Top 6 Eddie Bolts Suppliers (And How to Choose)

Introduction: Navigating the Global Market for eddie bolts

In the competitive landscape of the aerospace and manufacturing sectors, sourcing high-performance fastening solutions like Eddie bolts can be a daunting challenge for international B2B buyers. These advanced fastening systems, designed specifically for composite structures, offer significant advantages such as enhanced joint performance, high vibration resistance, and streamlined installation processes. However, navigating the complexities of product specifications, supplier reliability, and cost-effectiveness can overwhelm even the most experienced procurement professionals.

This comprehensive guide aims to demystify the global market for Eddie bolts, providing B2B buyers from regions such as Africa, South America, the Middle East, and Europe—particularly Nigeria and Brazil—with essential insights. We will explore various types of Eddie bolts, their applications across different industries, and best practices for vetting suppliers. Additionally, the guide will address pricing strategies and cost-saving opportunities, ensuring that buyers can make informed purchasing decisions that align with their operational needs.

By leveraging the information presented in this guide, international buyers will be empowered to navigate the Eddie bolt market confidently, ensuring they select the right fastening solutions to meet their specific requirements while maximizing their investment.

Understanding eddie bolts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Eddie-Bolt® 2 Pin | Five flutes for mechanical locking, free-running nut design | Aerospace composite structures | Pros: High clamping power, reduced installation time. Cons: Requires specific tooling for optimal performance. |

| Eddie-Bolt® 2 Nut | Designed for use with Eddie-Bolt® 2 Pins, low profile | Limited access installations | Pros: Simplifies installation in tight spaces. Cons: Compatibility limited to specific pin types. |

| Eddie-Bolt® 2 Shear Head | 100° flush shear head design | Aircraft assembly, automotive | Pros: Flush design reduces drag, enhancing aerodynamics. Cons: May require additional care during installation to prevent damage. |

| Eddie-Bolt® 2 High Vibration Resistance | True mechanical lock for vibration resistance | High-stress aerospace applications | Pros: Superior vibration resistance ensures reliability. Cons: Higher cost compared to standard fasteners. |

| Eddie-Bolt® 2 Titanium | Made from 6Al-4V titanium for weight and strength | High-performance aerospace | Pros: Lightweight yet strong, corrosion-resistant. Cons: Price point may be higher than steel alternatives. |

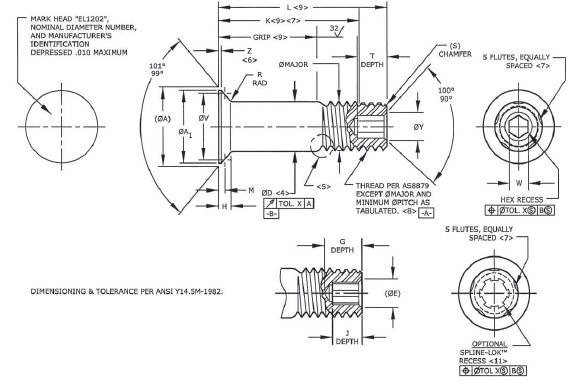

What are the Key Characteristics of Eddie-Bolt® 2 Pins?

Eddie-Bolt® 2 Pins are designed with five flutes that enhance mechanical locking during installation. This feature, combined with a free-running nut, allows for faster and more efficient assembly, particularly in aerospace composite structures. Buyers should consider the specific diameter and material options available, as these can impact the overall performance in demanding environments.

How Do Eddie-Bolt® 2 Nuts Enhance Installation Efficiency?

Eddie-Bolt® 2 Nuts are specifically engineered to complement the Eddie-Bolt® 2 Pins, featuring a low-profile design that facilitates installation in limited access areas. This is particularly beneficial in aerospace applications where space constraints are common. Buyers should evaluate the compatibility of these nuts with their existing fastener systems to maximize installation efficiency.

What Advantages Does the 100° Flush Shear Head Offer?

The 100° flush shear head design of the Eddie-Bolt® 2 enhances aerodynamics by reducing drag, making it ideal for applications in aircraft assembly and automotive industries. Buyers should consider the installation requirements, as this design may necessitate careful handling to avoid damage during assembly, which could lead to additional costs.

Why is High Vibration Resistance Important in Eddie-Bolt® 2 Systems?

Eddie-Bolt® 2 systems provide superior vibration resistance through a true mechanical lock, making them essential for high-stress aerospace applications. This feature ensures reliability and performance under extreme conditions. B2B buyers should weigh the benefits of investing in these systems against their specific operational demands, as the cost may be higher than standard fastening solutions.

What Makes Eddie-Bolt® 2 Titanium an Ideal Choice for Aerospace?

Constructed from 6Al-4V titanium, Eddie-Bolt® 2 Titanium fasteners offer an excellent strength-to-weight ratio, making them ideal for high-performance aerospace applications. They are also corrosion-resistant, ensuring longevity in challenging environments. Buyers must consider the higher price point but can justify it with the enhanced performance and reduced weight, leading to overall operational efficiencies.

Key Industrial Applications of eddie bolts

| Industry/Sector | Specific Application of eddie bolts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Fastening composite structures in aircraft manufacturing | Enhanced structural integrity and reduced installation time | Compliance with aerospace standards, material certifications |

| Automotive | Assembly of lightweight vehicle components | Improved fuel efficiency and reduced weight | Compatibility with high-volume production processes |

| Renewable Energy | Securing components in wind turbine installations | High vibration resistance leading to longer service life | Resistance to environmental conditions, sourcing of durable materials |

| Defense and Military | Fastening systems in military aircraft | Reliability in extreme conditions and reduced maintenance | Meeting stringent military specifications and certifications |

| Construction | Joining prefabricated structures | Faster construction timelines and reduced labor costs | Availability of various sizes and materials for diverse applications |

How are Eddie Bolts Used in Aerospace Applications?

In the aerospace sector, Eddie bolts are crucial for fastening composite structures, such as those found in modern aircraft. Their unique design allows for quicker installations and eliminates foreign object debris (FOD), which is critical in aviation. For international buyers, particularly from regions like Africa and South America, understanding the compliance with rigorous aerospace standards and the need for certified materials is essential to ensure safety and reliability.

What Role Do Eddie Bolts Play in Automotive Manufacturing?

In automotive manufacturing, Eddie bolts are utilized to assemble lightweight components, contributing to overall vehicle weight reduction. This plays a significant role in enhancing fuel efficiency and lowering emissions. Buyers in Europe and the Middle East should consider the compatibility of Eddie bolts with high-volume production processes, ensuring that they meet automotive industry standards for durability and performance.

How are Eddie Bolts Essential for Renewable Energy Projects?

Eddie bolts are increasingly used in securing components for wind turbine installations, where high vibration resistance is paramount. This characteristic ensures that the fastening systems maintain integrity over time, contributing to the longevity of renewable energy infrastructure. Buyers in regions with growing renewable energy sectors, such as Brazil, must source Eddie bolts that can withstand harsh environmental conditions, ensuring reliability in their applications.

What Benefits Do Eddie Bolts Offer in Defense and Military Applications?

In defense, Eddie bolts are employed in military aircraft, where reliability in extreme conditions is crucial. The mechanical locking feature of Eddie bolts reduces maintenance needs and enhances operational readiness. International buyers in defense sectors must be aware of the stringent specifications and certifications required for military applications to ensure compliance and performance.

Why are Eddie Bolts Important in Construction?

In the construction industry, Eddie bolts facilitate the joining of prefabricated structures, significantly speeding up construction timelines and reducing labor costs. Their versatility in sizes and materials allows for adaptation to various construction needs. Buyers should focus on sourcing Eddie bolts that meet specific project requirements, ensuring they have the necessary strength and durability for diverse applications.

3 Common User Pain Points for ‘eddie bolts’ & Their Solutions

Scenario 1: Difficulty in Ensuring Vibration Resistance in Aerospace Applications

The Problem: Many B2B buyers in the aerospace sector face challenges when selecting fastening systems that can withstand high levels of vibration, especially in composite structures. The consequences of using inadequate fasteners can lead to structural failures, costly rework, and safety concerns. Buyers often struggle to identify which fasteners offer superior vibration resistance, leading to anxiety over the reliability of their assemblies in critical applications.

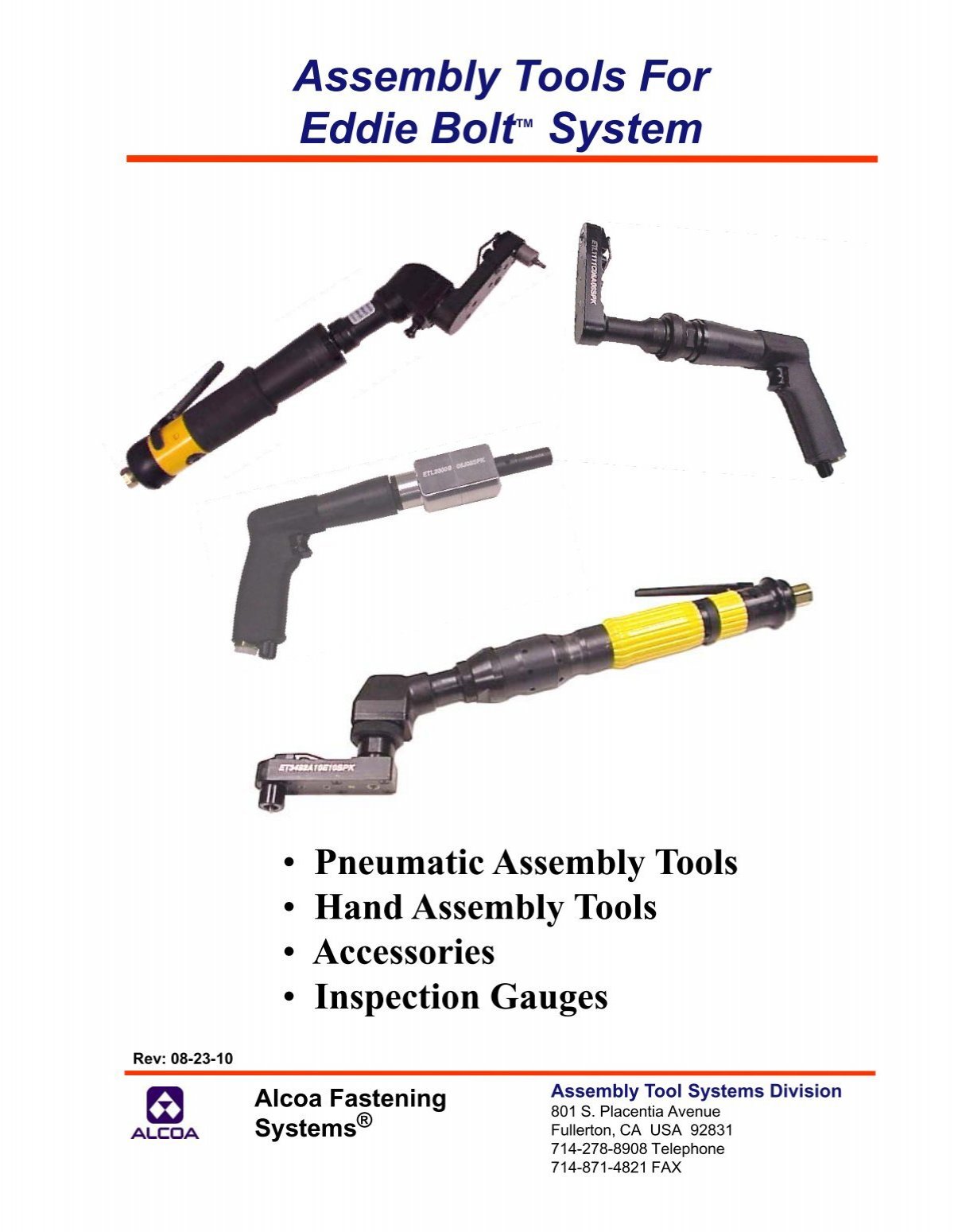

The Solution: To ensure the optimal performance of Eddie Bolts in high-vibration environments, buyers should prioritize sourcing fasteners with a proven mechanical locking mechanism, such as those found in the Eddie-Bolt® 2 system. The true mechanical lock provided by the Eddie-Bolt® 2 ensures superior vibration resistance compared to traditional friction locks. When specifying these fasteners, buyers should consult detailed performance data and installation guidelines to confirm that they meet the specific vibration resistance requirements of their applications. Additionally, training the installation team on the correct use of tools, like the Delta-Rad™ driver, can significantly enhance the effectiveness of the installation, ensuring that the fasteners achieve the required clamp load for optimal performance.

Scenario 2: Challenges with Limited Access Installation

The Problem: For B2B buyers working in environments where space is constrained—such as aircraft fuselages or other composite structures—installing traditional fastening systems can be problematic. Limited access can make it difficult to maneuver tools, leading to delays and increased labor costs. Buyers often find themselves frustrated with the inefficiencies that arise from these installation challenges.

The Solution: The Eddie-Bolt® 2 system is specifically designed with a lower profile pin and nut, allowing for easier access in tight spaces. Buyers should evaluate their operational environments and consider using Eddie Bolts in applications where traditional fasteners may not fit. It’s also beneficial to invest in specialized tooling that is compatible with the Eddie-Bolt® 2 system, which can enhance accessibility and streamline the installation process. By integrating this fastening system into their procurement strategy, buyers can reduce installation time and labor costs, ultimately increasing overall project efficiency.

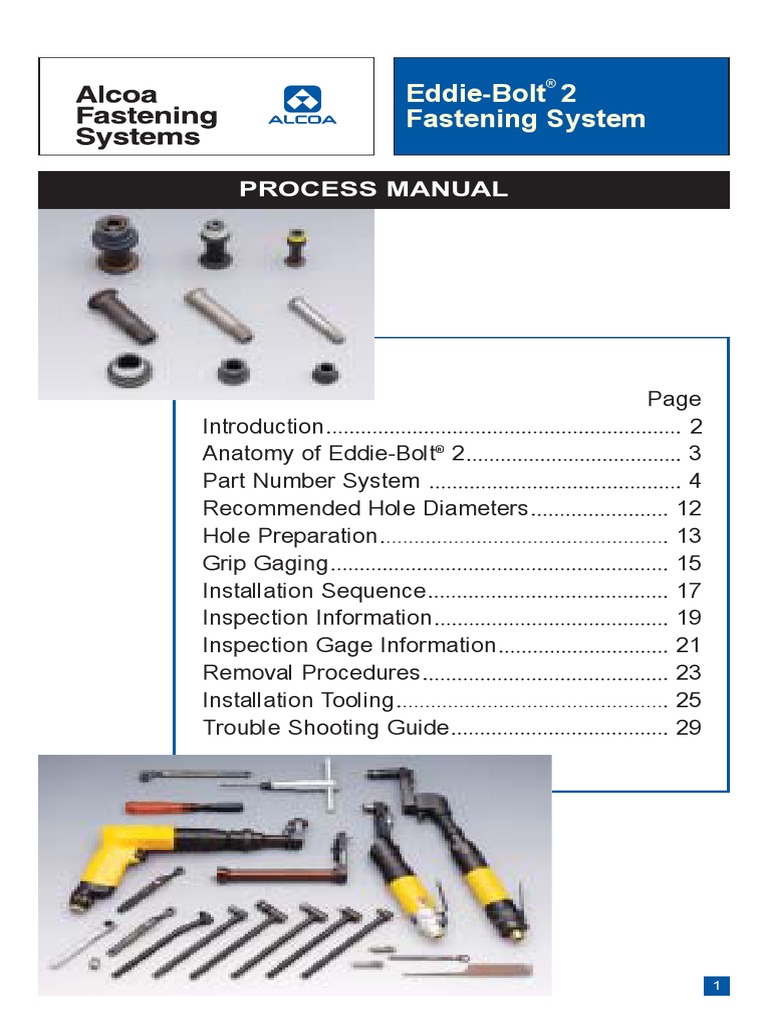

Illustrative image related to eddie bolts

Scenario 3: Concerns Over Foreign Object Debris (FOD)

The Problem: A significant concern for B2B buyers in the aerospace industry is the risk of foreign object debris (FOD) during assembly and installation. Traditional fastening methods, especially those involving frangible collars, can leave behind debris that poses severe risks to aircraft performance and safety. Buyers often worry about how to mitigate these risks effectively.

The Solution: Eddie Bolts provide a unique advantage as they are designed to eliminate the FOD associated with conventional fastening methods. The installation process of the Eddie-Bolt® 2 system, which does not involve frangible collars, minimizes the risk of debris generation. Buyers should ensure that their teams are trained on the installation procedures that maximize the benefits of the Eddie-Bolt® system. Furthermore, they should incorporate these fasteners into their standard operating procedures and quality assurance processes, emphasizing the importance of FOD prevention. By doing so, they can enhance safety, reduce liability, and maintain compliance with industry regulations.

By addressing these common pain points with actionable solutions tailored to the unique properties of Eddie Bolts, B2B buyers can improve their operational efficiency and overall project outcomes.

Strategic Material Selection Guide for eddie bolts

What Are the Key Properties of Common Materials Used for Eddie Bolts?

When selecting materials for Eddie bolts, it is crucial to consider their properties, performance characteristics, and suitability for specific applications. Here, we analyze four common materials used in the manufacturing of Eddie bolts: titanium, aluminum, stainless steel, and carbon steel.

Titanium: A Lightweight Champion

Key Properties: Titanium, particularly the 6Al-4V alloy, is renowned for its high strength-to-weight ratio and excellent corrosion resistance. It can withstand high temperatures, making it suitable for aerospace applications where thermal stability is critical.

Pros & Cons: The primary advantage of titanium is its durability and lightweight nature, which can enhance the overall performance of the aircraft. However, it is relatively expensive and can be challenging to machine, increasing manufacturing complexity.

Impact on Application: Titanium’s corrosion resistance makes it ideal for environments exposed to saltwater or harsh chemicals, which is beneficial for aerospace applications in coastal regions or areas with high humidity.

Considerations for International Buyers: Buyers from regions such as Africa and South America should be aware of the higher costs associated with titanium. Compliance with international standards like ASTM is essential, and buyers should ensure that suppliers can meet these specifications.

Aluminum: The Cost-Effective Alternative

Key Properties: Aluminum alloys, particularly 2024 and 7075, offer a good balance of strength, weight, and corrosion resistance. They are lightweight and have excellent thermal properties, making them suitable for various aerospace applications.

Pros & Cons: Aluminum is less expensive than titanium and easier to machine, which can reduce manufacturing lead times. However, it has lower fatigue resistance compared to titanium, which may limit its use in high-stress applications.

Illustrative image related to eddie bolts

Impact on Application: Aluminum is suitable for applications where weight savings are critical, such as in commercial aircraft. However, it may not be the best choice for environments with high corrosion potential unless treated with protective coatings.

Considerations for International Buyers: Buyers in Europe and the Middle East may prefer aluminum due to its cost-effectiveness. It is essential to verify that the aluminum used meets relevant standards such as DIN or JIS.

Stainless Steel: The Durable Workhorse

Key Properties: Stainless steel, particularly grades 304 and 316, is known for its excellent corrosion resistance and strength. It can withstand high temperatures and is less prone to galling compared to other materials.

Illustrative image related to eddie bolts

Pros & Cons: The durability of stainless steel makes it suitable for a wide range of applications. However, it is heavier than aluminum and titanium, which may impact overall weight-sensitive designs. Additionally, it can be more expensive than carbon steel.

Impact on Application: Stainless steel is ideal for applications requiring high strength and corrosion resistance, such as in marine environments or chemical processing. Its robustness ensures long-term reliability.

Considerations for International Buyers: Buyers from Africa and South America should consider the availability of stainless steel and its compliance with local standards. It is essential to choose suppliers familiar with international quality requirements.

Carbon Steel: The Budget-Friendly Option

Key Properties: Carbon steel offers good strength and toughness at a low cost. It is less corrosion-resistant than stainless steel and aluminum, making it less suitable for harsh environments.

Pros & Cons: The primary advantage of carbon steel is its affordability and ease of availability. However, its susceptibility to rust and corrosion limits its use in applications exposed to moisture or chemicals.

Impact on Application: Carbon steel can be used in applications where weight is less critical, and the environment is controlled, such as in non-aerospace industries.

Considerations for International Buyers: Buyers in regions like Brazil may find carbon steel to be a cost-effective solution. However, they must ensure that proper coatings or treatments are applied to mitigate corrosion risks.

Summary Table of Material Selection for Eddie Bolts

| Material | Typical Use Case for eddie bolts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Titanium | Aerospace applications | High strength-to-weight ratio | Expensive and difficult to machine | High |

| Aluminum | Commercial aircraft | Cost-effective and lightweight | Lower fatigue resistance | Medium |

| Stainless Steel | Marine and chemical processing | Excellent corrosion resistance | Heavier than aluminum | Medium |

| Carbon Steel | Non-aerospace industries | Affordable and readily available | Susceptible to corrosion | Low |

This material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of various materials used for Eddie bolts, aiding in informed purchasing decisions tailored to specific application needs.

Illustrative image related to eddie bolts

In-depth Look: Manufacturing Processes and Quality Assurance for eddie bolts

What Are the Key Stages in the Manufacturing Process of Eddie Bolts?

The manufacturing process of Eddie Bolts involves several critical stages that ensure the production of high-quality fastening systems. These stages include material preparation, forming, assembly, and finishing.

Material Preparation: How Is Raw Material Selected and Processed?

The process begins with selecting high-grade raw materials, typically titanium alloys such as 6Al-4V, known for their strength and lightweight properties, making them suitable for aerospace applications. Once the material is selected, it undergoes rigorous testing to assess its mechanical properties and ensure it meets industry specifications. The material is then cut into appropriate lengths and prepped for forming, which involves heating and machining to achieve the desired dimensions and tolerances.

Forming: What Techniques Are Used to Create Eddie Bolts?

During the forming stage, advanced techniques such as precision machining and cold heading are employed. Cold heading is particularly effective in shaping the bolt heads without compromising the material’s integrity. The Eddie Bolt design features unique characteristics, such as flutes in the threaded area, which are incorporated during this stage. CNC (Computer Numerical Control) machines are often utilized to achieve the precision required for aerospace applications. This level of precision is crucial for ensuring that the bolts fit seamlessly into composite structures.

Assembly: How Are Eddie Bolts Assembled for Optimal Performance?

The assembly process involves integrating the Eddie Bolt pins with their corresponding free-running nuts. This step is crucial as it ensures that the mechanical locking mechanism operates effectively. The Delta-Rad driver is used to apply torque during assembly, facilitating the deformation of the nut lobes into the pin flutes. This process guarantees a positive mechanical lock, which is essential for the performance of the fastening system.

What Finishing Processes Are Critical for Quality Assurance in Eddie Bolts?

Finishing is the final stage in the manufacturing process, where the bolts undergo surface treatments to enhance durability and resistance to corrosion. Common finishes include phosphate fluoride coatings that improve the bolts’ resistance to environmental factors. This step not only improves aesthetic appeal but also increases the longevity of the product, which is a significant consideration for international B2B buyers seeking reliable fastening solutions.

How Is Quality Assurance Implemented in Eddie Bolt Manufacturing?

Quality assurance (QA) is a vital aspect of the manufacturing process for Eddie Bolts, ensuring that each product meets stringent international standards. Manufacturers typically adhere to ISO 9001, a globally recognized standard for quality management systems. Additionally, industry-specific certifications such as CE and API are often pursued, particularly in sectors like aerospace and defense.

What Are the Key Quality Control Checkpoints in Eddie Bolt Production?

The QA process includes several checkpoints, categorized as Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

- IQC involves inspecting raw materials upon arrival to ensure they meet specified standards.

- IPQC occurs throughout the manufacturing process, where samples are tested for dimensional accuracy and mechanical properties.

- FQC is conducted after the final assembly, where the entire product is tested for functionality, including torque performance and vibration resistance.

Which Testing Methods Are Commonly Used to Ensure Eddie Bolt Quality?

Common testing methods include tensile strength tests, fatigue testing, and vibration resistance assessments. These tests help verify that the bolts can withstand the conditions they will face in real-world applications. Non-destructive testing (NDT) methods, such as ultrasonic testing, may also be employed to identify any internal flaws without damaging the product.

Illustrative image related to eddie bolts

How Can B2B Buyers Verify Supplier Quality Control Processes?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should adopt a proactive approach to verifying supplier quality control processes. This can be achieved through several strategies:

- Audits: Conducting regular audits of suppliers to ensure they comply with international standards and maintain robust quality management systems.

- Quality Reports: Requesting detailed quality reports that outline the results of various testing methods and quality control measures taken during production.

- Third-Party Inspections: Engaging independent third-party inspection services can provide unbiased assessments of the manufacturing processes and product quality.

What Are the Specific Quality Certification Nuances for International Buyers?

For buyers in diverse regions, understanding the nuances of quality certifications is crucial. Certain markets may prioritize specific certifications due to local regulations or industry standards. For instance, European buyers may require CE marking, while those in the Middle East might focus on compliance with local safety standards. Additionally, buyers should be aware of any regional trade agreements that could affect quality expectations and certification requirements.

In conclusion, the manufacturing processes and quality assurance measures for Eddie Bolts are meticulously designed to ensure that these fastening systems meet the high standards required in aerospace applications. By understanding these processes, B2B buyers can make informed decisions when sourcing Eddie Bolts, ensuring they receive products that are both reliable and compliant with international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘eddie bolts’

Introduction

This practical sourcing guide is designed to assist international B2B buyers in procuring Eddie Bolts, a high-performance fastening system ideal for aerospace applications. By following this step-by-step checklist, buyers can ensure they select the right product and supplier to meet their specific needs while optimizing cost and efficiency.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline the technical requirements for the Eddie Bolts you need. Consider factors such as diameter, material (e.g., 6Al-4V titanium), and finish (e.g., phosphate fluoride). Precise specifications will streamline supplier evaluation and ensure compatibility with your projects.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers specializing in Eddie Bolts. Look for companies with a proven track record in aerospace applications and experience with composite structures. Utilize industry directories, trade shows, and online platforms to gather a list of potential suppliers.

Step 3: Evaluate Supplier Certifications

Before proceeding, verify that your chosen suppliers possess the necessary industry certifications and quality assurance processes. Certifications such as AS9100 or ISO 9001 indicate a commitment to quality management systems. This step is vital to ensure that the products meet stringent aerospace standards and regulations.

Step 4: Request Product Samples

Once you have shortlisted suppliers, request product samples of Eddie Bolts for evaluation. Testing samples allows you to assess the quality, performance, and fit of the fasteners in your specific application. It’s an opportunity to identify any potential issues before making a bulk order.

Step 5: Analyze Pricing and Delivery Terms

Gather detailed quotes from your selected suppliers, comparing pricing, lead times, and delivery terms. Look for transparency in pricing structures and inquire about any additional costs, such as shipping or customs duties. Understanding the total cost of ownership will help you make an informed decision.

Step 6: Discuss Technical Support and Service

Engage suppliers in discussions about the technical support they offer. A reliable supplier should provide assistance with installation, troubleshooting, and ongoing maintenance. This is especially crucial for complex fastening systems like Eddie Bolts, where expert guidance can enhance operational efficiency.

Step 7: Finalize Contracts and Terms

Before placing your order, carefully review and finalize contracts with your chosen supplier. Ensure that all terms, including pricing, delivery schedules, and warranties, are clearly outlined. This will protect your interests and establish a solid foundation for a successful business relationship.

By following this checklist, B2B buyers can navigate the procurement of Eddie Bolts with confidence, ensuring that they select the right products and partners for their aerospace needs.

Comprehensive Cost and Pricing Analysis for eddie bolts Sourcing

What Are the Key Cost Components in Eddie Bolts Sourcing?

When sourcing Eddie Bolts, understanding the cost structure is essential for accurate budgeting and negotiation. The primary cost components include:

-

Materials: Eddie Bolts are typically made from high-performance materials such as 6Al-4V titanium, which ensures durability and strength but can also elevate costs. The choice of materials significantly impacts the final price, especially if custom specifications are required.

-

Labor: Labor costs encompass the workforce involved in manufacturing, assembling, and quality-checking the bolts. In regions like Africa and South America, labor costs may vary widely due to local economic conditions, affecting overall pricing.

-

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and equipment depreciation. High-tech manufacturing processes, such as those used for Eddie Bolts, may incur higher overheads due to the need for specialized machinery and skilled labor.

-

Tooling: The tooling costs for Eddie Bolts can be substantial, especially if custom molds or dies are needed for specific designs. These costs are often amortized over the production volume, influencing per-unit pricing.

-

Quality Control (QC): Rigorous quality assurance processes are vital, especially in aerospace applications. The cost of implementing QC measures, including testing and certification, is a critical factor in the overall pricing.

-

Logistics: Shipping and transportation costs can vary significantly based on the destination and Incoterms. Buyers should consider not only the freight charges but also potential tariffs, duties, and local delivery costs.

-

Margin: Suppliers will typically add a margin to cover their costs and ensure profitability. This margin can vary based on market competition, demand, and the supplier’s overall business strategy.

How Do Price Influencers Affect Eddie Bolt Pricing?

Several factors can influence the pricing of Eddie Bolts, which buyers should consider:

-

Volume/MOQ: Suppliers often have minimum order quantities (MOQs) that can affect pricing. Higher volumes may lead to bulk discounts, while smaller orders might incur higher per-unit costs.

-

Specifications and Customization: Custom requirements or specific certifications can lead to increased costs. Buyers should clearly communicate their needs to avoid unexpected price hikes.

-

Materials and Quality Certifications: The choice of materials directly impacts pricing. Bolts made from premium materials will cost more, and additional certifications for aerospace applications can further increase costs.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge a premium for their proven quality and service, while emerging suppliers might offer lower prices to gain market share.

-

Incoterms: Understanding the Incoterms used in the transaction is crucial. These terms dictate who is responsible for shipping costs, insurance, and tariffs, which can significantly impact the total cost.

What Are Some Effective Buyer Tips for Negotiating Eddie Bolt Prices?

When negotiating prices for Eddie Bolts, especially in the international B2B landscape, consider the following strategies:

-

Leverage Volume Discounts: Consolidating orders can help achieve better pricing. If feasible, collaborate with other companies to increase order volumes and negotiate more favorable terms.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also installation costs, maintenance, and longevity of the bolts. A higher upfront cost may be justified by lower long-term expenses.

-

Understand Pricing Nuances: Be aware of market trends and pricing fluctuations in different regions. For instance, the cost of titanium may vary based on local supply and demand dynamics.

-

Build Relationships with Suppliers: Establishing strong relationships can lead to better pricing, favorable payment terms, and priority service. Trust can often yield more flexible negotiations.

-

Request for Quotes (RFQs): Always solicit multiple quotes from different suppliers. This process helps in comparing prices and terms, ensuring that you secure the best deal.

Conclusion

Navigating the cost and pricing landscape of Eddie Bolts requires a thorough understanding of the various cost components and price influencers. By employing effective negotiation strategies and maintaining a focus on total cost of ownership, international B2B buyers can optimize their sourcing efforts, ensuring both quality and value in their purchases.

Alternatives Analysis: Comparing eddie bolts With Other Solutions

Exploring Alternatives to Eddie Bolts: A Comparative Analysis

When evaluating fastening solutions for aerospace and composite applications, it’s crucial to consider various alternatives to Eddie Bolts. Each option comes with unique advantages and drawbacks, influencing operational efficiency, cost-effectiveness, and ease of implementation. This analysis focuses on Eddie Bolts in comparison to two viable alternatives: Rivet Fastening Systems and Threaded Fasteners.

Comparison Table

| Comparison Aspect | Eddie Bolts | Rivet Fastening Systems | Threaded Fasteners |

|---|---|---|---|

| Performance | High clamping power, low vibration resistance | Moderate clamping strength, susceptible to shear failure | Strong load-bearing capability, but may loosen over time |

| Cost | Higher initial investment, long-term savings due to reduced rework | Lower initial costs, but potential for higher maintenance | Generally low cost, but may require additional components (washers, nuts) |

| Ease of Implementation | Quick installation, no FOD | Requires specialized tools and training | Simple installation, but may need torque control |

| Maintenance | Low maintenance due to mechanical lock | Moderate maintenance required due to wear | Higher maintenance as fasteners can loosen |

| Best Use Case | Aerospace composite structures | General applications, non-critical structures | High-load applications, mechanical assemblies |

Detailed Breakdown of Alternatives

Rivet Fastening Systems

Rivet fastening systems are widely used in various industries, particularly in aerospace applications. They provide a cost-effective solution with lower initial material costs compared to Eddie Bolts. However, rivets can be more susceptible to shear failure under high-stress conditions. Installation requires specialized tools and trained personnel, which can add to overall project costs. While they work well for general applications, rivets may not provide the same level of clamping power and vibration resistance as Eddie Bolts, making them less suitable for critical aerospace structures.

Illustrative image related to eddie bolts

Threaded Fasteners

Threaded fasteners are a common choice for many mechanical assemblies due to their versatility and ease of availability. They tend to have a lower upfront cost and can be easily sourced. However, they often require additional components like washers and nuts, which can complicate the assembly process. Threaded fasteners are prone to loosening under vibration, necessitating regular maintenance and checks to ensure joint integrity. They are best suited for high-load applications where consistent mechanical strength is needed but may not be ideal for environments where vibration resistance is critical.

Conclusion: How to Choose the Right Fastening Solution

Selecting the right fastening solution depends on various factors, including specific application requirements, budget constraints, and long-term maintenance considerations. B2B buyers should evaluate the unique benefits of Eddie Bolts against alternatives like rivet fastening systems and threaded fasteners based on performance needs and operational costs. For applications demanding high vibration resistance and superior joint performance, Eddie Bolts stand out, while rivets and threaded fasteners may offer suitable options for less critical applications. Ultimately, the choice should align with the operational goals and environmental conditions of the intended application, ensuring both reliability and cost-effectiveness.

Essential Technical Properties and Trade Terminology for eddie bolts

What Are the Essential Technical Properties of Eddie Bolts?

Eddie bolts are engineered fasteners widely used in aerospace applications, particularly for composite structures. Understanding their technical properties is crucial for B2B buyers looking to make informed purchasing decisions.

1. Material Grade: What Makes Eddie Bolts Durable?

Eddie bolts are typically made from advanced materials such as titanium alloys, specifically 6Al-4V titanium. This material is known for its high strength-to-weight ratio and corrosion resistance, making it ideal for aerospace applications where both durability and weight savings are critical. Selecting the right material grade ensures that the fasteners can withstand extreme operational environments, thereby enhancing the longevity of the components they secure.

2. Tolerance: Why Is Precision Important?

Tolerance refers to the allowable deviation from specified dimensions in the manufacturing process. Eddie bolts are produced with tight tolerances to ensure a precise fit with corresponding nuts and components. This precision is vital for maintaining structural integrity and performance, especially in high-stress applications. A proper fit minimizes the risk of mechanical failure, which is particularly important in aerospace and automotive industries where safety is paramount.

3. Grip Variation: How Does It Impact Performance?

Grip variation is the range of thickness that a fastener can accommodate when installed. Eddie bolts offer various grip lengths, allowing for versatility in application. Understanding grip variation is essential for ensuring that the fastener will effectively engage with the materials being joined, thus preventing issues like loosening or failure under load.

4. Shear Strength: What Does It Mean for Load-Bearing Applications?

Shear strength is a critical measure of a fastener’s ability to resist forces that could cause it to fail in shear. Eddie bolts are designed to provide superior shear strength, making them suitable for demanding applications where high loads are common. For B2B buyers, selecting fasteners with appropriate shear strength is essential to ensure the safety and reliability of their products.

5. Vibration Resistance: Why Is It Essential in Aerospace?

The vibration resistance of Eddie bolts is a key feature that distinguishes them from other fastening systems. The true mechanical lock formed during installation significantly reduces the risk of loosening due to vibrations. This is particularly important in aerospace applications, where even minor failures can have catastrophic consequences. Choosing fasteners with high vibration resistance can lead to lower maintenance costs and improved safety.

What Are Common Trade Terms Related to Eddie Bolts?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions.

1. OEM (Original Equipment Manufacturer): What Role Do They Play?

OEMs are companies that produce parts that are used in another company’s end product. In the context of Eddie bolts, OEMs may require custom fasteners tailored to specific applications. Understanding the OEM landscape helps buyers identify reliable suppliers and negotiate better contracts.

2. MOQ (Minimum Order Quantity): Why Does It Matter?

MOQ refers to the minimum number of units a supplier is willing to sell. For B2B buyers, knowing the MOQ is crucial for inventory management and budgeting. Suppliers often set MOQs based on production costs, and understanding this can help in negotiating favorable terms.

3. RFQ (Request for Quotation): How to Get Accurate Pricing?

An RFQ is a document sent to suppliers requesting detailed pricing and terms for specific products. For buyers of Eddie bolts, issuing an RFQ can streamline the procurement process, ensuring that they receive competitive pricing and clear terms from multiple suppliers.

4. Incoterms: What Do They Define in Shipping?

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in shipping goods. Understanding these terms is vital for international transactions, as they clarify who bears the risk and costs at various stages of the shipping process. This knowledge helps buyers avoid unexpected expenses and delays.

By grasping these technical properties and trade terms, B2B buyers can enhance their understanding of Eddie bolts and navigate the procurement process with greater confidence.

Navigating Market Dynamics and Sourcing Trends in the eddie bolts Sector

What Are the Current Market Dynamics and Key Trends for Eddie Bolts?

The global market for Eddie bolts is experiencing significant growth, driven by the aerospace industry’s increasing demand for lightweight, high-performance fastening solutions, particularly in composite structures. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe (e.g., Nigeria, Brazil) seek to enhance their manufacturing capabilities, there are several key trends to consider.

Firstly, technological advancements are paving the way for more innovative fastening solutions. The Eddie-Bolt® 2 fastening system, with its free-running nut and mechanical locking features, exemplifies the push towards systems that simplify installation while enhancing joint performance. This trend is particularly appealing in industries where labor costs are high or where skilled labor is scarce.

Moreover, the emphasis on speed and efficiency in manufacturing processes is leading companies to adopt systems that reduce installation time and minimize rework. The Eddie bolts’ design features, such as reduced friction and enhanced vibration resistance, align perfectly with these operational goals. Furthermore, the rise of digital procurement platforms is enabling B2B buyers to source these products more efficiently, facilitating real-time comparisons and streamlined logistics.

Sustainability is also becoming a crucial factor in sourcing decisions. As companies increasingly adopt eco-friendly practices, there is a growing demand for materials and processes that align with sustainable objectives. Buyers should be aware of suppliers offering green certifications and sustainable materials in their Eddie bolt offerings, which can enhance their brand reputation and comply with international regulations.

How Is Sustainability and Ethical Sourcing Influencing the Eddie Bolts Market?

Sustainability and ethical sourcing are rapidly transforming the landscape of the Eddie bolts market. The aerospace sector, in particular, is under pressure to reduce its environmental footprint, prompting manufacturers to adopt greener practices. This shift includes sourcing raw materials that are ethically produced and minimizing waste throughout the supply chain.

B2B buyers must prioritize suppliers who demonstrate a commitment to sustainable practices, such as using recycled materials or reducing carbon emissions during production. This focus on sustainability not only meets regulatory demands but also caters to the growing consumer preference for environmentally responsible products.

Moreover, certifications such as ISO 14001 for environmental management systems or other green certifications can provide buyers with assurance that their sourcing decisions align with sustainability goals. By opting for Eddie bolts that meet these criteria, companies can enhance their operational efficiency while fulfilling their corporate social responsibility commitments.

What Is the Brief Evolution and History of Eddie Bolts?

The evolution of Eddie bolts reflects the broader advancements in aerospace fastening technology. Initially developed to address the unique challenges presented by composite materials, Eddie bolts have undergone significant enhancements to improve performance, ease of installation, and overall reliability. The introduction of the Eddie-Bolt® 2 system marked a pivotal moment in this evolution, providing a fastener that not only simplifies installation but also significantly reduces the risk of foreign object debris (FOD).

As the aerospace industry continues to innovate, the demand for advanced fastening solutions like Eddie bolts is expected to rise. This evolution highlights the importance of staying abreast of technological advancements, ensuring that B2B buyers can make informed sourcing decisions that enhance their operational capabilities and align with market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of eddie bolts

1. What are the advantages of using Eddie-Bolt® fasteners in aerospace applications?

Eddie-Bolt® fasteners offer numerous advantages for aerospace applications, particularly in composite structures. Their unique design features, such as the free-running nut and five flutes on the pin, ensure a robust mechanical lock that enhances joint performance and provides excellent static and fatigue strengths. These fasteners also boast high vibration resistance and reduced risk of foreign object debris (FOD), making them ideal for demanding environments. Additionally, the simplified installation process reduces labor time and costs, which is crucial for manufacturers aiming to optimize productivity.

2. How can I ensure the quality of Eddie-Bolt® fasteners from international suppliers?

To ensure the quality of Eddie-Bolt® fasteners from international suppliers, it’s essential to conduct thorough due diligence. Start by verifying the supplier’s certifications, such as ISO 9001, which indicates a commitment to quality management. Request samples for inspection and testing to confirm compliance with aerospace standards. Additionally, consider engaging third-party quality assurance services to conduct audits or inspections during production. Establishing clear communication channels and maintaining regular contact can also help address any quality concerns proactively.

3. What customization options are available for Eddie-Bolt® fasteners?

Eddie-Bolt® fasteners can be customized in various ways to meet specific application needs. Buyers can choose from different materials, such as titanium or aluminum, and select various finishes to enhance corrosion resistance or aesthetic appeal. Custom diameters and grip lengths are also available, allowing for tailored solutions that fit unique design specifications. It’s advisable to discuss your requirements with the supplier early in the sourcing process to explore all customization options and ensure compatibility with your project.

4. What is the minimum order quantity (MOQ) for Eddie-Bolt® fasteners?

The minimum order quantity (MOQ) for Eddie-Bolt® fasteners varies by supplier and specific product type. Generally, MOQs can range from small quantities suitable for prototyping to larger volumes for mass production. When negotiating with suppliers, clarify the MOQ and discuss any potential flexibility, especially if you are looking to place a smaller initial order. Establishing a long-term relationship with suppliers can also lead to more favorable terms in future orders.

5. What payment terms should I expect when sourcing Eddie-Bolt® fasteners internationally?

Payment terms for international purchases of Eddie-Bolt® fasteners can differ significantly among suppliers. Common terms include upfront payment, a deposit with the balance due upon delivery, or net terms (e.g., net 30 or net 60 days). It’s essential to negotiate terms that align with your cash flow and financial policies. Additionally, consider using secure payment methods such as letters of credit or escrow services to protect your investment, especially when dealing with new suppliers.

6. How do logistics and shipping impact the procurement of Eddie-Bolt® fasteners?

Logistics and shipping play a crucial role in the procurement process for Eddie-Bolt® fasteners, especially when sourcing internationally. Factors such as lead times, shipping methods, and customs regulations can affect delivery schedules and overall project timelines. Work closely with suppliers to understand their shipping capabilities and choose logistics partners experienced in international freight. Additionally, consider the total landed cost, which includes shipping, tariffs, and duties, to ensure accurate budgeting for your procurement.

7. What are the common applications for Eddie-Bolt® fasteners in various industries?

Eddie-Bolt® fasteners are primarily designed for aerospace applications but are also utilized in other industries, such as automotive, marine, and industrial equipment. Their high strength-to-weight ratio and vibration resistance make them suitable for environments where reliability is critical. In automotive manufacturing, they can be used in composite structures, while in marine applications, their corrosion-resistant finishes are advantageous. Understanding the specific needs of your industry can help you leverage the benefits of Eddie-Bolt® fasteners effectively.

8. How can I evaluate potential suppliers of Eddie-Bolt® fasteners?

Evaluating potential suppliers of Eddie-Bolt® fasteners involves several key steps. First, research their industry reputation by checking customer reviews and case studies. Look for suppliers with a proven track record in aerospace and high-performance fastening solutions. Assess their production capabilities, quality control processes, and compliance with international standards. Finally, consider visiting their facilities if feasible or requesting virtual tours to gauge their operational standards. Building a relationship based on trust and transparency will help ensure a successful partnership.

Illustrative image related to eddie bolts

Top 6 Eddie Bolts Manufacturers & Suppliers List

1. Eddie-Bolt® – Aerospace Fastening System

Domain: ppedm.com

Registered: 2005 (20 years)

Introduction: Eddie-Bolt® is a cutting-edge aerospace fastening system designed for composite structures. Key features include: exceptional clamping power, a free-running nut for simplified installation, and a positive mechanical lock that prevents loosening due to vibrations. Eddie-Bolts are made from high-quality materials, including various alloys and finishes, to meet aerospace engineering standards. The re…

2. Air & Space Forces – Lockheed Martin F-35

Domain: airandspaceforces.com

Registered: 2022 (3 years)

Introduction: Lockheed Martin’s F-35 fighter jets potentially have incorrect structural fasteners installed in critical areas. The issue involves titanium fasteners being used instead of Inconel fasteners, which are required for greater strength and corrosion resistance. Titanium bolts cost approximately $5 each, while Inconel parts cost about $20 each. The F-35 has over 48,000 fasteners, with varying percentag…

3. Eddie Bolt – Spline-Lok® Key

Domain: aft.systems

Introduction: Eddie Bolt Tooling spares include various spline keys and gage sets. Key products and their prices are as follows: 093-9205 Spline-Lok® Key AU$169.22, 093-9334 Hex Key AU$36.85, 493-9002 5 Dia Eddie Bolt 1″ Spline Key AU$118.00, 493-9011 Spline Key AU$137.50, 493-9016 Spline Key AU$143.00, 493-9026 -8 Dia Eddie Bolt .3″ Spline Key AU$178.00, 493-9132 -10 Dia Eddie Bolt 1″ Spline Key AU$165.00, 493…

4. Eddie – 11 Pc Bolt Installation Removal Wrench Set

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“product_name”: “11 Pc Eddie Bolt Installation Removal Wrench Set”, “category”: “Aircraft Tools”, “condition”: “Used”, “condition_description”: “Excellent used condition.”, “price”: “$125.00 or Best Offer”, “shipping_cost”: “$8.95”, “estimated_delivery”: “Sat, Oct 4 – Sat, Oct 11”, “seller_feedback”: “99.4% positive feedback”, “quantity”: “1”, “returns_accepted”: true, “watchers”: 16, “seller”: “…

5. Omega Technologies – EBK14 Installation & Removal Kit

Domain: mrotools.com

Registered: 2003 (22 years)

Introduction: Omega Technologies EBK14 Installation And Removal 14PC Kit For Eddie-Bolt Fasteners And Collars

6. Omega Technologies – EBK14 Installation and Removal Kit

Domain: hiloktools.com

Registered: 2015 (10 years)

Introduction: {“Product Name”: “Omega Technologies EBK14 Installation And Removal 14PC Kit For Eddie-Bolt Fasteners And Collars”, “Part Number”: “EBK14”, “Number of Pieces”: 14, “Price”: “$3,192.19”, “Description”: “An advanced installation and removal kit engineered specifically for Eddie-Bolt fasteners and collars, featuring Delta Rad Installation Sockets and Savi Removal Sockets for various Eddie-Bolt sizes….

Strategic Sourcing Conclusion and Outlook for eddie bolts

In today’s competitive aerospace landscape, the Eddie-Bolt® 2 fastening system stands out as an essential solution for international B2B buyers. By leveraging its advanced features, such as exceptional clamping power, reduced installation time, and high vibration resistance, organizations can significantly enhance operational efficiency and product reliability. The Eddie-Bolt® 2’s ability to prevent foreign object debris (FOD) and facilitate easy installation in limited-access areas further underscores its value in complex aerospace applications.

For businesses in Africa, South America, the Middle East, and Europe, strategic sourcing of Eddie-Bolts can lead to lower manufacturing costs and improved product performance. As industries increasingly prioritize lightweight and durable materials, investing in high-performance fastening solutions like Eddie-Bolt® is crucial for staying ahead in the market.

Looking ahead, now is the time for international buyers to explore partnerships with suppliers of Eddie-Bolt® systems. By embracing these innovative fastening solutions, companies can not only streamline their production processes but also enhance their competitiveness on a global scale. Engage with your suppliers today to discover how Eddie-Bolt® can transform your aerospace projects.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.