local suppliers to reduce shipping times and costs. For international buyers, familiarize yourself with customs regulations and potential bottlenecks that could delay shipments. Utilizing a reliable logistics partner can also streamline the delivery process, ensuring that you receive your expanded metal sheets when needed, thus maintaining project schedules and client satisfaction.

Strategic Material Selection Guide for expanded metal sheet 4×8

What Are the Key Properties of Different Materials for Expanded Metal Sheets?

When selecting materials for expanded metal sheets, particularly the 4×8 size, it’s essential to consider the specific properties that affect performance in various applications. Here, we analyze four common materials used in expanded metal sheets: mild steel, galvanized steel, aluminum, and stainless steel.

How Does Mild Steel Perform as an Expanded Metal Sheet Material?

Mild steel is a popular choice for expanded metal sheets due to its excellent strength-to-weight ratio. It exhibits good mechanical properties, making it suitable for applications requiring durability, such as walkways and machine guards. However, mild steel is prone to corrosion if not treated or coated.

Pros:

– High strength and durability.

– Cost-effective compared to other metals.

– Easy to fabricate and weld.

Cons:

– Requires protective coatings to prevent rust.

– Limited in high-temperature applications.

For international buyers, particularly in regions like Africa and South America, compliance with local standards (e.g., ASTM) is crucial. Mild steel is widely available and often meets common construction requirements.

Illustrative image related to expanded metal sheet 4×8

What Advantages Does Galvanized Steel Offer for Expanded Metal Sheets?

Galvanized steel is mild steel that has been coated with zinc to enhance its corrosion resistance. This makes it an excellent choice for outdoor applications or environments exposed to moisture. The zinc coating provides a protective barrier, prolonging the lifespan of the material.

Pros:

– Enhanced corrosion resistance.

– Retains the strength of mild steel.

– Suitable for various environmental conditions.

Cons:

– Higher cost compared to untreated mild steel.

– The galvanization process can complicate welding.

For buyers in the Middle East or Europe, where environmental conditions may vary, galvanized steel often meets stringent compliance standards and is preferred for construction and architectural applications.

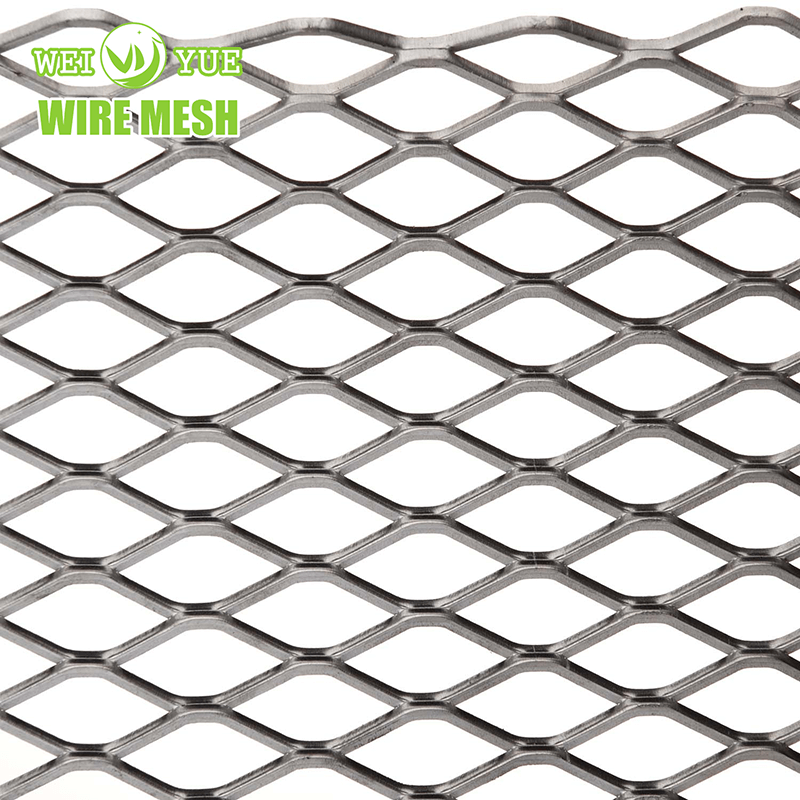

Why Choose Aluminum for Expanded Metal Sheets?

Aluminum expanded metal sheets are lightweight and resistant to corrosion, making them ideal for applications where weight savings are critical, such as in aerospace and automotive industries. Aluminum also offers excellent thermal and electrical conductivity.

Illustrative image related to expanded metal sheet 4×8

Pros:

– Lightweight and easy to handle.

– Excellent corrosion resistance without additional coatings.

– Good aesthetic appeal, suitable for decorative applications.

Cons:

– Generally more expensive than steel options.

– Lower tensile strength compared to mild or galvanized steel.

International buyers, especially those in Europe, may find aluminum expanded metal sheets comply with various standards (e.g., DIN) and are favored for both industrial and decorative uses.

What Are the Benefits of Using Stainless Steel for Expanded Metal Sheets?

Stainless steel is renowned for its exceptional corrosion resistance and high strength, making it suitable for harsh environments, including chemical processing and food production. It maintains structural integrity at high temperatures and is easy to clean.

Pros:

– Superior corrosion resistance.

– High strength and durability.

– Low maintenance requirements.

Cons:

– Higher cost than other materials.

– More challenging to fabricate and weld.

For B2B buyers in regions like Germany, where quality and compliance with standards (e.g., JIS) are paramount, stainless steel expanded metal sheets are often the material of choice for critical applications.

Summary Table of Material Selection for Expanded Metal Sheets

| Material | Typical Use Case for expanded metal sheet 4×8 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Mild Steel | Walkways, machine guards | High strength and cost-effective | Prone to corrosion without coating | Low |

| Galvanized Steel | Outdoor structures, fencing | Enhanced corrosion resistance | Higher cost, complicates welding | Medium |

| Aluminum | Aerospace, decorative applications | Lightweight, corrosion-resistant | Generally more expensive | High |

| Stainless Steel | Chemical processing, food production | Superior corrosion resistance | Higher cost, challenging to fabricate | High |

This guide provides a comprehensive overview of the materials available for expanded metal sheets, helping international B2B buyers make informed decisions based on their specific needs and regional compliance requirements.

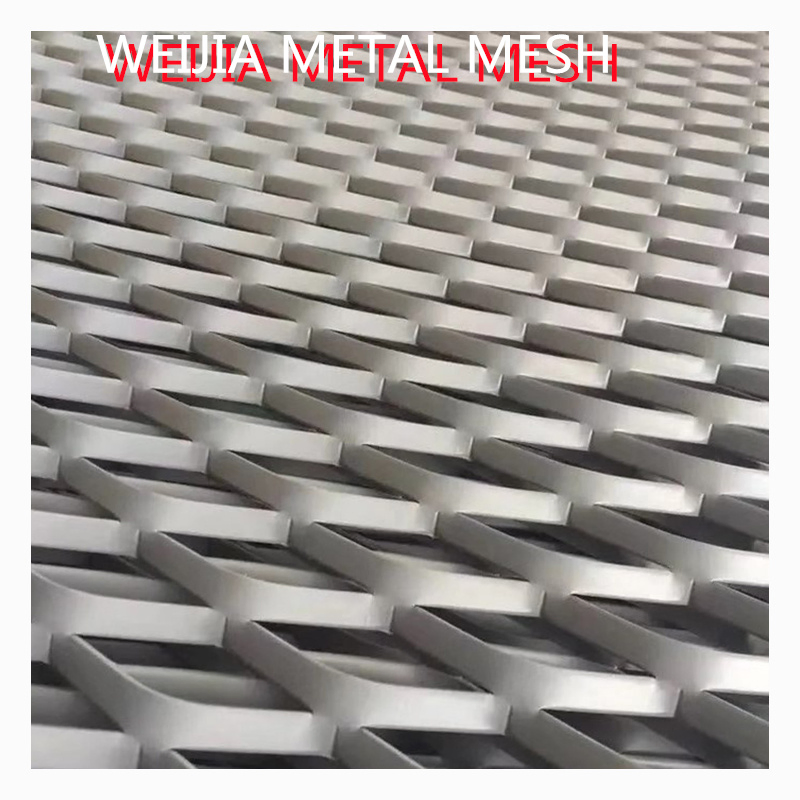

In-depth Look: Manufacturing Processes and Quality Assurance for expanded metal sheet 4×8

What Are the Main Stages in the Manufacturing Process of Expanded Metal Sheets?

The manufacturing of expanded metal sheets, particularly the 4×8 size, involves a systematic process that ensures both quality and efficiency. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with selecting the appropriate metal, often mild steel, stainless steel, or aluminum. The chosen metal is cut into sheets of the desired dimensions, typically 4 feet by 8 feet. During this stage, suppliers may perform surface treatments like galvanizing or anodizing to enhance corrosion resistance, depending on the intended application.

-

Forming: This is the critical stage where the sheet metal is slit and stretched to create the characteristic mesh pattern. The slitting is done using high-precision cutting machines that ensure uniformity in the cuts. The stretching process is executed using specialized machinery that expands the sheet into the desired diamond or other patterns. This method not only increases the surface area but also maintains the structural integrity of the material.

-

Assembly: Although expanded metal sheets typically do not require assembly in the traditional sense, further processing may include cutting to specific sizes or shapes based on client requirements. Suppliers often offer custom cuts to meet precise specifications, which is a significant advantage for B2B buyers looking for tailored solutions.

-

Finishing: The final stage involves various finishing processes, such as cleaning, deburring, and surface treatment. Depending on the application, expanded metal sheets may receive coatings (e.g., powder coating) to improve aesthetics and durability. This stage is crucial for ensuring that the sheets meet visual and functional standards required by end-users.

What Quality Assurance Measures Are Commonly Implemented?

Quality assurance is vital in the manufacturing of expanded metal sheets to ensure they meet international and industry-specific standards. Manufacturers typically follow a structured QC process that includes several checkpoints.

-

International Standards: Many manufacturers adhere to ISO 9001:2015, which outlines requirements for a quality management system. This certification ensures that the manufacturing processes are consistently monitored and improved. Additionally, other certifications, such as CE marking for products sold in Europe or API specifications for oil and gas applications, may apply depending on the industry.

-

Quality Checkpoints:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival at the manufacturing facility. Ensuring that materials meet specified standards before processing is critical to maintaining overall product quality.

– In-Process Quality Control (IPQC): During the manufacturing process, various checkpoints are established to monitor parameters such as thickness, pattern uniformity, and dimensional accuracy. This is often done using automated systems that can detect deviations in real time.

– Final Quality Control (FQC): After production, the finished expanded metal sheets undergo thorough inspection. This includes visual checks for defects, dimensional verification, and, if necessary, performance testing to ensure compliance with customer specifications. -

Common Testing Methods: Testing methods may include tensile strength tests, corrosion resistance tests, and dimensional accuracy assessments. These tests help verify that the expanded metal sheets meet the required specifications for strength and durability.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are some actionable steps buyers can take:

Illustrative image related to expanded metal sheet 4×8

-

Supplier Audits: Conducting on-site audits can provide valuable insights into a supplier’s manufacturing processes and quality control measures. During an audit, buyers can assess the supplier’s adherence to international standards, the effectiveness of their quality management system, and the condition of their manufacturing facilities.

-

Requesting Quality Reports: Buyers should request quality assurance reports that detail the outcomes of IQC, IPQC, and FQC processes. These reports should include testing results and compliance with relevant standards. Consistent documentation can indicate a reliable supplier.

-

Third-Party Inspections: Engaging third-party inspection services can add an additional layer of verification. Independent inspectors can assess the supplier’s processes and product quality objectively, providing buyers with peace of mind regarding their purchases.

-

Understanding Certification Nuances: Buyers should familiarize themselves with the certifications relevant to their region and industry. For instance, products sold in the EU must meet CE marking requirements, while those in the oil and gas sector may need to comply with API standards. Understanding these nuances helps buyers ensure that suppliers meet necessary compliance standards.

What Are the Specific Quality Control Considerations for International Markets?

Quality control considerations may vary significantly across different regions. For B2B buyers in Africa, South America, the Middle East, and Europe, understanding these regional distinctions is vital.

-

Regional Standards Compliance: Different regions may have specific compliance requirements. For example, European buyers may prioritize CE certification, while Middle Eastern buyers might look for compliance with local standards like GSO (Gulf Standardization Organization). Understanding these standards can help buyers select suppliers who meet their regional requirements.

-

Communication and Documentation: Clear communication regarding quality expectations is essential, especially when dealing with international suppliers. Buyers should ensure that all quality standards, testing methods, and certification requirements are documented in contracts to avoid misunderstandings later.

-

Cultural Considerations: Cultural differences can impact the interpretation of quality standards and expectations. It is beneficial for buyers to educate themselves about the cultural context of their suppliers, as this can influence everything from manufacturing practices to customer service.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing expanded metal sheets, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘expanded metal sheet 4×8’

In the competitive landscape of B2B procurement, sourcing expanded metal sheets—particularly in the 4×8 size—requires a methodical approach to ensure quality, cost-effectiveness, and suitability for your specific applications. This guide provides a step-by-step checklist to help international buyers navigate the procurement process effectively.

Step 1: Define Your Technical Specifications

Understanding the exact specifications of the expanded metal sheet you need is crucial. This includes the material type (e.g., mild steel, aluminum, or stainless steel), thickness, strand size, and surface treatment options. Clearly defined specifications will help in obtaining accurate quotes and ensure that the product meets your project’s requirements.

Illustrative image related to expanded metal sheet 4×8

Step 2: Research Market Prices

Conduct thorough market research to understand the price range for expanded metal sheets in your desired specifications. This step is vital to ensure that you are not overpaying. Use online resources, industry reports, and supplier catalogs to gather information on current pricing trends.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s essential to vet them thoroughly. Look for suppliers with a strong reputation in the industry, and request company profiles, case studies, and references from buyers in similar sectors. Ensure that the supplier can provide details about their manufacturing processes and quality control measures.

- Consider Certifications: Check for ISO certifications or other relevant industry standards that demonstrate quality assurance.

- Review Customer Feedback: Seek out reviews and testimonials to gauge customer satisfaction and reliability.

Step 4: Request Samples

Before finalizing your order, request samples of the expanded metal sheets. This will allow you to assess the material’s quality, finish, and dimensions firsthand. It’s a critical step to confirm that the product meets your specifications and expectations.

Step 5: Negotiate Terms and Pricing

Once you have selected potential suppliers, enter into negotiations regarding pricing, lead times, and payment terms. Be clear about your budget constraints and seek to understand the supplier’s pricing structure, including any discounts for bulk orders or long-term partnerships.

- Discuss Shipping Costs: Since you are dealing with international suppliers, clarify shipping arrangements and costs upfront to avoid surprises later.

Step 6: Verify Compliance with Regulations

Ensure that the expanded metal sheets comply with relevant industry regulations and standards in your region. This is particularly important for construction and industrial applications where safety standards are paramount. Request documentation that confirms compliance with local and international standards.

Step 7: Finalize the Order and Establish Communication

After all terms are agreed upon, finalize your order by placing it in writing. Establish clear lines of communication with your supplier for any future inquiries or issues that may arise during production or shipping. This proactive approach can help mitigate potential problems and foster a positive supplier relationship.

By following this checklist, B2B buyers can streamline their sourcing process for expanded metal sheets, ensuring they secure the right product at a competitive price while minimizing risks associated with procurement.

Comprehensive Cost and Pricing Analysis for expanded metal sheet 4×8 Sourcing

What Are the Key Cost Components in Sourcing Expanded Metal Sheet 4×8?

When considering the cost structure for sourcing expanded metal sheets measuring 4×8, several key components contribute to the overall pricing. These include:

-

Materials: The type of metal used—such as mild steel, aluminum, or stainless steel—significantly affects cost. For instance, stainless steel is more expensive than mild steel due to its corrosion resistance and durability.

-

Labor Costs: Labor is a critical factor, especially in regions with varying wage standards. The complexity of the manufacturing process, which involves slitting and stretching the metal, will also influence labor costs.

-

Manufacturing Overhead: This includes costs related to the facility, utilities, equipment maintenance, and administrative expenses. Efficient operations can help lower overhead, impacting the final price.

-

Tooling Costs: Custom tooling may be required for specific designs or sizes, adding to initial costs. Suppliers with advanced machinery can reduce these costs by maximizing production efficiency.

-

Quality Control (QC): Implementing strict QC measures ensures that the expanded metal sheets meet required specifications and standards. This can be a cost factor but is crucial for maintaining product integrity.

-

Logistics: Shipping costs vary based on distance, shipping method, and volume. International buyers need to consider potential tariffs and customs duties, which can significantly increase the total cost.

-

Margin: Supplier margins can vary widely based on their market positioning and the level of service provided. Understanding the margin expectations of suppliers can help buyers negotiate better deals.

How Do Price Influencers Affect Expanded Metal Sheet Sourcing?

Several factors influence the pricing of expanded metal sheets beyond the basic cost components:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes typically yield better pricing due to economies of scale. Suppliers may offer discounts for bulk orders, so negotiating MOQ can lead to significant savings.

-

Specifications and Customization: Custom sizes, thicknesses, or patterns can lead to increased costs. Buyers should clearly communicate their needs to avoid unexpected charges.

-

Material Quality and Certifications: Higher-quality materials or those with specific certifications (like ISO standards) may cost more upfront but can offer long-term savings through durability and performance.

-

Supplier Factors: Reputation, reliability, and the supplier’s location can affect pricing. Suppliers in regions with lower production costs may offer more competitive pricing.

-

Incoterms: The agreed Incoterms (International Commercial Terms) will determine the responsibilities of buyers and sellers concerning shipping, insurance, and tariffs, impacting the overall cost.

What Are the Best Negotiation and Cost-Efficiency Tips for B2B Buyers?

For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, several strategies can enhance cost efficiency:

-

Leverage Relationships: Building long-term relationships with suppliers can lead to better pricing and terms. Regular communication and feedback can foster trust and collaboration.

-

Explore Multiple Suppliers: Conducting thorough market research can help identify competitive pricing. Obtaining quotes from multiple suppliers can provide leverage in negotiations.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term costs associated with maintenance, durability, and potential replacement. A lower upfront cost may lead to higher TCO if the product is of inferior quality.

-

Stay Informed About Market Trends: Understanding market fluctuations in metal prices can help buyers time their purchases effectively. Staying updated on geopolitical factors and supply chain issues can also inform strategic sourcing decisions.

Conclusion

Navigating the cost and pricing landscape for expanded metal sheets requires a comprehensive understanding of the various components and influencers. By focusing on strategic negotiation, supplier relationships, and a holistic view of costs, international B2B buyers can optimize their sourcing strategies and achieve better outcomes. Always remember to account for potential price fluctuations and consult with suppliers for the most accurate and up-to-date pricing information.

Illustrative image related to expanded metal sheet 4×8

Alternatives Analysis: Comparing expanded metal sheet 4×8 With Other Solutions

Introduction: Exploring Alternatives to Expanded Metal Sheet 4×8

In the realm of industrial and architectural applications, selecting the right material is crucial for both functionality and cost-effectiveness. Expanded metal sheets, particularly in the 4×8 size, are popular for their strength, lightweight nature, and versatility. However, various alternatives can also meet similar requirements, depending on specific project needs. This section evaluates expanded metal sheets against two viable alternatives: perforated metal sheets and welded wire mesh.

Comparison Table

| Comparison Aspect | Expanded Metal Sheet 4X8 | Perforated Metal Sheet | Welded Wire Mesh |

|---|---|---|---|

| Performance | High strength, lightweight; allows air and light passage | Custom hole patterns; good strength depending on thickness | Good tensile strength; not as rigid as expanded metal |

| Cost | Moderate cost per sheet | Generally higher due to custom patterns | Generally lower cost, especially in larger rolls |

| Ease of Implementation | Easy to cut and install; minimal tools required | Requires precise measurements for custom cuts | Very easy to install; can be rolled out or cut to size |

| Maintenance | Low maintenance; resistant to corrosion with proper treatment | Low maintenance; depends on material type | Low maintenance; may require periodic inspection |

| Best Use Case | Walkways, security applications, decorative features | Filtration, architectural facades, sound barriers | Fencing, animal enclosures, gardening applications |

Detailed Breakdown of Alternatives

What Are the Advantages and Disadvantages of Perforated Metal Sheets?

Perforated metal sheets are created by punching holes into a solid sheet of metal, resulting in customizable patterns that can vary in size and shape. This alternative offers high versatility in design, making it suitable for applications that require aesthetics alongside functionality, such as decorative facades or sound barriers. However, the cost can be higher due to the manufacturing process, especially for unique designs. Additionally, the strength of perforated sheets can vary significantly based on the thickness and the size of the holes, which may limit their use in heavy-duty applications.

How Does Welded Wire Mesh Compare to Expanded Metal Sheets?

Welded wire mesh consists of wires that are welded together at intersections, creating a grid-like structure. This solution is often more affordable and is available in various mesh sizes and wire gauges, making it suitable for a range of applications, from fencing to gardening. The ease of installation is another significant advantage, as it can be rolled out or cut to size with minimal effort. However, it lacks the rigidity of expanded metal sheets, which may be a disadvantage in applications requiring high structural strength or load-bearing capabilities.

Conclusion: Choosing the Right Solution for Your Needs

When deciding between expanded metal sheets, perforated metal sheets, and welded wire mesh, B2B buyers should carefully consider their specific application requirements. Expanded metal sheets excel in strength and versatility, making them ideal for security and decorative uses. In contrast, perforated sheets offer design flexibility but at a higher cost, while welded wire mesh provides an economical solution for fencing and light-duty applications. By evaluating performance, cost, ease of implementation, maintenance, and best use cases, buyers can make informed decisions that align with their project goals and budget constraints.

Essential Technical Properties and Trade Terminology for expanded metal sheet 4×8

What Are the Key Technical Properties of Expanded Metal Sheet 4×8?

Expanded metal sheets, particularly the 4×8 size, are characterized by several critical specifications that impact their performance in various applications. Understanding these properties is essential for B2B buyers to ensure they select the right materials for their projects.

-

Material Grade: Expanded metal sheets are available in various material grades, including mild steel, stainless steel, and aluminum. The material grade determines the sheet’s strength, corrosion resistance, and weight. For instance, stainless steel is preferred in environments exposed to moisture, while mild steel is often used for general-purpose applications.

-

Thickness: The thickness of the expanded metal sheet typically ranges from 0.3mm to 10mm. Thicker sheets offer greater durability and load-bearing capacity, making them suitable for heavy-duty applications like walkways and industrial grating. Conversely, thinner sheets are often used for decorative purposes where weight savings are essential.

-

Strand Width and Length: These dimensions define the size of the diamond-shaped openings formed during the manufacturing process. Common strand widths (SWD) and lengths (LWD) include 2×3, 3×5, and 4×8. The choice of strand dimensions affects airflow, light transmission, and aesthetic appeal, which can be critical for architectural applications.

-

Open Area Percentage: This specification refers to the ratio of the open space in the sheet to the total area. A higher open area percentage allows for better ventilation and light passage, making it ideal for applications like fencing and security screens. Understanding this property helps buyers select sheets that meet functional requirements without compromising structural integrity.

-

Surface Treatment Options: Expanded metal sheets can undergo various surface treatments, such as powder coating, galvanization, and anodizing. These treatments enhance corrosion resistance and aesthetic qualities. For B2B buyers, selecting the right surface treatment is crucial for ensuring longevity and maintaining the desired appearance in specific environments.

-

Customizability: Many manufacturers offer customization options, allowing buyers to specify dimensions, patterns, and finishes. This flexibility can be essential for projects requiring unique specifications, ensuring that the expanded metal sheet integrates seamlessly into the final application.

What Common Trade Terms Should B2B Buyers Understand?

Navigating the B2B landscape of expanded metal sheets involves understanding specific industry jargon. Familiarity with these terms can facilitate smoother transactions and enhance communication with suppliers.

-

OEM (Original Equipment Manufacturer): This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of expanded metal sheets, an OEM might require specific sheet specifications to integrate into their products.

-

MOQ (Minimum Order Quantity): This is the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is vital for B2B buyers to manage inventory and budgeting effectively, especially when sourcing expanded metal sheets in bulk.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers requesting a price quote for specific products. For expanded metal sheets, including detailed specifications in the RFQ can lead to more accurate pricing and quicker responses from suppliers.

-

Incoterms (International Commercial Terms): These are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can help buyers negotiate better terms and understand shipping responsibilities.

-

Lead Time: This term refers to the amount of time it takes from placing an order until the product is delivered. Knowing the lead time for expanded metal sheets is essential for project planning and ensuring timely completion of construction or manufacturing tasks.

-

Surface Finish: This term describes the final texture or appearance of the metal sheet, which can include options like smooth, raised, or powder-coated finishes. Understanding surface finishes helps buyers select the right product for aesthetic and functional requirements.

By grasping these essential properties and terminology, B2B buyers can make informed decisions when procuring expanded metal sheets, ensuring that their projects are successful and meet all necessary specifications.

Navigating Market Dynamics and Sourcing Trends in the expanded metal sheet 4×8 Sector

What Are the Current Market Dynamics and Key Trends in the Expanded Metal Sheet 4×8 Sector?

The global expanded metal sheet market is experiencing significant growth, driven by increasing demand across various sectors such as construction, automotive, and architectural applications. In regions like Africa, South America, the Middle East, and Europe, the need for lightweight yet durable materials that allow for ventilation and aesthetic appeal is propelling this trend. Notably, the 4×8 size is particularly favored due to its versatility and ease of handling, making it suitable for a range of applications from flooring to decorative elements.

Illustrative image related to expanded metal sheet 4×8

Emerging B2B technologies are reshaping how companies source expanded metal sheets. Digital platforms that enable real-time pricing, inventory checks, and custom order placements are becoming increasingly popular among international buyers. Additionally, advancements in manufacturing processes, such as automated cutting and flattening techniques, are enhancing product quality and reducing lead times. Buyers are encouraged to leverage these technologies to optimize their procurement strategies.

Market dynamics are also influenced by fluctuating raw material prices and supply chain disruptions. Buyers should be proactive in establishing relationships with multiple suppliers to mitigate risks associated with price volatility and availability. Understanding local market conditions, regulations, and logistical challenges in target regions will provide buyers with a competitive edge in sourcing.

How Is Sustainability and Ethical Sourcing Reshaping the Expanded Metal Sheet Market?

Sustainability has become a critical consideration for B2B buyers in the expanded metal sheet sector. The environmental impact of metal production, including carbon emissions and resource depletion, has led to increased scrutiny of supply chains. Buyers are now prioritizing suppliers that demonstrate a commitment to sustainable practices, such as using recycled materials and implementing energy-efficient manufacturing processes.

Ethical sourcing is equally important, as buyers seek to ensure that their suppliers adhere to fair labor practices and environmental regulations. Certifications such as ISO 14001 for environmental management and LEED (Leadership in Energy and Environmental Design) are becoming essential criteria for selecting suppliers. By choosing partners with recognized green certifications, buyers can enhance their brand reputation and align with consumer demand for environmentally responsible products.

Furthermore, the trend toward green building practices is driving demand for expanded metal sheets made from sustainable materials. Buyers should actively seek out suppliers who offer eco-friendly options, such as aluminum and galvanized steel with minimal environmental footprints. This approach not only supports sustainability goals but also meets the growing demand for green building materials in various markets.

Illustrative image related to expanded metal sheet 4×8

What Is the Historical Context of Expanded Metal Sheet Production?

The evolution of expanded metal sheets dates back to the late 19th century, when the first manufacturing processes were developed to create this unique material. Initially used in industrial applications, the technology has advanced significantly over the years, allowing for a broader range of designs and materials. Today, expanded metal sheets are produced using a variety of metals, including mild steel, stainless steel, and aluminum, catering to diverse applications in construction, security, and decorative arts.

As industries have evolved, so too have the applications for expanded metal sheets. The introduction of advanced manufacturing techniques has led to the development of new patterns and finishes, enhancing both functionality and aesthetics. This historical context underscores the importance of innovation in meeting the evolving needs of B2B buyers, particularly in a global market that increasingly values versatility and sustainability.

Frequently Asked Questions (FAQs) for B2B Buyers of expanded metal sheet 4×8

-

1. How do I determine the right thickness for my expanded metal sheet needs?

When selecting the thickness of expanded metal sheets, consider the application and load requirements. For heavy-duty applications such as walkways or machine guards, opt for thicker sheets (around 3-10 mm). For decorative purposes or lightweight applications, thinner sheets (0.3-2 mm) may suffice. Always consult with suppliers about the specific strength and durability of their products, as different materials (like aluminum vs. mild steel) can also affect performance. -

2. What are the most common applications for 4×8 expanded metal sheets?

Expanded metal sheets of size 4×8 are versatile and used across various sectors. Common applications include industrial flooring, security barriers, decorative facades, and ventilation screens. They are also popular in construction for architectural designs and in agriculture for greenhouse benches. Knowing the intended use can help you select the right type, pattern, and material for your project. -

3. How can I verify the quality of expanded metal sheets from suppliers?

To ensure the quality of expanded metal sheets, request certifications such as ISO 9001 or other industry-specific standards from potential suppliers. Check for material specifications, including tensile strength and corrosion resistance, especially if sourcing from international suppliers. Additionally, ask for product samples or conduct field tests to evaluate performance under real-world conditions before making bulk purchases. -

4. What customization options are available for expanded metal sheets?

Most suppliers offer customization for expanded metal sheets, including various thicknesses, patterns, and coatings (such as powder coating or anodizing). You can also request specific dimensions beyond the standard 4×8 size. When discussing customization, provide your application requirements to the supplier to ensure they can meet your specifications effectively. -

5. What are typical minimum order quantities (MOQs) for expanded metal sheets?

Minimum order quantities for expanded metal sheets can vary significantly by supplier and region. Generally, MOQs may range from one sheet to several tons, depending on the manufacturer’s capabilities and the type of material used. It’s advisable to inquire directly with suppliers about their MOQs, as some may be flexible, especially for repeat customers or larger contracts. -

6. What payment terms should I expect when sourcing expanded metal sheets internationally?

Payment terms can differ widely among suppliers. Common practices include upfront payments, partial payments upon order confirmation, or payment upon delivery. For international transactions, it’s essential to discuss payment methods such as letters of credit, wire transfers, or escrow services to ensure secure and reliable transactions. Always clarify terms before placing an order to avoid misunderstandings. -

7. How can I manage logistics and shipping for expanded metal sheets?

When sourcing expanded metal sheets internationally, coordinate closely with your supplier regarding logistics. Discuss shipping options, costs, and estimated delivery times. Consider using freight forwarders who specialize in heavy or bulky materials to optimize shipping routes and costs. Additionally, ensure you understand customs regulations and import duties in your country to avoid delays upon arrival. -

8. What should I know about the surface treatments available for expanded metal sheets?

Surface treatments for expanded metal sheets enhance durability and aesthetic appeal. Common options include galvanization for rust prevention, powder coating for color and finish, and anodizing for aluminum sheets. When selecting a treatment, consider the environmental conditions the product will face, such as exposure to moisture or chemicals. Consult with suppliers to choose the best treatment that aligns with your application needs.

Top 6 Expanded Metal Sheet 4X8 Manufacturers & Suppliers List

1. MetalsDepot® – Expanded Steel Sheet

Domain: metalsdepot.com

Registered: 1999 (26 years)

Introduction: MetalsDepot® – Buy Expanded Steel Sheet Online! Steel Expanded Metal is a sheet product that has been slit and stretched to a wide array of diamond shaped openings. It offers savings in weight and metal, free passage of light, liquid, sound and air, while providing a decorative or ornamental effect. Specifications: MIL-M-17194D, ASTM F1267-91, Type I Standard (Raised) & Type II Flattened (smooth) …

2. Midwest Steel Supply – Steel Flattened Expanded Metal

Domain: midweststeelsupply.com

Registered: 2005 (20 years)

Introduction: Steel Flattened Expanded Metal (4ft x 8ft)\n- Sizes Available: 1/4″ x #18, 1/2″ x #18, 1/2″ x #16, 1/2″ x #13, 3/4″ x #16, 3/4″ x #13, 3/4″ x #9, 1-1/2″ x #13, 1-1/2″ x #9\n- Dimensions: 48″ x 96″\n- Material: Steel\n- Features: Slit and stretched into diamond-shaped openings, cold rolled to flatten into one plane, lightweight, allows passage of air, light, or liquid\n- Uses: Decorative and functi…

3. Metal Supermarkets – Expanded Sheet Metal

Domain: metalsupermarkets.com

Registered: 1996 (29 years)

Introduction: Expanded Sheet (or expanded metal) is a piece of metal with slits cut and stretched into a mesh with diamond-shaped spaces. Available in Aluminum and Mild Steel. No wasted product due to slits, reducing production costs while adding strength. Openings allow water, light, or air to pass through. Custom cut to size available.

4. Hole Metals – Diamond Expanded Metal

Domain: holemetals.com

Registered: 2016 (9 years)

Introduction: {“Product Name”: “Diamond Expanded Metal”, “Description”: “The most versatile and economical expanded metal mesh product made from sheets or coils of mild steel, galvanized steel, stainless steel, and aluminum, forming a diamond pattern of openings.”, “Materials”: [“Mild Steel”, “Galvanized Steel”, “Aluminum 1060”, “Aluminum alloy 3003”, “Aluminum alloy 5005”, “Stainless Steel 201”, “Stainless Ste…

5. Steel Supply LP – Expanded Metal Bar Gratings

Domain: steelsupplylp.com

Registered: 2005 (20 years)

Introduction: Steel Expanded Metal Bar Gratings: Widths: 2’ and 3’. Lengths: 20’ and 24’. Heights: 3/4″, 1″, 1-1/4″, 1-1/2″ and 2″. Thickness: 1/8″, 3/16″ and 1/4″. Finishes: Unpainted, Galvanized, Smooth and Serrated. Style: 19W4. Other styles available upon inquiry. Available in stainless steel, aluminum, and fiberglass. Expanded Metal Sheet sizes: 4’x 8’, 4’ x 10’, 5’ x 10’ and 6’ x 10’. Some patterns availa…

6. Wheeler Metals – Expanded Metal Products

Domain: wheelermetals.com

Registered: 1999 (26 years)

Introduction: Expanded Metal Products:

– 4 X 8 Heavy 3# Exp Metal – $119.00

– 4 X 8 X 1/2 #13 Exp Metal Flat – $56.00

– 4 X 8 X 1/2 #13 Exp Metal Standard – $56.00

– 4 X 8 X 3/4 #9 Exp Metal Flat – $58.80

– 4 X 8 X 3/4 #9 Exp Metal Standard – $58.80

– 4 X 8 X 3/4 #13 Exp Metal Flat – $37.80

– 4 X 8 X 3/4 #13 Exp Metal Standard – $37.80

– 4 X 8 X 1 1/2 #6 Exp Metal Standard – $99.40

– 5 X 10 X 1-1/2 #6 Exp Metal…

Strategic Sourcing Conclusion and Outlook for expanded metal sheet 4×8

In today’s competitive landscape, strategic sourcing of expanded metal sheets, particularly the 4×8 size, is essential for international B2B buyers. Understanding the diverse applications, ranging from construction to interior design, allows businesses to make informed procurement decisions. Buyers should prioritize suppliers who offer high-quality materials across various types, including mild steel, aluminum, and stainless steel, ensuring durability and reliability.

Moreover, leveraging the benefits of expanded metal sheets—such as lightweight structure, strength, and cost-effectiveness—can lead to significant operational efficiencies. As the market continues to evolve, businesses in Africa, South America, the Middle East, and Europe should remain vigilant about emerging trends and innovations in metal processing and design.

Illustrative image related to expanded metal sheet 4×8

Looking forward, it is crucial for B2B buyers to engage with reliable suppliers and explore tailored solutions that meet specific project requirements. By fostering partnerships and maintaining open communication, companies can enhance their supply chain resilience and drive sustainable growth. Embrace the opportunities that strategic sourcing presents and position your business for success in the dynamic global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.