Top 6 Dynamet Inc Suppliers (And How to Choose)

Introduction: Navigating the Global Market for dynamet inc

Navigating the global market for titanium products can be a daunting challenge for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. Sourcing high-quality titanium from a reliable supplier like Dynamet Inc. is crucial for industries ranging from aerospace to medical devices, where material integrity is paramount. This guide aims to demystify the complexities of sourcing titanium, offering comprehensive insights into the types of titanium products available, their applications across various sectors, and effective strategies for supplier vetting.

Understanding the nuances of titanium sourcing not only helps in ensuring compliance with industry standards but also in managing costs effectively. Buyers will benefit from detailed analysis on pricing structures, quality assurance processes, and logistical considerations, enabling them to make informed purchasing decisions.

As you delve deeper into this guide, you will discover how to evaluate potential suppliers, assess product specifications, and navigate the intricacies of international trade. By equipping yourself with this knowledge, you can mitigate risks associated with sourcing and enhance the reliability of your supply chain. Whether you are in Brazil, Vietnam, or elsewhere, this resource is designed to empower your procurement strategy, ensuring that you secure the best titanium solutions tailored to your specific operational needs.

Understanding dynamet inc Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Titanium Bars | Available in various grades and dimensions; high tensile strength. | Aerospace, automotive, and medical industries. | Pros: Excellent strength-to-weight ratio. Cons: Higher cost compared to other metals. |

| Titanium Sheets | Lightweight and corrosion-resistant; customizable thicknesses. | Chemical processing, marine applications. | Pros: Durable and versatile. Cons: Limited availability in some regions. |

| Titanium Tubes | Precision-engineered for high-performance applications. | Oil and gas, aerospace, and medical devices. | Pros: Excellent fatigue resistance. Cons: Requires specialized manufacturing processes. |

| Titanium Wires | High conductivity and ductility; available in various gauges. | Medical devices, aerospace components. | Pros: Easy to work with and shape. Cons: Can be prone to oxidation if not properly handled. |

| Titanium Forgings | Enhanced mechanical properties; suitable for complex shapes. | Defense and aerospace applications. | Pros: Superior strength and durability. Cons: Longer lead times for production. |

What are the Characteristics of Titanium Bars and Their Suitability for B2B Buyers?

Titanium bars are characterized by their exceptional strength-to-weight ratio, making them ideal for industries where weight reduction is crucial, such as aerospace and automotive. They are available in various grades, allowing buyers to select the most appropriate type for their specific applications. When purchasing titanium bars, B2B buyers should consider the required tensile strength, corrosion resistance, and the specific manufacturing processes needed for their end products.

Why Choose Titanium Sheets for Your Chemical Processing Needs?

Titanium sheets are renowned for their lightweight and corrosion-resistant properties, making them particularly suitable for chemical processing and marine applications. They can be customized to various thicknesses and dimensions, ensuring that buyers can meet their unique specifications. B2B purchasers should evaluate the sheet’s thickness, surface finish, and compliance with industry standards to ensure compatibility with their operational requirements.

How Do Precision-Engineered Titanium Tubes Benefit the Oil and Gas Industry?

Precision-engineered titanium tubes offer high performance and reliability, especially in demanding environments like oil and gas extraction. Their fatigue resistance and corrosion resistance make them a preferred choice for critical applications. Buyers should consider the tube’s dimensions, wall thickness, and specific grade to ensure it meets the rigorous demands of their projects, as well as the availability of the required specifications.

What Advantages Do Titanium Wires Offer for Medical Devices?

Titanium wires are valued for their high conductivity and ductility, making them ideal for applications in medical devices and aerospace components. Their availability in various gauges allows for flexibility in design and function. When sourcing titanium wires, B2B buyers should assess the wire’s gauge, tensile strength, and oxidation resistance, as proper handling is crucial to maintaining their integrity during use.

What Makes Titanium Forgings Suitable for Defense and Aerospace Applications?

Titanium forgings are known for their enhanced mechanical properties, allowing them to withstand extreme conditions often encountered in defense and aerospace applications. They can be manufactured into complex shapes, providing versatility in design. Buyers should consider lead times, the complexity of the required shapes, and the specific mechanical properties needed for their applications when purchasing titanium forgings to ensure they align with project timelines and performance expectations.

Key Industrial Applications of dynamet inc

| Industry/Sector | Specific Application of Dynamet Inc | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Manufacturing of aircraft components | Enhanced strength-to-weight ratio for improved fuel efficiency | Compliance with aerospace standards and certifications, timely delivery |

| Medical | Production of surgical instruments and implants | Biocompatibility and corrosion resistance for patient safety | Quality assurance, traceability of materials, regulatory compliance |

| Automotive | Development of lightweight components for vehicles | Improved performance and fuel efficiency, reduced emissions | Material specifications, cost-effectiveness, and production timelines |

| Chemical Processing | Construction of corrosion-resistant equipment | Longevity and reliability in harsh environments | Material grades suitable for specific chemicals, certifications |

| Marine | Fabrication of components for ships and offshore rigs | Resistance to seawater corrosion and structural integrity | Sourcing from reputable suppliers, adherence to marine industry standards |

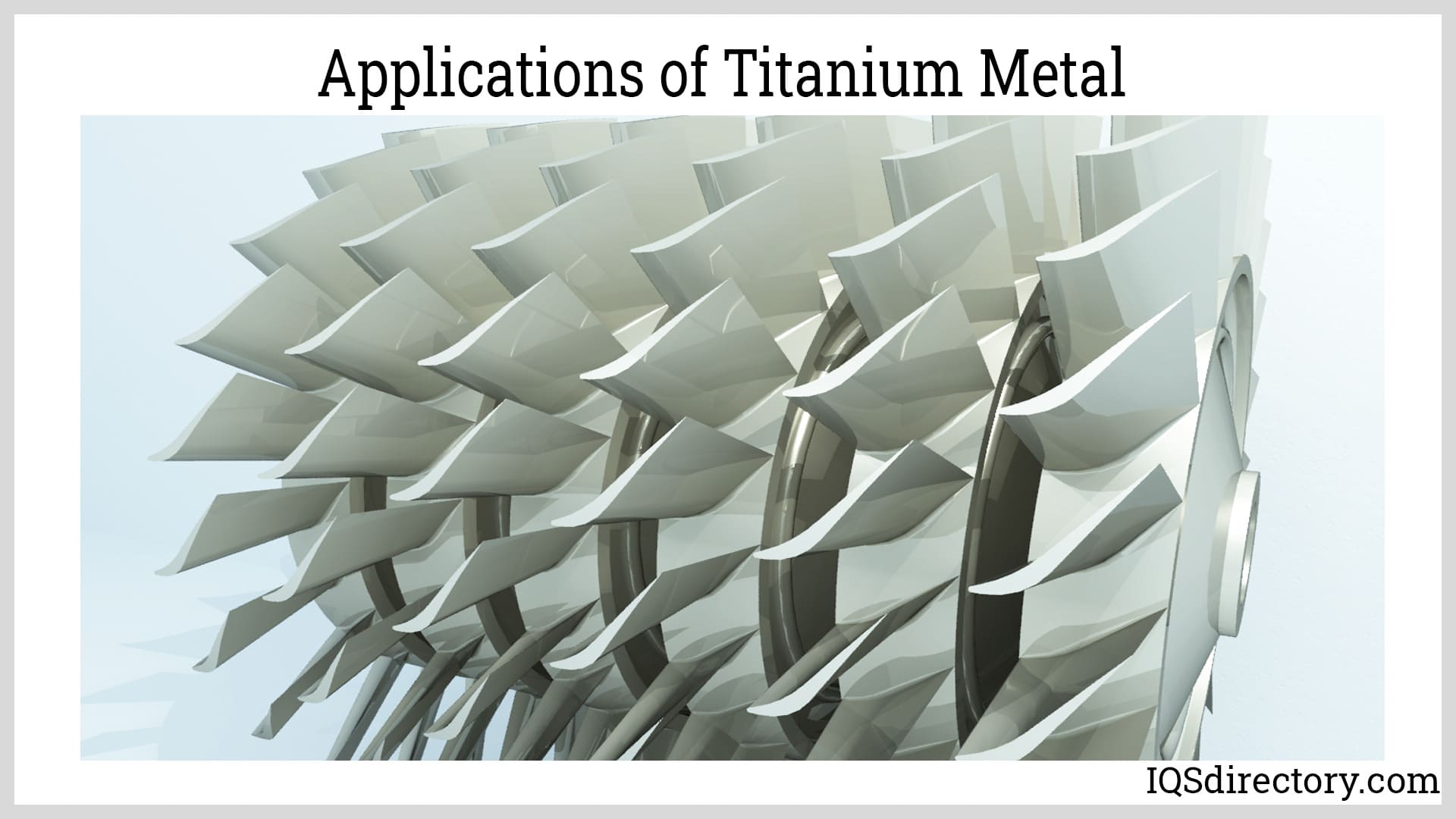

How is Dynamet Inc. Used in Aerospace Applications?

In the aerospace sector, Dynamet Inc. supplies high-performance titanium alloys used in manufacturing critical aircraft components such as frames, landing gear, and engine parts. These titanium products offer an exceptional strength-to-weight ratio, leading to improved fuel efficiency and enhanced performance. International buyers from regions like Europe and South America must ensure compliance with stringent aerospace standards and certifications, as well as timely delivery to meet production schedules.

What Role Does Dynamet Inc. Play in the Medical Industry?

Dynamet Inc. plays a crucial role in the medical industry by providing titanium products for surgical instruments and implants. The biocompatibility and corrosion resistance of titanium ensure patient safety and longevity of medical devices. Buyers in this sector need to prioritize quality assurance and traceability of materials, alongside compliance with healthcare regulations, especially when sourcing from international suppliers in Africa and the Middle East.

How is Dynamet Inc. Beneficial for Automotive Manufacturing?

In the automotive industry, Dynamet Inc. supplies lightweight titanium components that improve vehicle performance and fuel efficiency while reducing emissions. Applications include parts for engines, exhaust systems, and structural components. B2B buyers should focus on material specifications and cost-effectiveness when sourcing titanium, ensuring that production timelines align with automotive manufacturing schedules, particularly in emerging markets like Brazil and Vietnam.

Why is Dynamet Inc. Essential for Chemical Processing?

Dynamet Inc. provides titanium products that are essential in the chemical processing industry, particularly for constructing corrosion-resistant equipment. These titanium solutions enhance longevity and reliability, even in harsh environments. Buyers must consider material grades suitable for specific chemicals and ensure compliance with industry certifications when sourcing from international suppliers, particularly in regions with diverse chemical manufacturing needs.

How Does Dynamet Inc. Support Marine Applications?

Dynamet Inc. supplies titanium components for the marine industry, including parts for ships and offshore oil rigs. The inherent corrosion resistance of titanium against seawater ensures structural integrity and durability in marine environments. For international buyers, particularly in the Middle East and Europe, it is vital to source from reputable suppliers and adhere to marine industry standards to ensure the reliability and safety of marine operations.

3 Common User Pain Points for ‘dynamet inc’ & Their Solutions

Scenario 1: Navigating Titanium Supply Chain Challenges

The Problem: B2B buyers often face significant challenges in sourcing titanium products due to supply chain disruptions, fluctuating prices, and inconsistent quality. These issues can lead to project delays and increased costs, particularly for companies in industries such as aerospace and medical, where precision and reliability are paramount. For buyers from regions like Africa and South America, where local suppliers may be limited, finding a reliable international partner can feel overwhelming.

The Solution: To mitigate these challenges, buyers should leverage Dynamet Inc.’s robust logistics network and established reputation for quality. Begin by clearly outlining your project requirements, including specifications, timelines, and budget constraints. Utilize Dynamet’s extensive range of titanium products, such as bars, sheets, and tubes, which can be customized to meet specific needs. Engage directly with their sales team to gain insights into lead times and availability, ensuring that you can plan your projects effectively. By establishing a transparent communication channel with Dynamet, you can secure timely deliveries and maintain project momentum, ultimately enhancing your operational efficiency.

Scenario 2: Ensuring Compliance with Industry Standards

The Problem: Compliance with stringent industry standards and regulations is a common concern for B2B buyers, especially in sectors such as aerospace, medical, and chemical processing. Buyers may struggle to ensure that the titanium products they source from suppliers like Dynamet meet all necessary certifications and quality benchmarks. Non-compliance can lead to costly recalls, legal issues, and damage to a company’s reputation, making this a critical pain point.

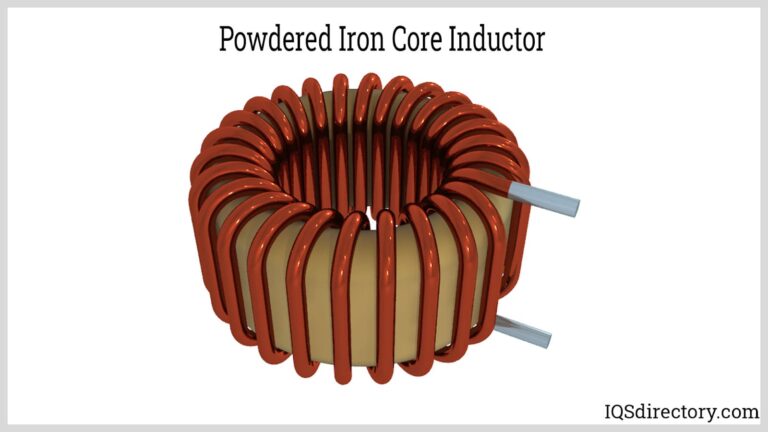

Illustrative image related to dynamet inc

The Solution: To address compliance concerns, buyers should conduct thorough due diligence on Dynamet’s quality assurance processes and certifications. Dynamet is ISO 9001 certified, which indicates a commitment to maintaining high-quality standards throughout their manufacturing operations. Request documentation that outlines compliance with industry-specific regulations and standards relevant to your sector. Additionally, consider scheduling a consultation with Dynamet’s technical team to discuss how their products can meet your specific compliance needs. This proactive approach will help ensure that you are sourcing materials that not only meet your requirements but also uphold the integrity of your operations.

Scenario 3: Understanding Product Specifications and Applications

The Problem: B2B buyers frequently encounter difficulties in understanding the specific grades and applications of titanium products. With various grades available, each with distinct properties and uses, making an informed choice can be overwhelming. Buyers in diverse sectors, from automotive to medical, may find it challenging to determine which titanium products will best suit their applications, potentially leading to suboptimal performance or increased costs.

The Solution: To navigate this complexity, buyers should engage with Dynamet’s expert team to gain a comprehensive understanding of titanium grades and their respective applications. Start by identifying the specific requirements of your project—consider factors such as strength, weight, corrosion resistance, and biocompatibility. Dynamet’s knowledgeable representatives can provide detailed insights into which titanium grades are best suited for your needs and help clarify any technical specifications. Additionally, consider utilizing their resources, such as product catalogs and case studies, to better understand how their titanium products have been successfully applied in similar projects. This tailored guidance will empower you to make well-informed purchasing decisions, ensuring optimal outcomes for your applications.

Strategic Material Selection Guide for dynamet inc

What Are the Key Properties of Titanium for B2B Applications?

Titanium is one of the most sought-after materials in various industries due to its unique properties. It boasts a high strength-to-weight ratio, making it ideal for applications where weight savings are crucial, such as aerospace and automotive sectors. Titanium exhibits excellent corrosion resistance, particularly in aggressive environments, which enhances its longevity and reliability. Additionally, it has a high melting point, enabling it to perform well under extreme temperatures. These properties make titanium a versatile choice for B2B buyers looking for durable and efficient materials.

What Are the Advantages and Disadvantages of Using Titanium?

While titanium offers numerous advantages, it also comes with some drawbacks. The primary benefit is its outstanding durability and resistance to corrosion, which can lead to lower maintenance costs over time. However, titanium is relatively expensive compared to other metals, which can be a significant consideration for budget-conscious buyers. The manufacturing complexity is another factor; titanium requires specialized processes for machining and forming, which may increase lead times and production costs. Understanding these pros and cons is vital for international B2B buyers who need to balance performance with cost-effectiveness.

How Does Titanium Impact Specific Applications?

The impact of titanium on applications is profound, particularly in industries such as aerospace, medical, and chemical processing. For instance, in aerospace, titanium’s lightweight nature contributes to fuel efficiency and overall performance. In the medical field, its biocompatibility makes it suitable for implants and surgical instruments. Furthermore, titanium’s compatibility with various media, including seawater and acidic environments, makes it an excellent choice for chemical processing applications. Buyers must consider these application-specific benefits when selecting materials for their projects.

What Should International B2B Buyers Consider When Sourcing Titanium?

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of compliance and standards that govern the use of titanium. Common standards such as ASTM, DIN, and JIS dictate material specifications and quality assurance processes. Buyers should also consider local regulations regarding environmental impact and sustainability, as these factors can influence purchasing decisions. Understanding these considerations will help ensure that the selected titanium products meet both performance and regulatory requirements.

Summary Table of Material Selection for Dynamet Inc.

| Material | Typical Use Case for dynamet inc | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Titanium | Aerospace components, medical implants | High strength-to-weight ratio, corrosion resistance | High cost, complex machining requirements | High |

| Stainless Steel | Chemical processing equipment, automotive parts | Cost-effective, good corrosion resistance | Heavier than titanium, lower strength | Medium |

| Aluminum | Lightweight structures, automotive parts | Low density, easy to machine | Limited high-temperature performance | Low |

| Nickel Alloys | Oil and gas applications, marine environments | Excellent corrosion resistance, high-temperature stability | High cost, difficult to weld | High |

This strategic material selection guide provides valuable insights for B2B buyers seeking to make informed decisions regarding titanium and other materials offered by Dynamet Inc. Understanding the properties, advantages, and international considerations associated with these materials will facilitate better procurement strategies and enhance operational efficiency.

In-depth Look: Manufacturing Processes and Quality Assurance for dynamet inc

What Are the Main Stages of Manufacturing Titanium Products at Dynamet Inc.?

Dynamet Inc. employs a comprehensive manufacturing process to produce high-quality titanium products. This process can be broken down into four main stages: material preparation, forming, assembly, and finishing. Each of these stages is designed to maximize efficiency and ensure that the final product meets the stringent requirements of various industries.

Material Preparation: How Does Dynamet Inc. Ensure Quality Raw Materials?

The first step in the manufacturing process involves sourcing titanium from reputable mines. Dynamet Inc. prioritizes the quality of raw materials, which is critical for the performance characteristics of the final products. The company utilizes advanced metallurgical techniques to analyze and prepare the titanium, ensuring it meets the required specifications. This phase may involve cleaning, alloying, and preparing the titanium for subsequent processing.

Illustrative image related to dynamet inc

Forming Techniques: What Methods Are Used to Shape Titanium?

Once the raw materials are prepared, the forming stage begins. Dynamet Inc. employs various techniques such as forging, rolling, and extrusion to shape titanium into the desired forms, including bars, sheets, tubes, and forgings. Each method is selected based on the specific requirements of the end product, taking into consideration factors such as strength, weight, and application. The use of state-of-the-art machinery allows for precision in shaping titanium, which is essential for industries like aerospace and medical devices where tolerances are critical.

Assembly: How Are Titanium Products Assembled?

In the assembly phase, various titanium components may be joined together, depending on the complexity of the product. Techniques such as welding, brazing, and mechanical fastening are commonly used. Dynamet Inc. ensures that assembly processes are performed under controlled conditions to maintain the integrity of the titanium. This attention to detail is particularly important for applications in sectors like aerospace, where safety and reliability are paramount.

Finishing: What Final Touches Are Applied to Titanium Products?

The finishing stage involves surface treatments and coatings that enhance the properties of titanium products. These processes may include anodizing, polishing, or applying protective coatings to improve corrosion resistance and aesthetic appeal. The finishing techniques used by Dynamet Inc. are aligned with industry standards, ensuring that the final products not only meet but exceed customer expectations.

How Does Dynamet Inc. Implement Quality Control in Manufacturing?

Quality assurance is integral to Dynamet Inc.’s manufacturing process. The company adheres to international standards such as ISO 9001, which outlines criteria for a quality management system. This commitment to quality ensures that every product is consistently manufactured to meet the highest standards.

What Are the Key Quality Control Checkpoints Used by Dynamet Inc.?

Dynamet Inc. employs several quality control checkpoints throughout the manufacturing process, including:

Illustrative image related to dynamet inc

-

Incoming Quality Control (IQC): This involves inspecting raw materials and components upon arrival to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify and rectify any deviations from quality standards in real-time.

-

Final Quality Control (FQC): Once the products are completed, they undergo a comprehensive inspection to verify that they meet all specifications before shipment.

These checkpoints are designed to catch potential issues early, reducing the risk of defects in the final product.

Which Testing Methods Are Commonly Used for Quality Assurance?

Dynamet Inc. employs a range of testing methods to verify the quality of titanium products. Common testing techniques include:

-

Mechanical Testing: To assess properties such as tensile strength, yield strength, and elongation.

-

Chemical Analysis: To ensure the composition of the titanium meets specified grades.

-

Non-Destructive Testing (NDT): Techniques like ultrasonic testing and radiographic testing are used to detect internal flaws without damaging the product.

These tests are crucial for industries that require high reliability, such as aerospace and medical applications.

How Can B2B Buyers Verify Quality Control Practices of Dynamet Inc.?

For international B2B buyers, verifying the quality control practices of a supplier like Dynamet Inc. is vital. Here are some actionable steps:

-

Conduct Supplier Audits: Buyers can request to perform audits of the manufacturing facilities to observe the quality control processes in action. This provides insights into the supplier’s adherence to industry standards.

-

Request Quality Assurance Reports: Suppliers should be able to provide documentation detailing their quality control measures, testing results, and compliance with international standards.

-

Engage Third-Party Inspectors: Utilizing independent inspectors can offer an unbiased assessment of the supplier’s quality practices. This is particularly beneficial for buyers from regions like Africa or South America, where establishing trust with new suppliers may be more challenging.

What Nuances Should International B2B Buyers Consider Regarding Quality Control?

International buyers, especially from Africa, South America, the Middle East, and Europe, should be aware of several nuances when it comes to quality control:

Illustrative image related to dynamet inc

-

Regional Standards Compliance: Different regions may have specific quality standards that must be adhered to. Buyers should ensure that the supplier is compliant with both local and international regulations.

-

Documentation and Certification: It is essential to verify that the supplier holds the necessary certifications (e.g., ISO 9001, CE, API) and that these certifications are up-to-date.

-

Cultural Considerations: Understanding cultural differences in business practices can aid in establishing stronger partnerships. For example, communication styles and expectations may vary significantly across regions.

By paying close attention to these factors, B2B buyers can make informed decisions when partnering with Dynamet Inc. for their titanium needs, ensuring they receive high-quality products backed by rigorous quality assurance processes.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘dynamet inc’

Introduction

Navigating the procurement of titanium products from Dynamet, Inc. can be a complex task, especially for international B2B buyers. This practical sourcing guide provides a step-by-step checklist to streamline your purchasing process, ensuring you secure high-quality titanium solutions tailored to your industry’s needs.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the titanium products you need, including grades, dimensions, and applications. This step is crucial as it ensures that the products will meet your operational demands and industry standards. Consider factors such as corrosion resistance, strength, and biocompatibility, especially if your application is in sensitive sectors like aerospace or medical.

Step 2: Research Supplier Capabilities

Investigate the capabilities of Dynamet, Inc. in relation to your specific needs. Look into their product portfolio, manufacturing processes, and any specialized services they offer, such as custom fabrication or rapid prototyping. Understanding their strengths will help you determine if they are the right partner for your project.

Step 3: Verify Supplier Certifications

Ensure that Dynamet, Inc. holds relevant industry certifications, such as ISO 9001. These certifications are indicators of a company’s commitment to quality and adherence to international standards. Request documentation to confirm compliance and evaluate how these certifications align with your own quality assurance processes.

Illustrative image related to dynamet inc

Step 4: Evaluate Quality Control Processes

Inquire about the quality control measures that Dynamet employs throughout their manufacturing operations. A robust quality assurance system is essential to guarantee product reliability and integrity. Look for details on their testing methods, inspection protocols, and how they handle non-conformance issues.

Step 5: Assess Logistics and Delivery Capabilities

Examine the logistics network and delivery capabilities of Dynamet, Inc. Timely delivery is crucial for maintaining your production schedules. Ask about their shipping options, lead times, and how they manage international logistics, particularly if you’re sourcing from regions like Africa or South America.

Step 6: Request Samples and Technical Data

Before finalizing your order, request samples of the titanium products along with detailed technical data sheets. This allows you to assess the material’s properties and ensure they meet your specifications. Evaluating samples can also provide insight into the supplier’s commitment to quality and customer service.

Step 7: Establish Communication Channels

Create clear communication channels with your contact at Dynamet, Inc. Establishing a direct line for inquiries and updates fosters a collaborative relationship. Regular communication can help resolve issues quickly and ensure that both parties are aligned throughout the sourcing process.

By following this checklist, you can make informed decisions when sourcing from Dynamet, Inc., ensuring that you procure the right titanium solutions to enhance your operations and maintain competitive advantages in your industry.

Illustrative image related to dynamet inc

Comprehensive Cost and Pricing Analysis for dynamet inc Sourcing

What Are the Key Cost Components in Sourcing from Dynamet Inc.?

When engaging with Dynamet Inc. for titanium sourcing, understanding the cost structure is crucial. Key components include:

-

Materials: The primary cost driver is the titanium itself, which can vary based on market conditions and the grade of titanium required. Dynamet sources titanium from reputable mines, ensuring high quality, which may come at a premium compared to lower-grade alternatives.

-

Labor: Labor costs encompass the skilled workforce required for titanium processing and manufacturing. Given the technical expertise needed for titanium products, these costs can be significant, especially in regions with higher wage standards.

-

Manufacturing Overhead: This includes the costs associated with running manufacturing facilities, such as utilities, equipment maintenance, and facility management. Efficient operations can help reduce these overheads, impacting overall pricing.

-

Tooling: Custom tooling may be necessary for specialized titanium products. The initial investment in tooling can be high but is often amortized over large production runs, making it a critical factor in pricing.

-

Quality Control (QC): Given the stringent standards in industries like aerospace and medical, QC processes are vital. The costs associated with quality assurance can add to the overall price but ensure reliability and compliance with industry standards.

-

Logistics: Transportation costs can vary significantly depending on the destination, with international shipping often incurring additional fees. Dynamet’s robust logistics network aims to mitigate these costs, but buyers should account for potential fluctuations.

-

Margin: Finally, the profit margin applied by Dynamet is influenced by their operational costs and market positioning. Understanding this can aid in negotiating fair pricing.

How Do Pricing Influencers Affect Costs When Sourcing Titanium?

Several factors can influence pricing when sourcing from Dynamet Inc.:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often qualify for bulk pricing, reducing per-unit costs. Understanding the MOQ can help buyers plan their purchases effectively.

-

Specifications and Customization: Custom specifications can lead to increased costs due to the need for specialized processes. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Material Quality and Certifications: Higher grades of titanium and compliance with certifications (such as ISO 9001) usually command higher prices. Buyers must balance their need for quality with budget constraints.

-

Supplier Factors: The relationship with Dynamet can impact pricing. Long-term partnerships may lead to better pricing and terms, while new buyers may face higher initial costs.

-

Incoterms: The terms of delivery (e.g., FOB, CIF) significantly affect pricing. Understanding these terms is essential for accurately calculating total costs, including shipping and insurance.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing?

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, can optimize their sourcing strategies with the following tips:

-

Negotiate Wisely: Leverage volume commitments to negotiate better pricing. Building a rapport with suppliers can also facilitate more favorable terms.

-

Consider Total Cost of Ownership (TCO): Assess not just the purchase price but also logistics, maintenance, and potential downtime costs. A lower upfront price might not always equate to a better deal.

-

Understand Pricing Nuances: Be aware of currency fluctuations and economic conditions in the supplier’s region, which can impact pricing. Staying informed can help in timing purchases effectively.

-

Explore Long-Term Partnerships: Establishing a long-term relationship with Dynamet can yield benefits such as loyalty discounts, priority service, and improved communication.

Are Prices Indicative and Subject to Change?

It is essential to note that the prices associated with titanium sourcing from Dynamet Inc. are indicative and can fluctuate based on various factors, including market demand, raw material costs, and geopolitical influences. Buyers should consult directly with Dynamet for precise quotations tailored to their specific needs and circumstances.

Alternatives Analysis: Comparing dynamet inc With Other Solutions

Understanding Alternatives in Titanium Solutions

When evaluating options for titanium products and services, it’s essential to consider various alternatives that may meet your business needs. Different suppliers and manufacturing methods can offer unique advantages and disadvantages, influencing factors such as performance, cost, and application suitability. This comparison focuses on Dynamet Inc. and two notable alternatives: Carpenter Technology and ATI Specialty Materials.

Comparison Table

| Comparison Aspect | Dynamet Inc | Carpenter Technology | ATI Specialty Materials |

|---|---|---|---|

| Performance | High-quality titanium with excellent corrosion resistance and biocompatibility. | Specializes in advanced specialty alloys with a focus on extreme performance in critical applications. | Offers a wide range of titanium products with a strong emphasis on aerospace and medical applications. |

| Cost | Competitive pricing with a focus on customer satisfaction. | Generally higher costs due to advanced R&D and specialty materials. | Mid-range pricing, but may vary based on specific alloys and applications. |

| Ease of Implementation | Streamlined ordering process and robust logistics for timely delivery. | Requires detailed specifications and may have longer lead times for custom orders. | Efficient ordering process, but may require more extensive documentation for regulatory compliance. |

| Maintenance | Low maintenance; products are designed for durability. | Higher maintenance for specialized alloys due to specific handling requirements. | Maintenance levels vary by product; generally low for standard titanium. |

| Best Use Case | Aerospace, automotive, and medical sectors needing reliable titanium solutions. | Applications requiring extreme material performance, such as aerospace and defense. | Best suited for industries focused on high-performance applications, particularly in the aerospace sector. |

Detailed Breakdown of Alternatives

Carpenter Technology

Carpenter Technology stands out for its extensive expertise in specialty alloys, making it a strong competitor in high-performance applications. Their focus on innovation allows them to develop advanced materials tailored for demanding environments, such as aerospace and defense. However, the cost associated with their products tends to be higher due to the extensive R&D efforts and specialty nature of their offerings. This could be a limitation for companies operating on tighter budgets. Additionally, the implementation process may involve longer lead times as they often require precise specifications.

ATI Specialty Materials

ATI Specialty Materials is recognized for its broad range of titanium solutions, particularly in aerospace and medical applications. They emphasize producing materials that meet stringent regulatory standards, which can be crucial for industries such as healthcare. While their products are generally reliable, the pricing can fluctuate based on the specific alloys needed. Companies might find the ordering process efficient; however, they may need to navigate additional documentation requirements to comply with industry regulations. This can add complexity to the procurement process.

Conclusion: How to Choose the Right Titanium Solution

Selecting the right titanium supplier involves assessing your specific needs against the strengths and weaknesses of available options. Dynamet Inc. is an excellent choice for businesses looking for high-quality titanium with reliable delivery and competitive pricing. In contrast, Carpenter Technology may be more suitable for those requiring advanced specialty alloys for critical applications, despite the higher costs. ATI Specialty Materials serves well in sectors needing robust materials with regulatory compliance but may introduce additional complexities in documentation. Ultimately, B2B buyers should prioritize their specific application requirements, budget constraints, and the level of support needed throughout the procurement process to make an informed decision.

Essential Technical Properties and Trade Terminology for dynamet inc

What Are the Key Technical Properties of Titanium Products from Dynamet Inc.?

Understanding the technical specifications of titanium products is crucial for international B2B buyers seeking to make informed purchasing decisions. Here are some critical specifications that define the quality and suitability of titanium products offered by Dynamet Inc.

-

Material Grade

Titanium is categorized into several grades based on its alloying elements and properties. Common grades include Grade 2 (commercially pure titanium) and Grade 5 (Ti-6Al-4V), known for their strength and corrosion resistance. Selecting the right grade is essential for ensuring performance in specific applications, such as aerospace or medical devices. -

Tolerance

Tolerance refers to the allowable deviation from a specified dimension in the manufacturing process. Tight tolerances are vital for applications requiring precision, such as components in aerospace engines. Understanding tolerance specifications helps buyers ensure compatibility with their project requirements. -

Corrosion Resistance

Titanium’s natural oxide layer gives it exceptional resistance to corrosion, making it suitable for harsh environments, such as marine and chemical processing applications. Buyers should evaluate corrosion resistance ratings to ensure longevity and reliability in their specific applications. -

Yield Strength

Yield strength indicates the maximum stress a material can withstand without permanent deformation. For instance, Grade 5 titanium has a yield strength of approximately 880 MPa. This property is critical for industries that require materials to endure high-stress conditions without failing. -

Biocompatibility

Biocompatibility is a crucial property for titanium products used in medical applications, such as implants and surgical instruments. Titanium’s ability to integrate with human tissue reduces the risk of rejection and enhances patient outcomes. Buyers in the medical field must prioritize biocompatibility when selecting titanium products. -

Dimensional Specifications

Dimensional specifications include the shape, size, and volume of titanium products, such as bars, sheets, and tubes. Buyers should verify that these dimensions align with their manufacturing processes and end-use applications to avoid costly rework or delays.

What Are Common Trade Terminologies Relevant to Dynamet Inc.?

Familiarity with industry terminology can facilitate smoother transactions and better communication between buyers and suppliers. Here are some essential trade terms relevant to Dynamet Inc.

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding this term helps buyers identify suppliers that provide components for their specific applications, ensuring compatibility and quality. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ is critical for inventory management and budgeting, particularly when dealing with high-value materials like titanium. -

RFQ (Request for Quotation)

An RFQ is a formal document that buyers use to solicit pricing and terms from suppliers. Submitting an RFQ allows buyers to compare offers from multiple suppliers, ensuring they receive competitive pricing and favorable terms. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers regarding shipping, risk, and costs. Familiarity with Incoterms is vital for international transactions, as they clarify who bears the risk at various points in the shipping process. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the goods. Understanding lead times is essential for supply chain management, as it impacts project timelines and inventory levels. -

Certification

Certification indicates that a product meets specific industry standards and regulations. For titanium products, certifications such as ISO 9001 ensure quality and reliability, which are paramount for industries like aerospace and medical. Buyers should seek suppliers that provide relevant certifications to mitigate risk.

By understanding these technical properties and trade terminologies, international B2B buyers can make more informed decisions when sourcing titanium products from Dynamet Inc., ensuring alignment with their operational needs and industry standards.

Illustrative image related to dynamet inc

Navigating Market Dynamics and Sourcing Trends in the dynamet inc Sector

What Are the Global Drivers and Key Trends Impacting the Titanium Market?

The titanium market is currently influenced by several global drivers, including the increasing demand for lightweight and high-strength materials across various industries, such as aerospace, automotive, and medical. As countries continue to invest in infrastructure and advanced manufacturing technologies, the need for titanium products is expected to rise. Emerging technologies, particularly in additive manufacturing and 3D printing, are creating new avenues for titanium applications, enabling manufacturers to produce complex geometries that were previously impossible.

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding these trends is crucial. The shift towards digital procurement processes is becoming more prevalent, with buyers seeking suppliers who can provide real-time data and transparency throughout the sourcing process. Additionally, the focus on sustainability is reshaping purchasing decisions, with companies increasingly opting for suppliers who demonstrate a commitment to environmental responsibility and ethical practices.

Furthermore, the titanium market is seeing a consolidation trend, where larger players are acquiring smaller firms to enhance their product offerings and market reach. This dynamic can lead to both opportunities and challenges for B2B buyers, as they may benefit from a broader range of products but also face increased competition and potential price fluctuations.

How Is Sustainability and Ethical Sourcing Shaping the Titanium Industry?

Sustainability is no longer just a buzzword; it has become a critical factor in the sourcing of titanium products. The environmental impact of titanium extraction and processing is significant, prompting buyers to seek suppliers that prioritize sustainable practices. Companies like Dynamet, Inc. are increasingly adopting eco-friendly manufacturing processes and sourcing materials from certified mines to minimize their carbon footprint.

Ethical sourcing is equally important. Buyers are demanding transparency in supply chains, ensuring that materials are sourced responsibly and that labor practices are fair. Certifications such as ISO 14001 for environmental management and adherence to the OECD Guidelines for Multinational Enterprises are becoming essential criteria for supplier selection. By prioritizing suppliers with ‘green’ certifications and sustainable materials, companies can not only reduce their environmental impact but also enhance their brand reputation and appeal to a growing base of environmentally conscious consumers.

Illustrative image related to dynamet inc

Furthermore, engaging in sustainable sourcing can yield long-term cost savings. By reducing waste and improving energy efficiency, suppliers can offer more competitive pricing, making sustainability a financially viable option for B2B buyers.

What Is the Evolution of Dynamet, Inc. and Its Impact on B2B Relationships?

Dynamet, Inc. has evolved significantly since its inception, positioning itself as a leading global provider of titanium products and services. Initially focused on meeting the needs of niche markets, the company has expanded its product portfolio to cater to a wide range of industries, including aerospace, automotive, and medical. This evolution has been driven by technological advancements and a commitment to quality, which have established Dynamet as a trusted partner in the titanium sector.

The company’s emphasis on rigorous quality control and compliance with industry standards has strengthened its B2B relationships, particularly in international markets. By maintaining ISO 9001 certification and adhering to stringent quality assurance processes, Dynamet ensures that its products meet the highest standards of reliability and performance. This focus on quality not only enhances customer satisfaction but also fosters long-term partnerships with businesses seeking dependable titanium solutions.

As the market continues to evolve, Dynamet’s commitment to innovation and customer service will play a pivotal role in shaping its future and that of its clients. By staying attuned to market dynamics and sourcing trends, the company is well-positioned to meet the diverse needs of its international B2B clientele.

Frequently Asked Questions (FAQs) for B2B Buyers of dynamet inc

-

1. How do I ensure the quality of titanium products from Dynamet Inc.?

To ensure the quality of titanium products, it is essential to inquire about Dynamet Inc.’s quality assurance processes and certifications. The company is ISO 9001 certified, which signifies adherence to international quality management standards. Additionally, you should request documentation on their sourcing practices, manufacturing processes, and any third-party testing they conduct. Establishing clear communication regarding your specifications and requirements will further help in achieving the desired quality in the products you order. -

2. What is the minimum order quantity (MOQ) for titanium products from Dynamet Inc.?

The minimum order quantity (MOQ) for titanium products can vary depending on the specific item and your requirements. Typically, larger orders may benefit from better pricing and availability, while smaller orders might be subject to additional fees or longer lead times. It’s advisable to directly contact Dynamet Inc. to discuss your needs, as they can provide tailored solutions and may offer flexibility based on your project size and urgency. -

3. How can I customize titanium products for my specific application?

Dynamet Inc. offers a range of customization options for titanium products, including variations in grades, dimensions, and finishes. To customize your order, provide detailed specifications regarding your application requirements, such as mechanical properties, corrosion resistance, and any specific industry standards. Collaborating with their technical support team will ensure that your product meets the necessary criteria for performance in your particular sector, whether it be aerospace, medical, or automotive. -

4. What payment terms does Dynamet Inc. offer for international buyers?

Dynamet Inc. typically offers flexible payment terms to accommodate international buyers, which may include options such as wire transfers, letters of credit, or installment payments. The specific terms can vary based on the order size, payment history, and negotiation during the procurement process. It’s important to discuss and agree upon payment terms upfront to ensure a smooth transaction and to understand any potential currency exchange implications. -

5. What logistics solutions does Dynamet Inc. provide for international shipments?

Dynamet Inc. has a robust logistics network designed to facilitate efficient international shipping. They can assist with various logistics options, including freight forwarding, customs clearance, and delivery tracking. When placing an order, inquire about their preferred shipping methods and estimated delivery times, as well as any additional services they may offer, such as warehousing or inventory management for ongoing supply needs. -

6. How can I verify Dynamet Inc.’s reputation as a supplier?

To verify Dynamet Inc.’s reputation, consider conducting thorough research, including reviewing client testimonials, case studies, and industry certifications. Engaging with existing customers or seeking feedback through professional networks can provide insights into their reliability and service quality. Additionally, checking their compliance with industry standards and regulations will further assure you of their commitment to excellence in titanium manufacturing. -

7. What industries does Dynamet Inc. supply titanium products to?

Dynamet Inc. supplies titanium products to a diverse range of industries, including aerospace, automotive, medical, marine, and chemical processing. Each industry has specific requirements regarding material properties and applications, so it’s beneficial to discuss your particular sector needs with their sales representatives. This will help you understand how their products can enhance performance and reliability in your applications. -

8. What should I consider when sourcing titanium from international suppliers like Dynamet Inc.?

When sourcing titanium from international suppliers, consider factors such as product quality, compliance with industry standards, lead times, and shipping logistics. It’s essential to evaluate the supplier’s manufacturing capabilities, certifications, and history of service. Additionally, understanding local regulations and customs requirements in your region can help avoid delays. Building a strong relationship with your supplier will also facilitate smoother transactions and better support for any future needs.

Top 6 Dynamet Inc Manufacturers & Suppliers List

1. Dynamet, Inc. – Titanium Products

Domain: titaniummanufacturers.com

Registered: 2012 (13 years)

Introduction: Dynamet, Inc. specializes in high-quality titanium products and services, offering an extensive range of titanium products including titanium bars, sheets, plates, tubes, wires, and forgings. These products are available in various grades, dimensions, and specifications to meet the needs of industries such as aerospace, automotive, chemical processing, marine, and medical. The titanium products ar…

2. Carpenter Technology – Specialty Alloys

Domain: carpentertechnology.com

Registered: 1999 (26 years)

Introduction: Carpenter Technology specializes in high-performance specialty alloys designed for mission-critical applications across various industries. Key product categories include: High Temperature Alloys, Nickel-Copper Alloys, Soft Magnetic Alloys, Stainless Steel, Titanium, Tool & Die Steels, and Medical Alloys. The company also offers parts and components, distributed alloys, and value-added services, a…

3. Dynamet, Inc. – Titanium Alloy Products

Domain: diversityjobs.com

Registered: 1999 (26 years)

Introduction: Dynamet, Inc. is a leading supplier of titanium alloy products for various industries including aerospace, medical, consumer products, motor sports, and recreation equipment. Their product offerings include wire, bar, fine wire, strip, and shaped products designed for applications that require superior corrosion resistance, light weight, strength, and biocompatibility.

4. Dynamet, Inc. – Titanium Alloy Products

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Dynamet, Inc. is a leading supplier of titanium alloy products, offering forms such as bar, wire, fine wire, shapes, and strip. The company serves various industries including aerospace, medical, consumer, motorsports, and recreation.

5. Indeed – Employee Benefits

Domain: indeed.com

Registered: 1998 (27 years)

Introduction: This company, Indeed – Employee Benefits, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Dynamet, Inc. – Titanium Alloy Products

Domain: local.observer-reporter.com

Registered: 1997 (28 years)

Introduction: Dynamet, Inc. is a leading supplier of titanium alloy products for various industries including aerospace, medical, consumer, motorsports, and recreation. The product forms offered include bar, wire, fine wire, shapes, and strip. Customers can view detailed technical datasheets for highlighted alloys or contact the company for additional product information.

Strategic Sourcing Conclusion and Outlook for dynamet inc

In the competitive landscape of titanium supply, Dynamet, Inc. stands out as a premier provider, emphasizing the importance of strategic sourcing for international B2B buyers. By offering a diverse range of high-quality titanium products, including bars, sheets, and tubes, Dynamet caters to various industries such as aerospace, automotive, and medical. This versatility not only enhances operational efficiency but also ensures compliance with stringent quality standards, giving buyers confidence in their sourcing decisions.

Strategic sourcing with Dynamet allows businesses to leverage superior materials that enhance product performance while maintaining cost-effectiveness. The company’s commitment to customer satisfaction, backed by a robust logistics network and ISO 9001 certification, ensures timely delivery and reliability, crucial for international operations.

Illustrative image related to dynamet inc

Looking ahead, the titanium market is poised for growth, driven by innovations and increasing demand across sectors. International buyers, particularly from Africa, South America, the Middle East, and Europe, should seize the opportunity to partner with Dynamet, Inc. to secure sustainable, high-quality titanium solutions that will help them stay competitive in their respective markets. Embrace the future of sourcing—connect with Dynamet today to explore tailored solutions for your business needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.